Submitted:

01 May 2024

Posted:

02 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

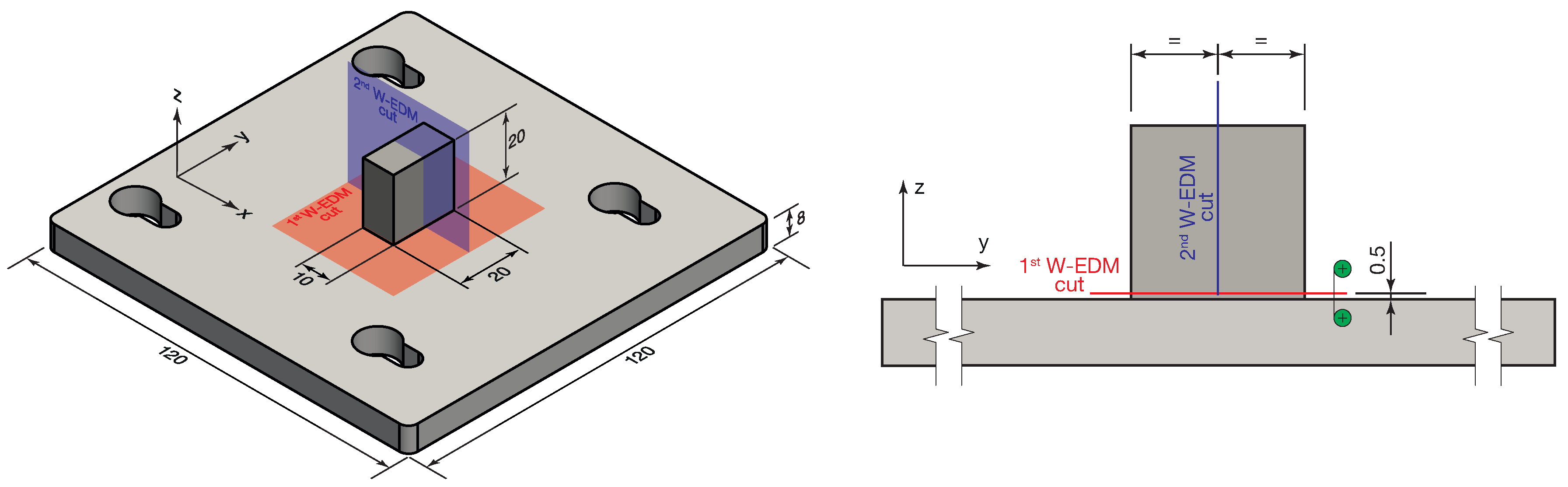

2.1. Sample Geometry, Production and Characterization

