Submitted:

09 May 2024

Posted:

10 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results

2.1. Composition of AS, PPJ, and the Beverage

2.1.1. HPLC Quantification of Monomers and Oligomers of the Carbohydrates of AS, PPJ and the Beverage

2.1.2. Content of Total Bioactive Compounds in AS, PPJ and Beverage

2.2. Potential Health-Promoting Compounds of AS, PPJ, and the Combined Beverage

2.2.1. Antioxidant Capacity

2.2.2. Glycemic Regulatory Properties

2.3. In Vitro Gut Fermentation

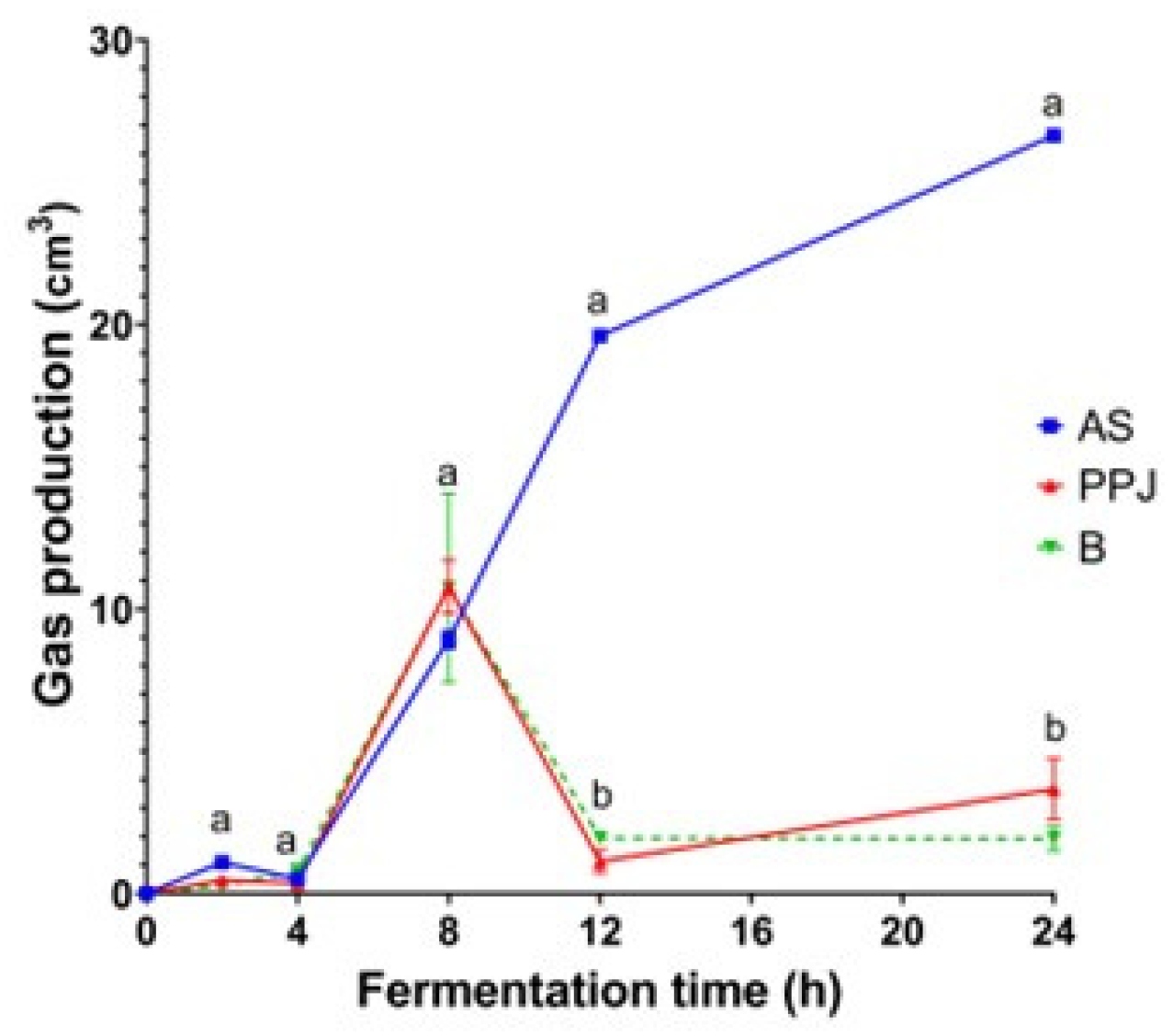

2.3.1. Gas Production

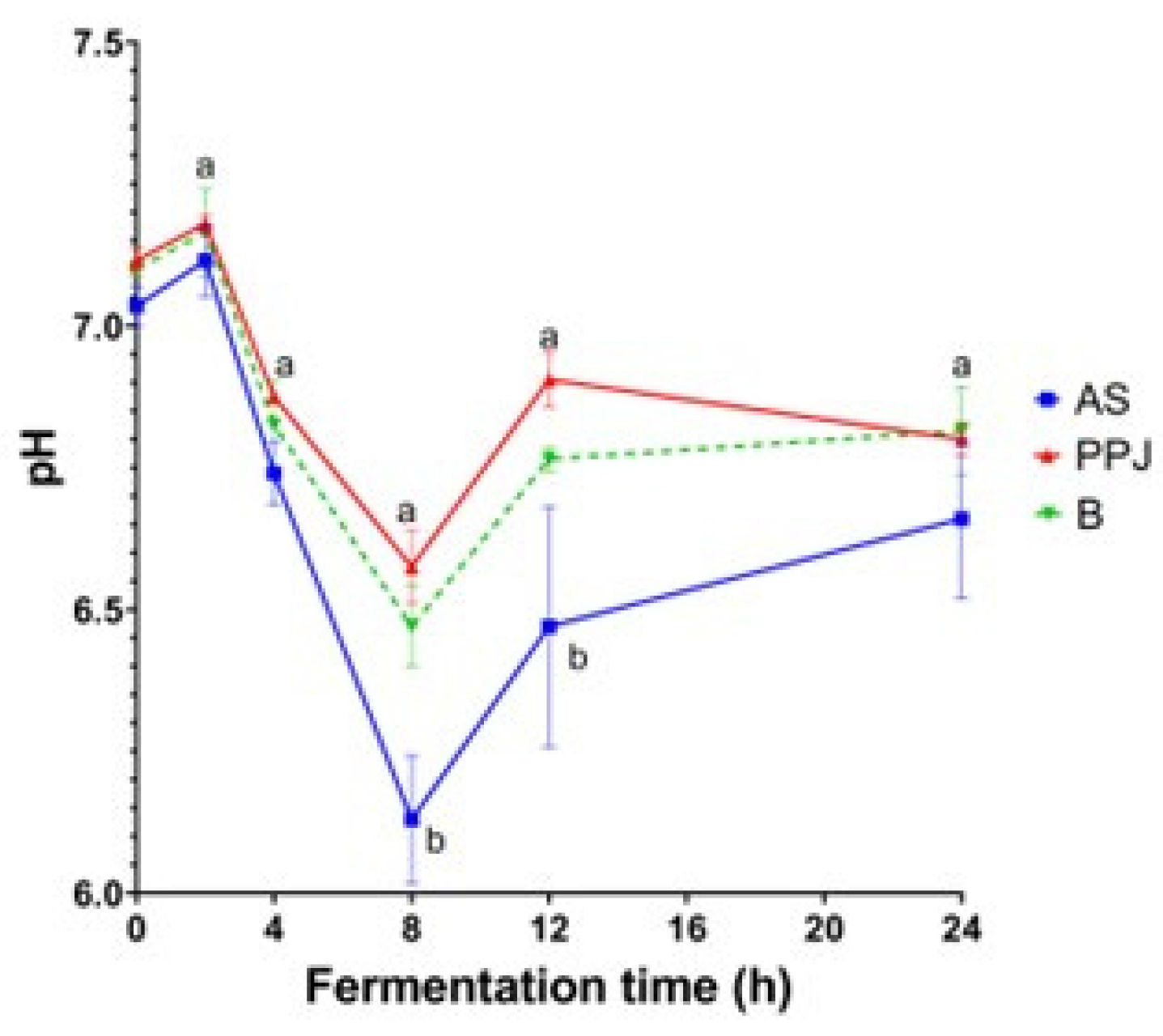

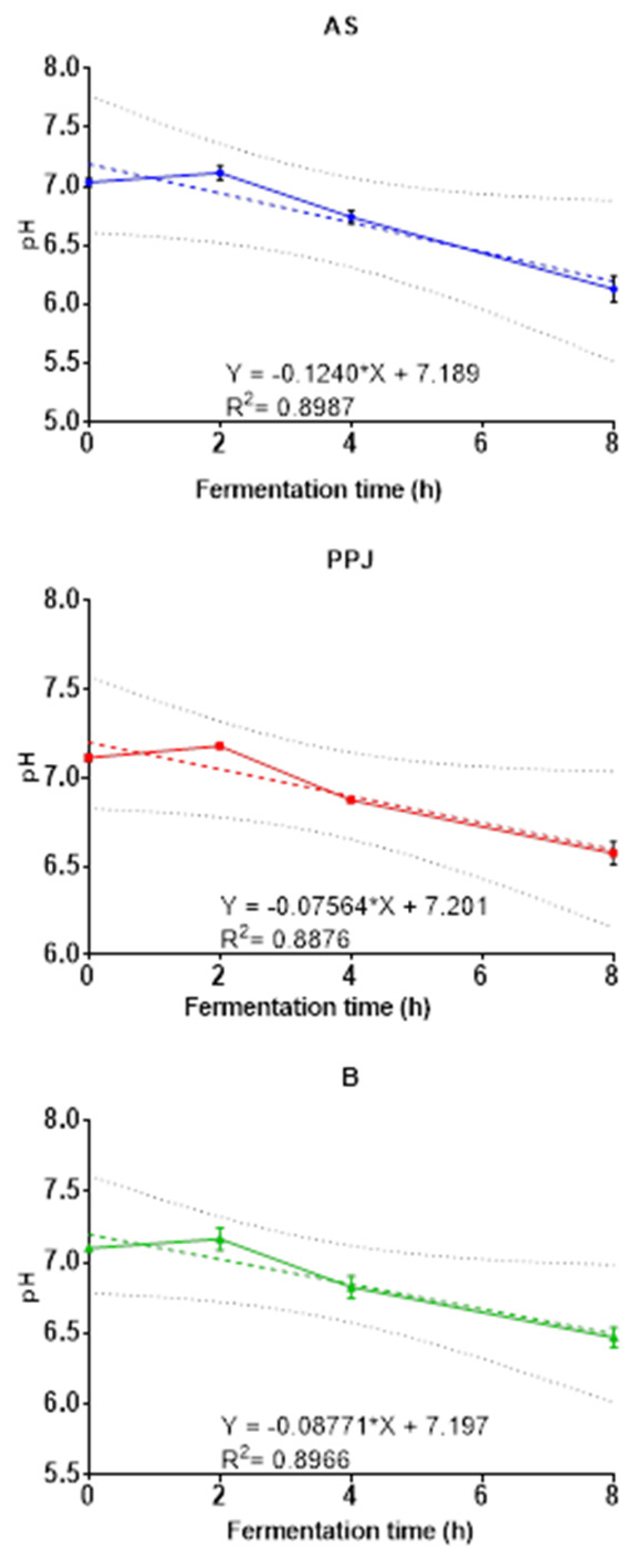

2.3.2. Variation of pH

