Submitted:

21 March 2024

Posted:

22 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

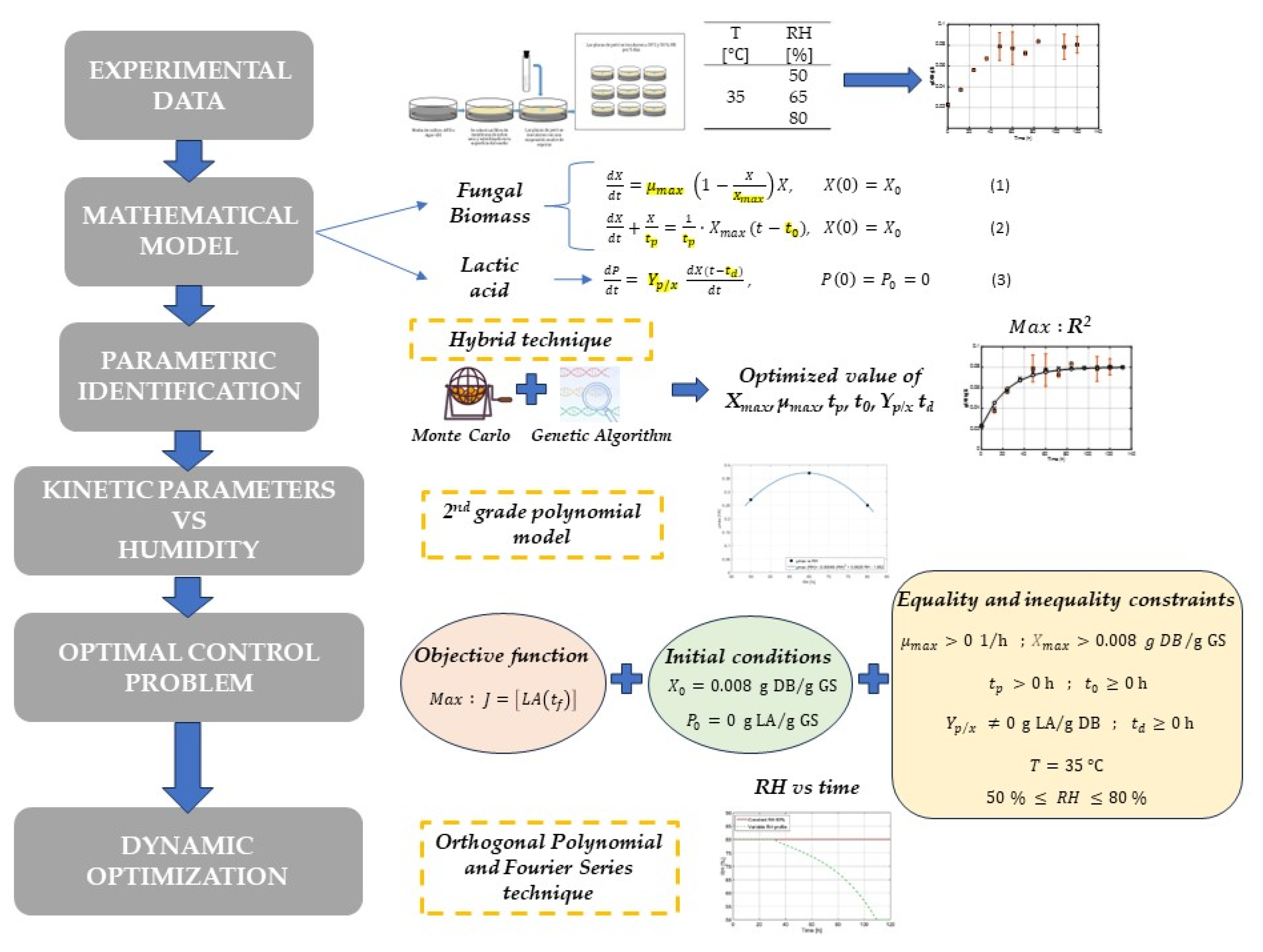

2. Materials and Methods

2.1. Experimental Data of SSF

- (a)

- To avoid the effect of the moisture gradient that may occur in the substrate of SSF, agar was chosen as it is a strong gelling agent with a high water retention capacity (up to 20 times its own weight) [23]. Additionally, a sufficient layer of culture medium (Agar+GS) was placed to ensure that it does not influence mass transfer effects.

