Submitted:

12 May 2024

Posted:

13 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

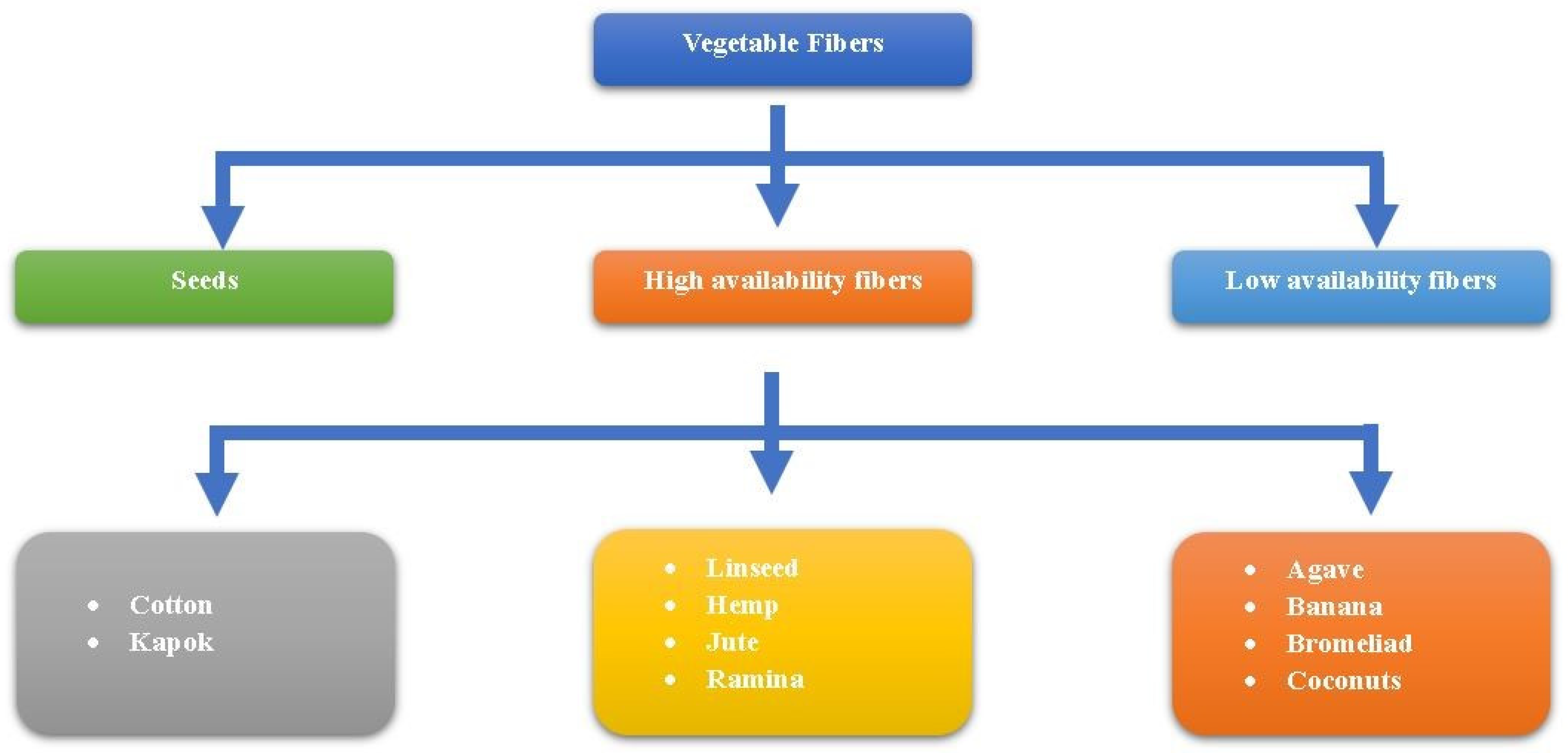

2. Classification of Vegetables Fibers

| Type of fiber | Fibers extracted from | Countries of origin | World production (103 ton) |

|---|---|---|---|

| Flax | Bast | Canada, France, Belgium, Spain | 830 |

| Hemp | Bast | China, France, Philippines, Poland, Spain | 214 |

| Jute | Bast | India, Egypt, Guyana, Jamaica, Ghana, Malawi, Sudan, Tanzania, Brazil, China, Bangladesh | 2300 |

| Kenaf | Bast | India, Bangladesh, USA, Iraq, Tanzania, Jamaica, South Africa, Cuba, Togo, Thailand | 970 |

| Ramie | Bast | China, Brazil, Philippines, India | 100 |

| Abaca | Leaf | Philippines, Ecuador, Costa Rica, Colombia | 70 |

| Curaua | Leaf | Brazil, Venezuela, Guyana, Columbia | >1 |

| Pineapple | Leaf | Philippines, Thailand, Indonesia | 74 |

| Sisal | Leaf | Brazil, East Africa, Haiti, Venezuela, Antiqua, Kenya, Tanzania, India | 378 |

| Coir | Seed | India, Sri Lanka, Philippines, Malaysia, Brazil | 100 |

| Cotton | Seed | China, India, USA | 25,000 |

| Oil Palm | Seed | Malaysia, Indonesia | 40 |

| Bagasse | Grass | Brazil, India, China | 75,000 |

| Bamboo | Grass | India, China, Indonesia | 30,000 |

- Vegetable Fibers:

| Advantages | Disadvantages |

|---|---|

|

|

| Fiber | Cellulose [wt%] |

Lignin [wt%] |

Hemicellulose [wt%] |

Pectin [wt%] |

Wax [wt%] |

Moisture [wt%] |

Ash [wt%] |

Micro-fibrillar angle [°] | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Abaca | 56-63 | 7-9 | 20-25 | - | 3 | - | - | 20-25 | [13] |

| Bamboo | 26-43 | 1-31 | 30 | - | - | 9.16 | - | - | [18] |

| Banana | 83 | 5 | - | - | - | 10.71 | - | 11-12 | [18] |

| Coir | 37 | 42 | - | - | - | 11.36 | - | 30.45 | [13] |

| Cotton | 82.7-91 | - | 3 | - | 0.6 | 7.85-8.5 | - | - | [13] |

| Curauá | 73.6 | 7.5 | 9.9 | - | - | - | - | - | [18] |

| Flax | 64.1-71.9 | 2-2.2 | 64.1-71.9 | 1.8-2.3 | 1.7 | 8-1.2 | - | 5-10 | [19] |

| Hemp | 70.2-74.4 | 3.7-5.7 | 17.9-22.4 | 0.9 | 0.8 | 6.2-1.2 | 0.8 | 2-6.2 | [18] |

