Submitted:

31 January 2024

Posted:

31 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

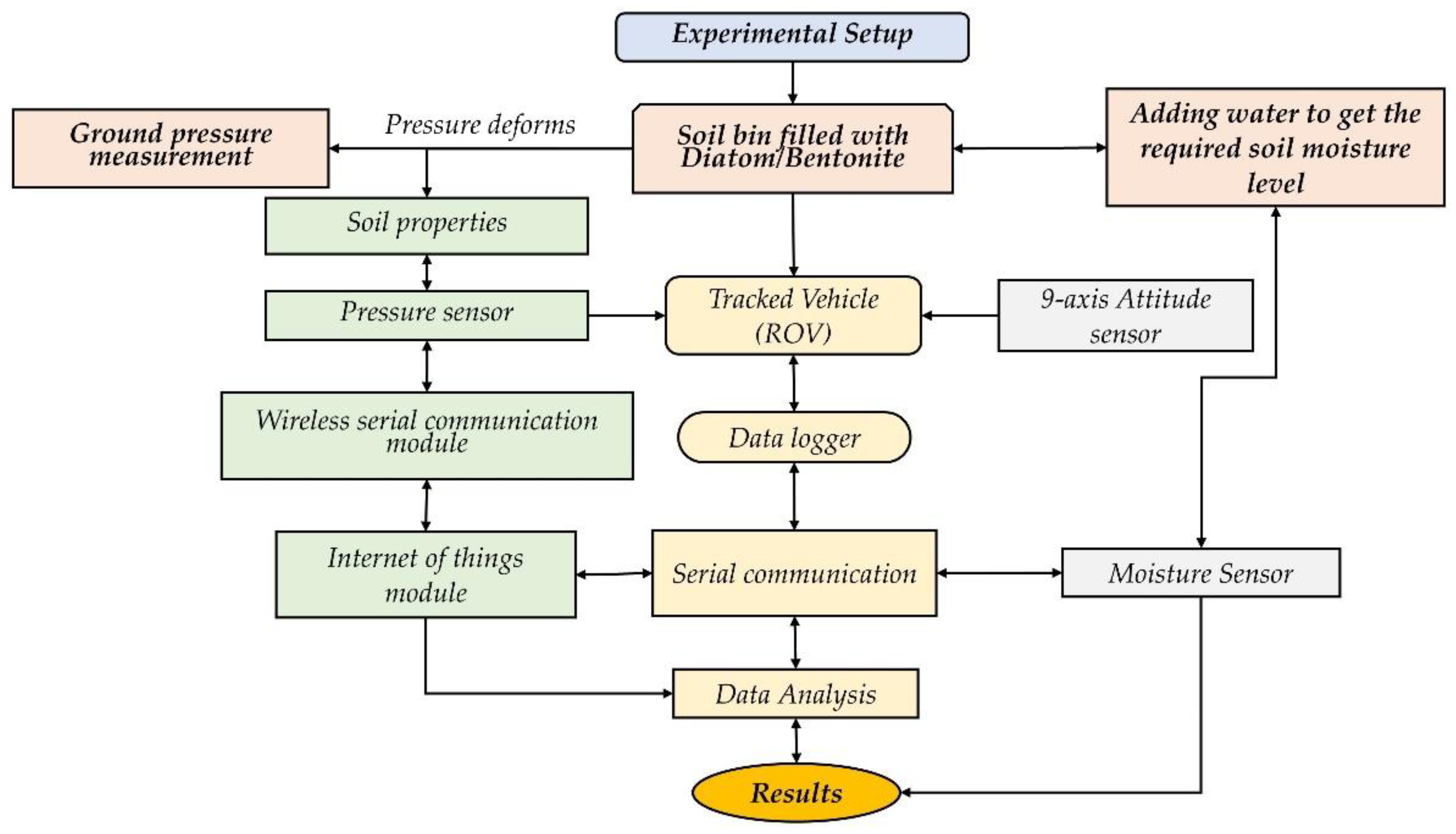

2. Materials and Methods

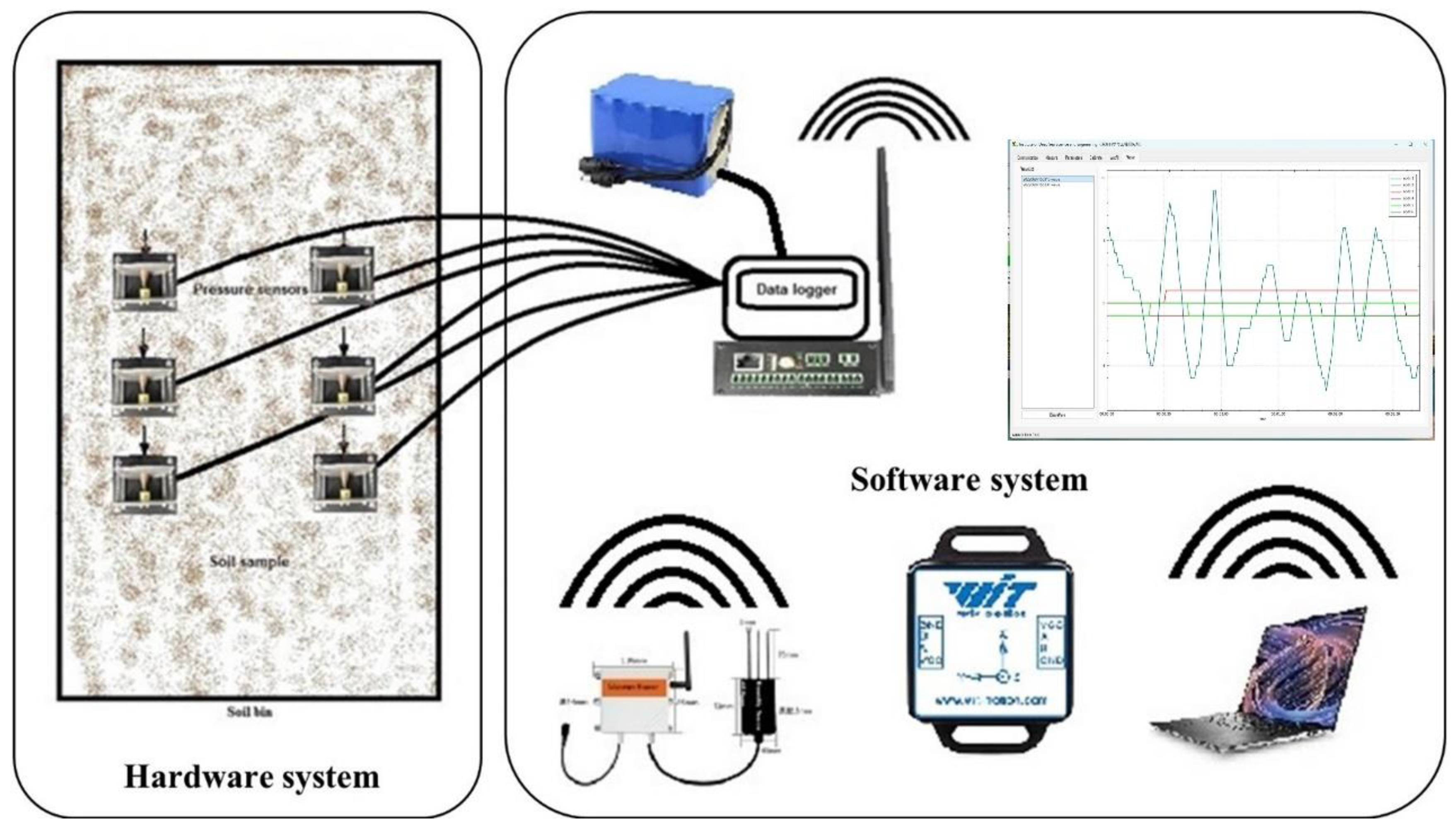

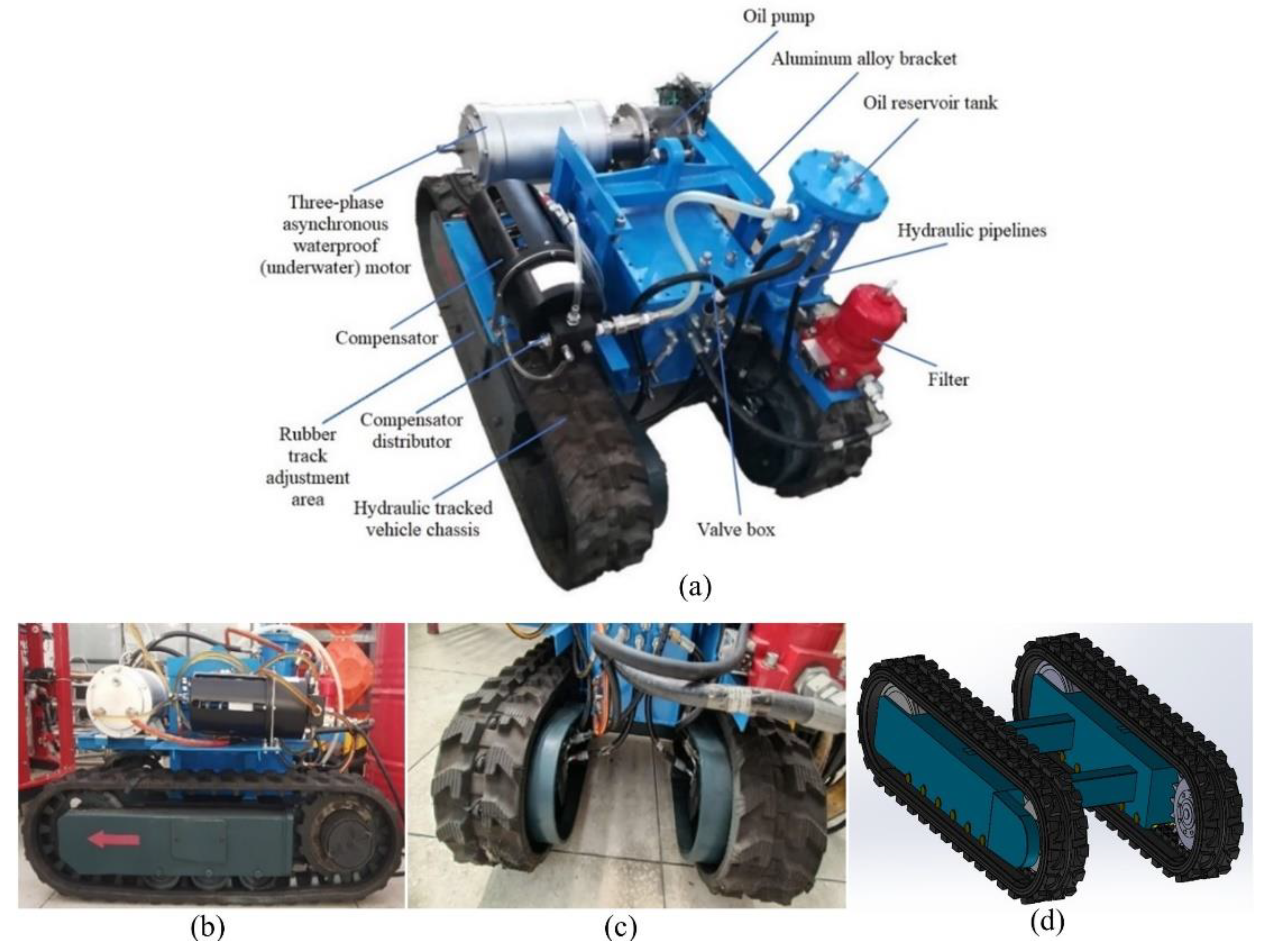

2.1. Tools and Sensors

2.2. Experimental Procedure

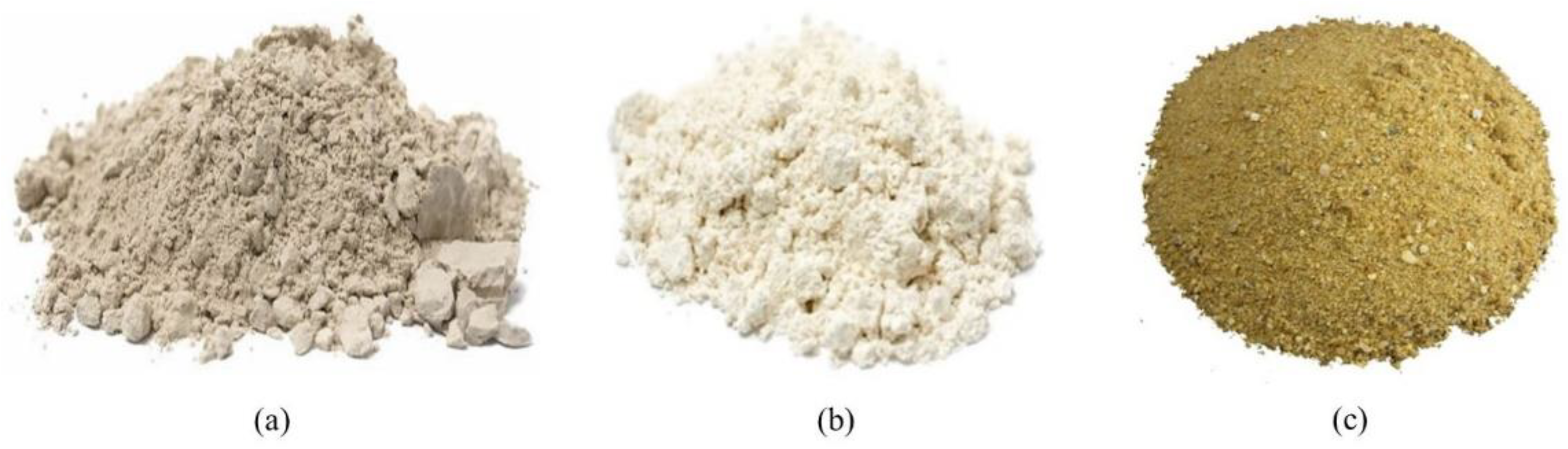

2.3. Soil Path Setup and Experimentation

2.4 Pressure Sensors and Brackets

2.5 Safety Protocols

3. Results and Discussion

3.1. Track Vehicle and Sinkage Observations

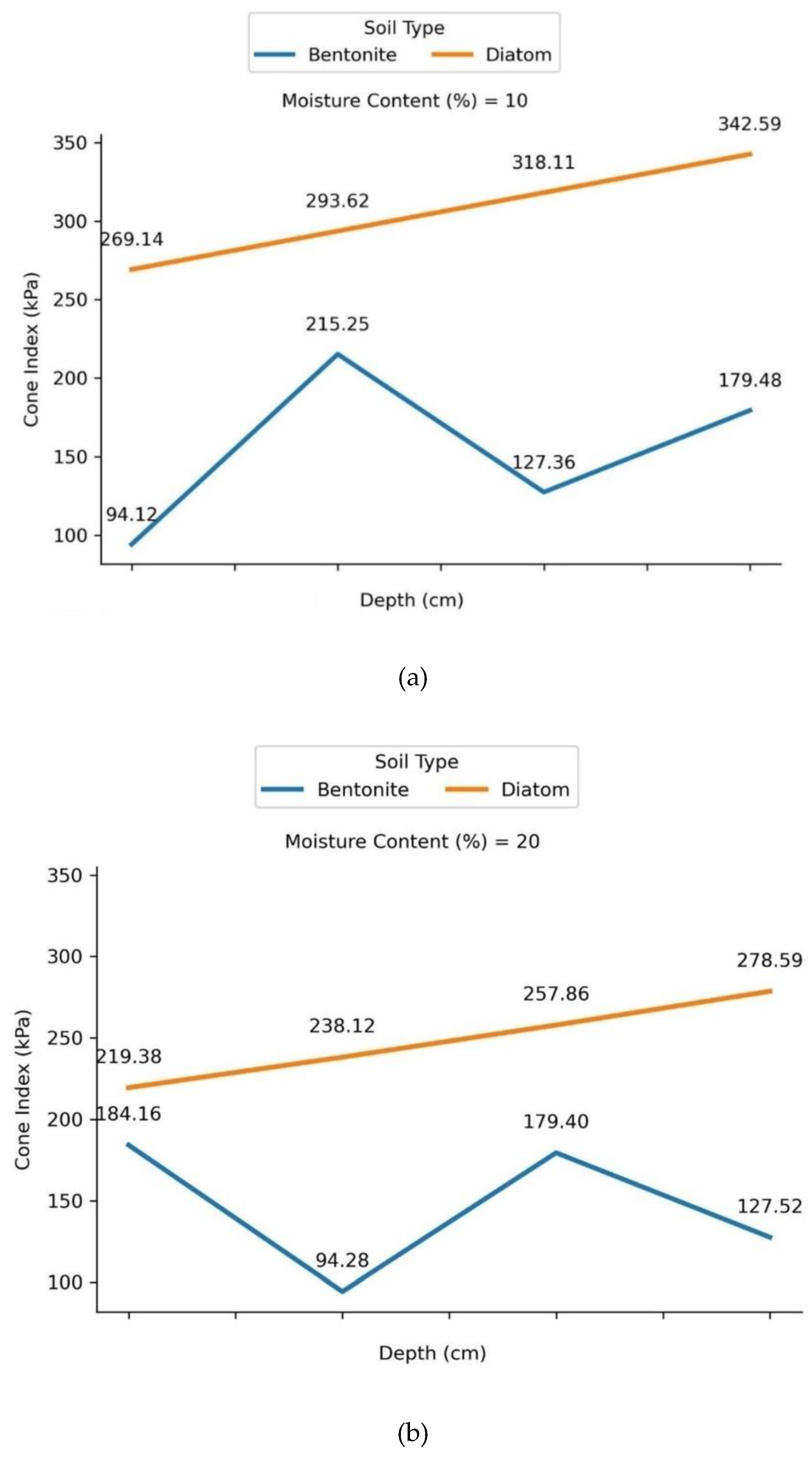

3.2. Soil Behavior

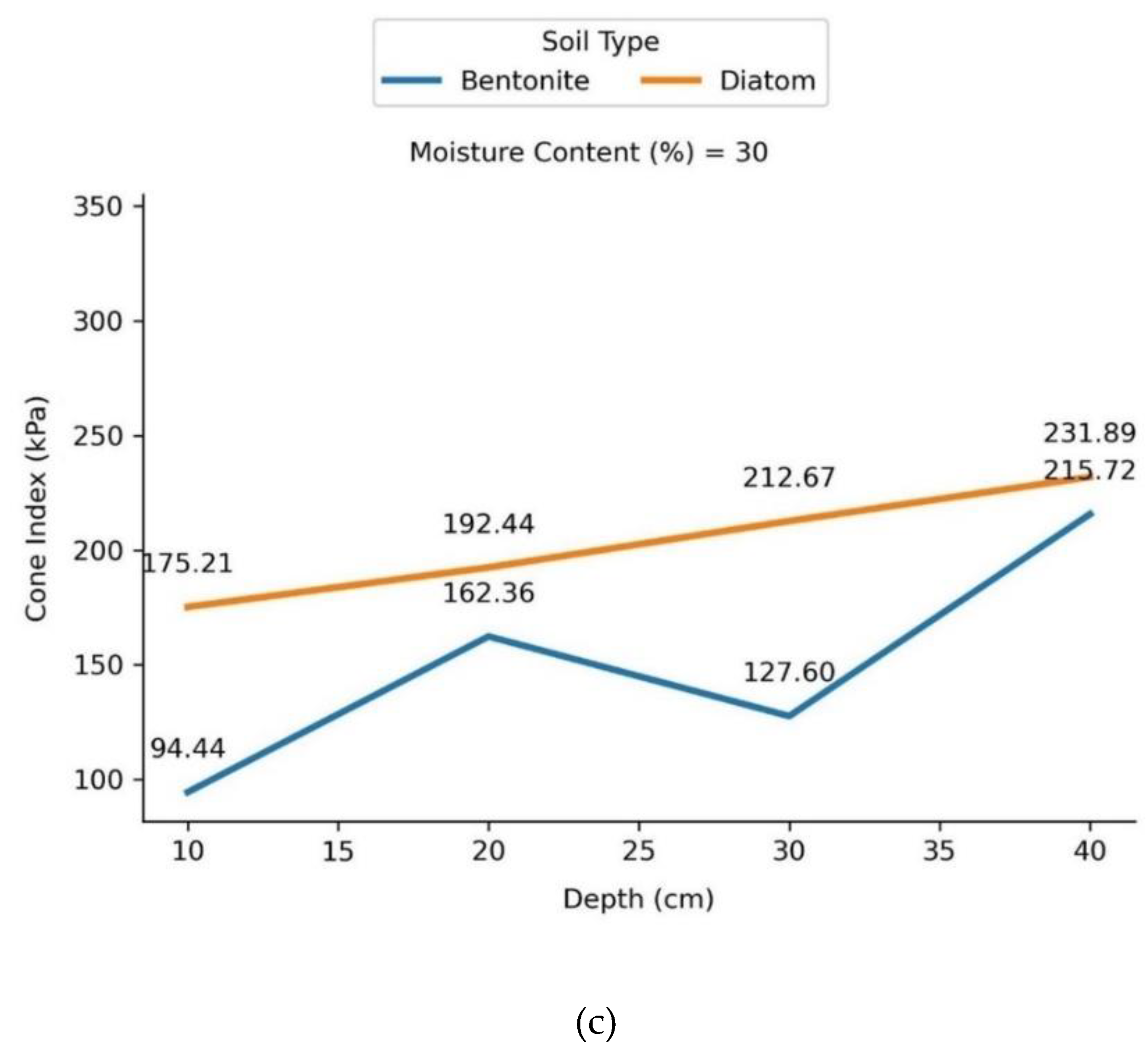

