Submitted:

27 May 2024

Posted:

28 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- Carbon Matrix Composites (CAMC) are made from a carbon matrix reinforced with a variety of fibers, whiskers, or particles and have the characteristics of a low density, strong mechanical properties, high thermal stability, outstanding electrical conductivity, a high thermal conductivity, and excellent fracture toughness [5]. The reinforcing materials are categorized as Nanocomposites. Nanomaterial’s, such as carbon nanotubes or graphene added to a polymer matrix, or silicon nanoparticles added to steel, are commonly used for reinforcement to enhance rigidity, strength, and electrical or thermal conductivity.

- Glass Fiber Reinforced Polymers (GFRPs) are another type of polymer matrix composite that is reinforced with epoxy and polyester bound glass fiber materials to enhance lay-up quality and provide better strength at a cost.

- Hybrid composites (HCs) are composite materials that contain at least two distinct kinds of matrix or reinforcement to meet the demands of design, allowing composites to achieve a customized set of characteristics that can involve thermal endurance, stiffness, strength, toughness, fatigue and resistance to impact [6].

- Natural Fiber Composites (NFCs): Natural fibers including jute, flax, cotton, and wood are utilized in several applications to increase strength and provide a wood appearance.

- Carbon Fiber Reinforced Polymers (CFRPs) are another type of polymer matrix composites. The adhesive polymer is often a thermoplastic or thermoset resin such as epoxy, but it can also be a thermoset or thermoplastic polymer such as polyester, vinyl ester, or nylon, which is lightweight, durable, stiff, and resistant to corrosion. Aramid Fiber Reinforced Polymers (AFRPs) are another type of polymer matrix composite that uses aramid as a reinforcing material. Aramid fiber composites are utilized for high-impact applications. Functionally Graded Composites (FGCs) are subsets of any sort of composite in which the component elements can be adjusted in the application or type.

