Submitted:

12 March 2024

Posted:

15 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

2.1. Response Surface Methodology

3. Experimental Procedure

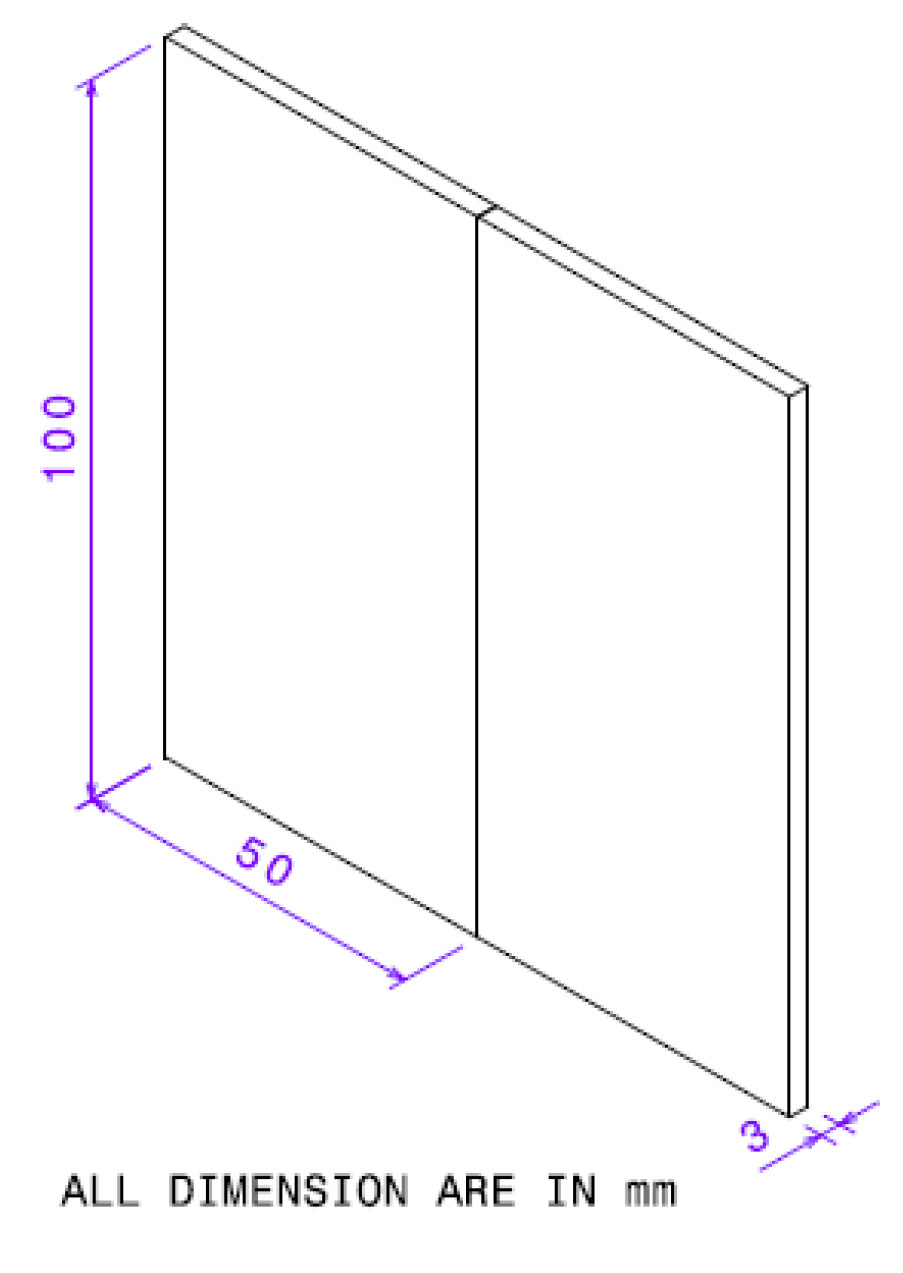

3.1. Dimensions of Butt Joint

3.2. Tool Design

4. Design of Experiments

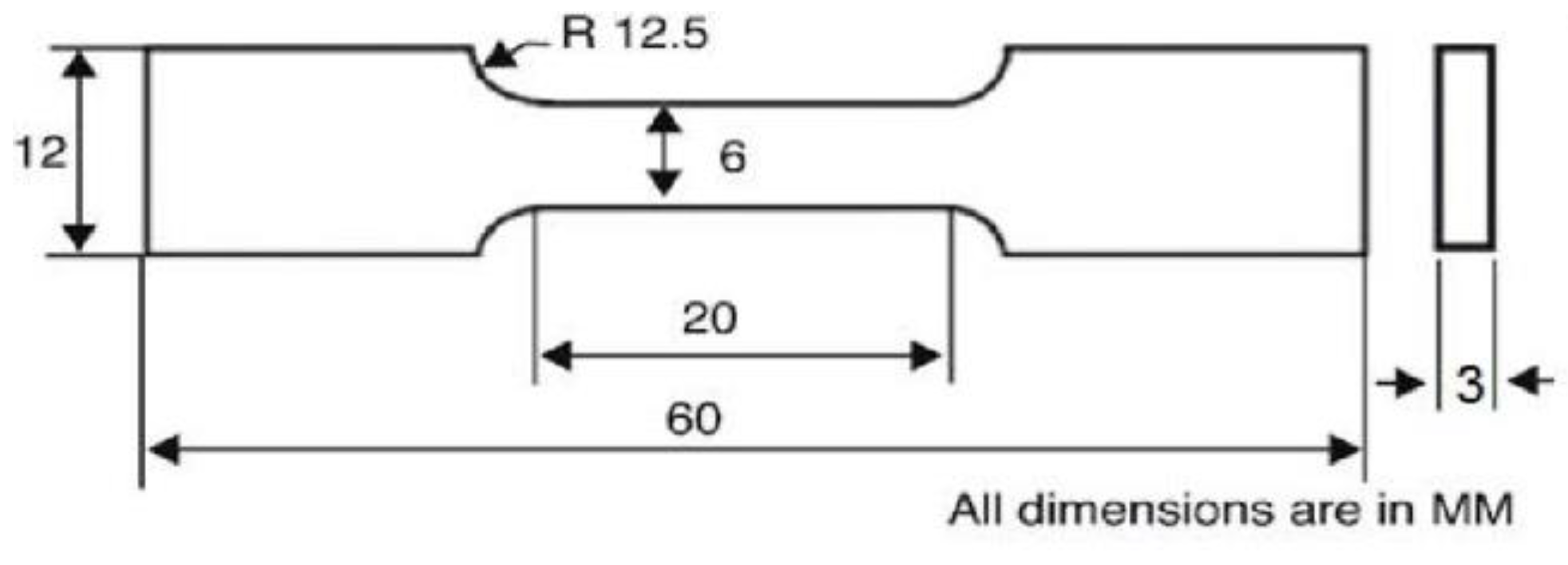

4.1. Specimen Preparation for Tensile Strength

4.2. Specimen Preparation for Hardness

5. Results and Discussion

5.1. Optimization Software

- Factorial Designs – Identify the vital factors that affect your process or product. Then you can make breakthrough improvements.

- Response Surface Methods (RSM) – Find the ideal process settings. Achieve optimal performance.

- Mixture design techniques – Discover the optimal formulation.

- Combined designs - Combine process variables, mixture components and categoric factors in one design.