- (b)

- The nylon filter (0.2 µm porosity) placed between the culture medium and the fungus allows the fungus to grow under the existing ambient conditions above the nylon filter. However, at the same time, the fungus is in indirect contact with the culture medium, which contains retained water for the proper metabolic development of the fungus.

2.2. Mathematical Modeling and Parametric Identification

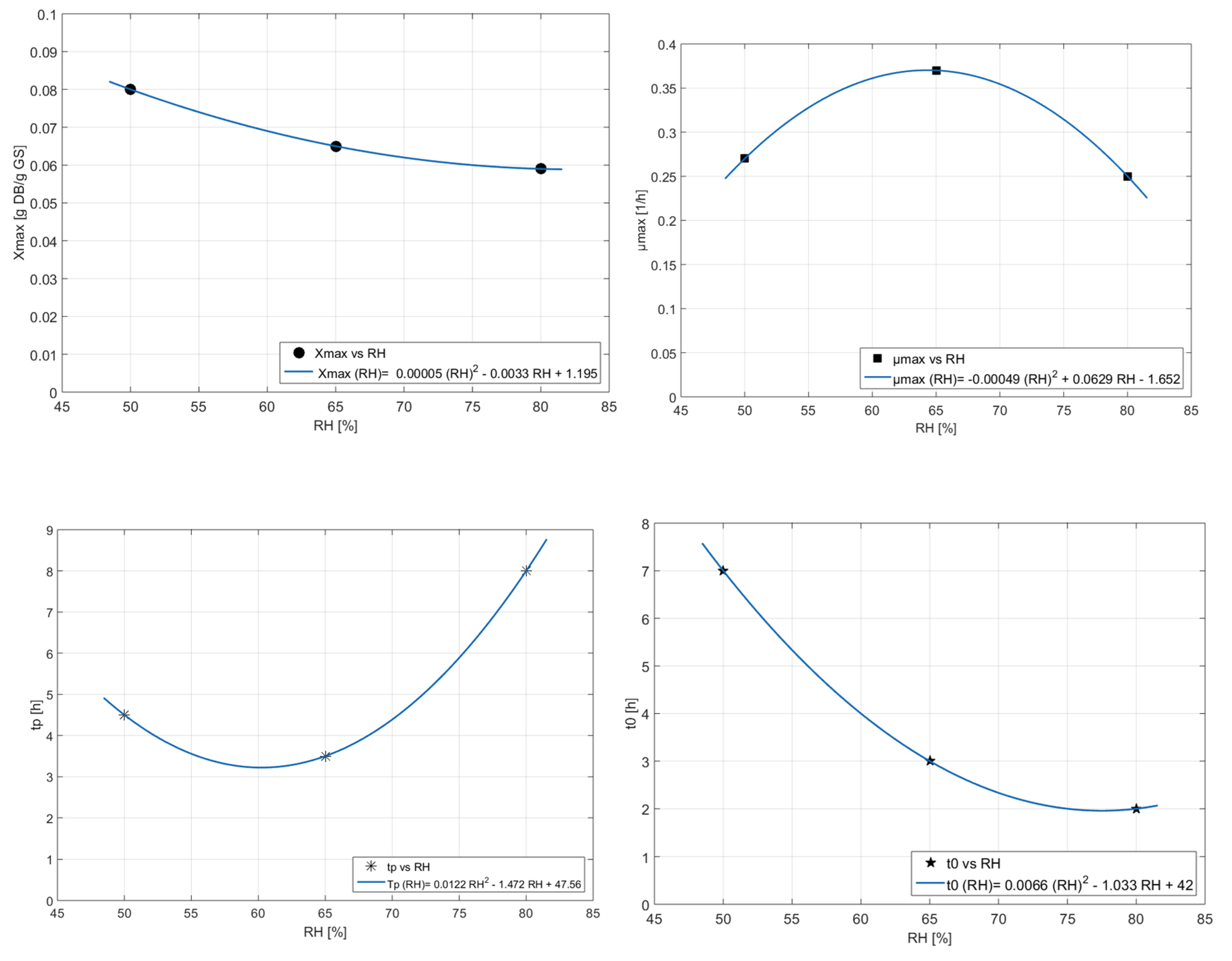

2.3. Humidity Polynomial Relationship with the Kinetic Parameters

