1. Introduction

In the recent years and with the raise of the Industry 4.0, simulation and data analytics methodologies have become more relevant due to their capacity of predict results and being more sustainable compared with the traditional approaches. The need of developing lighter materials in aerospace and automotive industry is increasing to improve the fuel efficiency reducing the environmental impact and increasing the payload to be carried out. Multi-material forming has become a solution because of the capacity to reduce the weight by joining dissimilar materials and also to customize the mechanical properties of the final part to fulfil with the in-service requirements.

Because of this, the Mg and Ti alloys specially AZ31B and Ti6Al4V have become more and more popular due to their low density and good specific strength [

1] in the case of Magnesium and their combination of excellent mechanical and physical-chemical properties together with very good strength to weight ratio and superior corrosion resistance [

2].

Within multi-material forming highlights co-extrusion process to obtain bimetallic billets composed of a cylindrical sleeve and core made of different materials. Some application cases of multi-material forming processes with these two alloys that can be highlighted are the ones performed by Fernández et al. [

3,

4] who analysed the effect of the different co-extrusion process parameters by Finite Element Analysis (FEM) simulation using Analysis of Variance (ANOVA) to determine the most relevant ones and also investigated the effect of the selection die material on the co-extrusion process of bimetallic cylindrical billets made of magnesium alloy core and titanium alloy sleeve. Other interesting contributions are the ones performed by Negendanka et al. [

5] who carried out a study about the diffusion layer formation under different die angle values in a Mg–core and Al–sleeve billet or Gall et al. [

6], who studied the co-extrusion of bimetallic Al–Mg billets into hollow profiles by means of Finite Element Method (FEM) simulation together with experiments.

On the other hand, Machine Learning (ML) [

7] has been gaining more relevance in the industry as preferred method to forecast results and anticipate problems [

8] by means of algorithms based on statistical methods to detect patterns from data. Support Vector Machines (SVM) is one of the most popular supervised learning methods within ML. It was introduced by Vladimir Vapnik [

9] in 1995 and its main applications are classification and regression analysis. For this last one is especially interesting the Support Vector Regression (SVR) module implemented within SVM to estimate discrete values and thus predict future results. Some examples of SVR applications in the industry are the prediction of the laser cutting process cost for AISI316L stainless steel [

10], prediction of the cutting force and temperature in bone drilling [

11], prediction of the drilling force drilling an internal hole in carbon-fiber-reinforced polymer (CFRP) [

12] and applied to wear prediction it can be highlighted the research performed by Benkedjouh et al. [

13].

Apart from ML, there are other approaches that allow to take decisions in situations where there are several requirements to fulfil in a complex environment and involving large number of variables. Multi-Criteria Decision Making (MCDM) methods based on multi objective optimization are applied to find the compromise solution to the problem. The first MCDM method was applied by Pareto in 1896 [

14] with his famous 80/20 principle. Another example is Saaty in 1977 [

15], who used multi-criteria models to solve problems with conflicting goals. Several MCDM methods have been developed and applied to support decision-making in different areas such as, manufacturing process selection [

16], supply chain managing contract selection [

17] and material selection [

18]. In this research a combination of VIKOR [

19,

20] together with Entropy weighting methods [

21,

22] has been chosen as MCDM methodology to establish the optimum die material selection.

This study develops two methodologies, one based on SVR and the other applying Entropy weighting method together with MCDM VIKOR, for material selection of the die in a multi-material co-extrusion process to obtain bimetallic billets made of Ti6Al4V-AZ31B. Both methodologies and their results are compared to establish which one gives better results for the problem proposed.

2. Materials and Methods

2.1. Materials, Geometrical Dimensions and Process Parameters

In this study a bimetallic billet made of a Ti6Al4V titanium alloy sleeve and AZ31B magnesium alloy core during a co-extrusion process is analysed.

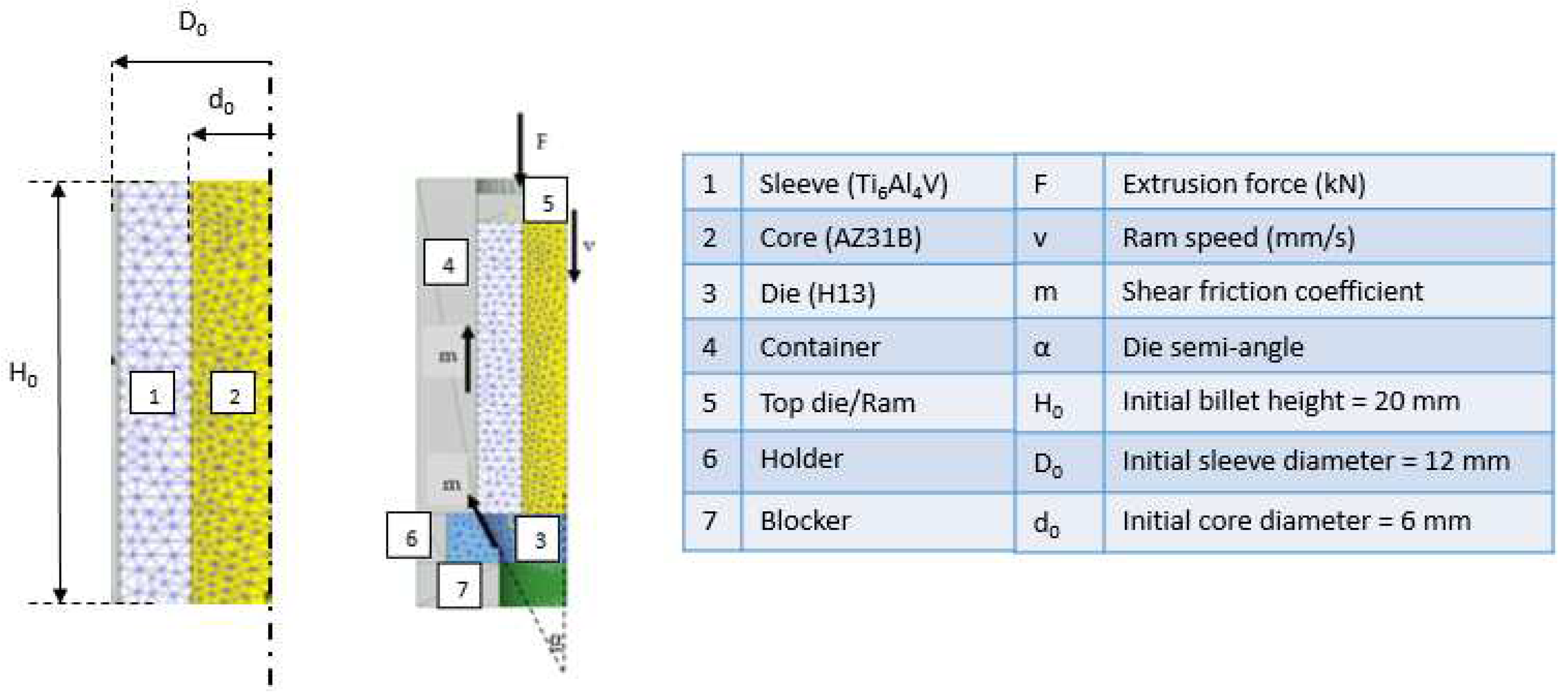

Figure 1 shows the co-extrusion set up with process parameters and initial dimensions.

Main physical and mechanical properties for Ti6Al4V and AZ31B are shown in

Table 1:

Chemical compositions for Ti6Al4V and AZ31B are collected in

Table 2 and

Table 3 respectively:

The material candidates for the die are extracted from Daniel et al. [

4] which chemical composition and physical and mechanical properties are shown in

Table 4 and

Table 5 respectively.

The extrusion process parameters evaluated during this research are the following:

Process parameters: Ram speed (mm/s) and temperature (°C).

Tooling parameters: Die semi-angle (°), shear friction factor, and extrusion ratio (A0/Af).

Geometric parameters: Shape factor (H0/D0) and diameter ratio (D0/d0).

where A0 and Af are the initial and final area of the cross-section of the billet, D0 and d0 the initial external diameter and internal diameter of the sleeve and H0 the initial billet height.

2.2. Finite Element Modeling and Simulation preparation

Commercial software DEFORM3D© (v11.2) [

31] was used to perform finite element simulations.

All parts were meshed with 7000 tetrahedral elements and due to the axial symmetry of the process, only one-quarter of the problem was modeled to reduce the computation time and to avoid heavy database files.

Contact condition among the objects of the simulation is defined as follows. Rigid and elastic objects were considered “masters” (those that deform) and the plastic objects were considered “slaves” (those that are deformed). In the case of the sleeve and core interaction, where both objects are plastic, the titanium alloy was defined as the “master” and the magnesium alloy was defined as the “slave”. All materials were assumed to be isotropic throughout the process.

Heat transfer coefficient between sleeve and core and between sleeve and die was set to 11 N/(s·mm·°C), while between extrusion tooling elements and die was set to 5 N/(s·mm·°C). All the objects of the simulation have 0.02 N/(s·mm·°C) heat transfer coefficient with the air.

The exponential model defined by Wen-juan et al. (2012) [

32] was used to define the behaviour of AZ31B while Johnson-Cook constitutive equations [

33] were used for the definition of stress-strain curves for the Ti6Al4V.

2.2.1. Tool wear model

Archard’s wear model is used to calculate the wear produced on the surface of the die [

34,

35,

36]. This model is based on Equation (1):

where K is the wear coefficient, P is the interface pressure, v is the sliding velocity between die and billet, H is the hardness and a, b and c are experimentally calibrated coefficients.

The commonly taken value for a and b is 1 while for c is 2 in the case of steel alloys.

K = 2 × 10−5.

Taking into account Equation (1) the parameters to evaluate the wear are ram speed and friction as they can influence in the sliding velocity together with temperature because it has a direct influence in the stress-strain curves.