| Jute | 61-71.5 | 12-13 | 17.9-22.4 | 0.2 | 0.5 | 12.5-13.7 | 0.5-2 | 8 | [20] |

| Kenaf | 45-57 | 21.5 | 8-13 | 0.6 | 0.8 | 6.2-12 | 2-5 | 2-6.2 | [13] |

| Rachis | 42.75 | 26 | - | - | - | - | - | 28-37 | [18] |

| Ramie | 68.6-91 | 0.4-0.7 | 5-14.7 | 1.9 | - | - | - | 69-83 | [13] |

| Rice husk | 38-45 | - | 12-20 | - | - | - | 20 | - | [18] |

| Sea Grass | 57 | 5 | 38 | 10 | - | - | - | - | [18] |

| Sisal | 78 | 8 | 10 | - | 2 | 11 | 1 | - | [13] |

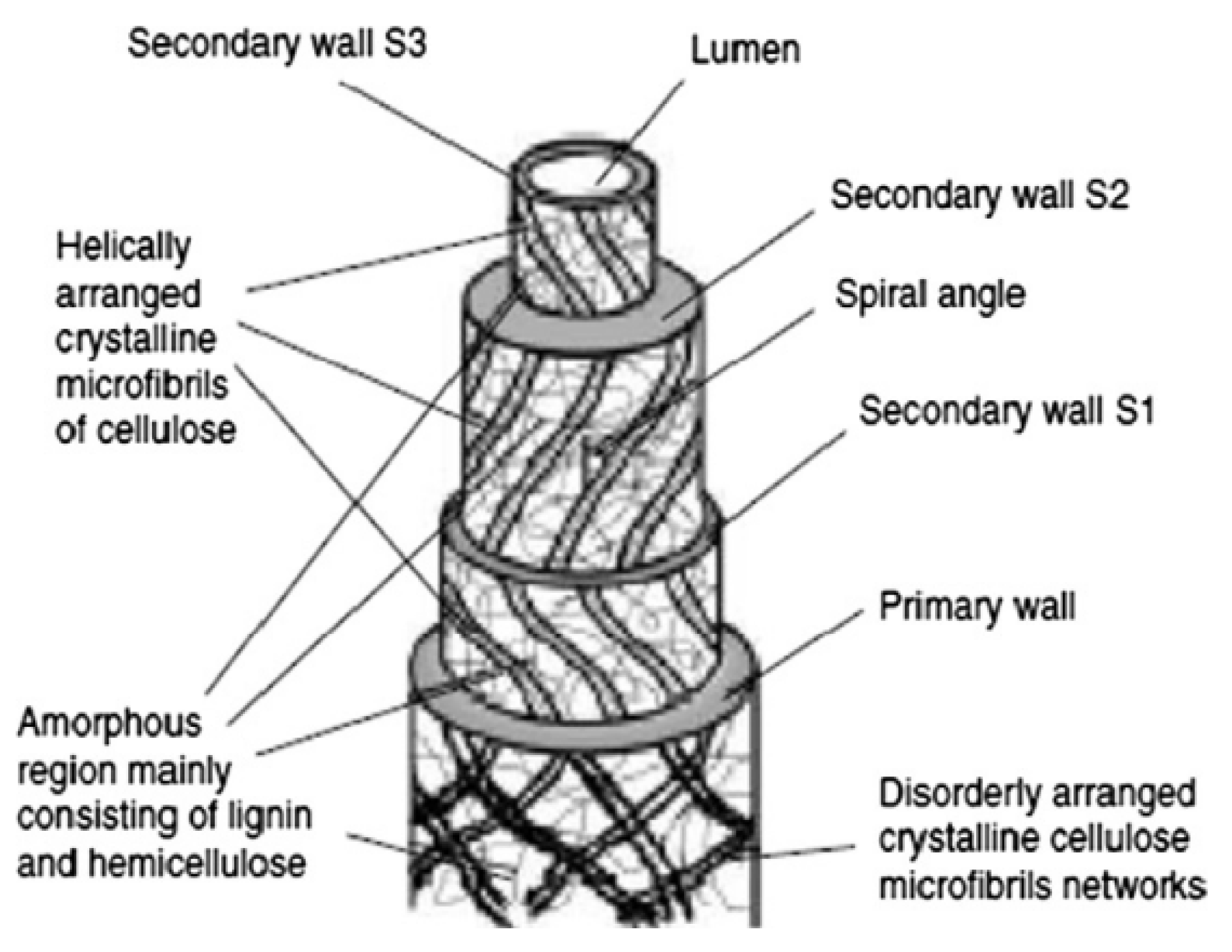

3. Physical and Mechanical Properties of Vegetables Fibers

4. Applications of Vegetable Fibers

5. Advantages of Plant Fiber Reinforced Plastics

6. Mechanical and Physical Properties of Composites

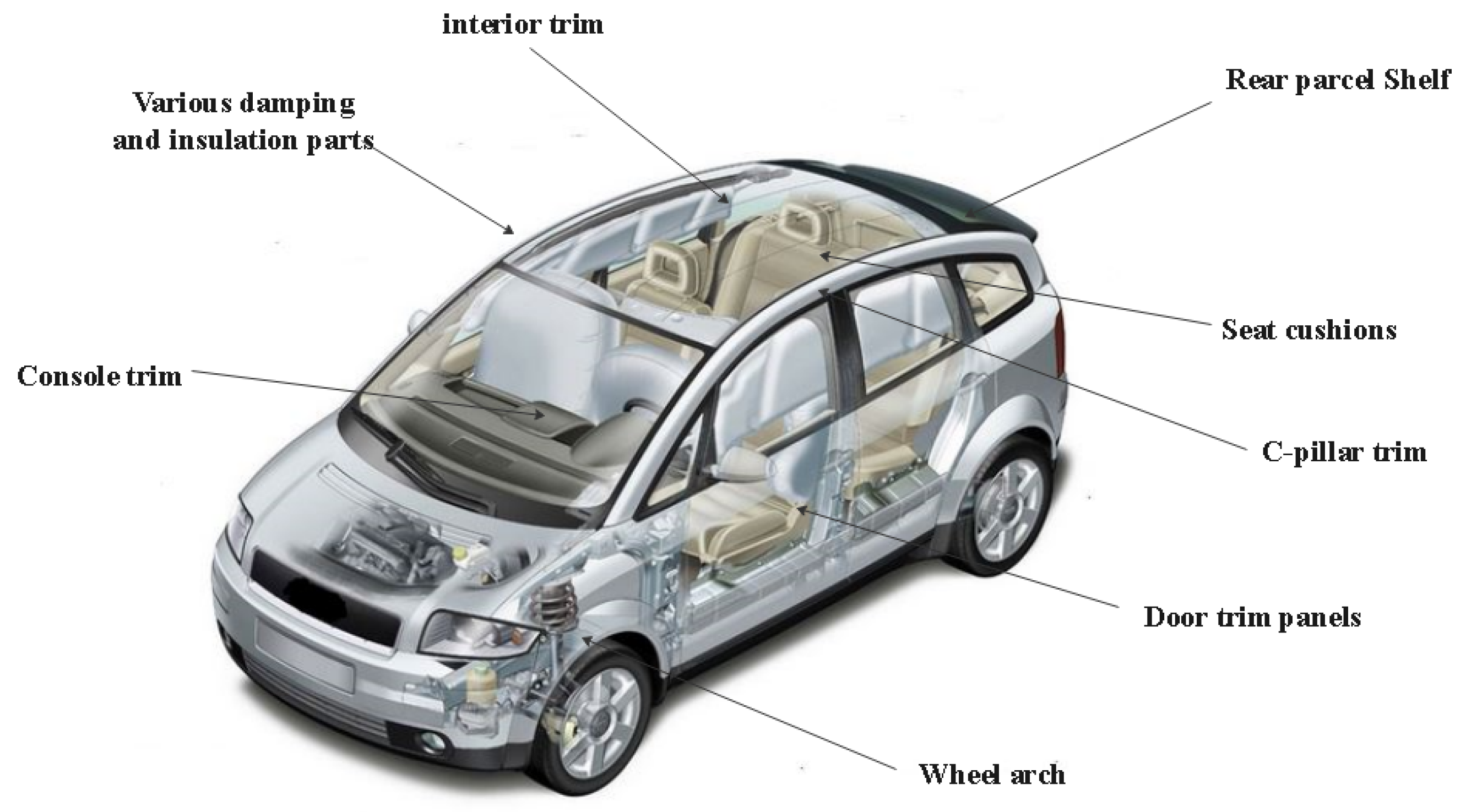

7. NFRP’s Applications

| Manufacturer | Car model | Applications |

|---|---|---|

| Audi | A2, A3, A4, A4 Avant, A6, A8, Roadstar, Coupe | Boot-liner, spare tire-lining, side and back door panel, seat back, and hat rack |

| BMW | 3,5 and 7 series and other Pilot | Seat back, headliner panel, boot-lining, door panels, noise insulation panels, and molded foot well linings. |

| Citroen | C5 | Interior door paneling |

| Daimler | A, C, E, and S class, EvoBus | Pillar cover panel, door panels, car windshield/car dashboard, and business table |

| Fiat | Punto, Brava, Marea, Alfa Romeo 146, 156, 159 | Door panel |

| Ford | Mondeo CD 162, Focus | Floor trays, door inserts, door panels, B-pillar, and boot-liner |

| General Motors | Cadillac De Ville, Chevrolet Trail Blazer | Seat backs, cargo area floor mat |

| Honda | Pilot | Cargo area |

| Lotus | Eco Elise | Body panels, spoiler, seats, and interior carpets |

| Mercedes Benz | C, S, E, and A classes | Door panels, glove box, instrument panel support, insulation, molding rod, seat backrest panel, trunk panel, and seat surface/backrest |

| Opel | Vectra, Astra, Zafira | Door panels, pillar cover panel, head-liner panel, and instrumental panel |

| Peugeot | 406 | Front and rear door panels, seat backs, and parcel shelf |

| Renault | Clio, Twingo | Rear parcel shelf |

| Rover | 2000 and others | Rear storage shelf/panel, and insulations |

| Toyota | ES3 | Pillar garnish and other interior parts |

| Volkswagen | Passat Variant, Golf, A4, Bora | Seat back, door panel, boot-lid finish panel, and boot-liner |