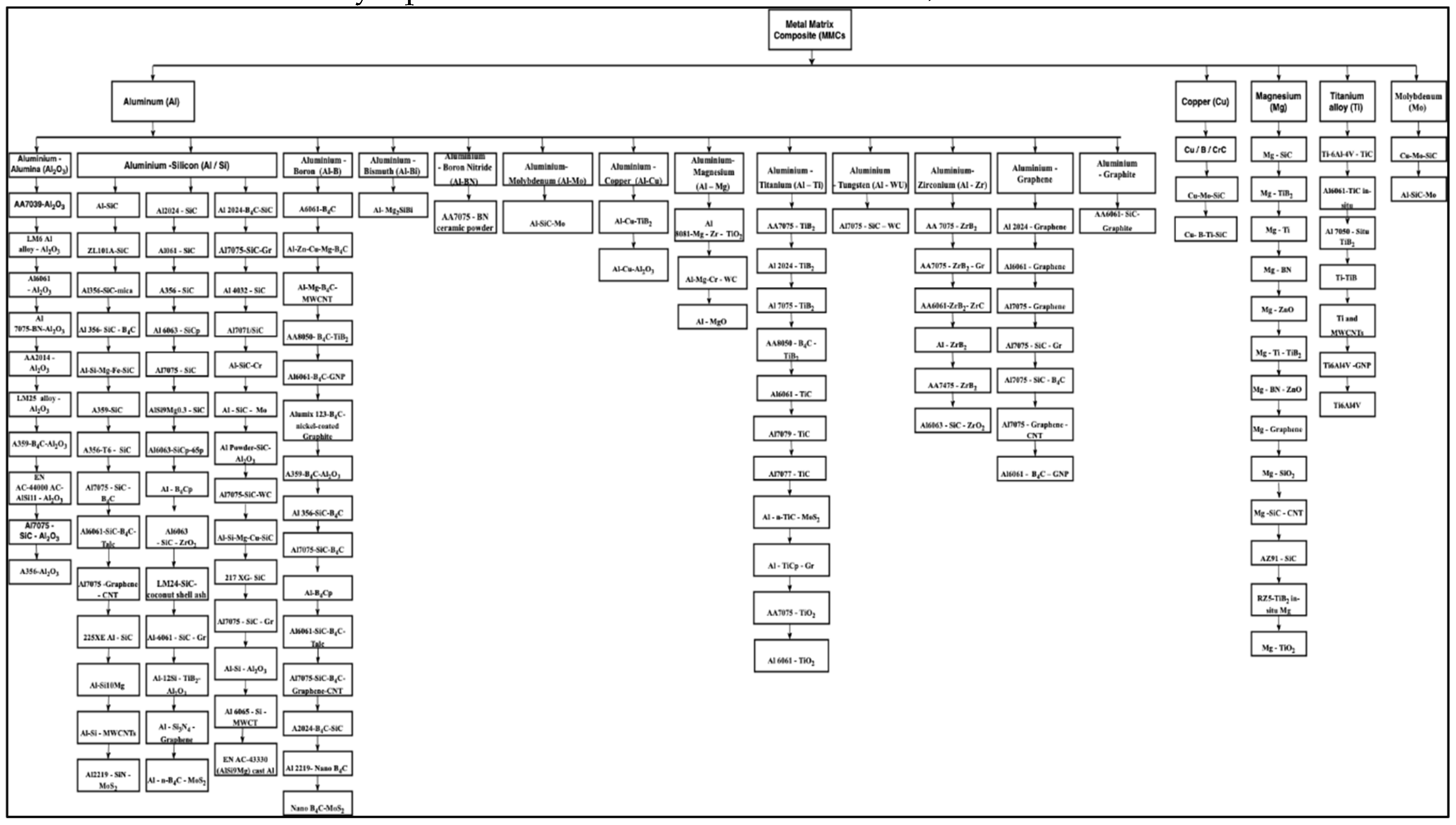

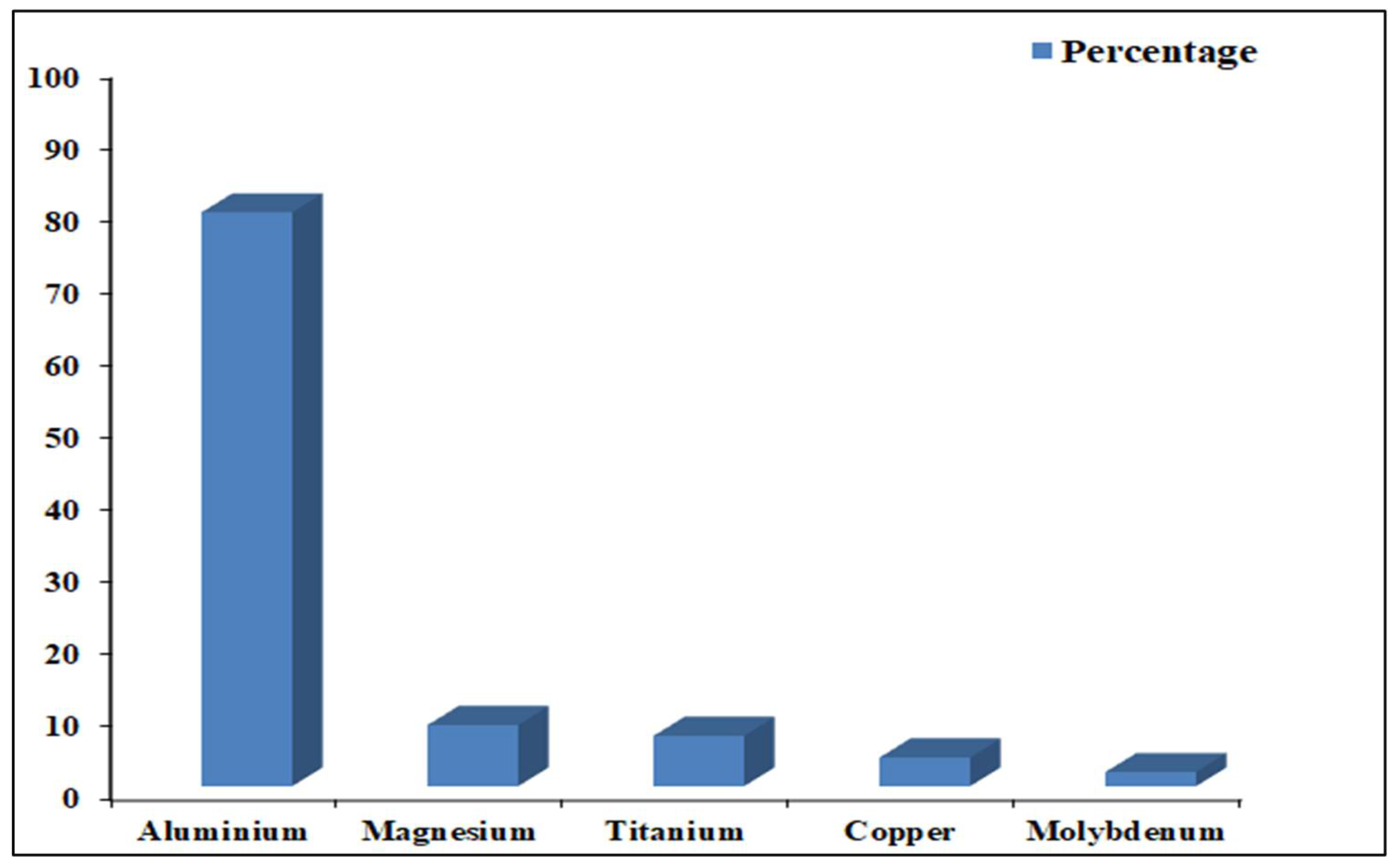

2. Machining of MMCs

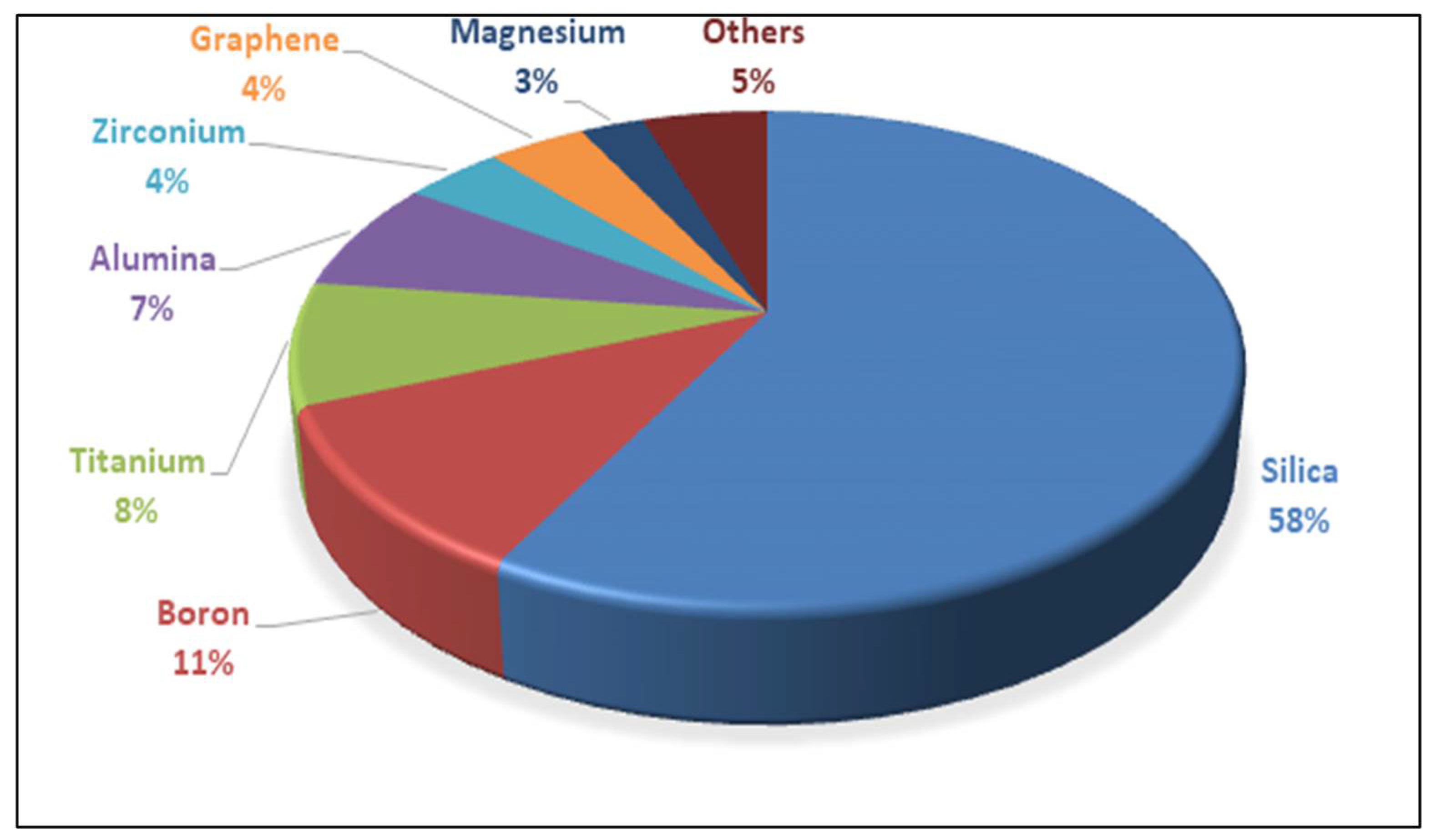

2.1. Aluminum Metal Matrix Composites (AlMMCs)

2.1.1. Aluminium Reinforced with Alumina (Al/Al2O3)

2.1.2. Aluminium Reinforced with Silicon (Al/Si)

2.1.3. Aluminium Reinforced with Boron (Al-B)

2.1.4. Aluminium Reinforced with Titanium (Al-Ti)

2.1.5. Aluminium Reinforced with Zirconium (Al-Zr)

2.1.6. Other Aluminium Matrix Composites

2.2. Copper (Cu) Reinforced Metal Matrix Composites

2.3. Magnesium (Mg) Reinforced Metal Matrix Composites

2.4. Titanium alloy (Ti) Reinforced Metal Matric Composites

2.5. Molybdenum (Mo) reinforced Metal Matrix Composites

3. Discussion of Soft Computing Techniques

4. Discussion on Conventional Machining of MMCs and Future Trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Beaumont, P. W., Zweben, C. H., Gdutos, E., Talreja, R., Poursartip, A., Clyne, T. W., ... & Soutis, C. (Eds.). (2018). Comprehensive composite materials II (Vol. 6). Amsterdam, The Netherlands: Elsevier.

- Shalin, R. E. (Ed.). (2012). Polymer matrix composites (Vol. 4). Springer Science & Business Media.

- Chawla, K. K., & Chawla, K. K. (2019). Ceramic matrix composites. Composite Materials: Science and Engineering, 251-296.

- Qinglong, A. N. , Jie, C. H. E. N., Weiwei, M. I. N. G., & Ming, C. H. E. N. (2021). Machining of SiC ceramic matrix composites: A review. Chinese Journal of Aeronautics, 34(4), 540-567. [CrossRef]

- Ramanathan, A. , Krishnan, P. K., & Muraliraja, R. (2019). A review on the production of metal matrix composites through stir casting–Furnace design, properties, challenges, and research opportunities. Journal of Manufacturing processes, 42, 213-245. [CrossRef]

- De Menezes, E. A. , Eggers, F., Marczak, R. J., Iturrioz, I., & Amico, S. C. (2020). Hybrid composites: Experimental, numerical and analytical assessment aided by online software. Mechanics of Materials, 148, 103533. [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S.; Atreya TS, A.; Vignesh, V.; Subramanian, C. Aluminium metal matrix composites–a review. Rev. Adv. Mater. Sci 2014, 38, 55–60. [Google Scholar]

- Singh, L. , Singh, B., & Saxena, K. K. (2020). Manufacturing techniques for metal matrix composites (MMC): an overview. Advances in Materials and Processing Technologies, 6(2), 441-457. [CrossRef]

- Luna Ramírez, A. , Porcayo-Calderon, J., Mazur, Z., Salinas-Bravo, V. M., & Martinez-Gomez, L. (2016). Microstructural changes during high temperature service of a cobalt-based superalloy first stage nozzle. Advances in Materials Science and Engineering, 2016. [CrossRef]

- Saravanan, C.; Subramanian, K.; Krishnan, V.A.; Narayanan, R.S. Effect of particulate reinforced aluminium metal matrix composite–a review. Mechanics and Mechanical Engineering 2015, 19, 23–30. [Google Scholar]

- Ashebir, D. A., Mengesha, G. A., & Sinha, D. K. (2022). An insight into mechanical and metallurgical behavior of hybrid reinforced aluminum metal matrix composite. Advances in Materials Science and Engineering, 2022. [CrossRef]

- Dandekar, C. R. , & Shin, Y. C. (2012). Modeling of machining of composite materials: a review. International Journal of Machine tools and manufacture, 57, 102-121. [CrossRef]

- Sharma, A. K. , Bhandari, R., Aherwar, A., Rimašauskienė, R., & Pinca-Bretotean, C. (2020). A study of advancement in application opportunities of aluminum metal matrix composites. Materials Today: Proceedings, 26, 2419-2424. [CrossRef]

- Sadeghi, B. , Cavaliere, P., & Perrone, A. (2018). Effect of Al2O3, SiO2 and carbon nanotubes on the microstructural and mechanical behavior of spark plasma sintered aluminum based nanocomposites. Particulate Science and Technology. [CrossRef]

- Karabulut, Ş. (2015). Optimization of surface roughness and cutting force during AA7039/Al2O3 metal matrix composites milling using neural networks and Taguchi method. Measurement, 66, 139-149. [CrossRef]

- Kannan, R. , Narayanaperumal, A., & Rao, M. S. R. (2015, June). Nanocrystalline Diamond Coated Tool Performance in Machining of LM6 Aluminium Alloy/Alumina MMC. In International Manufacturing Science and Engineering Conference (Vol. 56833, p. V002T01A008). American Society of Mechanical Engineers.

