Submitted:

07 March 2024

Posted:

08 March 2024

You are already at the latest version

Abstract

Keywords:

I. Introduction

II. Analysis

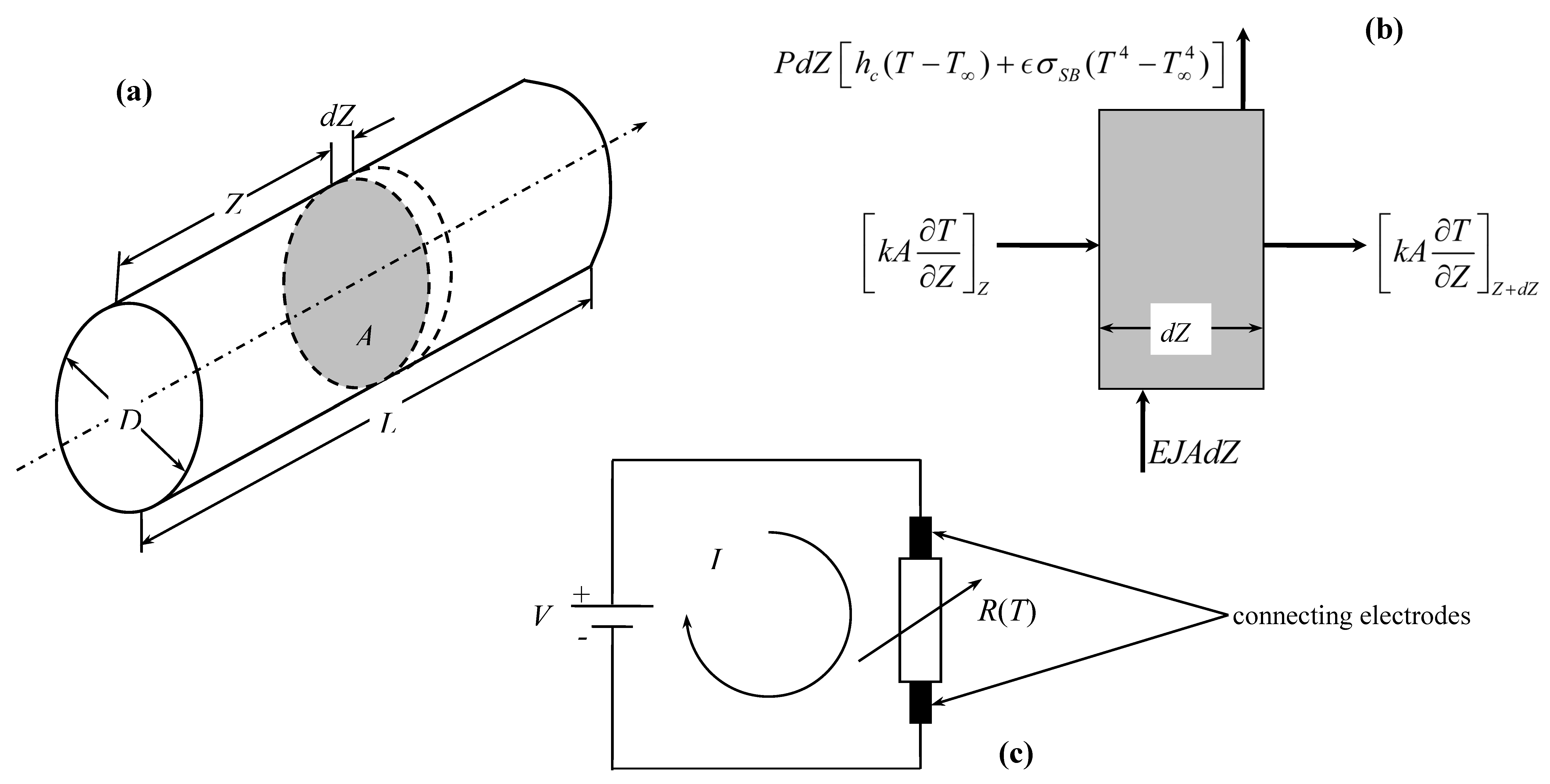