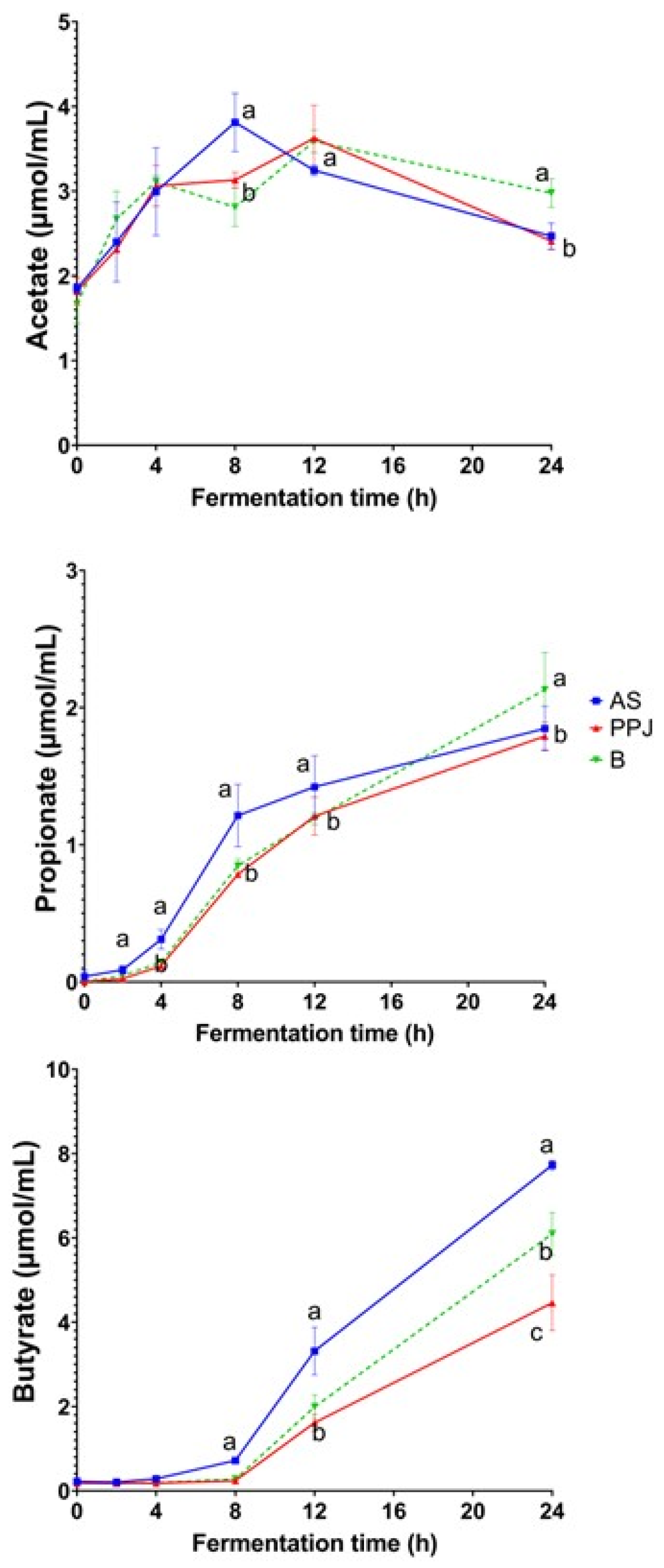

2.3.3. Short-Chain Fatty Acid Production

3. Discussion

3.1. Composition of AS, PPJ, and the Beverage

3.1.2. HPLC Quantification of Monomers and Oligomers of the Carbohydrates of AS, PPJ and the Beverage

3.1.3. Content of Total Bioactive Compounds in AS, PPJ and Beverage

3.2. Potential Health-Promoting Compounds of AS, PPJ, and the Combined Beverage

3.2.1. Antioxidant Capacity

3.2.2. Glycemic Regulatory Properties

2.3.4. Bioactive Compounds Interaction

3.3. In Vitro Gut Fermentation

3.3.1. Gas Production

3.3.2. Variation of pH

3.3.3. Short-chain fatty acid production

4. Materials and Methods

4.1. Collection

4.2. Composition

4.3. Free Carbohydrate Quantification

4.4. Bioactive Compounds Analysis of AS, PPJ and the Beverage

4.4.1. Total Phenolic Compounds and Flavonoids

4.4.2. Individual Bioactive Compounds Identification and Quantification

4.5. Health-Related Biofunctionality

4.5.1. Antioxidant Capacity

4.5.2. Glycemic Index

4.5.3. Enzymatic Inhibition of Carbohydrases

4.6. In Vitro Gut Fermentation

4.6.1. Quantification of Fermentation by-Products

4.7. Statistical Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AACC. (2000). Approved methods of the American Association of Cereal Chemists. Minneapolis, USA. In Approved methods of the American Association of Cereal Chemists: Vols. I–II (10th ed.).

