Submitted:

27 March 2024

Posted:

28 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Ink Formulation

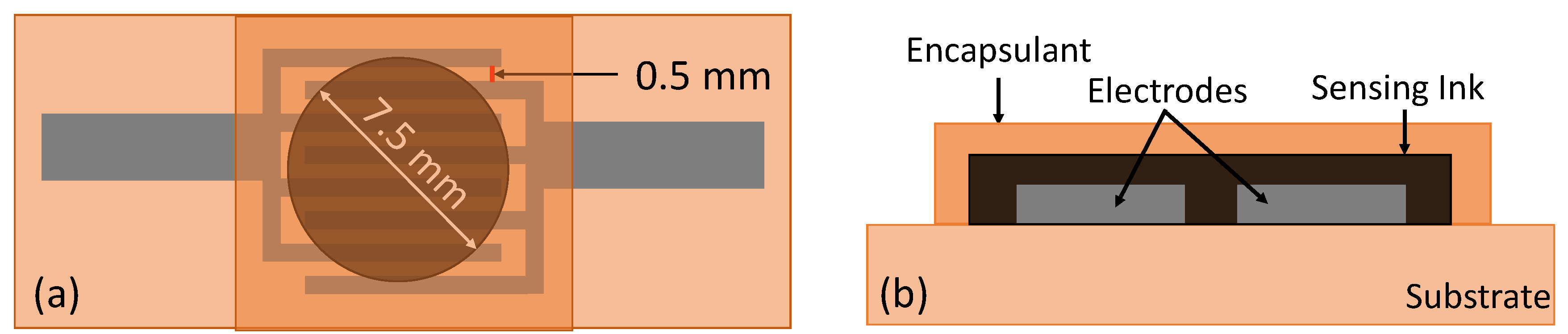

2.3. Device Design and Fabrication

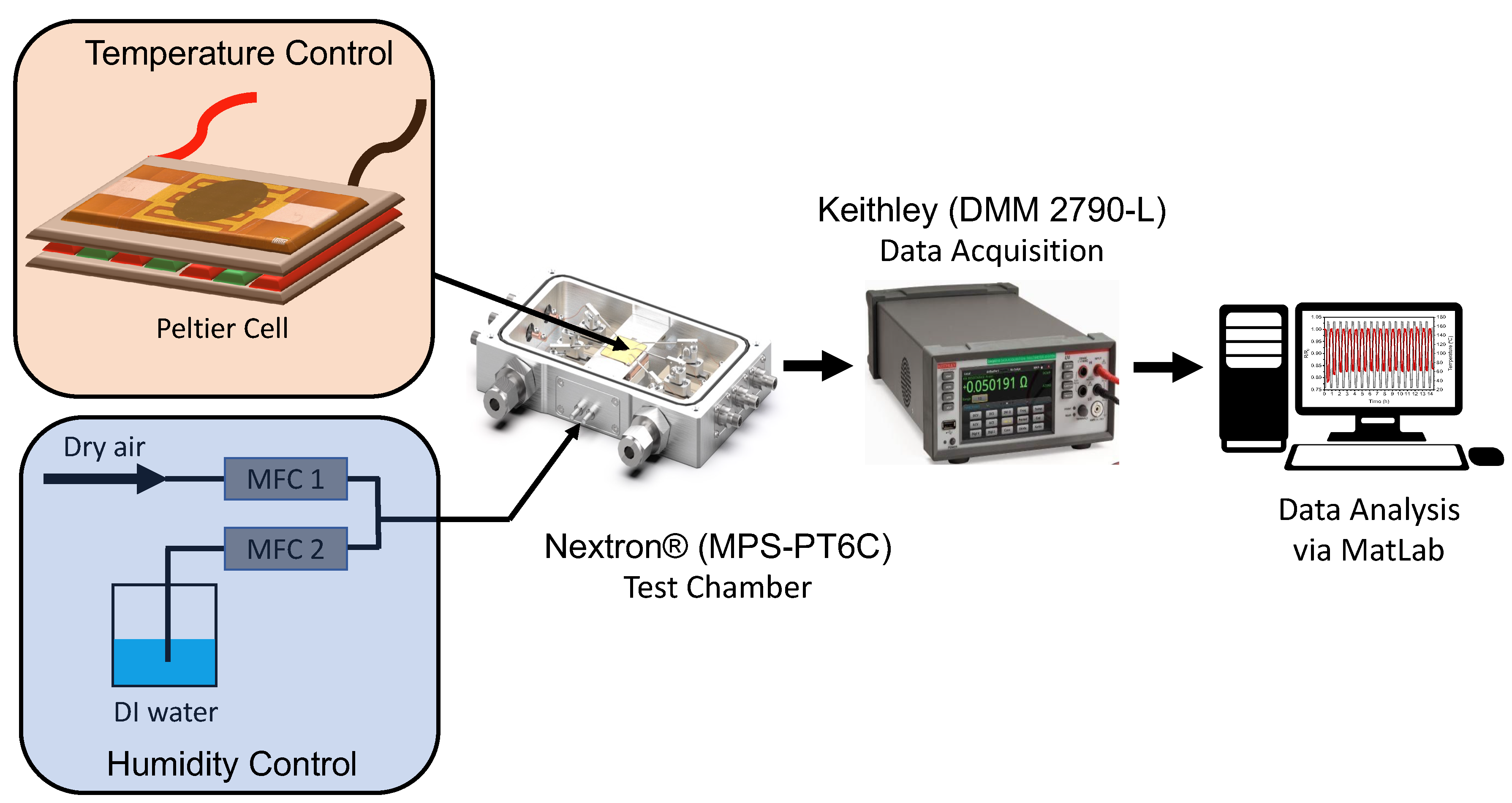

2.4. Characterization Methods

3. Results and Discussion

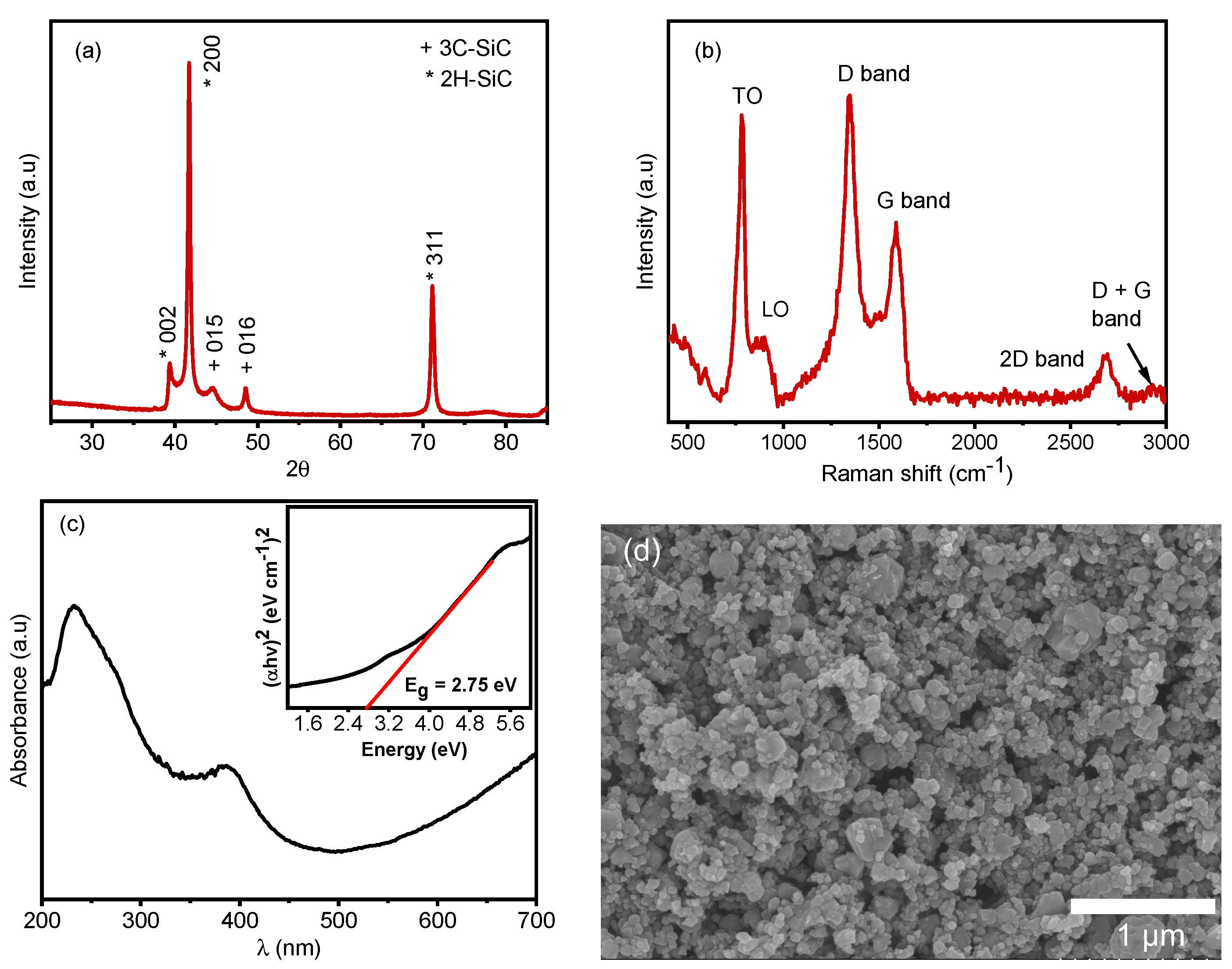

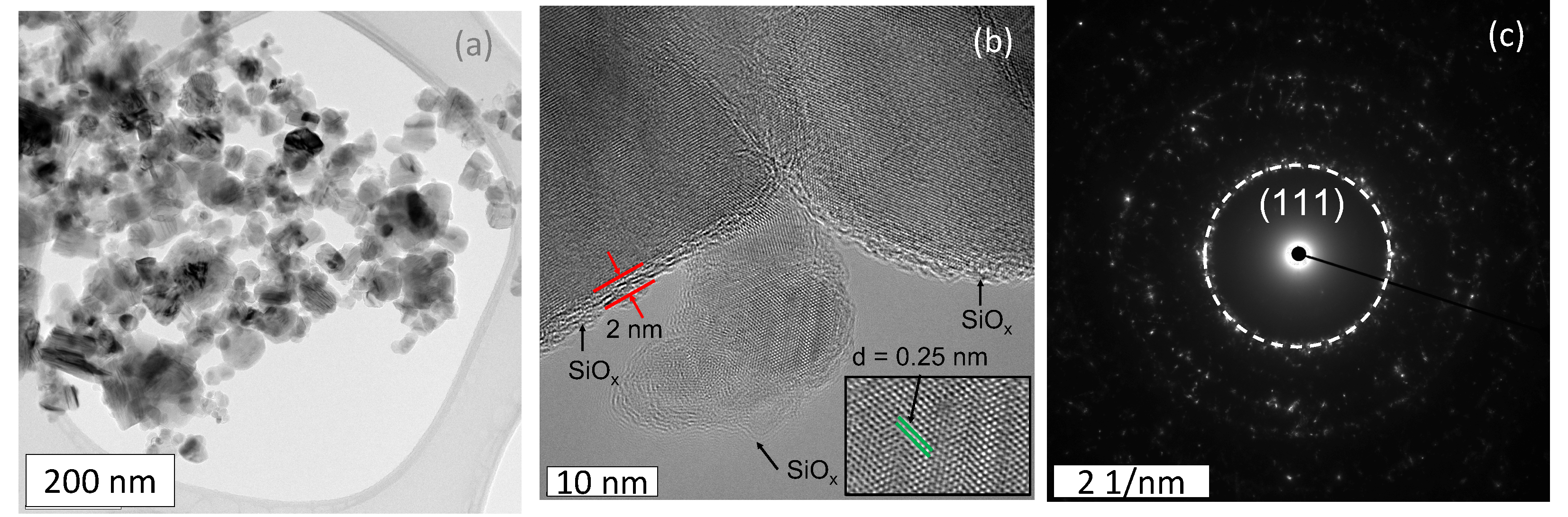