II.1. Energy Balance

II.2. Heat Transfer Model

II.3. Electric Resistivity. The Heywang–Jonker Model

II.4. The Electrothermal Model in Dimensionless Form

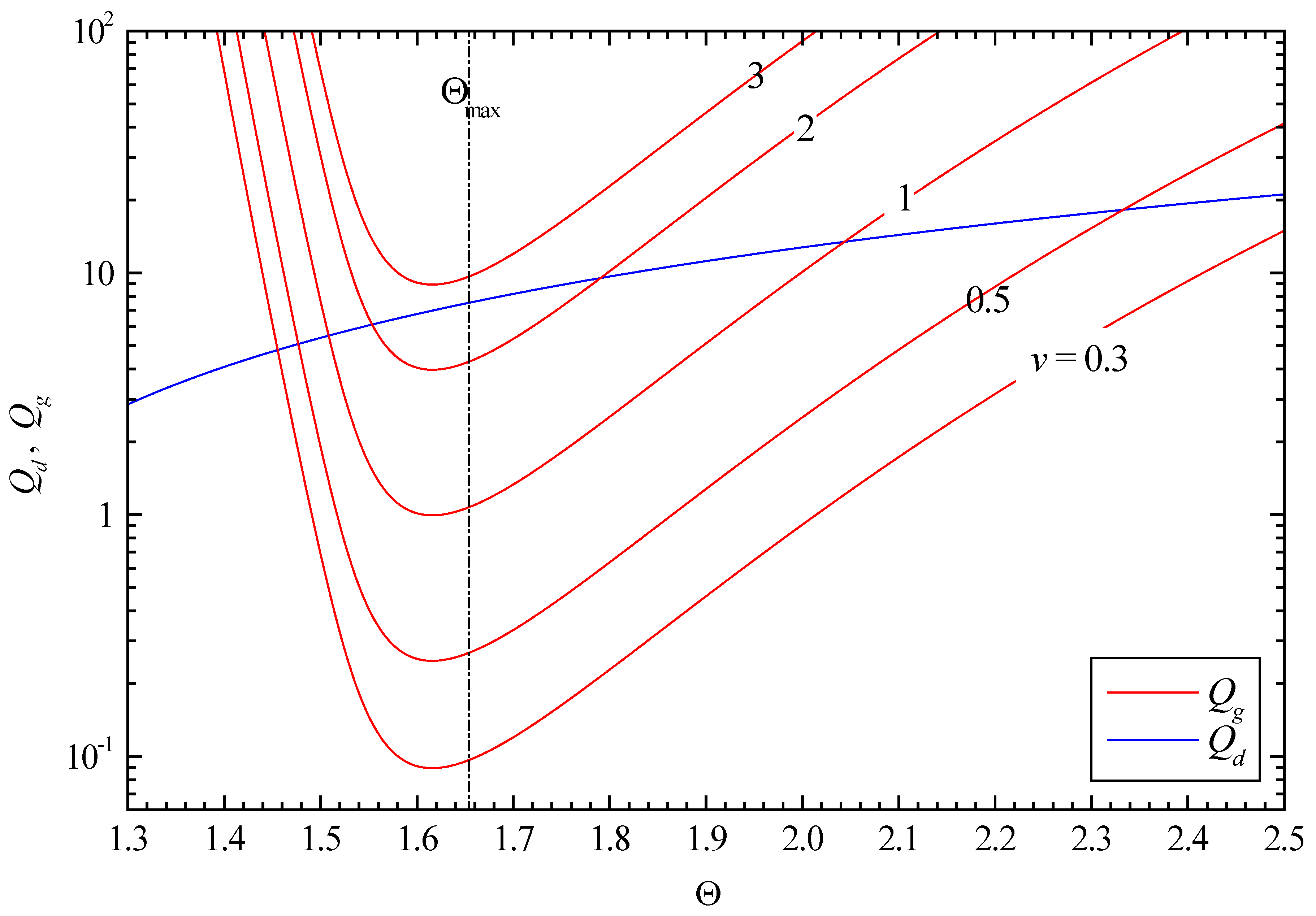