- Adisakwattana, S. , Ruengsamran, T., Kampa, P., & Sompong, W. (2012). In vitro inhibitory effects of plant-based foods and their combinations on intestinal α-glucosidase and pancreatic α-amylase. BMC Complementary and Alternative Medicine. [CrossRef]

- Aguirre, M. , Ramiro-Garcia, J., Koenen, M. E., & Venema, K. (2014). To pool or not to pool? Impact of the use of individual and pooled fecal samples for in vitro fermentation studies. Journal of Microbiological Methods. [CrossRef]

- Aleixandre, A. , Gil, J. V., Sineiro, J., & Rosell, C. M. (2022). Understanding phenolic acids inhibition of α-amylase and α-glucosidase and influence of reaction conditions. Food Chemistry. [CrossRef]

- Alongi, M. , Frías Celayeta, J. M., Vriz, R., Kinsella, G. K., Rulikowska, A., & Anese, M. (2021). In vitro digestion nullified the differences triggered by roasting in phenolic composition and α-glucosidase inhibitory capacity of coffee. Food Chemistry, 20 May 1282. [Google Scholar] [CrossRef]

- Alvarado-Jasso, G. M. , Camacho-Díaz, B. H., Arenas Ocampo, M. L., Jiménez-Ferrer, J. E., Mora-Escobedo, R., & Osorio-Díaz, P. (2020). Prebiotic effects of a mixture of agavins and green banana flour in a mouse model of obesity. Journal of Functional Foods. [CrossRef]

- Astó, E. , Méndez, I., Rodríguez-Prado, M., Cuñé, J., Espadaler, J., & Farran-Codina, A. (2019). Effect of the degree of polymerization of fructans on ex vivo fermented human gut microbiome. Nutrients. [CrossRef]

- Atkinson, F. S. , Brand-Miller, J. C., Foster-Powell, K., Buyken, A. E., Goletzke, J., & Brand-Miller, J. C. (2008). International tables of glycemic index and glycemic load values: 2008. Diabetes Care, 2283. [Google Scholar] [CrossRef]

- Ball, S. , Bullock, S., Lloyd, L., Mapp, K., & Ewen, A. (2011). Analysis of carbohydrates, alcohols, and organic acids by Ion-Exchange Chromatography. Agilent Hi-Plex Columns Applications Compendium, Agilent Technologies.

- Brodkorb, A. , Egger, L., Alminger, M., Alvito, P., Assunção, R., Ballance, S., Bohn, T., Bourlieu-Lacanal, C., Boutrou, R., Carrière, F., Clemente, A., Corredig, M., Dupont, D., Dufour, C., Edwards, C., Golding, M., Karakaya, S., Kirkhus, B., Le Feunteun, S., … Recio, I. (2019). INFOGEST static in vitro simulation of gastrointestinal food digestion. Nature Protocols, 1014. [Google Scholar] [CrossRef]

- Cani, P. D. , Everard, A., & Duparc, T. (2013). Gut microbiota, enteroendocrine functions and metabolism. In Current Opinion in Pharmacology (Vol. 13, Issue 6, pp. 935–940). [CrossRef]

- Cerda, K. (2011). Evaluación del contenido de fenólicos, actividad antioxidante y efectos antidiabéticos de extractos de jarabes de agave (A. atrovirens Karw). Director.

- Cha, M. N. , Jun, H. Il, Lee, W. J., Kim, M. J., Kim, M. K., & Kim, Y. S. (2013). Chemical composition and antioxidant activity of Korean cactus (Opuntia humifusa) fruit. S. ( 22(2), 523–529. [CrossRef]

- Chavez-Santoscoy, R. A. , Gutierrez-Uribe, J. A., Serna-Saldivar, S. O., & Serna-Saldívar, S. O. (2009). Phenolic composition, antioxidant capacity and in vitro cancer cell cytotoxicity of nine prickly pear (Opuntia spp.) juices. Plant Foods for Human Nutrition. [CrossRef]

- Chen, G. , Li, C., & Chen, K. (2016). Fructooligosaccharides: A review on their mechanisms of action and effects. Studies in Natural Products Chemistry. [CrossRef]

- Cockburn, D. W. , & Koropatkin, N. M. (2016). Polysaccharide Degradation by the Intestinal Microbiota and Its Influence on Human Health and Disease. In Journal of Molecular Biology (Vol. 428, Issue 16, pp. 3230–3252). [CrossRef]

- Cronin, P. , & Joyce, S. A. (2021). Dietary fibre modulates the gut microbiota. Nutrients. [CrossRef]

- Daniloski, D. , D’Cunha, N. M., Speer, H., McKune, A. J., Alexopoulos, N., Panagiotakos, D. B., Petkoska, A. T., & Naumovski, N. (2022). Recent developments on Opuntia spp., their bioactive composition, nutritional values, and health effects. Food Bioscience, 1016. [Google Scholar] [CrossRef]

- Das, A. B. , Goud, V. V., & Das, C. (2019). Phenolic Compounds as Functional Ingredients in Drinks. In Value-Added Ingredients and Enrichments of Drinks (Issue 1). Elsevier Inc. [CrossRef]

