Submitted:

21 March 2024

Posted:

21 March 2024

You are already at the latest version

Abstract

Keywords:

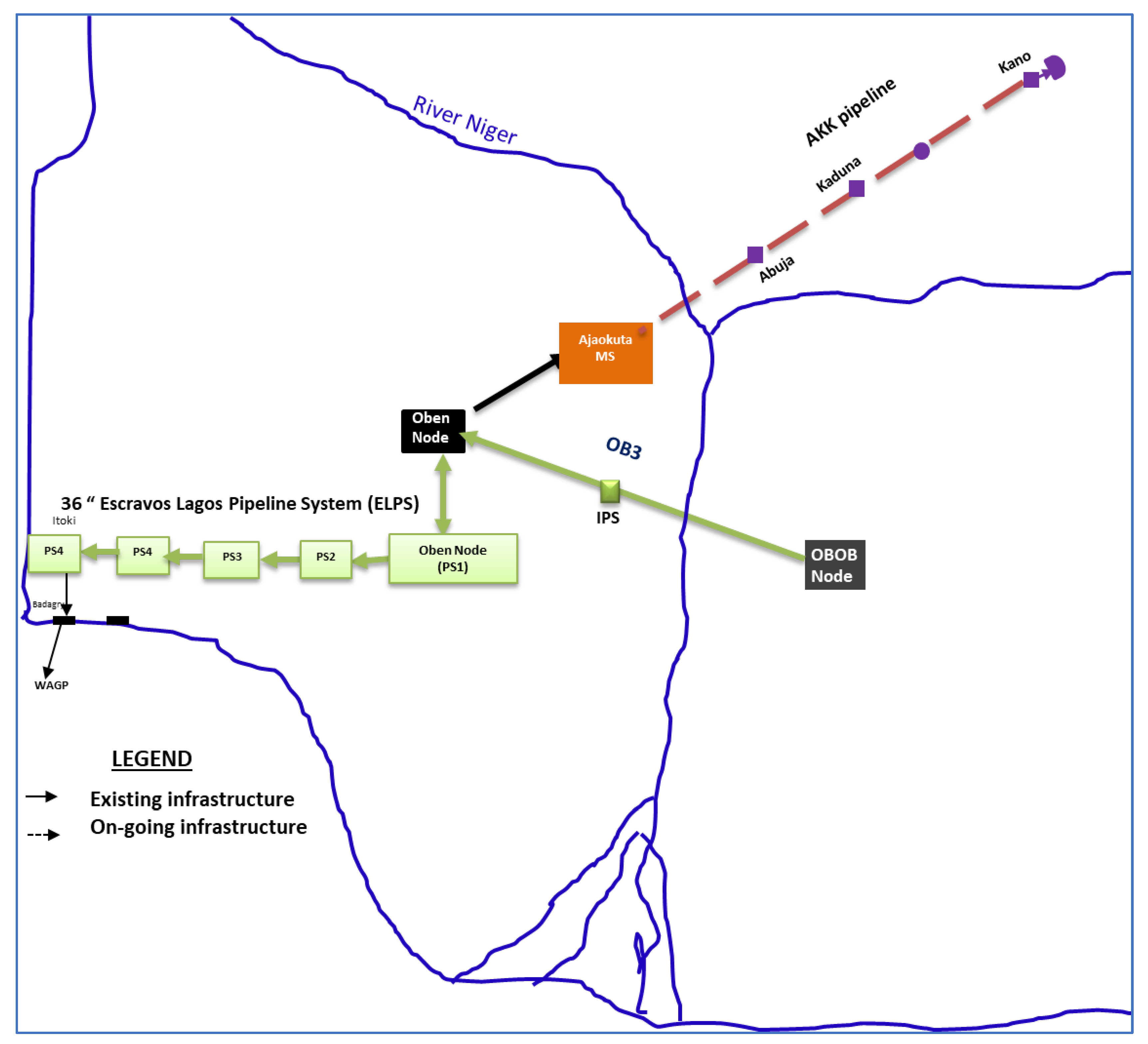

1. Introduction

2.2. Introduction to Pipeline Expansion

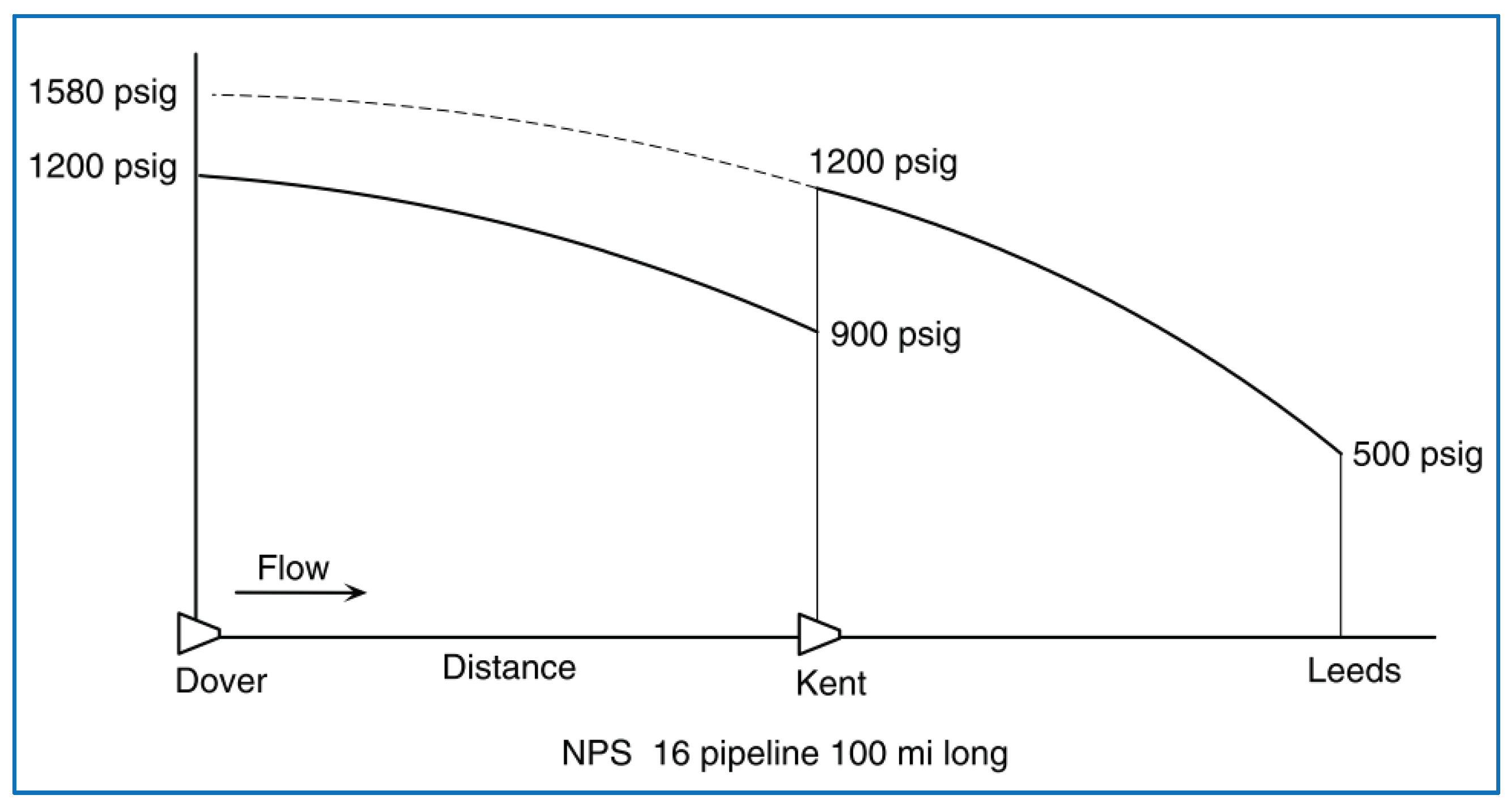

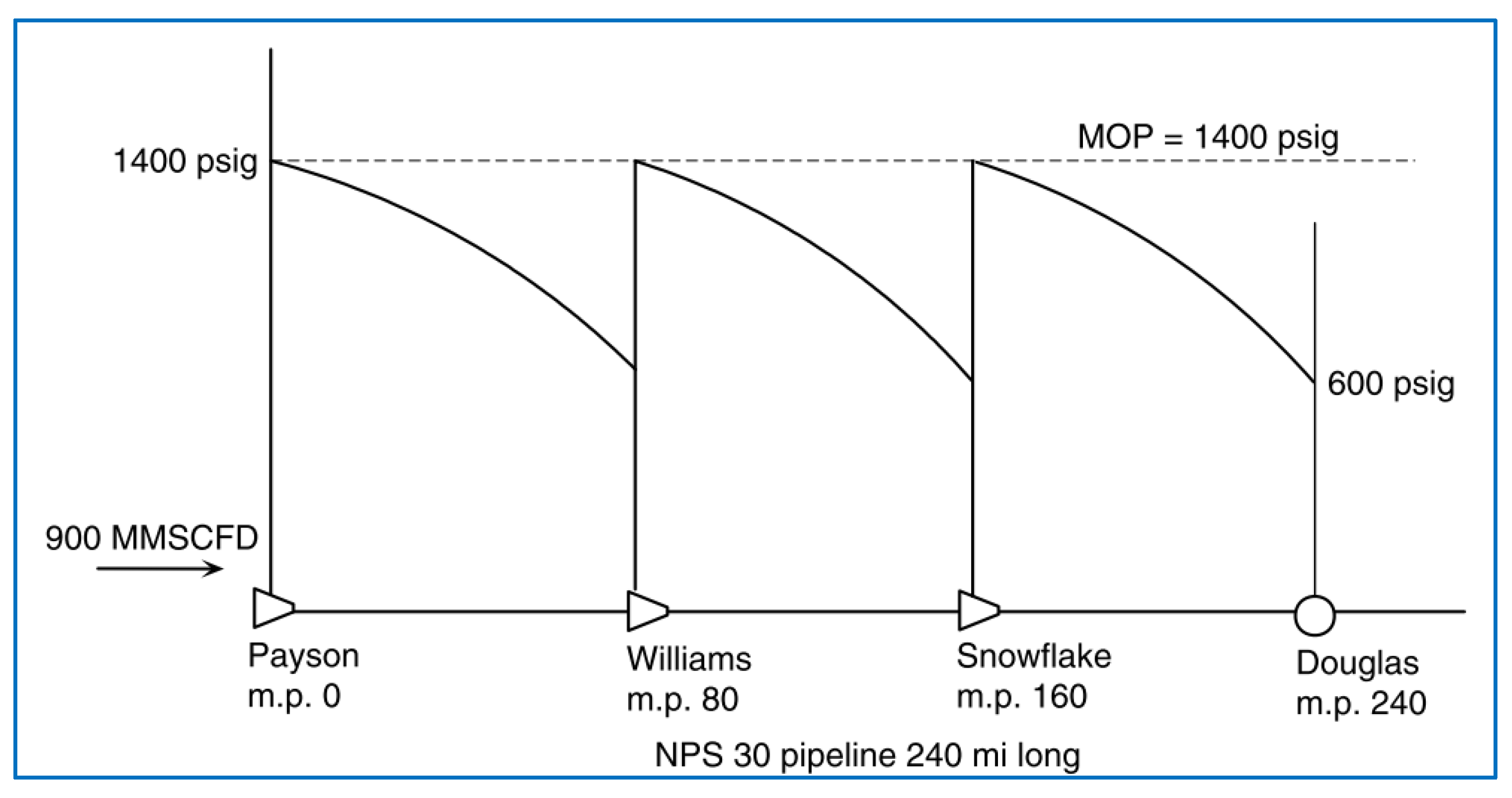

2.1. Pipeline Expansion by Compression

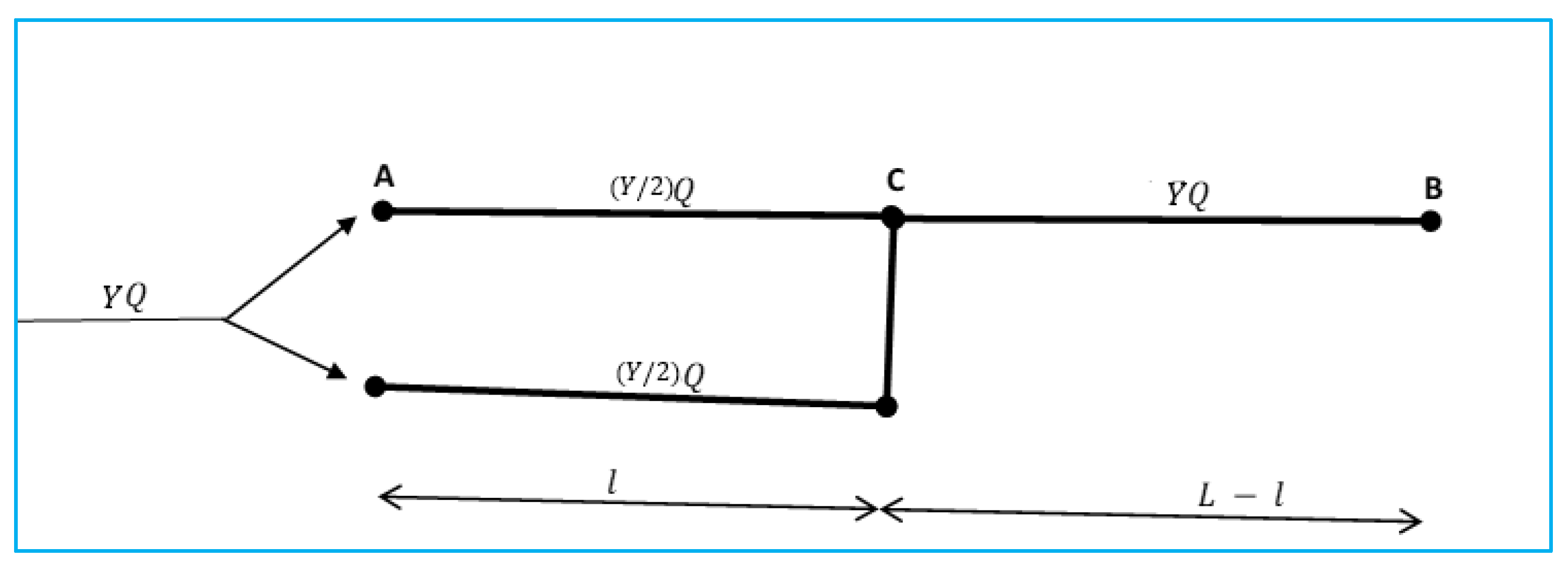

2.2. Pipeline Expansion by Looping

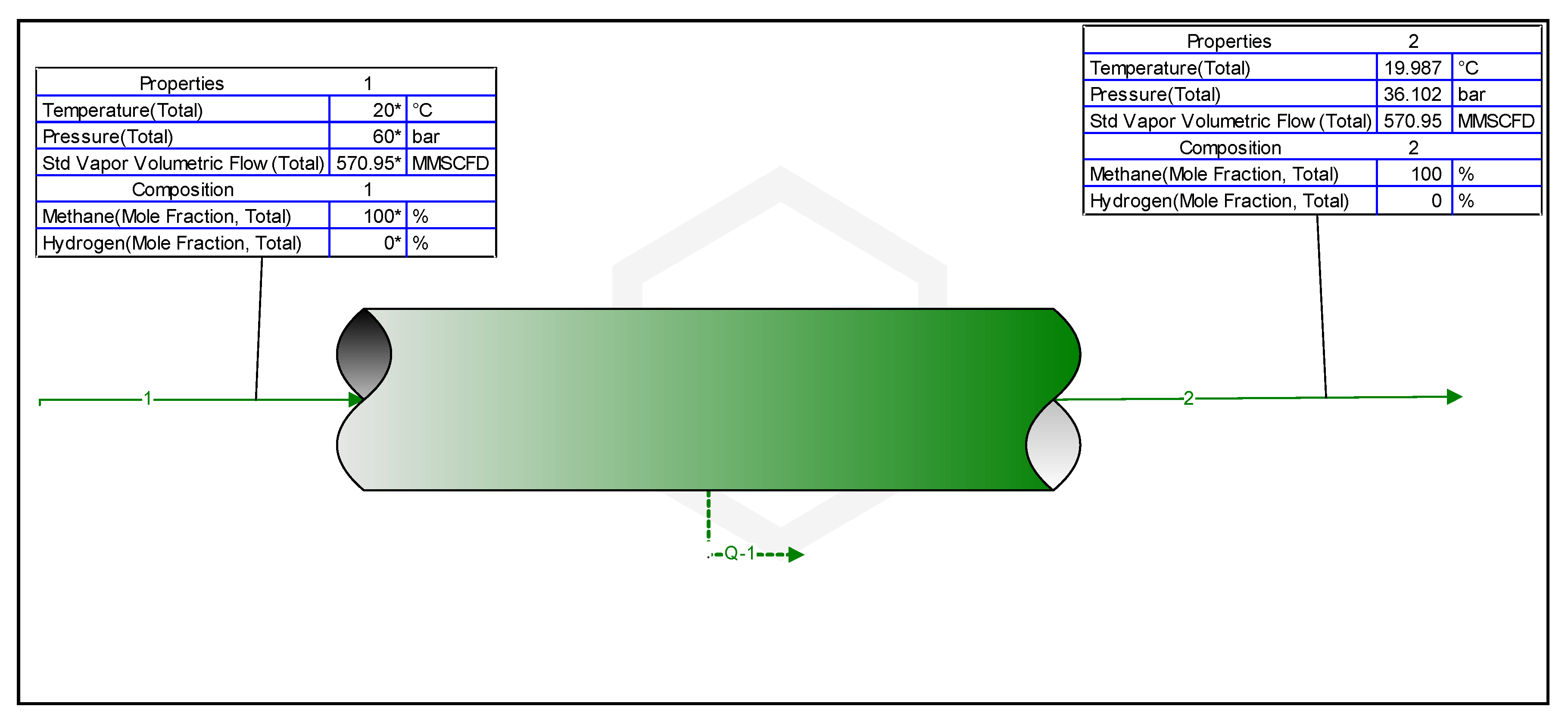

2.3. Gas Network Modelling

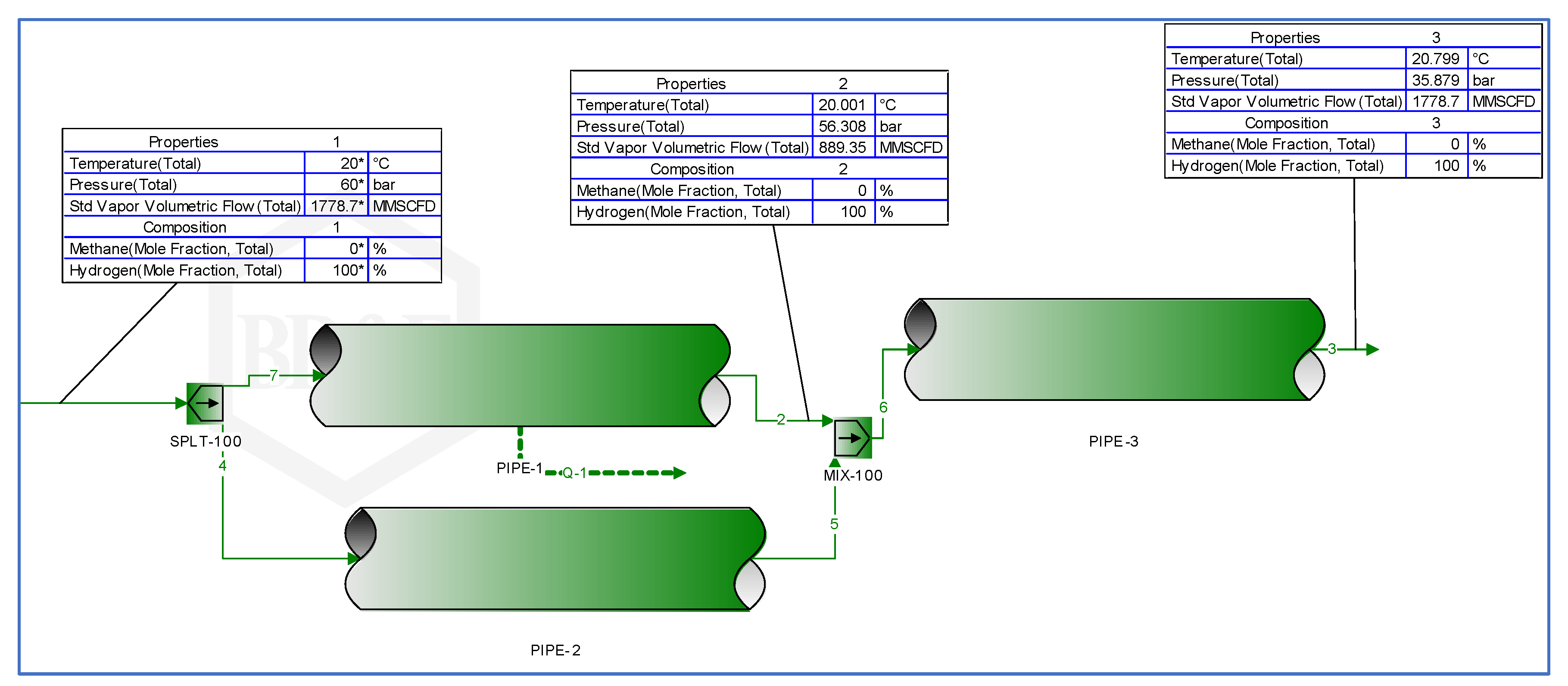

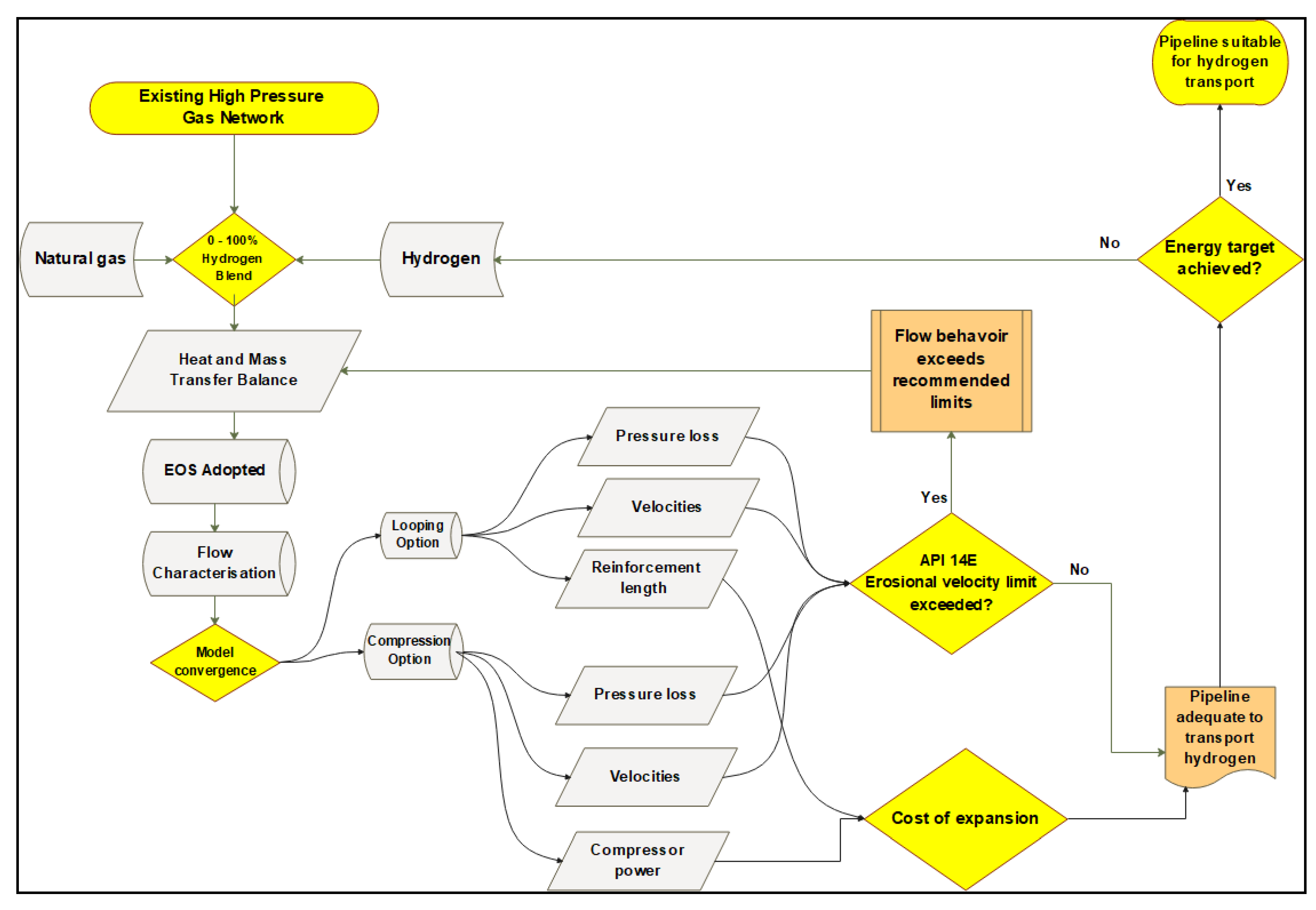

3. Study Methodology

3.1. Gas Network Expansion Options Analysis

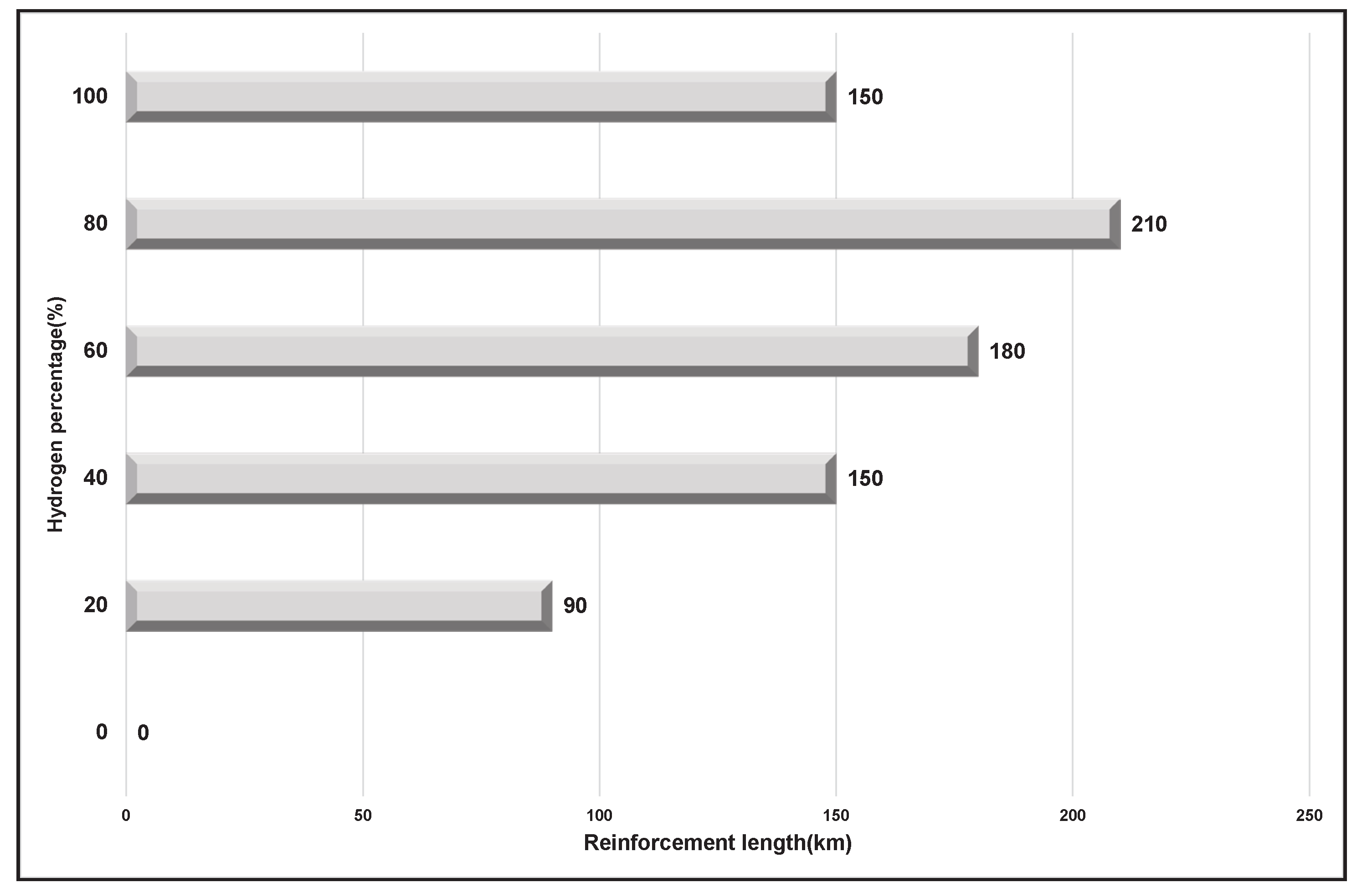

3.1.1. Gas Network Expansion with Looping/Pipeline Reinforcement

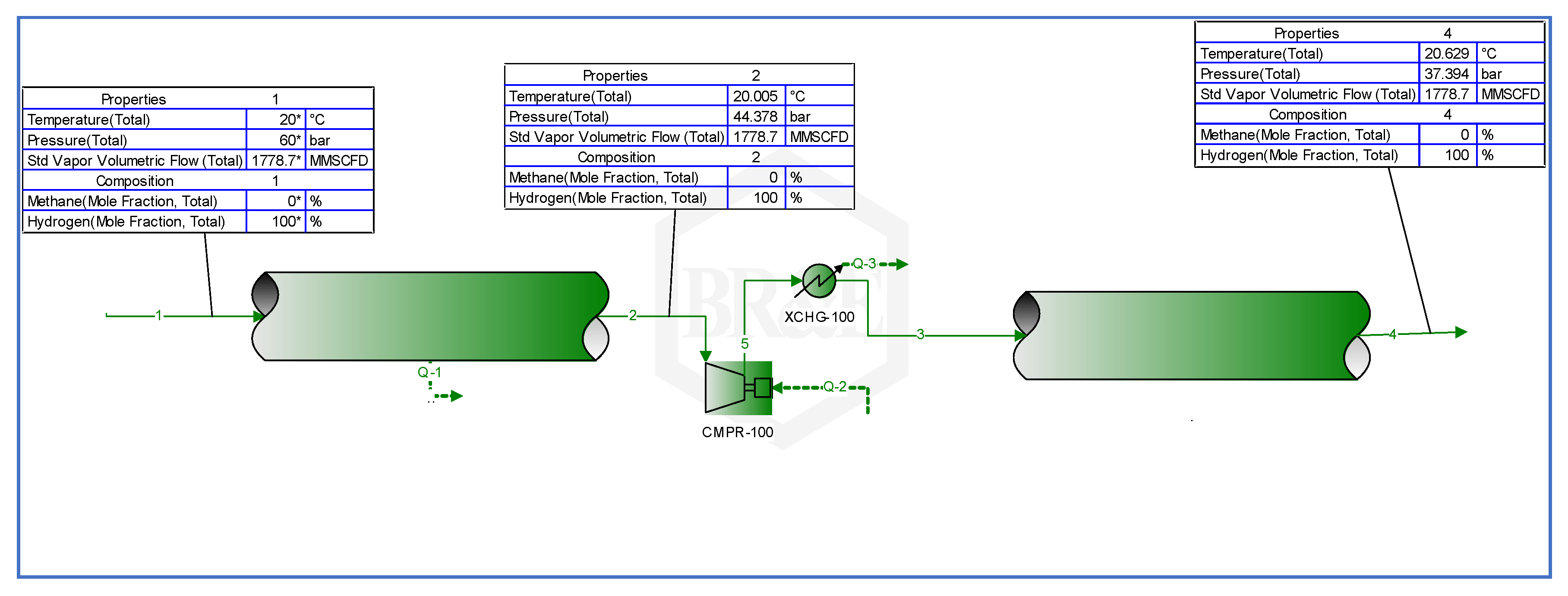