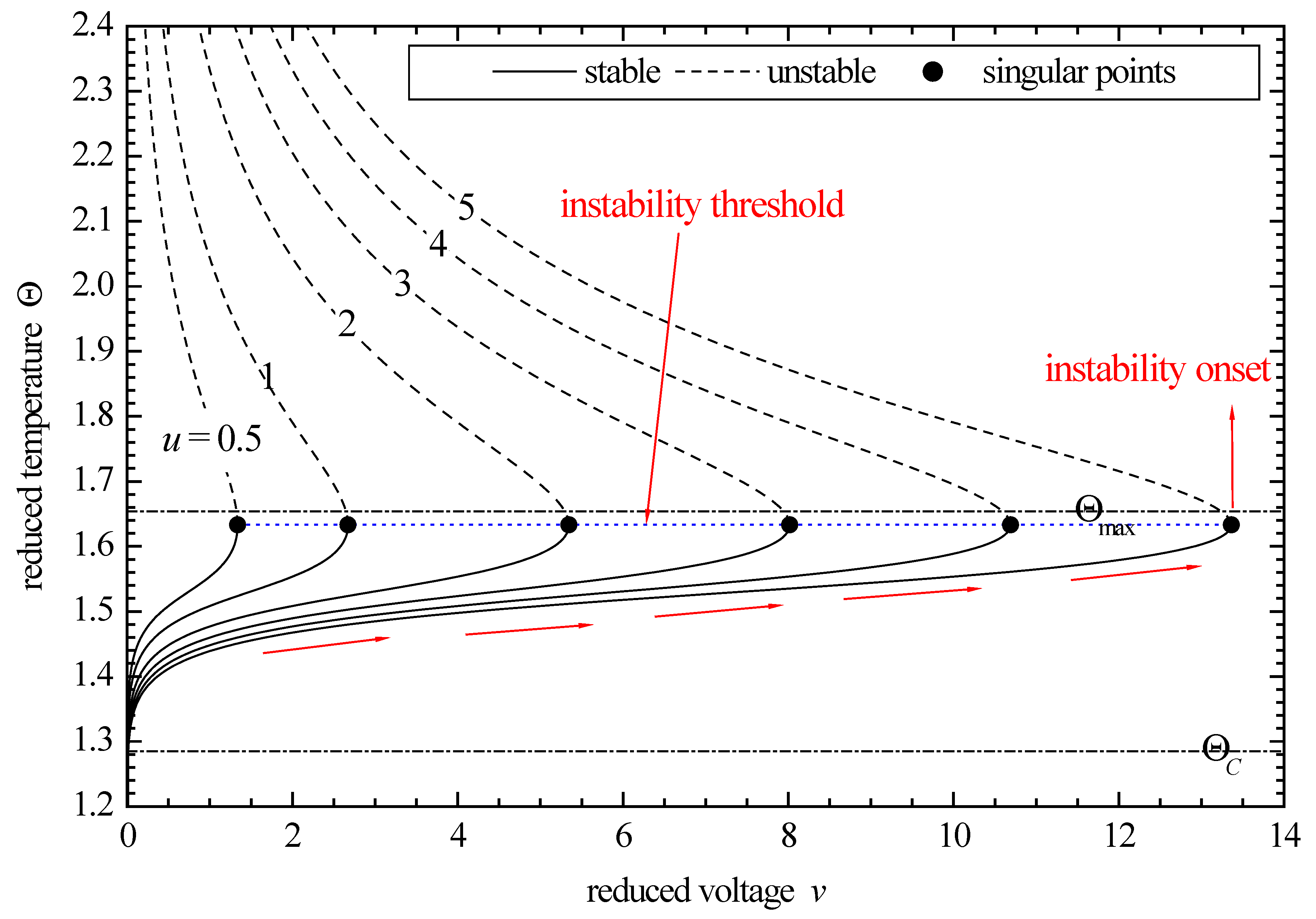

II.5. Stability

III. Numerical Methods

IV. Results and Discussion

IV.1. The Relationship between Temperature and Mechanical Failure