2.3. Support Vector Regression

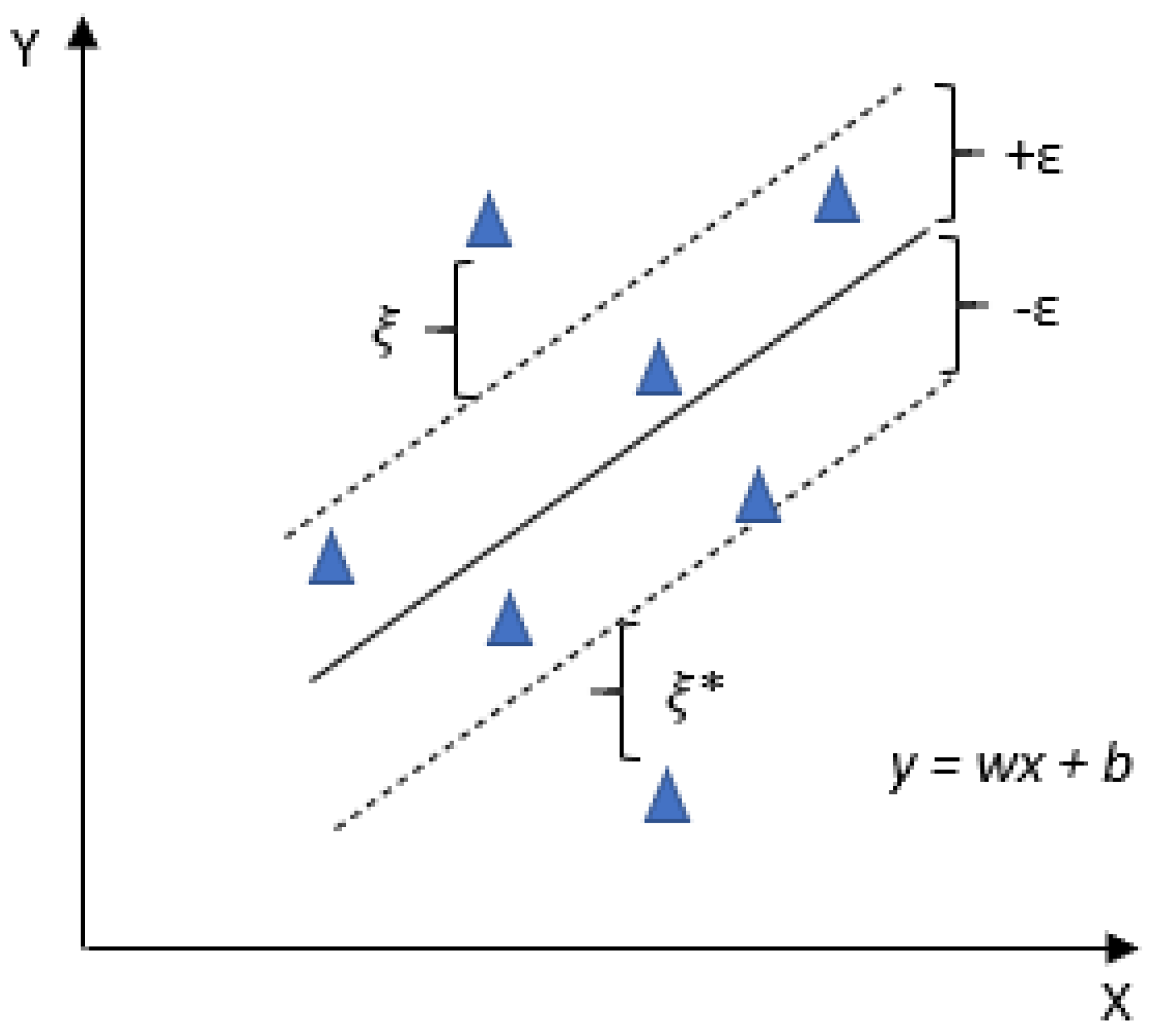

SVM works by finding a hyperplane in a high-dimensional space that best separates data into different classes. It aims to maximize the margin (the distance between the hyperplane and the nearest data points of each class) while minimizing classification errors. SVM can handle both linear and non-linear classification problems by using various kernel functions. Unlike SVM used for classification tasks, SVR seeks to find a hyperplane that best fits the data points in a continuous space.

SVR [

37] gives the flexibility to define how much error is acceptable in our model and will find an appropriate line (or hyperplane in higher dimensions) to fit the data. Therefore, the goal of SVR is to find a function that approximates the relationship between the input variables and a continuous target variable, while minimizing the prediction error.

As it was said before the idea is to minimize the Equation (2), taking into account the constraints of Equations (3), (4) and (5):

where ε is the margin of error while ξ is the deviation from ε also called tolerance margin and w is the classification vector. C is known as the regularized parameter.

The prediction error can be calculated in different ways. One of the most representative is the determination factor (R

2) which shows the quality of correlation between the real measured data and the value predicted by Equation (6). A more precise correlation will be obtained for the value of the determination factor nearer to 100%.

where is the measurement data,

is the predicted magnitude in accordance with SVR,

is the mean of the measurement data and

is the mean of the prediction.

2.4. Entropy method

Entropy method [

21,

22] is classified within the category of objective weighting methods and it is applicable when the data of decision matrix are known. The entropy is a measure of randomness and disorder in the universe.

Starting with the decision matrix D the project outcomes

pij are calculated by means of Equation (7).

where

n is the number of criteria and

m the number of alternatives.

The entropy measure of project outcomes is obtained as it is shown in Equation (8).

With k = 1/ln (m).

Objective weight-based definition is given by Equation (9).

2.5. VIKOR method

VIKOR method [

38,

39] stands for VIseKriterijumska Optimizacija I Kompromisno Resenje, which means Multi-criteria Optimization and Compromise Solution.

This methodology is based on the concept that the compromise solution is the one which is at minimum distance for the ideal solution and at the same time at maximum distance for the anti-ideal solution. VIKOR request a validation step before declaring the compromise solution feasible.

After the criteria to be evaluated are defined the decision matrix (D) is built.

At this point, the best and worst for each criteria rating values of the decision matrix.

Whether the objective is to maximize the criteria.

Whether the objective is to minimize the criteria.

Where b = 1 …m being m the number of criteria took into account and i = 1 …n and n is the number of the alternatives.

Utility measure (S

j) and Regret measure (R

j) are calculated according with Equations (10) and (11):

where W

b are the weight values obtained in the case of this study after applied Entropy weighting methods explained above.

Index Q can be obtained by means of the Equation (12):

υ is a parameter which represents the type of voting used during the process (υ > 0.5 means “vote by majority rule”, υ = 0.5 “vote by consensus” and υ < 0.5 “with vote”).

The lowest Qa value indicates the best alternative solution and it can be recommended if the following conditions are satisfied:

The “acceptable advantage” condition means that Q(a’’) – Q(a’)

DQ. Being a’’ the alternative in second position in the ranking list by Q

a and a’ the first one. DQ is defined by Equation (13):

where n is the number or alternatives.

Finally, the “Acceptable stability in decision making” condition implies that a’ alternative must also be the best ranked in Sj and/or Rj. If one of the conditions is not fulfilled, then a set of compromise solutions is proposed.

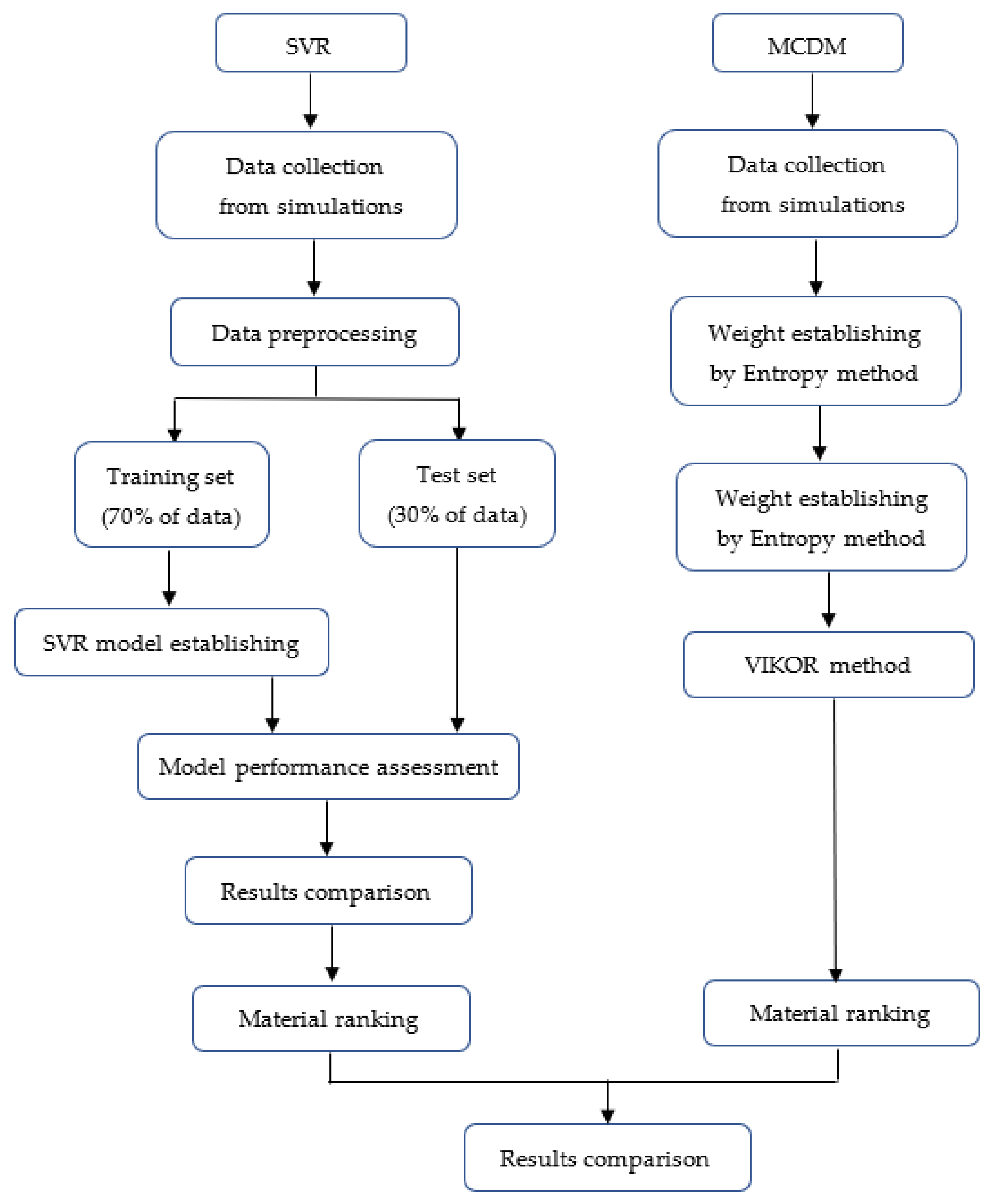

2.5. Methodology

Two different methodologies have been proposed for the selection of the optimal die material in order to obtain the minimum extrusion force and die wear. The methodology steps are shown in

Figure 3 flowchart.

The criteria for the final results comparison are:

- ➢

Simplicity.

- ➢

Amount of data from simulations.

- ➢

Time consuming.

The prediction was carried out in Python software [

40].

3. Results

In this paper a set of simulations of a multi-material co-extrusion process have been performed by using commercial software DEFORM3D© (v11.2) followed by application of two different methodologies to choose which is the best die material to obtain minimum extrusion force and minimum wear during the process. For the list of simulations carried out in the present work see

Table A1 in the

Appendix A.

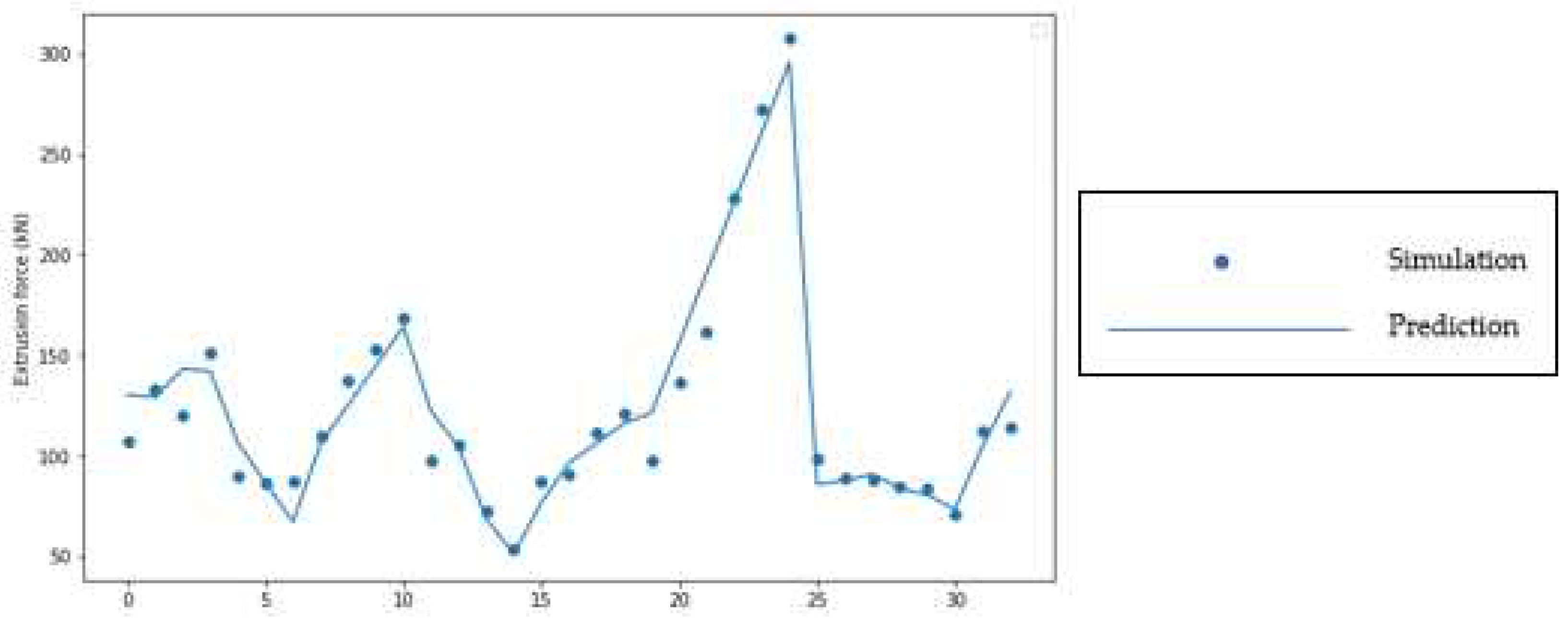

3.1. SVR Methodology

As explained above the dataset is obtained from

Table 6 and for each material and each parameter to be predicted, several dataframes were obtained by using “pandas” together with “sklearn” libraries.