3.1. Material Characterization

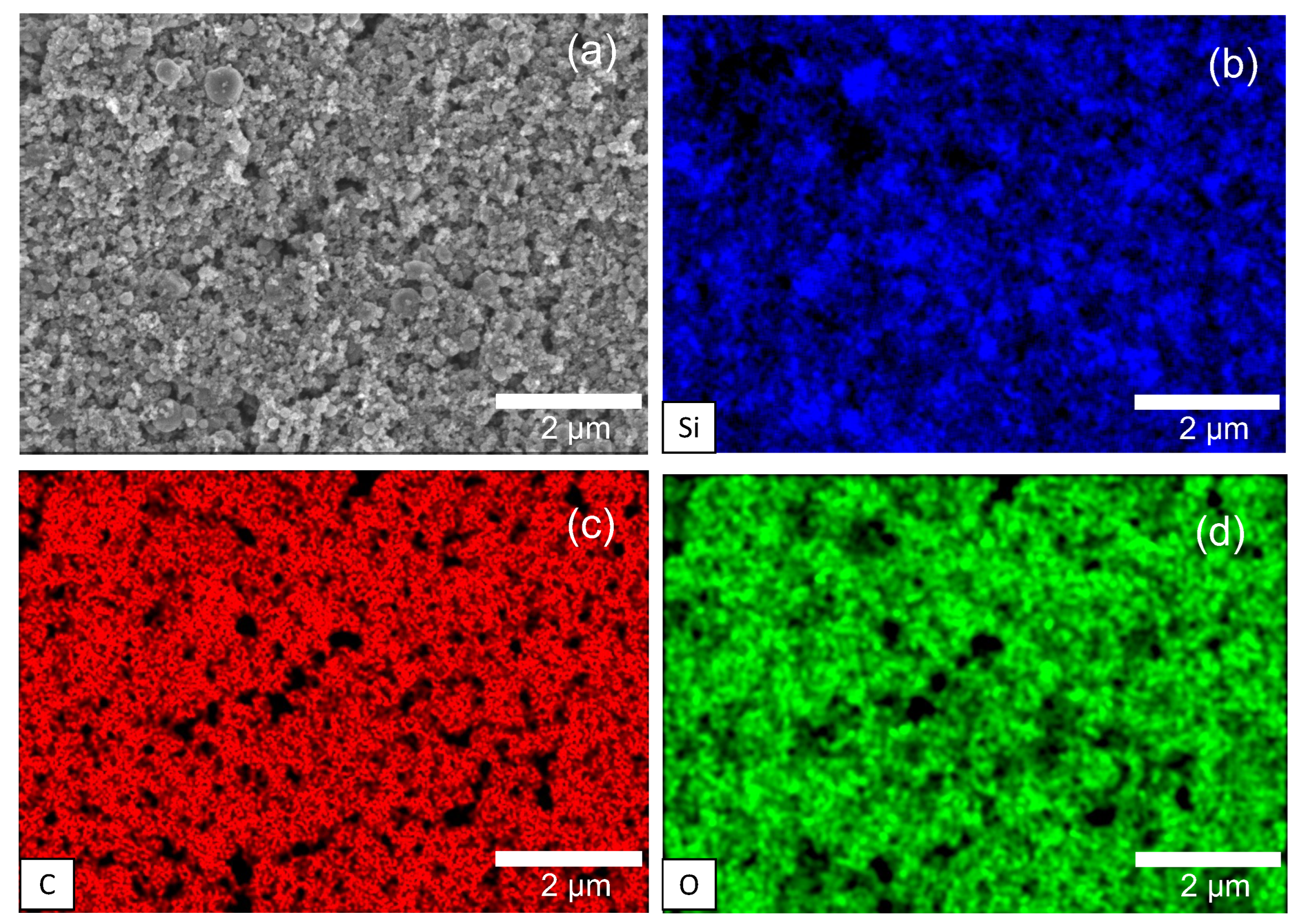

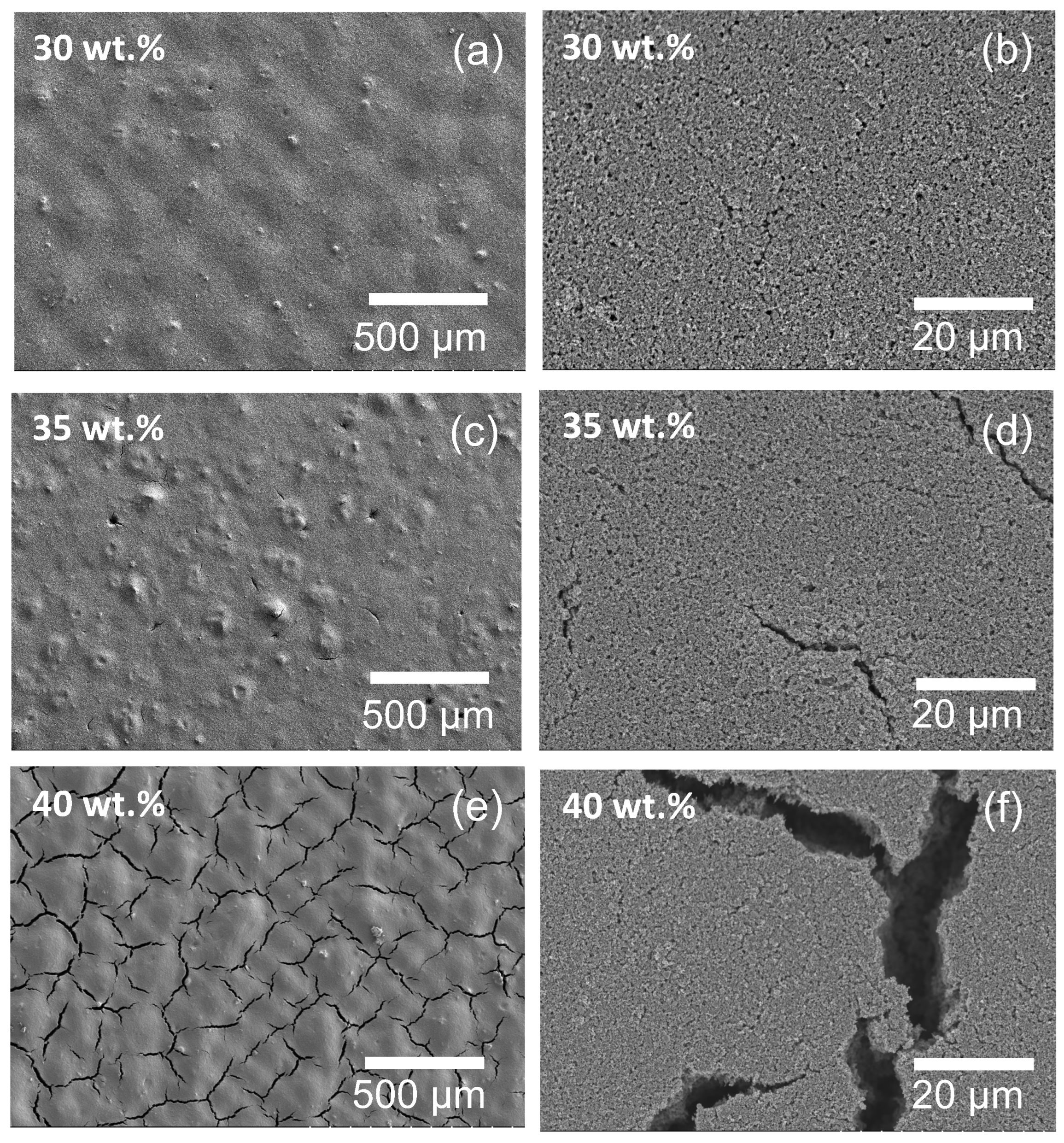

3.2. Morphology

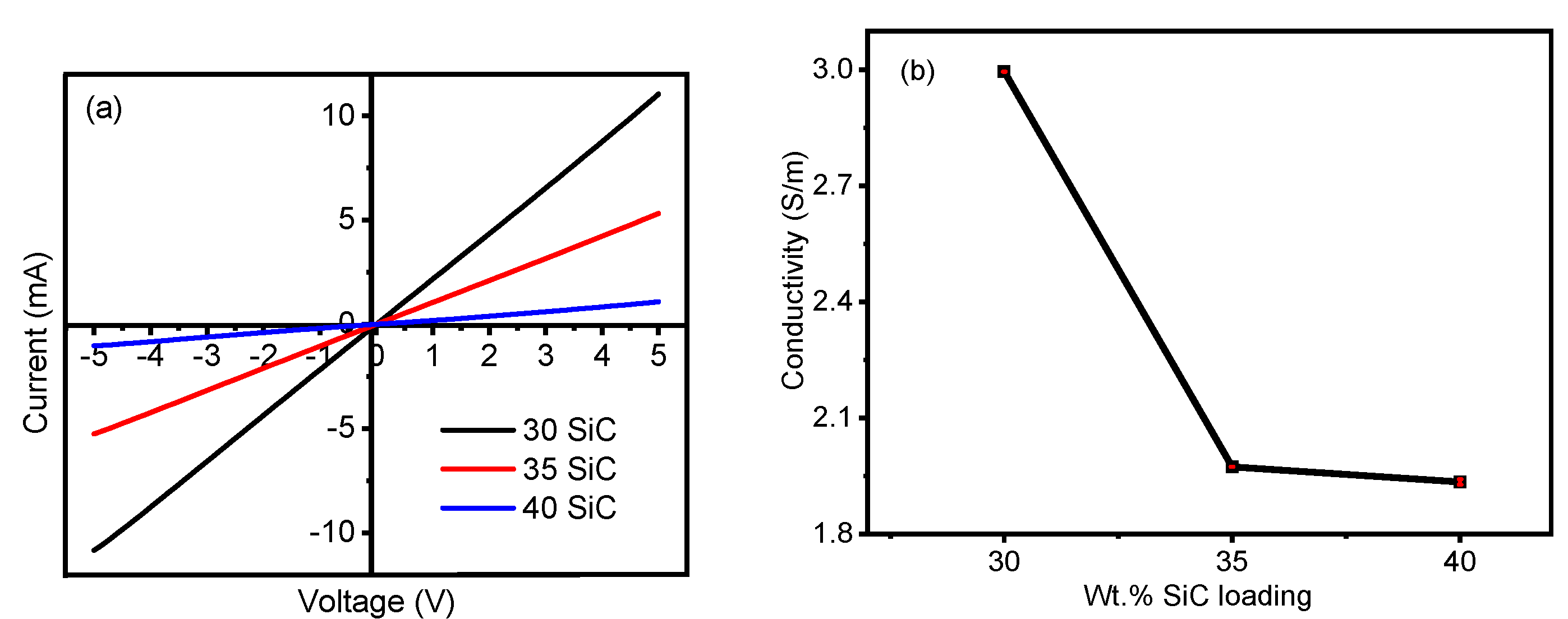

3.3. Printed SiC Thermistor Characterization

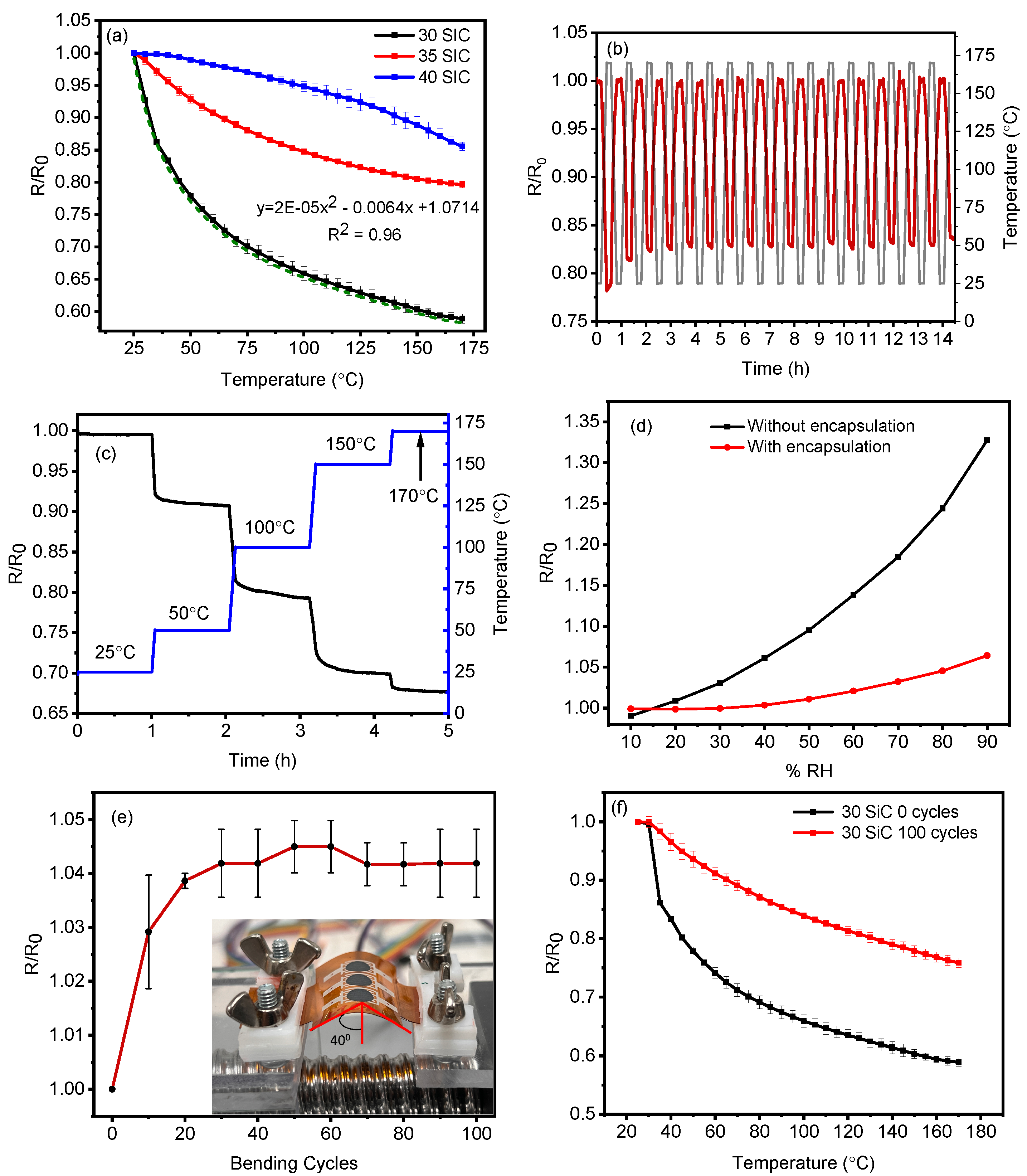

3.4. Thermistor Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gierth, P.; Rebenklau, L.; Augsburg, K.; Bachmann, E.; Niedermeyer, L. Novel thermocouples for automotive applications. Journal of Sensors and Sensor systems 2018, 7, 43–49. [Google Scholar] [CrossRef]

- Ma, L.Y.; Soin, N. Recent progress in printed physical sensing electronics for wearable health-monitoring devices: A review. IEEE Sensors Journal 2022, 22, 3844–3859. [Google Scholar] [CrossRef]

- Ali, S.; Khan, S.; Bermak, A. Inkjet-printed human body temperature sensor for wearable electronics. IEEE Access 2019, 7, 163981–163987. [Google Scholar] [CrossRef]

- Fapanni, T.; Sardini, E.; Borghetti, M.; Serpelloni, M.; Bellotti, S. Preliminary Results on Fully-Printed and Silver-Based Temperature Sensors for Aerospace Industry. 2023 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4. 0&IoT). IEEE, 2023, pp. 200–204.

