Submitted:

15 March 2024

Posted:

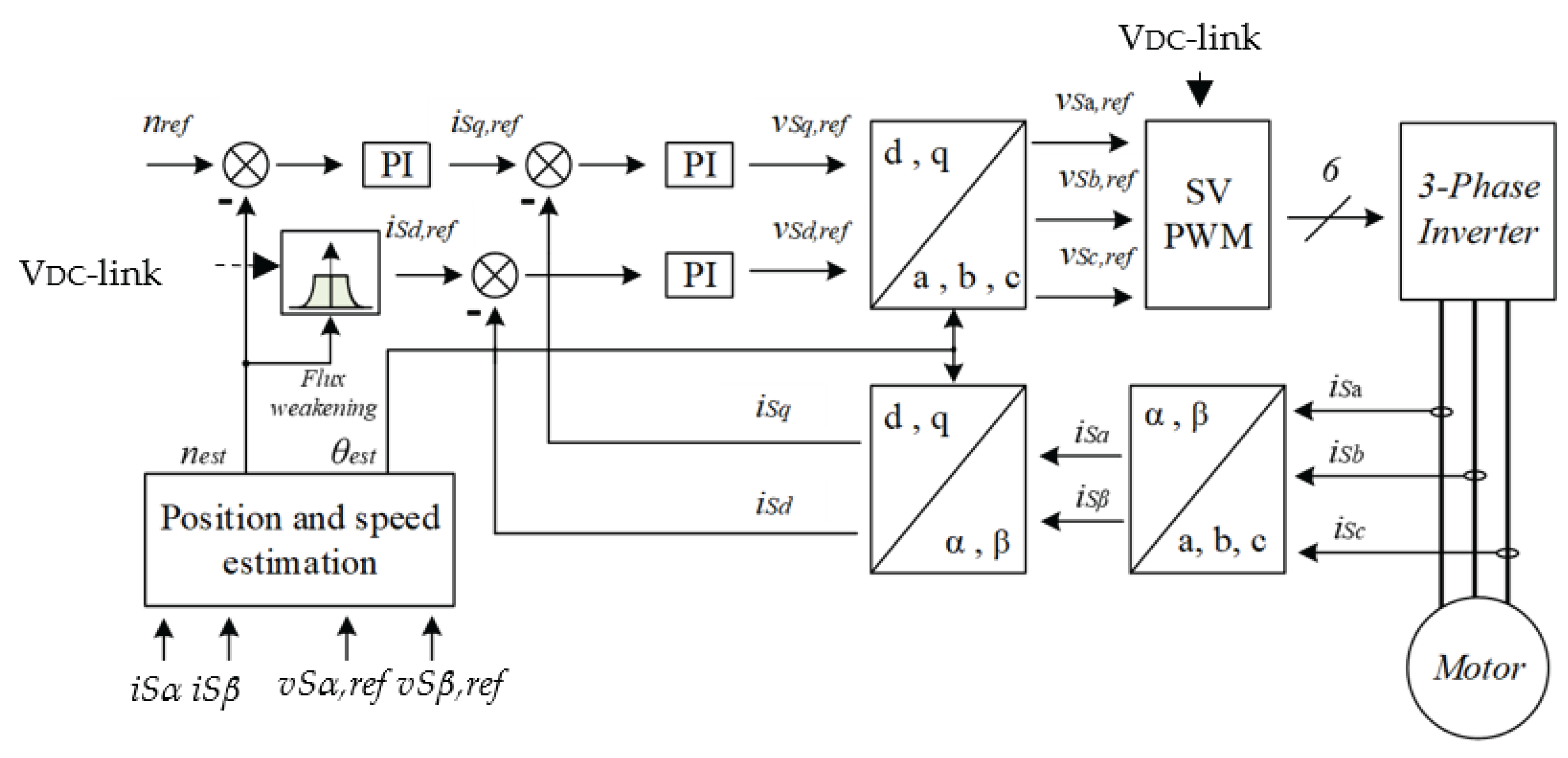

18 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

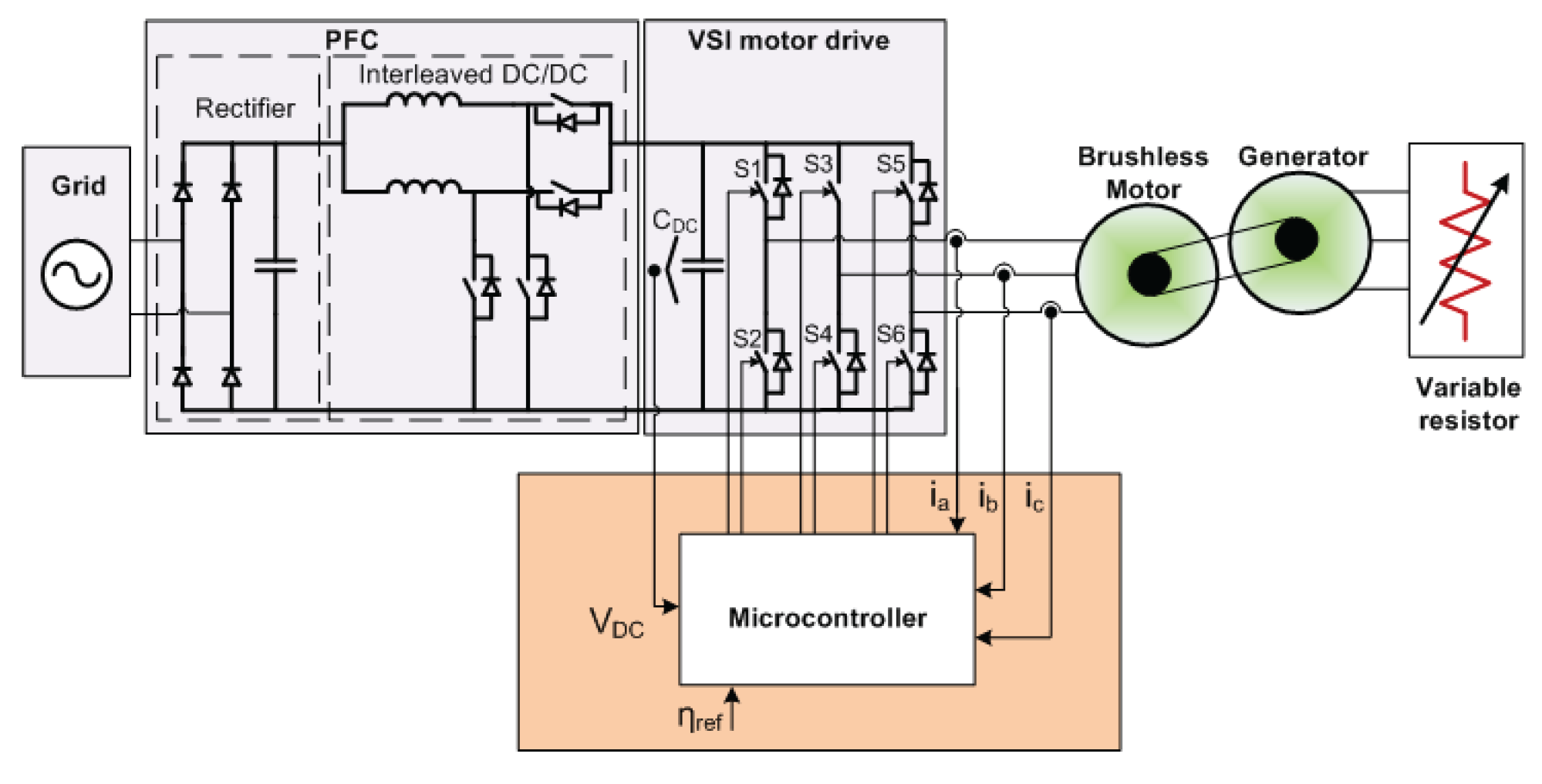

2. System under Study

3. FOC Description

4. Inverter Voltage Drop Modeling

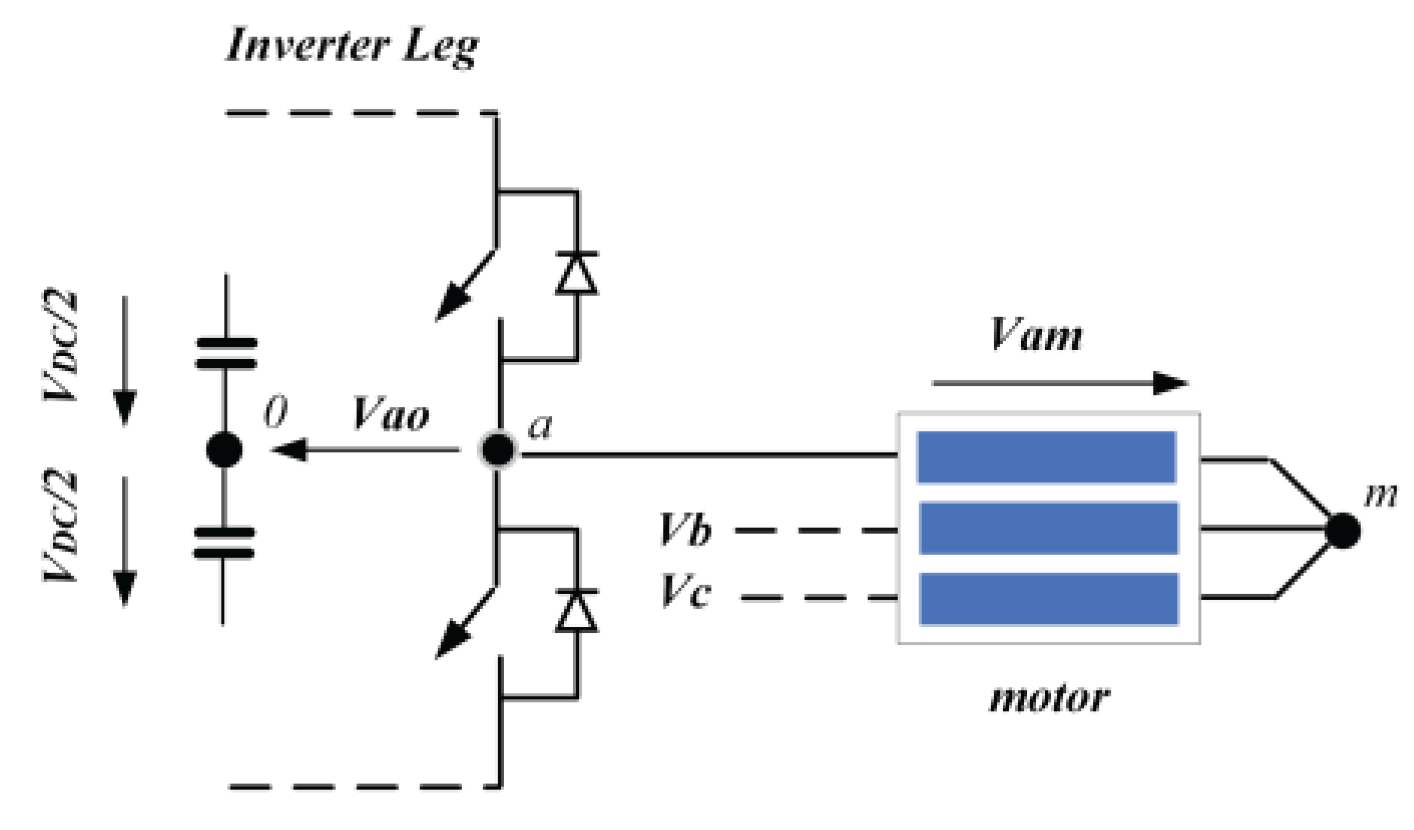