3.1.2. Gas Network Expansion through Compression

4. Results and Discussion

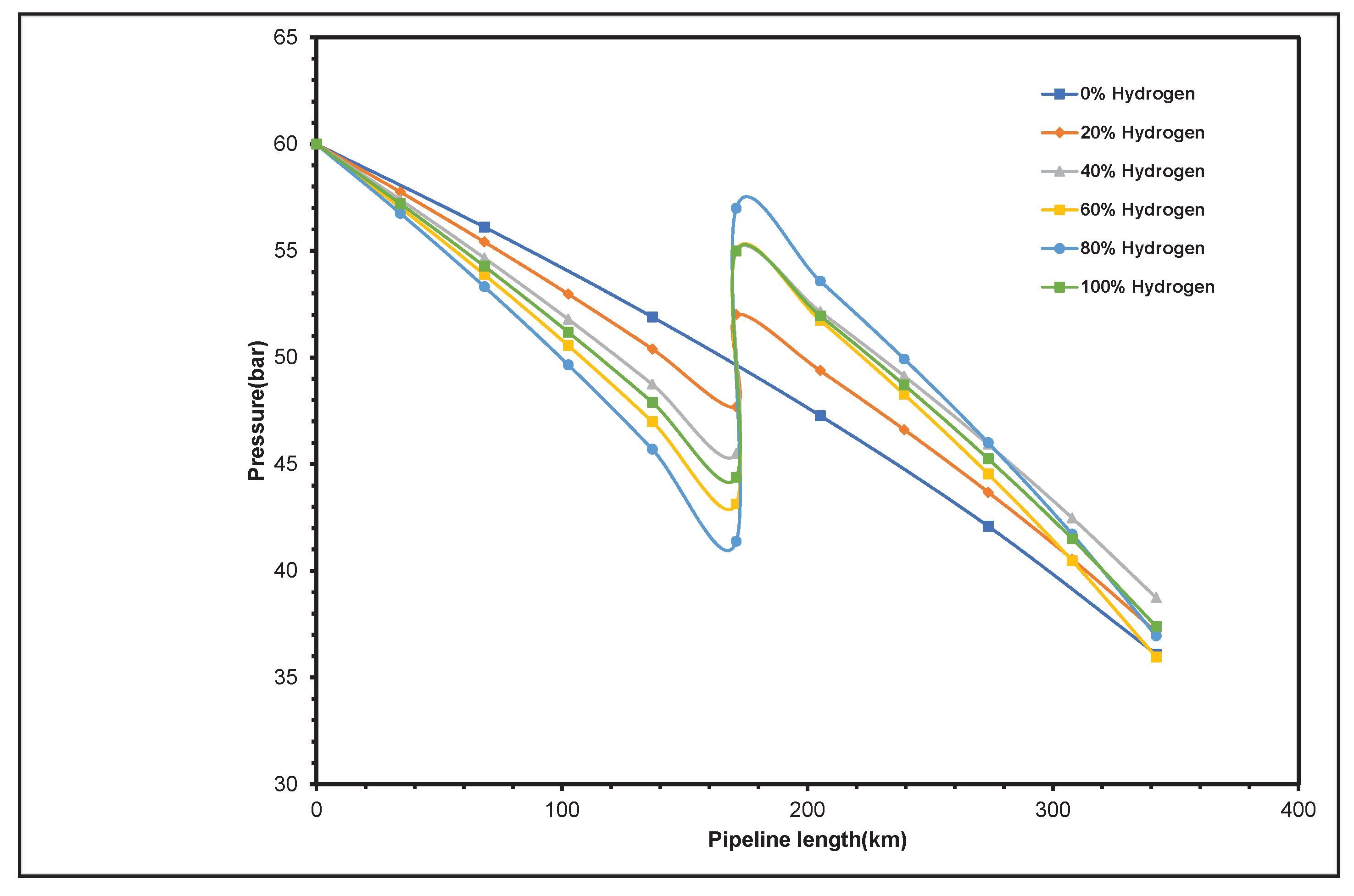

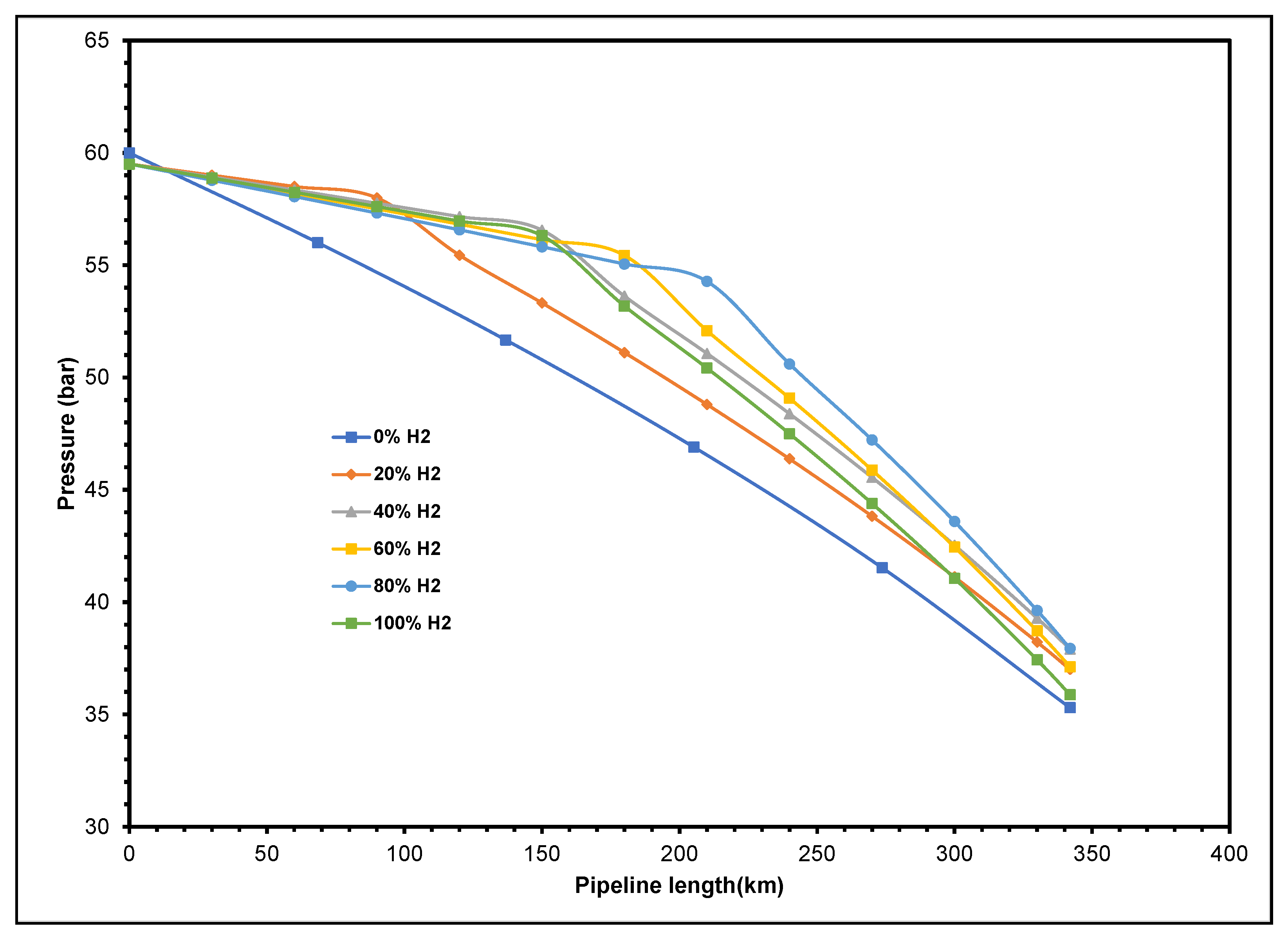

4.1. Pipe Looping/Reinforcement Expansion Option Analysis

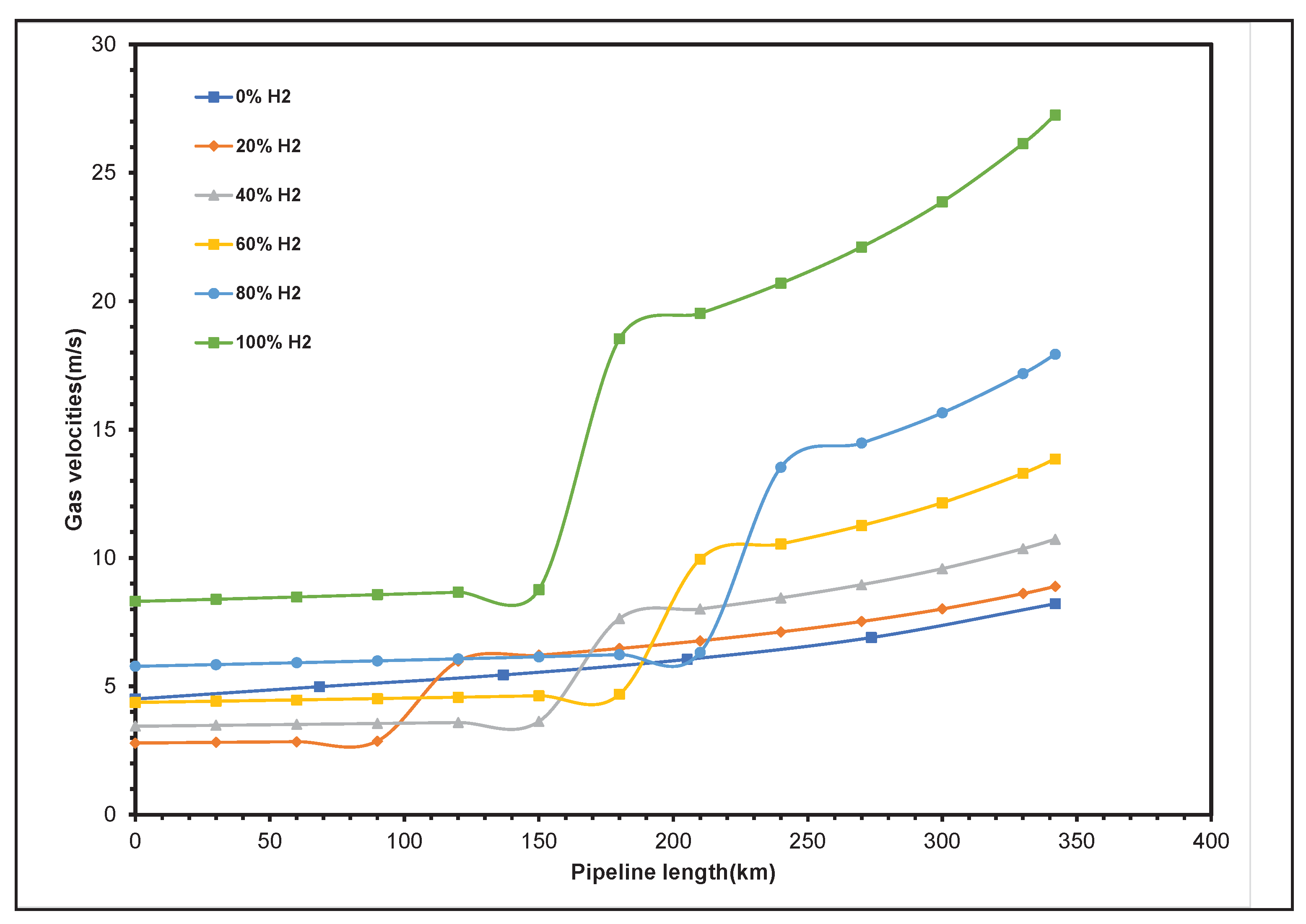

4.1.1. Flow Characteristics

4.1.2. Reinforcement (or Loop Pipe) Length

4.2. Gas Network Expansion with Compression Option

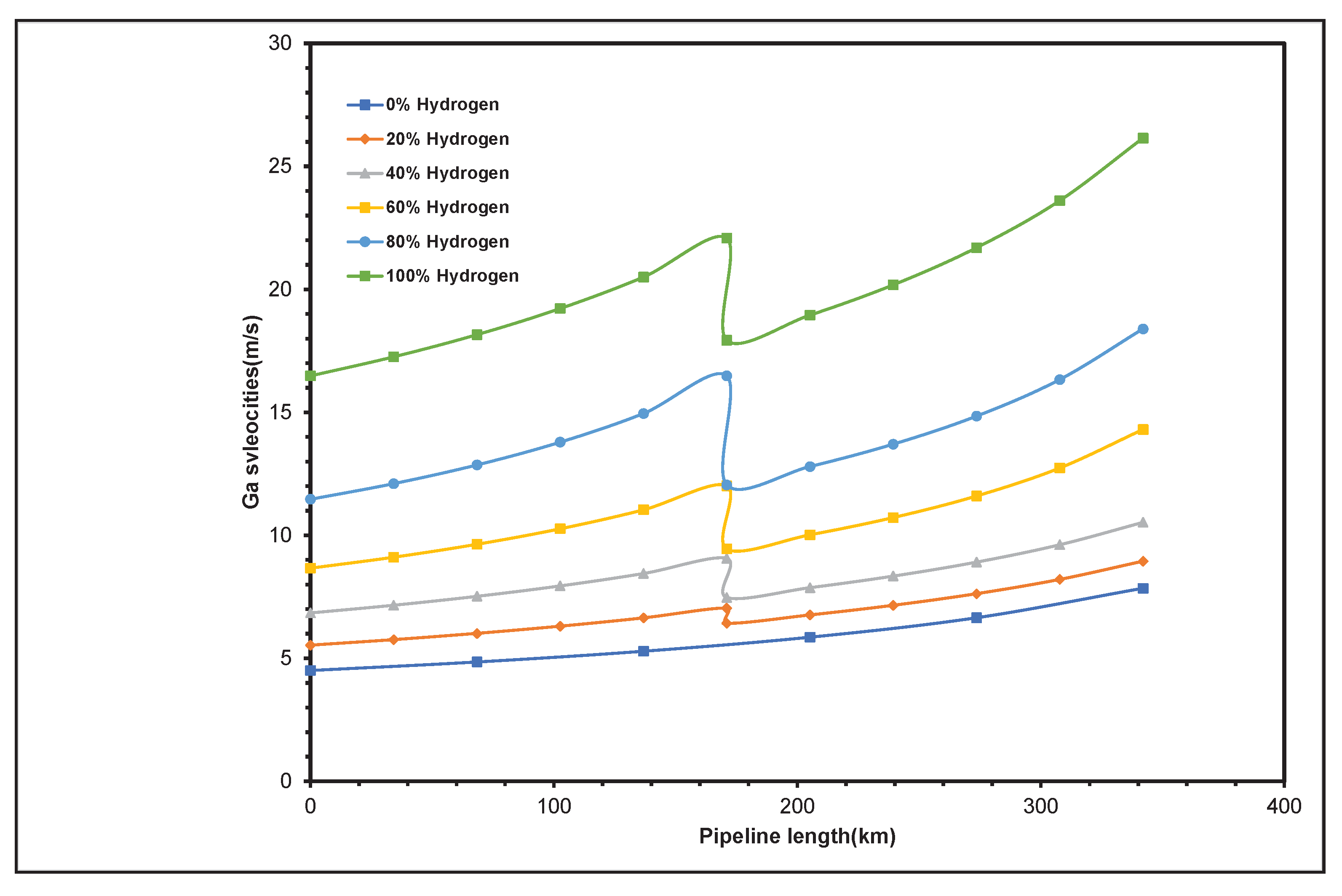

4.2.1. Flow Characteristics

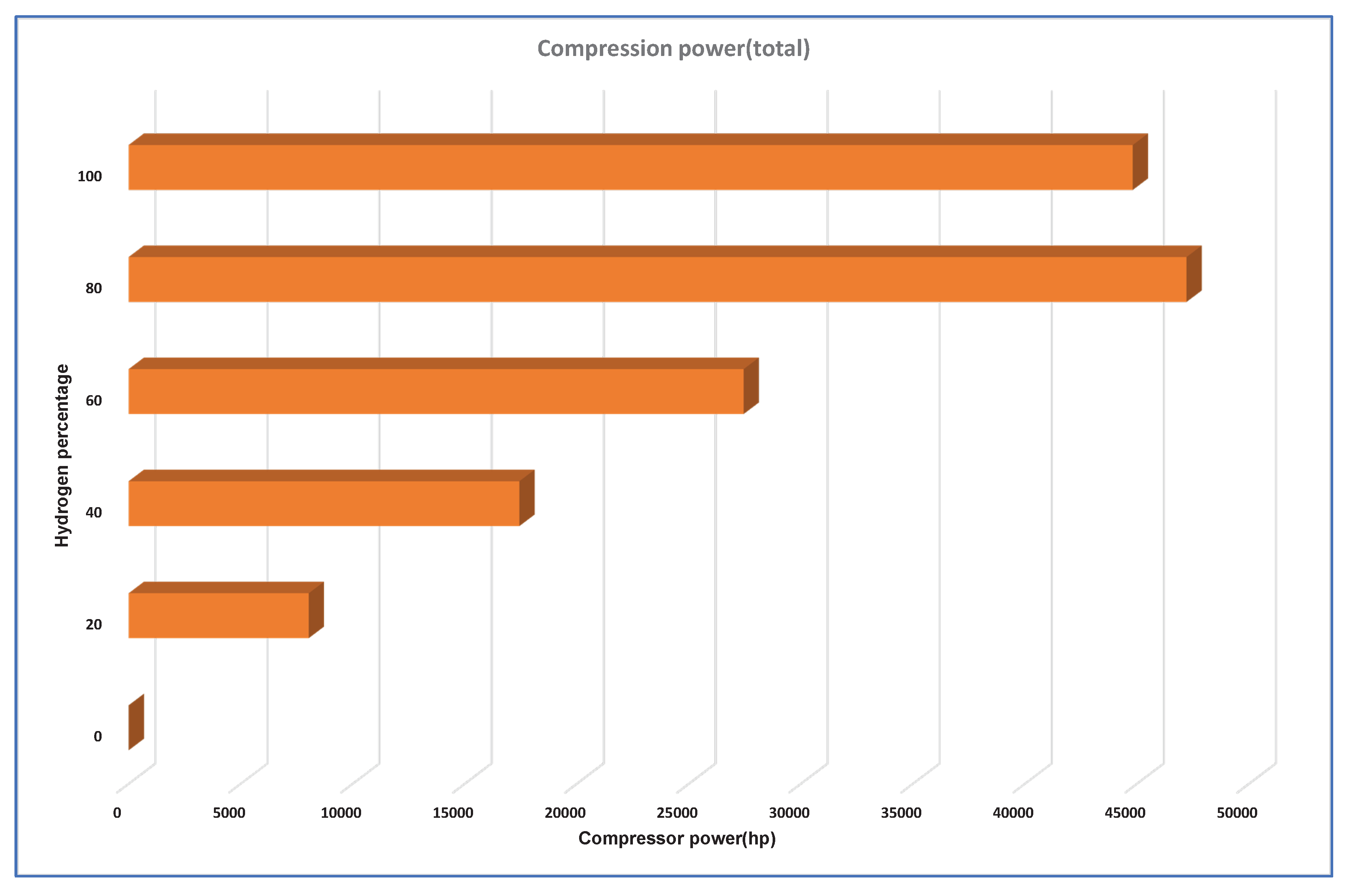

4.2.2. Estimating Compressors Horsepower for Pipeline Expansion via Compressor Stations

4.3. Cost Analysis

4.3.1. Cost of Natural Gas Pipeline Expansion Projects

4.3.1.1. Estimating the Cost of Pipeline Expansion by Looping for the Escravos – Lagos, Nigeria Pipeline