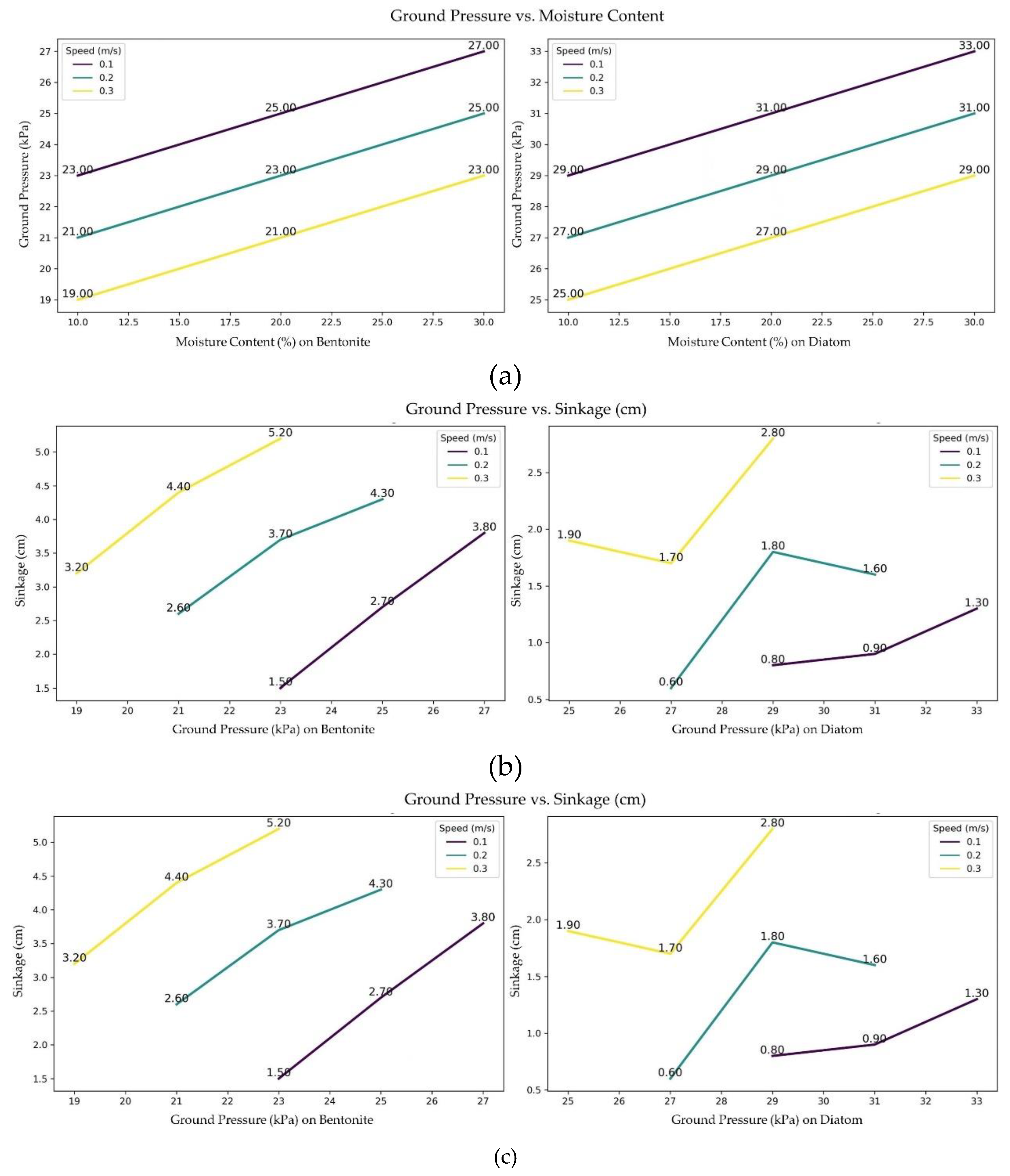

3.3. Ground Pressure and Sinkage Test Results

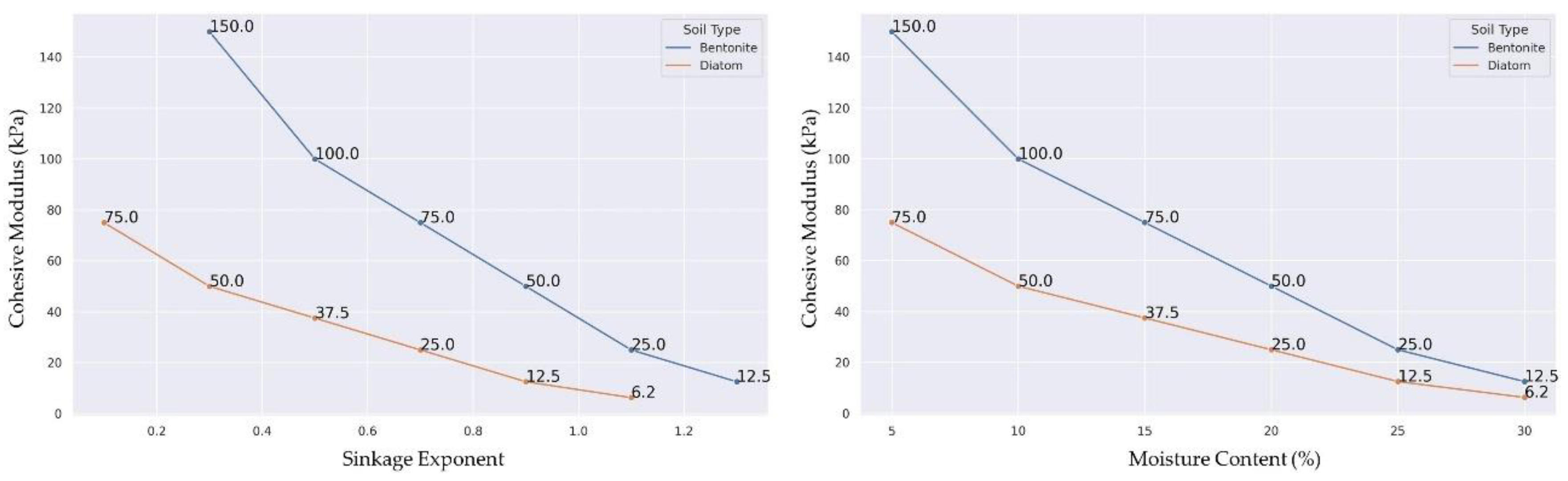

3.4. Impact of Moist Soil Content on Sinkage Exponent

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wong, J.Y. Terramechanics and Off-Road Vehicle Engineering: Terrain Behaviour. off-road vehicle performance and design 2010, 129–149. [Google Scholar]

- Zhang, Y.; Qiu, M.; Liu, X.; Li, J.; Song, H.; Zhai, Y.; Hu, H. Research on Characteristics of Tracked Vehicle Steering on Slope. Math Probl Eng 2021, 2021, 1–18. [Google Scholar] [CrossRef]