- Rayhana, R.; Xiao, G.G.; Liu, Z. Printed sensor technologies for monitoring applications in smart farming: A review. IEEE Transactions on Instrumentation and Measurement 2021, 70, 1–19. [Google Scholar] [CrossRef]

- Kuzubasoglu, B.A.; Bahadir, S.K. Flexible temperature sensors: A review. Sensors and Actuators A: Physical 2020, 315, 112282. [Google Scholar] [CrossRef]

- Khan, S.; Ali, S.; Khan, A.; Bermak, A. Wearable printed temperature sensors: Short review on latest advances for biomedical applications. IEEE reviews in biomedical engineering 2021. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Tian, B.; Zhang, B.; Zhang, Z.; Liu, J.; Zhao, L.; Shi, P.; Lin, Q.; Jiang, Z. High-Performance Temperature Sensor by Employing Screen Printing Technology. Micromachines 2021, 12, 924. [Google Scholar] [CrossRef] [PubMed]

- Turkani, V.S.; Narakathu, B.B.; Maddipatla, D.; Altay, B.N.; Fleming, P.D.; Bazuin, B.J.; Atashbar, M.Z. Nickel based printed resistance temperature detector on flexible polyimide substrate. 2018 IEEE SENSORS. IEEE, 2018, pp. 1–4.

- Knoll, M.; Offenzeller, C.; Mayrhofer, B.; Jakoby, B.; Hilber, W. A screen printed thermocouple-array on a flexible substrate for condition monitoring. Proceedings. MDPI, 2018, Vol. 2, p. 803.

- Katerinopoulou, D.; Zalar, P.; Sweelssen, J.; Kiriakidis, G.; Rentrop, C.; Groen, P.; Gelinck, G.H.; van den Brand, J.; Smits, E.C. Large-area all-printed temperature sensing surfaces using novel composite thermistor materials. Advanced Electronic Materials 2019, 5, 1800605. [Google Scholar] [CrossRef]

- Elliott, C.; Large, M.; Pearce, J.; Machin, G. Compatibility of materials for use at high temperatures with W–Re thermocouples. International Journal of Thermophysics 2014, 35, 1202–1214. [Google Scholar] [CrossRef]

- Feteira, A. Negative temperature coefficient resistance (NTCR) ceramic thermistors: an industrial perspective. Journal of the American Ceramic Society 2009, 92, 967–983. [Google Scholar] [CrossRef]

- Fourmont, P.; Bai, Y.; Fortier, F.X.; Cloutier, S.G. Graphene-enhanced screen-printed BiFeO3-based thermistors. ACS Applied Electronic Materials 2022, 4, 5905–5913. [Google Scholar] [CrossRef]

- Aleksić, O.S.; Nikolić, P.M. Recent advances in NTC thick film thermistor properties and applications. Facta universitatis-series: Electronics and Energetics 2017, 30, 267–284. [Google Scholar] [CrossRef]

- Turkani, V.S.; Maddipatla, D.; Narakathu, B.B.; Bazuin, B.J.; Atashbar, M.Z. A carbon nanotube based NTC thermistor using additive print manufacturing processes. Sensors and Actuators A: Physical 2018, 279, 1–9. [Google Scholar] [CrossRef]

- Yan, C.; Wang, J.; Lee, P.S. Stretchable graphene thermistor with tunable thermal index. ACS nano 2015, 9, 2130–2137. [Google Scholar] [CrossRef]

- Inomata, N.; Inaoka, R.; Okabe, K.; Funatsu, T.; Ono, T. Short-term temperature change detections and frequency signals in single cultured cells using a microfabricated thermistor. Sensing and Bio-Sensing Research 2020, 27, 100309. [Google Scholar] [CrossRef]

- Chatterjee, S.; Sengupta, K.; Maiti, H.S. A miniature PTC thermistor based sensor element fabricated by tape casting technique. Sensors and Actuators B: Chemical 1999, 60, 155–160. [Google Scholar] [CrossRef]

- Barmpakos, D.; Kaltsas, G. A review on humidity, temperature and strain printed sensors—Current trends and future perspectives. Sensors 2021, 21, 739. [Google Scholar] [CrossRef]

- Huang, C.C.; Kao, Z.K.; Liao, Y.C. Flexible miniaturized nickel oxide thermistor arrays via inkjet printing technology. ACS applied materials & interfaces 2013, 5, 12954–12959. [Google Scholar]

- Wang, C.; Hong, G.Y.; Li, K.M.; Young, H.T. A miniaturized nickel oxide thermistor via aerosol jet technology. Sensors 2017, 17, 2602. [Google Scholar] [CrossRef]

- Khalaf, A.M.; Ramírez, J.L.; Mohamed, S.A.; Issa, H.H. Highly sensitive interdigitated thermistor based on PEDOT: PSS for human body temperature monitoring. Flexible and Printed Electronics 2022, 7, 045012. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, C.; Bin, W.; Zheng, X.; San, H.; Hofmann, W. Dual-axis thermal convective inclinometer based on CNT/PDMS composite. Journal of Materials Science: Materials in Electronics 2018, 29, 18997–19004. [Google Scholar] [CrossRef]

- Romero, F.J.; Rivadeneyra, A.; Toral, V.; Castillo, E.; García-Ruiz, F.; Morales, D.P.; Rodriguez, N. Design guidelines of laser reduced graphene oxide conformal thermistor for IoT applications. Sensors and Actuators A: Physical 2018, 274, 148–154. [Google Scholar] [CrossRef]

- Li, X.; Cui, T.; Li, X.; Liu, H.; Li, D.; Jian, J.; Li, Z.; Yang, Y.; Ren, T. Wearable Temperature Sensors Based on Reduced Graphene Oxide Films. Materials 2023, 16, 5952. [Google Scholar] [CrossRef] [PubMed]

- Kabiri Ameri, S.; Ho, R.; Jang, H.; Tao, L.; Wang, Y.; Wang, L.; Schnyer, D.M.; Akinwande, D.; Lu, N. Graphene electronic tattoo sensors. ACS nano 2017, 11, 7634–7641. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Tan, Q.; Lu, X.; Zhang, G.; Zhang, W.; Xiong, J. Wireless passive separated LC temperature sensor based on high-temperature co-fired ceramic operating up to 1500° C. Journal of Micromechanics and Microengineering 2019, 29, 035015. [Google Scholar] [CrossRef]

- Reimann, T.; Töpfer, J.; Barth, S.; Bartsch, H.; Müller, J. Low-Temperature Sintered NTC Thermistor Ceramics for Thick-Film Temperature Sensors. International Journal of Applied Ceramic Technology 2013, 10, 428–434. [Google Scholar] [CrossRef]

- Tan, Q.; Luo, T.; Xiong, J.; Kang, H.; Ji, X.; Zhang, Y.; Yang, M.; Wang, X.; Xue, C.; Liu, J.; others. A harsh environment-oriented wireless passive temperature sensor realized by LTCC technology. Sensors 2014, 14, 4154–4166. [Google Scholar] [CrossRef]