2.4. Optimal Control Problem Statement and Lactic Acid Maximization Using Dynamic Optimization

3. Results and Discussion

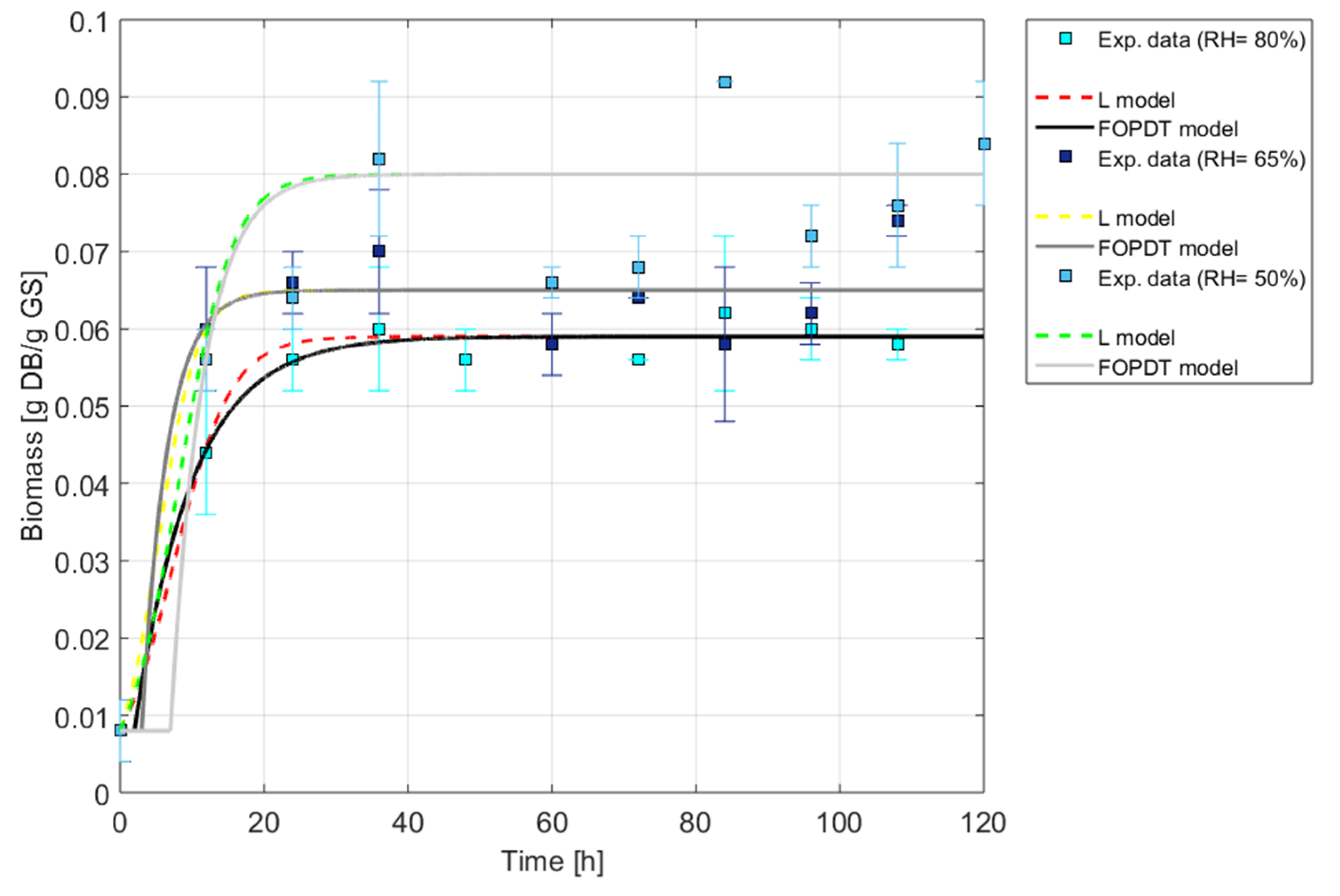

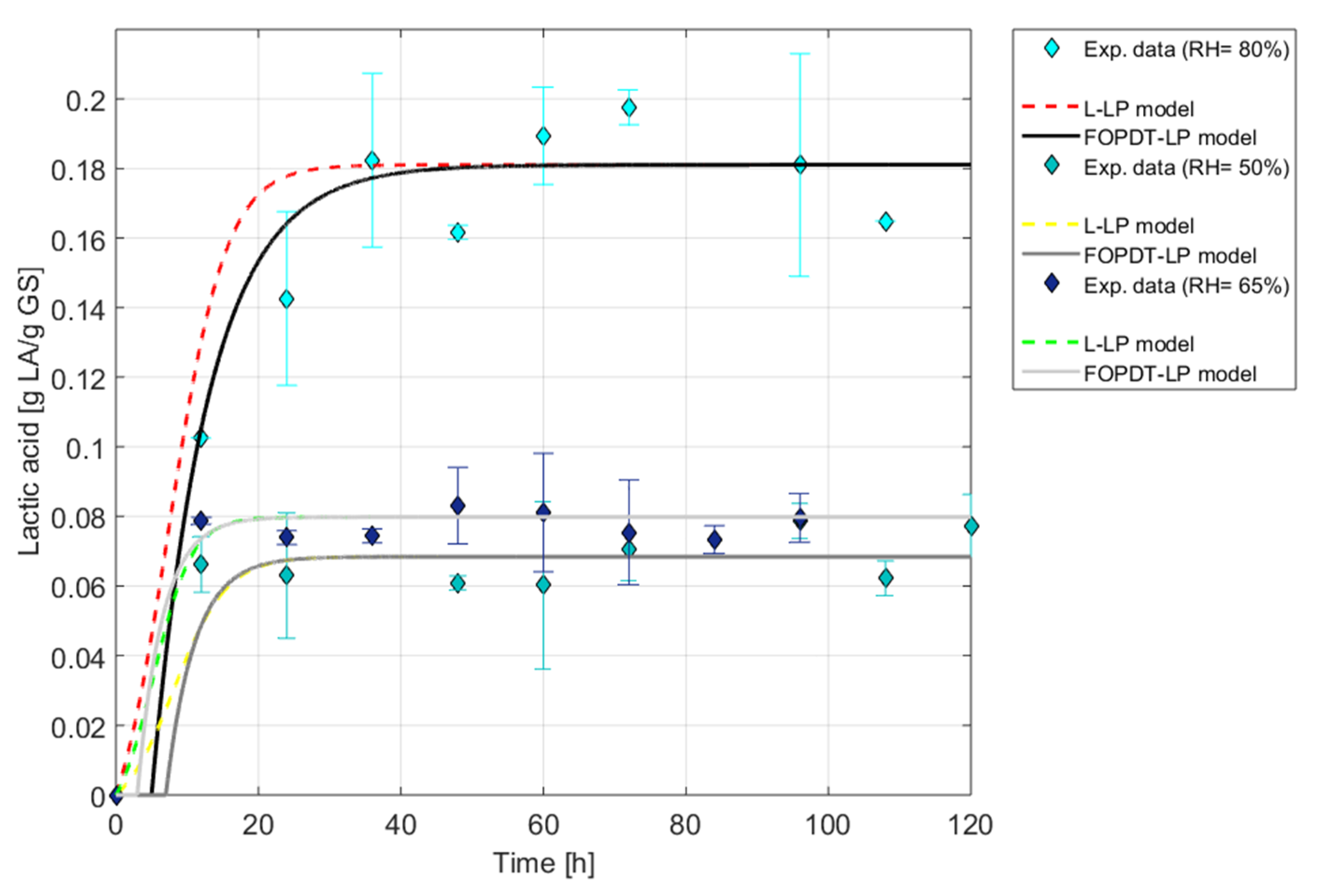

3.1. Experimental Data of SSF, Mathematical Modeling and Parametric Identification

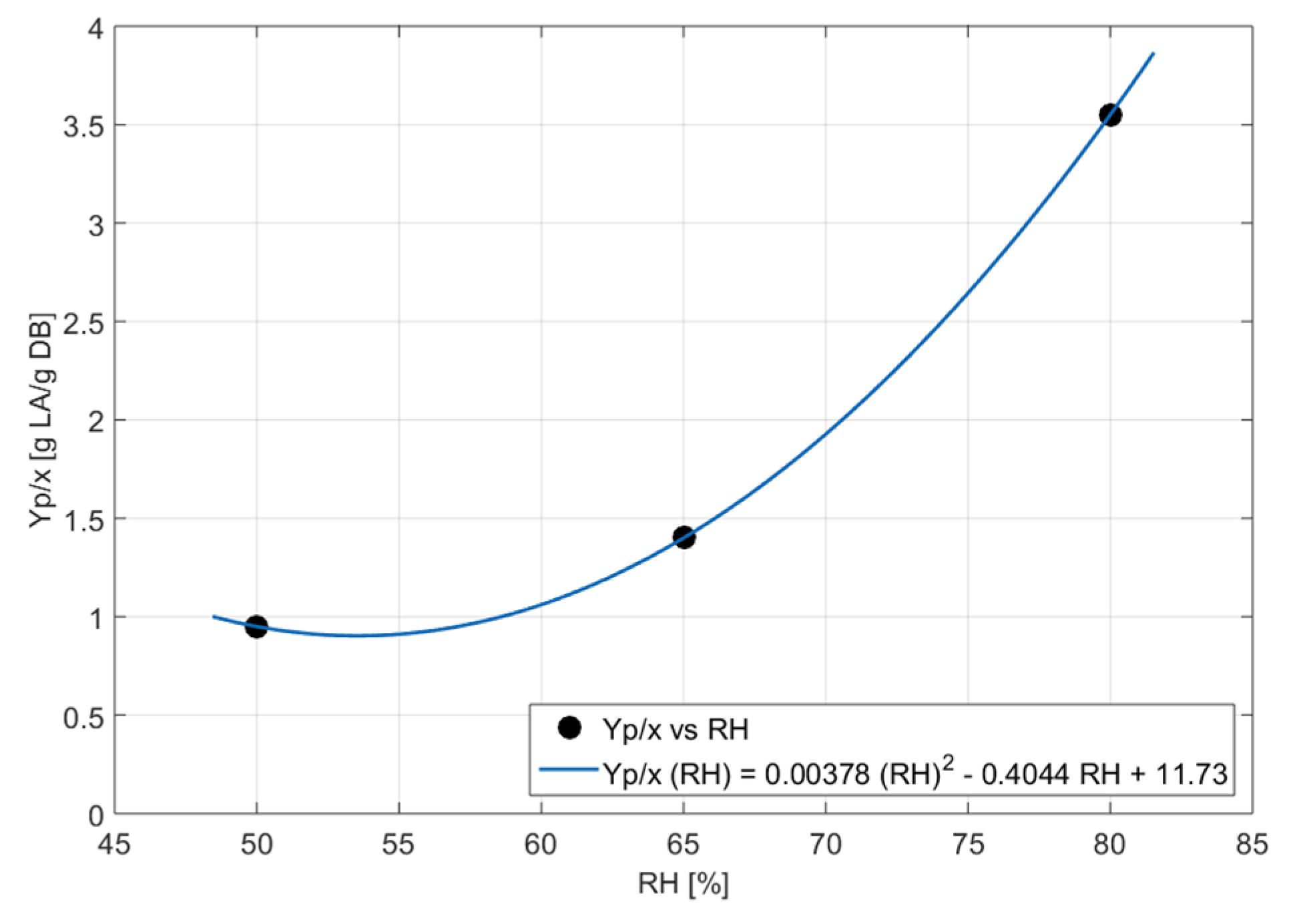

3.2. Humidity Polynomial Relationship with the Kinetic Parameters

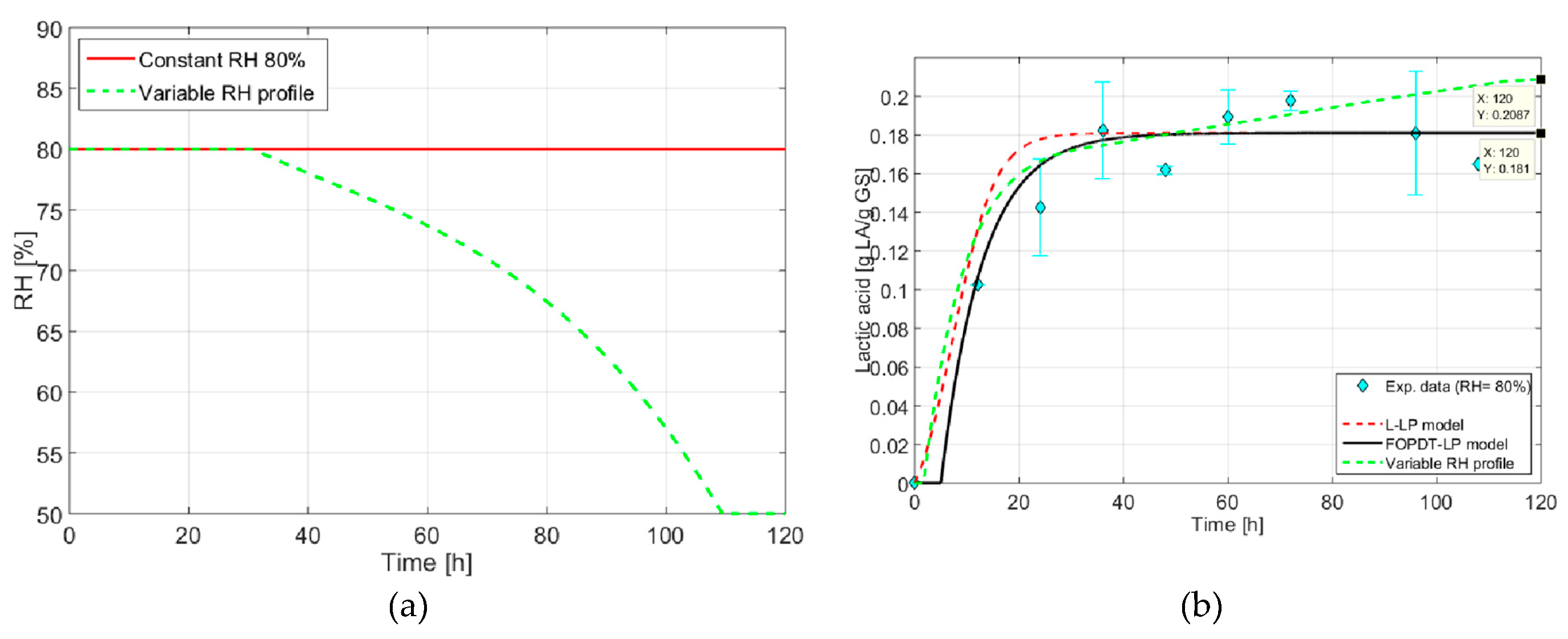

3.3. Lactic acid Maximization Using Dynamic Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alves De Oliveira, R.; Komesu, A.; Vaz Rossell, C.E.; Filho, R.M. Challenges