Using “RFE” module for Regression Feature Selection from “sklearn.feature_selection” together with “SVR” module from “sklearn.svm”, the influence of the process parameters are ranked in accordance with their influence in the extrusion force as it is shown in

Table 6.

Taking into account these results, it can be said that friction is the most important process parameter while temperature is the less important one. As there is not a clear pattern about the influence of each process parameters and this influence is clearly dependent on the die material, for the prediction model all the parameters will be implemented.

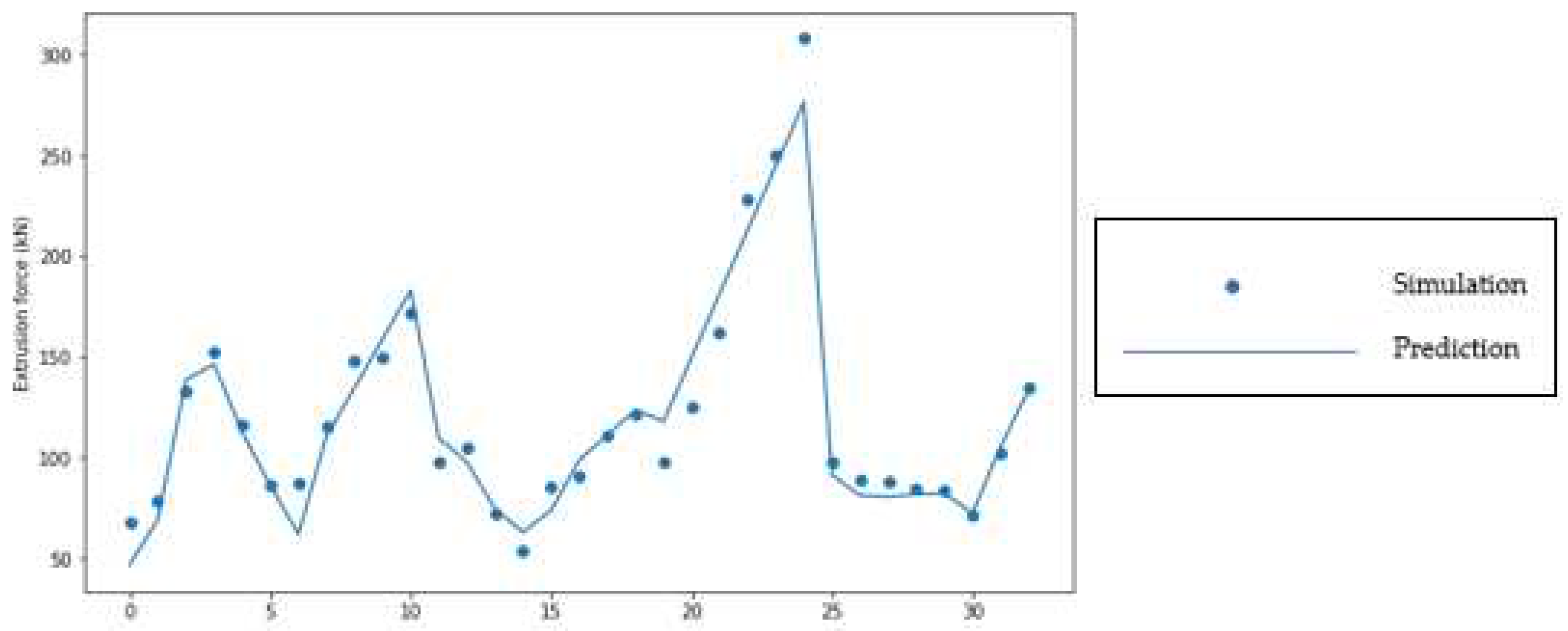

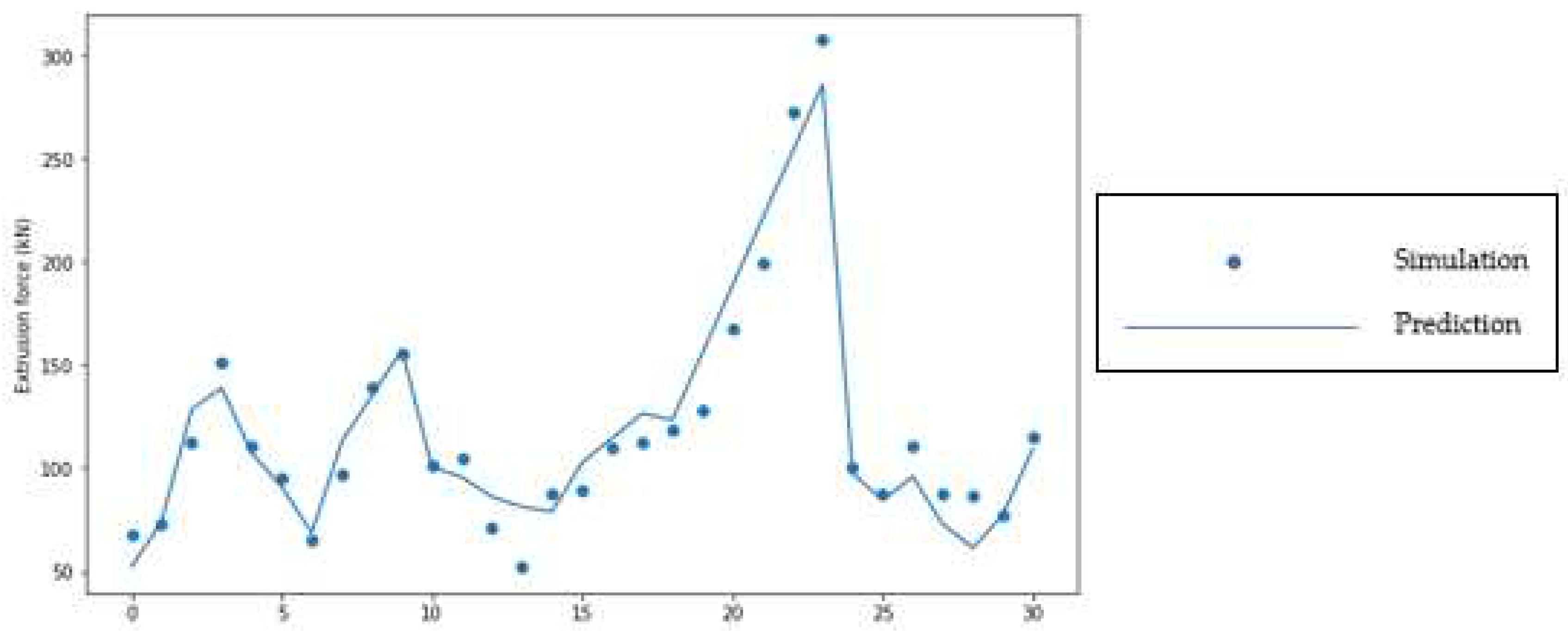

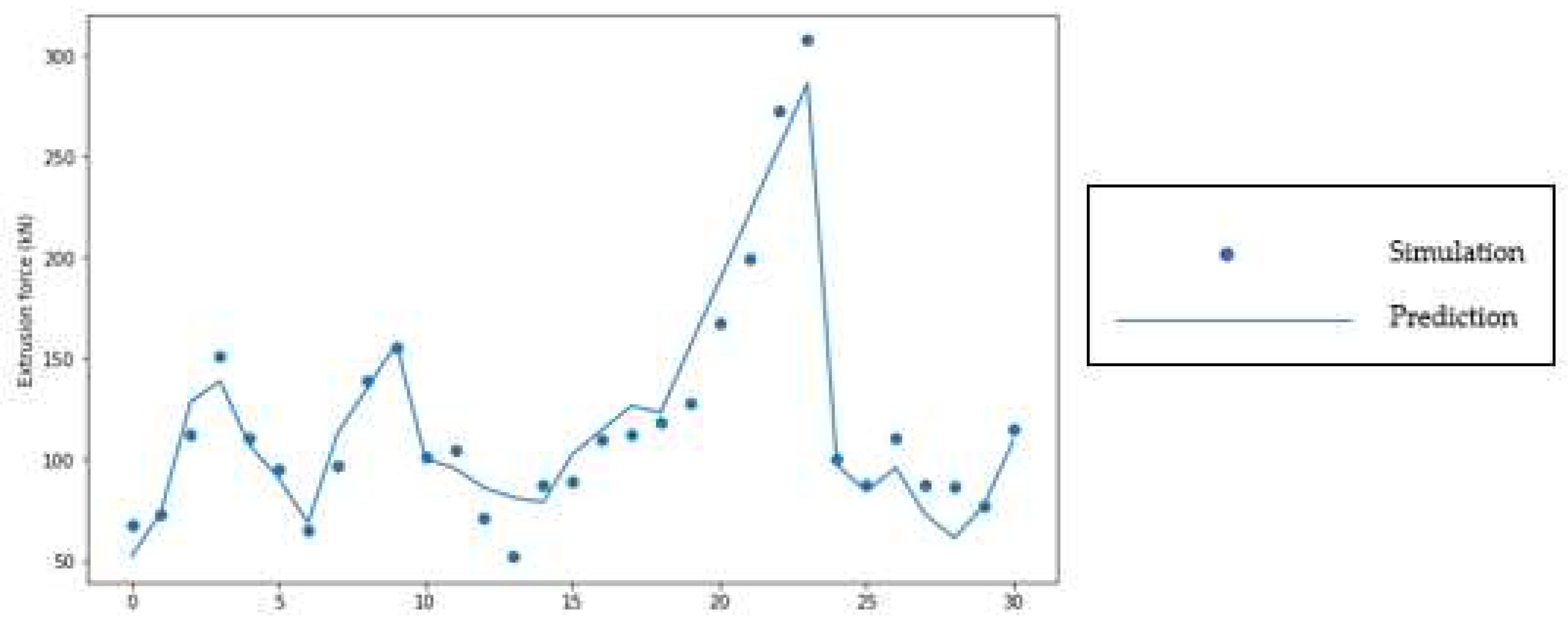

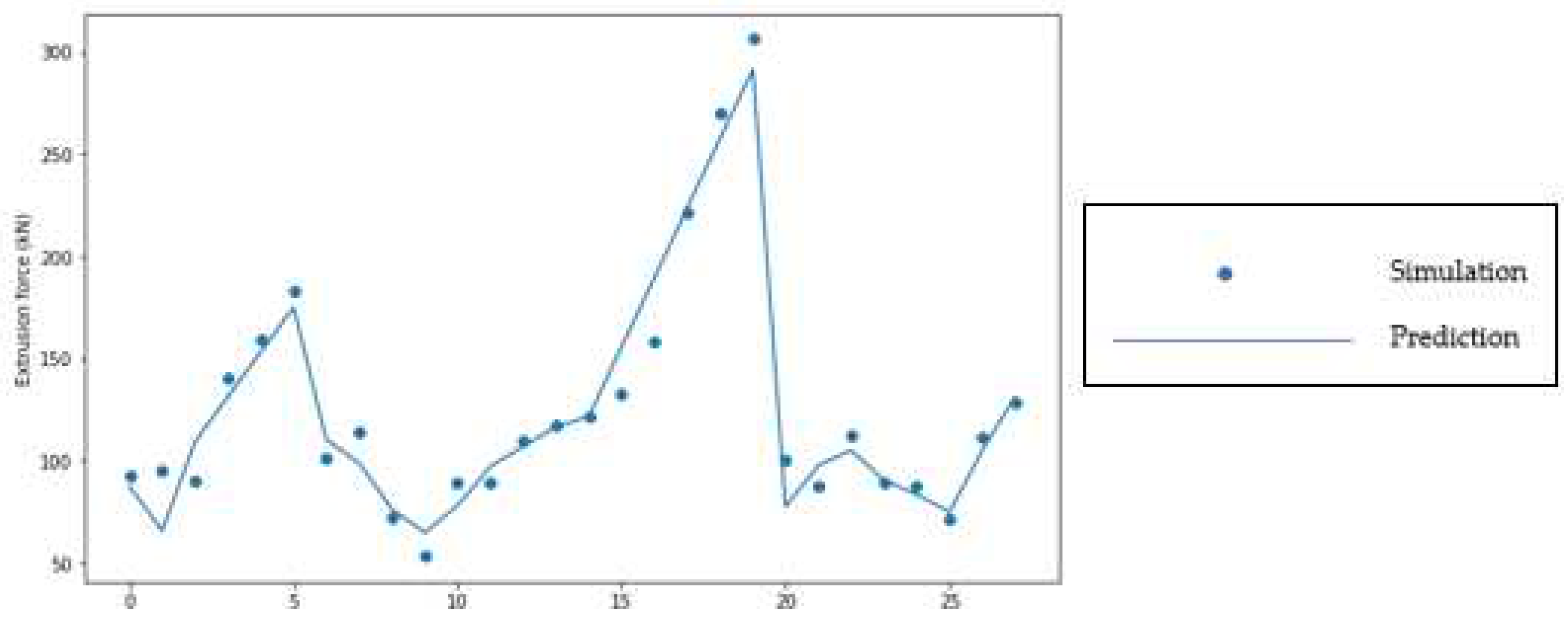

For the prediction model of the extrusion force, the dataframes for each material were split in two groups, one for training and one for testing using the “train_test_split” function from “sklearn.model_selection” module, being the test size 0.3.

After applying the “LinearRegression” function from “sklearn.linear_model” to build the prediction model using the training data and afterwards evaluate the model using the test data, the determination factor (R

2) for each material is shown in

Table 7:

Using the prediction models for each die material a bigger number of results for the extrusion force can be compared without the need of performing more simulations.

Table 8 show the ranking of the die materials as function of the times that their prediction value for the extrusion force is the lowest one.

If there was only the minimum extrusion force as requirement for the die material election, AISI3310 would be the chosen one followed by AISI316 and H13 sharing the second position in the ranking.