- Tan, Q.; Wei, T.; Chen, X.; Luo, T.; Wu, G.; Li, C.; Xiong, J. Antenna-resonator integrated wireless passive temperature sensor based on low-temperature co-fired ceramic for harsh environment. Sensors and Actuators A: Physical 2015, 236, 299–308. [Google Scholar] [CrossRef]

- Uppuluri, K.; Szwagierczak, D. Fabrication and characterization of screen printed NiMn2O4 spinel based thermistors. Sensor Review 2022, 42, 177–186. [Google Scholar] [CrossRef]

- Le, D.T.; Ju, H. Solution synthesis of cubic spinel Mn–Ni–Cu–O thermistor powder. Materials 2021, 14, 1389. [Google Scholar] [CrossRef]

- Reimann, T.; Töpfer, J.; Barth, S.; Bartsch, H.; Muller, J. Low-Temperature Sintered NTC Thermistor Ceramics for Thick-Film Temperature Sensors. International Journal of Applied Ceramic Technology 2013, 10, 428–434. [Google Scholar] [CrossRef]

- Nguyen, N.K.; Nguyen, T.; Nguyen, T.K.; Yadav, S.; Dinh, T.; Masud, M.K.; Singha, P.; Do, T.N.; Barton, M.J.; Ta, H.T.; others. Wide-band-gap semiconductors for biointegrated electronics: recent advances and future directions. ACS Applied Electronic Materials 2021, 3, 1959–1981. [Google Scholar] [CrossRef]

- Oliveros, A.; Guiseppi-Elie, A.; Saddow, S.E. Silicon carbide: a versatile material for biosensor applications. Biomedical microdevices 2013, 15, 353–368. [Google Scholar] [CrossRef] [PubMed]

- Zorman, C.A. Silicon carbide as a material for biomedical microsystems. 2009 Symposium on Design, Test, Integration & Packaging of MEMS/MOEMS. IEEE, 2009, pp. 1–7.

- Kotzar, G.; Freas, M.; Abel, P.; Fleischman, A.; Roy, S.; Zorman, C.; Moran, J.M.; Melzak, J. Evaluation of MEMS materials of construction for implantable medical devices. Biomaterials 2002, 23, 2737–2750. [Google Scholar] [CrossRef]

- Coletti, C.; Jaroszeski, M.; Pallaoro, A.; Hoff, A.; Iannotta, S.; Saddow, S. Biocompatibility and wettability of crystalline SiC and Si surfaces. 2007 29th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. IEEE, 2007, pp. 5849–5852.

- Yang, L.; Zhao, H.; Fan, S.; Deng, S.; Lv, Q.; Lin, J.; Li, C.P. Label-free electrochemical immunosensor based on gold–silicon carbide nanocomposites for sensitive detection of human chorionic gonadotrophin. Biosensors and Bioelectronics 2014, 57, 199–206. [Google Scholar] [CrossRef] [PubMed]

- de Vasconcelos, E.A.; Khan, S.; Zhang, W.; Uchida, H.; Katsube, T. Highly sensitive thermistors based on high-purity polycrystalline cubic silicon carbide. Sensors and Actuators A: Physical 2000, 83, 167–171. [Google Scholar] [CrossRef]

- Phan, H.P.; Nguyen, T.K.; Dinh, T.; Qamar, A.; Iacopi, A.; Lu, J.; Dao, D.V.; Rais-Zadeh, M.; Nguyen, N.T. Wireless battery-free SiC sensors operating in harsh environments using resonant inductive coupling. IEEE Electron Device Letters 2019, 40, 609–612. [Google Scholar] [CrossRef]

- Dakshinamurthy, S.; Quick, N.; Kar, A. Temperature-dependent optical properties of silicon carbide for wireless temperature sensors. Journal of Physics D: Applied Physics 2007, 40, 353. [Google Scholar] [CrossRef]

- Boltovets, N.; Kholevchuk, V.; Konakova, R.; Kudryk, Y.Y.; Lytvyn, P.; Milenin, V.; Mitin, V.; Mitin, E. A silicon carbide thermistor. Semiconductor Physics Quantum Electronics & Optoelectronics.

- Phan, H.P.; Zhong, Y.; Nguyen, T.K.; Park, Y.; Dinh, T.; Song, E.; Vadivelu, R.K.; Masud, M.K.; Li, J.; Shiddiky, M.J.; others. Long-lived, transferred crystalline silicon carbide nanomembranes for implantable flexible electronics. ACS nano 2019, 13, 11572–11581. [Google Scholar] [CrossRef]

- Larson, C.M.; Choi, J.J.; Gallardo, P.A.; Henderson, S.W.; Niemack, M.D.; Rajagopalan, G.; Shepherd, R.F. Direct ink writing of silicon carbide for microwave optics. Advanced Engineering Materials 2016, 18, 39–45. [Google Scholar] [CrossRef]

- Mott, M.; Evans, J.R. Solid freeforming of silicon carbide by inkjet printing using a polymeric precursor. Journal of the American Ceramic Society 2001, 84, 307–13. [Google Scholar] [CrossRef]

- Guo, Z.; An, L.; Khuje, S.; Chivate, A.; Li, J.; Wu, Y.; Hu, Y.; Armstrong, J.; Ren, S.; Zhou, C. 3D-printed electrically conductive silicon carbide. Additive Manufacturing 2022, 59, 103109. [Google Scholar] [CrossRef]

- Hallaj, R.; Soltani, E.; Mafakheri, S.; Ghadermazi, M. A surface-modified silicon carbide nanoparticles based electrochemical sensor for free interferences determination of caffeine in tea and coffee. Materials Science and Engineering: B 2021, 274, 115473. [Google Scholar] [CrossRef]

- Roushani, M.; Nezhadali, A.; Jalilian, Z.; Azadbakht, A. Development of novel electrochemical sensor on the base of molecular imprinted polymer decorated on SiC nanoparticles modified glassy carbon electrode for selective determination of loratadine. Materials Science and Engineering: C 2017, 71, 1106–1114. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhang, J.; Wang, M.; Li, Y. High-temperature hydrogen sensor based on platinum nanoparticle-decorated SiC nanowire device. Sensors and Actuators B: Chemical 2014, 201, 402–406. [Google Scholar] [CrossRef]

- Ahmed, H.; Abduljalil, H.M.; Hashim, A. Structural, optical and electronic properties of novel (PVA–MgO)/SiC nanocomposites films for humidity sensors. Transactions on Electrical and Electronic Materials 2019, 20, 218–232. [Google Scholar] [CrossRef]

- Aljasar, S.A.; Xu, Y.; Qasaimeh, M.R. Design, Fabrication and Characterization of flexible laser reduced Silicon Carbide nanoparticle thermal heater sensor. 2022 4th International Youth Conference on Radio Electronics, Electrical and Power Engineering (REEPE). IEEE, 2022, pp. 1–5.