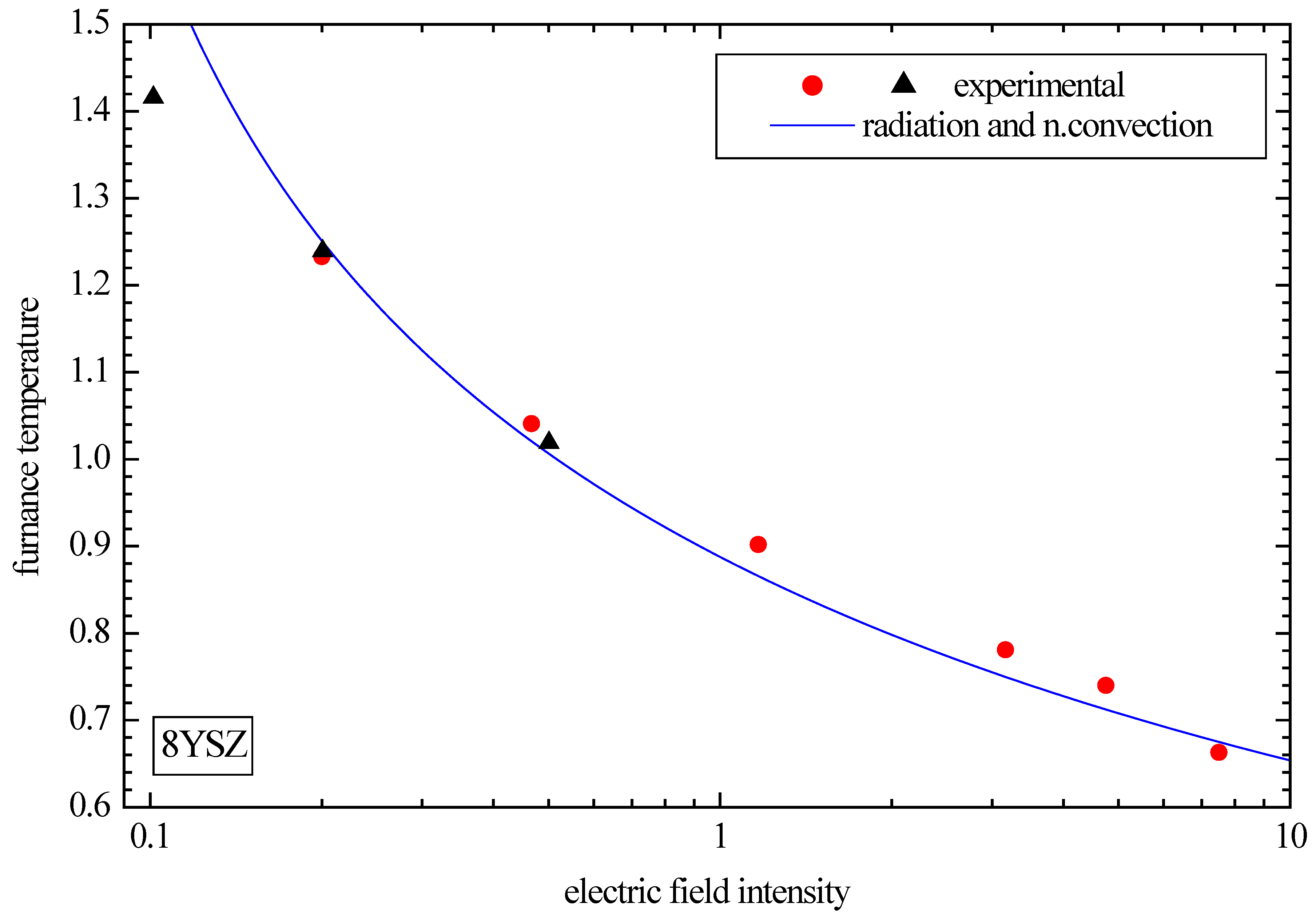

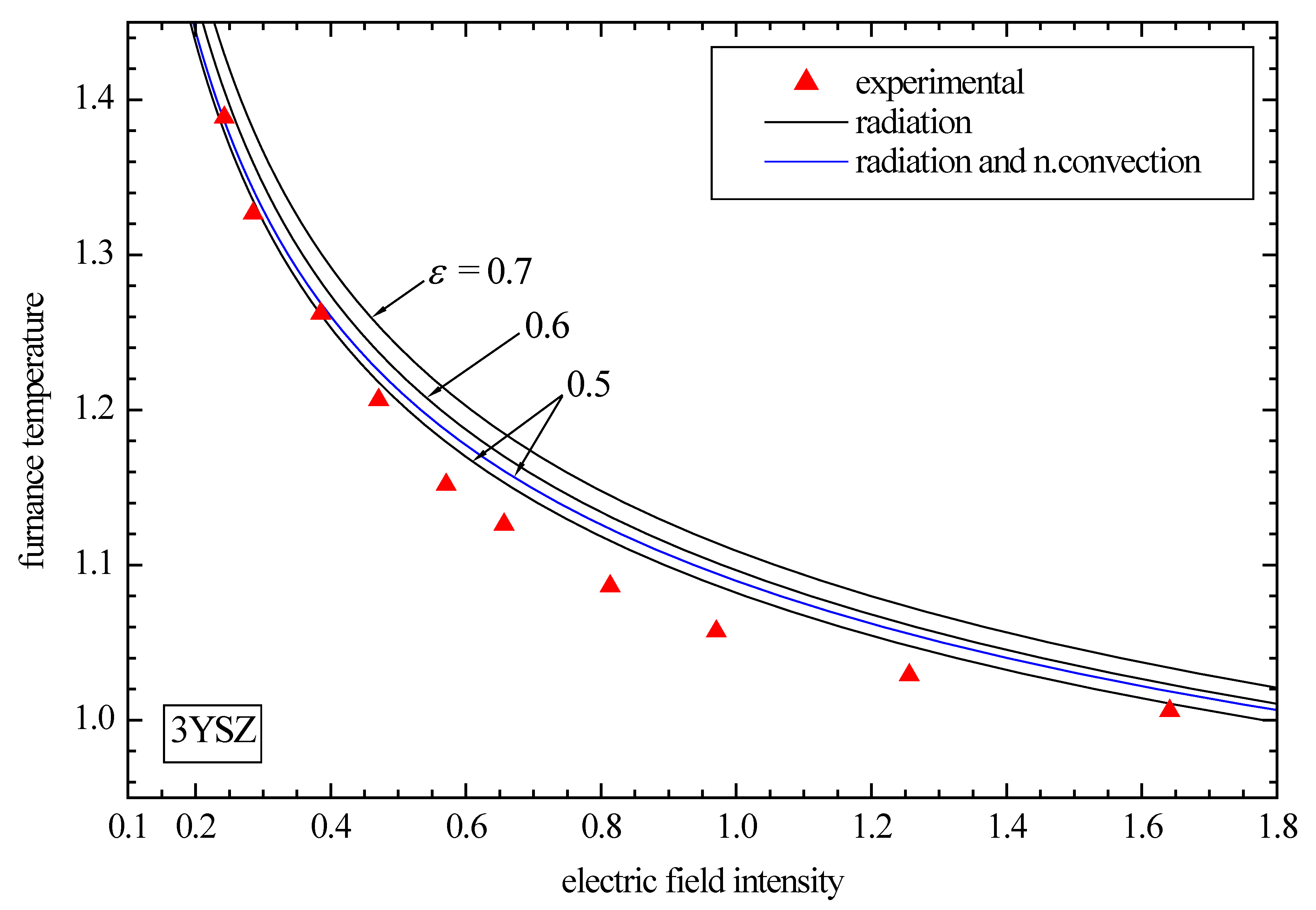

IV.2. Comparison with Experiments

V. Conclusions

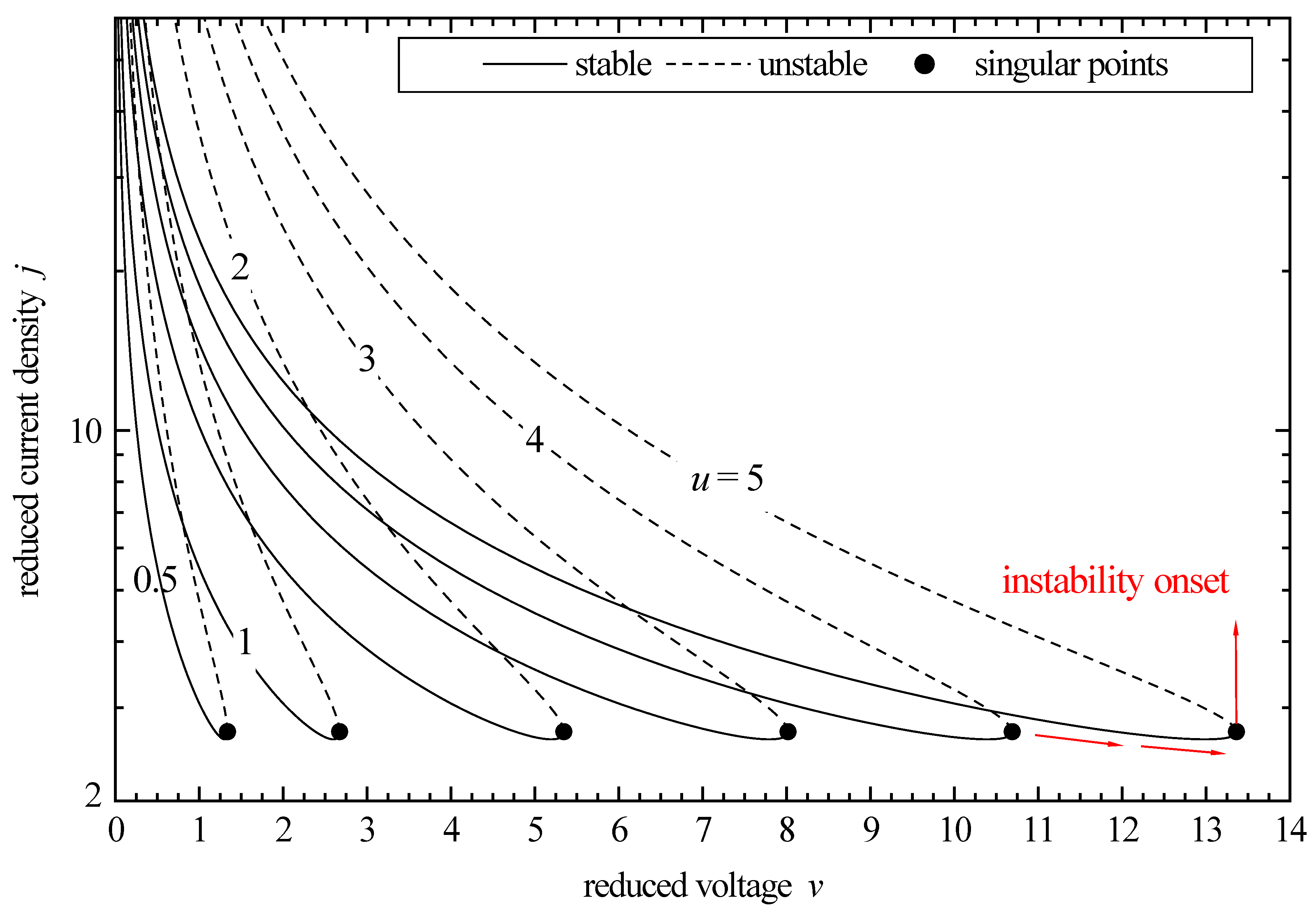