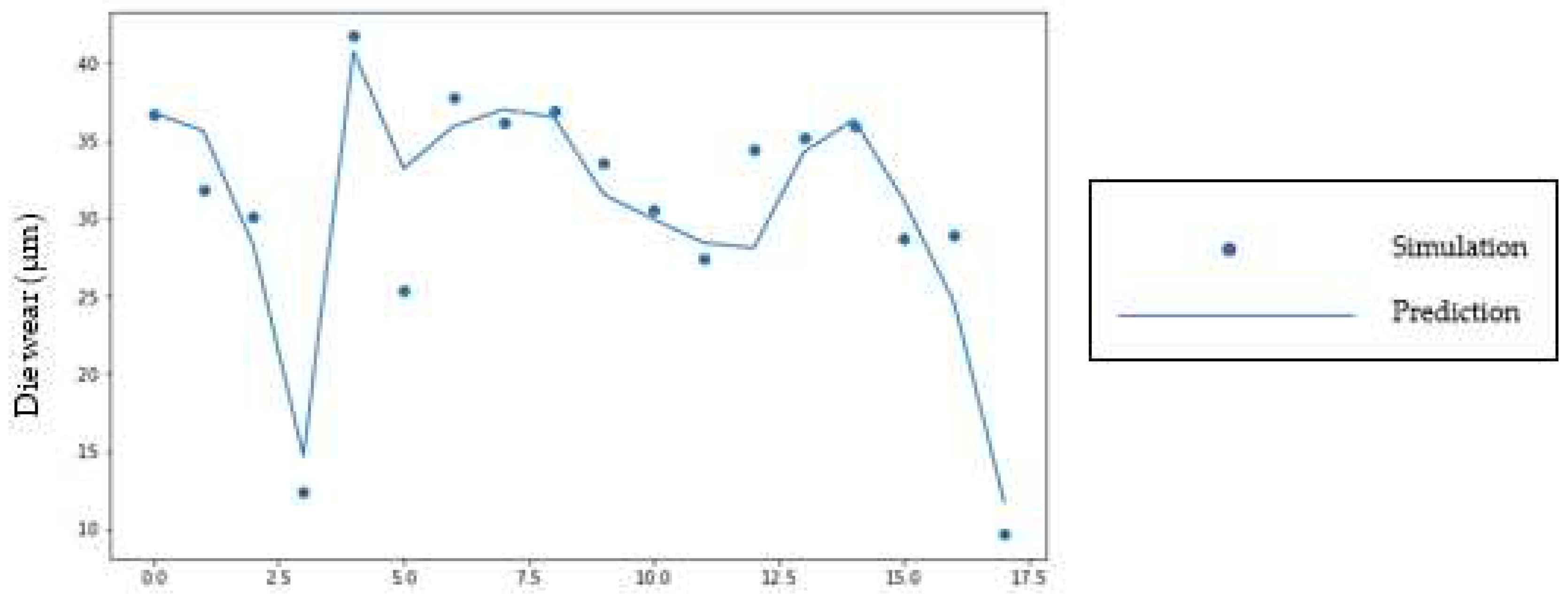

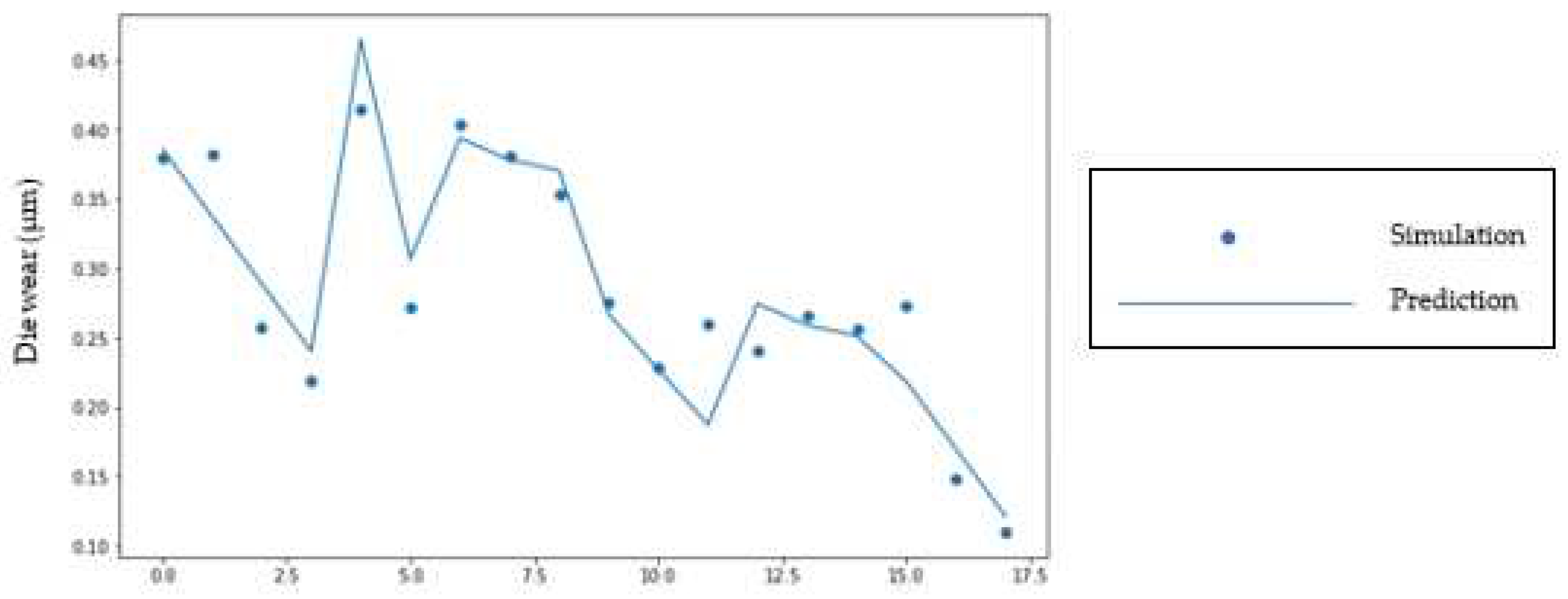

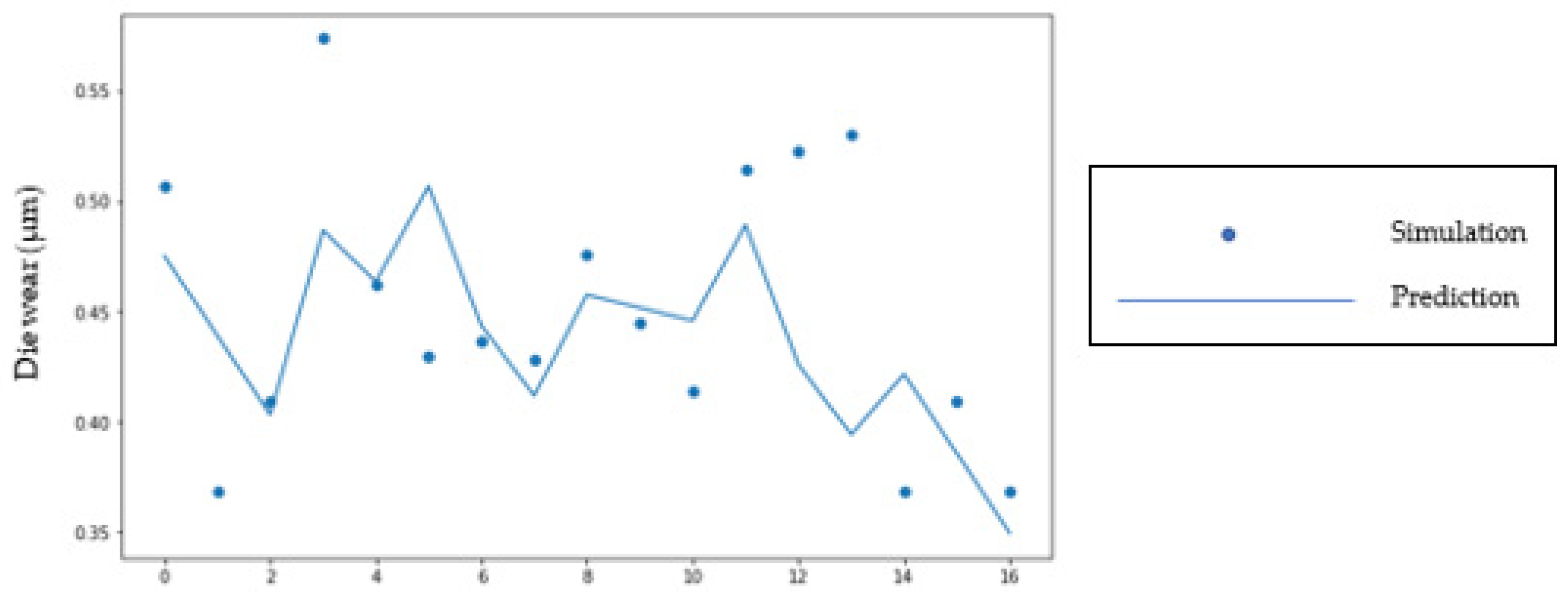

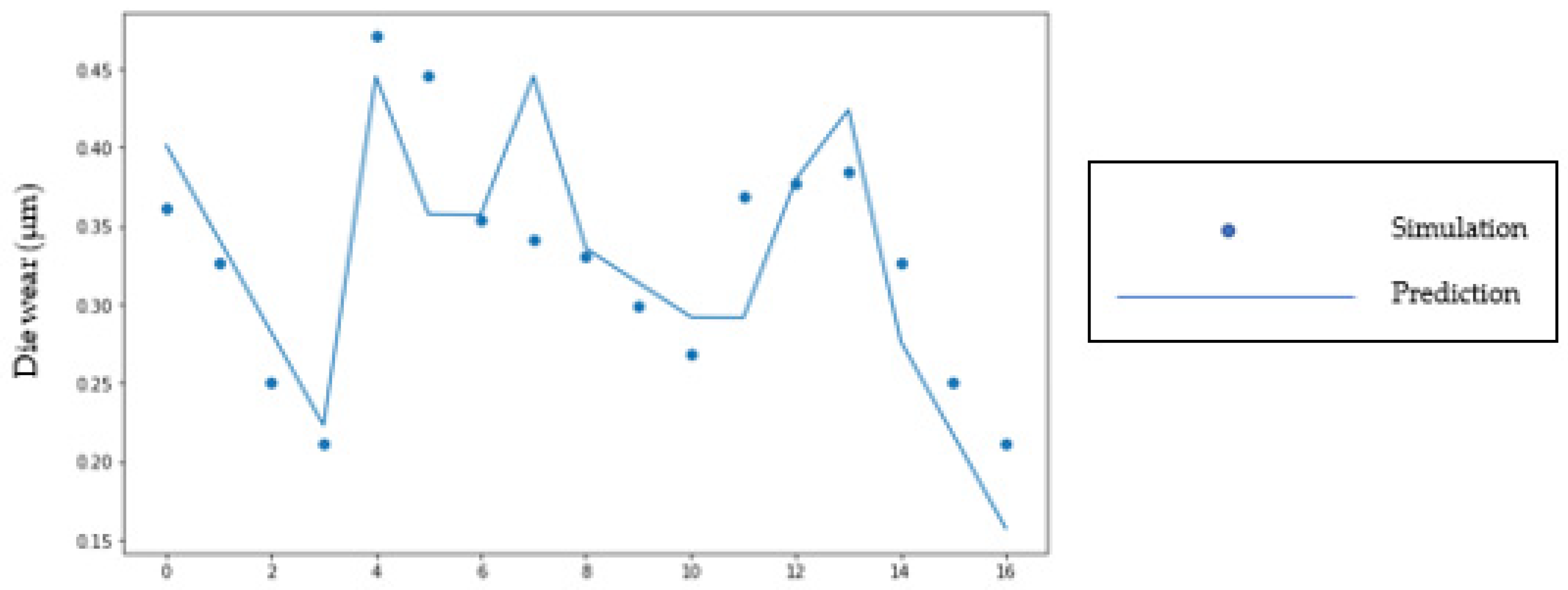

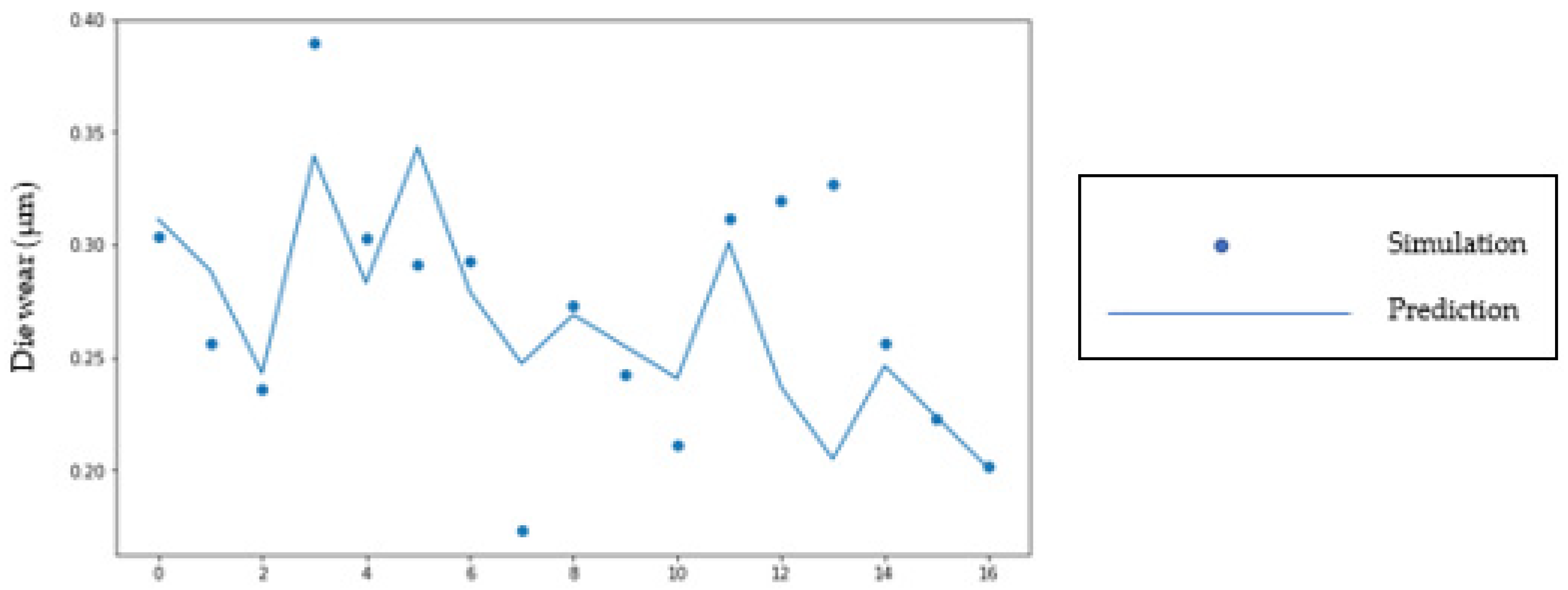

The SVR methodology is now applied for the wear prediction with the following modification.

Due to the results variation is not possible to apply a linear model regression but a polynomial one. In order to do this is necessary to import “PolynomialFeatures” module from “sklearn.preprocessing” library to generate a new feature matrix consisting of all polynomial combinations of the features with degree less than or equal to the specified degree (in this case a 2 degree polynomial is used).

In

Table 9 and

Table 10 are shown the process parameters ranking and the determination factor (R

2) for the wear model:

The prediction model is not as accurate as the one for the extrusion force. This can be due to the number of simulations performed to obtain the wear distribution are lower than for the extrusion force because of Archad’s wear model only takes into account temperature, friction and ram speed as it was mentioned in paragraph 2.2.1.

Table 11 show the ranking of the die materials as function of the times that their prediction value for the die wear is the lowest one.

Finally, a crosscheck between

Table 8 and

Table 11 is performed to rank the die material which fulfil better the minimum extrusion force and the minimum die wear as it can be seen in

Table 12.

In both rankings AISI3310 is the best choice to reduce the extrusion force and die wear. AISI316 and H13 have the same position for the extrusion force but not for the die wear, this is the reason because in the final ranking AISI316 is positioned better thank H13. The die materials that can be rejected as feasible option are AISI52100 and 25CrMo4.

3.2. MCDM Methodology

As explained in paragraph 3. the dataset is obtained from

Table A1. In the MCDM methodology the weights are calculated by means of Entropy method and afterwards VIKOR method is applied to classify the different materials based on criteria rating values decision.

For the Entropy method, the normalized matrix is:

| 0.1923 |

0.2079 |

0.2110 |

0.1998 |

0.1968 |

0.2021 |

0.1727 |

0.1947 |

0.1947 |

0.1913 |

0.1925 |

0.2011 |

0.1000 |

0.1842 |

0.1459 |

0.2035 |

0.1993 |

0.2214 |

| 0.1926 |

0.1903 |

0.2102 |

0.2001 |

0.1972 |

0.2023 |

0.1729 |

0.1954 |

0.1949 |

0.1977 |

0.2311 |

0.1717 |

0.1764 |

0.1829 |

0.1563 |

0.2175 |

0.2105 |

0.2118 |

| 0.2137 |

0.1952 |

0.1842 |

0.1999 |

0.2011 |

0.1996 |

0.2179 |

0.2008 |

0.2010 |

0.1884 |

0.1978 |

0.1667 |

0.1701 |

0.2078 |

0.2568 |

0.1908 |

0.1881 |

0.2067 |

| 0.1947 |

0.2046 |

0.1903 |

0.2011 |

0.2024 |

0.1967 |

0.2162 |

0.2034 |

0.2059 |

0.2642 |

0.2233 |

0.2733 |

0.3639 |

0.2532 |

0.2665 |

0.2315 |

0.2407 |

0.2565 |

| 0.2068 |

0.2019 |