- Henager, C.H.; Alvine, K.J.; Roosendaal, T.J.; Shin, Y.; Nguyen, B.N.; Borlaug, B.A.; Jiang, W.; Arreguin, S.A. Nanocrystalline SiC and Ti3SiC2 Alloys for Reactor Materials: Annual Report. [CrossRef]

- Sun, B.; Xie, R.; Yu, C.; Li, C.; Xu, H. Structural characterization of SiC nanoparticles. Journal of Semiconductors 2017, 38, 103002. [Google Scholar] [CrossRef]

- Iwanowski, R.; Fronc, K.; Paszkowicz, W.; Heinonen, M. XPS and XRD study of crystalline 3C-SiC grown by sublimation method. Journal of alloys and compounds 1999, 286, 143–147. [Google Scholar] [CrossRef]

- Shekhawat, D.; Sudhahar, D.; Döll, J.; Grieseler, R.; Pezoldt, J. Phase formation of cubic silicon carbide from reactive silicon–carbon multilayers. MRS Advances 2023, 1–5. [Google Scholar]

- Lebedev, A.; Oganesyan, G.; Kozlovski, V.; Eliseyev, I.; Bulat, P. Radiation defects in heterostructures 3C-SiC/4H-SiC. Crystals 2019, 9, 115. [Google Scholar] [CrossRef]

- Nakashima, S.i.; Harima, H. Raman investigation of SiC polytypes. physica status solidi (a) 1997, 162, 39–64. [Google Scholar] [CrossRef]

- Dragomir, M.; Valant, M.; Fanetti, M.; Mozharivskyj, Y. A facile chemical method for the synthesis of 3C–SiC nanoflakes. RSC advances 2016, 6, 21795–21801. [Google Scholar] [CrossRef]

- Zhu, K.; Guo, L.; Lin, J.; Hao, W.; Shang, J.; Jia, Y.; Chen, L.; Jin, S.; Wang, W.; Chen, X. Graphene covered SiC powder as advanced photocatalytic material. Applied Physics Letters 2012, 100. [Google Scholar] [CrossRef]

- Peng, P.; Hu, A.; Gerlich, A.P.; Zou, G.; Liu, L.; Zhou, Y.N. Joining of Silver Nanomaterials at Low Temperatures: Processes, Properties, and Applications. ACS Applied Materials & Interfaces 2015, 7, 12597–12618. [Google Scholar] [CrossRef]

- Batha, H.; Carroll, P. Unicrystalline Silicon Carbide Thermistor. IEEE Transactions on Component Parts 1964, 11, 129–134. [Google Scholar] [CrossRef]

- Shuaib, E.P.; Yogesh, G.K.; Sastikumar, D. Amorphous and photoluminescent crystalline silicon carbide nanoparticles synthesized by laser ablation in liquids. Materials Today: Proceedings 2022, 50, 2745–2750. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Srinivasan, N. Role of SiOx on the photoluminescence properties of β-SiC. Ceramics International 2016, 42, 8900–8908. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Zhang, H.; Han, L.; Bi, Y.; Wang, H.; Song, S.; Zhang, S. Low-temperature catalytic synthesis of SiC nanopowder from liquid phenolic resin and diatomite. Advances in Applied Ceramics 2018, 117, 147–154. [Google Scholar] [CrossRef]

- Somalu, M.; Yufit, V.; Brandon, N. The effect of solids loading on the screen-printing and properties of nickel/scandia-stabilized-zirconia anodes for solid oxide fuel cells. International journal of hydrogen energy 2013, 38, 9500–9510. [Google Scholar] [CrossRef]

- Kaiser, T.; Cordill, M.J.; Kirchlechner, C.; Menzel, A. Electrical and mechanical behaviour of metal thin films with deformation-induced cracks predicted by computational homogenisation. International Journal of Fracture 2021, 231, 223–242. [Google Scholar] [CrossRef]

- Kim, B.J.; Haas, T.; Friederich, A.; Lee, J.H.; Nam, D.H.; Binder, J.R.; Bauer, W.; Choi, I.S.; Joo, Y.C.; Gruber, P.A.; others. Improving mechanical fatigue resistance by optimizing the nanoporous structure of inkjet-printed Ag electrodes for flexible devices. Nanotechnology 2014, 25, 125706. [Google Scholar] [CrossRef]

- Diaham, S. Polyimide in electronics: Applications and processability overview. Polyimide for Electronic and Electrical Engineering Applications, 2020. [Google Scholar]

- Yuan, W.; Cui, X.; Li, Y.; Ma, C. Effects of relative humidity on thermistor mount measurements. 2015 40th International Conference on Infrared, Millimeter, and Terahertz waves (IRMMW-THz). IEEE, 2015, pp. 1–2.

- Connolly, E.; Pham, H.; Groeneweg, J.; Sarro, P.; French, P. Silicon carbide membrane relative humidity sensor with aluminium electrodes. 17th IEEE International Conference on Micro Electro Mechanical Systems. Maastricht MEMS 2004 Technical Digest. IEEE, 2004, pp. 193–196.

- Sun, L.; Wang, B.; Wang, Y. A novel silicon carbide nanosheet for high-performance humidity sensor. Advanced Materials Interfaces 2018, 5, 1701300. [Google Scholar] [CrossRef]

- Sarrión, M.L.M.; Morales, M. Preparation and characterization of NTC thermistors: nickel manganites doped with lithium. Journal of the American Ceramic Society 1995, 78, 915–921. [Google Scholar] [CrossRef]

- Steinhart, J.S.; Hart, S.R. Calibration curves for thermistors. Deep sea research and oceanographic abstracts. Elsevier, 1968, Vol. 15, pp. 497–503.

- Wasa, K.; Tohda, T.; Kasahara, Y.; Hayakawa, S. Highly-reliable temperature sensor using rf-sputtered SiC thin film. Review of Scientific Instruments 1979, 50, 1084–1088. [Google Scholar] [CrossRef] [PubMed]

- Thermistor Vs Rtd Temperature Measurement Accuracy – Application Note, 2020. Accessed on , 2024. 11 March.

- What Is A Thermistor And How Does It Work?, 2020. Accessed on , 2024. 11 March.