and Opportunities in Lactic Acid Bioprocess Design—From Economic to Production Aspects. Biochem. Eng. J. 2018, 133, 219–239. [Google Scholar] [CrossRef]

- Obi, F.; Ugwuishiwu, B.; Nwakaire, J. Agricultural Waste Concept, Generation, Utilization and Management. Niger. J. Technol. 2016, 35, 957. [Google Scholar] [CrossRef]

- Papaioannou, E.H.; Mazzei, R.; Bazzarelli, F.; Piacentini, E.; Giannakopoulos, V.; Roberts, M.R.; Giorno, L. Agri-Food Industry Waste as Resource of Chemicals: The Role of Membrane Technology in Their Sustainable Recycling. Sustain. 2022, 14, 1–21. [Google Scholar] [CrossRef]

- MordorIntelligence Análisis de Participación y Tamaño Del Mercado de Productos Biológicos Tendencias de Crecimiento y Pronósticos (2024-2029) Available online: https://www.mordorintelligence.com/es/industry-reports/biologics-market.

- Arthur, D. Little Why Bio-Based Materials Market Finally Poised Growth? Available online: https://www.adlittle.com/en/insights/prism/why-bio-based-materials-market-finally-poised-growth.

- Baeza, J.A. Principles of Bioprocess Control. In Current Developments in Biotechnology and Bioengineering: Bioprocesses, Bioreactors and Controls; Elsevier B.V., 2017; pp. 527–561 ISBN 9780444636744.

- Ge, X.; Vasco-Correa, J.; Li, Y. Solid-State Fermentation Bioreactors and Fundamentals. In Current Developments in Biotechnology and Bioengineering: Bioprocesses, Bioreactors and Controls; 2017; pp. 381–402 ISBN 9780444636744.

- Pandey, A. Solid-State Fermentation. Biochem. Eng. J. 2003, 13, 81–84. [Google Scholar] [CrossRef]

- Utilizing, P.; Grain, C.; Manandhar, A.; Shah, A. Techno-Economic Analysis of Bio-Based Lactic Acid. 2020.