0.2043 |

0.1990 |

0.2025 |

0.1994 |

0.2202 |

0.2057 |

0.2036 |

0.1584 |

0.1553 |

0.1871 |

0.1897 |

0.1719 |

0.1744 |

0.1567 |

0.1614 |

0.1037 |

Then, the entropy array (Ej) is calculated:

Ej = [0.999418867 0.999681506 0.999085371 0.999996437 0.999952024 0.999966715 0.996102816 0.999852667 0.999839187 0.990960752 0.99430503 0.989129167 0.944884512 0.993690857 0.979914551 0.994771731 0.99470602 0.976990905]

In VIKOR the best

and worst

values for each criterion are obtained directly from decision matrix

D.

| |

86.019 |

136.529 |

228.511 |

307.324 |

97.898 |

88.621 |

88.040 |

84.512 |

83.759 |

0.367 |

0.318 |

0.302 |

0.124 |

0.417 |

0.253 |

0.378 |

0.361 |

0.370 |

| |

86.153 |

124.955 |

227.644 |

307.783 |

98.095 |

88.706 |

88.140 |

84.799 |

83.850 |

0.379 |

0.382 |

0.257 |

0.219 |

0.414 |

0.271 |

0.404 |

0.381 |

0.354 |

| |

95.608 |

128.196 |

199.579 |

307.520 |

100.048 |

87.505 |

111.049 |

87.149 |

86.484 |

0.361 |

0.327 |

0.250 |

0.211 |

0.471 |

0.445 |

0.354 |

0.341 |

0.345 |

| |

87.120 |

134.333 |

206.128 |

309.397 |

100.654 |

86.238 |

110.203 |

88.307 |

88.602 |

0.507 |

0.369 |

0.410 |

0.452 |

0.573 |

0.462 |

0.430 |

0.436 |

0.428 |

| |

92.531 |

132.578 |

221.350 |

306.154 |

100.708 |

87.422 |

112.221 |

89.296 |

87.588 |

0.304 |

0.257 |

0.281 |

0.236 |

0.389 |

0.303 |

0.291 |

0.292 |

0.173 |

| |

447.431 |

656.591 |

1083.212 |

1538.178 |

497.402 |

438.492 |

509.653 |

434.063 |

430.283 |

1.918 |

1.652 |

1.499 |

1.242 |

2.265 |

1.735 |

1.856 |

1.812 |

1.669 |

| fi* |

86.019 |

124.955 |

199.579 |

306.154 |

97.898 |

86.238 |

88.040 |

84.512 |

83.759 |

0.304 |

0.257 |

0.250 |

0.124 |

0.389 |

0.253 |

0.291 |

0.292 |

0.173 |

| fi- |

95.608 |

136.529 |

228.511 |

309.397 |

100.708 |

88.706 |

112.221 |

89.296 |

88.602 |

0.507 |

0.382 |

0.410 |

0.452 |

0.573 |

0.462 |

0.430 |

0.436 |

0.428 |

Utility measure (

Sj) and Regret measure (

Rj) are obtained:

| |

Sj |

|

Ri |

| |

0.23758265 |

|

0.12075866 |

| |

0.36022622 |

|

0.11092085 |

| |

0.44932592 |

|

0.1258087 |

| |

0.98459134 |

|

0.37557176 |

| |

0.21183731 |

|

0.12764252 |

| S* |

0.21183731 |

R* |

0.11092085 |

| S- |

0.98459134 |

R- |

0.37557176 |

Using the values

S*, S-, R* and

R- together with the assumption of vote by consensus (

υ = 0.5), the index

Q is calculated:

| |

Qi |

| AISI3310 |

0.03524455 |

| H13 |

0.09601303 |

| AISI52100 |

0.18179111 |

| 25CrMo4 |

1 |

| AISI3310 |

0.03159193 |

In VIKOR the index Q is ranked from the lowest to the highest value, therefore the best material to obtain minimum extrusion force and minimum die wear is AISI3310. But before recommending this material as best compromise solution the conditions of “Acceptable advantages” and “Acceptable stability in decision making” have to be fulfilled.