- Ghandehariun, A. , Kishawy, H. A., Umer, U., & Hussein, H. M. (2016). Analysis of tool-particle interactions during cutting process of metal matrix composites. The International Journal of Advanced Manufacturing Technology, 82, 143-152. 10. [CrossRef]

- Kannan, C. , Ramanujam, R., & Balan, A. S. S. (2018). Machinability studies on Al 7075/BN/Al2O3 squeeze cast hybrid nanocomposite under different machining environments. Materials and Manufacturing Processes, 33(5), 587-595. [CrossRef]

- Prakash, M., & Iqbal, U. M. (2018). Parametric optimization in turning of AA2014/Al2O3 nano composite for machinability assessment using sensors. In IOP Conference Series: Materials Science and Engineering (Vol. 402, No. 1, p. 012013). IOP Publishing. [CrossRef]

- Thankachan, T.P. Production and Machining Performance Study of Nano Al 2 O 3 Particle Reinforced LM25 Aluminum Alloy Composites. Journal of Applied Mechanics and Technical Physics 2019, 60, 136–143. [Google Scholar] [CrossRef]

- Srivastava, A. K. , Maurya, M., Saxena, A., Kumar, N., & Dwivedi, S. P. (2021). Statistical optimization by response surface methodology of process parameters during the CNC turning operation of hybrid metal matrix composite. [CrossRef]

- Szymański, M., Przestacki, D., & Szymański, P. (2022). Tool Wear and Surface Roughness in Turning of Metal Matrix Composite Built of Al2O3 Sinter Saturated by Aluminum Alloy in Vacuum Condition. Materials, 15(23), 8375. [CrossRef] [PubMed]

- Ravikumar, M. , & Suresh, R. (2023). Study on mechanical and machinability characteristics of n-Al2O3/SiC-reinforced Al7075 composite by design of experiment technique. Multiscale and Multidisciplinary Modeling, Experiments and Design, 1-14. [CrossRef]

- Sunar, T. , Parenti, P., Tunçay, T., Özyürek, D., & Annoni, M. (2023). The Effects of Nanoparticle Reinforcement on the Micromilling Process of A356/Al2O3 Nanocomposites. Journal of Manufacturing and Materials Processing, 7(4), 125. [CrossRef]

- 2015 - Arun Premnath, A., Suryatheja, P., Srinath, A., & Karthikeyan, S. (2015). Analyses of tool wear while milling hybrid metal matrix composites. Applied Mechanics and Materials, 813, 279-284. 10.4028/www.scientific.net/AMM.813-814.279.

- Somiya, S. (Ed.). (2012). Advanced Materials' 93: Ceramics, Powders, Corrosion and Advanced Processing. Newnes.

- Kremer, A. , Devillez, A., Dominiak, S., Dudzinski, D., & El Mansori, M. (2008). Machinability of AI/SiC particulate metal-matrix composites under dry conditions with CVD diamond-coated carbide tools. Machining Science and Technology, 12(2), 214-233. [CrossRef]

- Ge, Y. F. , Xu, J. H., Yang, H., Luo, S. B., & Fu, Y. C. (2008). Machining induced defects and the influence factors when diamond turning of SiCp/Al composites. Applied Mechanics and Materials, 10, 626-630. 10.4028/www.scientific.net/AMM.10-12.

- Ge, Y. F. , Xu, J. H., Yang, H., Luo, S. B., & Fu, Y. C. (2008). Workpiece surface quality when ultra-precision turning of SiCp/Al composites. Journal of materials processing technology, 203(1-3), 166-175. 10.1016/j.jmatprotec.2007.09.

- Krishnaraj, V.; Raghavendran, N.; Sudhan, R.; Vignesh, R. An investigation on end milling of aluminium based metal matrix composites for optimising machining parameters. Journal of Machining and Forming Technologies 2012, 4, 265. [Google Scholar]

- Krishnaraj, V. (2013). Optimisation of End Milling Parameters on Aluminium/SiC Composites Using Response Surface and Artificial Neural Network Methodologies. In Materials Science Forum (Vol. 766, pp. 59-75). Trans Tech Publications Ltd. 10.4028/www.scientific.net/MSF.766.59.

- Rajmohan, T.; Palanikumar, K.; Kathirvel, M. Optimization of machining parameters in drilling hybrid aluminium metal matrix composites. Transactions of Nonferrous Metals Society of China 2012, 22, 1286–1297. [Google Scholar] [CrossRef]

- Rajmohan, T. , & Palanikumar, K. (2012). Optimization of machining parameters for multi-performance characteristics in drilling hybrid metal matrix composites. Journal of Composite Materials, 46(7), 869-878. [CrossRef]

- Rajmohan, T., & Palanikumar, K. (2013). Application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. Measurement, 46(4), 1470-1481. [CrossRef]

- Jayakumar, K., Mathew, J., Joseph, M. A., Kumar, R. S., & Chakravarthy, P. (2012). Processing and end milling behavioural study of A356-SiCp Composite. In Materials Science Forum (Vol. 710, pp. 338-343). Trans Tech Publications Ltd. 10.4028/www.scientific.net/MSF.710.

- Jeyakumar, S. , Marimuthu, K., & Ramachandran, T. (2013). Prediction of cutting force, tool wear and surface roughness of Al6061/SiC composite for end milling operations using RSM. Journal of Mechanical Science and Technology, 27, 2813-2822. [CrossRef]

- Muthukrishnan, N. , Babu, T. M., & Ramanujam, R. (2012). Fabrication and turning of Al/SiC/B4C hybrid metal matrix composites optimization using desirability analysis. Journal of the Chinese Institute of Industrial Engineers, 29(8), 515-525. [CrossRef]

- Peng, S. , Xie, L. J., Wang, X. B., Fu, N. X., & Shi, X. K. (2014). Investigation on the cutting force of high-speed milling of high volume fraction of SiCp/Al composites with PCD tools. Advanced Materials Research, 873, 350-360. [CrossRef]

- Palanikumar, K. , Muthukrishnan, N., & Hariprasad, K. S. (2014). Surface roughness parameters optimization in machining A356/SiC/20p metal matrix composites by PCD tool using response surface methodology and desirability function. Machining Science and Technology, 12(4), 529-545. [CrossRef]

- Venkatesan, K. , Ramanujam, R., Joel, J., Jeyapandiarajan, P., Vignesh, M., Tolia, D. J., & Krishna, R. V. (2014). Study of cutting force and surface roughness in machining of Al alloy hybrid composite and optimized using response surface methodology. Procedia Engineering, 97, 677-686. [CrossRef]

- Dabade, U. A. , Sonawane, H. A., & Joshi, S. S. (2014). Cutting forces and surface roughness in machining Al/SiCp composites of varying composition. Machining Science and Technology, 14(2), 258-279. [CrossRef]

- Vivek, S.; Vijayraj, S.; Prabhu, G.; Singh, J.V.M. Experimental Investigation for the Machining of Al-Sic Nano Composites using Response Surface Method. International Journal of Applied Engineering Research 2015, 10. [Google Scholar]

- Vijayraj, S.; Arivazhagan, A.; Prakash, G.; Prabhu, G. Optimization of machining parameters of Al-SiC nano composites using DOE. Int. J. Appl. Eng. Res 2015, 10, 5863–5869. [Google Scholar]

- El-Kady, E. Y., Gaafer, A. M., Ghaith, M. H. G., Khalil, T., & Mostafa, A. A. (2015). The effect of machining parameters on the cutting forces, tool wear, and machined surface roughness of metal matrix nano composite material. Advances in Materials, 4(3), 43-50. [CrossRef]

- Karabulut, Ş. , Çinici, H., & Karakoç, H. (2016). Experimental investigation and optimization of cutting force and tool wear in milling Al7075 and open-cell SiC foam composite. Arabian Journal for Science and Engineering, 41, 1797-1812. [CrossRef]

- Thamizharasan, M. M. , Nithiya Sandhiya, Y. J., Sekar, K. V., & Bhanu Prasad, V. V. (2016). Finite element analysis of the effect of cutting speed on the orthogonal turning of A359/SiCp MMC. Applied Mechanics and Materials, 852, 304-310. [CrossRef]

- Jadhav, M. R. , & Dabade, U. A. (2016). Modelling and simulation of Al/SiCp MMCs during hot machining. In ASME international mechanical engineering congress and exposition (Vol. 50527, p. V002T02A023). American Society of Mechanical Engineers.