- Material cost: $1,706,100 per km (33%)

- Labor cost: $2,533,300 per km (49%)

- Right of way cost: $310,200 per km (6%)

- Miscellaneous cost: $620,400 per km (12%)

4.3.1.2. Estimating the Cost of Pipeline Expansion with Compressor Stations for the Escravos – Lagos, Nigeria Pipeline

- Labour: 31% higher due to expatriate engagement and contracting to international firms.

- Right of way: 50% higher due to the complexity of the land acquisition process and the need to compensate various stakeholders.

- Materials: 25% higher due to Nigeria importing most of its materials.

- Miscellaneous: 10% higher due to additional costs associated with doing business in Nigeria.

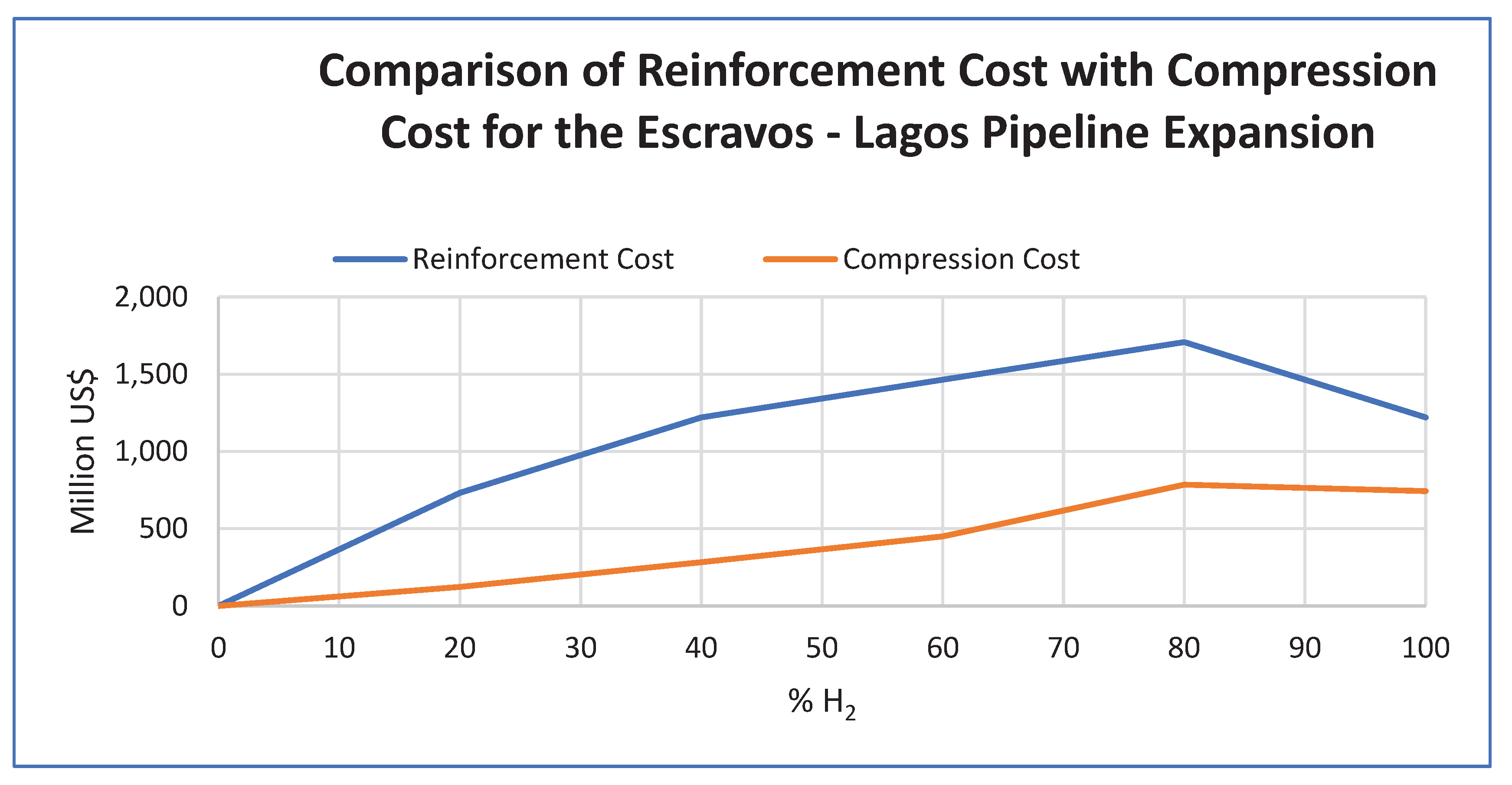