5.2. Design Matrix with Responses

5.3. Checking for Adequacy of Model

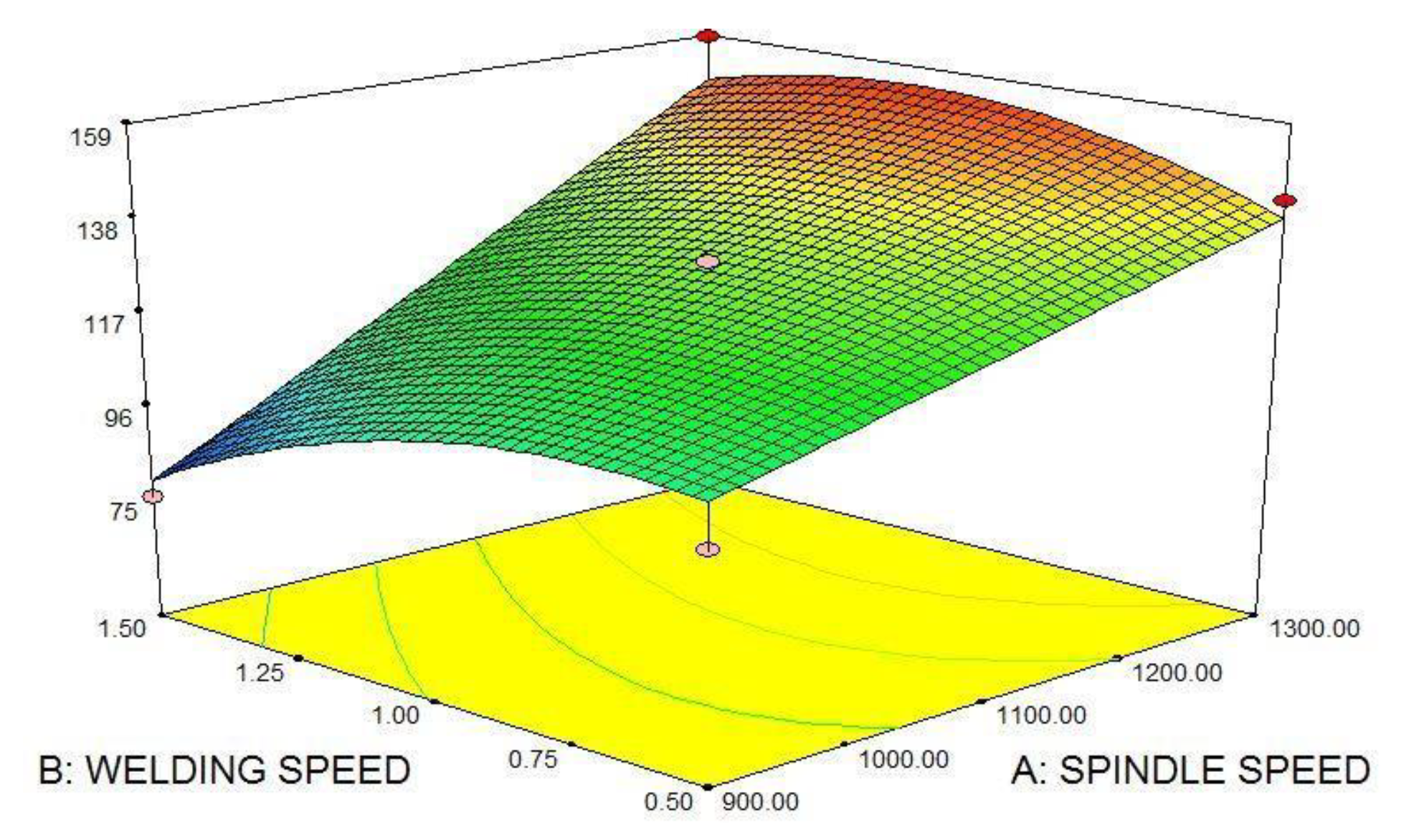

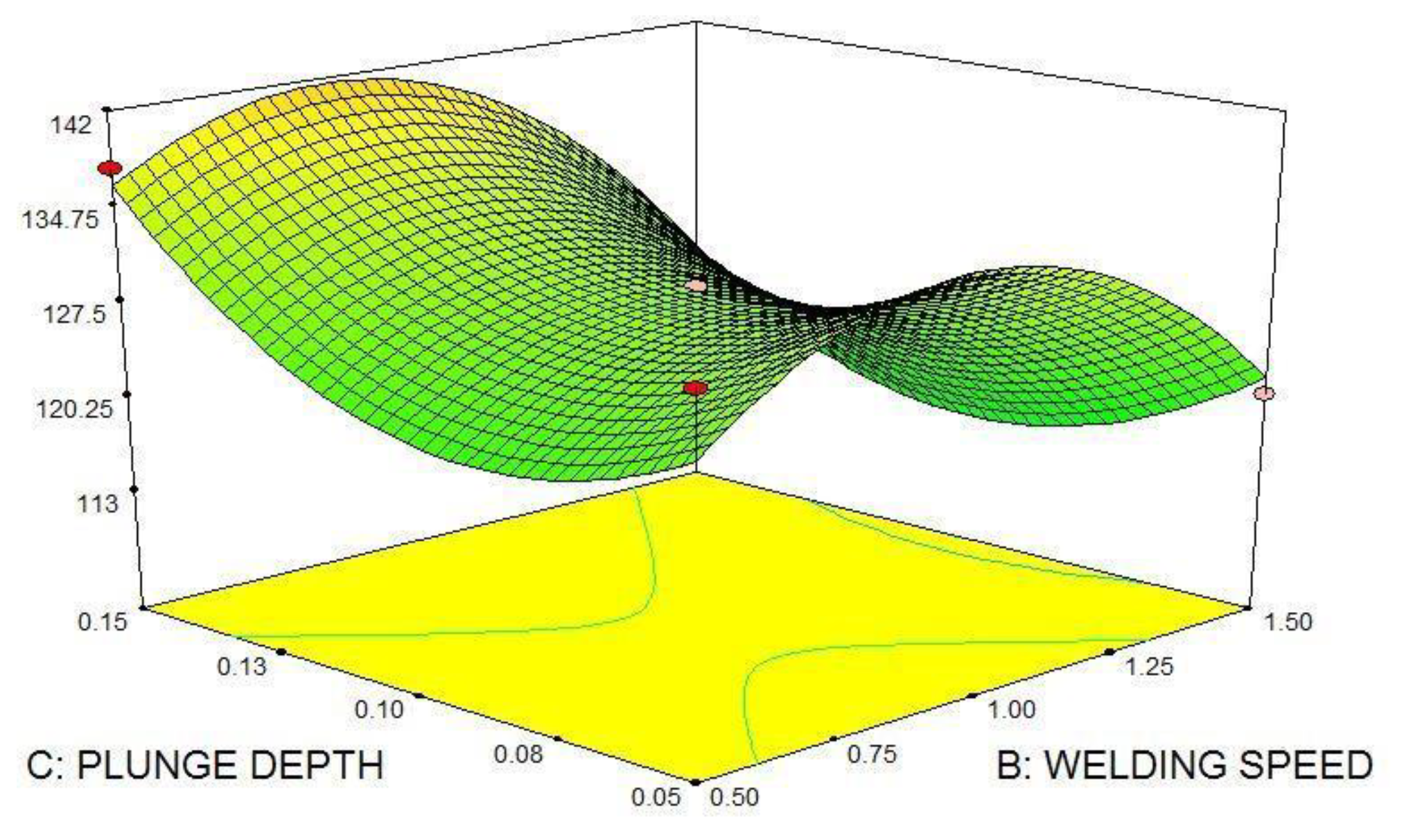