- Wu, Q., Xu, W., & Zhang, L. (2018). A micromechanics analysis of the material removal mechanisms in the cutting of ceramic particle reinforced metal matrix composites. Machining Science and Technology, 22(4), 638-651. [CrossRef]

- Bushlya, V. , Lenrick, F., Gutnichenko, O., Petrusha, I., Osipov, O., Kristiansson, S., & Stahl, J. E. (2017). Performance and wear mechanisms of novel superhard diamond and boron nitride based tools in machining Al-SiCp metal matrix composite. Wear, 376, 152-164. [CrossRef]

- Elsadek, A.A.; Gaafer, A.; Lashin, A.M.A. Prediction of Roughness and Tool Wear in Turning of Metal Matrix Nanocomposites. J. Eng. App. Sci 2017, 64, 387–408. [Google Scholar]

- Ghoreishi, R. , Roohi, A. H., & Ghadikolaei, A. D. (2018). Analysis of the influence of cutting parameters on surface roughness and cutting forces in high speed face milling of Al/SiC MMC. Materials Research Express, 5(8), 086521. [CrossRef]

- Ghoreishi, R. , Roohi, A. H., & Ghadikolaei, A. D. (2019). Evaluation of tool wear in high-speed face milling of Al/SiC metal matrix composites. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41(3), 146. [CrossRef]

- Deng, B. , Wang, H., Peng, F., Yan, R., & Zhou, L. (2018). Experimental and theoretical investigations on tool wear and surface quality in micro milling of SiCp/Al composites under dry and MQL conditions. In ASME International Mechanical Engineering Congress and Exposition (Vol. 52019, p. V002T02A001). American Society of Mechanical Engineers.

- Xiang, J. , Pang, S., Xie, L., Hu, X., Peng, S., & Wang, T. (2018). Investigation of cutting forces, surface integrity, and tool wear when high-speed milling of high-volume fraction SiC p/Al6063 composites in PCD tooling. The International Journal of Advanced Manufacturing Technology, 98, 1237-1251. [CrossRef]

- Pramanik, A. , Basak, A. K., Dong, Y., Shankar, S., & Littlefair, G. (2018). Milling of nanoparticles reinforced Al-based metal matrix composites. Journal of Composites Science, 2(1), 13. [CrossRef]

- Wang, Z. , Xu, J., Yu, H., Yu, Z., Li, Y., & Du, Q. (2018). Process characteristics of laser-assisted micro machining of SiC p/2024Al composites. The International Journal of Advanced Manufacturing Technology, 94, 3679-3690. [CrossRef]

- Teng, X. , Chen, W., Huo, D., Shyha, I., & Lin, C. (2018). Comparison of cutting mechanism when machining micro and nano-particles reinforced SiC/Al metal matrix composites. Composite Structures, 203, 636-647. [CrossRef]

- Kumar, S. , & Sood, P. K. (2019). Leverage of machining parameters and non-oxide nano ceramic fillers loading on machinability of aluminium matrix based nano-composites. Materials Research Express, 6(5), 056516. [CrossRef]

- Niu, Z. (2018). Investigation on the multiscale multiphysics based approach to modelling and analysis of precision machining of metal matrix composites (MMCs) and its application perspectives (Doctoral dissertation, Brunel University London).

- Ramesh Kumar, C. , JaiGanesh, V., & Malarvannan, R. R. R. (2019). Optimization of drilling parameters in hybrid (Al6061/SiC/B 4 C/talc) composites by grey relational analysis. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41, 1-10. [CrossRef]

- Nandakumar, A., Rajmohan, T., & Vijayabhaskar, S. (2019). Experimental evaluation of the lubrication performance in MQL grinding of nano SiC reinforced Al matrix composites. Silicon, 11(6), 2987-2999. [CrossRef]

- Mirshamsi, S. M. A. , Movahhedy, M. R., & Khodaygan, S. (2019). Experimental modeling and optimizing process parameters in the laser assisted machining of silicon carbide particle-reinforced aluminum matrix composites. Materials Research Express, 6(8), 086591. [CrossRef]

- Tripathy, P. , & Maity, K. P. (2019). Experimental Investigation during Micro-Milling of Hybrid Al6063 MMC Reinforced with SiC and ZrO2. In Advanced Engineering Forum (Vol. 33, pp. 1-9). Trans Tech Publications Ltd. 10.4028/www.scientific.net/AEF.33.

- Ajithkumar, J. P., & Xavior, M. A. (2019). Cutting force and surface roughness analysis during turning of Al 7075 based hybrid composites. Procedia Manufacturing, 30, 180-187. [CrossRef]

- Ajithkumar, J. P., & Xavior, M. A. (2019). Flank and crater wear analysis during turning of Al 7075 based hybrid composites. Materials Research Express, 6(8), 086560. [CrossRef]

- Arulraj, M.; Palani, P.K.; Venkatesh, L. Optimization of Machining Parameters In Turning of Hybrid Aluminium-Matrix (LM24–SiCp–Coconut Shell Ash) Composite. Materiali in tehnologije / Materials and technology 2019, 53, 263–268. [Google Scholar] [CrossRef]

- Wang, Z. , Xu, J., Yu, Z., Liu, Q., Pei, Q., & Zhai, C. (2019). Study on Laser-assisted Machining of Aluminum-based Silicon Carbide. In 2019 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO) (pp. 24-28). IEEE.

- Ramasubramanian, K. , Arunachalam, N., & Rao, M. R. (2019). Wear performance of nano-engineered boron doped graded layer CVD diamond coated cutting tool for machining of Al-SiC MMC. Wear, 426, 1536-1547. [CrossRef]

- Thirukkumaran, K. , Menaka, M., Mukhopadhyay, C. K., & Venkatraman, B. (2020). A study on temperature rise, tool wear, and surface roughness during drilling of Al–5% SiC composite. Arabian Journal for Science and Engineering, 45, 5407-5419. [CrossRef]

- Abbas, C. A. , Huang, C., Wang, J., Wang, Z., Liu, H., & Zhu, H. (2020). Machinability investigations on high-speed drilling of aluminum reinforced with silicon carbide metal matrix composites. The International Journal of Advanced Manufacturing Technology, 108, 1601-1611. [CrossRef]

- Wiciak-Pikula, M. , Felusiak, A., & Twardowski, P. (2020). Artificial Neural Network models for tool wear prediction during Aluminium Matrix Composite milling. In 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace) (pp. 255-259). IEEE.

- Wiciak-Pikuła, M. , Felusiak-Czyryca, A., & Twardowski, P. (2020). Tool wear prediction based on artificial neural network during aluminum matrix composite milling. Sensors, 20(20), 5798. [CrossRef]

- Zhao, G. , Mao, P., Li, L., Iqbal, A., & He, N. (2020). Micro-milling of 65 vol% SiCp/Al composites with a novel laser-assisted hybrid process. Ceramics International, 46(16), 26121-26128. [CrossRef]

- Zhao, G. , Hu, M., Li, L., Zhao, C., Zhang, J., & Zhang, X. (2020). Enhanced machinability of SiCp/Al composites with laser-induced oxidation assisted milling. Ceramics International, 46(11), 18592-18600. [CrossRef]

- Zhou, G. , Xu, C., Ma, Y., Wang, X. H., Feng, P. F., & Zhang, M. (2020). Prediction and control of surface roughness for the milling of Al/SiC metal matrix composites based on neural networks. Advances in Manufacturing, 8, 486-507. [CrossRef]

- Liu, C. , Gao, L., Jiang, X., Xu, W., Liu, S., & Yang, T. (2020). Analytical modeling of subsurface damage depth in machining of SiCp/Al composites. International Journal of Mechanical Sciences, 185, 105874. [CrossRef]