- Deehan, E. C. , Duar, R. M., Armet, A. M., Perez-Muñoz, M. E., Jin, M., & Walter, J. (2017). Modulation of the gastrointestinal microbiome with nondigestible fermentable carbohydrates to improve human health. ( 5(5), 1–24. [CrossRef] [PubMed]

- Díaz Medina, E. M. , Rodríguez Rodríguez, E. M., & Díaz Romero, C. (2007). Chemical characterization of Opuntia dillenii and Opuntia ficus indica fruits. Food Chemistry. [CrossRef]

- Dubey, P. , Thakur, V., & Chattopadhyay, M. (2020). Role of minerals and trace elements in diabetes and insulin resistance. In Nutrients (Vol. 12, Issue 6, pp. 1–17). Nutrients. [CrossRef]

- El-Hawary, S. S. , El-Kammar, H. A., Farag, M. A., Saleh, D. O., & El Dine, R. S. (2020). Metabolomic profiling of five Agave leaf taxa via UHPLC/PDA/ESI-MS inrelation to their anti-inflammatory, immunomodulatory and ulceroprotective activities. Steroids. [CrossRef]

- El Kossori, R. L. , Villaume, C., El Boustani, E., Sauvaire, Y., & Méjean, L. (1998). Composition of pulp, skin and seeds of prickly pears fruit (Opuntia ficus indica sp.). ( 52(3), 263–270. [CrossRef] [PubMed]

- Fu, M. , Shen, W., Gao, W., Namujia, L., Yang, X., Cao, J., & Sun, L. (2021). Essential moieties of myricetins, quercetins and catechins for binding and inhibitory activity against α-Glucosidase. Bioorganic Chemistry. [CrossRef]

- García-Gamboa, R. , Gradilla-Hernández, M. S., Ortiz-Basurto, R. I., García-Reyes, R. A., & González-Avila, M. (2020). Assessment of intermediate-and long-chains agave fructan fermentation on the growth of intestinal bacteria cultured in a gastrointestinal tract. Revista Mexicana de Ingeniera Quimica. [CrossRef]

- Gómez-Maqueo, A. , García-Cayuela, T., Fernández-López, R., Welti-Chanes, J., & Cano, M. P. (2019). Inhibitory potential of prickly pears and their isolated bioactives against digestive enzymes linked to type 2 diabetes and inflammatory response. P. ( 99(14), 6380–6391. [CrossRef] [PubMed]

- Goñi, I. , Garcia-Alonso, A., & Saura-Calixto, F. (1997). A starch hydrolysis procedure to estimate glycemic index. ( 17(3), 427–437. [CrossRef]

- Goñi, I. , & Martín-Carrón, N. (1998). In vitro fermentation and hydration properties of commercial diatary fiber-rich supplements. Nutrition Research, 1077. [Google Scholar]

- González-Vázquez, M. , Calderón-Domínguez, G., Mora-Escobedo, R., Salgado-Cruz, M. P., Arreguín-Centeno, J. H., & Monterrubio-López, R. (2022). Polysaccharides of nutritional interest in jicama (Pachyrhizus erosus) during root development. Food Science and Nutrition, 1158. [Google Scholar] [CrossRef]

- Gulfi, M. , Arrigoni, E., & Amadò, R. (2005). Influence of structure on in vitro fermentability of commercial pectins and partially hydrolysed pectin preparations. ( 59(2), 247–255. [CrossRef]

- Gulfi, M. , Arrigoni, E., & Amadò, R. (2006). The chemical characteristics of apple pectin influence its fermentability in vitro. LWT - Food Science and Technology. [CrossRef]

- Gupta, D. (2015). Methods for determination of antioxidant capacity: A review. International Journal of Pharmaceutical Sciences and Research. [CrossRef]

- Habibi, Y. , Heyraud, A., Mahrouz, M., & Vignon, M. R. (2004). Structural features of pectic polysaccharides from the skin of Opuntia ficus-indica prickly pear fruits. Carbohydrate Research, 1127. [Google Scholar] [CrossRef]

- Hernot, D. C. , Boileau, T. W., Bauer, L. L., Middelbos, I. S., Murphy, M. R., Swanson, K. S., & Fahey, G. C. (2009). In vitro fermentation profiles, gas production rates, and microbiota modulation as affected by certain fructans, galactooligosaccharides, and polydextrose. C. ( 57(4), 1354–1361. [CrossRef] [PubMed]

- Islam, J. , & Kabir, Y. (2019). Effects and mechanisms of antioxidant-rich functional drinks on disease prevention. In Functional and Medicinal Drinks: Volume 11: The Science of Drinks. Elsevier Inc. [CrossRef]

- Kashyap, P. , Riar, C. S., & Jindal, N. (2022). Effect of extraction methods and simulated in vitro gastrointestinal digestion on phenolic compound profile, bio-accessibility, and antioxidant activity of Meghalayan cherry (Prunus nepalensis) pomace extracts. Lwt. [CrossRef]

- Kaur, A. , Rose, D. J., Rumpagaporn, P., Patterson, J. A., & Hamaker, B. R. (2011). In Vitro Batch Fecal Fermentation Comparison of Gas and Short-Chain Fatty Acid Production Using “Slowly Fermentable” Dietary Fibers. Journal of Food Science. [CrossRef]