5.4. Effect of Process Parameters on Tensile Strength

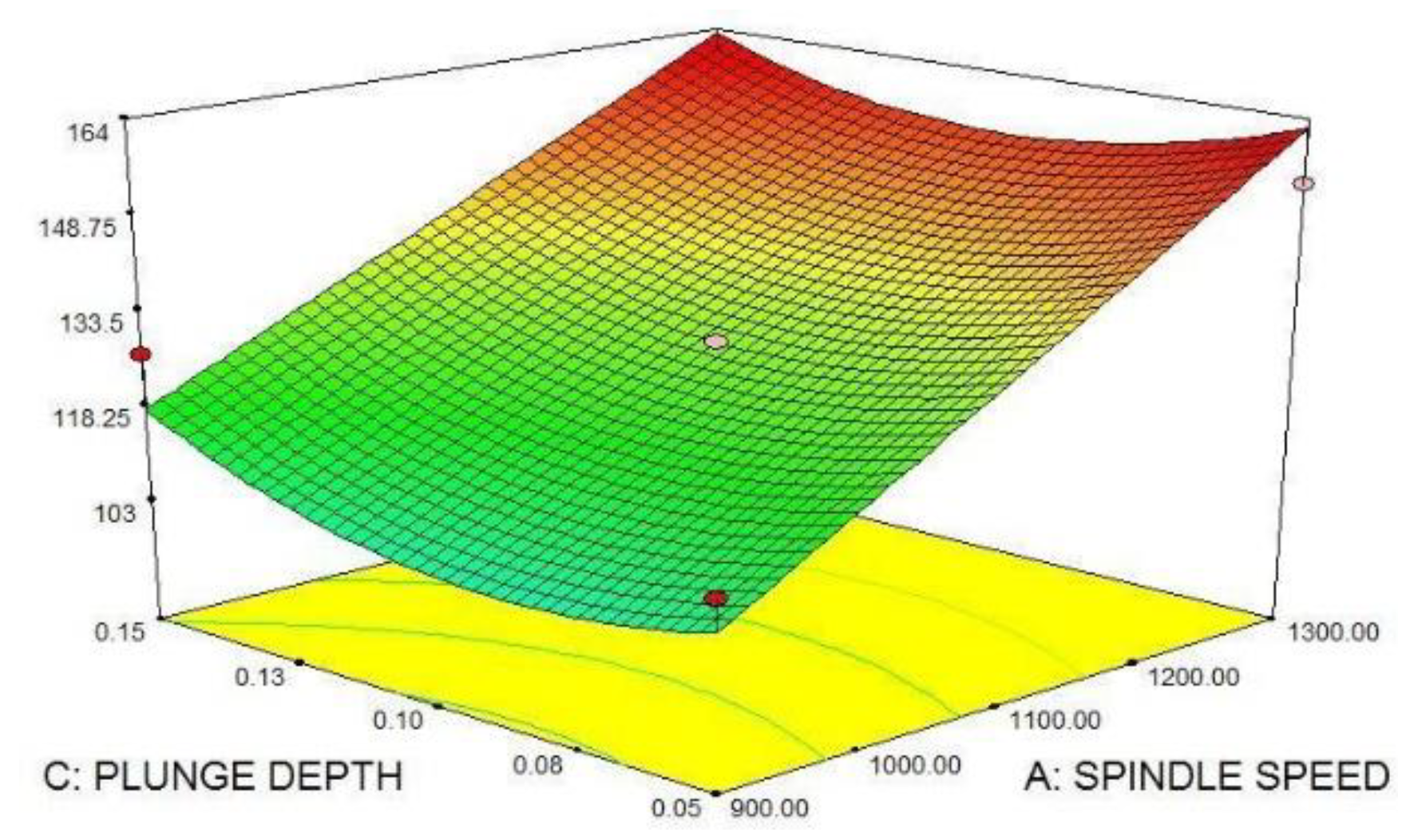

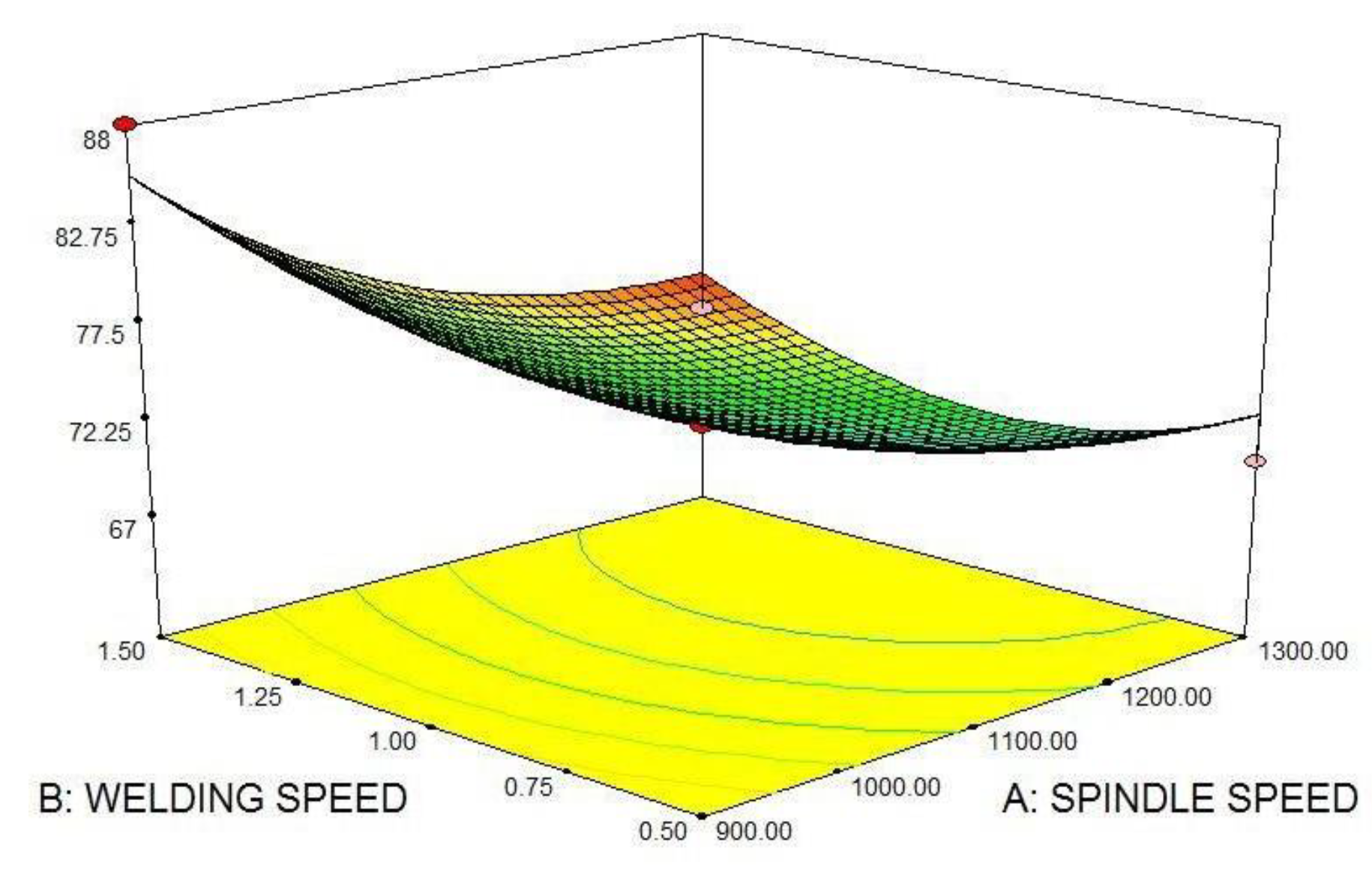