- Repeto, D. , Fernández-Vidal, S. R., Mayuet, P. F., Salguero, J., & Batista, M. (2020). On the machinability of an Al-63% SiC metal matrix composite. Materials, 13(5), 1186. [CrossRef]

- Swain, P. K. , Mohapatra, K. D., Das, R., Sahoo, A. K., & Panda, A. (2020). Experimental investigation into characterization and machining of Al+ SiCp nano-composites using coated carbide tool. Mechanics & Industry, 21(3), 307. [CrossRef]

- Swain, P.K.; Mohapatra, K.D.; Swain, P.K. Optimization, error analysis and mathematical modelling of Al-SiCp metal matrix nano composites using coated carbide insert. Materials Today: Proceedings 2020, 26, 620–631. [Google Scholar] [CrossRef]

- Das, D. , Chakraborty, V., Nayak, B. B., Satpathy, M. P., & Samal, C. (2020). Machining of aluminium-based metal matrix composite-a particle swarm optimisation approach. International Journal of Machining and Machinability of Materials, 22(1), 79-97. [CrossRef]

- Bhushan, R. K. (2022). Optimization of machining parameters for minimizing cutting forces during machining of Al alloy SiC particle composites. Australian Journal of Mechanical Engineering, 20(2), 372-386. [CrossRef]

- Bhushan, R. K. (2021). Minimizing tool wear by optimization (ANOVA) of cutting parameters in machining of 7075Al Alloy SiC particle composite. Australian Journal of Mechanical Engineering, 21(2), 499-517. [CrossRef]

- Chakravarthy, V. K., Rajmohan, T., Vijayan, D., & Palanikumar, K. (2021). Sustainable drilling of nano SiC reinforced Al matrix composites using MQL and cryogenic cooling for achieving the better surface integrity. Silicon, 1-19. [CrossRef]

- Çevik, Z. A. , Karabacak, A. H., Kök, M., Canakçı, A., Kumar, S. S., & Varol, T. (2021). The effect of machining processes on the physical and surface characteristics of AA2024-B4C-SiC hybrid nanocomposites fabricated by hot pressing method. Journal of Composite Materials, 55(19), 2657-2671.

- Shihab, S. K. , Gattmah, J., & Kadhim, H. M. (2021). Experimental investigation of surface integrity and multi-objective optimization of end milling for hybrid Al7075 matrix composites. Silicon, 13(5), 1403-1419. [CrossRef]

- Saini, P. , & Singh, P. K. (2021). Optimization of end milling parameters for rough and finish machining of Al-4032/3% SiC metal matrix composite. Engineering Research Express, 3(4), 045009. [CrossRef]

- Saini, P. , Singh, P. K., & Kumar, D. (2022). Effect of machining parameters for surface finish and material removal rate of Al-4032/SiC composite during end milling using TGRA and ANN. Journal of Advanced Manufacturing Systems, 21(01), 85-109. [CrossRef]

- Saini, P. , & Singh, P. K. (2022). Effect of machining parameters on surface roughness and energy consumption during end milling of stir cast Al-4032/6% SiC composite. Surface Topography: Metrology and Properties, 10(3), 035029. [CrossRef]

- Patil, P. P., & Lila, M. K. (2021). Impact of Machining Variables on Tool wear and surface roughness of 7071 Al with SiC Hybrid Materials. Webology, 18(5), 2910-2916. [CrossRef]

- Kumar, J. , Singh, D., Kalsi, N. S., & Sharma, S. (2021). Influence of Reinforcement Contents and Turning Parameters on the Machining Behaviour of Al/SiC/Cr Hybrid Aluminium Matrix Composites. Additive and Subtractive Manufacturing of Composites, 33-51. [CrossRef]

- Kumar, J. , Singh, D., Kalsi, N. S., Sharma, S., Mia, M., Singh, J.,... & Rao, K. V. (2021). Investigation on the mechanical, tribological, morphological and machinability behavior of stir-casted Al/SiC/Mo reinforced MMCs. Journal of Materials Research and Technology, 12, 930-946. [CrossRef]

- Abedinzadeh, R. , Norouzi, E., & Toghraie, D. (2021). Experimental investigation of machinability in laser-assisted machining of aluminum-based nanocomposites. Journal of Materials Research and Technology, 15, 3481-3491. [CrossRef]

- Zhou, J. , Lu, M., Lin, J., & Du, Y. (2021). Elliptic vibration assisted cutting of metal matrix composite reinforced by silicon carbide: an investigation of machining mechanisms and surface integrity. Journal of Materials Research and Technology, 15, 1115-1129. [CrossRef]

- Devaraj, S. , Malkapuram, R., & Singaravel, B. (2021). Performance analysis of micro textured cutting insert design parameters on machining of Al-MMC in turning process. International Journal of Lightweight Materials and Manufacture, 4(2), 210-217. [CrossRef]

- Liu, C. , Wang, Z., Gao, L., Zhang, X., Wang, G., Yang, T., & Du, Y. (2022). A novel tool wear modeling method in drilling of particle reinforced metal matrix composite. The International Journal of Advanced Manufacturing Technology, 119(11-12), 7089-7107. [CrossRef]

- Babu, S. S. , Dhanasekaran, C., Anbuchezhiyan, G., & Palani, K. (2022). Parametric analysis on drilling of aluminium alloy hybrid composites reinforced with SIC/WC. Engineering Research Express, 4(2), 025036. [CrossRef]

- Nagarajan, N., & Kamalakannan, R. (2022). Analyze the Effect of Crater Cutting Tool Wear Modeling in the Machining of Aluminium Composite. Materials Research, 25. [CrossRef]

- Behera, R. K. , Samal, B. P., Panigrahi, S. C., Das, S. R., Mohamed, A., Muduli, K.,... & Das, R. (2022). Experimental analysis on machinability aspects of sintered aluminium metal matrix (Al+ Si+ Mg+ Cu+ SiC) composite-a novel product produced by powder metallurgy method. International Journal of Materials Engineering Innovation, 13(1), 1-22. [CrossRef]

- Kim, J. , Zani, L., Abdul-Kadir, A., Ribeiro, M. L., Roy, A., Baxevanakis, K. P.,... & Silberschmidt, V. V. (2022). Ultrasonically assisted turning of micro-SiCp/Al 2124 composite. Procedia Structural Integrity, 37, 282-291. [CrossRef]

- Laghari, R. A. , He, N., Jamil, M., & Gupta, M. K. (2023). Tribological and machining characteristics of milling SiCp/Al MMC composites under sustainable cooling conditions. The International Journal of Advanced Manufacturing Technology, 128(5-6), 2613-2630. [CrossRef]

- Laghari, R. A. , Mekid, S., Akhtar, S. S., Laghari, A. A., & Jamil, M. (2022). Investigating the Tribological Aspects of Tool Wear Mechanism and Tool Life in Sustainable Lubri-Cooling Face Milling Process of Particle Reinforced SiCp/Al Metal Matrix Composites. In ASME International Mechanical Engineering Congress and Exposition (Vol. 86649, p. V02BT02A062). American Society of Mechanical Engineers. [CrossRef]

- Priyadarshi, D. , & Sharma, R. K. (2016). Optimization for turning of Al-6061-SiC-Gr hybrid nanocomposites using response surface methodologies. Materials and Manufacturing Processes, 31(10), 1342-1350. [CrossRef]

- Priyadarshi, D., & Sharma, R. K. (2016). Effect of type and percentage of reinforcement for optimization of the cutting force in turning of Aluminium matrix nanocomposites using response surface methodologies. Journal of Mechanical Science and Technology, 30, 1095-1101. [CrossRef]

- Shihab, S. K. , Gattmah, J., & Kadhim, H. M. (2021). Experimental investigation of surface integrity and multi-objective optimization of end milling for hybrid Al7075 matrix composites. Silicon, 13(5), 1403-1419. [CrossRef]

- Kannan, V. , & Kannan, V. V. (2018). A Study on the Turning Characteristics and Optimization of MOS 2 p and SiCp-Reinforced Al-Si10Mg Metal Matrix Composites (No. 2018-28-0043). SAE Technical Paper. [CrossRef]

- Guolong, Z. H. A. O. , Lianjia, X. I. N., Liang, L. I., Zhang, Y., Ning, H. E., & Hansen, H. N. (2023). Cutting force model and damage formation mechanism in milling of 70wt% Si/Al composite. Chinese Journal of Aeronautics, 36(7), 114-128. [CrossRef]

- Şap, S. (2023). Machining and energy aspect assessment with sustainable cutting fluid strategies of Al–12Si based hybrid composites. International Journal of Precision Engineering and Manufacturing-Green Technology, 1-21. [CrossRef]