- Li, J.; Khajepour, A.; Huang, Y.; Wang, H.; Tang, C.; Qin, Y. A New Coordinated Control Strategy for Tracked Vehicle Ride Comfort. Proceedings of the Institution of Mechanical Engineers, Part K: Journal of Multi-body Dynamics 2018, 232, 330–341. [Google Scholar] [CrossRef]

- Wong, J.Y. Optimization of the Tractive Performance of Articulated Tracked Vehicles Using an Advanced Computer Simulation Model. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering 1992, 206, 29–45. [Google Scholar] [CrossRef]

- Beketov, S.A. The Concept of the Controlled Movement of the Tracked Vehicle. Izvestiya MGTU MAMI 2018, 12, 16–20. [Google Scholar] [CrossRef]

- Reece; Wong, J. -Y., A.R. Prediction of Rigid Wheel Performance Based on the Analysis of Soil-Wheel Stresses Part I. Performance of Driven Rigid Wheels. J Terramech 1967, 4, 81–98. [Google Scholar] [CrossRef]

- Wong, J.-Y.; Reece, A.R. Prediction of Rigid Wheel Performance Based on the Analysis of Soil-Wheel Stresses: Part II. Performance of Towed Rigid Wheels. J Terramech 1967, 4, 7–25. [Google Scholar] [CrossRef]

- Bekker, M.G. Introduction to Terrain-Vehicle Systems. Part i: The Terrain. Part Ii: The Vehicle. 1969.

- Shibly, H.; Iagnemma, K.; Dubowsky, S. An Equivalent Soil Mechanics Formulation for Rigid Wheels in Deformable Terrain, with Application to Planetary Exploration Rovers. J Terramech 2005, 42, 1–13. [Google Scholar] [CrossRef]