In this case DQ = 0.25 according with Equation (13). Then:

Q(2) – Q(1) = 0.0365261

Q(3) – Q(1) = 0.0644211

Q(4) – Q(1) = 0.15019917

Q(5) – Q(1) = 0.96840807 > DQ

Q(1) = S*

As only the second condition is fulfilled, a set of compromise solution is presented and ranked in

Table 14

4. Discussion

In this paper two methodologies are proposed to choose the best material for the die in a multi-material coextrusion process, taking into account that the process has to fulfil the requirements of minimum extrusion force and minimum die wear.

The first methodology proposed is the SVR based on SVM. The main advantage is the prediction model obtained during the process which allows the engineers to know the outcomes when varying the process parameters. On the other hand, the disadvantages are the number of simulations needed to obtain a good prediction model and depending on the results of those simulations the complexity to obtain the prediction model can be very high.

MCDM methodology allows to select the best die material with a smaller number of simulations than the SVR one and without considering the accuracy or complexity of prediction models. Also, it is less time consuming because Entropy and VIKOR methods can be applied directly to the data and there is no need to have knowledge in programming languages like Python.

The results for the top three materials selected are the same independently of the methodology applied. Therefore, if there is no need to obtain a prediction model to forecast results by applying other values to the parameters, the die material selection methodology recommended is MCDM one due to its simplicity and time consuming to implement it.

Finally, for future research it would be interested a comparison among different machine learning methods to obtain a more robust prediction model not only for the wear but also for other parameters such as damage factor, mean stresses, microstructure resultant and so on.

Author Contributions

Conceptualization, D.F., A.R.-P., and A.M.C.; methodology, D.F.; formal analysis, D.F., A.R.-P., and A.M.C.; investigation, D.F., A.R.-P., and A.M.C.; resources, A.R.-P. and A.M.C.; writing—original draft preparation, D.F.; writing—review and editing, A.R.-P. and A.M.C.; supervision, A.R.-P. and A.M.C.; project administration, A.R.-P. and A.M.C.; funding acquisition, A.R.-P. and A.M.C. All authors read and agreed to the published version of the manuscript.

Funding

This research was funded within the framework of the “Doctorate Program in Industrial Technologies” of the UNED and it has been funded by the project 2021V/-TAJOV/006 (awarded in the UNED Research Projects call named “Young Talents 2021”).

Data Availability Statement

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Acknowledgments

We would like to extend our acknowledgement to the Research Group of the UNED “Industrial Production and Manufacturing Engineering (IPME)” and the Industrial Research Group “Advanced Failure Prognosis for Engineering Applications”.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A

Table A1.

List of simulations performed by DEFORM3D© (v11.2).

Table A1.

List of simulations performed by DEFORM3D© (v11.2).

| Simulation |

Material |

Ram speed(mm/s) |

Core

diameter (mm) |

Billet

Height (H) |

Temperature(⁰ C) |

Friction |

Die

semi-angle (⁰) |

Extrusion

Ratio |

| 1 |

AISI316 |

2 |

5 |

20 |

200 |

0.2 |

30 |

1.78 |

| 2 |

AISI316 |

2 |

6 |

15 |

100 |

0.2 |

30 |

2.25 |

| 3 |

AISI316 |

2 |

7 |

25 |

100 |

0.3 |

30 |

1.44 |

| 4 |

AISI316 |

3 |

6 |

15 |

200 |

0.3 |

15 |

2.25 |

| 5 |

AISI316 |

3 |

7 |

15 |

300 |

0.2 |

45 |

1.44 |

| 6 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.78 |

| 7 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

15 |

1.78 |

| 8 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

45 |

1.78 |

| 9 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

60 |

1.78 |

| 10 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

75 |

1.78 |

| 11 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

90 |

1.78 |

| 12 |

AISI316 |

2 |

2 |

20 |

200 |

0.1 |

30 |

1.78 |

| 13 |

AISI316 |

2 |

4 |

20 |

200 |

0.1 |

30 |

1.78 |

| 14 |

AISI316 |

2 |

8 |

20 |

200 |

0.1 |

30 |

1.78 |

| 15 |

AISI316 |

2 |

10 |

20 |

200 |

0.1 |

30 |

1.78 |

| 16 |

AISI316 |

2 |

6 |

15 |

200 |

0.1 |

30 |

1.78 |

| 17 |

AISI316 |

2 |

6 |

25 |

200 |

0.1 |

30 |

1.78 |

| 18 |

AISI316 |

2 |

6 |

30 |

200 |

0.1 |

30 |

1.78 |

| 19 |

AISI316 |

2 |

6 |

35 |

200 |

0.1 |

30 |

1.78 |

| 20 |

AISI316 |

2 |

6 |

20 |

200 |

0.2 |

30 |

1.78 |

| 21 |

AISI316 |

2 |

6 |

20 |

200 |

0.3 |

30 |

1.78 |

| 22 |

AISI316 |

2 |

6 |

20 |

200 |

0.4 |

30 |

1.78 |

| 23 |

AISI316 |

2 |

6 |

20 |

200 |

0.5 |

30 |

1.78 |

| 24 |

AISI316 |

2 |

6 |

20 |

200 |

0.6 |

30 |

1.78 |

| 25 |

AISI316 |

2 |

6 |

20 |

200 |

0.7 |

30 |

1.78 |

| 26 |

AISI316 |

2 |

6 |

20 |

100 |

0.1 |

30 |

1.78 |

| 27 |

AISI316 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 28 |

AISI316 |

1 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 29 |

AISI316 |

3 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 30 |

AISI316 |

4 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 31 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.44 |

| 32 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.25 |

| 33 |

AISI316 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.94 |

| 34 |

H13 |

2 |

5 |

15 |

100 |

0.1 |

15 |

1.44 |

| 35 |

H13 |

2 |

6 |

25 |

300 |

0.1 |

15 |

1.78 |

| 36 |

H13 |

3 |

5 |

15 |

300 |

0.3 |

30 |

1.78 |

| 37 |

H13 |

3 |

6 |

25 |

100 |

0.2 |

45 |

1.44 |

| 38 |

H13 |

3 |

7 |

25 |

200 |

0.1 |

30 |

2.25 |

| 39 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.78 |

| 40 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

15 |

1.78 |

| 41 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

45 |

1.78 |

| 42 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

60 |

1.78 |

| 43 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

75 |

1.78 |

| 44 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

90 |

1.78 |

| 45 |

H13 |

2 |

2 |

20 |

200 |

0.1 |

30 |

1.78 |

| 46 |

H13 |

2 |

4 |

20 |

200 |

0.1 |

30 |

1.78 |

| 47 |

H13 |

2 |

8 |

20 |

200 |

0.1 |

30 |

1.78 |

| 48 |

H13 |

2 |

10 |

20 |

200 |

0.1 |

30 |

1.78 |

| 49 |

H13 |

2 |

6 |

15 |

200 |

0.1 |

30 |

1.78 |

| 50 |

H13 |

2 |

6 |

25 |

200 |

0.1 |

30 |

1.78 |

| 51 |

H13 |

2 |

6 |

30 |

200 |

0.1 |

30 |

1.78 |

| 52 |

H13 |

2 |

6 |

35 |

200 |

0.1 |

30 |

1.78 |

| 53 |

H13 |

2 |

6 |

20 |

200 |

0.2 |

30 |

1.78 |

| 54 |

H13 |

2 |

6 |

20 |

200 |

0.3 |

30 |

1.78 |

| 55 |

H13 |

2 |

6 |

20 |

200 |

0.4 |

30 |

1.78 |

| 56 |

H13 |

2 |

6 |

20 |

200 |

0.5 |

30 |

1.78 |

| 57 |

H13 |

2 |

6 |

20 |

200 |

0.6 |

30 |

1.78 |

| 58 |

H13 |

2 |

6 |

20 |

200 |

0.7 |

30 |

1.78 |

| 59 |

H13 |

2 |

6 |

20 |

100 |

0.1 |

30 |

1.78 |

| 60 |

H13 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 61 |

H13 |

1 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 62 |

H13 |

3 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 63 |

H13 |

4 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 64 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.44 |

| 65 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.25 |

| 66 |

H13 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.94 |

| 67 |

AISI52100 |

2 |

5 |

15 |

100 |

0.1 |

15 |

1.44 |

| 68 |

AISI52100 |

2 |

6 |

25 |

300 |

0.1 |

15 |

1.78 |

| 69 |

AISI52100 |

3 |

5 |

15 |

300 |

0.3 |

30 |

1.78 |

| 70 |

AISI52100 |

3 |

6 |

25 |

100 |

0.2 |

45 |

1.44 |

| 71 |

AISI52100 |

3 |

7 |

25 |

200 |

0.1 |

30 |

2.25 |

| 72 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.78 |

| 73 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

15 |

1.78 |

| 74 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

45 |

1.78 |

| 75 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

60 |

1.78 |

| 76 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

75 |

1.78 |

| 77 |

AISI52100 |

2 |

2 |

20 |

200 |

0.1 |

30 |

1.78 |

| 78 |

AISI52100 |

2 |

4 |

20 |

200 |

0.1 |

30 |

1.78 |

| 79 |

AISI52100 |

2 |

8 |

20 |

200 |

0.1 |

30 |

1.78 |

| 80 |

AISI52100 |

2 |

10 |

20 |

200 |

0.1 |

30 |

1.78 |

| 81 |

AISI52100 |

2 |

6 |

15 |

200 |

0.1 |

30 |

1.78 |

| 82 |

AISI52100 |

2 |

6 |

25 |

200 |

0.1 |

30 |

1.78 |

| 83 |

AISI52100 |

2 |

6 |

30 |

200 |

0.1 |

30 |

1.78 |

| 84 |

AISI52100 |

2 |

6 |

35 |

200 |

0.1 |

30 |

1.78 |

| 85 |

AISI52100 |

2 |

6 |

20 |

200 |

0.2 |

30 |

1.78 |

| 86 |

AISI52100 |

2 |

6 |

20 |

200 |

0.3 |

30 |

1.78 |

| 87 |

AISI52100 |

2 |

6 |

20 |

200 |

0.4 |

30 |

1.78 |

| 88 |

AISI52100 |

2 |

6 |

20 |

200 |

0.5 |

30 |

1.78 |

| 89 |

AISI52100 |

2 |

6 |

20 |

200 |

0.6 |

30 |

1.78 |

| 90 |

AISI52100 |

2 |

6 |

20 |

200 |

0.7 |

30 |

1.78 |

| 91 |

AISI52100 |

2 |

6 |

20 |

100 |

0.1 |

30 |

1.78 |

| 92 |

AISI52100 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 93 |

AISI52100 |

1 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 94 |

AISI52100 |

3 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 95 |

AISI52100 |

4 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 96 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.44 |