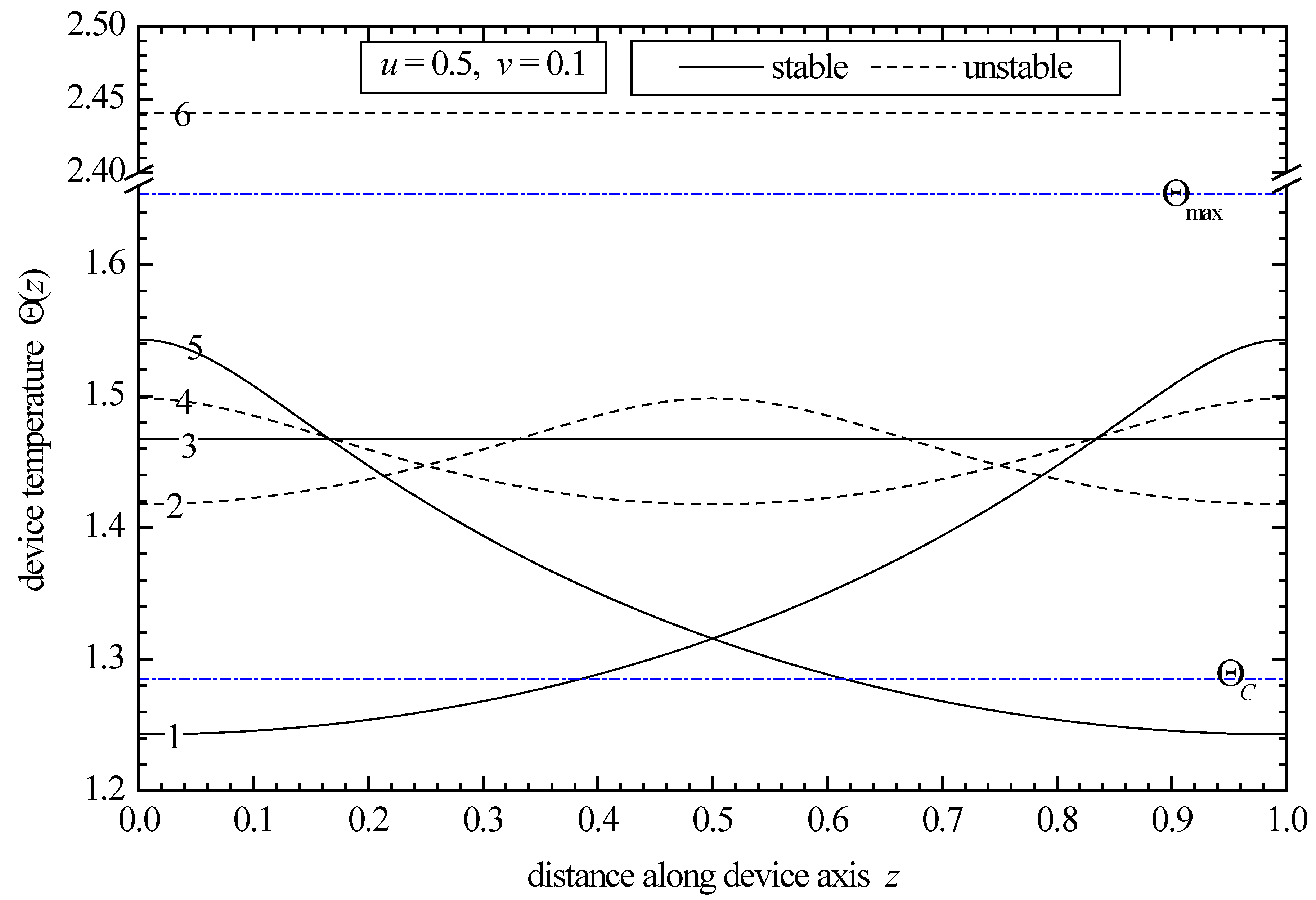

- The PTC effect gives rise to multiple solutions mainly in the temperature range between the Curie and the maximum resistivity points.