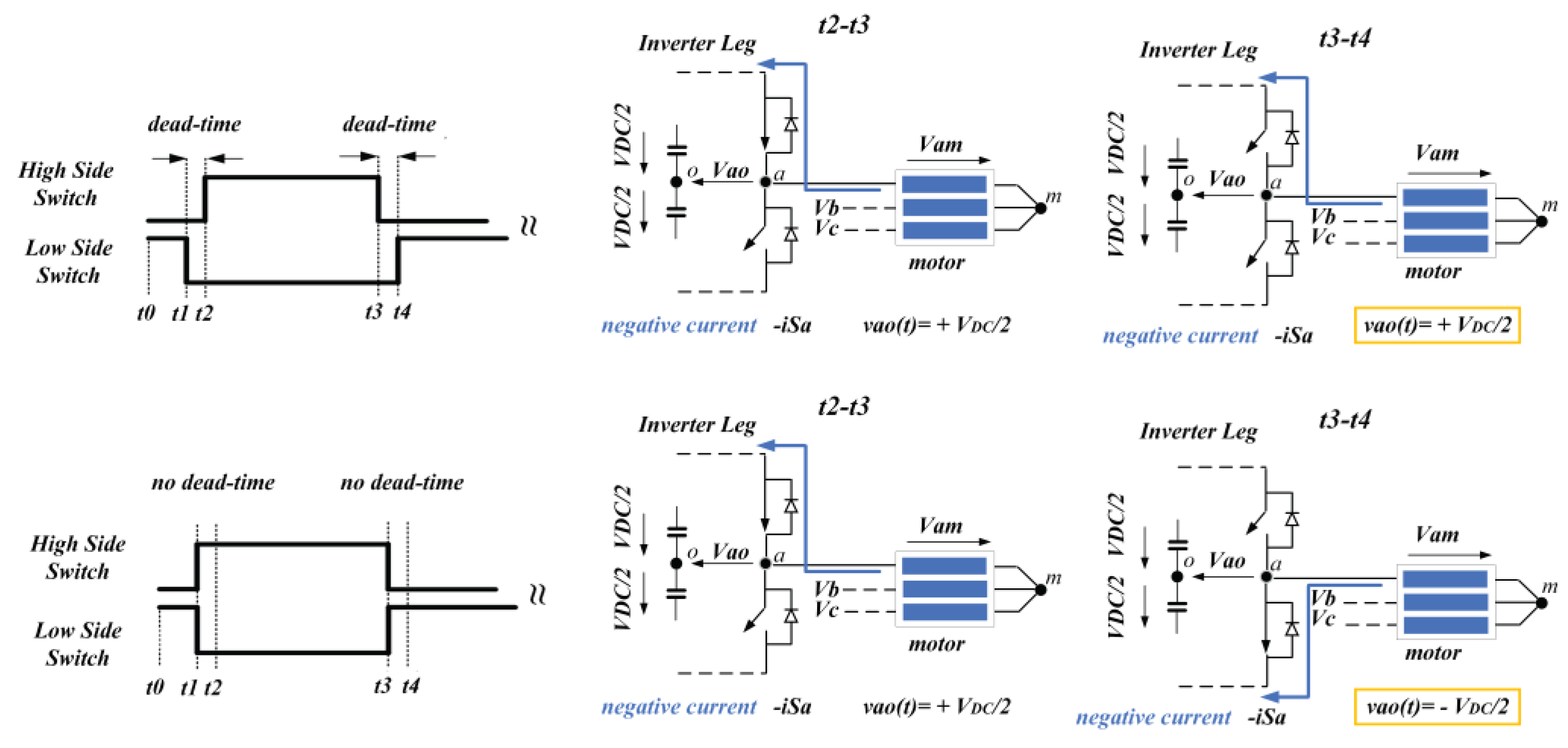

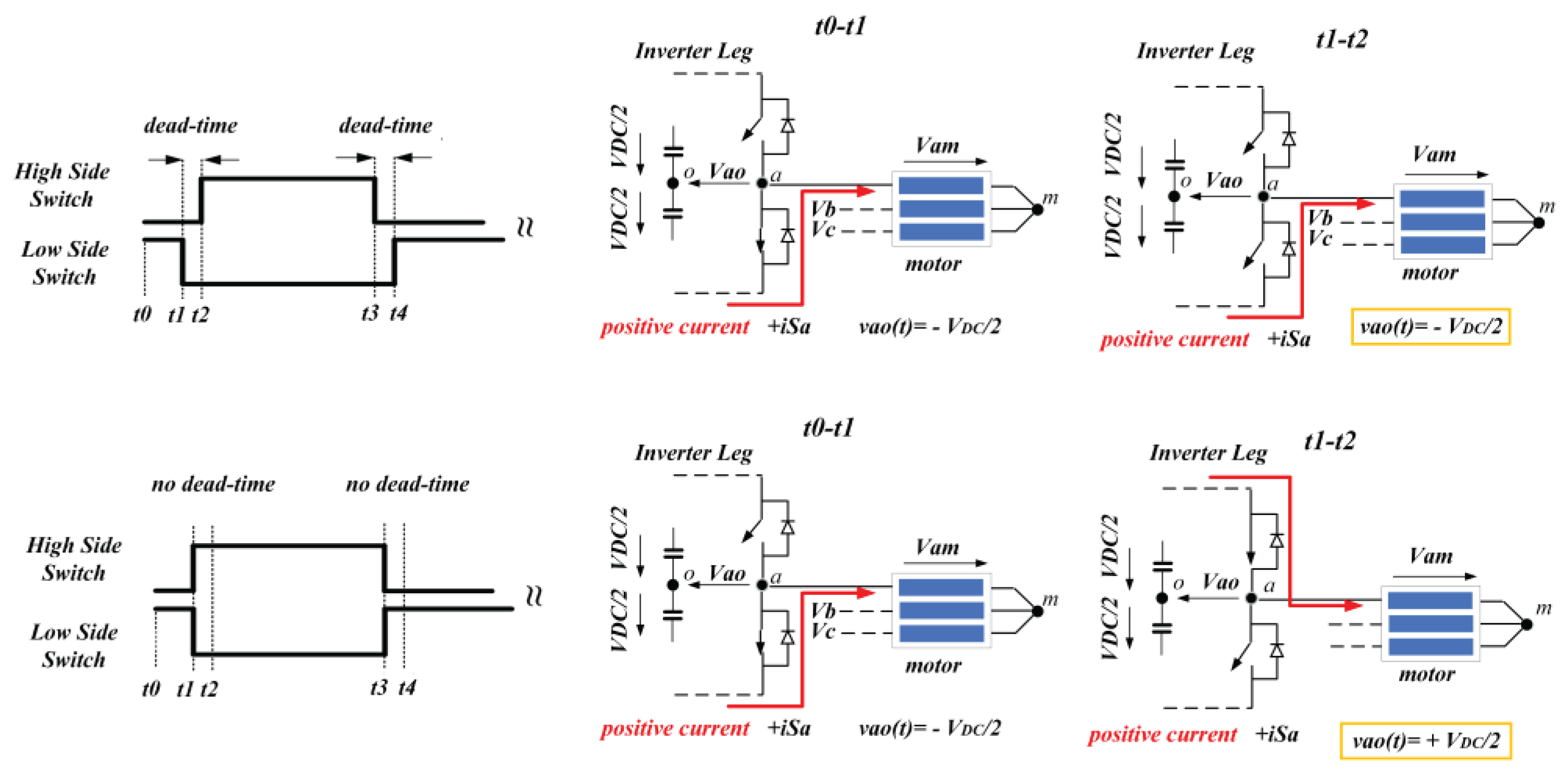

4.1. Basic Analysis of Inverter Voltage Drop

- IGBTs/diodes conduction & switching losses (such us IGBTs forward voltage, and on state resistance, diodes forward voltage-drop).

- PWM dead-time.