| Volvo | V70, C70 | Seat padding, natural foams, and cargo floor tray |

8. Challenges and Opportunities

9. Definitions

- -

- Abaca: abaca or banana fiber is cellulosic fiber obtained from banana fiber (Musa sepi-entum). It is generally found in tropical countries such as the Philippines and Ecuador, and its production is based on banana crop waste [70].

- -

- Bamboo: bamboo is a plant belonging to the grass family, its production is typically found in Indonesia, India and China [26].

- -

- Banana/Musa: banana fiber, obtained by processing the bark of the banana tree, is a type of lignocellulosic fiber, its major production is located in India, with about 22% of world production [101].

- -

- Coir: light and strong fiber, extracted from coconut husk, compared to other fibers, coconut fiber has more lignin and less cellulose and hemicellulose. The country with the largest production of coir is located in Kerala, India with approximately 60% of the world demand [32,65].

- -

- Cotton: a fiber with a high amount of cellulose and a low percentage of hemicellulose, the countries with the highest cotton production are China, USA, India and Pakistan [25].

- -

- Hemp: a fiber based on cellulose, hemicellulose, lignin and pectin. It is the second most cultivated fiber worldwide [49].

Abbreviations

| FRP | Fiber Reinforced Polymer |

| PP | Polypropylene |

| PE | Polyethylene |

| NFRPs | Natural Fiber Reinforced Polymer |

| HDPE | High Density Polyethylene |

| Kgy | Unit of radiation in the English system, amount of energy absorbed by the system. [J/Kg]. |

References

- S. K. Ramamoorthy, M. Skrifvars, and A. Persson, “A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers,” Polym. Rev., vol. 55, no. 1, pp. 107–162, 2015. [CrossRef]

- M. J. John and S. Thomas, “Biofibres and biocomposites,” Carbohydr. Polym., vol. 71, no. 3, pp. 343–364, 2008. [CrossRef]

- A. K. Bledzki and J. Gassan, “Composites reinforced with cellulose_Bledzki_1999.pdf,” Prog. Polym. Sci., vol. 24, pp. 221–274, 1999, [Online]. Available online: http://ac.els-cdn.com/S0079670098000185/1-s2.0-S0079670098000185-main.pdf?_tid=af34542c-0260-11e7-a49c-00000aab0f27&acdnat=1488800173_c95596c7ddcc4673fe88c8ec84262bb9.