- Ruslan, N.A.I.; Amer, N.H.; Hudha, K.; Kadir, Z.A.; Ishak, S.A.F.M.; Dardin, S.M.F.S. Modelling and Control Strategies in Path Tracking Control for Autonomous Tracked Vehicles: A Review of State of the Art and Challenges. J Terramech 2023, 105, 67–79. [Google Scholar] [CrossRef]

- Wong, J.Y. Dynamics of Tracked Vehicles. Vehicle system dynamics 1997, 28, 197–219. [Google Scholar] [CrossRef]

- Shafaei, S.M.; Mousazadeh, H. On the Power Characteristics of an Unmanned Tracked Vehicle for Autonomous Transportation of Agricultural Payloads. J Terramech 2023, 109, 21–36. [Google Scholar] [CrossRef]

- Dallas, J.; Jain, K.; Dong, Z.; Sapronov, L.; Cole, M.P.; Jayakumar, P.; Ersal, T. Online Terrain Estimation for Autonomous Vehicles on Deformable Terrains. J Terramech 2020, 91, 11–22. [Google Scholar] [CrossRef]

- Nampoothiri, M.G.H.; Vinayakumar, B.; Sunny, Y.; Antony, R. Recent Developments in Terrain Identification, Classification, Parameter Estimation for the Navigation of Autonomous Robots. SN Appl Sci 2021, 3, 1–14. [Google Scholar] [CrossRef]

- Bekker, M.G. Introduction to Terrain-Vehicle Systems. Part i: The Terrain. Part Ii: The Vehicle. 1969.