- Al-Kandary, M., Habib, S., EH Mansour, S., & S Mahmoud, T. (2019). On The Optimization Of The Machinability Characteristics Of Al-Si/Al2O3 AND Al-Si/MWCNTs Metal Matrix Nanocomposites. Engineering Research Journal-Faculty of Engineering (Shoubra), 42(1), 9-14. [CrossRef]

- Raj, P. , Biju, P. L., Deepanraj, B., & Senthilkumar, N. (2023). Optimizing the machining conditions in turning hybrid aluminium nanocomposites adopting teaching–learning based optimization and MOORA technique. International Journal on Interactive Design and Manufacturing (IJIDeM), 1-13. [CrossRef]

- Puttaswamy, S. J. , & Venkatagiriyappa, R. B. (2021). Effect of Machining Parameters on Surface Roughness, Power Consumption, and Material Removal Rate of Aluminium 6065-Si-MWCT Metal Matrix Composite in Turning Operations. IIUM Engineering Journal, 22(2), 283-293. [CrossRef]

- Kannan, V. V. , Kannan, V., Sundararajan, D., Seth, A., Sood, N., & Babu, A. (2019). Fabrication and Machinability Study of Al2219 Metal Matrix Composites Reinforced with SiN/MoS 2 Nanoparticles (No. 2019-28-0170). SAE Technical Paper. [CrossRef]

- Siddeshkumar, N. G., Suresh, R., Shivaramu, L., & Shankar, G. S. (2022). Analysis of Cutting Forces and Surface Roughness in Machining Al2219, Unhybrid and Hybrid Metal Matrix Nano Composites using CCD Design of Experiment. Trends in Sciences, 19(11), 4499-4499. [CrossRef]

- Ghalme, S. G. , & Karolczak, P. (2023). Optimization of Drilling Parameters for Aluminum Metal Matrix Composite Using Entropy-Weighted TOPSIS under MQL Conditions. Engineering Transactions. [CrossRef]

- Wiciak-Pikuła, M., Twardowski, P., Bartkowska, A., & Felusiak-Czyryca, A. (2021). Experimental investigation of surface roughness in milling of duralcanTM composite. Materials, 14(20), 6010. [CrossRef] [PubMed]

- Kuliiev, R. (2020).

- Smart, D. R. , Varghese, P., & George, L. J. (2013). Experimental investigation of effect of gear milling parameters of Al-B4C composite gears on surface roughness. Advanced Materials Research, 690, 2523-2528. [CrossRef]

- Taşkesen, A. , & Kütükde, K. (2014). Experimental investigation and multi-objective analysis on drilling of boron carbide reinforced metal matrix composites using grey relational analysis. Measurement, 47, 321-330. [CrossRef]

- Hiremath, V. , Bharath, V., Auradi, V., Dundur, S. T., & Nagaral, M. (2022). Machining of hard-to-cut materials: impact of varying weight proportion of boron carbide particle addition on cutting force and surface roughness of Al6061. Journal of Materials Engineering and Performance, 1-8. [CrossRef]

- Sekhar, R. , Singh, T. P., & Shah, P. (2022). Machine learning based predictive modeling and control of surface roughness generation while machining micro boron carbide and carbon nanotube particle reinforced Al-Mg matrix composites. Particulate Science and Technology, 40(3), 355-372. [CrossRef]

- Sathish, T. , Vinayagam, M., Raja, T., Seikh, A. H., Siddique, M. H., Subbiah, R., & Hailu, B. (2022). Synthesis of AA8050/B4C/TiB2 Hybrid Nanocomposites and Evaluation of Computer-Aided Machining Parameters. Journal of Nanomaterials, 2022. [CrossRef]

- Pul, M. , & Yağmur, S. (2022). Examination of the effect of B4C and GNP reinforcements on machinability in the machining of Al 6061 matrix B4C/GNP reinforced hybrid composites. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 44(10), 469. [CrossRef]

- Ekici, E. , Motorcu, A. R., & Uzun, G. (2017). An investigation of the effects of cutting parameters and graphite reinforcement on quality characteristics during the drilling of Al/10B4C composites. Measurement, 95, 395-404. [CrossRef]

- Pugazhenthi, A., Kanagaraj, G., Dinaharan, I., & Selvam, J. D. R. (2018). Turning characteristics of in situ formed TiB2 ceramic particulate reinforced AA7075 aluminum matrix composites using polycrystalline diamond cutting tool. Measurement, 121, 39-46. [CrossRef]

- Yu, W. , Chen, J., Li, Y., Zuo, Z., Chen, D., An, Q.,... & Wang, H. (2021). Comprehensive study on the cutting specific energy and surface roughness of milled in situ TiB2/Al composites and Al alloys. The International Journal of Advanced Manufacturing Technology, 112, 2717-2729. [CrossRef]

- Chen, J. , Yu, W., Zuo, Z., Li, Y., Chen, D., An, Q.,... & Chen, M. (2021). Tribological properties and tool wear in milling of in-situ TiB2/7075 Al composite under various cryogenic MQL conditions. Tribology International, 160, 107021. [CrossRef]

- Parasuraman, S. , Elamvazuthi, I., Kanagaraj, G., Natarajan, E., & Pugazhenthi, A. (2021). Assessments of process parameters on cutting force and surface roughness during drilling of AA7075/TiB2 in situ composite. Materials, 14(7), 1726. [CrossRef]

- Kishore, D. S. C. , Rao, K. P., & Mahamani, A. (2014). Investigation of cutting force, surface roughness and flank wear in turning of In-situ Al6061-TiC metal matrix composite. Procedia materials science, 6, 1040-1050. [CrossRef]

- Kishore, D. S. C. , Rao, K. P., & Mahamani, A. (2014). Effects of PCD and uncoated tungsten carbide inserts in turning of in-situ Al6061-TiC metal matrix composite. Procedia Materials Science, 5, 1574-1583. [CrossRef]

- Sujith, S. V. , & Mulik, R. S. (2022). Surface integrity and flank wear response under pure coconut oil-Al2O3 nano minimum quantity lubrication turning of Al-7079/7 wt%-TiC in situ metal matrix composites. Journal of Tribology, 144(5), 051701. [CrossRef]

- Thangavel, S.; Murugan, M.; Zeelanbasha, N. Investigation of cutting force in end milling of Al/n-Tic/MoS 2 sintered nano composite. Metalurgija 2019, 58, 251–254. [Google Scholar]

- Sozhamannan, C. G. , Naveenkumar, K., Mathiarasu, A., Velmurugan, K., & Venkatachalapathy, V. S. K. (2018). Machining characteristics of Al/Ticp/Gr hybrid composites. Materials Today: Proceedings, 5(2), 5940-5946. [CrossRef]

- Raveendran, P. , Alagarsamy, S. V., Ravichandran, M., & Meignanamoorthy, M. (2021). Effect of machining parameters on surface roughness for aluminium matrix composite by using Taguchi method with decision tree algorithm. Surface Review and Letters, 28(04), 2150021. [CrossRef]

- Maganti, N. V. R., & Potturi, R. R. (2023). Investigation on Mechanical and Machinability Properties of Aluminium Metal Matrix Composite Reinforced with Titanium Oxide (TiO2) and Graphite (Gr) Particles. Trends in Sciences, 20(11), 5682-5682. [CrossRef]

- Sivasankaran, S. , Saminathan, E., Sidharth, S., Harisagar, P. T., & Sasikumar, P. (2014). Effect of Graphite addition on surface roughness during turning of AA 7075-ZrB2 in-situ metal matrix composites. Procedia Materials Science, 5, 2122-2131. [CrossRef]

- Ruban, S. R. , Selvam, J. D. R., Wins, K. L. D., & Kandavalli, S. R. (2020). Optimization of cutting parameters of hybrid metal matrix composite AA6061/ZrB2 and ZrC during dry turning. In IOP Conference Series: Materials Science and Engineering (Vol. 993, No. 1, p. 012135). IOP Publishing. [CrossRef]

- Ruban, S. R. , Dev Wins, K. L., Raja Selvam, J. D., & S Rai, R. (2023). Influence of turning parameters on the machinability of Al6061/ZrB2 & ZrC hybrid in-situ Aluminium Matrix Composite. Australian Journal of Mechanical Engineering, 21(4), 1218-1229. [CrossRef]

- Yerigeri, S. V. Yerigeri, S. V., & Biradar, S. K. (2022). Effect of ZrB2 Nano-Ingredient on Uncoated Tool Wear for Aluminum Alloys-Based Metal Matrix Composite. In Innovations in Mechanical Engineering: Select Proceedings of ICIME 2021 (pp. 515-532). Singapore: Springer Nature Singapore. [CrossRef]

- Mahesha, C. R. , Suprabha, R., Suresh Kumar, R., Chowdary, C. M., Upadhyay, V. V., Soumya, M.,... & Diriba, A. (2023). Effect of ZrB 2 Particles on Machining Parameters of AA7475 Alloy-Based Composites by Optimization Technique. Advances in Materials Science and Engineering. [CrossRef]

- Razavykia, A. (2014). Effects of Machining Parameters and Bismuth Addition on Al-20% Mg2Si Machinability During Dry Turning (Doctoral dissertation, Universiti Teknologi Malaysia).