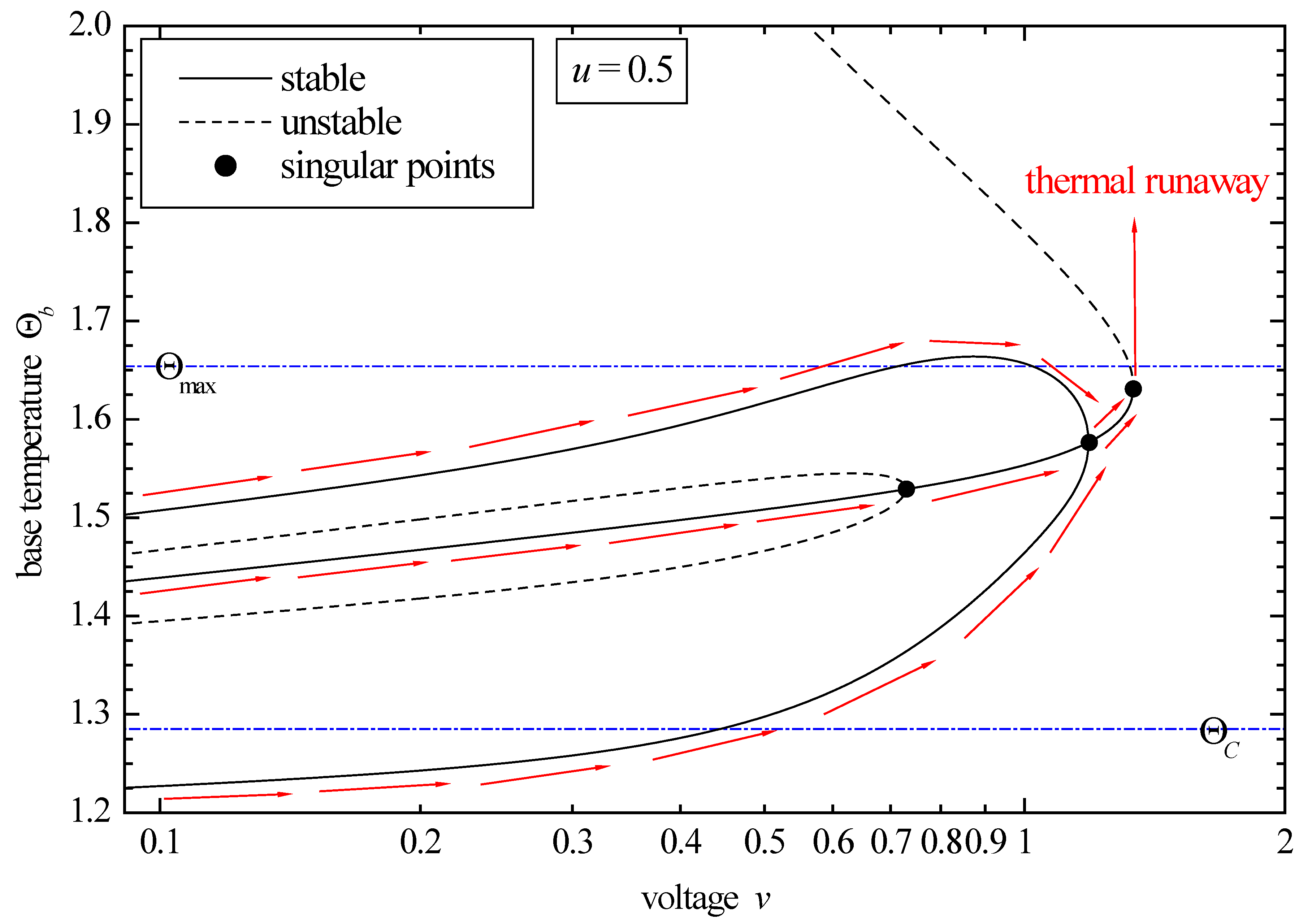

- Thermal runaway is due to the NTC effect. The runaway voltage depends on the conduction–convection parameter u.

- Thermal runaway as a thermal shock is a potential reason for the thermo–mechanical failures observed (delamination fracture).

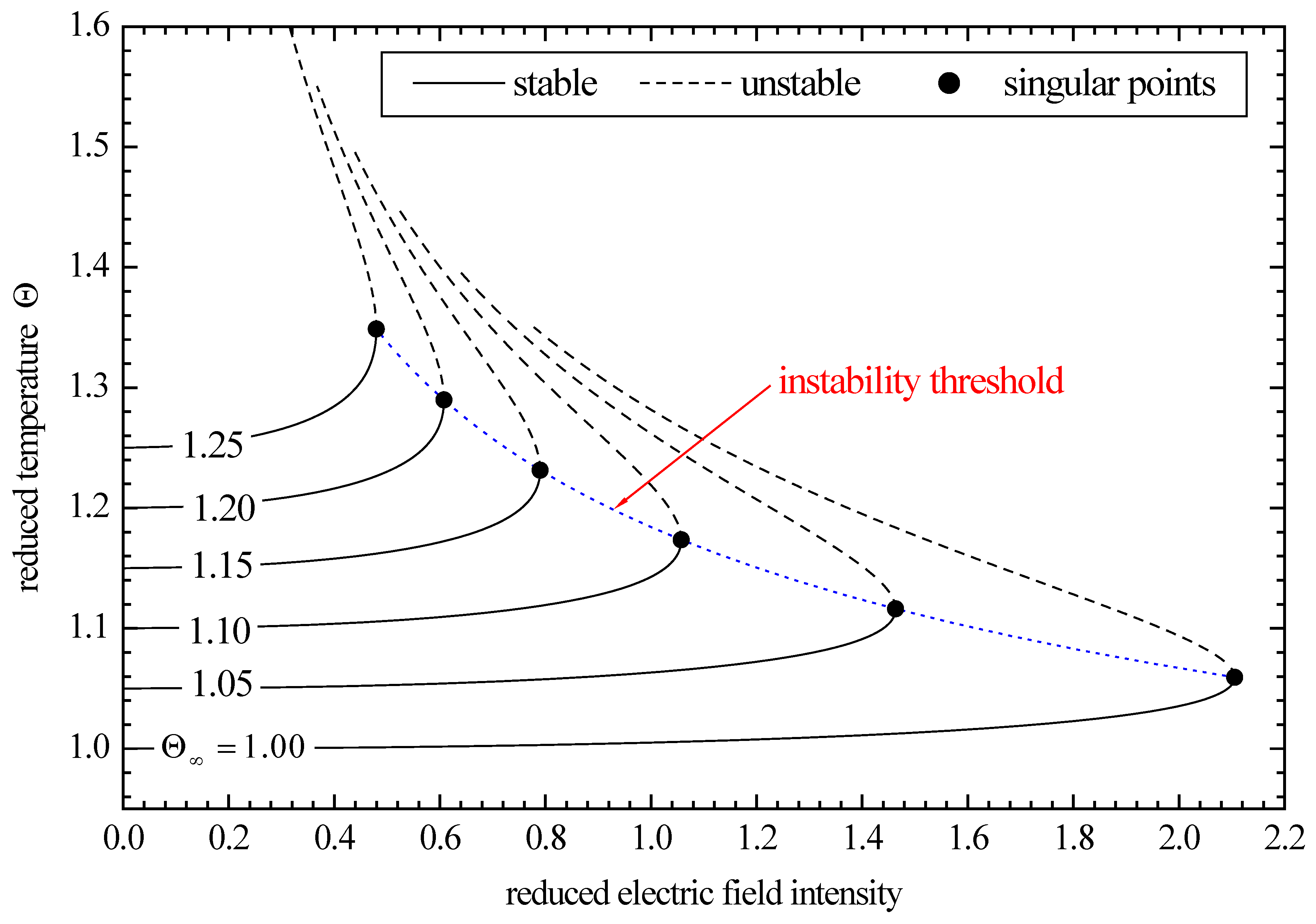

- For the NTC regime (flash sintering) when Neumann boundary conditions are imposed to the distributed model, only uniform solutions are admitted one stable and one unstable.