4.3.2. Cost Comparison of Natural Gas Pipeline Expansion Options for Hydrogen Transportation

| CH4-H2 Blend (%H2) |

Required loop pipe length (km) |

Required compressor power (hp) |

Unit Cost of Looping ($/km) |

Unit cost of Compression ($/hp) |

|---|---|---|---|---|

| 20 | 90 | 7,223 | 732 | 123 |

| 40 | 150 | 16,637 | 1,220 | 284 |

| 60 | 180 | 26,373 | 1,464 | 450 |

| 80 | 210 | 46,012 | 1,708 | 785 |

| 100 | 150 | 43,578 | 1,220 | 744 |

5. Conclusions

- The introduction of hydrogen in a natural gas flow stream increases the pressure of the system due to the increased expansion that the lighter hydrogen gas causes when blended with natural gas. It is therefore important to consider making changes to fittings, connection, pressure gauges, etc. to accommodate these changes when adopting a natural gas network for hydrogen processing and transportation.

- The use of pipeline looping and compressor station options effectively kept flow parameters within recommended and safe values/ranges. For the Excravos – Lagos natural gas pipeline studied, expanding the network via these options resulted in lowering the erosional velocity profiles of the flow stream. Such that, besides the flow of pure hydrogen, the internal velocity value was maintained below the 20m/s estimated for the maximum erosional velocity limit, as per the API 14E RP, across the entire 340km length of the pipeline.

- Generally, the amount of compression or extent of looping that is needed is in direct proportionality with the fraction of hydrogen