- A. K. Mohanty, M. Misra, and G. Hinrichsen, “Biofibres, biodegradable polymers and biocomposites: An overview,” Macromol. Mater. Eng., vol. 276–277, pp. 1–24, 2000. [CrossRef]

- H. M. Akil, M. F. Omar, A. A. M. Mazuki, S. Safiee, Z. A. M. Ishak, and A. Abu Bakar, “Kenaf fiber reinforced composites: A review,” Mater. Des., vol. 32, no. 8–9, pp. 4107–4121, 2011. [CrossRef]

- V. Chauhan, T. Kärki, and J. Varis, “Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques,” J. Thermoplast. Compos. Mater., vol. 35, no. 8, pp. 1169–1209, 2022. [CrossRef]

- J. Holbery and D. Houston, “Natural-fiber-reinforced polymer composites in automotive applications,” Jom, vol. 58, no. 11, pp. 80–86, 2006. [CrossRef]

- N. Jauhari, R. Mishra, and H. Thakur, “Natural Fibre Reinforced Composite Laminates - A Review,” Mater. Today Proc., vol. 2, no. 4–5, pp. 2868–2877, 2015. [CrossRef]

- M. Jawaid and H. P. S. Abdul Khalil, “Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review,” Carbohydr. Polym., vol. 86, no. 1, pp. 1–18, 2011. [CrossRef]

- M. R. Sanjay, G. R. Arpitha, and B. Yogesha, “Study on Mechanical Properties of Natural - Glass Fibre Reinforced Polymer Hybrid Composites: A Review,” Mater. Today Proc., vol. 2, no. 4–5, pp. 2959–2967, 2015. [CrossRef]

- J. Agarwal, S. Sahoo, S. Mohanty, and S. K. Nayak, “Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review,” J. Thermoplast. Compos. Mater., vol. 33, no. 7, pp. 978–1013, 2020. [CrossRef]

- S. Brischetto, “Analysis of natural fibre composites for aerospace structures,” Aircr. Eng. Aerosp. Technol., vol. 90, no. 9, pp. 1372–1384, 2018. [CrossRef]

- F. Ahmad, H. S. Choi, and M. K. Park, “A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties,” Macromol. Mater. Eng., vol. 300, no. 1, pp. 10–24, 2015. [CrossRef]

- R. Vinayagamoorthy, “A review on the polymeric laminates reinforced with natural fibers,” J. Reinf. Plast. Compos., vol. 36, no. 21, pp. 1577–1589, 2017. [CrossRef]

- O. Adekomaya, T. Jamiru, R. Sadiku, and Z. Huan, “A review on the sustainability of natural fiber in matrix reinforcement - A practical perspective,” J. Reinf. Plast. Compos., vol. 35, no. 1, pp. 3–7, 2016. [CrossRef]

- K. Majeed et al., “Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites,” Mater. Des., vol. 46, pp. 391–410, 2013. [CrossRef]

- M. F. Gomez Berrezueta and P. W. Méndez, “Polipropileno Reforzado con Fibra Natural para Fabricación de Paneles Internos de las Puertas de un Automóvil,” INNOVA Res. J., vol. 2, no. 10.1, pp. 109–137, 2017. [CrossRef]

- M. S. Huda, L. T. Drzal, A. K. Mohanty, and M. Misra, “Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: A comparative study,” Compos. Sci. Technol., vol. 66, no. 11–12, pp. 1813–1824, 2006. [CrossRef]

- R. M. Rowell, A. R. Sanadi, D. F. Caulfield, and R. E. Jacobson, “Utilization of Natural Fibers in Plastic Composites: Problems and Opportunities,” Lignocellul. Compos., pp. 23–51, 1997, [Online]. Available online: http://www.fpl.fs.fed.us/documnts/pdf1997/rowel97d.pdf.

- J. Summerscales, N. P. J. Dissanayake, A. S. Virk, and W. Hall, “A review of bast fibres and their composites. Part 1 - Fibres as reinforcements,” Compos. Part A Appl. Sci. Manuf., vol. 41, no. 10, pp. 1329–1335, 2010. [CrossRef]

- D. Nabi Saheb and J. P. Jog, “Natural fiber polymer composites: A review,” Adv. Polym. Technol., vol. 18, no. 4, pp. 351–363, 1999. [CrossRef]

- D. Rouison, M. Sain, and M. Couturier, “Resin transfer molding of natural fiber reinforced composites: Cure simulation,” Compos. Sci. Technol., vol. 64, no. 5, pp. 629–644, 2004. [CrossRef]

- R. M. Rowell, The use of biomass to produce bio-based composites and building materials. Woodhead Publishing Limited, 2014.

- R. M. Rowell, “Natural fibres: Types and properties,” Prop. Perform. Nat. Compos., pp. 3–66, 2008. [CrossRef]

- J. Singh Dhaliwal, “Natural Fibers: Applications,” Gener. Dev. Modif. Nat. Fibers, pp. 1–23, 2020. [CrossRef]

- W. Fatriasari, W. Syafii, N. J. Wistara, K. Syamsu, and B. Prasetya, “The characteristic changes of betung bamboo (Dendrocalamus asper) pretreated by fungal pretreatment,” Int. J. Renew. Energy Dev., vol. 3, no. 2, pp. 133–143, 2014. [CrossRef]

- K. Oksman et al., “Review of the recent developments in cellulose nanocomposite processing,” Compos. Part A Appl. Sci. Manuf., vol. 83, pp. 2–18, 2016. [CrossRef]

- U. S. Gupta, M. Dhamarikar, A. Dharkar, S. Tiwari, and R. Namdeo, “Study on the effects of fibre volume percentage on banana-reinforced epoxy composite by finite element method,” Adv. Compos. Hybrid Mater., vol. 3, no. 4, pp. 530–540, 2020. [CrossRef]

- A. Karimah et al., “A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations,” J. Mater. Res. Technol., vol. 13, pp. 2442–2458, 2021. [CrossRef]

- O. Suparno, “Potensi Dan Masa Depan Serat Alam Indonesia Sebagai Bahan Baku Aneka Industri,” J. Teknol. Ind. Pertan., vol. 30, no. 2, pp. 221–227, 2020. [CrossRef]

- I. P. C. and S. R., “Characterization of a new natural cellulosic fiber extracted from Derris scandens stem,” Int. J. Biol. Macromol., vol. 165, pp. 2303–2313, 2020. [CrossRef]

- Y. G. Thyavihalli Girijappa, S. Mavinkere Rangappa, J. Parameswaranpillai, and S. Siengchin, “Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review,” Front. Mater., vol. 6, no. September, pp. 1–14, 2019. [CrossRef]

- A. Putra, I. Prasetiyo, and Z. Selamat, Green Acoustic Absorber from Pineapple Leaf Fibers. 2020.

- S. N. Kane, A. Mishra, and A. K. Dutta, “Post-treatment Effect of Particleboard on Dimensional Stability and Durability Properties of Particleboard Made From Sorghum Bagasse,” J. Phys. Conf. Ser., vol. 755, no. 1, 2016. [CrossRef]

- A. Heri Iswanto, S. Supriyanto, W. Fatriasari, and A. Susilowati, “Effect of particle treatment and adhesive type on physical, mechanical, and durability properties of particleboard made from Sorghum Bagasse,” IOP Conf. Ser. Earth Environ. Sci., vol. 126, no. 1, 2018. [CrossRef]

- F. A. Syamani, D. Ramatia, Sudarmanto, F. Akbar, S. S. Kusumah, and D. Hermawan, “Combination of citric acid and maltodextrin as bonding agent in sorghum bagasse particleboard,” IOP Conf. Ser. Mater. Sci. Eng., vol. 935, no. 1, 2020. [CrossRef]

- S. K. S and S. S. Hiremath, Natural Fiber Reinforced Composites in the Context of Biodegradability: A Review, vol. 1–5. Elsevier Ltd., 2020.