References

- Haayman, P.; Dam, R.; Klasens, H. Verfahren zur Herstellung halbleitenden Materials. German Patent 929350.

- Huybrechts, B.; Ishizaki, K.; Takata, M. The positive temperature coefficient of resistivity in barium titanate. J. Mater. Sci. 1995, 30, 2463–2474. [Google Scholar] [CrossRef]

- Preis, W.; Sitte, W. Electrical properties of grain boundaries in interfacially controlled functional ceramics. J. Electroceram. 2015, 34, 185–206. [Google Scholar] [CrossRef]

- Danzer, R.; Kaufmann, B.; Supancic, P. Failure of high power varistor ceramic components. J. Eur. Ceram Soc. 2020, 40, 3766–3770. [Google Scholar] [CrossRef]

- Dewitte, C.; Elst, R.; Delannay, F. On the mechanism of delamination fracture of BaTiO3–based PTC thermistors. J. Eur. Ceram. Soc. 1994, 14, 481–492. [Google Scholar] [CrossRef]

- Supancic, P. Mechanical stability of BaTiO3–based PTC thermistors components: experimental investigation and theoretical modeling. J. Eur. Ceram. Soc. 2000, 20, 2009–2024. [Google Scholar] [CrossRef]

- Chlup, Z.; Drdlík, D.; Hadraba, H. Temperature effect on elastic and fracture behaviour of lead-free piezoceramic BaTiO3. J. Eur. Ceram. Soc. 2023, 43, 1509–1522. [Google Scholar] [CrossRef]

- Smith, D.; Ghayoub, N.; Charissou, I.; Bellon, O.; Abélard, P.; Edwards, A. Transient Thermal Gradients in Barium Titanate Positive Temperature Coefficient (PTC) Thermistors. J. Am. Ceram Soc. 1998, 81, 1789–1796. [Google Scholar] [CrossRef]

- Mader, G.; Meixner, H.; Kleinschmidt, P. Study of microscopic heat sources in semiconducting barium titanate ceramics. J. Appl. Phys. 1984, 56, 2832–2836. [Google Scholar] [CrossRef]

- Heinen, B.; Waser, R. Influence of the thickness and area of NiCr/Ag electrodes on the characteristics of BaTiO3–ceramic based positive–temperature–coefficient thermistor. J. Mat. Sci. 1998, 33, 4603–4608. [Google Scholar]

- Karpov, E. Bistability, autowaves and dissipative structures in semiconductor fibers with anomalous resistivity properties. Philosophical Magazine. 2012, 92, 1300–1316. [Google Scholar] [CrossRef]

- Platzer, A.; Supancic, P.; Danzer, R. Thermography and Simulation of Advanced Nonlinear Electroceramic Components. Adv. Engin. Mater. 2006, 8, 1134–1139. [Google Scholar] [CrossRef]

- Krikkis, R. Multiplicity Analysis of a Thermistor problem – A Possible Explanation of Delamination Fracture. J. 2023, 6, 517–535. [Google Scholar] [CrossRef]

- Cimatti, G. Remark on existence and uniqueness for the thermistor problem under mixed boundary conditions. Quart. Appl. Math. 1989, 47, 117–121. [Google Scholar] [CrossRef]

- Fowler, A.; Frigaard, I.; Howison, S. Temperature surges in current-limiting circuit devices. SIAM J. Appl. Math. 1992, 52, 998–1011. [Google Scholar] [CrossRef]

- Howison, S.; Rodrigues, J.; Shilor, M. Stationary solutions to the thermistor problem. J. Math. Anal. Appl. 1993, 174, 573–588. [Google Scholar] [CrossRef]

- Zhou, S.; Westbrook, D. Numerical solutions of the thermistor equations. J. Comput. Appl. Math.; 1997, 79, 101–118. [Google Scholar] [CrossRef]

- Golosnoy, I.; Sykulski, J. Numerical modeling of non-linear coupled thermo-electric problems. A comparative study. COMPEL. 2009, 28, 639–655. [Google Scholar]

- Liero, M.; Koprucki, T.; Fisher, A.; Scholz, R.; Glitzky, A. p–Laplace thermistor modeling of electrothermal feedback in organic semiconductor devices. Z. Angew. Math. Phys. 2009, 66, 639–655. [Google Scholar] [CrossRef]

- Romanovskii, V.; Watanabe, K. Operating modes of high- composite superconductors and thermal runaway conditions under current charging. Supercond. Sci. Technol. 2006, 19, 541–550. [Google Scholar] [CrossRef]

- Krikkis, R. On the Thermal Dynamics of Metallic and Superconducting Wires. Bifurcations, Quench, the Destruction of Bistability and Temperature Blowup. J 2021, 4, 803–823. [Google Scholar] [CrossRef]

- Metaxas, A. Foundations of Electroheat. A Unified Approach; Wiley, 1996. [Google Scholar]

- Lupi, S. Fundamentals of Electroheat. Electrical Technologies for Process Heating; Springer, 2017. [Google Scholar]

- Churchill, S.; Chu, H.H. Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transfer. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Faghri, M.; Sparrow, E. Forced convection in a horizontal pipe subjected to nonlinear external natural convection and to external radiation. Int. J. Heat Mass Transfer. 1986, 23, 861–872. [Google Scholar] [CrossRef]

- Heywang, W. Resistivity Anomaly in Doped Barium Titanate. J. Am. Ceram. Soc. 1964, 47, 484–490. [Google Scholar] [CrossRef]

- Jonker, G. Some aspects of semiconducting barium titanate. Solid State Electron. 1964, 7, 895–903. [Google Scholar] [CrossRef]

- Kulwicki, B.; Purdes, A. Diffusion potentials in BaTiO3 and the theory of PTC materials. Ferroelectrics. 1970, 1, 253–263. [Google Scholar] [CrossRef]