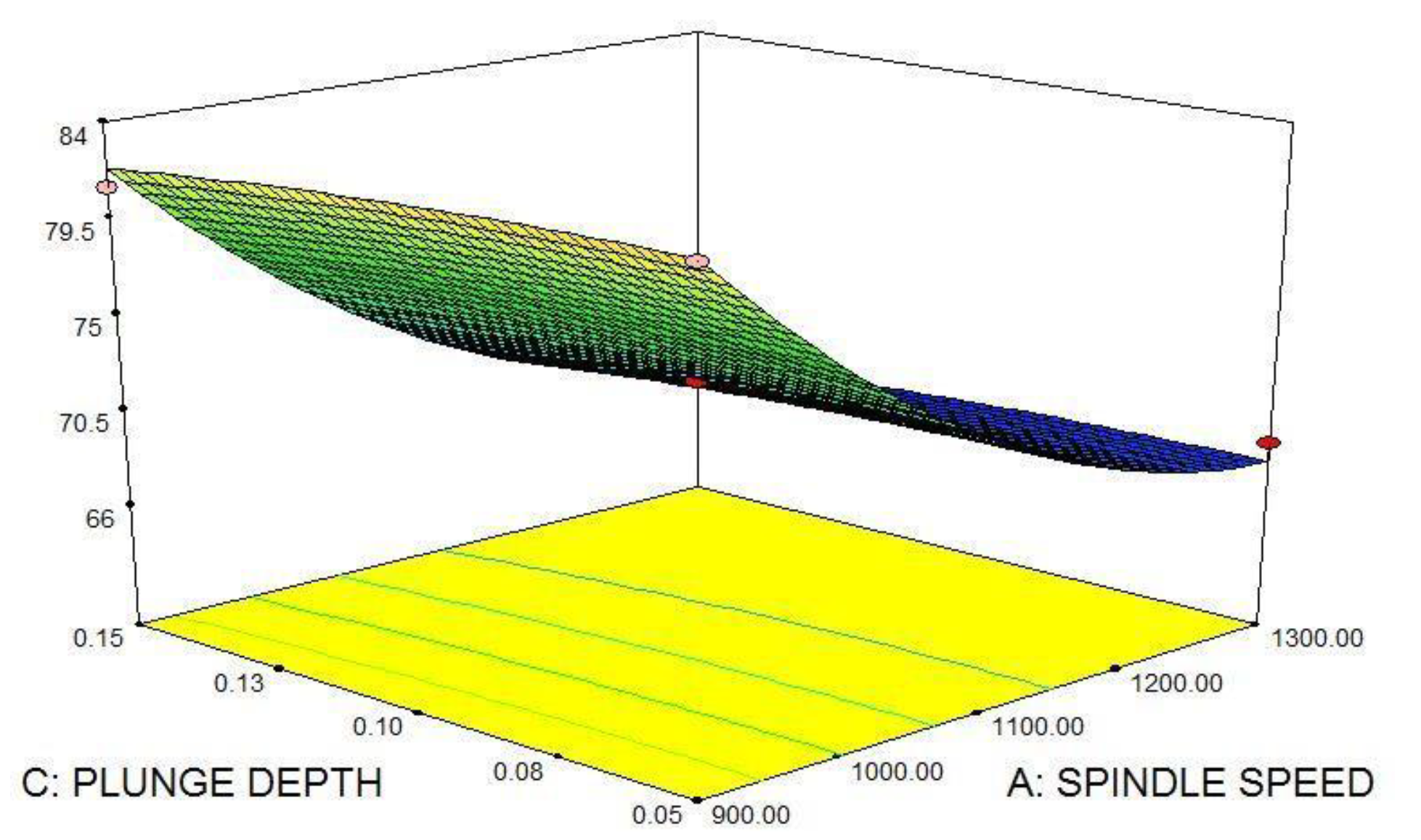

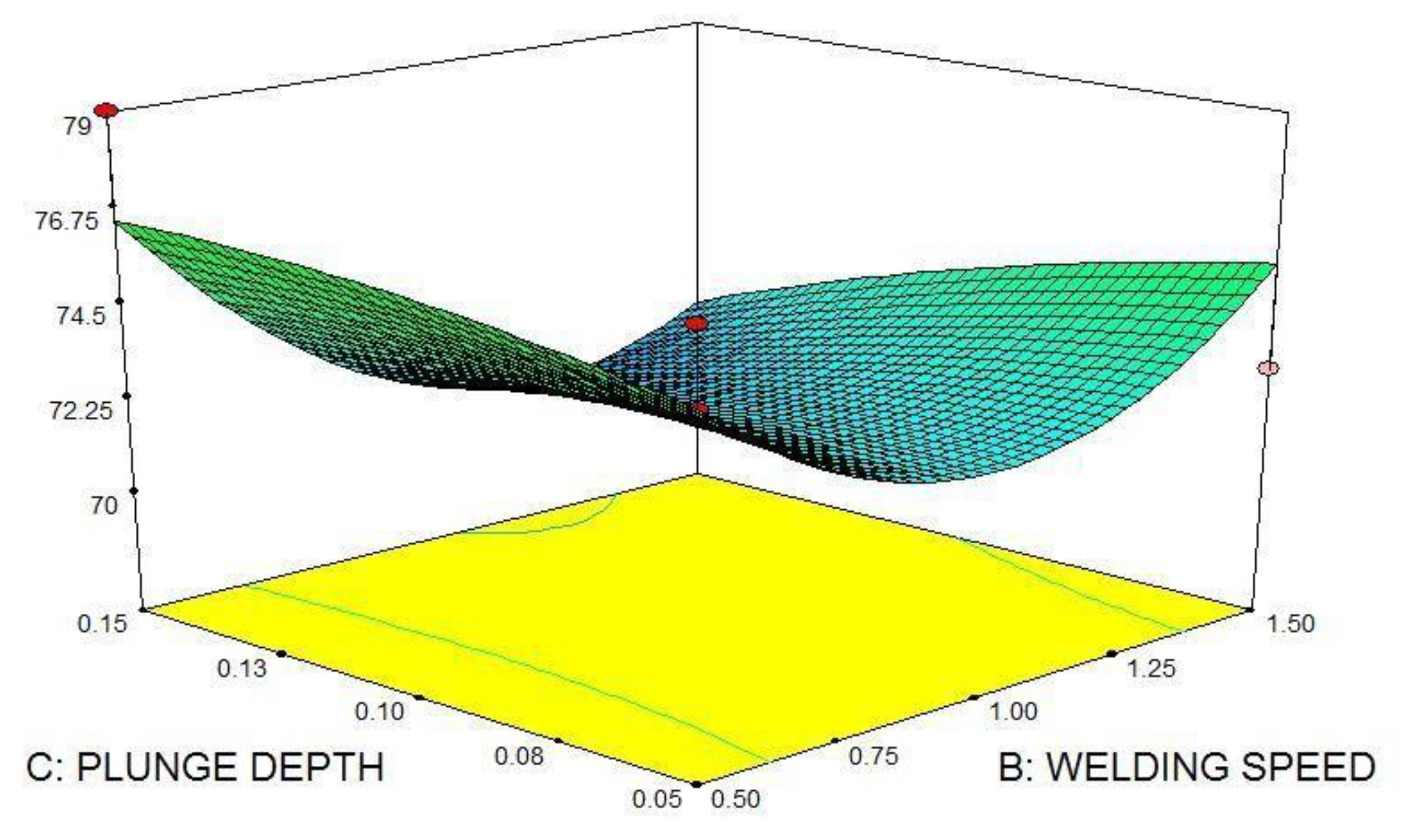

5.5. Effect of Process Parameters on Hardness

5.6. Optimizing the Process Parameters

6. Conclusions

References

- C.Elanchezhian, B.Vijaya Ramnath, P.Venkatesan, S.Sathish,T.Vignesh, R.V.Siddharth, B.Vinay, K. Gopinath “Parameter Optimization of Friction Stir Welding Of AA8011-6062Using Mathematical Method”12th Global Congress On Manufacturing And Management, Gcmm 2014.