in the blend. The higher the percentage of hydrogen in the blend, the higher the ratings of the compressor station that would be needed (for pipeline expansion with compressor station option), and the higher the pipe length that would be needed for pipe looping.

- The economic analysis shows that the use of compressor stations is more economical for pipeline expansion relative to pipe looping for all proportions of hydrogen in the natural gas blend. For the Escravos – Pipeline network, Figure 15 shows that the difference can be as high as a 495% increase in the cost of pipeline network expansion by looping that is required to repurpose the gas network over the cost of using compressor stations, for the flow of 20% hydrogen in the flow stream.

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

References

- G. Di Lullo, A. O. Oni, and A. Kumar, “Blending Blue Hydrogen with Natural Gas for Direct Consumption: Examining the Effect of Hydrogen Concentration on Transportation and Well-To-Combustion Greenhouse Gas Emissions,” Int J Hydrogen Energy, vol. 46, no. 36, pp. 19202–19216, 2021. [CrossRef]

- E. Abohamzeh, F. Salehi, M. Sheikholeslami, R. Abbassi, and F. Khan, “Review of Hydrogen Safety during Storage, Transmission, and Applications Processes,” J Loss Prev Process Ind, vol. 72, no. June, p. 104569, 2021. [CrossRef]

- J. Capelle, J. Gilgert, I. Dmytrakh, and G. Pluvinage, “Sensitivity of pipelines with Steel API X52 to Hydrogen Embrittlement,” Int J Hydrogen Energy, vol. 33, pp. 7630–7641, 2008.