| 97 |

AISI52100 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.25 |

| 98 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.3 |

45 |

1.44 |

| 99 |

25CrMo4 |

2 |

7 |

15 |

200 |

0.1 |

45 |

1.78 |

| 100 |

25CrMo4 |

3 |

5 |

25 |

200 |

0.2 |

15 |

1.44 |

| 101 |

25CrMo4 |

3 |

7 |

20 |

100 |

0.3 |

15 |

1.78 |

| 102 |

25CrMo4 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 103 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.78 |

| 104 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

15 |

1.78 |

| 105 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

45 |

1.78 |

| 106 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

60 |

1.78 |

| 107 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

75 |

1.78 |

| 108 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

90 |

1.78 |

| 109 |

25CrMo4 |

2 |

2 |

20 |

200 |

0.1 |

30 |

1.78 |

| 110 |

25CrMo4 |

2 |

4 |

20 |

200 |

0.1 |

30 |

1.78 |

| 111 |

25CrMo4 |

2 |

8 |

20 |

200 |

0.1 |

30 |

1.78 |

| 112 |

25CrMo4 |

2 |

10 |

20 |

200 |

0.1 |

30 |

1.78 |

| 113 |

25CrMo4 |

2 |

6 |

15 |

200 |

0.1 |

30 |

1.78 |

| 114 |

25CrMo4 |

2 |

6 |

25 |

200 |

0.1 |

30 |

1.78 |

| 115 |

25CrMo4 |

2 |

6 |

30 |

200 |

0.1 |

30 |

1.78 |

| 116 |

25CrMo4 |

2 |

6 |

35 |

200 |

0.1 |

30 |

1.78 |

| 117 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.2 |

30 |

1.78 |

| 118 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.3 |

30 |

1.78 |

| 119 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.4 |

30 |

1.78 |

| 120 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.5 |

30 |

1.78 |

| 121 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.6 |

30 |

1.78 |

| 122 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.7 |

30 |

1.78 |

| 123 |

25CrMo4 |

2 |

6 |

20 |

100 |

0.1 |

30 |

1.78 |

| 124 |

25CrMo4 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 125 |

25CrMo4 |

1 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 126 |

25CrMo4 |

3 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 127 |

25CrMo4 |

4 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 128 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.44 |

| 129 |

25CrMo4 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.25 |

| 130 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.78 |

| 131 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

15 |

1.78 |

| 132 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

45 |

1.78 |

| 133 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

60 |

1.78 |

| 134 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

75 |

1.78 |

| 135 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

90 |

1.78 |

| 136 |

AISI3310 |

2 |

2 |

20 |

200 |

0.1 |

30 |

1.78 |

| 137 |

AISI3310 |

2 |

4 |

20 |

200 |

0.1 |

30 |

1.78 |

| 138 |

AISI3310 |

2 |

8 |

20 |

200 |

0.1 |

30 |

1.78 |

| 139 |

AISI3310 |

2 |

10 |

20 |

200 |

0.1 |

30 |

1.78 |

| 140 |

AISI3310 |

2 |

6 |

15 |

200 |

0.1 |

30 |

1.78 |

| 141 |

AISI3310 |

2 |

6 |

25 |

200 |

0.1 |

30 |

1.78 |

| 142 |

AISI3310 |

2 |

6 |

30 |

200 |

0.1 |

30 |

1.78 |

| 143 |

AISI3310 |

2 |

6 |

35 |

200 |

0.1 |

30 |

1.78 |

| 144 |

AISI3310 |

2 |

6 |

20 |

200 |

0.2 |

30 |

1.78 |

| 145 |

AISI3310 |

2 |

6 |

20 |

200 |

0.3 |

30 |

1.78 |

| 146 |

AISI3310 |

2 |

6 |

20 |

200 |

0.4 |

30 |

1.78 |

| 147 |

AISI3310 |

2 |

6 |

20 |

200 |

0.5 |

30 |

1.78 |

| 148 |

AISI3310 |

2 |

6 |

20 |

200 |

0.6 |

30 |

1.78 |

| 149 |

AISI3310 |

2 |

6 |

20 |

200 |

0.7 |

30 |

1.78 |

| 150 |

AISI3310 |

2 |

6 |

20 |

100 |

0.1 |

30 |

1.78 |

| 151 |

AISI3310 |

2 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 152 |

AISI3310 |

1 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 153 |

AISI3310 |

3 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 154 |

AISI3310 |

4 |

6 |

20 |

300 |

0.1 |

30 |

1.78 |

| 155 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

30 |

1.44 |

| 156 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.25 |

| 157 |

AISI3310 |

2 |

6 |

20 |

200 |

0.1 |

30 |

2.94 |

References

- Sheng, L.Y.; Du, B.N.; Hu, Z.Y.; Qiao, Y.X.; Xiao, Z.P.; Wang, B.J.; Xu, D.K.; Zheng, Y.F.; Xi, T.F. Effects of annealing treatment on microstructure and tensile behaviour of the Mg-Zn-Y-Nd alloy. Journal of Magnesium Alloys 2020, 8, 601–613. [Google Scholar] [CrossRef]

- Bermudo, C.; Andersson, T.; Svensson, D.; Trujillo, F.J.; Martín-Béjar, S.; Sevilla, L. Modeling of the fracture energy on the finite element simulation in Ti6Al4V alloy machining. Scientific Reports 2021, 11, 18490. [Google Scholar] [CrossRef]

- Fernández, D.; Rodríguez-Prieto, A.; Camacho, A.M. Effect of Process Parameters and Definition of Favorable Conditions in Multi-material Extrusion of Bimetallic AZ31B-Ti6Al4V Billets. Appl. Sci. 2020, 10, 8048. [Google Scholar] [CrossRef]

- Fernández, D.; Rodríguez-Prieto, A.; Camacho, A.M. Selection of Die Material and Its Impact on the Multi-Material Extrusion of Bimetallic AZ31B-Ti6Al4V Components for Aeronautical Applications. Materials 2021, 4, 7568. [Google Scholar] [CrossRef] [PubMed]

- Negendanka, M.; Mueller, S.; Reimers, W. Co-extrusion of Mg–Al macrocomposites. J. Mater. Process. Technol. 2021, 212, 1954–1962. [Google Scholar] [CrossRef]

- Gall, S.; Müller, S.; Reimers, W. Aluminum coating of magnesium hollow profiles by using the co-extrusion process. Alum. Int. J. 2009, 85, 63–67. [Google Scholar]

- Rai, R.; Tiwari, M.K.; Ivanov, D.; Dolgui, A. Machine learning in manufacturing and industry 4.0 applications. Int. J. Prod. Res. 2021, 59, 4773–4778. [Google Scholar] [CrossRef]

- Dalzochio, J.; Kunst, R.; Pignaton, E.; Binotto, A.; Sanyal, S.; Favilla, J.; Barbosa, J. Machine learning and reasoning for predictive maintenance in Industry 4.0: Current status and challenges. Comput. Ind. 2020, 123, 103298. [Google Scholar] [CrossRef]

- Vapnik, V. The Nature of Statistical Learning Theory; Springer: New York, NY, USA, 1995. [Google Scholar]

- Jović, S.; Radović, A.; Šarkoćević, Ž.; Petković, D.; Alizamir, M. Estimation of the laser cutting operating cost by support vector regression methodology. Appl. Phys. A 2016, 122, 798. [Google Scholar] [CrossRef]

- Rabiee, A.H.; Tahmasbi, V.; Qasemi, M. Experimental evaluation, modeling and sensitivity analysis of temperature and cutting force in bone micro-milling using support vector regression and EFAST methods. Eng. Appl. Artif. Intell. 2023, 120, 105874. [Google Scholar] [CrossRef]

- Xu, C.; Yao, S.; Wang, G.; Wang, Y.; Xu, J. A prediction model of drilling force in CFRP internal chip removal hole drilling based on support vector regression. Int. J. Adv. Manuf. Technol. 2021, 117, 1505–1516. [Google Scholar] [CrossRef]

- Benkedjouh, T.; Medjaher, K.; Zerhouni, N.; Rechak, S. Health assessment and life prediction of cutting tools based on support vector regression. J. Intell. Manuf. 2015, 26, 213–223. [Google Scholar] [CrossRef]

- Rebello, C.M.; Martins, M.A.F.; Santana, D.D.; Rodrigues, A.E.; Loureiro, J.M.; Ribeiro, A.M.; Nogueira, I.B.R. From a Pareto Front to Pareto Regions: A Novel Standpoint for Multiobjective Optimization. Mathematics 2021, 9, 3152. [Google Scholar] [CrossRef]

- Saaty, T.L. A scaling method for priorities in heirachical structures. J. Math. Psychol. 1977, 15, 234–281. [Google Scholar] [CrossRef]

- Ghaleb, A.M.; Kaid, H.; Alsamhan, A.; Mian, S.H.; Hidri, L. Hindawi Assessment and Comparison of Various MCDM Approaches in the Selection of Manufacturing Process. Adv. Mater. Sci. Eng. 2020, 4039253. [Google Scholar]

- Karbassi Yazdi, A.; Tan, Y.; Spulbar, C.; Birau, R.; Alfaro, J. An Approach for Supply Chain Management Contract Selection in the Oil and Gas Industry: Combination of Uncertainty and Multi-Criteria Decision-Making Methods. Mathematics 2022, 10, 3230. [Google Scholar] [CrossRef]

- Rodríguez-Prieto, A.; Camacho, A.M.; Sebastián, M.A. Multi-criteria materials selection for extreme operating conditions base on a multi-objective analysis of irradiation embrittlement and hot cracking prediction models. Int. J. Mech. Mater. Des. 2018, 14, 617–634. [Google Scholar] [CrossRef]

- Fernández, D.; Rodríguez-Prieto, Á.; Camacho, A.M. Optimal Parameters Selection in Advanced Multi-Metallic Co-Extrusion Based on Independent MCDM Analytical Approaches and Numerical Simulation. Mathematics 2022, 10, 4489. [Google Scholar] [CrossRef]

- Alrababah, S.A.A.; Gan, K.H. Effects of the Hybrid CRITIC–VIKOR Method on Product Aspect Ranking in Customer Reviews. Appl. Sci. 2023, 13, 9176. [Google Scholar] [CrossRef]

- Kao, C. Weight determination for consistently ranking alternatives in multiple criteria decision analysis. Appl. Math. Model. 2010, 34, 1779–1787. [Google Scholar] [CrossRef]

- Dev, S.; Aherwar, A.; Patnaik, A. Material Selection for Automotive Piston Component Using Entropy-VIKOR method. Silicon 2020, 12. [Google Scholar] [CrossRef]

- Donachie, M.J. Titanium: A Technical Guide; ASM International: Novelty, OH, USA, 1988. [Google Scholar]

- Avedesiam, M.; Baker, H. ASM Speciality Handbook: Magnesium and Magnesium Alloys; ASM International: Novelty, OH, USA, 1999. [Google Scholar]

- Karmakar, D.; Muvvala, G.; Kumar, A. High-temperature abrasive wear characteristics of H13 steel modified by laser remelting and cladded with Stellite 6 and Stellite 6/30% WC. Surf. Coat. Technol. 2021, 422, 127498. [Google Scholar] [CrossRef]

- Li, D.; Zhu, Z.; Xiao, S.; Zhang, G.; Lu, Y. Plastic flow behavior based on thermal activation and dynamic constitutive equation of 25CrMo4 steel during impact compression. Mater. Sci. Eng. A 2017, 707, 459–465. [Google Scholar] [CrossRef]