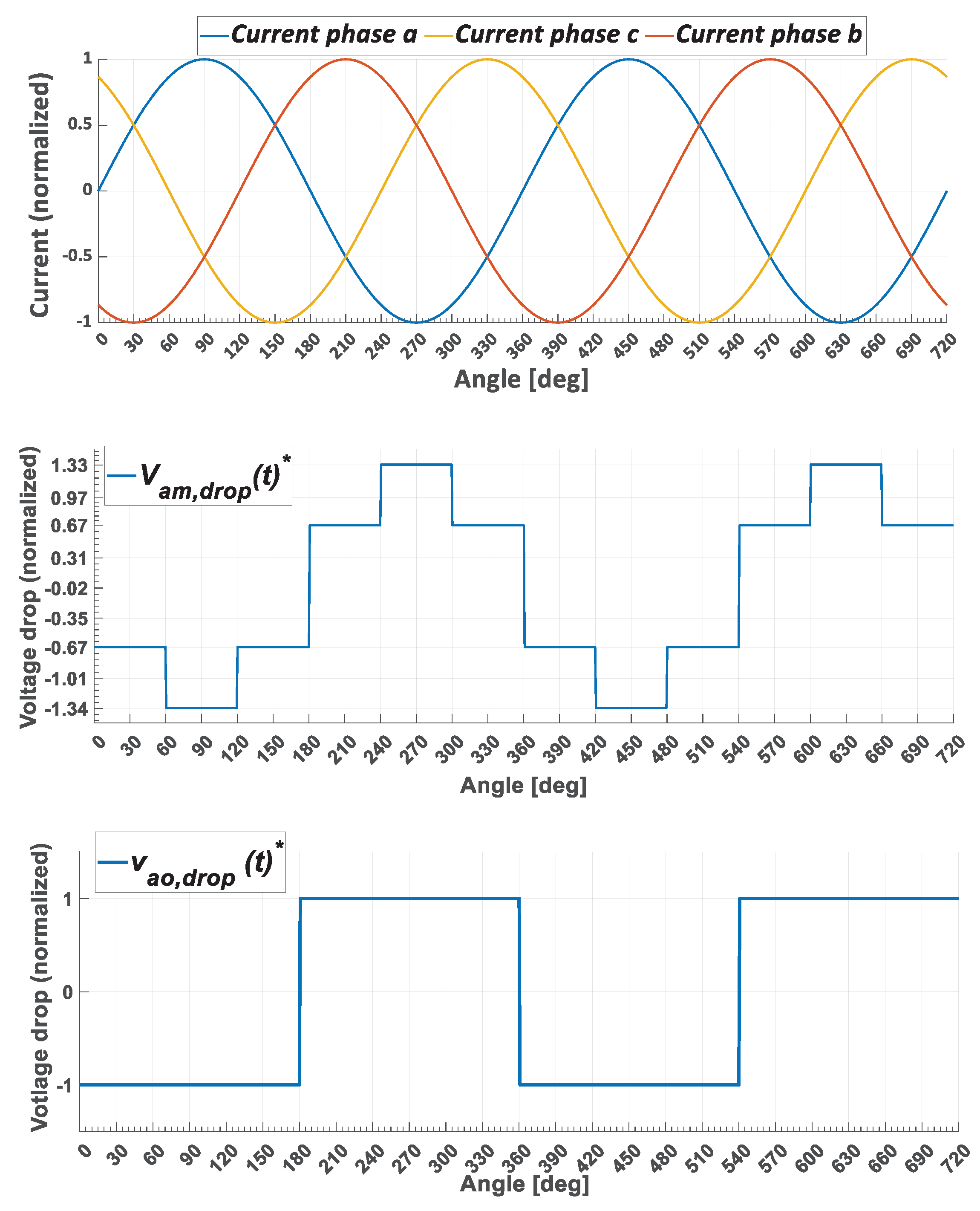

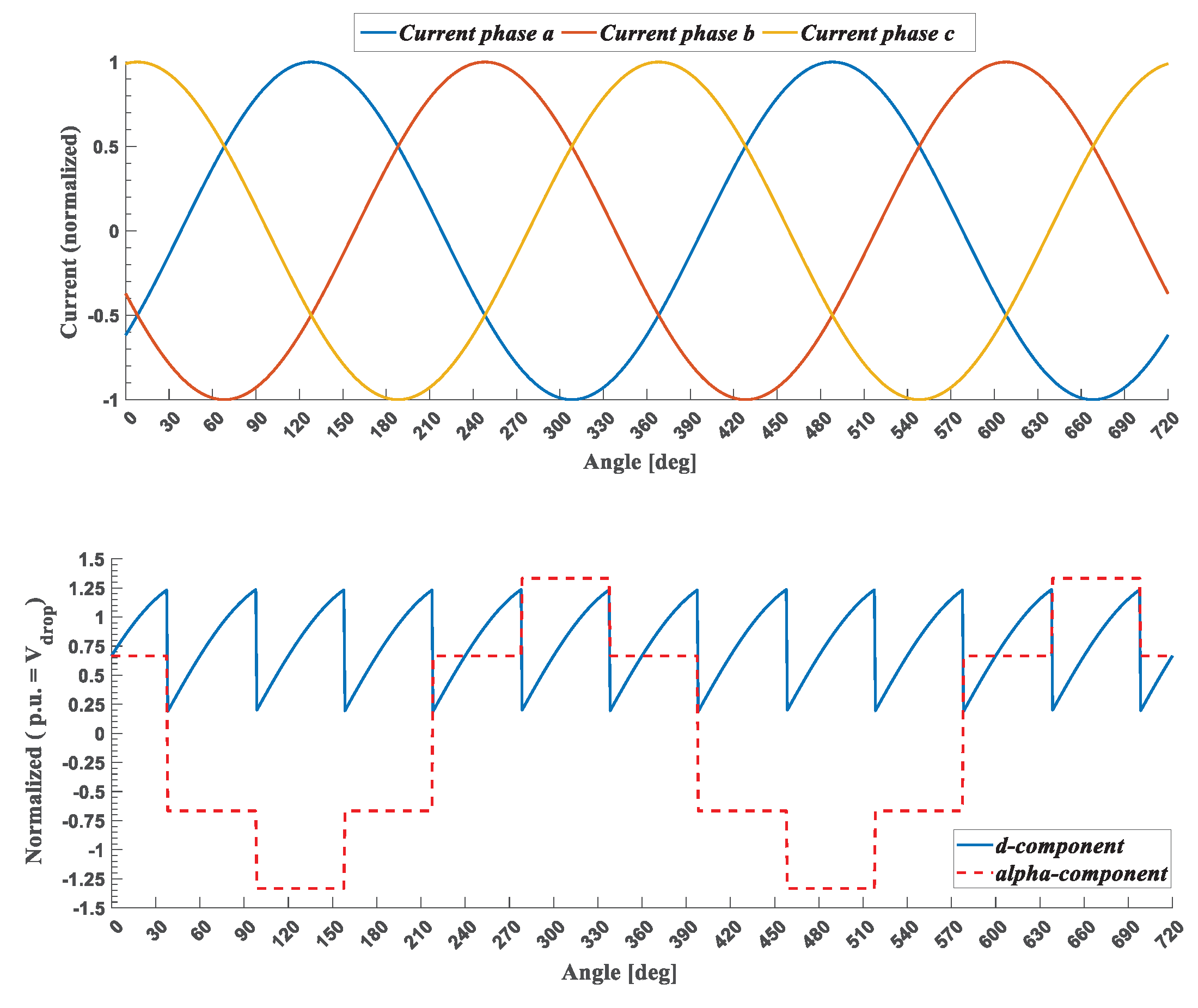

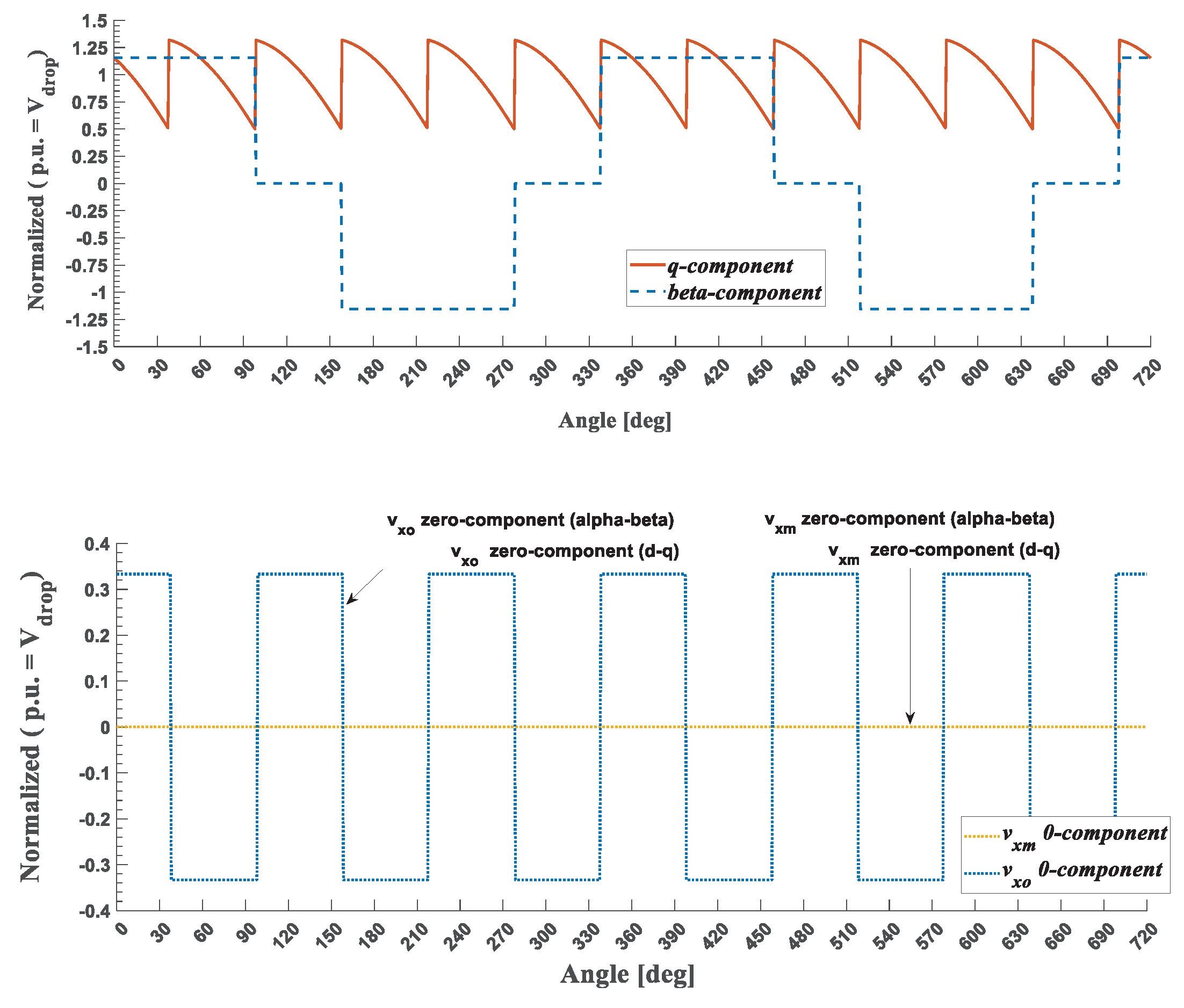

4.2. Voltage Drop: Modeling in aβ and dq-Synchronous Reference Frame

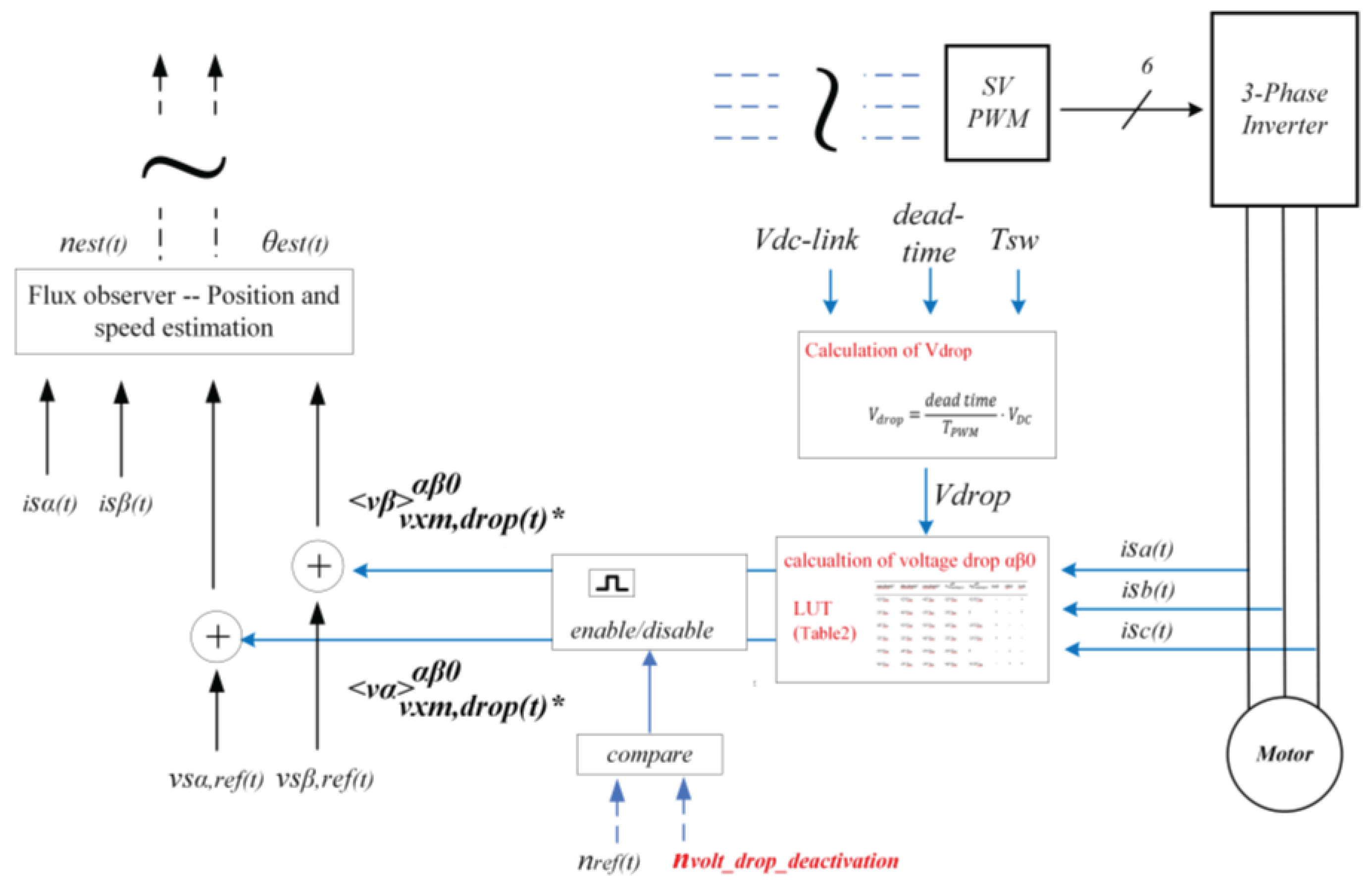

4.3. Voltage Drop: Insertion in FOC aβ-Reference Frame

| vam,drop(t)* | vbm,drop(t)* | vcm,drop(t)* | iSa(t) | iSb(t) | iSc(t) | ||

|---|---|---|---|---|---|---|---|

| +2/3 Vdrop | +2/3 Vdrop | -4/3 Vdrop | +2/3 Vdrop | +2/√3 Vdrop | - | - | + |

| -2/3 Vdrop | +4/3 Vdrop | -2/3 Vdrop | -2/3 Vdrop | 0 | + | - | + |

| -4/3 Vdrop | +2/3 Vdrop | +2/3 Vdrop | -4/3 Vdrop | -2/√3 Vdrop | + | - | - |

| -2/3 Vdrop | -2/3 Vdrop | +4/3 Vdrop | -2/3 Vdrop | -2/√3 Vdrop | + | + | - |

| +2/3 Vdrop | -4/3 Vdrop | +2/3 Vdrop | +2/3 Vdrop | 0 | - | + | - |

| +4/3 Vdrop | -2/3 Vdrop | -2/3 Vdrop | +4/3 Vdrop | +2/√3 Vdrop | - | + | + |

5. Simulation Results

| PFC & VSI characteristics | Value | Motor characteristics | Value |

|---|---|---|---|

| Inverter dc-link volt. (V) | 400 | Motor nominal speed (rpm) | 6,000 |

| VSI Switching Freq. (kHz) | 16 | Motor maximum speed (rpm) | 7,000 |

| Dead-time (us) | variable | Motor winding Inductance (mH) | 16 |

| Dead-time utilization | asymm. | Motor winding resistance (Ω) | 2.5 |

| Modulation | SV-PWM | Motor Pole Pairs | 4 |

| Deactivation speed of proposed methodology (rpm) | 1,000 | BEMF constant (voltage1/rpm) | 0.028138 |