- S. Elaoud, Z. Hafsi, and L. Hadj-Taieb, “Numerical Modelling of Hydrogen-Natural Gas Mixtures FLOWS IN Looped Networks,” J Pet Sci Eng, vol. 159, no. December 2016, pp. 532–541, 2017. [CrossRef]

- F. Tabkhi, C. Azzaro-Pantel, L. Pibouleau, and S. Domenech, “A Mathematical Framework for Modelling and Evaluating Natural Gas Pipeline Networks under Hydrogen Injection,” Int J Hydrogen Energy, vol. 33, no. 21, pp. 6222–6231, 2008. [CrossRef]

- F. Bainier, R. Kurz, and P. Bass, “Managing the Pressure to Increase the H2 Capacity Through a Natural Gas Transmission Network,” Proceedings of the ASME Turbo Expo, vol. 9, no. 4, pp. 1–9, 2020. [CrossRef]

- D. Woldeyohannes and M. A. A. Majid, “Simulation Model for Natural Gas Transmission Pipeline Network System,” Simul Model Pract Theory, vol. 19, no. 1, pp. 196–212, 2011. [CrossRef]

- E. S. Menon, Gas Pipeline Hydraulics. 2005. [CrossRef]

- G. G. Nasr and N. E. Connor, Natural Gas Engineering and Safety Challenges: Downstream Process, Analysis, Utilization and Safety, vol. 9783319089. 2014. [CrossRef]

- K. Sundar, S. Misra, A. Zlotnik, and R. Bent, “Robust Gas Pipeline Network Expansion Planning to Support Power System Reliability,” Proceedings of the American Control Conference, vol. 2021-May, pp. 620–627, 2021. [CrossRef]

- M. Chaudry, N. Jenkins, M. Qadrdan, and J. Wu, “Combined Gas and Electricity Network Expansion Planning,” Appl Energy, vol. 113, pp. 1171–1187, 2014. [CrossRef]

- GAZPROM, “Looping,” Gazprom Informatorium. Accessed: Apr. 25, 2022. [Online]. Available: http://www.gazprominfo.com/terms/looping/.

- B. Rioux, R. Shabaneh, and S. Griffiths, “An Economic Analysis of Gas Pipeline Trade Cooperation in the GCC,” Energy Policy, vol. 157, p. 112449, 2021. [CrossRef]

- S. Scherer, “Canada Says Hydrogen Better Than LNG for German Needs,” Reuters, London, UK, p. 1, Aug. 19, 2022.

- IEA, “The Future of Hydrogen: Seizing today’s Opportunities,” IEA Publications, no. June, pp. 14, 37–64, 2019.

- J. Kestler-D’Amours, “Environmentalists Welcome New Canada-Germany Hydrogen Pact | Oil and Gas News,” Al Jazeera, Economy | Oil and Gas, Aug. 26, 2022.

- J. Abbas, H. Hassani, M. Burby, and I. J. John, “An Investigation into the Volumetric Flow Rate Requirement of Hydrogen Transportation in Existing Natural Gas Pipelines and Its Safety Implications,” Gases, vol. 1, no. 4, pp. 156–179, 2021. [CrossRef]

- N. Klopčič, T. Stöhr, I. Grimmer, M. Sartory, and A. Trattner, “Refurbishment of Natural Gas Pipelines towards 100% Hydrogen—A Thermodynamic-Based Analysis,” Energies (Basel), vol. 15, no. 24, Dec. 2022. [CrossRef]

- S. Lipiäinen, K. Lipiäinen, A. Ahola, and E. Vakkilainen, “Use of Existing Gas Infrastructure in European Hydrogen Economy,” Int J Hydrogen Energy, vol. 48, no. 80, pp. 31317–31329, Sep. 2023. [CrossRef]

- G. G. Nasr and N. E. Connor, Natural Gas Engineering and Safety Challenges. 2014. [CrossRef]

- W. Alliander, “Gas Distribution Network Modelling and Optimization - New Methods for Smarter Observation and Operation of Large-Scale Gas Networks,” Delft University of Technology (TUDelft), 2016. [CrossRef]

- Firooz Tabkhi, “Optimization of Gas Transmission Networks,” NATIONAL POLYTECHNIQUE INSTITUTE OF TOULOUSE, 2007.

- Herrán-González, J. M. De La Cruz, B. De Andrés-Toro, and J. L. Risco-Martín, “Modeling And Simulation of a Gas Distribution Pipeline Network,” Appl Math Model, vol. 33, no. 3, pp. 1584–1600, 2009. [CrossRef]

- Ekhtiari, I. Dassios, M. Liu, and E. Syron, “A Novel Approach to Model a Gas Network,” Applied Sciences (Switzerland), vol. 9, no. 6, 2019. [CrossRef]

- J. Zeng, C. Sun, Z. Zhu, J. Wu, and H. Chen, “Uncertainty Analysis for Natural Gas Transport Pipeline Network Layout: A New Methodology Based on Monte Carlo Method,” J Adv Transp, vol. 2018, 2018. [CrossRef]

- E. Fokken, S. Göttlich, and M. Herty, “Efficient Simulation of Coupled Gas and Power Networks under Uncertain Demands,” August 2021.

- J. André et al., “Design and Dimensioning of Hydrogen Transmission Pipeline Networks,” Eur J Oper Res, vol. 229, no. 1, pp. 239–251, 2013. [CrossRef]

- “ProMax - Wikipedia.” Accessed: Mar. 06, 2023. [Online]. Available: https://en.wikipedia.org/wiki/ProMax.

- M. Bonyadi, M. R. Rahimpour, and F. Esmaeilzadeh, “A New Fast Technique for Calculation of Gas Condensate Well Productivity by Using Pseudopressure Method,” J Nat Gas Sci Eng, vol. 4, pp. 35–43, 2012. [CrossRef]

- F. Esmaeilzadeh and M. Roshanfekr, “A New Cubic Equation of State for Reservoir Fluids,” Fluid Phase Equilib, vol. 239, no. 1, pp. 83–90, 2006. [CrossRef]

- H. D. Beggs and J. P. Brill, “A Study of Two-Phase Flow in Inclined Pipes,” Journal of Petroleum Technology, vol. 25, no. 05, pp. 607–617, 1973.

- EIA, “U.S. Natural Gas Pipeline Projects,” 2022.

- G. Molnar and G. Molnar, “Economics of Gas Transportation by Pipeline and LNG,” The Palgrave Handbook of International Energy Economics, pp. 23–57, 2022. [CrossRef]

- COMTRADE, “Nigeria Imports of Iron and Steel - 2023 Data 2024 Forecast 1996-2021 Historical.” Accessed: Apr. 02, 2023. [Online]. Available: https://tradingeconomics.com/nigeria/imports/iron-steel.

- Essen, “Nigeria Imports $3.3 Billion Steel Product,” The Guardian Nigeria News - Nigeria and World News, Nov. 30, 2018.

| Property | Methane | Hydrogen |

|---|---|---|

| Molecular weight (g/mol) | ||

| Density (kg/m3) | ||

| Specific gravity | ||

| Dynamic viscosity (Pa·s) | ||

| Kinematic viscosity (m2/s) | ||

| Gross heating value (MJ/m3) | ||

| Thermal conductivity(W/(m·K) |

| Component | Mole fraction (%) |

|---|---|

| Methane (C1) | 95 |

| Ethane (C2) | 10 |

| Propane (C3) | 8 |

| Butane + Paraffine (C4+) | 5 |

| Nitrogen (N2) | 0.03 |

| Carbon Dioxide (CO2) | 0.04 |

| Input Variable | Value | Unit |

|---|---|---|

| Pipe length | 342 | km |

| Nominal pipe size, NPS | 36 | inch |

| Pipe wall thickness | 0.25 | inch |

| Maximum allowable operating pressure, MAOP (inlet) | 70 | bar (g) |

| Outlet pressure | 17.34 | bar (g) |

| Gas specific heat ratio | 1.4 | NA |

| Standard temperature | 15.5 | °C |

| Atmospheric pressure | 1.01325 | bar |

| Number of the length of pipe increment | 200 | NA |

| The material for pipe construction | Carbon steel | NA |

| Inclination angle | 0 | Degrees |

| Inlet pressure | 60 | bar (g) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).