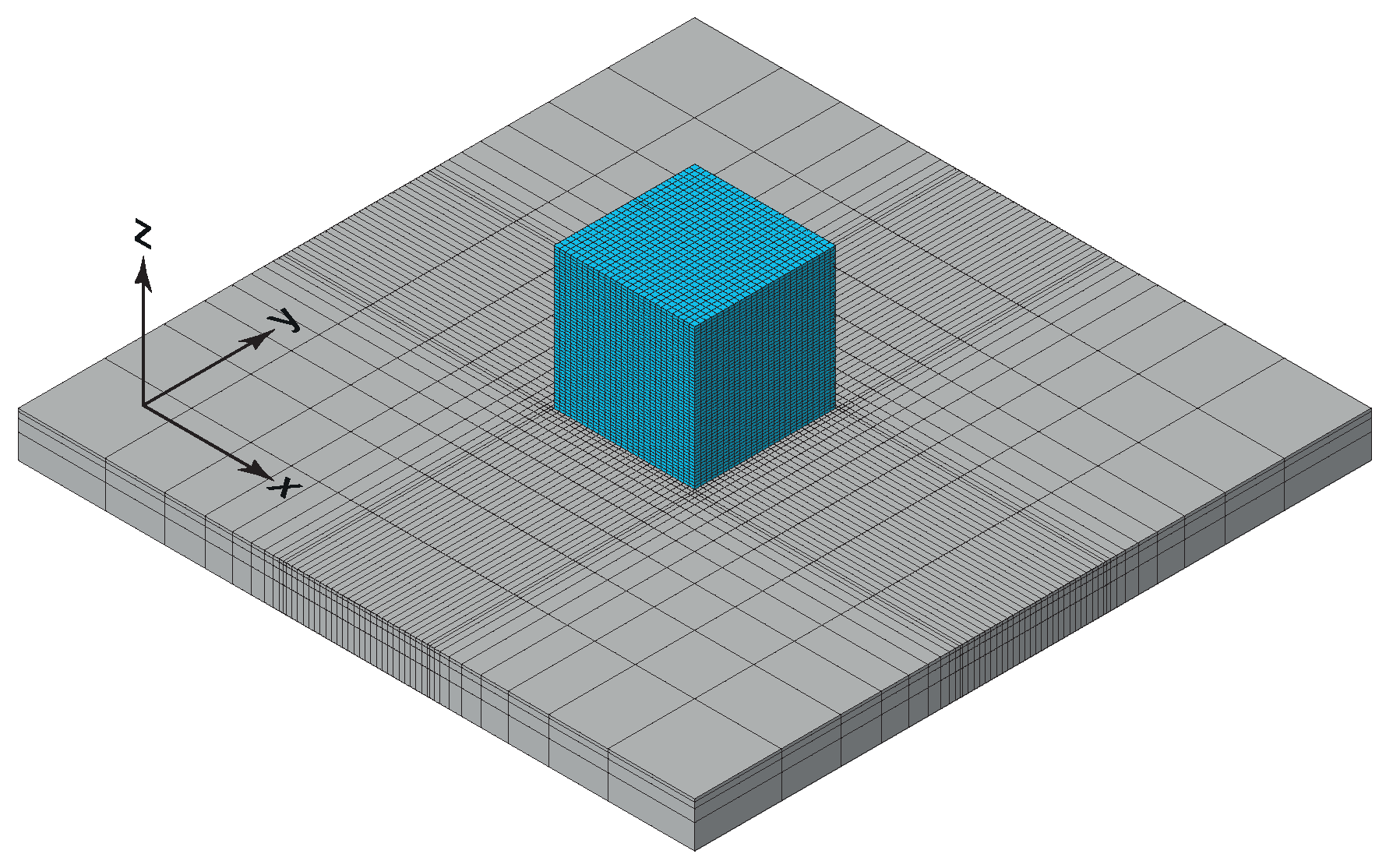

2.2. Three-Dimensional Numerical Thermal Model

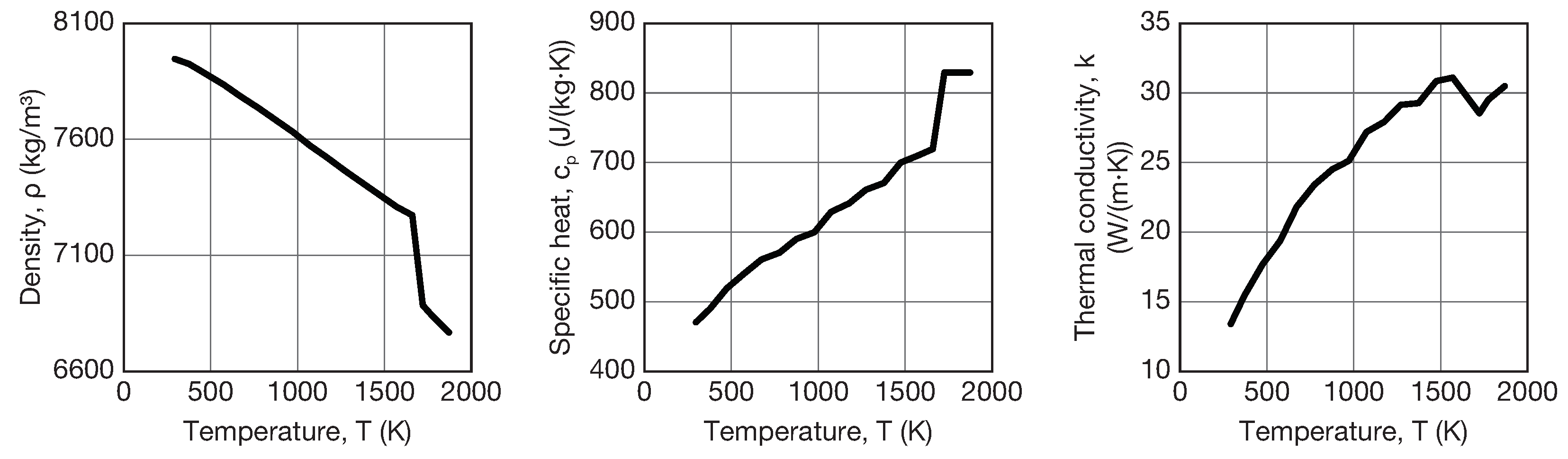

2.2.1. Assumptions and Material Properties

3. Results