- Ihrig, H.; Puschert, W. A systematic experimental and theoretical investigation of the grain boundary resistivities of n–doped BaTiO3 ceramics. J. Appl. Phys. 1977, 48, 3081–3088. [Google Scholar] [CrossRef]

- Mallick, G.; Emtage, P. Current–Voltage Characteristics of Semiconducting Barium Titanate Ceramic. J. Appl. Phys. 1968, 39, 3088–3094. [Google Scholar] [CrossRef]

- Preis, W.; Sitte, W. Modeling of transport properties of interfacially controlled electroceramics: Application to n–conducting barium titanate. J. Electroceram. 2011, 27, 83–88. [Google Scholar] [CrossRef]

- Kriegsmann, G. Pattern formation in microwave heated ceramics: cylinders and slabs. IMA Journal of Applied Mathematics. 2001, 66, 1–32. [Google Scholar] [CrossRef]

- Wacker, A.; Schöll, E. Criteria for stability in bistable electrical devices with S– or Z–shaped current voltage characteristic. J. Appl. Phys. 1995, 78, 7352–7357. [Google Scholar] [CrossRef]

- Romanowskii, V.; Watanabe, K. Multi-Stable Static Resistive States of High Tc Superconductors With Temperature-Decreasing Power Exponent of Their Voltage-Current Characteristic. IEEE Transactions on Applied Superconductivity. 2010, 20, 2134–2137. [Google Scholar] [CrossRef]

- Fisher, A.; Pfalz, M.; Vandewal, K.; Lenk, S.; Liero, M.; Glitzky, A.; Reineke, S. Full Electrothermal OLED Model Including Nonlinera Self–heating Effects. Phys. Rev. Applied. 2018, 10, 014023. [Google Scholar] [CrossRef]

- Elmer, F. Limit cycles of the ballast resistor caused by intrinsic instabilities. Z. Phys. B–Cond. Mat. 1992, 87, 377–386. [Google Scholar] [CrossRef]

- Krikkis, R. Analysis of High-Temperature Superconducting Current Leads: Multiple Solutions, Thermal Runaway, and Protection. J. 2023, 6, 302–317. [Google Scholar] [CrossRef]

- Gupta, T. Application of Zinc Oxide Varistors. J. Amer. Ceram Soc. 1990, 73, 1817–1840. [Google Scholar] [CrossRef]

- Clarke, D. Varistor Ceramics. J. Am. Ceram Soc. 1999, 82, 485–502. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Cheng, P.; Alim, M. Advances in ZnO–Bi2O3 based varistors. J Mater Sci: Mater Electron. 2015, 26, 4782–4809. [Google Scholar] [CrossRef]

- Mahan, G.; Philipp, H. Theory of conduction in ZnO varistors. J. Appl. Phys. 1979, 50, 2799–2812. [Google Scholar] [CrossRef]

- Blatter, G.; Greuter, F. Carrier transport through grain boundaries in semiconductors. Phys. Rev B. 1986, 33, 3952–3966. [Google Scholar] [CrossRef] [PubMed]

- Greuter, F.; Blatter, G. Electrical properties of grain boundaries in polycrystalline compound semiconductors. Semicond. Sci. Tech. 1990, 5, 111–137. [Google Scholar] [CrossRef]

- Eda, K. Destruction mechanism of ZnO varistors due to high currents. J. Appl. Phys. 1984, 56, 2948–2955. [Google Scholar] [CrossRef]

- Späck-Leigsnering, Y.; Gjonaj, E.; De Gersem, H.; Weiland, T.; Gießel, M.; Hinrichsen, V. Electroquasistatic-Thermal Modeling and Simulation of Station Class Surge Arresters. IEEE Trans. Magn. 2016, 42. [Google Scholar] [CrossRef]

- Seyyedbarzegar, S.; Mirzaie, M. Thermal balance diagram modelling of surge arrester for thermal stability analysis considering ZnO varistor degradation effect. IET Gener. Transm. Distrib. 2016, 10, 1570–1581. [Google Scholar] [CrossRef]

- Likitha, S.; Kanyakumari, M.; Pauly, P.J.; Aradhya, R.S.; Vasudev, N. Estimation of Critical Resistive Leakage Current of polymer housed ZnO surge arrester by electro-thermal modeling. J. Elec. Sys. Inf. Tech. 2018, 5, 861–873. [Google Scholar] [CrossRef]

- Cologna, M.; Raskova, B.; Raj, R. Flash Sintering of Nanograin Zirconia in < 5 s at 850°C. J. Am. Ceram Soc. 2010, 93, 3556–3559. [Google Scholar]

- Todd, R.; Zapata-Solvas, E.; Bonilla, R.; Sneddon, T.; Wilshaw, P. Electrical characteristics of flash sintering: thermal runaway of Joule heating. J. Eur. Ceram. Soc. 2015, 35, 1865–1877. [Google Scholar] [CrossRef]

- Yu, M.; Grasso, S.; Mckinnon, R.; Saunders, T.; Reece, M. Review of flash sintering: materials, mechanisms and modeling. Advances in Applied Ceramics. 2016. [Google Scholar] [CrossRef]

- Biesuz, M.; Sglavo, V. Flash sintering of ceramics. J. Eur. Ceram. Soc. 2019, 39, 115–145. [Google Scholar] [CrossRef]

- Zhou, H.; Li, X.; Zhu, Y.; et al. Review of flash sintering with strong electric field. High Voltage. 2022, 7, 1–11. [Google Scholar] [CrossRef]

- Hewitt, I.; Lacey, A.; Todd, R. A mathematical model for flash sintering. Math. Model. Nat. Phenom. 2015, 10, 77–89. [Google Scholar] [CrossRef]

- Downs, J.; Sglavo, V. Electric Field Assisted Sintering of Cubic Zirconia at 390°C. J. Am. Ceram. Soc. 2013, 96, 1342–1344. [Google Scholar] [CrossRef]

- Dong, Y.; Chen, I.W. Predicting the Onset of Flash Sintering. J. Am. Ceram. Soc. 2015, 98, 2333–2335. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).