- Kadaganchi, R.; Gankidi, M.R.; Gokhale, H. Optimization of process parameters of aluminum alloy AA 2014-T6 friction stir welds by response surface methodology. Def. Technol. 2015, 11, 209–219. [Google Scholar] [CrossRef]

- Panda, M.R.; Mahapatraand, S.S.; Mohanty, C.P. Parametric Investigation of Friction Stir Welding on AA6061 Using Taguchi technique. Mater. Today: Proc. 2015, 2, 2399–2406. [Google Scholar] [CrossRef]

- Padmanaban, R.; Balusamy, V.; Saikrishna, V.; Niranthar, K.G. Simulated Annealing Based Parameter Optimization for Friction Stir Welding of Dissimilar Aluminum Alloys. Procedia Eng. 2014, 97, 864–870. [Google Scholar] [CrossRef]

- Al-Jarrah, J.A.; Swalha, S.; Abu Mansour, T.; Ibrahim, M.; Al-Rashdan, M.; Al-Qahsi, D.A. Optimization of friction stir welding parameters for joining Aluminum alloys using RSM. Adv. Theor. Appl. Mech. 2013, 6, 13–26. [Google Scholar] [CrossRef]

- Elatharasan, G.; Kumar, V.S. An Experimental Analysis and Optimization of Process Parameter on Friction Stir Welding of AA 6061-T6 Aluminum Alloy using RSM. Procedia Eng. 2013, 64, 1227–1234. [Google Scholar] [CrossRef]

- Bisadi, H.; Tavakoli, A.; Sangsaraki, M.T.; Sangsaraki, K.T. The influences of rotational and welding speeds on microstructures and mechanical properties of friction stir welded Al5083 and commercially pure copper sheets lap joints. Mater. Des. 2013, 43, 80–88. [Google Scholar] [CrossRef]

- Palanivel, R.; Mathews, P.K.; Dinaharan, I.; Murugan, N. Mechanical and metallurgical properties of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 58–65. [Google Scholar] [CrossRef]

- Aval, H.J.; Serajzadeh, S.; Kokabi, A. Evolution of microstructures and mechanical properties in similar and dissimilar friction stir welding of AA5086 and AA6061. Mater. Sci. Eng. A 2011, 528, 8071–8083. [Google Scholar] [CrossRef]

- Vaidyanathan, R.M.; Patel, M.; Raman, N.S.; Tedwors, D. EFFECTS OF PROCESS PARAMETERS ON FRICTION STIR WELDING OF 6063 ALUMINUM ALLOY. Int. J. Des. Manuf. Technol. 2015, 6. [Google Scholar] [CrossRef]

- RajKumar, V.; VenkateshKannan, M.; Sadeesh, P.; Arivazhagan, N.; Ramkumar, K.D. Studies on Effect of Tool Design and Welding Parameters on the Friction Stir Welding of Dissimilar Aluminium Alloys AA 5052 – AA 6061. Procedia Eng. 2014, 75, 93–97. [Google Scholar] [CrossRef]

- Prasanna, P.; Penchalayya, C.H.; Rao, D.A. Effect of tool pin profiles and heat treatment process in the friction stir welding of AA 6061 aluminium alloy. Am. J. Eng. Res. 2013, 2, 7–15. [Google Scholar]

- Tolephih, M.H.; Mahmood, H.M.; Hashem, A.H.; Abdullah, E.T. Effect of tool offset and tilt angle on weld strength of butt joint friction stir welded specimens of AA2024 aluminum alloy welded to commercial pure cupper. Chem. Mater. Res 2013, 3, 49–58. [Google Scholar]

- Kumbhar, N.T.; Bhanumurthy, K. Friction stir welding of Al 5052 with Al 6061 alloys. J. Metall. 2012, 2012, 112–119. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Sik, A. Mechanical, fatigue and microstructural properties of friction stir welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 56, 84–90. [Google Scholar] [CrossRef]

| Material | Mg | Si | Mn | Cr | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA6061 | 1.2 | 0.8 | 0.15 | 0.35 | 0.7 | 0.4 | 0.25 | 0.15 | Bal |