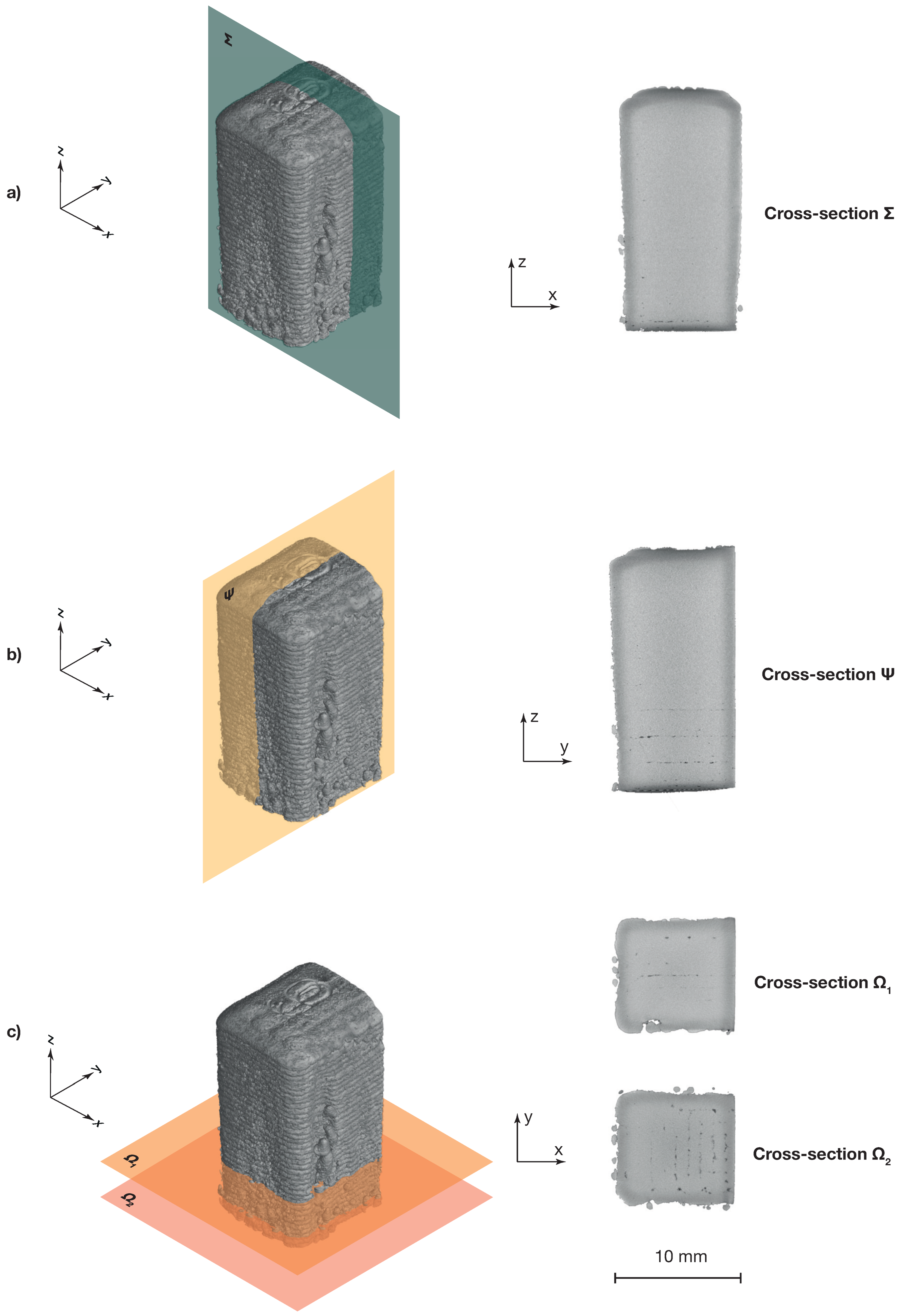

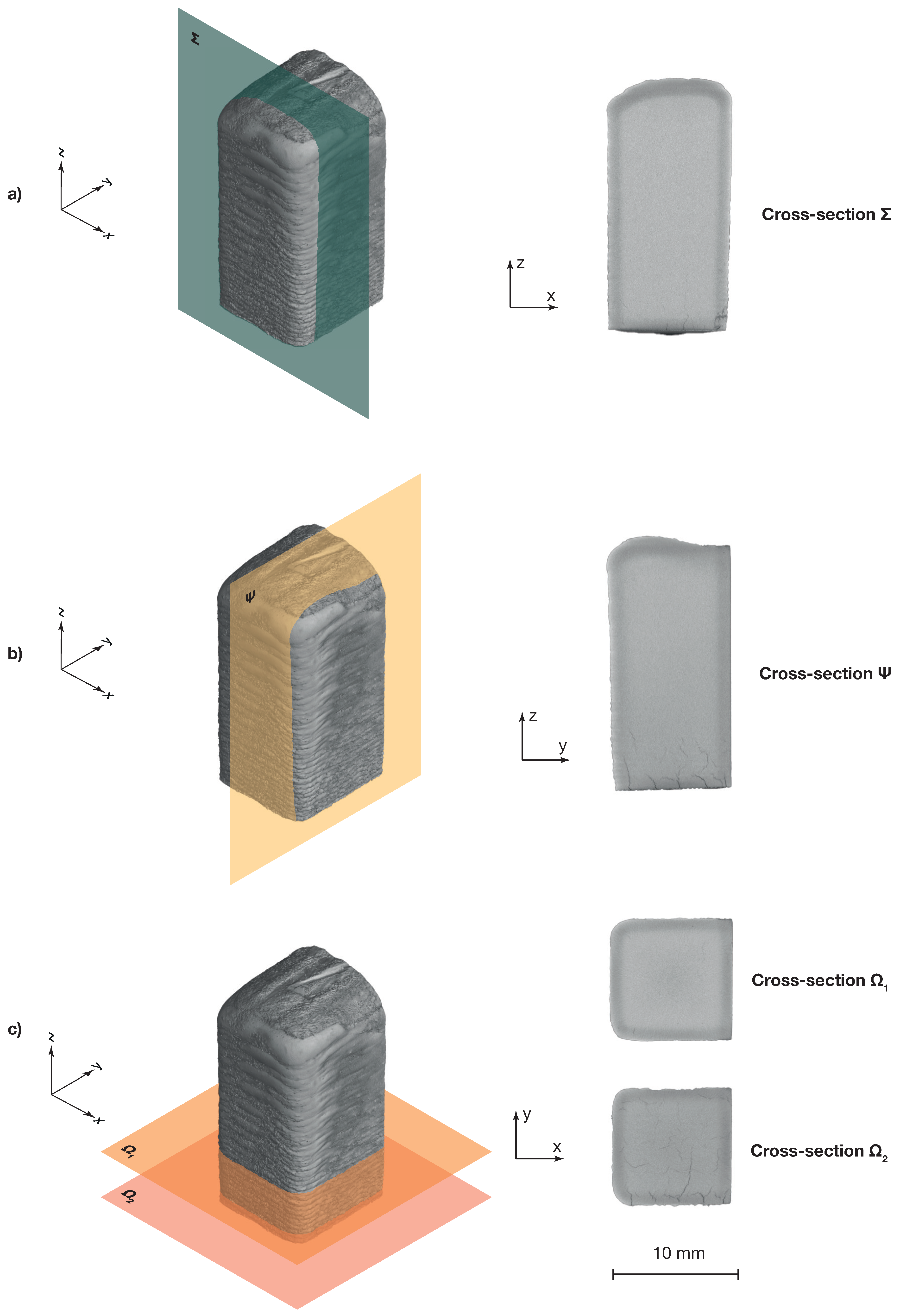

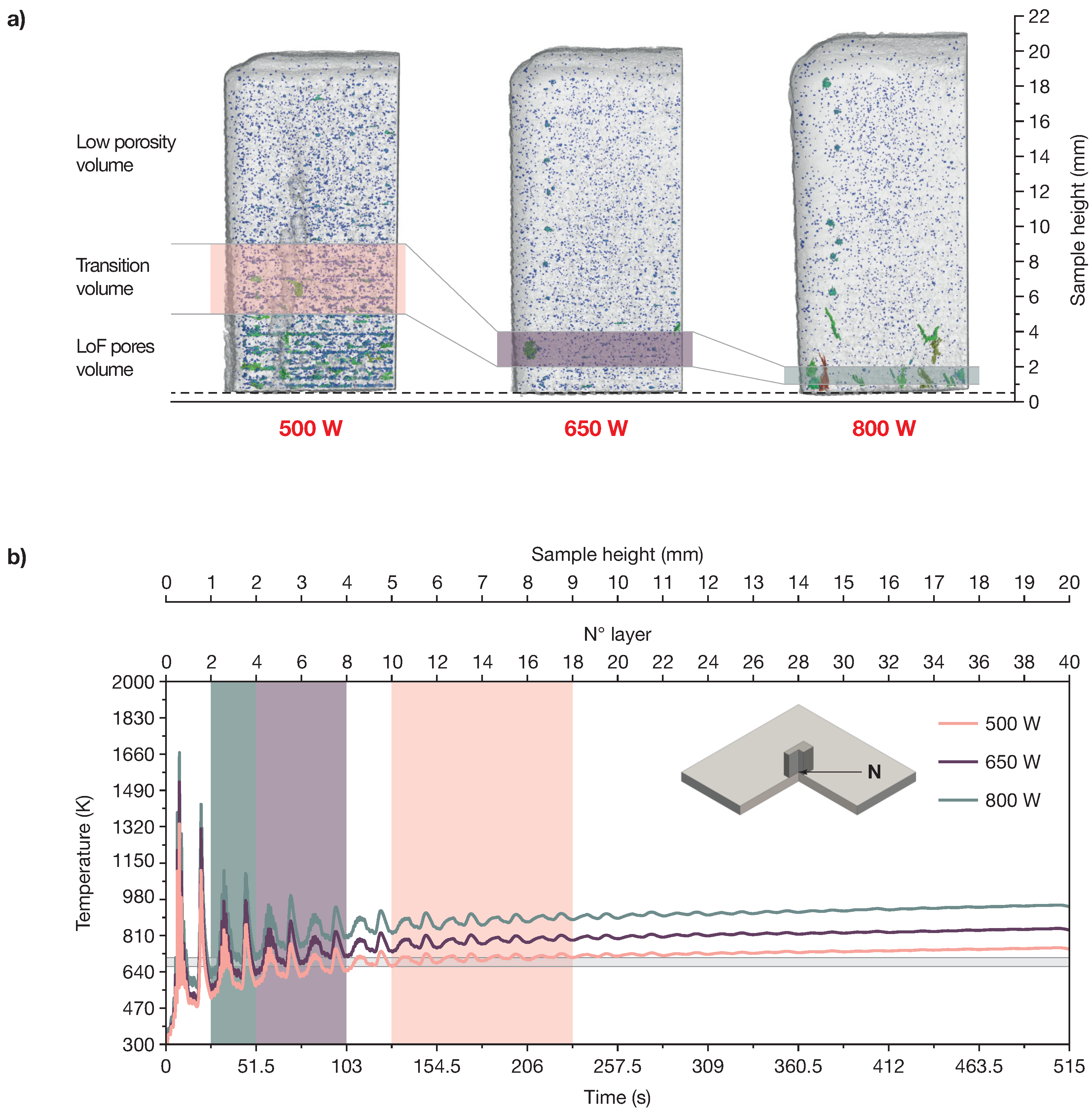

3.1. Porosity Analysis and Effect of Process Parameters

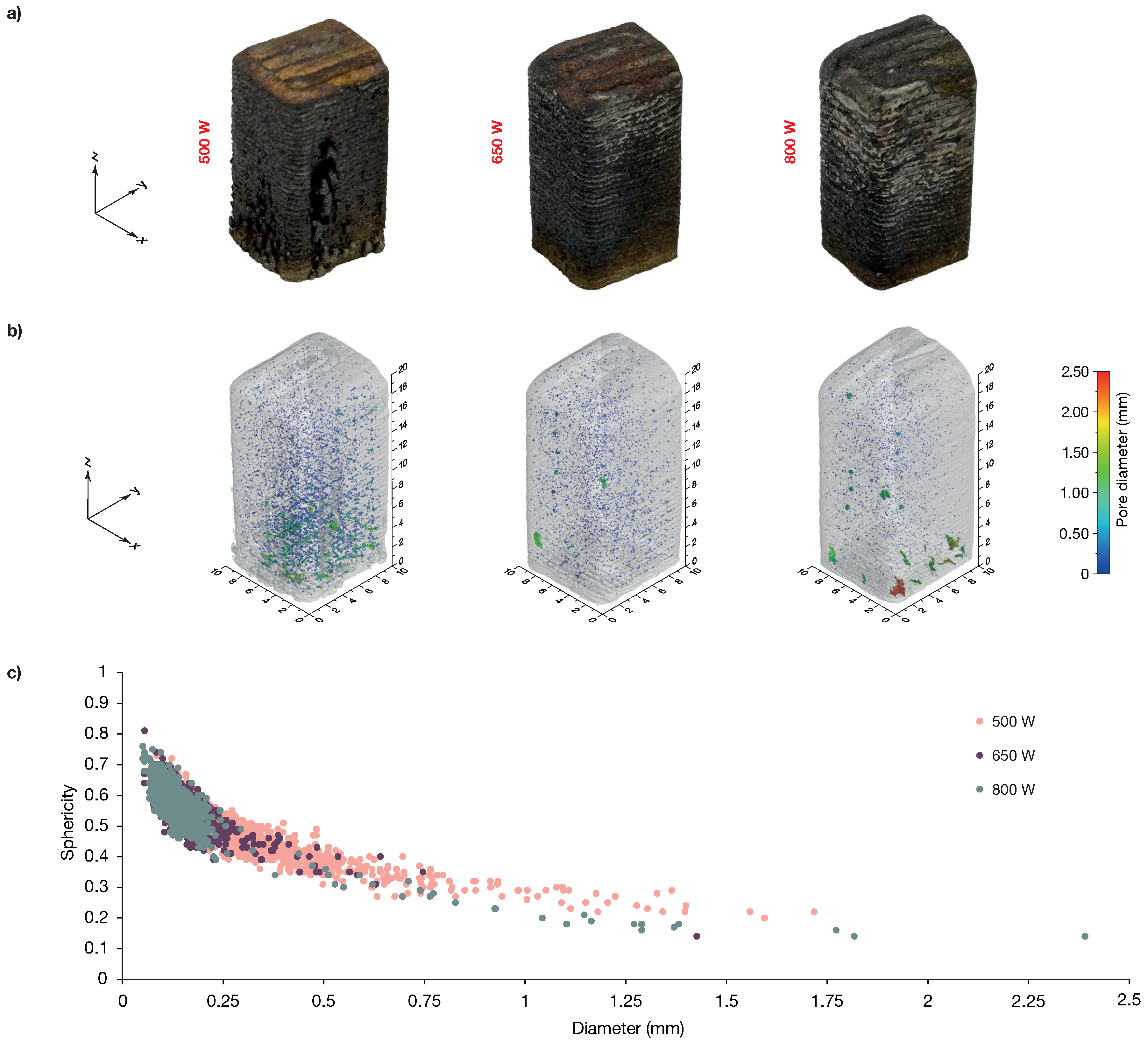