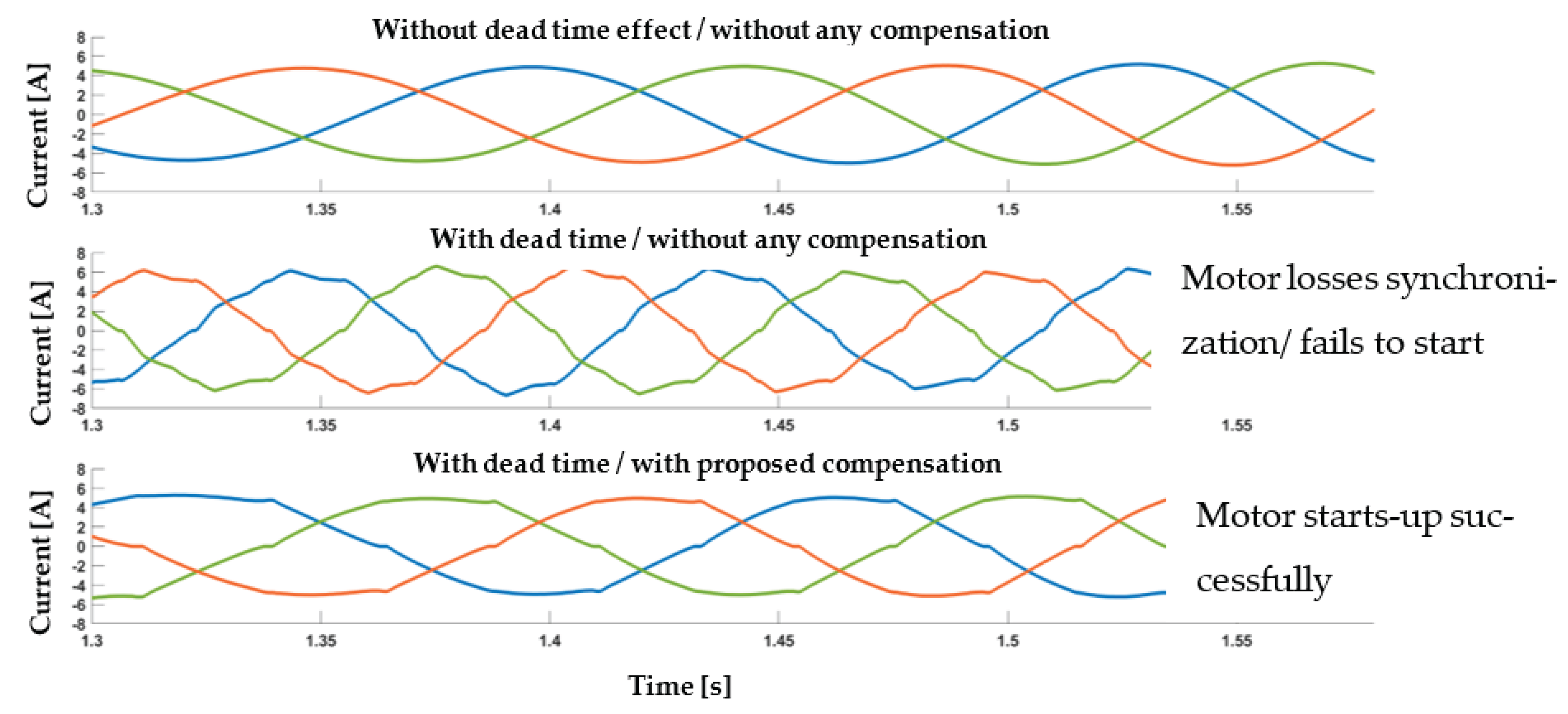

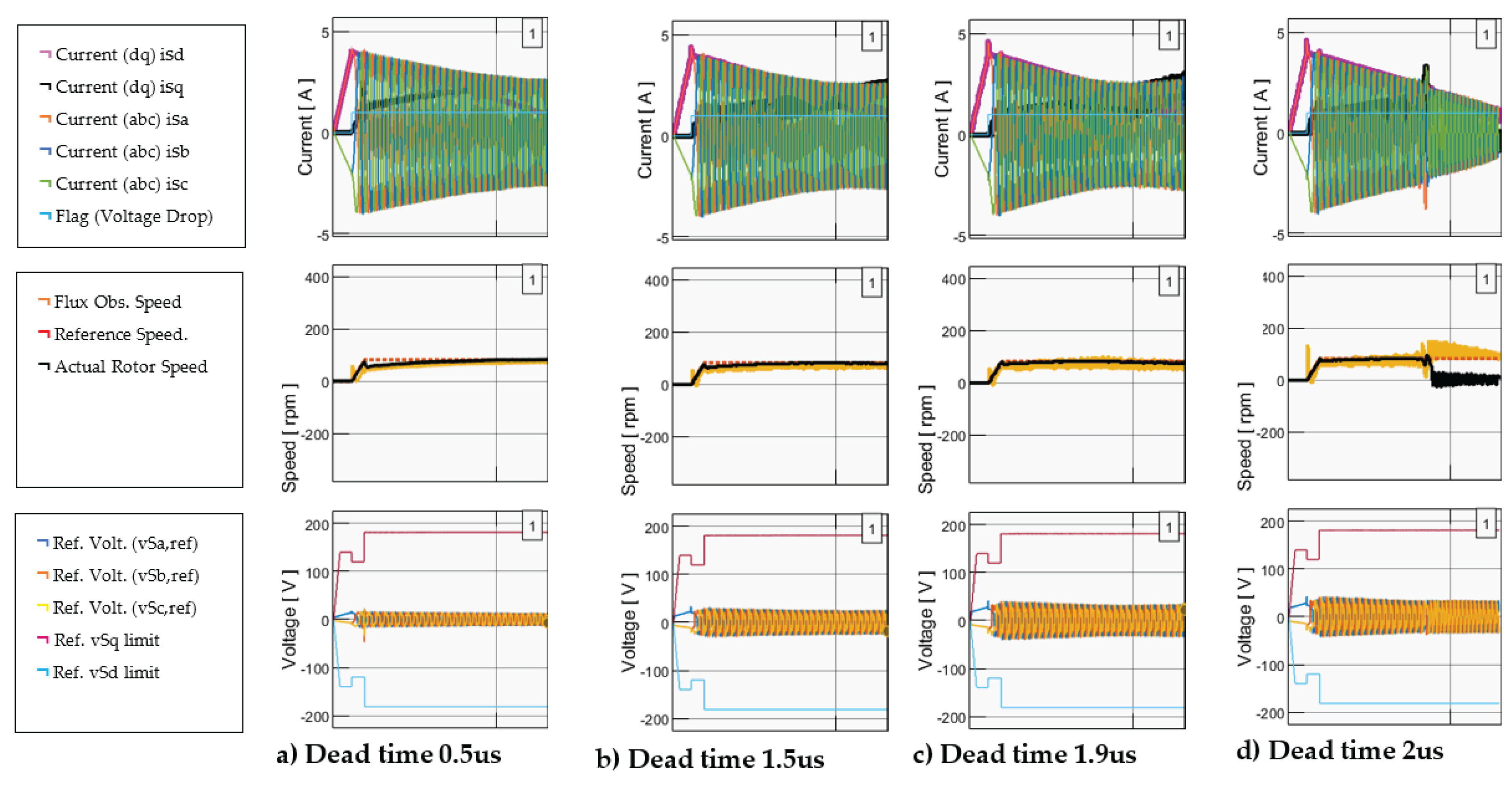

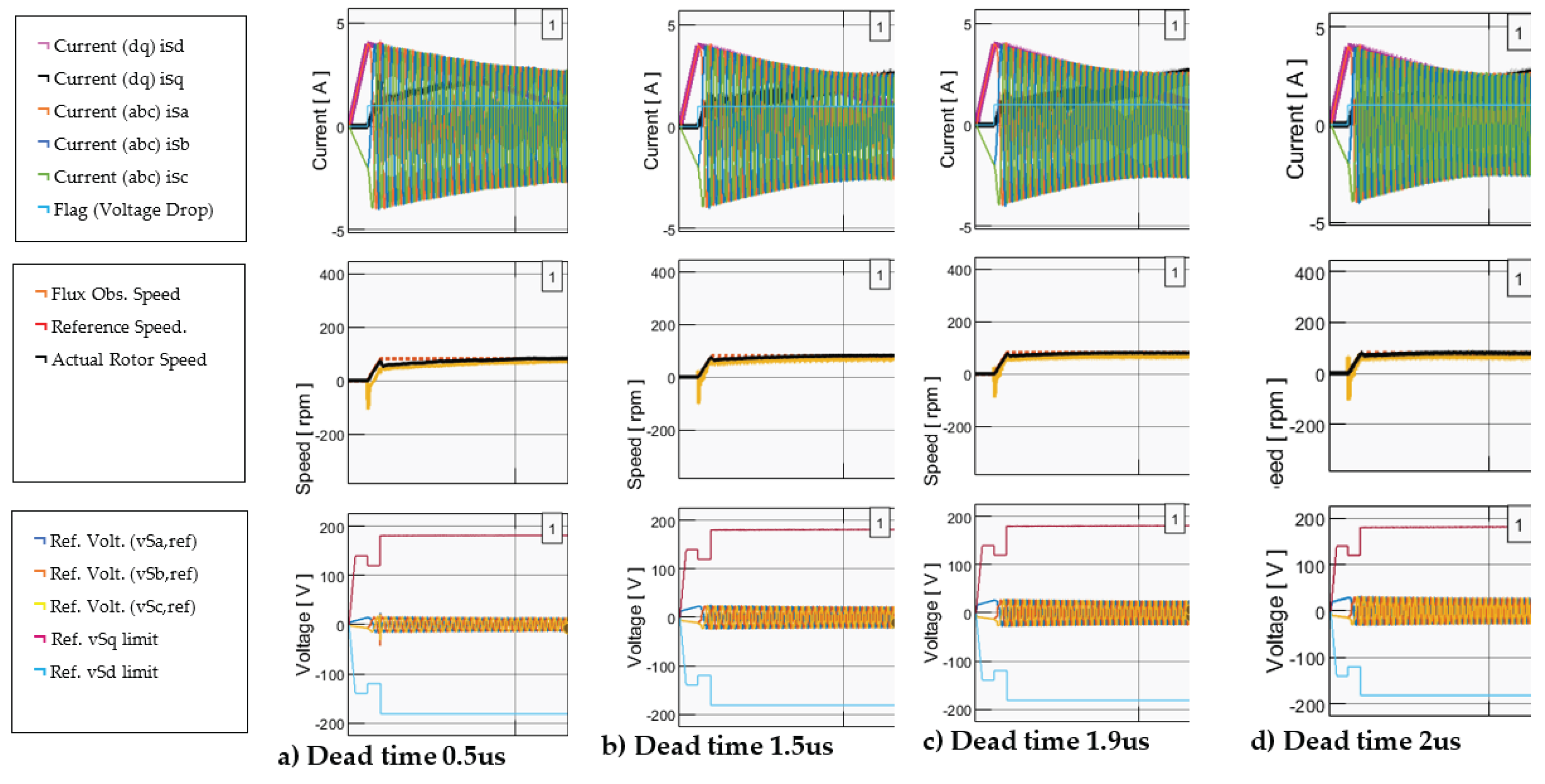

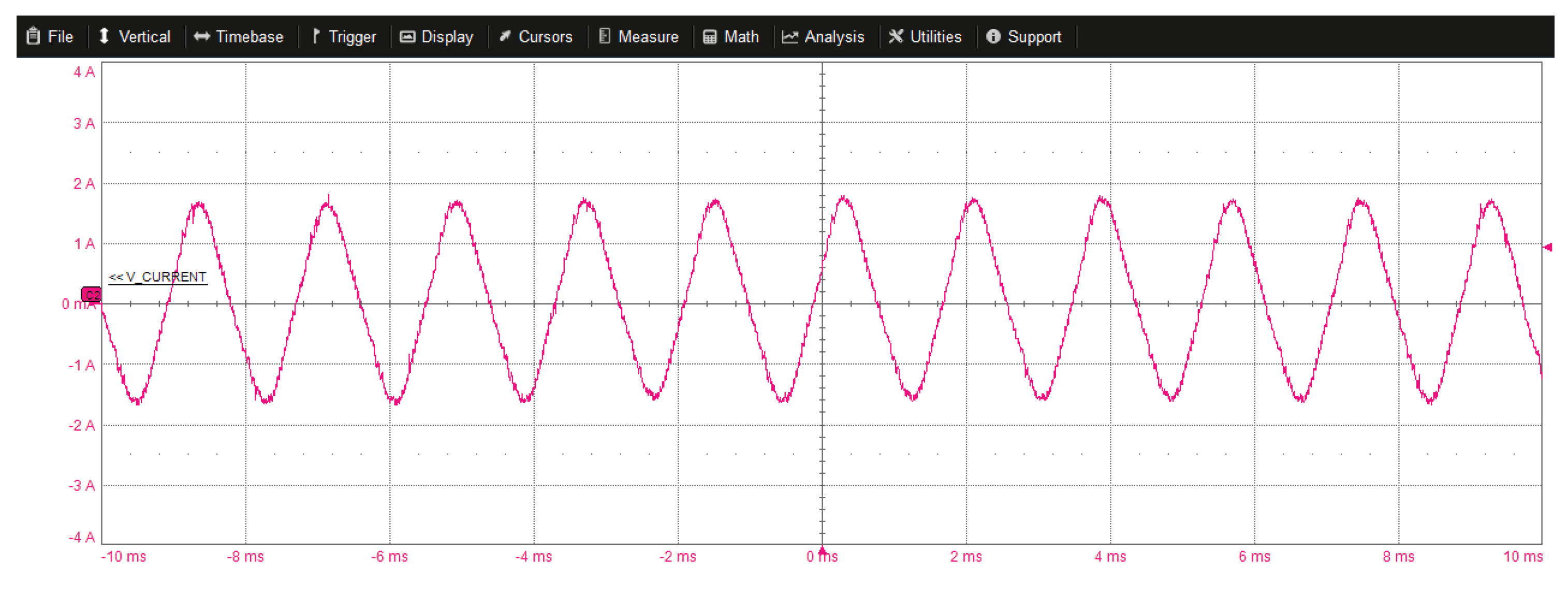

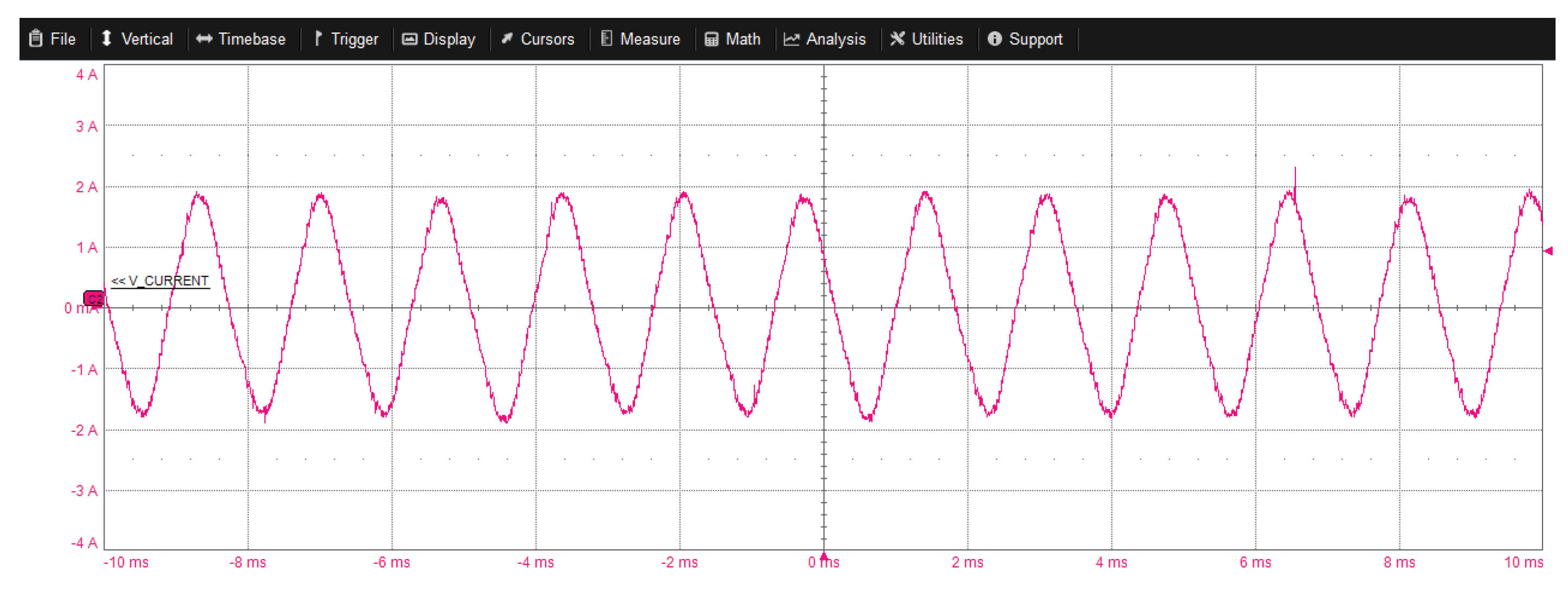

5.1. Proposed Voltage Drop Compensation Scheme

- In the top graph, the system operates ideally with no dead-time introduced.

- In the middle graph, the system is non-ideal, featuring a 2 us dead-time but without any compensation method.

- In the bottom graph, the system is non-ideal and incorporates a 2 us dead-time along with the application of our proposed compensation method.