| AA8011 | 0.05 | 0.9 | 0.2 | - | 1 | 0.1 | 0.1 | 0.08 | Bal |

| Parameters | Level -1 | Level 0 | Level 1 |

|---|---|---|---|

| Spindle speed(rpm) | 900 | 1100 | 1300 |

| Welding speed(mm/sec) | 0.5 | 1.0 | 1.5 |

| Plunge depth(mm) | 0.05 | 0.10 | 0.15 |

| RUN | SPINDLE SPEED, (rpm) |

WELDING SPEED, (mm/s) |

PLUNGE DEPTH, (mm) |

|---|---|---|---|

| 1 | 1300.00 | 1.00 | 0.15 |

| 2 | 1100.00 | 1.00 | 0.10 |

| 3 | 900.00 | 0.50 | 0.10 |

| 4 | 1300.00 | 1.00 | 0.05 |

| 5 | 900.00 | 1.00 | 0.15 |

| 6 | 1100.00 | 1.00 | 0.10 |

| 7 | 1100.00 | 1.50 | 0.15 |

| 8 | 1100.00 | 1.00 | 0.10 |

| 9 | 900.00 | 1.50 | 0.10 |

| 10 | 1100.00 | 0.50 | 0.15 |

| 11 | 1100.00 | 1.00 | 0.10 |

| 12 | 1300.00 | 0.50 | 0.10 |

| 13 | 1100.00 | 1.50 | 0.05 |

| 14 | 1100.00 | 0.50 | 0.05 |

| 15 | 1300.00 | 1.50 | 0.10 |

| 16 | 900.00 | 1.00 | 0.05 |

| 17 | 1100.00 | 1.00 | 0.10 |

| RUN | SPINDLE SPEED, (rpm) |

WELDING SPEED, (mm/s) |

PLUNGE DEPTH, (mm) |

HARDNESS, (BHN) | TENSILE STRENGTH, (MPa) |

|---|---|---|---|---|---|

| 1 | 1300.00 | 1.00 | 0.15 | 69 | 158.3 |

| 2 | 1100.00 | 1.00 | 0.10 | 77 | 128.9 |

| 3 | 900.00 | 0.50 | 0.10 | 88 | 97.1 |

| 4 | 1300.00 | 1.00 | 0.05 | 79 | 153.7 |

| 5 | 900.00 | 1.00 | 0.15 | 72 | 126.7 |

| 6 | 1100.00 | 1.00 | 0.10 | 72 | 128.9 |

| 7 | 1100.00 | 1.50 | 0.15 | 67 | 118.4 |

| 8 | 1100.00 | 1.00 | 0.10 | 72 | 128.9 |

| 9 | 900.00 | 1.50 | 0.10 | 73 | 75.4 |

| 10 | 1100.00 | 0.50 | 0.15 | 85 | 137.7 |

| 11 | 1100.00 | 1.00 | 0.10 | 72 | 128.9 |

| 12 | 1300.00 | 0.50 | 0.10 | 72 | 142.1 |

| 13 | 1100.00 | 1.50 | 0.05 | 70 | 120.6 |

| 14 | 1100.00 | 0.50 | 0.05 | 71 | 131.2 |

| 15 | 1300.00 | 1.50 | 0.10 | 83 | 158.7 |

| 16 | 900.00 | 1.00 | 0.05 | 81 | 112.3 |

| 17 | 1100.00 | 1.00 | 0.10 | 70 | 128.9 |

| Source | Sum of Squares | df | Mean Square | F Value | p-value Prob > F |

|---|---|---|---|---|---|

| Model | 6458.75 | 9 | 717.64 | 10.33 | 0.0028 |

| A-SPINDLE SPEED | 5065.21 | 1 | 5065.21 | 72.93 | < 0.0001 |

| B-WELDING SPEED | 153.12 | 1 | 153.12 | 2.20 | 0.1812 |

| C-PLUNGE DEPTH | 67.86 | 1 | 67.86 | 0.98 | 0.3558 |

| AB | 366.72 | 1 | 366.72 | 5.28 | 0.0552 |

| AC | 24.01 | 1 | 24.01 | 0.35 | 0.5750 |

| BC | 18.92 | 1 | 18.92 | 0.27 | 0.6178 |

| A2 | 0.042 | 1 | 0.042 | 6.063E-004 | 0.9810 |

| B2 | 479.81 | 1 | 479.81 | 6.91 | 0.0340 |

| C2 | 322.37 | 1 | 322.37 | 4.64 | 0.0682 |

| Residual | 486.15 | 7 | 69.45 | ||

| Lack of Fit | 486.15 | 3 | 162.05 | ||

| Pure Error | 0.000 | 4 | 0.000 | ||

| Cor Error | 6944.90 | 16 |

| Source | Sum of Squares | df | Mean Square | F Value | p-value Prob > F |

| Model | 564.51 | 9 | 62.72 | 11.19 | 0.0022 |

| A-SPINDLE SPEED | 450.00 | 1 | 450.00 | 80.25 | < 0.0001 |

| B-WELDING SPEED | 10.12 | 1 | 10.12 | 1.81 | 0.2209 |

| C-PLUNGE DEPTH | 3.13 | 1 | 3.13 | 0.56 | 0.4797 |

| AB | 1.00 | 1 | 1.00 | 0.18 | 0.6855 |

| AC | 0.000 | 1 | 0.000 | 0.000 | 1.0000 |

| BC | 6.25 | 1 | 6.25 | 1.11 | 0.3261 |

| A2 | 47.96 | 1 | 47.96 | 8.55 | 0.0222 |

| B2 | 41.12 | 1 | 41.12 | 7.33 | 0.0303 |

| C2 | 0.59 | 1 | 0.59 | 0.11 | 0.7547 |

| Residual | 39.25 | 7 | 5.61 | ||

| Lack of Fit | 39.25 | 3 | 13.08 | ||

| Pure Error | 0.000 | 4 | 0.000 | ||

| Cor Total | 603.76 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).