- K. tak Lau, P. yan Hung, M. H. Zhu, and D. Hui, “Properties of natural fibre composites for structural engineering applications,” Compos. Part B Eng., vol. 136, no. September 2017, pp. 222–233, 2018. [CrossRef]

- S. Hassanzadeh and H. Hasani, “A review on milkweed fiber properties as a high-potential raw material in textile applications,” J. Ind. Text., vol. 46, no. 6, pp. 1412–1436, 2017. [CrossRef]

- S. S. Munawar, K. Umemura, and S. Kawai, “Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles,” J. Wood Sci., vol. 53, no. 2, pp. 108–113, 2007. [CrossRef]

- P. Kandachar and R. Brouwer, “Applications of bio-composites in industrial products,” Mater. Res. Soc. Symp. - Proc., vol. 702, pp. 101–112, 2002. [CrossRef]

- K. Joseph, R. D. Tolêdo Filho, B. James, S. Thomas, and L. H. de Carvalho, “a Review on Sisal Fiber Reinforced Polymer Composites,” Rev. Bras. Eng. Agrícola e Ambient., vol. 3, no. 3, pp. 367–379, 1999. [CrossRef]

- V. Chaudhary, P. K. Bajpai, and S. Maheshwari, “Effect of moisture absorption on the mechanical performance of natural fiber reinforced woven hybrid bio-composites,” J. Nat. Fibers, vol. 17, no. 1, pp. 84–100, 2020. [CrossRef]

- J. Wei and C. Meyer, “Utilization of rice husk ash in green natural fiber-reinforced cement composites: Mitigating degradation of sisal fiber,” Cem. Concr. Res., vol. 81, pp. 94–111, 2016. [CrossRef]

- P. J. Herrera-Franco and A. Valadez-González, “A study of the mechanical properties of short natural-fiber reinforced composites,” Compos. Part B Eng., vol. 36, no. 8, pp. 597–608, 2005. [CrossRef]

- K. Oksman, A. P. Mathew, R. Långström, B. Nyström, and K. Joseph, “The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene,” Compos. Sci. Technol., vol. 69, no. 11–12, pp. 1847–1853, 2009. [CrossRef]

- M. Cai, H. Takagi, A. N. Nakagaito, Y. Li, and G. I. N. Waterhouse, “Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites,” Compos. Part A Appl. Sci. Manuf., vol. 90, pp. 589–597, 2016. [CrossRef]

- M. Mejri, L. Toubal, J. C. Cuillière, and V. François, “Hygrothermal aging effects on mechanical and fatigue behaviors of a short- natural-fiber-reinforced composite,” Int. J. Fatigue, vol. 108, pp. 96–108, 2018. [CrossRef]

- A. Q. Dayo et al., “Natural hemp fiber reinforced polybenzoxazine composites: Curing behavior, mechanical and thermal properties,” Compos. Sci. Technol., vol. 144, pp. 114–124, 2017. [CrossRef]

- R. Basak, P. L. Choudhury, and K. M. Pandey, “Effect of Temperature Variation on Surface Treatment of Short Jute Fiber-Reinforced Epoxy Composites,” Mater. Today Proc., vol. 5, no. 1, pp. 1271–1277, 2018. [CrossRef]

- V. Chaudhary, P. K. Bajpai, and S. Maheshwari, “Studies on Mechanical and Morphological Characterization of Developed Jute/Hemp/Flax Reinforced Hybrid Composites for Structural Applications,” J. Nat. Fibers, vol. 15, no. 1, pp. 80–97, 2018. [CrossRef]

- J. Giridhar, Kishore, and R. M. V. G. K. Rao, “Moisture absorption characteristics of natural fibre composites,” no. April, pp. 141–150, 1986.

- P. K. Bajpai, K. Debnath, and I. Singh, “Hole making in natural fiber-reinforced polylactic acid laminates: An experimental investigation,” J. Thermoplast. Compos. Mater., vol. 30, no. 1, pp. 30–46, 2017. [CrossRef]

- A. Arbelaiz, B. Fernández, J. A. Ramos, and I. Mondragon, “Thermal and crystallization studies of short flax fibre reinforced polypropylene matrix composites: Effect of treatments,” Thermochim. Acta, vol. 440, no. 2, pp. 111–121, 2006. [CrossRef]

- J. Andersons, E. Sparniņš, R. Joffe, and L. Wallström, “Strength distribution of elementary flax fibres,” Compos. Sci. Technol., vol. 65, no. 3–4, pp. 693–702, 2005. [CrossRef]

- S. N. Monteiro et al., “Natural Curaua Fiber-Reinforced Composites in Multilayered Ballistic Armor,” Metall. Mater. Trans. A Phys. Metall. Mater. Sci., vol. 46, no. 10, pp. 4567–4577, 2015. [CrossRef]

- F. A. Chaves and D. Jiménez, “Physico-mechanical and wear properties of novel sustainable sour-weed fiber reinforced polyester composites,” Nanotechnology, vol. 29, no. 27, 2018.

- C. Alves et al., “Ecodesign of automotive components making use of natural jute fiber composites,” J. Clean. Prod., vol. 18, no. 4, pp. 313–327, 2010. [CrossRef]

- K. G. Satyanarayana, G. G. C. Arizaga, and F. Wypych, “Biodegradable composites based on lignocellulosic fibers-An overview,” Prog. Polym. Sci., vol. 34, no. 9, pp. 982–1021, 2009. [CrossRef]

- H. Ku, H. Wang, N. Pattarachaiyakoop, and M. Trada, “A review on the tensile properties of natural fiber reinforced polymer composites,” Compos. Part B Eng., vol. 42, no. 4, pp. 856–873, 2011. [CrossRef]

- B. C. Mitra, “Environment friendly composite materials: Biocomposites and green composites,” Def. Sci. J., vol. 64, no. 3, pp. 244–261, 2014. [CrossRef]

- P. Wambua, J. Ivens, and I. Verpoest, “Natural fibres: Can they replace glass in fibre reinforced plastics?,” Compos. Sci. Technol., vol. 63, no. 9, pp. 1259–1264, 2003. [CrossRef]