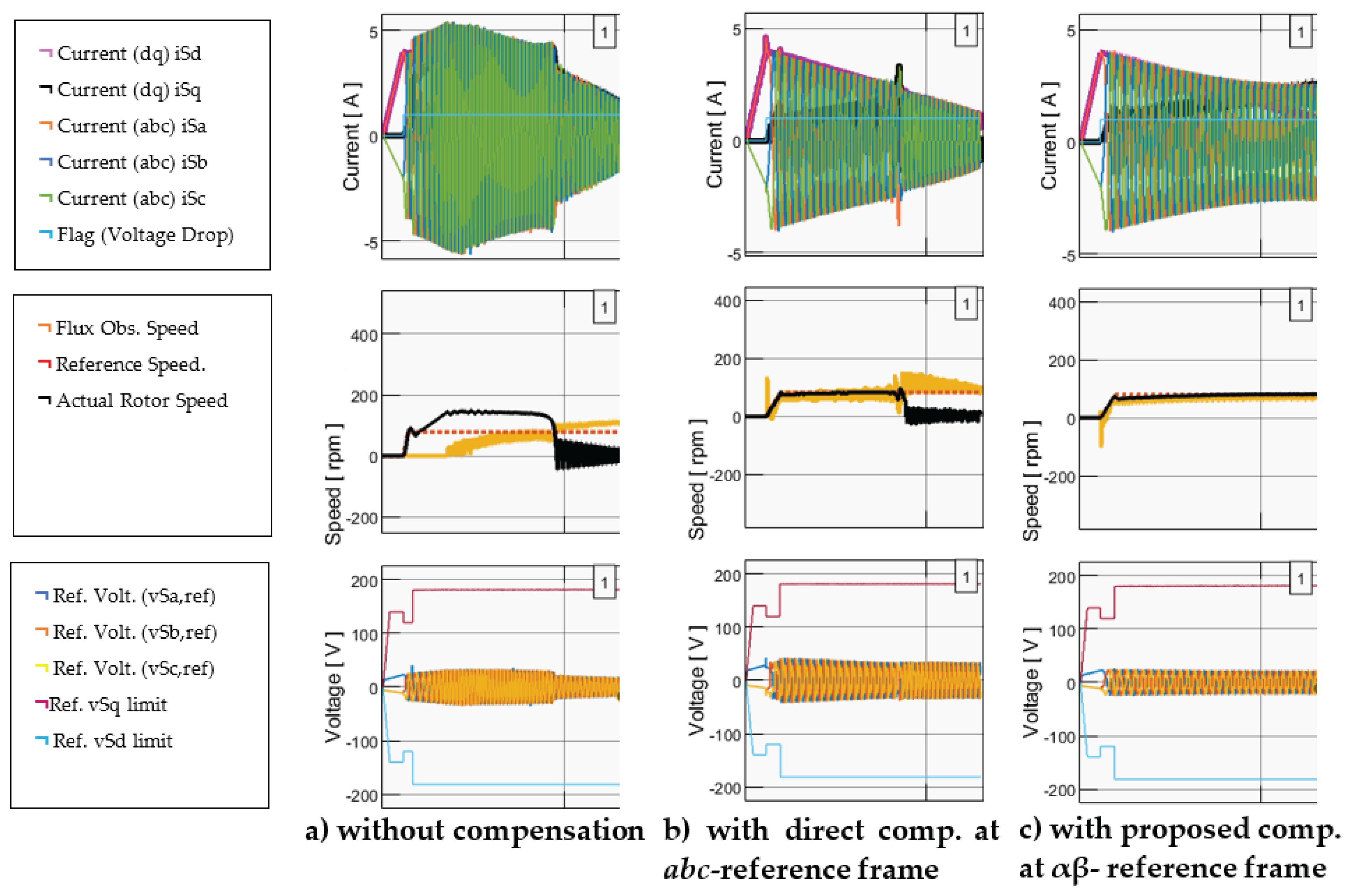

5.2. Comparison on Voltage Drop Compensation Location

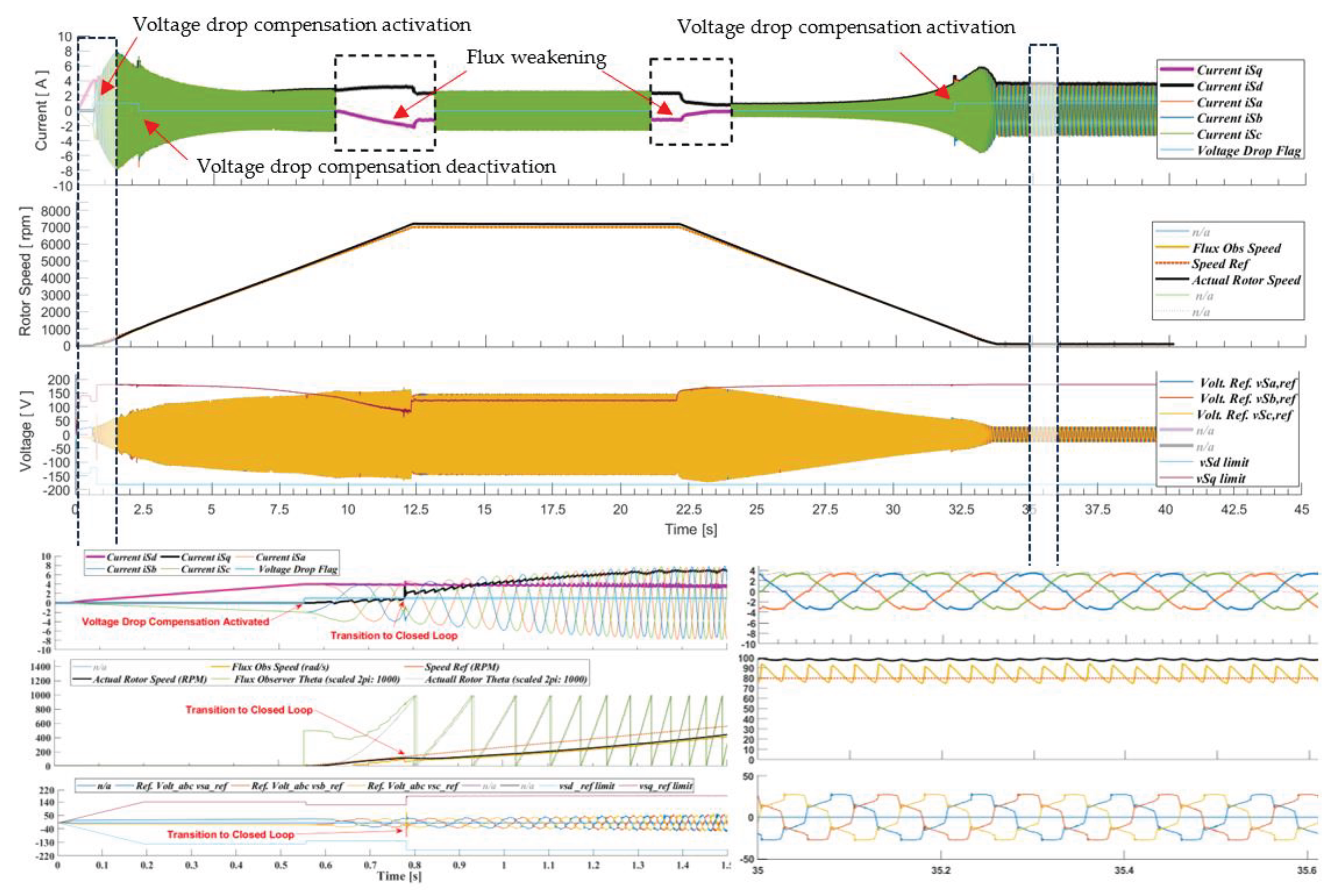

5.3. Enhanced FOC Validation over the Entire Motor Speed Range

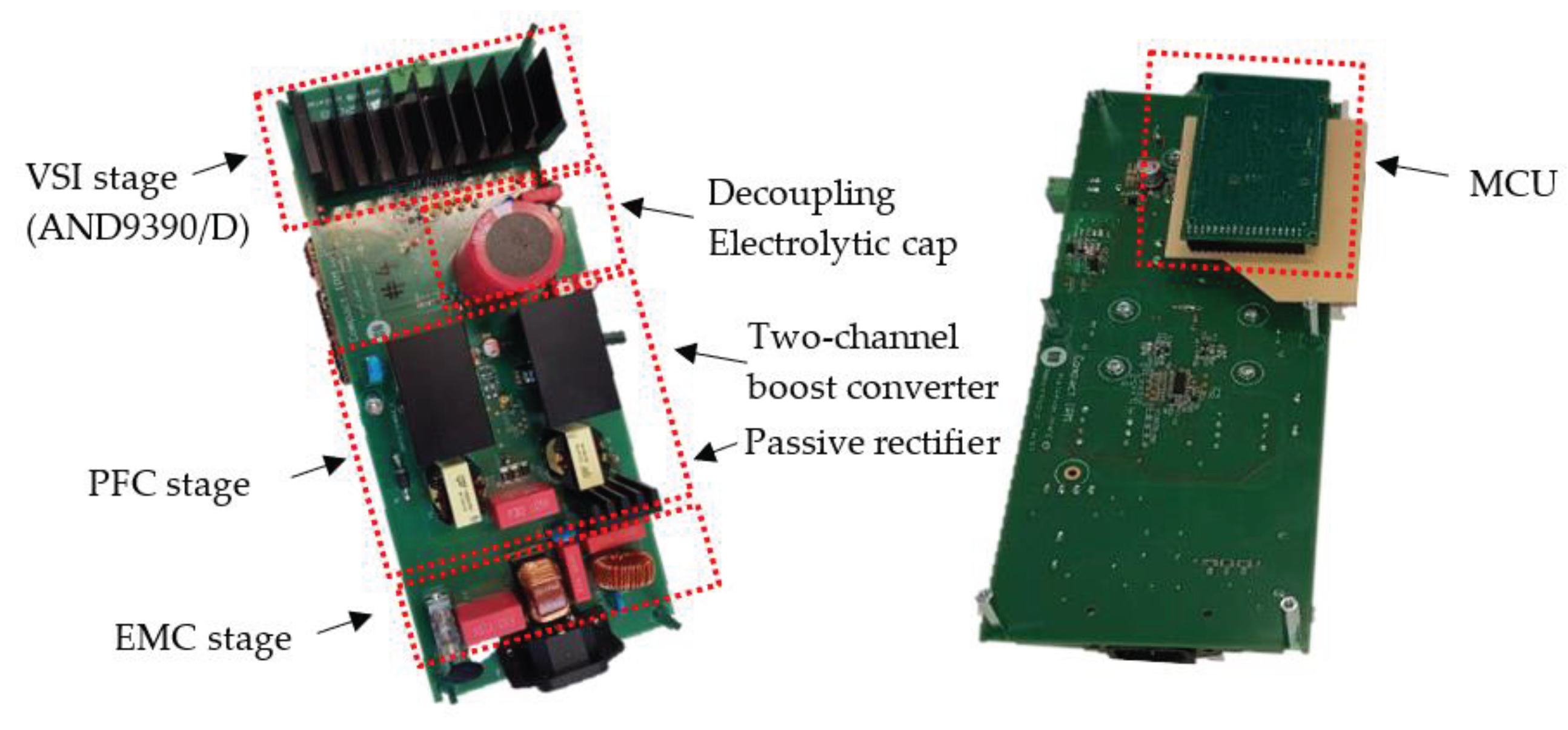

6. Experimental Results

- The EMC filter.

- The PFC.

- The VSI.

- The MCU.

- The Driving system.