- Wong, J.Y. Theory of Ground Vehicles; John Wiley & Sons, 2022; ISBN 1119719704.

- Harnisch, C.; Lach, B.; Jakobs, R.; Troulis, M.; Nehls, O. A New Tyre–Soil Interaction Model for Vehicle Simulation on Deformable Ground. Vehicle system dynamics 2005, 43, 384–394. [Google Scholar] [CrossRef]

- Wong, J.Y. Theory of Ground Vehicles; John Wiley & Sons, 2022; ISBN 1119719704.

- Gotteland, P.; Benoit, O. Sinkage Tests for Mobility Study, Modelling and Experimental Validation. J Terramech 2006, 43, 451–467. [Google Scholar] [CrossRef]

- Mohtashami, S.; Eliasson, L.; Jansson, G.; Sonesson, J. Influence of Soil Type, Cartographic Depth-to-Water, Road Reinforcement and Traffic Intensity on Rut Formation in Logging Operations: A Survey Study in Sweden. Silva Fennica 2017, 51. [Google Scholar] [CrossRef]

- Liu, K.; Ayers, P.; Howard, H.; Anderson, A. Influence of Soil and Vehicle Parameters on Soil Rut Formation. J Terramech 2010, 47, 143–150. [Google Scholar] [CrossRef]

- Diserens, E.; Défossez, P.; Duboisset, A.; Alaoui, A. Prediction of the Contact Area of Agricultural Traction Tyres on Firm Soil. Biosyst Eng 2011, 110, 73–82. [Google Scholar] [CrossRef]

- Meirion-Griffith, G.; Spenko, M. A Modified Pressure–Sinkage Model for Small, Rigid Wheels on Deformable Terrains. J Terramech 2011, 48, 149–155. [Google Scholar] [CrossRef]

- Solis, J.M.; Longoria, R.G. Modeling Track–Terrain Interaction for Transient Robotic Vehicle Maneuvers. J Terramech 2008, 45, 65–78. [Google Scholar] [CrossRef]

- Szpaczyńska, D.; Łopatka, M.J.; Krogul, P. Susceptibility Modeling of a Rubber Track for Lightweight Mobile Robots. Applied Sciences 2023, 13, 10533. [Google Scholar] [CrossRef]

- Hu, K.; Cheng, K. Dynamic Modelling and Stability Analysis of the Articulated Tracked Vehicle Considering Transient Track-Terrain Interaction. Journal of Mechanical Science and Technology 2021, 35, 1343–1356. [Google Scholar] [CrossRef]

- Shibly, H.; Iagnemma, K.; Dubowsky, S. An Equivalent Soil Mechanics Formulation for Rigid Wheels in Deformable Terrain, with Application to Planetary Exploration Rovers. J Terramech 2005, 42, 1–13. [Google Scholar] [CrossRef]

- Ani, O.A.; Uzoejinwa, B.B.; Ezeama, A.O.; Onwualu, A.P.; Ugwu, S.N.; Ohagwu, C.J. Overview of Soil-Machine Interaction Studies in Soil Bins. Soil Tillage Res 2018, 175, 13–27. [Google Scholar] [CrossRef]

- Badgujar, C.M.; Flippo, D.; Brokesh, E.; Welch, S. Experimental Investigation on Traction, Mobility, and Energy Usage of a Tracked Autonomous Ground Vehicle on a Sloped Soil Bin. Journal of the ASABE 2022, 65, 835–847. [Google Scholar] [CrossRef]

- Badgujar, C.; Flippo, D.; Welch, S. Artificial Neural Network to Predict Traction Performance of Autonomous Ground Vehicle on a Sloped Soil Bin and Uncertainty Analysis. Comput Electron Agric 2022, 196, 106867. [Google Scholar] [CrossRef]

- Ivanov, S.É.; Belyakov, A. V Diatomite and Its Applications. Glass & Ceramics 2008, 65. [Google Scholar]

- Diaz-Rodríguez, J.A. Diatomaceous Soils: Monotonic Behavior. In Deformation characteristics of geomaterials; IOS Press, 2011; pp. 865–871.

- Wagner, J.-F. Mechanical Properties of Clays and Clay Minerals. In Developments in clay science; Elsevier, 2013; Vol. 5, pp. 347–381 ISBN 1572-4352.

- Chaudhary, V.; Yadav, J.S.; Dutta, R.K. Geotechnical Properties of Bentonite Mixed with Nanosilica. Multiscale and Multidisciplinary Modeling, Experiments and Design 2023, 2023, 1–18. [Google Scholar] [CrossRef]

- Tang, A.-M.; Cui, Y.-J.; Eslami, J.; Défossez, P. Analysing the Form of the Confined Uniaxial Compression Curve of Various Soils. Geoderma 2009, 148, 282–290. [Google Scholar] [CrossRef]

- Kochmanov, N.; Tanakai, H. Influence of the Soil Fabric on the Mechanical Properties of Unsaturated Clays. Soils and Foundations 2011, 51, 275–286. [Google Scholar] [CrossRef]