- K. L. Fung, X. S. Xing, R. K. Y. Li, S. C. Tjong, and Y. W. Mai, “An investigation on the processing of sisal fibre reinforced polypropylene composites,” Compos. Sci. Technol., vol. 63, no. 9, pp. 1255–1258, 2003. [CrossRef]

- H. Anuar and A. Zuraida, “Improvement in mechanical properties of reinforced thermoplastic elastomer composite with kenaf bast fibre,” Compos. Part B Eng., vol. 42, no. 3, pp. 462–465, 2011. [CrossRef]

- S. Harish, D. P. Michael, A. Bensely, D. M. Lal, and A. Rajadurai, “Mechanical property evaluation of natural fiber coir composite,” Mater. Charact., vol. 60, no. 1, pp. 44–49, 2009. [CrossRef]

- H. P. Guimarães Santafé, F. P. Duarte Lopes, and S. N. Monteiro, “Mechanical properties of tensile tested coir fiber reinforced polyester composites,” 65th ABM Int. Congr. 18th IFHTSE Congr. 1st TMS/ABM Int. Mater. Congr. 2010, vol. 6, pp. 4987–4993, 2010.

- I. O. Bakare, F. E. Okieimen, C. Pavithran, H. P. S. Abdul Khalil, and M. Brahmakumar, “Mechanical and thermal properties of sisal fiber-reinforced rubber seed oil-based polyurethane composites,” Mater. Des., vol. 31, no. 9, pp. 4274–4280, 2010. [CrossRef]

- M. Ashok Kumar, G. Ramachandra Reddy, Y. Siva Bharathi, S. Venkata Naidu, and V. Naga Prasad Naidu, “Frictional coefficient, hardness, impact strength, and chemical resistance of reinforced sisal-glass fiber epoxy hybrid composites,” J. Compos. Mater., vol. 44, no. 26, pp. 3195–3202, 2010. [CrossRef]

- B. H. Lee, H. J. Kim, and W. R. Yu, “Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties,” Fibers Polym., vol. 10, no. 1, pp. 83–90, 2009. [CrossRef]

- A. K. Bledzki, A. A. Mamun, and O. Faruk, “Abaca fibre reinforced PP composites and comparison with jute and flax fibre PP composites,” Express Polym. Lett., vol. 1, no. 11, pp. 755–762, 2007. [CrossRef]

- B. H. Lee, H. S. Kim, S. Lee, H. J. Kim, and J. R. Dorgan, “Bio-composites of kenaf fibers in polylactide: Role of improved interfacial adhesion in the carding process,” Compos. Sci. Technol., vol. 69, no. 15–16, pp. 2573–2579, 2009. [CrossRef]

- C. W. Chin and B. F. Yousif, “Potential of kenaf fibres as reinforcement for tribological applications,” Wear, vol. 267, no. 9–10, pp. 1550–1557, 2009. [CrossRef]

- Z. N. Azwa and B. F. Yousif, “Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation,” Polym. Degrad. Stab., vol. 98, no. 12, pp. 2752–2759, 2013. [CrossRef]

- R. M. N. Arib, S. M. Sapuan, M. M. H. M. Ahmad, M. T. Paridah, and H. M. D. Khairul Zaman, “Mechanical properties of pineapple leaf fibre reinforced polypropylene composites,” Mater. Des., vol. 27, no. 5, pp. 391–396, 2006. [CrossRef]

- M. S. Anbupalani, C. D. Venkatachalam, and R. Rathanasamy, “Influence of coupling agent on altering the reinforcing efficiency of natural fibre-incorporated polymers – A review,” J. Reinf. Plast. Compos., vol. 39, no. 13–14, pp. 520–544, 2020. [CrossRef]

- K. N. Keya, N. A. Kona, F. A. Koly, K. M. Maraz, M. N. Islam, and R. A. Khan, “Natural fiber reinforced polymer composites: history, types, advantages, and applications,” Mater. Eng. Res., vol. 1, no. 2, pp. 69–87, 2019. [CrossRef]

- R. S. Jagadish and B. Raj, “Properties and sorption studies of polyethylene oxide-starch blended films,” Food Hydrocoll., vol. 25, no. 6, pp. 1572–1580, 2011. [CrossRef]

- R. G. Raj, B. V. Kokta, D. Maldas, and C. Daneault, “Use of wood fibers in thermoplastics. VII. The effect of coupling agents in polyethylene–wood fiber composites,” J. Appl. Polym. Sci., vol. 37, no. 4, pp. 1089–1103, 1989. [CrossRef]

- O. Faruk and A. K. Bledzki, “Wood Plastic Composite: Present and Future,” Wiley Encycl. Compos., 2012. [CrossRef]

- T. Of, N. Fiber, R. Composites, and W. Polyester, “Development and Testing Of Natural Fiber Reinforced Composites With Polyester Resin,” Int. J. Eng. Sci. Res. Technol., vol. 2, no. 10, pp. 2701–2706, 2013.

- A. G. Pedroso and D. S. Rosa, “Mechanical, thermal and morphological characterization of recycled LDPE/corn starch blends,” Carbohydr. Polym., vol. 59, no. 1, pp. 1–9, 2005. [CrossRef]

- Y. Men, X. Du, J. Shen, L. Wang, and Z. Liu, “Preparation of corn starch-g-polystyrene copolymer in ionic liquid: 1-Ethyl-3-methylimidazolium acetate,” Carbohydr. Polym., vol. 121, pp. 348–354, 2015. [CrossRef]

- J. B. Zeng, L. Jiao, Y. D. Li, M. Srinivasan, T. Li, and Y. Z. Wang, “Bio-based blends of starch and poly(butylene succinate) with improved miscibility, mechanical properties, and reduced water absorption,” Carbohydr. Polym., vol. 83, no. 2, pp. 762–768, 2011. [CrossRef]

- F. Chegdani, S. Mezghani, M. El Mansori, and A. Mkaddem, “Fiber type effect on tribological behavior when cutting natural fiber reinforced plastics,” Wear, vol. 332–333, pp. 772–779, 2015. [CrossRef]

- A. Amri et al., “Properties enhancement of cassava starch based bioplastics with addition of graphene oxide,” IOP Conf. Ser. Mater. Sci. Eng., vol. 345, no. 1, 2018. [CrossRef]

- K. T. Chaka, F. E. Ahmed, L. H. Zegeye, and B. G. Worku, “Compressive Strength of Floor Tile Composites from Recycled PET Reinforced with Natural Fibers,” J. Nat. Fibers, vol. 00, no. 00, pp. 1–14, 2022. [CrossRef]

- N. Bansal, S. Ahuja, S. Lal, and S. Arora, “Agricultural-waste Sesamum indicum L. / recycled-low density polyethylene bio- composites: Impact of gamma radiation on mechanical and thermal properties,” 2023. [CrossRef]

- A. N. M. Masudur Rahman, S. Alimuzzaman, R. A. Khan, and J. Hossen, “Evaluating the performance of gamma irradiated okra fiber reinforced polypropylene (PP) composites: comparative study with jute/PP,” Fash. Text., vol. 5, no. 1, 2018. [CrossRef]

- A. S. Singha and V. K. Thakur, “Mechanical properties of natural fibre reinforced polymer composites,” Bull. Mater. Sci., vol. 31, no. 5, pp. 791–799, 2008. [CrossRef]

- M. A. Maleque, A. Atiqah, R. J. Talib, and H. Zahurin, “New natural fibre reinforced aluminium composite for automotive brake pad,” Int. J. Mech. Mater. Eng., vol. 7, no. 2, pp. 166–170, 2012.