- Khouloud, A. , Abedelmalek, S., Chtourou, H., & Souissi, N. (2018). The effect of Opuntia ficus-indica juice supplementation on oxidative stress, cardiovascular parameters, and biochemical markers following yo-yo Intermittent recovery test. Food Science and Nutrition. [CrossRef]

- Leite, A. V. , Malta, L. G., Riccio, M. F., Eberlin, M. N., Pastore, G. M., & Maróstica Júnior, M. R. (2011). Antioxidant potential of rat plasma by administration of freeze-dried jaboticaba peel (Myrciaria jaboticaba Vell Berg). Journal of Agricultural and Food Chemistry, 2283. [Google Scholar] [CrossRef]

- Li, X. , & Siddique, K. H. M. (2020). Future Smart Food: harnessing the potential of neglected and underutilized species for Zero Hunger. Maternal and Child Nutrition. [CrossRef]

- Liu, Y. J. , Zhan, J., Liu, X. L., Wang, Y., Ji, J., & He, Q. Q. (2014). Dietary flavonoids intake and risk of type 2 diabetes: A meta-analysis of prospective cohort studies. Clinical Nutrition. [CrossRef]

- Lobo, V. , Patil, A., Phatak, A., & Chandra, N. (2010). Free radicals, antioxidants and functional foods: Impact on human health. Pharmacognosy Reviews. [CrossRef]

- Louis, P. , & Flint, H. J. (2017). Formation of propionate and butyrate by the human colonic microbiota. J. ( 19(1), 29–41. [CrossRef] [PubMed]

- Macfarlane, G. T. , & Macfarlane, S. (2012). Bacteria, colonic fermentation, and gastrointestinal health. ( 95(1), 50–60. [CrossRef] [PubMed]

- Macfarlane, G. T. , & McBain, A. J. (1999). The Human Colonic Microbiota. In Colonic Microbiota, Nutrition and Health (pp. 1–25). [CrossRef]

- Magallanes-Cruz, P. A. , Flores-Silva, P. C., & Bello-Perez, L. A. (2017). Starch Structure Influences Its Digestibility: A Review. In Journal of Food Science (Vol. 82, Issue 9, pp. 2016–2023). [CrossRef]

- Márquez-Berber, S. R. , Torcuato-Calderón, C., Almaguer-Vargas, G., Colinas-León, M. T., & Gardezi, A. K. (2012). El sistema productivo del nopal tunero (Opuntia albicarpa y O. megacantha) en axapusco, Estado de México. Problemática y alternativas. Revista Chapingo, Serie Horticultura.

- Meza, D. L. M. , & Valdés, R. M. (2015). Inhibición in vitro de las enzimas alfa-amilasa y lipasa pancreática por fracciones fenólicas de extractos etanólicos de hojas de Yacón (Smallanthus sonchifolius Poepp. & Endl). Avances En Quimica.

- Mi, S. , Liu, J., Liu, X., Fu, Y., Yi, J., & Cai, S. (2021). Inhibitory Effects of Myricetrin and Dihydromyricetin toward α -Glucosidase and Pancreatic Lipase with Molecular Docking Analyses and Their Interaction. Journal of Food Quality. [CrossRef]

- Mohammadifard, N. , Humphries, K. H., Gotay, C., Mena-Sánchez, G., Salas-Salvadó, J., Esmaillzadeh, A., Ignaszewski, A., & Sarrafzadegan, N. (2019). Trace minerals intake: Risks and benefits for cardiovascular health. Critical Reviews in Food Science and Nutrition, 1346. [Google Scholar] [CrossRef]

- Moreno-Vilet, L. , Camacho-Ruiz, R. M., & Portales-Pérez, D. P. (2016). Prebiotic Agave Fructans and Immune Aspects. In Probiotics, Prebiotics, and Synbiotics: Bioactive Foods in Health Promotion. Elsevier Inc. [CrossRef]

- Moro Cantu-Jungles, T. , do Nascimento, G. E., Zhang, X., Iacomini, M., Cordeiro, L. M. C., & Hamaker, B. R. (2019). Soluble xyloglucan generates bigger bacterial community shifts than pectic polymers during in vitro fecal fermentation. Carbohydrate Polymers. [CrossRef]

- Mothibedi, K. (2013). A study of electrospun nanofibers and diatomaceous earth materials for the extraction of alkaloids, flavonoids and aromatic amines in various matrices.

- Nazir, M. , Arif, S., Khan, R. S., Nazir, W., Khalid, N., & Maqsood, S. (2019). Opportunities and challenges for functional and medicinal drinks: Current and future trends. Trends in Food Science and Technology, 20 May. [CrossRef]

- Ondarza, M. A. (2016). Cactus Mucilages : Nutritional, Health Benefits and Clinical Trials. Journal of Medical and Biological Science Research.