3.1.1. Effect of Laser Power

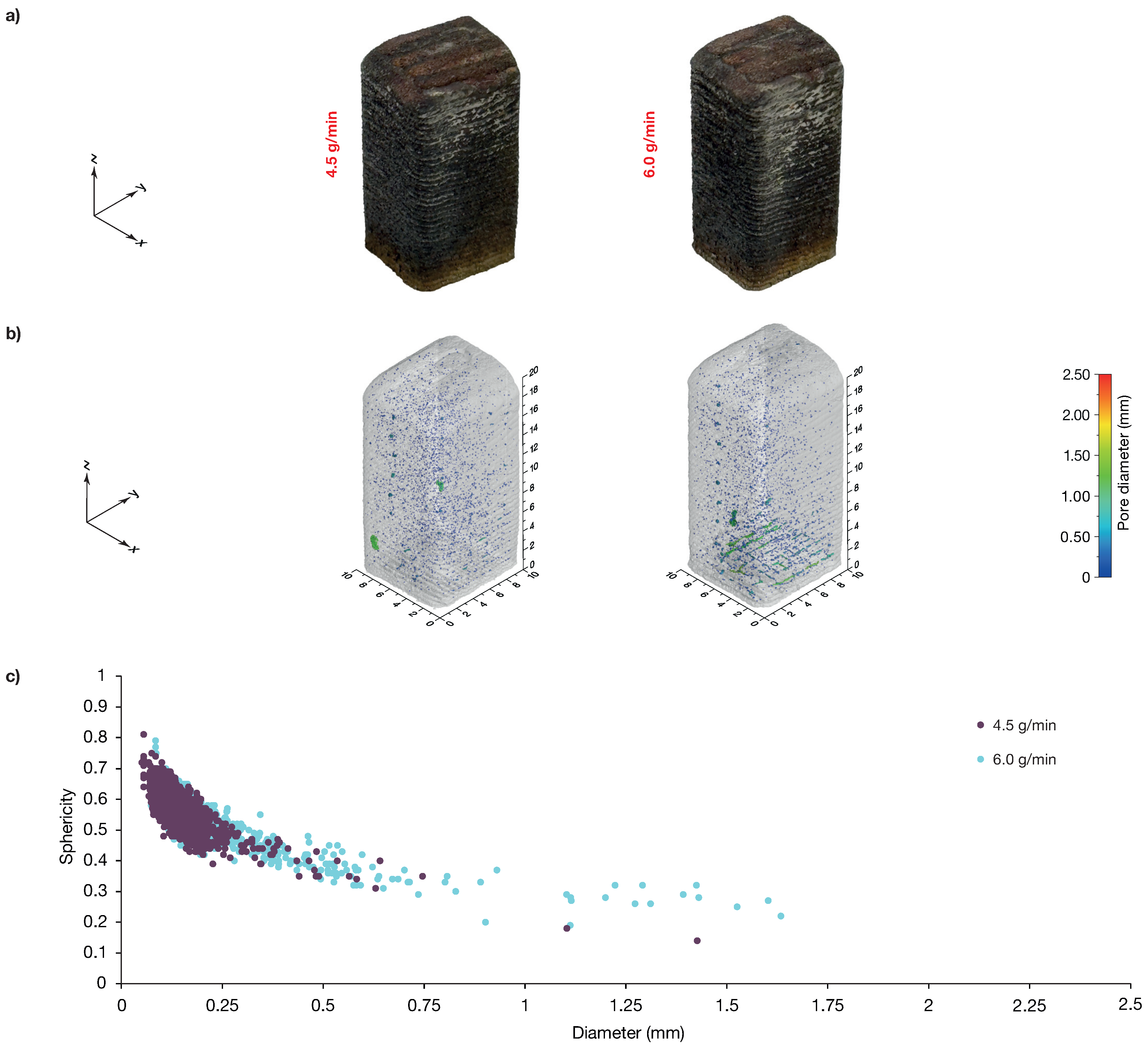

3.1.2. Effect of Powder Mass Flow Rate

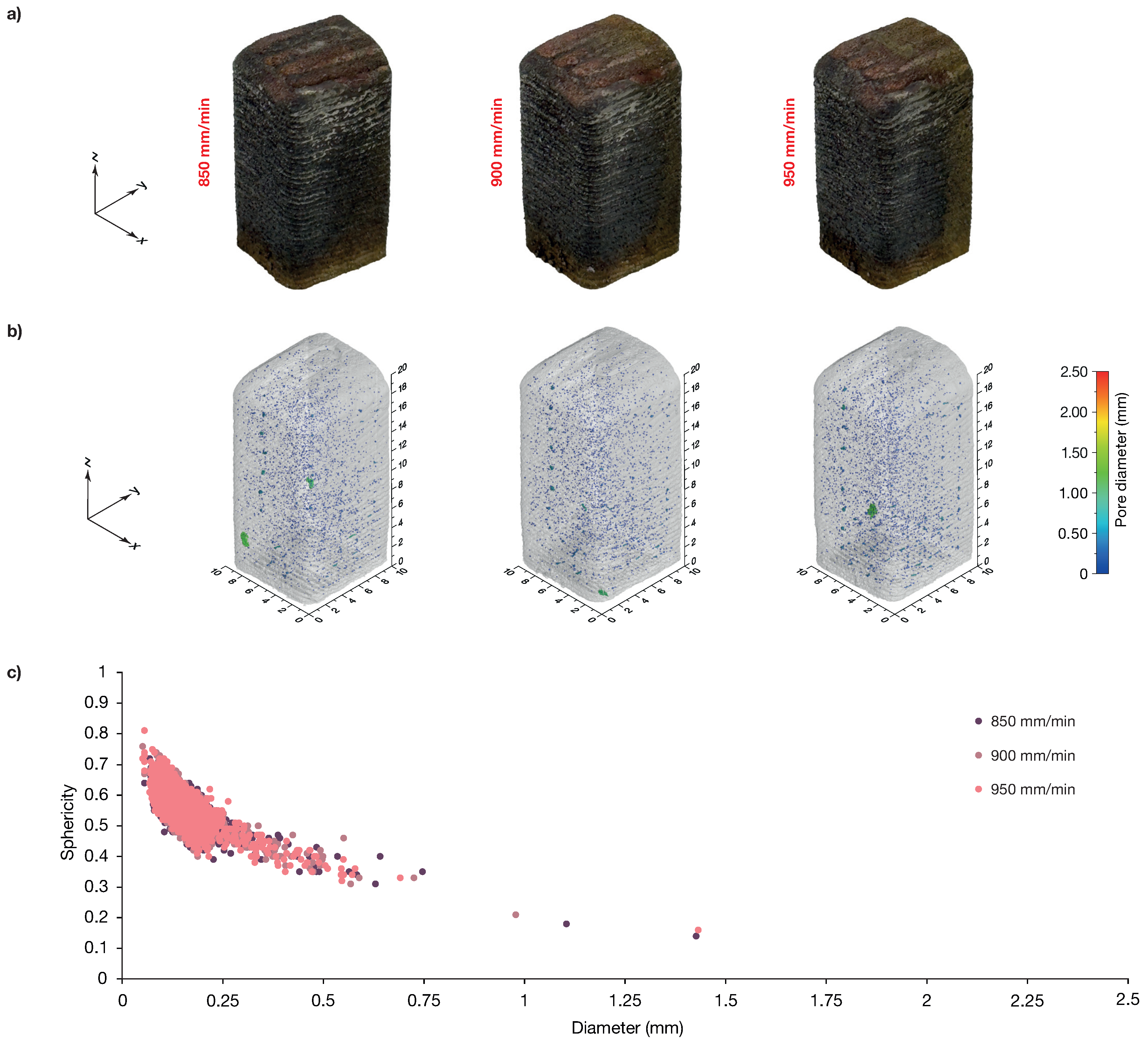

3.1.3. Effect of Travel Speed