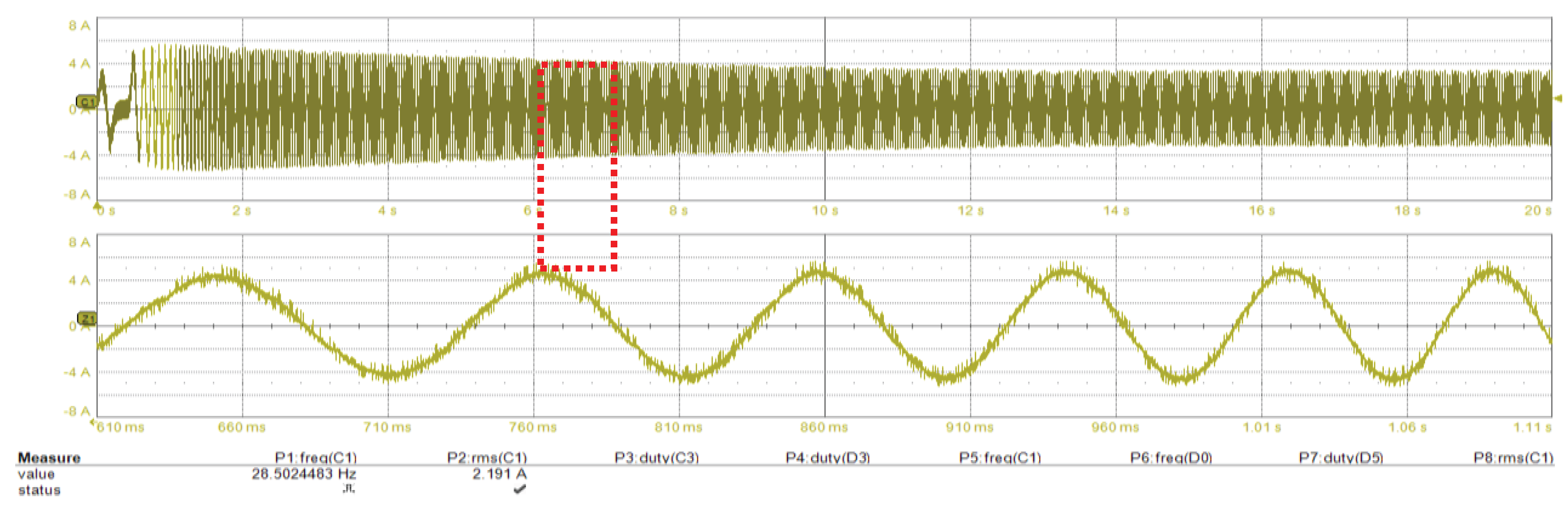

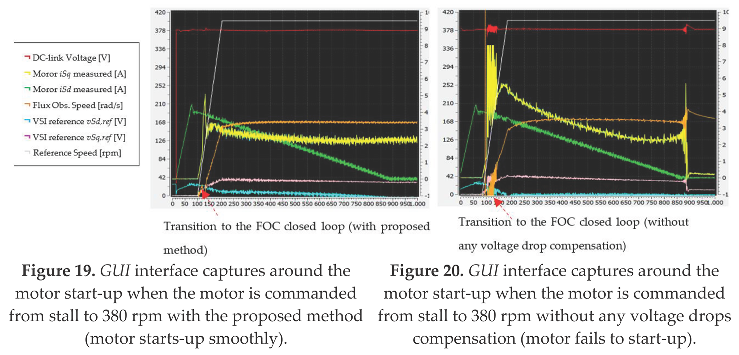

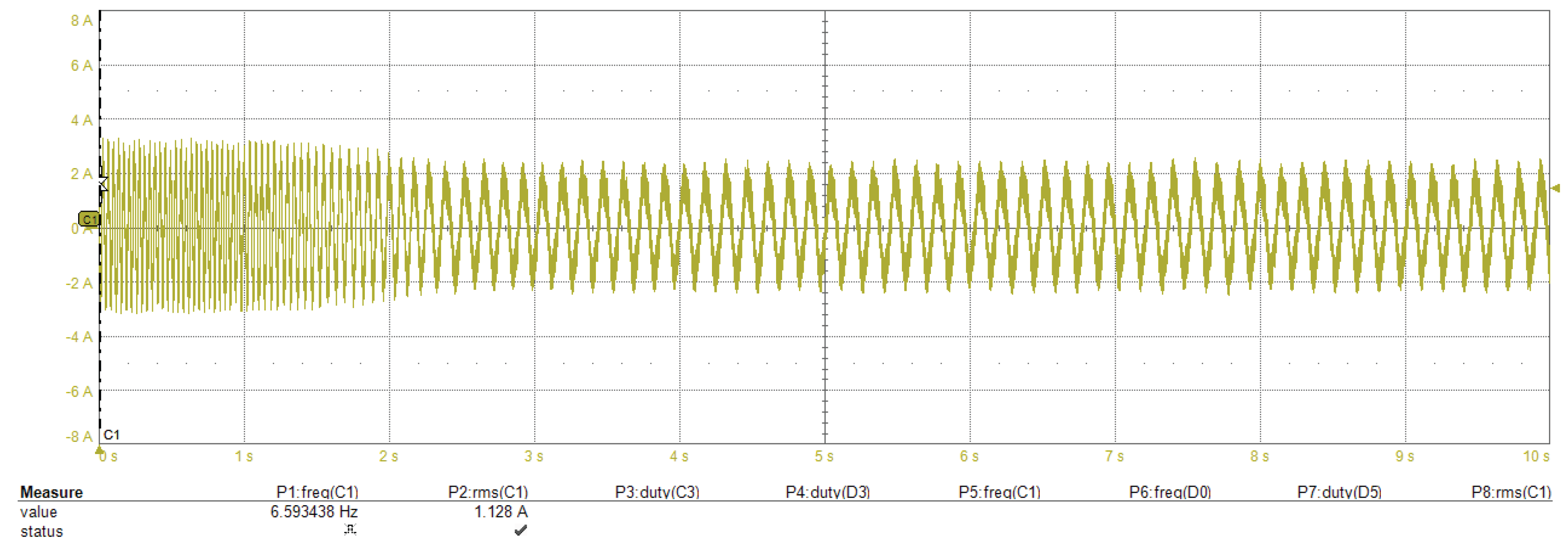

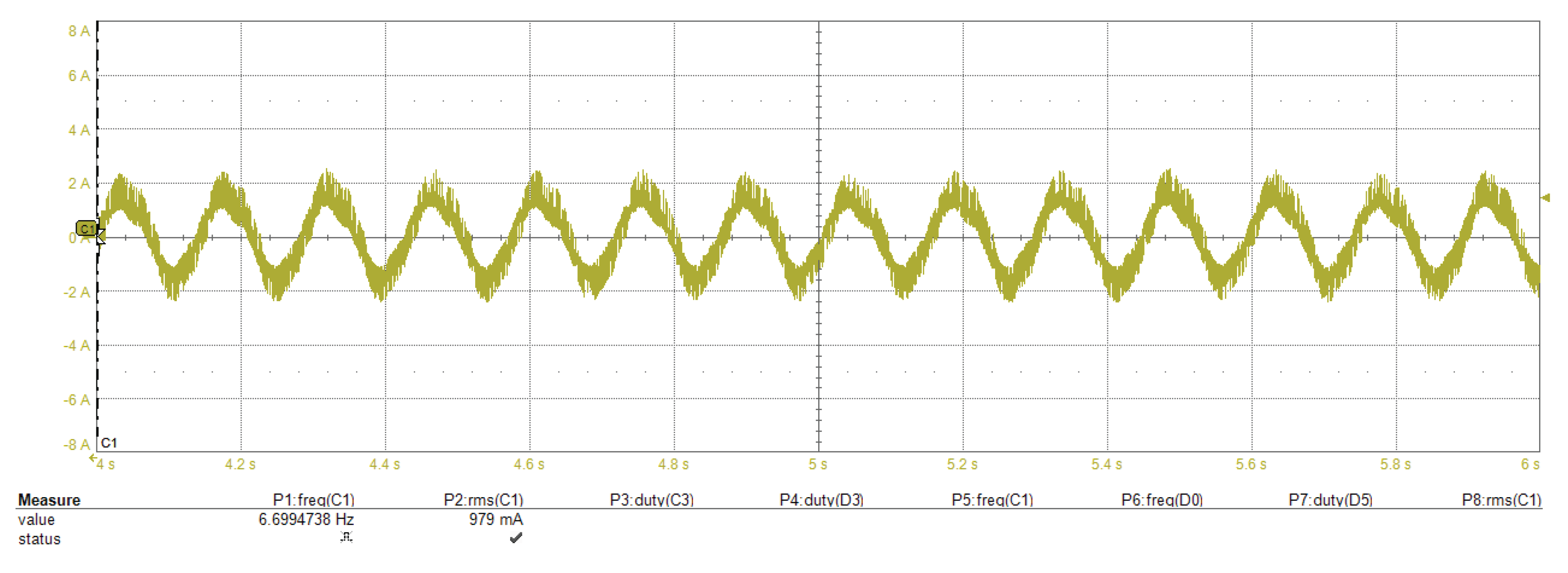

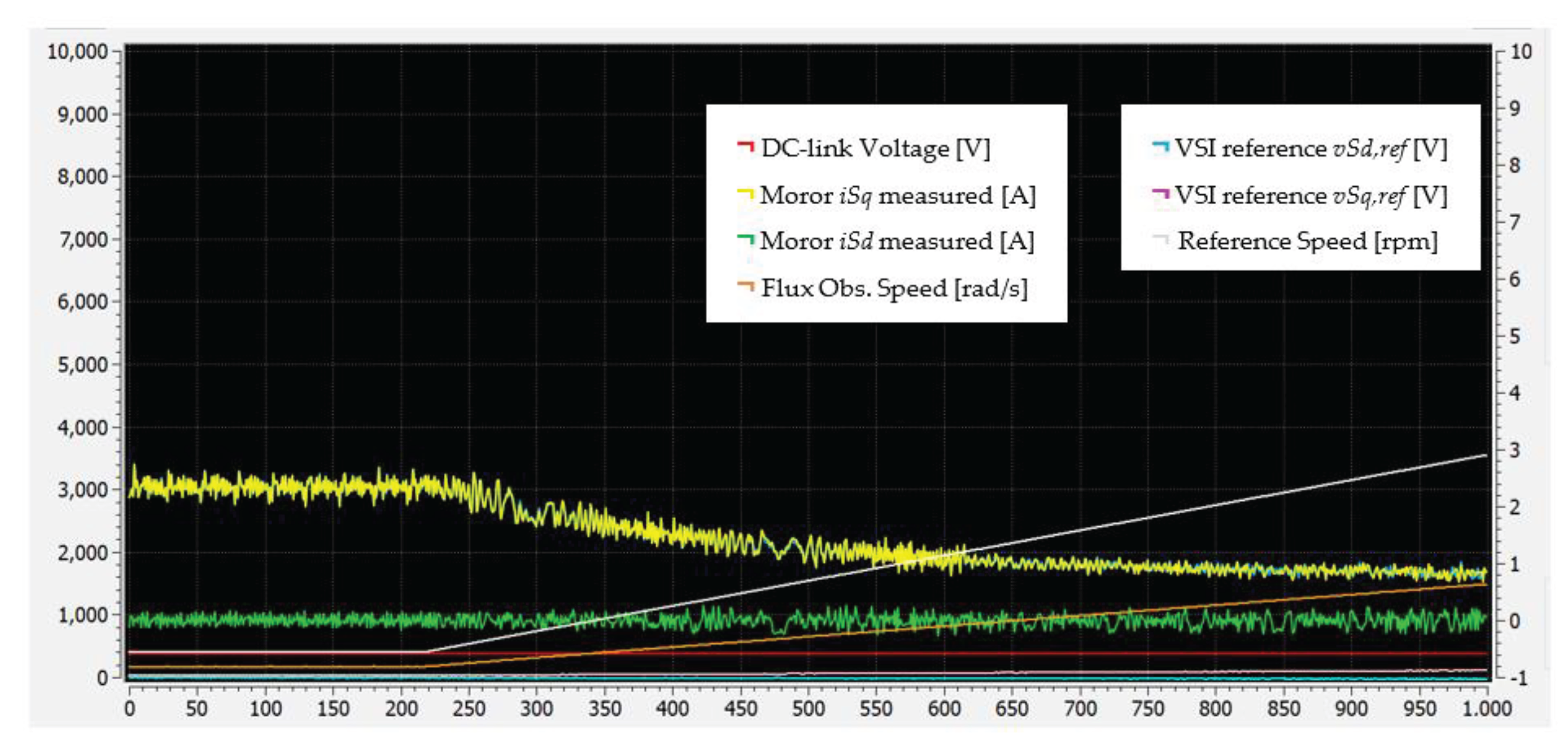

6.1. Start-Up to Low-Speed Validation

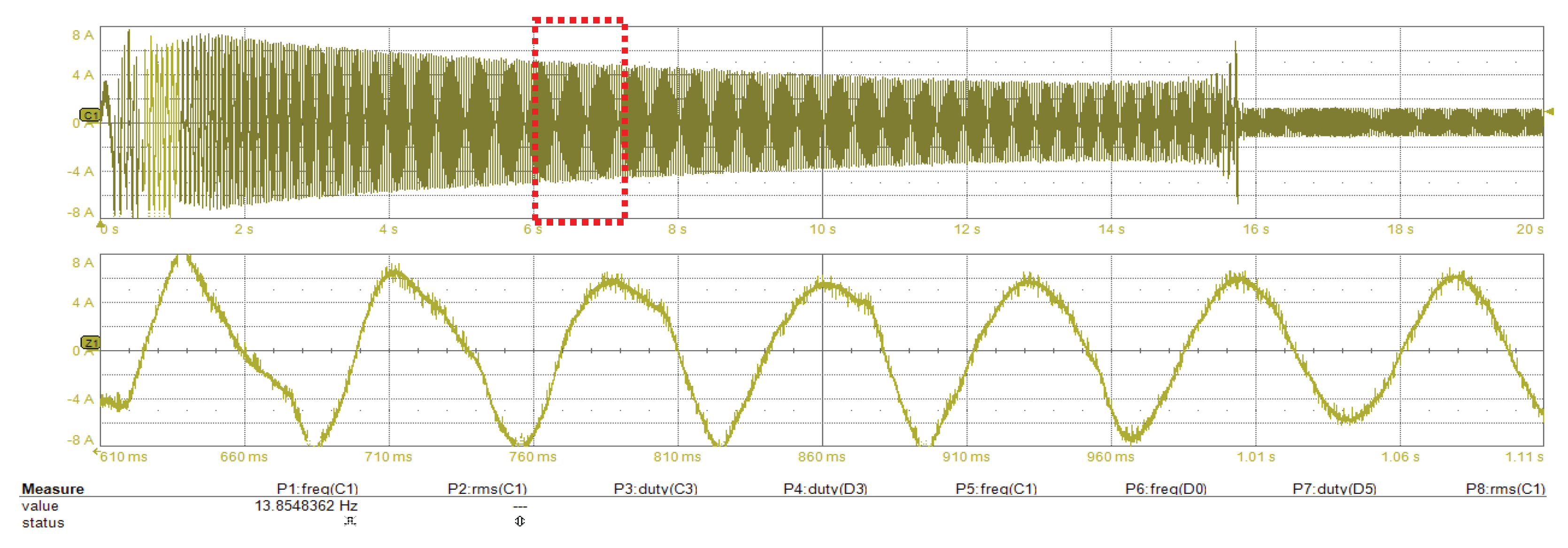

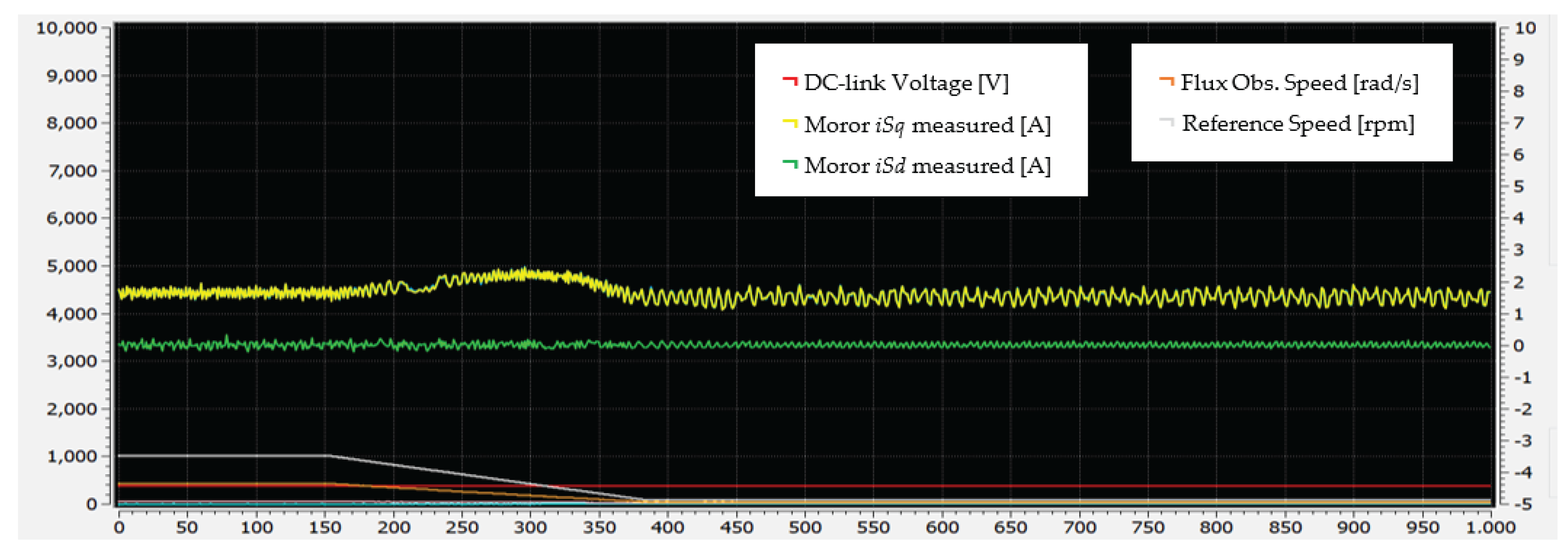

6.2. Deceleration to Low-Speed Validation

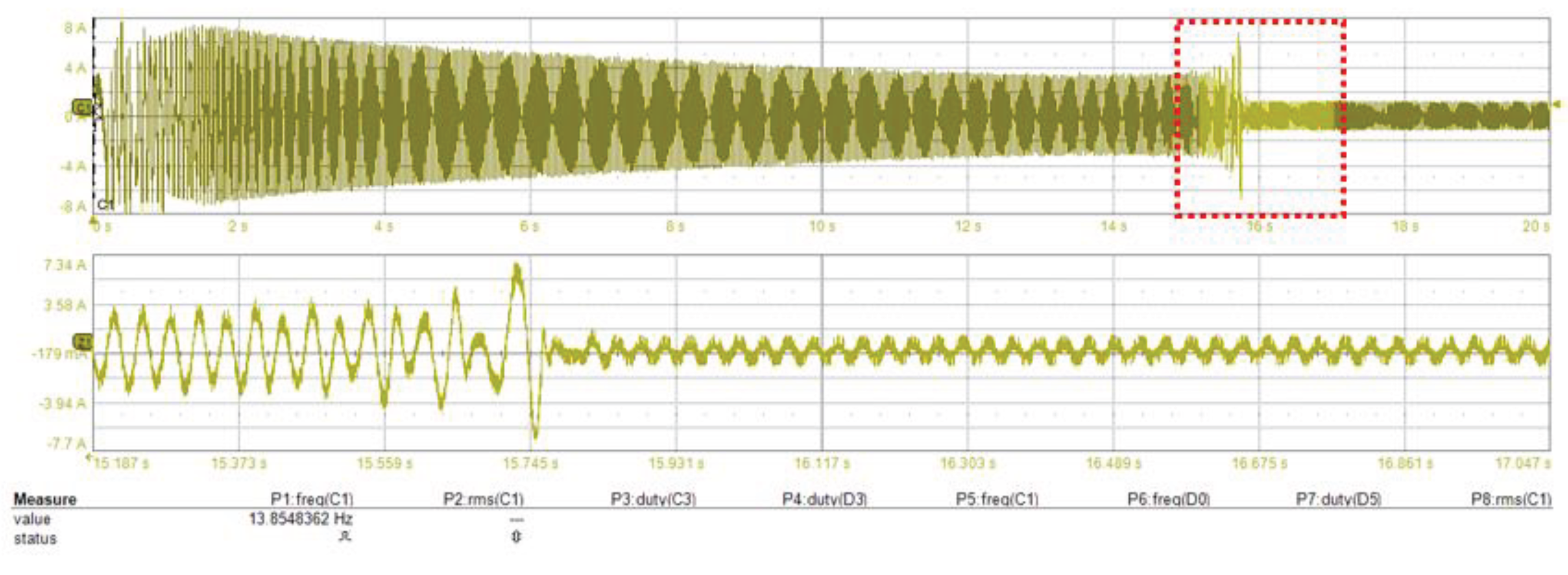

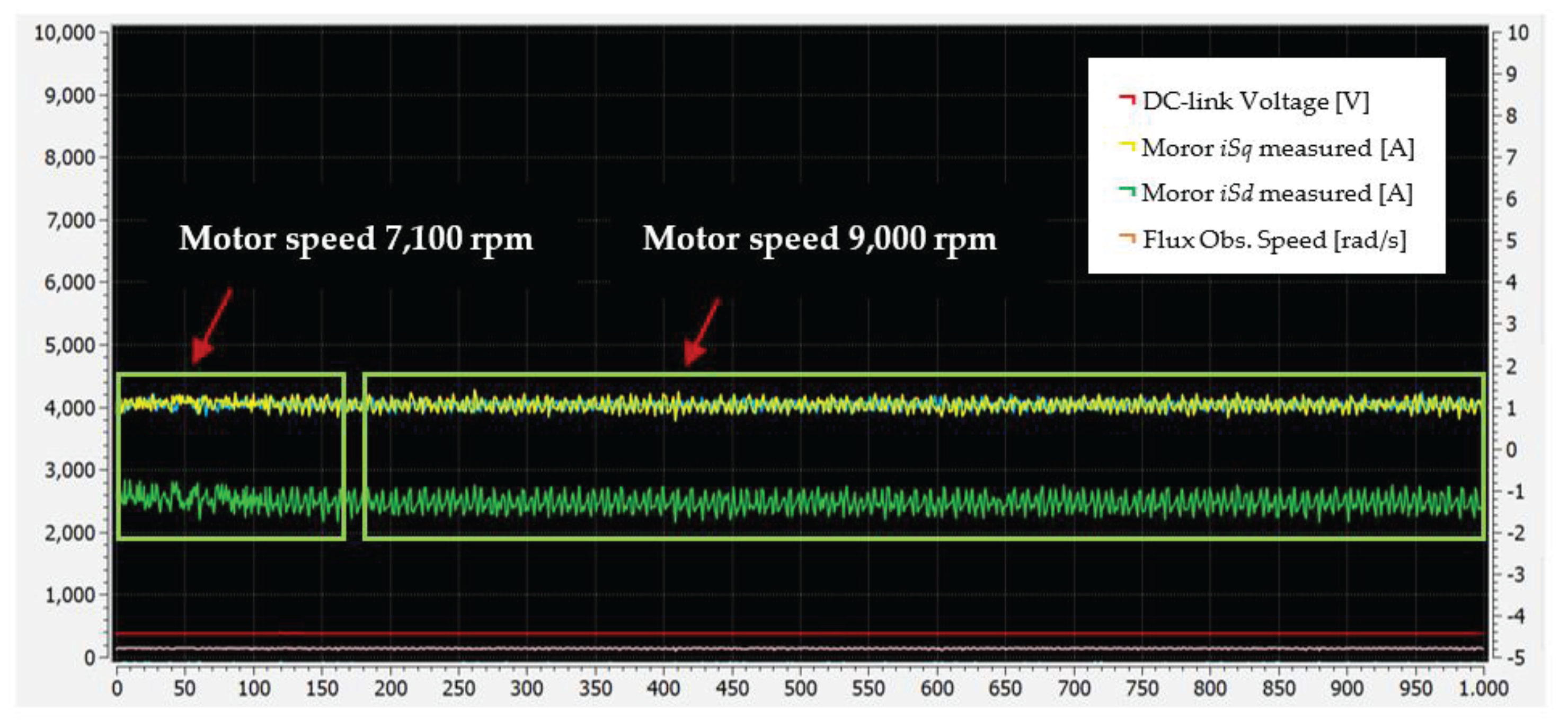

6.3. High Speed Validation

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leonhard, W. Control of Electrical Drives. Berlin, Germany: Springer-Verlag, 1996.

- Santisteban, J.A.; Stephan, R.M. Vector control methods for induction machines: an overview. IEEE Trans. Educ. 2001, 44, 170–175. [CrossRef]

- M. Ahmad, “High Performance AC Drives: Modelling Analysis and Control,” published by Springer-Verlag, 2010.

- AlShanfari, A.K.; Wang, J. Influence of control bandwidth on stability of permanent magnet brushless motor drive for ‘more electric’ aircraft systems. Proc. Int. Conf. Elect. Mach. Syst. (ICEMS) 2011, 1–7.

- www.infineon.com. Available online: https://www.infineon.com/cms/en/product/microcontroller/32-bit-industrial-microcontroller-based-on-arm-cortex-m/32-bit-xmc1000-industrial-microcontroller-arm-cortex-m0/xmc1400/ (05 January 2024).

- www.infineon.com. Available online: https://www.infineon.com/cms/en/product/microcontroller/32-bit-psoc-arm-cortex-microcontroller/psoc-4-32-bit-arm-cortex-m0-mcu/?term=PSoC4&view=kwr&intc=searchkwr (05 January 2024).

- https://www.st.com. Available online: https://www.st.com/content/st_com/en/search.html#q=STM32G0-t=products-page=1 (05 January 2024).

- www.ti.com. Available online: https://www.ti.com/microcontrollers-mcus-processors/arm-based-microcontrollers/products.html (05 January 2024).

- www.nxp.com. Available online: https://www.nxp.com/products/processors-and-microcontrollers/arm-microcontrollers/general-purpose-mcus/lpc800-arm-cortex-m0-plus-:MC_71785 (05 January 2024).