- Rahim, N.A.; Luthfi, A.A.I.; Abdul, P.M.; Jahim, J.M.; Bukhari, N.A. Towards Sustainable Production of Bio-Based Lactic Acid via a Bio-Based Technical Route: Recent Developments and the Use of Palm Kernel Cakes in the Bioconversion. BioResources 2022, 17, 3781–3809. [Google Scholar] [CrossRef]

- Webb, C.; Manan, M.A. Design Aspects of Solid State Fermentation as Applied to Microbial Bioprocessing. J. Appl. Biotechnol. Bioeng. 2017, 4, 511–532. [Google Scholar] [CrossRef]

- Mitchell, D.A.; Berovič, M.; Krieger, N. Solid-State Fermentation Bioreactors; Springer: Berlin, Heidelberg, 2006; ISBN 9783540312857. [Google Scholar]

- He, Q.; Peng, H.; Sheng, M.; Hu, S.; Qiu, J.; Gu, J. Humidity Control Strategies for Solid-State Fermentation: Capillary Water Supply by Water-Retention Materials and Negative-Pressure Auto-Controlled Irrigation. Front. Bioeng. Biotechnol. 2019, 7, 1–13. [Google Scholar] [CrossRef]

- Sentís-Moré, P.; Romero-Fabregat, M.P.; Rodríguez-Marca, C.; Guerra-Sánchez, A.J.; Ortega-Olivé, N. Design Optimization of a Tray Bioreactor for Solid-State Fermentation: Study of Process Parameters through Protein Modification of By-Products. Fermentation 2023, 9. [Google Scholar] [CrossRef]

- Wang, H.; Sun, C.; Yang, S.; Ruan, Y.; Lyu, L.; Guo, X.; Wu, X.; Chen, Y. Exploring the Impact of Initial Moisture Content on Microbial Community and Flavor Generation in Xiaoqu Baijiu Fermentation. Food Chem. X 2023, 20, 100981. [Google Scholar] [CrossRef]

- Saithi, S.; Borg, J.; Nopharatana, M.; Tongta, A. Mathematical Modeling of Biomass and Enzyme Production Kinetics by Aspergillus Niger in Solid-State Fermentation at Various Temperatures and Moisture Contents. J. Microb. Biochem. Technol. 2016, 08, 123–130. [Google Scholar] [CrossRef]

- Carboué, Q.; Rébufa, C.; Hamrouni, R.; Roussos, S.; Bombarda, I. Statistical Approach to Evaluate Effect of Temperature and Moisture Content on the Production of Antioxidant Naphtho-Gamma-Pyrones and Hydroxycinnamic Acids by Aspergillus Tubingensis in Solid-State Fermentation. Bioprocess Biosyst. Eng. 2020, 43, 2283–2294. [Google Scholar] [CrossRef]

- Zain, N.A.M.; Aziman, S.N.; Suhaimi, M.S.; Idris, A. Optimization of L(+) Lactic Acid Production from Solid Pineapple Waste (SPW) by Rhizopus Oryzae NRRL 395. J. Polym. Environ. 2021, 29, 230–249. [Google Scholar] [CrossRef]

- Pirota, R.D.P.B.; Tonelotto, M.; Delabona, P.S.; Fonseca, R.F.; Paixão, D.A.A.; Baleeiro, F.C.F.; Bertucci Neto, V.; Farinas, C.S. Bioprocess Developments for Cellulase Production by Aspergillus Oryzae Cultivated under Solid-State Fermentation. Brazilian J. Chem. Eng. 2016, 33, 21–31. [Google Scholar] [CrossRef]

- Groff, M.C.; Scaglia, G.; Gaido, M.; Kassuha, D.; Ortiz, O.A.; Noriega, S.E. Kinetic Modeling of Fungal Biomass Growth and Lactic Acid Production in Rhizopus Oryzae Fermentation by Using Grape Stalk as a Solid Substrate. Biocatal. Agric. Biotechnol. 2022, 39. [Google Scholar] [CrossRef]

- Borshchevskaya, L.N.; Gordeeva, T.L.; Kalinina, A.N.; Sineokii, S.P. Spectrophotometric Determination of Lactic Acid. J. Anal. Chem. 2016, 71, 755–758. [Google Scholar] [CrossRef]

- Webb, C. Design Aspects of Solid State Fermentation as Applied to Microbial Bioprocessing. J. Appl. Biotechnol. Bioeng. 2017, 4, 511–532. [Google Scholar] [CrossRef]

- Bermudez, A. AGAR-AGAR, La Versatilidad de Un Ingrediente En Expansión Available online: https://granotec.com.ar/agar-agar-la-versatilidad-de-un-ingrediente-en-expansion/#:~:text=La funcionalidad del agar radica,resistentes que la gelatina común.