- Raja, K.; Chandra Sekar, V.S.; Vignesh Kumar, V.; Ramkumar, T.; Ganeshan, P. Microstructure characterization and performance evaluation on AA7075 metal matrix composites using RSM technique. Arabian Journal for Science and Engineering 2020, 45, 9481–9495. [Google Scholar] [CrossRef]

- Arulkirubakaran, D.; Senthilkumar, V.; Chilamwar, V.L.; Senthil, P. Performance of surface textured tools during machining of Al-Cu/TiB2 composite. Measurement 2019, 137, 636–646. [Google Scholar] [CrossRef]

- Dandekar, C. R. , & Shin, Y. C. (2010). Laser-assisted machining of a fiber reinforced metal matrix composite.

- Prasad, B. S. , KarakaVVNR, C. M., & Annavarapu, V. S. (2022). Surface morphology and microstructural analysis of al 8081-mg/zr/TiO2 nano metal matrix composite–A base for performance evaluation of polycrystalline diamond and poly cubic boron nitride tools. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 236(10), 5678-5686. [CrossRef]

- Jaswanth, A. , & Anbuchezhiyan, G. (2022). Analyzing the surface roughness of WC particulate hardened MMCs with Al-Mg-Cr alloys. Journal of Pharmaceutical Negative Results, 310-318.

- Pul, M. Investigation of effects of MgO ratio on the surface quality and tool wear in turning Al–MgO composites. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 2018, 232, 2122–2131. [Google Scholar] [CrossRef]

- Joel, J. , & Anthony Xavior, M. (2017). Machinability analysis of aluminum alloy-graphene metal matrix composites using uncoated and dlc-coated carbide insert. In ASME International Mechanical Engineering Congress and Exposition (Vol. 58356, p. V002T02A002). American Society of Mechanical Engineers.

- Joel, J., & Xavior, A. (2019). Optimization on machining parameters of aluminium alloy hybrid composite using carbide insert. Materials Research Express, 6(11), 116532. [CrossRef]

- Lagisetti, V. K. , & Sukjamsri, C. (2022). Machinability Study on AA6061/2 SiC/Graphite Hybrid Nanocomposites Fabricated through Ultrasonic Assisted Stir Casting. International Journal of Automotive and Mechanical Engineering, 19(3), 9950-9963. [CrossRef]

- Sathish, T. , Mohanavel, V., Karthick, A., Arunkumar, M., Ravichandran, M., & Rajkumar, S. (2021). Study on Compaction and machinability of silicon nitride (Si3N4) reinforced copper alloy composite through P/M route. International Journal of Polymer Science, 2021, 1-10. [CrossRef]

- Usca, Ü. A. , Uzun, M., Kuntoğlu, M., Sap, E., & Gupta, M. K. (2021). Investigations on tool wear, surface roughness, cutting temperature, and chip formation in machining of Cu-B-CrC composites. The International Journal of Advanced Manufacturing Technology, 116, 3011-3025. [CrossRef]

- Usca, Ü. A. , Uzun, M., Şap, S., Kuntoğlu, M., Giasin, K., Pimenov, D. Y., & Wojciechowski, S. (2022). Tool wear, surface roughness, cutting temperature and chips morphology evaluation of Al/TiN coated carbide cutting tools in milling of Cu–B–CrC based ceramic matrix composites. journal of materials research and technology, 16, 1243-1259. [CrossRef]

- Usca, Ü. A. , Şap, S., Uzun, M., Kuntoğlu, M., Salur, E., Karabiber, A.,... & Wojciechowski, S. (2022). Estimation, optimization and analysis based investigation of the energy consumption in machinability of ceramic-based metal matrix composite materials. journal of materials research and technology, 17, 2987-2998. [CrossRef]

- Şap, E. , Usca, U. A., Gupta, M. K., & Kuntoğlu, M. (2021). Tool wear and machinability investigations in dry turning of Cu/Mo-SiCp hybrid composites. The International Journal of Advanced Manufacturing Technology, 114(1-2), 379-396. [CrossRef]

- Şap, E. , Usca, Ü. A., Gupta, M. K., Kuntoğlu, M., Sarıkaya, M., Pimenov, D. Y., & Mia, M. (2021). Parametric optimization for improving the machining process of cu/mo-sicp composites produced by powder metallurgy. Materials, 14(8), 1921. [CrossRef]

- Şap, S., Usca, Ü. A., Uzun, M., Kuntoğlu, M., Salur, E., & Pimenov, D. Y. (2022). Investigation of the effects of cooling and lubricating strategies on tribological characteristics in machining of hybrid composites. Lubricants, 10(4), 63. [CrossRef]

- Serhat Sap, Mahir Uzun, U¨ same Ali Usca, Danil Yu Pimenov, Khaled Giasin, Szymon Wojciechowski (2022). Investigation of machinability of TieB-SiCp reinforced Cu hybrid composites in dry turning. Journal of materials research and technology, 18(1474), e1487. [CrossRef]

- Li, J. , Liu, J., & Xu, C. (2010). Machinability study of SiC nano-particles reinforced magnesium nanocomposites during micro-milling processes. In International Manufacturing Science and Engineering Conference (Vol. 49477, pp. 391-398).

- Li, J. , Liu, J., Liu, J., Ji, Y., & Xu, C. (2013). Experimental investigation on the machinability of SiC nano-particles reinforced magnesium nanocomposites during micro-milling processes. International Journal of Manufacturing Research, 8(1), 64-84. [CrossRef]

- Teng, X. , Huo, D., Wong, W. L. E., & Gupta, M. (2015). Experiment based investigation into micro machinability of Mg based metal matrix composites (MMCs) with nano-sized reinforcements. In 2015 21st International Conference on Automation and Computing (ICAC) (pp. 1-6). IEEE.

- Teng, X. , Huo, D., Wong, E., Meenashisundaram, G., & Gupta, M. (2016). Micro-machinability of nanoparticle-reinforced Mg-based MMCs: an experimental investigation. The International Journal of Advanced Manufacturing Technology, 87, 2165-2178. [CrossRef]

- Teng, X. , Huo, D., Wong, W. L. E., Sankaranarayanan, S., & Gupta, M. (2017). Machinability Investigation in Micro-milling of Mg Based MMCs with Nano-Sized Particles. In Magnesium Technology 2017 (pp. 61-69). Springer International Publishing. [CrossRef]

- Teng, X. (2018). Investigation into micro machinability of Mg based metal matrix compostites (MMCs) reinforced with nanoparticles (Doctoral dissertation, Newcastle University).

- Teng, X. , Huo, D., Shyha, I., Chen, W., & Wong, E. (2018). An experimental study on tool wear behaviour in micro milling of nano Mg/Ti metal matrix composites. The International Journal of Advanced Manufacturing Technology, 96, 2127-2140. [CrossRef]

- Gao, C. , & Jia, J. (2017). Factor analysis of key parameters on cutting force in micromachining of graphene-reinforced magnesium matrix nanocomposites based on FE simulation. The International Journal of Advanced Manufacturing Technology, 92, 3123-3136. [CrossRef]

- Sun, F. , Huo, D., Fu, G., Teng, X., Kannan, S., & Zhang, H. (2020). Micro-drilling of Mg-based MMCs reinforced with SiO2 nanoparticles: An experimental approach. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 234(12), 1473-1485. [CrossRef]

- Babu, J. S. , Heo, M., & Kang, C. G. (2020). Study of Machining Parameter Optimization in Drilling of Magnesium Based Hybrid Composites Reinforced with Sic/CNT. Key Engineering Materials, 846, 42-46. [CrossRef]

- Asgari, A. , & Sedighi, M. (2023). Investigation on the optimal machining of Mg-based composites considering surface roughness, tool life, cutting forces, and productivity. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 237(5), 1139-1152. [CrossRef]

- Gobivel, K., & Vijay Sekar, K. S. (2022). Machinability studies on the turning of magnesium metal matrix composites. Archives of Metallurgy and Materials, 939-948. [CrossRef]