- K. K. Alaneme, B. O. Ademilua, and M. O. Bodunrin, “Mechanical properties and corrosion behaviour of aluminium hybrid composites reinforced with silicon carbide and bamboo leaf ash,” Tribol. Ind., vol. 35, no. 1, pp. 25–35, 2013.

- T. Sen and H. N. J. Reddy, “Various Industrial Applications Of Hemp, Kinaf, Flax and Ramie Natural Fibres,” vol. 2, no. 3, 2011.

- S. Ochi, “Tensile Properties of Bamboo Fiber Reinforced Biodegradable Plastics,” Int. J. Compos. Mater., vol. 2, no. 1, pp. 1–4, 2012. [CrossRef]

- Farideh Namvar et al. et al., “Potential Use of Plant Fibres and their Composites for Biomedical Applications,” Bioresources, vol. 9, no. 3, pp. 5688–5706, 2016, [Online]. Available online: http://bioresources.com.

- S. J. Eichhorn et al., “Current international research into cellulosic fibres and composites,” J. Mater. Sci., vol. 36, no. 9, pp. 2107–2131, 2001. [CrossRef]

- M. G. Maya, S. C. George, T. Jose, M. S. Sreekala, and S. Thomas, “Mechanical properties of short sisal fibre reinforced phenol formaldehyde eco-friendly composites,” Polym. from Renew. Resour., vol. 8, no. 1, pp. 27–42, 2017. [CrossRef]

- S. Sabinesh, “Investigation on Tensile and Flexural properties of Cotton Fiber Reinforced Isophthallic Polyester Composites,” Int. J. Curr. Eng. Technol., vol. 2, no. 2, pp. 213–219, 2013. [CrossRef]

- N. Lu, R. H. Swan, and I. Ferguson, “Composition, structure, and mechanical properties of hemp fiber reinforced composite with recycled high-density polyethylene matrix,” J. Compos. Mater., vol. 46, no. 16, pp. 1915–1924, 2012. [CrossRef]

- T. Gurunathan, S. Mohanty, and S. K. Nayak, “A review of the recent developments in biocomposites based on natural fibres and their application perspectives,” Compos. Part A Appl. Sci. Manuf., vol. 77, pp. 1–25, 2015. [CrossRef]

- N. M. Barkoula, B. Alcock, N. O. Cabrera, and T. Peijs, “Flame-Retardancy Properties of Intumescent Ammonium Poly(Phosphate) and Mineral Filler Magnesium Hydroxide in Combination with Graphene,” Polym. Polym. Compos., vol. 16, no. 2, pp. 101–113, 2008.

- H. Das, P. Saikia, and D. Kalita, “Physico-mechanical properties of banana fiber reinforced polymer composite as an alternative building material,” Key Eng. Mater., vol. 650, pp. 131–138, 2015. [CrossRef]

- T. Sonar, S. Patil, V. Deshmukh, and R. Acharya, “Natural Fiber Reinforced Polymer Composite Material-A Review,” IOSR J. Mech. Civ. Eng., pp. 142–147, 2015.

- A. Honda, M. Morita, A. Taniguchi, A. Tabuchi, and S. Kubo, “Successful extracorporeal membrane oxygenation for a patient with nearly fatal hypoxemia induced by transfusion-related acute lung injury,” Japanese J. Anesthesiol., vol. 64, no. 11, pp. 1181–1185, 2015.

- H. Yan Cheung, M. po Ho, K. tak Lau, F. Cardona, and D. Hui, “Natural fibre-reinforced composites for bioengineering and environmental engineering applications,” Compos. Part B Eng., vol. 40, no. 7, pp. 655–663, 2009. [CrossRef]

- B. M. Zaidi, J. Zhang, K. Magniez, H. Gu, and M. Miao, “Optimizing twisted yarn structure for natural fiber-reinforced polymeric composites,” J. Compos. Mater., vol. 52, no. 3, pp. 373–381, 2018. [CrossRef]

- L. Mohammed, M. N. M. Ansari, G. Pua, M. Jawaid, and M. S. Islam, “A Review on Natural Fiber Reinforced Polymer Composite and Its Applications,” Int. J. Polym. Sci., vol. 2015, 2015. [CrossRef]

- O. Faruk, A. K. Bledzki, H. P. Fink, and M. Sain, “Progress report on natural fiber reinforced composites,” Macromol. Mater. Eng., vol. 299, no. 1, pp. 9–26, 2014. [CrossRef]