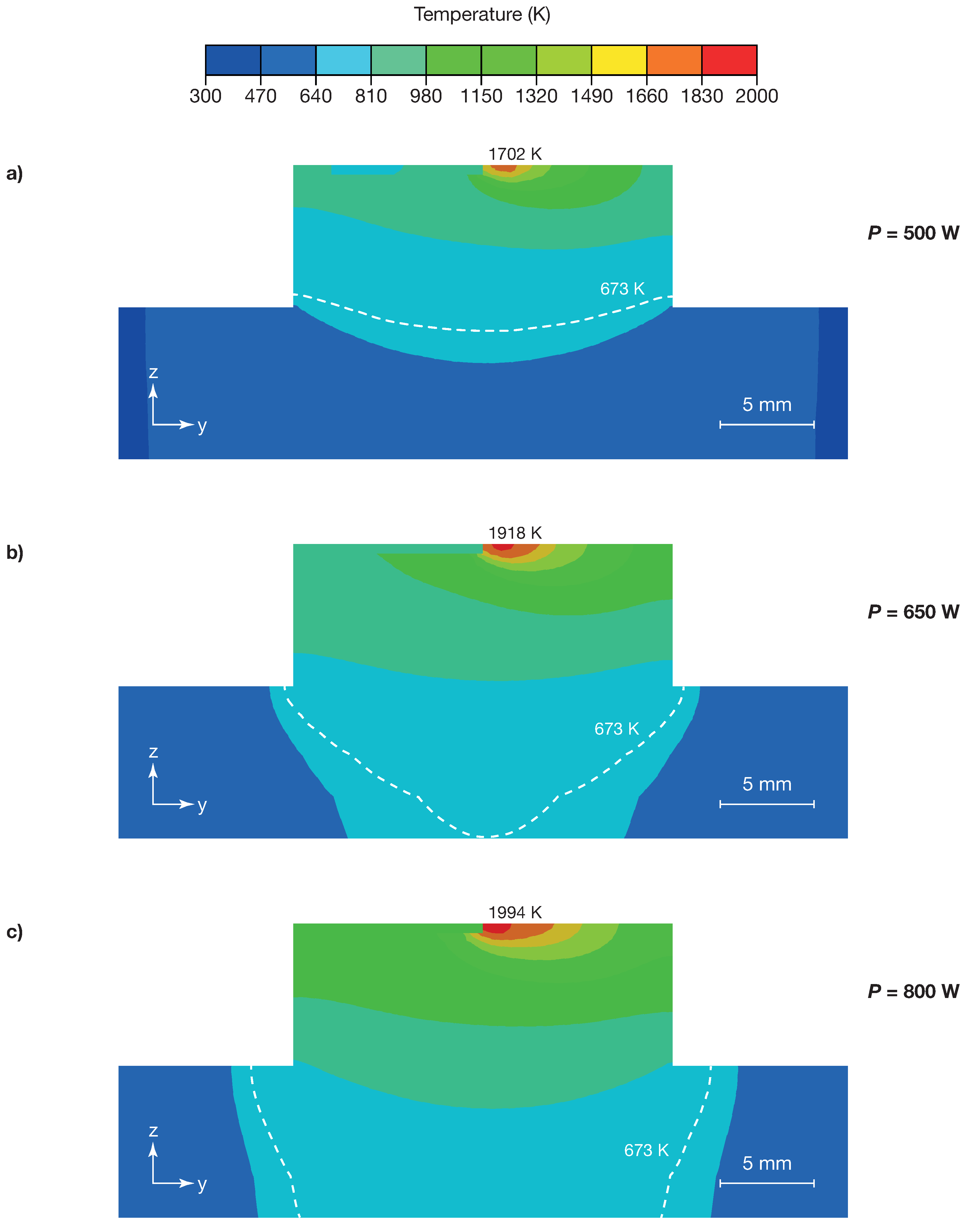

3.2. Temperature Distribution

3.2.1. Correlation between Temperature and Lack-of-Fusion Porosity

4. Conclusions

- The laser power had the higher influence on porosity. Increasing laser power has a beneficial effect in reducing porosity. However, excessive laser power could lead to the formation of cracks at the interface with the substrate;