- Ortiz-Basurto, R. I. , Pourcelly, G., Doco, T., Williams, P., Dormer, M., & Belleville, M. P. (2008). Analysis of the main components of the aguamiel produced by the maguey-pulquero (Agave mapisaga) throughout the harvest period. Journal of Agricultural and Food Chemistry, 3687. [Google Scholar] [CrossRef]

- Oyaizu, M. (1986). Studies on products of browning reaction. Antioxidative activities of products of browning reaction prepared from glucosamine. The Japanese Journal of Nutrition and Dietetics. [CrossRef]

- Palafox-Carlos, H. , Ayala-Zavala, J. F., & González-Aguilar, G. A. (2011). The Role of Dietary Fiber in the Bioaccessibility and Bioavailability of Fruit and Vegetable Antioxidants. Journal of Food Science. [CrossRef]

- Park, S. H. , Jeong, B. G., Song, W., Jung, J., & Chun, J. (2021). Enhancement of functional and sensory properties of eastern prickly pear (Opuntia humifusa) by fermentation with yuza peel and guava leaf. Food Bioscience, 20 December. [CrossRef]

- Peralta-García, I. , González-Muñoz, F., Elena, R. A. M., Sánchez-Flores, A., & López Munguía, A. (2020). Evolution of fructans in aguamiel (agave sap) suring the plant production lifetime. ( 7(October), 1–15. [CrossRef] [PubMed]

- Perron, N. R. , & Brumaghim, J. L. (2009). A review of the antioxidant mechanisms of polyphenol compounds related to iron binding. L. ( 53(2), 75–100. [CrossRef] [PubMed]

- Qelliny, M. , Aly, U., Elgarhy, O., & Khaled, K. (2019). Colon Drug Delivery Systems for the Treatment of Inflammatory Bowel Disease. ( 2(4), 164–184. [CrossRef]

- Ramírez-Cuellar, L. I. , Alfaro-Rodríguez, C., Ramos-Muñoz, L. G., Hernández -Castañeda, V. N., & Carranza-Concha, J. (2018). Capacidad antioxidante, fenoles totales y análisis microbiológico del Aguamiel. Investigación y Desarrollo En Ciencia y Tecnologia de Alimentos.

- Romero-López, M. R. , Osorio-Díaz, P., Flores-Morales, A., Robledo, N., & Mora-Escobedo, R. (2015). Chemical composition, antioxidant capacity and prebiotic effect of aguamiel (Agave atrovirens) during in vitro fermentation. Revista Mexicana de Ingeniera Quimica.

- Ross, S. A. , Gulve, E. A., & Wang, M. (2004). Chemistry and biochemistry of type 2 diabetes. ( 104(3), 1255–1282. [CrossRef] [PubMed]

- Ruiz Canizales, J. , Heredia, J. B., Domínguez Avila, J. A., Madera Santana, T. J., Villegas Ochoa, M. A., Robles Sánchez, R. M., & González Aguilar, G. A. (2019). Microencapsulation of blue maize (Zea mays L.) polyphenols in two matrices: their stability during storage and in vitro digestion release. Journal of Food Measurement and Characterization. [CrossRef]

- Santos-Zea, L. , Leal-Díaz, A. M., Jacobo-Velázquez, D. A., Rodríguez-Rodríguez, J., García-Lara, S., & Gutiérrez-Uribe, J. A. (2016). Characterization of concentrated agave saps and storage effects on browning, antioxidant capacity and amino acid content. Journal of Food Composition and Analysis. [CrossRef]

- Saura-Calixto, F. , Garcia-Alonso, A., Goni, I., & Bravo, L. (2000). In vitro determination of the indigestible fraction in foods: An alternative to dietary fiber analysis. Journal of Agricultural and Food Chemistry, 3347. [Google Scholar] [CrossRef]

- Schönfeld, P. , & Wojtczak, L. (2016). Short- and medium-chain fatty acids in energy metabolism: The cellular perspective. In Journal of Lipid Research (Vol. 57, Issue 6, pp. 943–954). [CrossRef]

- Shahidi, F. , Chandrasekara, A., & Zhong, Y. (2018). Bioactive phytochemicals in vegetables. Handbook of Vegetables and Vegetable Processing: Second Edition. [CrossRef]

- Song, J. , He, Y., Luo, C., Feng, B., Ran, F., Xu, H., Ci, Z., Xu, R., Han, L., & Zhang, D. (2020). New progress in the pharmacology of protocatechuic acid: A compound ingested in daily foods and herbs frequently and heavily. In Pharmacological Research (Vol. 161). [CrossRef]

- Tungland, B. (2018). Short-Chain Fatty Acid Production and Functional Aspects on Host Metabolism. In Human Microbiota in Health and Disease. Elsevier Inc. [CrossRef]

- Tveter, K. M. , Villa-Rodriguez, J. A., Cabales, A. J., Zhang, L., Bawagan, F. G., Duran, R. M., & Roopchand, D. E. (2020). Polyphenol-induced improvements in glucose metabolism are associated with bile acid signaling to intestinal farnesoid X receptor. BMJ Open Diabetes Research and Care. [CrossRef]

- Udenigwe, C. C. , Lu, Y. L., Han, C. H., Hou, W. C., & Aluko, R. E. (2009). Flaxseed protein-derived peptide fractions: Antioxidant properties and inhibition of lipopolysaccharide-induced nitric oxide production in murine macrophages. Food Chemistry. [CrossRef]

- Ursell, L. K. , Haiser, H. J., Van Treuren, W., Garg, N., Reddivari, L., Vanamala, J., Dorrestein, P. C., Turnbaugh, P. J., & Knight, R. (2014). The intestinal metabolome: An intersection between microbiota and host. Gastroenterology, 1476. [Google Scholar] [CrossRef]

- Van De Wiele, T. , Boon, N., Possemiers, S., Jacobs, H., & Verstraete, W. (2007). Inulin-type fructans of longer degree of polymerization exert more pronounced in vitro prebiotic effects. Journal of Applied Microbiology. [CrossRef]