- Bhandarkar, L.; Behera, M.; Mohanty, P.; Sarangi, S. Experimental investigation and multi-objective optimization of process parameters during machining of AISI 52100 using high performance coated tools. Measurement 2021, 172, 108842. [Google Scholar] [CrossRef]

- Bedekar, V.; Voothaluru, R.; Yu, D.; Wong, A.; Galindo-Nava, E.; Gorti, S.B.; An, K.; Hyde, R.S. Effect of nickel on the kinematic stability of retained austenite in carburized bearing steels—In-situ neutron diffraction and crystal plasticity modeling of uniaxial tension tests in AISI 8620, 4320 and 3310 steels. Int. J. Plast. 2020, 131, 102748. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.; Toumpis, A.; Steel, R.; Zhu, W.; Iqbal, N. Enhanced erosion performance of cold spray co-deposited AISI316 MMCs modified by friction stir processing. Mater. Des. 2017, 120, 22–35. [Google Scholar] [CrossRef]

- Davis, J.R. ASM Speciality Handbook—Stainless Steels; ASM International: Novelty, OH, USA, 1999. [Google Scholar]

- Scientific Forming Technologies. DEFORM v11.2 User’s Manual; Scientific Forming Technologies Corporation: Columbus, OH, USA, 2017. [Google Scholar]

- Li, W.; Zhao, G.; Ma, X.; Gao, J. Flow Stress Characteristics of AZ31B Magnesium Alloy Sheet at Elevated Temperatures. Int. J. Appl. Phys. Math. 2012, 2, 83–88. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, J.; Zhu, N.; Li, Z. A comparative study on Johnson—Cook constitutive modelling for Ti6Al4V alloy using automated ball indentation (ABI) technique. J. Alloys Compd. 2015, 633, 220–228. [Google Scholar] [CrossRef]

- Zhang, C.; Zhao, G.; Li, T.; Guan, Y.; Chen, H.; Li, P. An Investigation of Die Wear Behavior during Aluminum Alloy 7075 Tube Extrusion. J. Tribol. 2012, 135, 011602. [Google Scholar] [CrossRef]

- Li, T.; Zhao, G.; Zhang, C.; Guan, Y.; Sun, X.; Li, H. Effect of Process Parameters on Die Wear Behavior of Aluminum Alloy Rod Extrusion. Mater. Manuf. Process. 2013, 28, 312–318. [Google Scholar] [CrossRef]

- Lepadatu, D.; Hambli, R.; Kobi, A.; Barreau, A. Statistical investigation of die wear in metal extrusion processes. Int. J. Adv. Manuf. Technol. 2005, 28, 272–278. [Google Scholar] [CrossRef]

- Safari, M.; Rabiee, A.H.; Joudaki, J. Developing a Support Vector Regression (SVR) Model for Prediction of Main and Lateral Bending Angles in Laser Tube Bending Process. Materials 2023, 16, 3251. [Google Scholar] [CrossRef] [PubMed]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Sasanka, C.T.; Ravindra, K. Implementation of VIKOR Method for Selection of Magnesium Alloy to Suit Automotive Applications. International Journal of Advanced Science and Technology 2015, 83, 49–58. [Google Scholar] [CrossRef]

- Raschka, S.; Mirjalili, V. Python Machine Learning. Second Edition. Packt Publishing. Birminghan, UK, 2017.

Figure 1.

Co-extrusion set up with process parameters and initial billet dimensions.

Figure 1.

Co-extrusion set up with process parameters and initial billet dimensions.

Figure 2.

2D hyperplane representation.

Figure 2.

2D hyperplane representation.

Figure 3.

Methodology flowchart.

Figure 3.

Methodology flowchart.

Figure 4.

AISI316 extrusion force prediction comparison.

Figure 4.

AISI316 extrusion force prediction comparison.

Figure 5.

H13 extrusion force prediction comparison.

Figure 5.

H13 extrusion force prediction comparison.

Figure 6.

25CrMo4 extrusion force prediction comparison.

Figure 6.

25CrMo4 extrusion force prediction comparison.

Figure 7.

AISI52100 extrusion force prediction comparison.

Figure 7.

AISI52100 extrusion force prediction comparison.

Figure 8.

AISI3310 extrusion force prediction comparison.

Figure 8.

AISI3310 extrusion force prediction comparison.

Figure 9.

AISI316 die wear prediction comparison.

Figure 9.

AISI316 die wear prediction comparison.

Figure 10.

H13 die wear prediction comparison.

Figure 10.

H13 die wear prediction comparison.

Figure 11.

25CrMo4 die wear prediction comparison.

Figure 11.

25CrMo4 die wear prediction comparison.

Figure 12.

AISI52100 die wear prediction comparison.

Figure 12.

AISI52100 die wear prediction comparison.

Figure 13.

AISI3310 die wear prediction comparison .

Figure 13.

AISI3310 die wear prediction comparison .

Table 1.

Physical and mechanical properties of the titanium alloy Ti6Al4V and magnesium alloy AZ31B [

23,

24].

Table 1.

Physical and mechanical properties of the titanium alloy Ti6Al4V and magnesium alloy AZ31B [

23,

24].

| Property |

Ti6Al4V |

AZ31B |

| Density (g/cm3) |

4.46 |

1.74 |

| Tensile strength (MPa) |

895 |

260 |

| Yield strength (MPa) |

828 |

200 |

| Elastic modulus (GPa) |

110 |

44.80 |

| Poisson’s ratio |

0.31 |

0.35 |

Table 2.

Table 2. Chemical composition of titanium alloy Ti6Al4V [

23].

Table 2.

Table 2. Chemical composition of titanium alloy Ti6Al4V [

23].

| Ti (wt.%) |

Al (wt.%) |

V (wt.%) |

Fe (wt.%) |

C (wt.%) |

O (wt.%) |

N (wt.%) |

H (wt.%) |

| Bal. |

5.5–6.5 |

3.5–4.5 |

0.25 |

0.08 |

0.13 |

0.040 |

0.012 |

Table 3.

Chemical composition of magnesium alloy AZ31B [

24].

Table 3.

Chemical composition of magnesium alloy AZ31B [

24].

| Mg (wt.%) |

Al (wt.%) |

Zn (wt.%) |

Mn (wt.%) |

Si (wt.%) |

Cu (wt.%) |

Ca (wt.%) |

Fe (wt.%) |

Ni (wt.%) |

| 97 |

2.5–3.5 |

0.6–1.4 |

0.20 |

0.1 |

0.05 |

0.04 |

0.005 |

0.005 |

Table 4.

Table 4. Chemical composition of die steels [

25,

26,

27,

28,

29].

Table 4.

Table 4. Chemical composition of die steels [

25,

26,

27,

28,

29].

| Material |

C (wt.%) |

Mn (wt.%) |

Si (wt.%) |

Cr (wt.%) |

Mo (wt.%) |

Ni (wt.%) |

| AISI316 |

0.08 |

2 |

0.75 |

16–18 |

2–3 |

10–14 |

| H13 |

0.32–0.45 |

0.2–0. 5 |

0.8–1.20 |

4.75–5.50 |

1.10–1.75 |

0.30 max |

| 25CrMo4 |

0.22–0.29 |

0.60–0.90 |

0.10–0.40 |

0.90–1.20 |

0.15–0.30 |

- |

| AISI52100 |

0.1 |

0.45 |

0.26 |

1.51 |

0.06 |

3.39 |

| AISI3310 |

0.99 |

0.39 |

0.16 |

1.4 |

- |

1.4 |

Table 5.

Physical and mechanical properties of die steels [

30].

Table 5.

Physical and mechanical properties of die steels [

30].

| Property |

AISI316 |

H13 |

25CrMo4 |

AISI52100 |

AISI3310 |

| Density (g/cm3) |

8.03 |

7.78 |

7.85 |

7.83 |

7.81 |

| Tensile strength (MPa) |

550 |

1990 |

670 |

992 |

1866 |

| Yield strength (MPa) |

240 |

1650 |

435 |

579 |

1800 |

| Elastic modulus (GPa) |

210 |

210 |

205 |

200 |

210 |

| Poisson’s ratio |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

Table 6.

Process parameters ranking for extrusion force.

Table 6.

Process parameters ranking for extrusion force.

| Material |

Parameters |

| AISI316 |

Extrusion ratio, friction, ram speed, core diameter, billet height, die semi-angle and temperature. |

| H13 |

Friction, extrusion ratio, core diameter, billet height, die semi-angle, ram speed and temperature. |

| 25CrMo4 |

Friction, ram speed, billet height, core diameter, die semi-angle, temperature and extrusion ratio. |

| AISI52100 |

Friction, core diameter, die semi-angle, extrusion ratio, billet height, ram speed and temperature. |

| AISI3310 |

Ram speed, core diameter, friction, extrusion ratio, die semi-angle, billet height and temperature. |

Table 7.

Determination factor (R2) for extrusion force linear regression model.

Table 7.

Determination factor (R2) for extrusion force linear regression model.

| Material |

R2 |

| AISI316 |

0.91461 |

| H13 |

0.92245 |

| 25CrMo4 |

0.70708 |

| AISI52100 |

0.86922 |

| AISI3310 |

0.91966 |

Table 8.

Die materials ranking as function of the lowest extrusion force produced.

Table 8.

Die materials ranking as function of the lowest extrusion force produced.

| Material |

Ranking |

| AISI316 |

2 |

| H13 |

2 |

| 25CrMo4 |

5 |

| AISI52100 |

3 |

| AISI3310 |

1 |

Table 9.

Process parameters ranking for die wear.

Table 9.

Process parameters ranking for die wear.

| Material |

Parameters |

| AISI316 |

Friction, ram speed and temperature. |

| H13 |

Friction, ram speed and temperature. |

| 25CrMo4 |

Temperature, friction and ram speed. |

| AISI52100 |

Friction, temperature and ram speed. |

| AISI3310 |

Temperature, ram speed and friction. |

Table 10.

Determination factor (R2) for extrusion force linear regression model.

Table 10.

Determination factor (R2) for extrusion force linear regression model.

| Material |

R2 |

| AISI316 |

0.75695 |

| H13 |

0.74873 |

| 25CrMo4 |

0.63223 |

| AISI52100 |

0.80571 |

| AISI3310 |

0.65881 |

Table 11.

Die materials ranking as function of the minimum wear in the die produced.

Table 11.

Die materials ranking as function of the minimum wear in the die produced.

| Material |

Ranking |

| AISI316 |

2 |

| H13 |

3 |

| 25CrMo4 |

N/A |

| AISI52100 |

N/A |

| AISI3310 |

1 |

Table 12.

Die materials ranking as function of the minimum extrusion force and the minimum die wear.

Table 12.

Die materials ranking as function of the minimum extrusion force and the minimum die wear.

| Material |

Ranking |

| AISI316 |

2 |

| H13 |

3 |

| 25CrMo4 |

5 |

| AISI52100 |

4 |

| AISI3310 |

1 |

Table 13.

Table 13. Entropy method weights.

Table 13.

Table 13. Entropy method weights.

W.

1(%) |

W.

2(%) |

W.

3(%) |

W.

4(%) |

W.

5(%) |

W.

6(%) |

W.

7(%) |

W.

8(%) |

W.

9(%) |

W.

10(%) |

W.

11(%) |

W.

12(%) |

W.

13(%) |

W.

14(%) |

W.

15(%) |

W.

16(%) |

W.

17(%) |

W.

18(%) |

| 0.40 |

0.22 |

0.62 |

0 |

0.03 |

0.02 |

2.66 |

0.10 |

0.11 |

6.16 |

3.88 |

7.41 |

37.56 |

4.30 |

13.69 |

3.56 |

3.61 |

15.68 |

Table 14.

Die materials VIKOR ranking.

Table 14.

Die materials VIKOR ranking.

| Material |

Ranking |

| AISI316 |

2 |

| H13 |

3 |

| 25CrMo4 |

4 |

| AISI52100 |

5 |

| AISI3310 |

1 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).