- The powder mass flow rate influenced both gas-induced pores and lack-of-fusion pores. In detail, the increase of powder mass flow rate led to a reduction of gas-induced pores and this was related to the reduction of melt pool depth. On the other hand, the lack-of-fusion pores increased due to the melt pool width reduction;

- The travel speed had no significant influence on the porosity level with deviations in line with the process variability;

- A correlation was found between the thermal history and the presence and position of lack-of-fusion pores. This suggests that the numerical model can be a useful tool to predict the presence of such porosity.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| DED | Directed Energy Deposition |

| PBF | Powder Bed Fusion |

| DED-LB/Powder | Powder Laser Beam Directed Energy Deposition |

| CT | Computed Tomography |

| FE | Finite Element |

Appendix A. Detailed Cross-Section Views for Porosity Analysis

References

- Praveena, B.; Lokesh, N.; Buradi, A.; Santhosh, N.; Praveena, B.L.; Vignesh, R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Materials Today: Proceedings 2022, 52, 1309–1313. [CrossRef]

- Bandyopadhyay, A.; Traxel, K.D.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy design via additive manufacturing: Advantages, challenges, applications and perspectives. Materials Today 2022, 52, 207–224. [CrossRef]

- Ampower GmbH & Co. KG. Metal Additive Manufacturing Report. AMPOWER Report 2020, 2020. Available online: http://www.additive-manufacturing-report.com (accessed on 27-01-2021).

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. International Journal of Precision Engineering and Manufacturing - Green Technology 2021, 8, 703–742. [CrossRef]

- Izadi, M.; Farzaneh, A.; Mohammed, M.; Gibson, I.; Rolfe, B. A review of laser engineered net shaping (LENS) build and process parameters of metallic parts. Rapid Prototyping Journal 2020, 26, 1059–1078. [CrossRef]

- ASTM International, West Conshohocken, PA. Standard Guide for Directed Energy Deposition of Metals, 2016. Available online: https://www.astm.org/f3187-16.html (accessed on 25-04-2024).

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. International Journal of Advanced Manufacturing Technology 2022, 119, 6893–6917. [CrossRef]

- Piscopo, G.; Atzeni, E.; Saboori, A.; Salmi, A. An Overview of the Process Mechanisms in the Laser Powder Directed Energy Deposition. Applied Sciences (Switzerland) 2023, 13. [CrossRef]

- Sohn, H.; Liu, P.; Yoon, H.; Yi, K.; Yang, L.; Kim, S. Real-time porosity reduction during metal directed energy deposition using a pulse laser. Journal of Materials Science & Technology 2022, 116, 214–223. [CrossRef]

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: a critical review. Materials Research Express 2020, 7. [CrossRef]

- Tan, Z.E.; Pang, J.H.L.; Kaminski, J.; Pepin, H. Characterisation of porosity, density, and microstructure of directed energy deposited stainless steel AISI 316L. Additive Manufacturing 2019, 25, 286–296. [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Materials Today 2021, 49, 271–295. [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components – Process, structure and properties. Progress in Materials Science 2018, 92, 112–224. [CrossRef]

- Chen, L.; Yao, X.; Tan, C.; He, W.; Su, J.; Weng, F.; Chew, Y.; Ng, N.P.H.; Moon, S.K. In-situ crack and keyhole pore detection in laser directed energy deposition through acoustic signal and deep learning. Additive Manufacturing 2023, 69. [CrossRef]

- Wolff, S.J.; Wang, H.; Gould, B.; Parab, N.; Wu, Z.; Zhao, C.; Greco, A.; Sun, T. In situ X-ray imaging of pore formation mechanisms and dynamics in laser powder-blown directed energy deposition additive manufacturing. International Journal of Machine Tools and Manufacture 2021, 166. [CrossRef]

- Svetlizky, D.; Zheng, B.; Buta, T.; Zhou, Y.; Golan, O.; Breiman, U.; Haj-Ali, R.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition of Al 5xxx alloy using Laser Engineered Net Shaping (LENS®). Materials & Design 2020, 192. [CrossRef]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9. [CrossRef]

- Susan, D.F.; Puskar, J.D.; Brooks, J.A.; Robino, C.V. Quantitative characterization of porosity in stainless steel LENS powders and deposits. Materials Characterization 2006, 57, 36–43. [CrossRef]

- Ahsan, M.N.; Bradley, R.; Pinkerton, A.J. Microcomputed tomography analysis of intralayer porosity generation in laser direct metal deposition and its causes. Journal of Laser Applications 2011, 23. [CrossRef]

- Rahman Rashid, R.A.; Abaspour, S.; Palanisamy, S.; Matthews, N.; Dargusch, M.S. Metallurgical and geometrical characterisation of the 316L stainless steel clad deposited on a mild steel substrate. Surface and Coatings Technology 2017, 327, 174–184. [CrossRef]

- Zheng, B.; Haley, J.C.; Yang, N.; Yee, J.; Terrassa, K.W.; Zhou, Y.; Lavernia, E.J.; Schoenung, J.M. On the evolution of microstructure and defect control in 316L SS components fabricated via directed energy deposition. Materials Science and Engineering: A 2019, 764, 138243. [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T., Modelling of Process Parameters Influence on Degree of Porosity in Laser Metal Deposition Process. In Transactions on Engineering Technologies; Springer Netherlands, 2015; book section Chapter 3, pp. 31–42. [CrossRef]

- Amar, E.; Popov, V.; Sharma, V.M.; Andreev Batat, S.; Halperin, D.; Eliaz, N. Response Surface Methodology (RSM) Approach for Optimizing the Processing Parameters of 316L SS in Directed Energy Deposition. Materials 2023, 16. [CrossRef]