- A. Anuchin, M. Gulyaeva, and F. Briz “Modeling of AC voltage source inverter with dead-time and voltage drop compensation for DPWM with switching loss minimization,” in Proc. the 7 th International Conference on Modern Power Systems 2017, Jul. 2017.

- D. C. Pham, “Modeling and simulation of two level three-phase voltage source inverter with voltage drop,” Seventh Int. Conf. on Information Science and Technology, pp. 317–322, 2017.

- Y. Nakamura, H. Funato, and S. Ogasawara, “Compensation of output voltage distortion analysis of pwm inverter with lc filter caused by device voltage drop,” in Power Electronics and Applications, 2007 European Conference on, pp. 1–9, IEEE, 2007.

- Choi, J.-W.; Sul, S.-K. Inverter output voltage synthesis using novel dead time compensation. IEEE Trans. Power Electron. 1996, 11, 221–227. [CrossRef]

- Leggate, D.; Kerkman, R.J. Pulse-based dead-time compensator for PWM voltage inverters. IEEE Trans. Ind. Electron. 1997, 44, 191–197. [CrossRef]

- Zhang, Z.; Xu, L. Dead-Time Compensation of Inverters Considering Snubber and Parasitic Capacitance. IEEE Trans. Power Electr. 2014, 29, 3179–3187. [CrossRef]

- Urasaki, N.; Senjyu, T.; Uezato, K.; Funabashi, T. An adaptive deadtime compensation strategy for voltage source inverter fed motor drives. IEEE Trans. Power Electron. 2005, 20, 1150–1160. [CrossRef]

- Cichowski, A.; Nieznanski, J. Self-tuning dead-time compensation method for voltage-source inverters. IEEE Power Electron. Lett. 2005, 3, 72–75. [CrossRef]

- G. Zhao S. Nalakath Y. Sun J. Wiseman and A. Emadi "Inverter voltage drop characterisation considering junction temperature effects" Proc. IEEE Transp. Electrific. Conf. Expo. pp. 1-6 Jun. 2019.

- R. Bojoi E. Armando G. Pellegrino and S. G. Rosu "Self-commissioning of inverter nonlinear effects in AC drives" Proc. IEEE Energy Conf. Exhib pp. 213-218 Sep. 9–12 2012.

- Shang, C.; Yang, M.; Long, J.; Xu, D.; Zhang, J.; Zhang, J. An accurate VSI nonlinearity modeling and compensation method accounting for DC-link voltage variation based on LUT. IEEE Trans. Ind. Electron. 2022, 69, 8645–8655. [CrossRef]