| Vegetable Fibers |

Density (g/cm3) |

Diameter (μm) |

Tensile Strength (MPa) | Module of Young’s (GPa) | Breaking strain (%) |

|---|---|---|---|---|---|

| Abaca | 1.5 | 10-30 | 400 | 12 | 3-10 |

| Alpha | 0.89 | - | 350 | 22 | 5.8 |

| Bagasse | 1.25 | 490 | 70 | 17 | 3-5 |

| Bamboo | 0.88-1.1 | 100-200 | 391-713 | 18-55 | 1.3 |

| Banana | 1.35 | 50-250 | 500-550 | 12-20 | 5-6 |

| Coconuit | 0.8 | 100-450 | 131-175 | 4-13 | 15-40 |

| Coir | 1.2 | 10-16 | 175 | 4-6 | 30 |

| Cotton | 1.5-1.6 | 20 | 287-597 | 5-13 | 7-8 |

| Curagua | 1.38 | 66 | 913 | 50-70 | 3.9 |

| Date palm | 1-1.2 | 14-18 | 97-196 | 2.5-5.4 | 2-4.5 |

| Flax | 1.5 | 50-100 | 345-1035 | 50-70 | 2.7-3.2 |

| Hemp | 1.1 | 120 | 389-900 | 35 | 1.6 |

| Henequen | 1.49 | 180 | 430-580 | 10.1-16.3 | 1.6 |

| Ixora | 1.2-1.3 | 10 | 500-600 | - | 5-6 |

| Jute | 1.3 | 260 | 393-773 | 23-27 | 1.4 |

| Kenaf | 1.31 | 106 | 427-519 | 23-27 | 1.8 |

| licuri | - | 132-165 | 287-597 | 5-13 | 7.8 |

| nettle | 1.5 | 20-80 | 650 | 38 | 1.7 |

| Oil palm | 0.7-1.55 | 150-250 | 248 | 25 | 3.2 |

| Palmira palm tree | 1.2 | 300-320 | 276 | 8.99 | 3.08 |

| Piasava | 1.4 | - | 134-143 | 1.07-4.59 | 7.8-21.9 |

| Pineapple | 0.8-1,6 | 25-34 | 400-627 | 14.5 | 1.44 |

| Ramia | 1.5 | 34 | 560 | 24.5 | 2.5 |

| Sisal | 1.5 | 50-80 | 511-635 | 9.4-22 | 2.0-2.5 |

| Softwood kraft | 1.5 | - | 1000 | 40 | 4.4 |

| Spider silk | 0.014 | 2-8 | 875-972 | 11-13 | 17-18 |

| Talipot | - | 80-800 | 143-263 | 10-13 | 5.1 |

| Vetiver | 1.5 | 100-220 | 247-723 | 12-49.8 | 1.6-2.4 |

| Wool | - | 20-30 | 120-174 | 2.3-3.4 | 25-35 |

| Linen | 1.4 | 12-60 | 8000 | 50-70 | 2.7-3.5 |

| Synthetic fibers | |||||

| Aramid | 1.4 | - | 3000-3150 | 63-67 | 3.3-3.7 |

| Carbon | 1.4 | 5-9 | 4000 | 230-240 | 1.4-1.8 |

| E-Glass | 2.5 | 9-15 | 200-3500 | 70 | 2.5 |

| S-Glass | 2.5 | 5-25 | 4570 | 86 | 2.8 |

| Natural fibers | Applications | Ref. |

|---|---|---|

| Abaca | They include textiles, clothing, functional papers such as money, magazine paper, checks, and composite materials | [25] |

| Bamboo | They include lactic acid, construction, vinegar, charcoal, methane, composite reinforcement, footwear, food, textiles, pulp and paper production, shock absorbers, and bioenergy sources. | [26] |

| Banana/Musa | Banana/Musa They include products such as ropes, placemats, paper cardboard, rope threads, tea bags, high-quality textile fabrics, paper money, mushrooms, arts/crafts, ropes, cushion covers, tablecloths, curtains, natural wastewater absorbents colored, oil absorbent, lightweight compounds, and biofertilizers | [27,28] |

| Biduri | Biduri Heat insulating materials | [29] |

| Coir | Coir They are fillers used as reinforcement in composite materials and lightweight composites. | [27,28,29,30] |

| Collagen fiber | Collagen fiber Their application is tissue manipulation and the use of sewing thread for surgery. | [30] |

| Cotton | Cotton Their applications are in fabrics, clothing, and threads in the furniture industry as covering materials. | [25] |

| Derris scanden | Alternative reinforcing agents to replace synthetic fibers in polymer matrix composites are being investigated. | [31] |

| Hemp | These include bags, tarps, carpets, ropes, furniture materials, fabrics, textiles, garden mulches, fleeces and felts, lightweight composites, composites, and the geotextile and geotextile insulation industry. | [32] |

| Jute | These include bags, sacks, carpets, carpet upholstery, geotextiles for transport or construction, electrical insulation and ropes, tarpaulins, packaging, furniture materials, fabrics, and lightweight composites. | [30] |

| Pineapple | Pineapple Included are bags, tablecloths, mats, ropes, paper pulp material, tote bags, composites, lightweight duck cloth, conveyor belt cords, coasters, and other interior design products and applications in livestock breeding and agriculture. | [33] |

| Kenaf | There are products made from pulp and paper. | [30] |

| Ramie | They include textiles, paper, pulp, yarn, biofuel, fabric, oil, resin, wax, foods made from seeds, composites, livestock and agriculture. | [30] |

| Silk | Cloth and silk thread are found | [30] |

| Wool | The party favors and wool thread is included [32]. | [30] |

| Sorghum bagasse | These include particle board, sugar production sources, and pulp and paper. | [29,30,31,32,33,34,35,36] |

| Natural fiber reinforcement | Polymer resin (Matrix) |

Properties studied | Ref. |

|---|---|---|---|

|

Polypropylene |

|

[62] |

|

Polypropylene |

|

[63] |

|

|

|

[64] |

|

Epoxy-CY205 |

|

[65] |

|

Polyester resin |

|

[66] |

|

Rubber seed oil-based polyurethane |

|

[67] |

|

Epoxy resin |

|

[68] |

|

Polypropylene |

|

[46] |

|

Polypropylene |

|

[69] |

|

Polypropylene |

|

[70] |

|

Poly lactic acid (PLA) |

|

[71] |

|

Epoxy resin |

|

[72] |

|

Epoxy resin |

|

[74] |

|

Polypropylene |

|

[74] |

| Fiber | Tensile strength (MPa) | Elongation at break (%) | Young´s modulus (GPa) | Density (g/cm3) |

Ref. |

|---|---|---|---|---|---|

| Yute | 400-800 | 1.5 | 10-30 | 1.46 | [95] |

| Sisal (Henequen) | 400-700 | 05-14 | 09-12 | 1.45 | [96] |

| Coconut fiber | 175 | 30 | 4-6 | 1.2 | [97] |

| Hemp | 550-900 | 1.6 | 70 | 1.48 | [98] |

| Cotton | 287-597 | 2-10 | 6-10 | 1.21 | [99] |

| Pineapple | 413 | 1.6 | 6.21 | 1.526 | [100] |

| Abaca | 980 | 10-12 | 9.0-28 | 1.5 | [9] |

| Kenaf | 930 | 1.6 | 53 | 1.45 | [21] |

| Ramie | 511-635 | 3.6-3.8 | 9.4-22 | 1.5 | [76] |

| Oil palm | 71 | 11 | 1.703 | - | [76] |

| Flax | 500-1500 | 2.7-3.2 | 27.6 | - | [76] |

| Banana | 10.854 | 6.085 | 1.63 | 1.02 | [101] |

| Bagasse | 290 | 1.1 | 17 | 1.25 | [76] |

| Kevlar 49 | 3650 | 2.5 | 124 | 1.44 | [76] |

| Date palm | 97-196 | 2-4.50 | 2.50-5.40 | 1-1.20 | [102] |

| Bamboo | 73-505 | 4.11 | 10-40 | 4.3 | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).