- Majumdar, J.D.; Pinkerton, A.; Liu, Z.; Manna, I.; Li, L. Microstructure characterisation and process optimization of laser assisted rapid fabrication of 316L stainless steel. Applied Surface Science 2005, 247, 320–327. [CrossRef]

- Lin, P.Y.; Shen, F.C.; Wu, K.T.; Hwang, S.J.; Lee, H.H. Process optimization for directed energy deposition of SS316L components. The International Journal of Advanced Manufacturing Technology 2020, 111, 1387–1400. [CrossRef]

- Kartikeya Sarma, I.; Srinivas, V.; Kanmani Subbu, S. Effect of process parameters on micro hardness, bulk hardness and porosity of LENSTM deposited SS 316L alloy. Materials Today: Proceedings 2021, 46, 2616–2624. [CrossRef]

- Savitha, U.; Reddy, G.J.; Venkataramana, A.; Gokhale, A.A.; Sundararaman, M. Effect of Process Parameters on Solidification Structure and Properties of Laser Deposited SS316 Alloy. Transactions of the Indian Institute of Metals 2015, 68, 1017–1022. [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Additive Manufacturing 2015, 8, 36–62. [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes, 2nd ed.; Springer: New York, 2015; book section Chapter 10, pp. 245–268. [CrossRef]

- Piscopo, G.; Atzeni, E.; Salmi, A.; Iuliano, L.; Gatto, A.; Marchiandi, G.; Balestrucci, A. Mesoscale modelling of laser powder-based directed energy deposition process. 2020, Vol. 88, pp. 393–398. [CrossRef]

- Guan, X.; Zhao, Y.F. Modeling of the laser powder–based directed energy deposition process for additive manufacturing: a review. The International Journal of Advanced Manufacturing Technology 2020, 107, 1959–1982. [CrossRef]

- Vincic, J. Laser Directed Energy Deposition for Processing and Repairing Steels. PhD thesis, Politecnico di Torino, 2024.

- Piscopo, G.; Salmi, A.; Atzeni, E. Investigation of dimensional and geometrical tolerances of laser powder directed energy deposition process. Precision Engineering 2024, 85, 217–225. [CrossRef]

- Piscopo, G.; Atzeni, E.; Salmi, A. A Hybrid Modeling of the Physics-Driven Evolution of Material Addition and Track Generation in Laser Powder Directed Energy Deposition. Materials 2019, 12. [CrossRef]

- Unocic, R.R.; DuPont, J.N. Process efficiency measurements in the laser engineered net shaping process. Metallurgical and Materials Transactions B 2004, 35, 143–152. [CrossRef]

- Gouge, M.F.; Heigel, J.C.; Michaleris, P.; Palmer, T.A. Modeling forced convection in the thermal simulation of laser cladding processes. The International Journal of Advanced Manufacturing Technology 2015, 79, 307–320. [CrossRef]

- Yadav, S.; Paul, C.; Jinoop, A.; Rai, A.; Bindra, K. Laser Directed Energy Deposition based Additive Manufacturing of Copper: Process Development and Material Characterizations. Journal of Manufacturing Processes 2020, 58, 984–997. [CrossRef]

- Zhang, W.; Xu, C.; Li, C.; Wu, S. Advances in Ultrasonic-Assisted Directed Energy Deposition (DED) for Metal Additive Manufacturing. Crystals 2024, 14. [CrossRef]

- Huang, G.; Wei, K.; Deng, J.; Liu, M.; Zeng, X. High-power laser powder bed fusion of 316L stainless steel: Defects, microstructure, and mechanical properties. Journal of Manufacturing Processes 2022, 83, 235–245. [CrossRef]

- Lim, S.H.; Ryou, K.; Jang, K.; Choi, W.S.; Lee, H.M.; Choi, P.P. Hot cracking behavior of additively manufactured D2 steel. Materials Characterization 2021, 178. [CrossRef]

- Bennett, J.; Webster, S.; Byers, J.; Johnson, O.; Wolff, S.; Ehmann, K.; Cao, J. Powder-borne porosity in directed energy deposition. Journal of Manufacturing Processes 2022, 80, 69–74. [CrossRef]

- Biyikli, M.; Karagoz, T.; Calli, M.; Muslim, T.; Ozalp, A.A.; Bayram, A. Single Track Geometry Prediction of Laser Metal Deposited 316L-Si Via Multi-Physics Modelling and Regression Analysis with Experimental Validation. Metals and Materials International 2022, 29, 807–820. [CrossRef]

- Jeon, I.; Liu, P.; Sohn, H. Real-time melt pool depth estimation and control during metal-directed energy deposition for porosity reduction. The International Journal of Advanced Manufacturing Technology. [CrossRef]

- Piscopo, G.; Salmi, A.; Atzeni, E. Influence of High-Productivity Process Parameters on the Surface Quality and Residual Stress State of AISI 316L Components Produced by Directed Energy Deposition. Journal of Materials Engineering and Performance 2021, 30, 6691–6702. [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by Laser Metal Deposition Shaping. Materials & Design 2014, 55, 104–119. [CrossRef]

| Process parameter | Values |

|---|---|

| Laser power, P () | 500 – 650 – 800 |

| Powder mass flow rate, () | 4.5 – 6.0 |

| Travel speed, v () | 850 – 900 – 950 |

| CT process parameter | Values |

|---|---|

| Voltage, V () | 200 |

| Current, I () | 110 |

| Filter | of copper |

| Timing () | 333 |

| Averaging | 3 |

| Skip frames | 2 |

| Deposits | P (W) | (g/min) | v (mm/min) | Porosity (%) |

|---|---|---|---|---|

| Set 1 | 500 | 4.5 | 850 | 0.26 |

| 650* | 0.07 | |||

| 800 | 0.07 | |||

| Set 2 | 650* | 4.5* | 850 | 0.07 |

| 6.0 | 0.10 | |||

| Set 3 | 650* | 4.5* | 850* | 0.07 |

| 900 | 0.07 | |||

| 950 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).