- Van Loo, J. , Cummings, J., Delzenne, N., Englyst, H., Franck, A., Hopkins, M., Kok, N., Macfarlane, G. T., Newton, D., Quigley, M., Roberfroid, M., Van Vliet, T., & Van Den Heuvel, E. (1999). Functional food properties of non-digestible oligosaccharides: A consensus report from the ENDO project (DGXII AIRII-CT94-1095). British Journal of Nutrition. [CrossRef]

- Villamarín-Gallegos, D. , Oviedo-Pereira, D. G., Evangelista-Lozano, S., Sepúlveda-Jiménez, G., Molina-Torres, J., & Rodríguez-Monroy, M. (2020). Trichoderma asperellum, an inoculant for the production of steviol glycosides in Stevia rebaudiana Bertoni plants micropropagated in a temporary immersion bioreactor. Revista Mexicana de Ingeniera Quimica, 1161. [Google Scholar] [CrossRef]

- Virgen-Carrillo, C. A. , Valdés Miramontes, E. H., Fonseca Hernández, D., Luna-Vital, D. A., & Mojica, L. (2022). West Mexico Berries Modulate α-Amylase, α-Glucosidase and Pancreatic Lipase Using In Vitro and In Silico Approaches. Pharmaceuticals. [CrossRef]

- Wang, B. , Yao, M., Lv, L., Ling, Z., & Li, L. (2017). The human microbiota in health and disease. ( 3(1), 71–82. [CrossRef] [PubMed]

- Wang, M. , Wichienchot, S., He, X., Fu, X., Huang, Q., & Zhang, B. (2019). In vitro colonic fermentation of dietary fibers: Fermentation rate, short-chain fatty acid production and changes in microbiota. In Trends in Food Science and Technology (Vol. 88, Issue 18, pp. 1–9). Elsevier. 20 November. [CrossRef]

- Wong, J. M. W. , De Souza, R., Kendall, C. W. C., Emam, A., & Jenkins, D. J. A. (2006). Colonic health: fermentation and short chain fatty acids. Journal of Clinical Gastroenterology. [CrossRef]

- Yao, C. K. , Muir, J. G., & Gibson, P. R. (2016). Review article: Insights into colonic protein fermentation, its modulation and potential health implications. Alimentary Pharmacology and Therapeutics. [CrossRef]

- Yuan, T. , Wan, C., Liu, K., & Seeram, N. P. (2012). New maplexins F-I and phenolic glycosides from red maple (Acer rubrum) bark. Tetrahedron. [CrossRef]

| Component (g/100 mL) | AS | PPJ | Beverage |

| Moisture | 90.04±0.11a | 87.53±0.08c | 89.80±0.09b |

| Ash | 0.13±0.03a | 0.30±0.06a | 0.18±0.04a |

| Protein | 0.25±0.25a | 0.21±0.15a | 0.26±0.18a |

| Carbohydrate (mg/100 mL) | AS | PPJ | Beverage |

| Nystose | 78.52±3.93a | 52.57±1.88b | 72.98±3.83a |

| Kestose | 44.8±2.24a | 33.45±1.67c | 39.26±1.96b |

| Sucrose | 74.43±2.62a | 71.51±3.29a | 70.08±3.50a |

| Glucose | 43.46±2.17c | 226.27±4.09a | 142.15±5.67b |

| Fructose | 191.43±9.65a | 103.26±2.36c | 158.16±8.86b |

| Galacturonic acid | 113.08±6.43c | 411.96±1.91a | 217.74±13.46b |

| Mannose | 238.54±13.63a | - | 151.28±2.04b |

| Galactose | - | 192.24±4.63a | 100.85±1.15b |

| Rhamnose | 222.53+10.87b | 274.09±4.84a | 227.00±1.58b |

| Total quantified | 1006.79±25.29c | 1365.35±29.51a | 1179.50±77.84b |

| AS | PPJ | Beverage | |

| TPC (GAE) | 22.95±1.29c | 62.415±0.24a | 48.179±0.42b |

| Flavonoids (QE) | 1.33±0.18c | 15.92±1.85a | 7.52±0.10b |

| Catechin (mg/100 mL) | 30.00±1.40c | 63.53±3.20a | 46.05±2.16b |

| Protocatechuic acid (mg/100 mL) | 33.89±0.36c | 84.43±0.75a | 55.03±0.39b |

| Gallic acid (mg/100 mL) | 1.31±0.09 | 1.23±0.02a | 1.58±0.05a |

| Myricetin (mg/100 mL) | 10.28±4.86a | - | 4.70±1.20a |

| Total quantified (mg/100 mL) | 79.97±6.79c | 153.78±4.1a | 112.56±3.88b |

| Ascorbic acid (mg/100 mL) | 4.49±0.08a | 4.59±0.13a | 5.20±0.08a |

| Method | AS | PPJ | Beverage |

| PFRAP (%) | 96.05±0.26c | 88.04±0.99a | 95.29±0.11b |

| SASA (%) | 10.34±0.16c | 15.63±0.52a | 13.47±0.30b |

| ABTS (TE) | 873.33±70.24c | 2853.33±23.01a | 2000.00±55.34b |

| Glycemic index | |||

| AS | PPJ | Beverage | |

| 37.35±0.42a | 30.04±0.44b | 26.39±0.19c | |

| Enzymatic inhibition (%) | |||

| α-amylase | - | NA | - |

| α-glucosidase | 93.92±6.44b | NA | 95.56±3.09a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).