- Pellegrino, G.; Bojoi, I.R.; Guglielmi, P.; Cupertino, F. Accurate inverter error compensation and related self-commissioning scheme in sensorless induction motor drives. IEEE Trans. Ind. Appl. 2010, 46, 1970–1978. [CrossRef]

- Tuovinen, T.; Hinkkanen, M. Comparison of a reduced-order observer and a full-order observer for sensorless synchronous motor drives. IEEE Trans. Ind. Appl. 2012, 48, 1959–196. [CrossRef]

- K. Bose, “Modern Power Electronics and AC Drives,” Prentice Hall, Upper Saddle River, 2002.

- Miguel-Espinar, C.; Heredero-Peris, D.; Villafafila-Robles, R.; Montesinos-Miracle, D. Review of Flux-Weakening Algorithms to Extend the Speed Range in Electric Vehicle Applications With Permanent Magnet Synchronous Machines. IEEE Access 2023, 11, 22961–22981. [CrossRef]

- Maksimović, Dragan and Robert W. Erickson. “Advances in Averaged Switch Modeling and Simulation.” (1999).

- https://www.onsemi.com. Available online https://www.onsemi.com/solutions/technology/motor-development-kit-mdk (15 February 2024).

- https://www.onsemi.com. Available online: https://www.onsemi.com/pub/Collateral/AND9390-D.PDF (15 February 2024).

| vam,drop(t)* | vao,drop(t)* | isa | isb | isc |

|---|---|---|---|---|

| -2/3 Vdrop | -1 Vdrop | + | - | + |

| -4/3 Vdrop | -1 Vdrop | + | - | - |

| -2/3 Vdrop | -1 Vdrop | + | + | - |

| +2/3 Vdrop | +1 Vdrop | - | + | - |

| +4/3 Vdrop | +1 Vdrop | - | + | + |

| +2/3 Vdrop | +1 Vdrop | - | - | + |

| SECO-1KW-MCTRL-GEVB | Value | Bosch Motor | Value |

|---|---|---|---|

| PFC output voltage (V) | 380 | Motor nominal power (W) | 545 |

| VSI Switch. Frequency (kHz) | 16 | Motor nominal speed (rpm) | 6,000 |

| Dead-time (us) | 2 (asymm.) | Motor maximum speed (rpm) | 9,500 |

| System efficiency PFC+VSI | 96%??? | Motor winding inductance (mH) | 16 |

| Modulation | SV-PWM | Motor winding resistance (Ω) | 2.5 |

| MCU PWM resolution (bits) | 10.29 | Motor Pole Pairs | 4 |

| 3Actual MCU ADC interval | 6 us | BEMF constant (voltage2/rpm) | 0.028138 |

| Proposed methodology deactivation speed (rpm) | 2,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).