- Groff, M.C.; Scaglia, G.; Ortiz, O.A.; Noriega, S.E. Modification of the Luedeking and Piret Model with a Delay Time Parameter for Biotechnological Lactic Acid Production. Biotechnol. Lett. 2022, 0. [Google Scholar] [CrossRef]

- Groff, M.C.; Noriega, S.E.; Gil, R.M.; Pantano, N.; Scaglia, G. Dynamic Optimization of Lactic Acid Production from Grape Stalk Solid-State Fermentation with Rhizopus Oryzae Applying a Variable Temperature Profile. Fermentation 2024, 10, 101. [Google Scholar] [CrossRef]

- Fernández, C.; Pantano, N.; Godoy, S.; Serrano, E.; Scaglia, G. Optimización de Parámetros Utilizando Los Métodos de Monte Carlo y Algoritmos Evolutivos. Aplicación a Un Controlador de Seguimiento de Trayectoria En Sistemas No Lineales. Rev. Iberoam. Automática e Informática Ind. 2018, 00, 1–4. [Google Scholar] [CrossRef]

- Kuchen, B.; Garay, S.A.; Gil, R.M.; Vazquez, F.; Scaglia, G.J.E. Optimization of Batch Reactors : Application to the Biocontrol of Spoilage Yeasts in Wines. IEEE Lat. Am. Trans. 2022; 100. [Google Scholar]

- Pantano, M.N.; Fernández, M.C.; Ortiz, O.A.; Scaglia, G.J.E.; Vega, J.R. A Fourier-Based Control Vector Parameterization for the Optimization of Nonlinear Dynamic Processes with a Finite Terminal Time. Comput. Chem. Eng. 2020, 134, 106721. [Google Scholar] [CrossRef]

- Agarwal, R.P. Difference Equations and Inequalities: Theory, Methods, and Applications; CRC Press. 2000. [Google Scholar]

- John, B. Conway A Course in Functional Analysis; second; Springer: New York, NY, USA, 2007; volume 5, ISBN 9788578110796. [Google Scholar]

- Oliver, P.J.; Shakiban, C. Applied Linear Algebra; Springer International Publishing AG, 2018; ISBN 9783319910406.

- Manpreet, S.; Sawraj, S.; Sachin, D.; Pankaj, S.; Banerjee, U.C. Influence of Process Parameters on the Production of Metabolites in Solid-State Fermentation. Malalaysian Jounal Microbiol. 2005, 1, 1–9. [Google Scholar] [CrossRef]

- Chen, H. Modern Solid State Fermentation Theory and Practice; Springer.: Netherlands, 2013; ISBN 9789400760424. [Google Scholar]

- Hamidi-Esfahani, Z.; Shojaosadati, S.A.; Rinzema, A. Modelling of Simultaneous Effect of Moisture and Temperature on A. Niger Growth in Solid-State Fermentation. Biochem. Eng. J. 2004, 21, 265–272. [Google Scholar] [CrossRef]

| Experimental Conditions | R. oryzae Growth | |||||||

|---|---|---|---|---|---|---|---|---|

| Logistic Model | FOPDT Model | |||||||

| T | RH | X0 | Xmax | µmax | R2 | tp | t0 | R2 |

| 35 | 50 | 0.008 ± 0.002 | 0.080 ± 0.002 | 0.270 ± 0.008 | 82.77 | 4.50 ± 0.12 | 7.00 ± 0.23 | 83.55 |

| 65 | 0.065 ± 0.002 | 0.370 ± 0.011 | 91.68 | 3.50 ± 0.11 | 3.00 ± 0.08 | 91.67 | ||

| 80 | 0.059 ± 0.002 | 0.250 ± 0.008 | 98.13 | 8.00 ± 0.25 | 2.00 ± 0.05 | 98.31 | ||

| Experimental Conditions | Lactic Acid Production | ||||||

|---|---|---|---|---|---|---|---|

| Luedeking and Piret with Delay Time model | |||||||

| Logistic Model | FOPDT Model | ||||||

| T | RH | X0 | Yp/x | R2 | Yp/x | td | R2 |

| 35 | 50 | 0.008 ± 0.002 | 0.95 ± 0.027 | 82.45 | 0.95 ± 0.027 | 0 | 81.09 |

| 65 | 1.40 ± 0.040 | 83.76 | 1.40 ± 0.040 | 0 | 96.89 | ||

| 80 | 3.55 ± 0.370 | 84.33 | 3.55 ± 0.370 | 5 ± 0.16 | 94.52 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).