- Abro, D.M.; Dablé, P.; Cortés-Salazar, F.; Amstutz, V.; Girault, H. Characterization of surface state of inert particles: case of Si and SiC. Journal of Minerals and Materials Characterization and Engineering 2016, 4, 62–72. [Google Scholar] [CrossRef]

- Constantin, C.P.; Aflori, M.; Damian, R.F.; Rusu, R.D. Biocompatibility of polyimides: A mini-review. Materials 2019, 12, 3166. [Google Scholar] [CrossRef]

- Huseynov, E.M.; Naghiyev, T.G. Various thermal parameters investigation of 3C-SiC nanoparticles at the different heating rates. Applied Physics A 2022, 128, 115. [Google Scholar] [CrossRef]

- Batha, H.; Carroll, P. Unicrystalline silicon carbide thermistor. IEEE Transactions on Component Parts 1964, 11, 129–134. [Google Scholar] [CrossRef]

- de Vasconcelos, E.A.; Zhang, W.Y.; Uchida, H.; Katsube, T. Potential of high-purity polycrystalline silicon carbide for thermistor applications. Japanese journal of applied physics 1998, 37, 5078. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, W.; Zhang, Q.; Zheng, K.; Xu, J.; Xu, W.; Shang, E.; Jiang, J.; Zhang, J.; Liu, Y. 3D-printed graphene/polydimethylsiloxane composites for stretchable and strain-insensitive temperature sensors. ACS applied materials & interfaces 2018, 11, 1344–1352. [Google Scholar]

- Kong, D.; Le, L.T.; Li, Y.; Zunino, J.L.; Lee, W. Temperature-dependent electrical properties of graphene inkjet-printed on flexible materials. Langmuir 2012, 28, 13467–13472. [Google Scholar] [CrossRef]

- Umadevi, P.; Nagendra, C.; Thutupalli, G. Structural, electrical and infrared optical properties of vanadium pentoxide (V2O5) thick-film thermistors. Sensors and Actuators A: Physical 1993, 39, 59–69. [Google Scholar] [CrossRef]

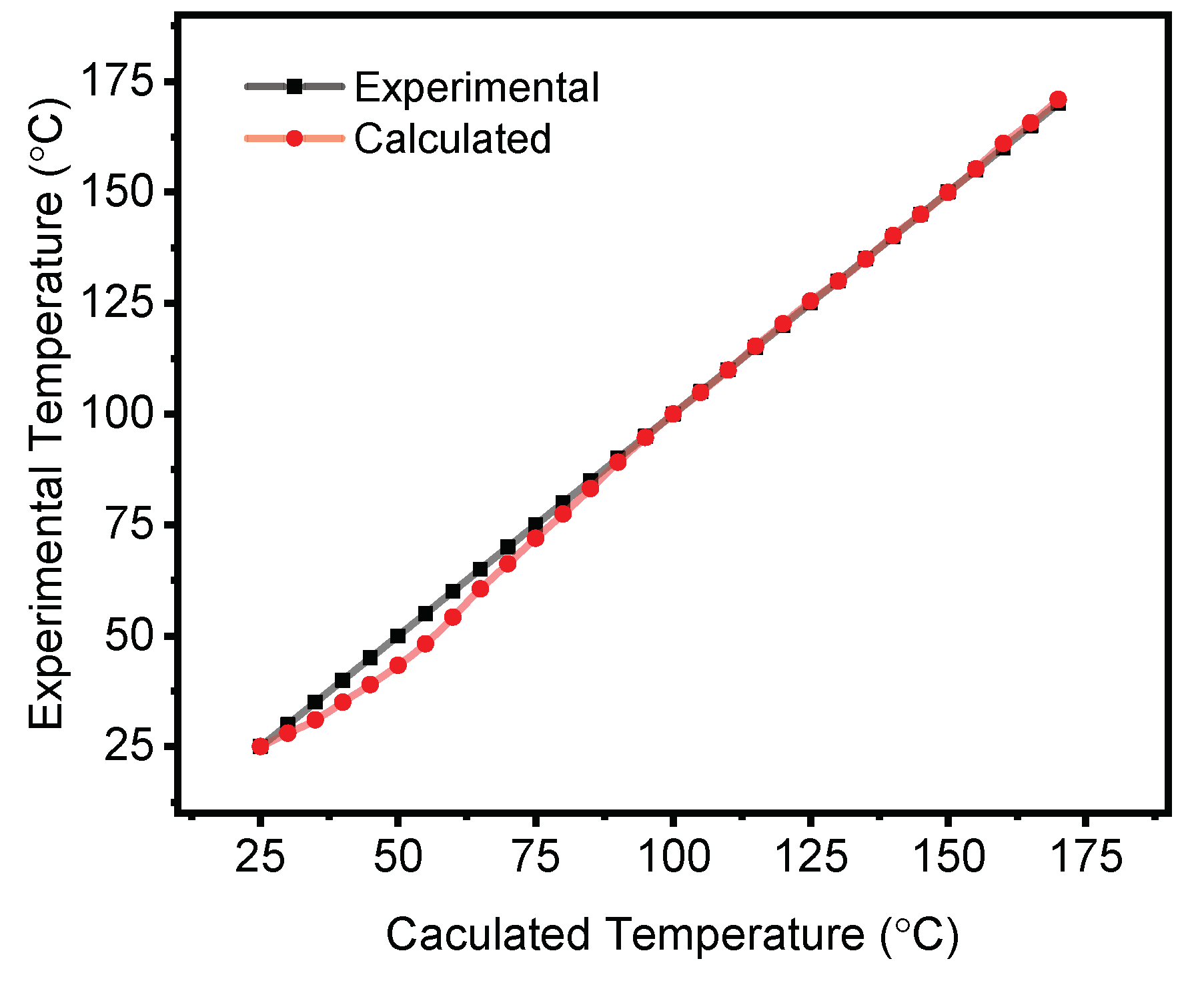

| Ink Name | 3C-SiC wt% | PI resin wt% | TCR (%/°C) | Activation energy (eV) | Thermal index (K) |

|---|---|---|---|---|---|

| 30 | 70 | -0.556 ± 0.012 | 0.08 ± 0.001 | 502 ± 11 | |

| 35 | 65 | -0.227 ± 0.008 | 0.035 ± 0.001 | 205 ± 7.4 | |

| 40 | 60 | -0.157 ± 0.0068 | 0.025 ± 0.001 | 142 ± 6 |

| Sensing material | Electrodes | Fabrication Method | Temperature Range | TCR | Reference |

|---|---|---|---|---|---|

| Silicon Carbide based thermistors | |||||

| On undoped wafer | , , Pt-Pd alloy | CVD | 25 °C - 400 °C | -7.9%/K | [41] |

| Anodic bonding on glass | Ni/Al | CVD | 300K - 600K | -13,000 ppm/K at 300K -3,000 ppm/K at 600K | [45] |

| n-type single crystal 21R- wafer | -- | magnetron sputtering | 77K - 450K | 10 times change in resistance | [44] |

| Doped unicrystalline SiC wafer | W (Tungsten) | welding | °C - 300 °C | 1.9%/°C | [82] |

| Polycrystalline CVD-SiC wafer | Pt-Pd alloy | Vacuum vapor deposition | 25 °C - 365 °C | -5.5%/°C | [83] |

| Printed Thermistors | |||||

| Carbon nanotubes | Screen printing | °C - 100 °C | -0.4%/°C | [16] | |

| PDMS + graphene | Copper wire | 3D printing | 25 °C - 70 °C | 0.008/°C | [84] |

| graphene oxide | Inkjet printing | 25 °C - 85 °C | -1.19%/°C | [85] | |

| + 3.5 wt% graphene | Ag | Screen printing | 25 °C - 170 °C | -0.961%/°C | [14] |

| Screen printing | 200K - 400K | -37,000 to -17,000 ppm/K | [86] | ||

| Screen printing | 25 °C- 170 °C | -0.556%/°C | This work | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).