- Meher, A. , Mahapatra, M. M., Samal, P., Vundavilli, P. R., & Shankar, K. V. (2022). Statistical Modeling of the Machinability of an In-Situ Synthesized RZ5/TiB2 Magnesium Matrix Composite in Dry Turning Condition. Crystals, 12(10), 1353. [CrossRef]

- Meher, A. , & Mahapatra, M. M. (2023). Investigation on the Effect of Machining Parameters on Machinability of RZ5/TiB2 In-Situ Magnesium Matrix Composite. Journal of Materials Engineering and Performance, 32(17), 7706-7720. [CrossRef]

- Radhakrishnan, G. (2023). Experimental investigation on the effect of process parameters on machinability and surface integrity during end milling of Mg-TiO2 nanocomposite. International Journal of Materials and Product Technology, 66(3-4), 312-327. [CrossRef]

- Radhakrishnan, G. , Mathialagan, S., Shankaranarayanan, S., & Pushparaj, J. P. (2023). Investigation on the machinability of TiN nano particulate reinforced magnesium matrix composite. Materials Today: Proceedings, 72, 2281-2288. [CrossRef]

- Aramesh, M. , Shi, B., Nassef, A. O., Attia, H., Balazinski, M., & Kishawy, H. A. (2013). Meta-modeling optimization of the cutting process during turning titanium metal matrix composites (Ti-MMCs). Procedia CIRP, 8, 576-581. [CrossRef]

- Aramesh, M. , Attia, M. H., Kishawy, H. A., & Balazinski, M. (2016). Estimating the remaining useful tool life of worn tools under different cutting parameters: A survival life analysis during turning of titanium metal matrix composites (Ti-MMCs). CIRP Journal of Manufacturing Science and Technology, 12, 35-43. [CrossRef]

- Aramesh, M. , Shaban, Y., Yacout, S., Attia, M. H., Kishawy, H. A., & Balazinski, M. (2016). Survival life analysis applied to tool life estimation with variable cutting conditions when machining titanium metal matrix composites (Ti-MMCs). Machining Science and Technology, 20(1), 132-147. [CrossRef]

- Kishore, D. S. C. , Rao, K. P., & Ramesh, A. (2015). Optimization of machining parameters for improving cutting force and surface roughness in turning of Al6061-TiC in-situ metal matrix composites by using Taguchi method. Materials Today: Proceedings, 2(4-5), 3075-3083. [CrossRef]

- Duong, X., Mayer, J. R. R., & Balazinski, M. (2016). Initial tool wear behavior during machining of titanium metal matrix composite (TiMMCs). International Journal of Refractory Metals and Hard Materials, 60, 169-176. [CrossRef]

- Niknam, S. A. , Kamalizadeh, S., Asgari, A., & Balazinski, M. (2018). Turning titanium metal matrix composites (Ti-MMCs) with carbide and CBN inserts. The International Journal of Advanced Manufacturing Technology, 97, 253-265. [CrossRef]

- Xiong, Y., Wang, W., Jiang, R., & Lin, K. (2018). Machinability of in situ TiB2 particle reinforced 7050Al matrix composites with TiAlN coating tool. The International Journal of Advanced Manufacturing Technology, 97, 3813-3825. [CrossRef]

- Ramkumar, T. , Selvakumar, M., Mohanraj, M., & Chandrasekar, P. (2019). Experimental investigation and analysis of drilling parameters of metal matrix (Ti/TiB) composites. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 41, 1-12. [CrossRef]

- Kamalizadeh, S. , Niknam, S. A., Asgari, A., & Balazinski, M. (2019). Tool wear characterization in high-speed milling of titanium metal matrix composites. The International Journal of Advanced Manufacturing Technology, 100, 2901-2913. [CrossRef]

- Li, G. , Munir, K., Wen, C., Li, Y., & Ding, S. (2020). Machinablility of titanium matrix composites (TMC) reinforced with multi-walled carbon nanotubes. Journal of Manufacturing Processes, 56, 131-146. [CrossRef]

- Nasr, M. M., Anwar, S., Al-Samhan, A. M., Abdo, H. S., & Dabwan, A. (2020). On the machining analysis of graphene nanoplatelets reinforced Ti6Al4V matrix nanocomposites. Journal of Manufacturing Processes, 61, 574-589. [CrossRef]

- Das, L., Nayak, R., Saxena, K. K., Nanda, J., Jena, S. P., Behera, A., ... & Abdul-Zahra, D. S. (2022). Determination of optimum machining parameters for face milling process of Ti6A14V metal matrix composite. Materials, 15(14), 4765. [CrossRef]

| Al reinforced with | Machining Process | Input/Output parameters |

Optimization method | Summary of the studies |

References |

|---|---|---|---|---|---|

| Bismuth (Al-Bi) | Turning | Input: Feed Rate on Cutting Force Output: Surface roughness and cutting force |

DOE, SEM | Analyzed the relationship between machining parameters and cutting forces, surface roughness and the Bi modifier | [139] |

| Boron Nitride (Al-BN) | Drilling | Input: % of Reinforcement, Spindle speed, Feed, Point of angle Output: Thrust force and surface roughness |

RSM, ANOVA | Hardness was increased with increase in wt% of the reinforcement materials | [140] |

| Molybdenum (Al-Mo) | Turning | Input: Cutting speed, feed, depth of cut, coating thickness and chromium Output: Surface roughness, tool wear rate, MRR |

Taguchi GRA and ANOVA | The cutting speed, feed are the most influencing parameter for Ra Depth of cut is the most significant parameter for highest MRR. |

[91] |

| Copper (Al-Cu) | Turning | Input: Cutting speed, Feed Output: Cutting forces, tool wear rates, surface roughness, and chip morphology |

OM, SEM | The specific cutting energy is reduced by an amount of 25% in dry and 30% in lubricating condition during machining of Al-Cu/TiB2composite | [141] |

| LAM, Turning | Input: Tool rake angle, cutting speed and material removal temperature. Output: Cutting forces, specific cutting energy, surface roughness, tool damage |

FEM | LAM significantly reduced the cutting energy, surface roughness, and tool wear as compared to conventional machining. | [142] | |

| Magnesium (Al-Mg) | Turning | Input: Cutting speed, feed, depth of cut Output: Surface roughness |

Machine learning | Minimum settling times of the controller responses for consistent surface quality and machining productivity | [119] |

| Milling | Input: Cutting speed, Feed. Output: surface morphology, tool failure |

SEM | The evolution of displacement in the PCBN tool is 24.7 μm, which is better compared to 34.3 μm in the PCD tool at 3000 r/min. | [143] | |

| Drilling | Input: Tool diameter, spindle speed, load capacity Output: Surface roughness |

SPSS | WC-reinforced Al-Mg-Cr composite has higher surface roughness than Al-Mg-Cr alloy | [144] | |

| Turning | Input: Feed rates, cutting speeds, depth of cut Output: Surface roughness |

SEM | surface roughness values was reduced with the increased cutting speed | [145] |

|

| Tungsten (Al-Wu) | Drilling | Input: Point angle, Feed, Speed, Output: Thrust Force, Surface roughness, Roundness error |

RSM, MLR, ANN and DFA | Feed rate and point angle are found to have significant influence during drilling process | [96] |

| Graphene | Turning | Input: Cutting speed, Depth of cut and feed rate Output: Surface roughness |

HRSEM, XRD, Taguchi', ANOVA | Detachment of reinforcement materials from the composite and their impact of the surface quality. |

[146,147] |

| Milling | Input: Spindle speed and feed rate, depth of cut, the weight percentage of reinforced materials. Output: MRR, surface roughness, micro hardness. |

ANOVA, RSM | Spindle speed and feed rate, the weight percentage of reinforced materials significantly affects the surface integrity | [85,86] | |

| Turning | Input: Tool, cutting speed, feed rate, and depth of cut Output: Flank wear and crater wear and chip morphology |

Taguchi method | The reinforcement particles of SiC, B4C, Graphene and CNT had a higher influence in chip morphology and shape. | [64,65], | |

| Turning | Input: cutting speeds, feed rates Output: Cutting forces , Surface roughness, Tool wear |

SEM | The cutting forces increased with the increase in the feed rate. The highest tool wear was observed in tools where 10% B4C reinforced composites without GNP reinforcement were machined. |

[121] |

|

| Graphite | Turning | Input: Cutting speed, Depth of cut and feed rate Output: Cutting force and surface roughness |

ANOVA | High cutting speeds accompanied by low feed and depth of cut have resulted in reduced cutting forces and better surface finish | [149] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).