- Cuisinier, O.; Auriol, J.-C.; Le Borgne, T.; Deneele, D. Microstructure and Hydraulic Conductivity of a Compacted Lime-Treated Soil. Eng Geol 2011, 123, 187–193. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, Y.-J.; Tang, A.M.; Barnichon, J.-D.; Saba, S.; Ye, W.-M. Hydraulic Conductivity and Microstructure Changes of Compacted Bentonite/Sand Mixture during Hydration. Eng Geol 2013, 164, 67–76. [Google Scholar] [CrossRef]

- Alaoui, A.; Helbling, A. Evaluation of Soil Compaction Using Hydrodynamic Water Content Variation: Comparison between Compacted and Non-Compacted Soil. Geoderma 2006, 134, 97–108. [Google Scholar] [CrossRef]

- Zhang, S.; Grip, H.; Lövdahl, L. Effect of Soil Compaction on Hydraulic Properties of Two Loess Soils in China. Soil Tillage Res 2006, 90, 117–125. [Google Scholar] [CrossRef]

- Samuel, T.M.; Ajav, E.A. Optimum Tillage System for Pepper Production in an Alfisol of South-Western Nigeria. Afr J Agric Res 2010, 5, 2647–2652. [Google Scholar]

- Botta, G.F.; Becerra, A.T.; Tourn, F.B. Effect of the Number of Tractor Passes on Soil Rut Depth and Compaction in Two Tillage Regimes. Soil Tillage Res 2009, 103, 381–386. [Google Scholar] [CrossRef]

- Mishra, A.K.; Ohtsubo, M.; Li, L.Y.; Higashi, T. Influence of the Bentonite on the Consolidation Behaviour of Soil–Bentonite Mixtures. Carbonates Evaporites 2010, 25, 43–49. [Google Scholar] [CrossRef]

- Sha, F.; Xi, M.; Chen, X.; Liu, X.; Niu, H.; Zuo, Y. A Recent Review on Multi-Physics Coupling between Deep-Sea Mining Equipment and Marine Sediment. Ocean Engineering 2023, 276, 114229. [Google Scholar] [CrossRef]

- Yang, C.; Yang, G.; Liu, Z.; Chen, H.; Zhao, Y. A Method for Deducing Pressure–Sinkage of Tracked Vehicle in Rough Terrain Considering Moisture and Sinkage Speed. J Terramech 2018, 79, 99–113. [Google Scholar] [CrossRef]

| Items | Model | Operating Voltage | Measuring Range | Measurement Accuracy |

|---|---|---|---|---|

| Pressure sensor | ZNHM-D1-2T-22121401 | 5-15V DC | 214.5kPa -40 to 85°C |

99.9% ±0.5% FS |

| Moisture sensor | JXBS-3001-TR_4G | 12-24V DC | 0-100% -40 ℃-80 ℃ |

3% in the range of 0-53% 5% in the range of 53-100% |

| Cone Penetrometer | SC 900 | 4 AAA alkaline batteries | 0 - 18” (0 - 45 cm) 0 – 1000 PSI (0 - 7000 kPa) |

±0.5” (±1.25 cm) ±15 PSI (±103 kPa) |

| Data logger built-in Wireless serial communication module | FD0843 (6 Channel) |

9~24V DC, <10W | 100/200/400/800/1600 | Temp: -30°~ 65℃ Relative humidity: 10%~ 95% A/D Update rate: 1600Hz Data transfer rate:100Mb/s |

| Direct Shear Apparatus | ZJ-1B | 110-240V AC | Shear Displacement: 0-50 mm Normal Load: 0-400 kN |

Shear Displacement: ±0.01 mmNormal Load: ±0.5% of applied load Shear Load: ±0.5% of measured value |

| 9-axis attitude sensor | WT901BLECL5.0 | 3.7V – 260mah | TCP: 1~10Hz UDP: 1~200Hz |

Angular accuracy X, Y axis 0.2°, Z axis 1° |

| Parameter Name | Symbol | Parameter Content |

|---|---|---|

| Track length × width × Height (cm) | Lx×Ly×Lz | 120 × 90 × 80 |

| Contact length of rubber track | cm | 90 |

| Width of single rubber track | cm | 20 |

| Drive wheel diameter | cm | 26 |

| Front idler diameter | cm | 32 |

| Lugs | cm | 19 |

| Weight of the tracked vehicle | W (kg) | 544 |

| Weight of the vehicle in the water | Ww (kg) | 523.25 |

| Contact Pressure | P (kPa) | 13.889 |

| Contact Pressure in the water | Pw (kPa) | 12.5 |

| Soil | Depth (cm) | Cone Penetration Resistance kPa @ Moisture (± %) | ||

|---|---|---|---|---|

| 10 ± % | 20 ± % | 30 ± % | ||

| Bentonite | 0-5 | 10 kPa | 20 kPa | 40 kPa |

| 5-15 | 15 kPa | 30 kPa | 45 kPa | |

| 15-30 | 20 kPa | 25 kPa | 50 kPa | |

| Diatom | 0-5 | 15 kPa | 18 kPa | 20 kPa |

| 5-15 | 18 kPa | 20 kPa | 22 kPa | |

| 15-30 | 20 kPa | 22 kPa | 25 kPa | |

| Soil | Moisture (%) | Speed (m/s) | Sinkage (cm) | Track-Soil Observations |

|---|---|---|---|---|

| Bentonite | 5 | 0.1 | 1.10 | Normal wear and tear on tracks |

| Bentonite | 10 | 0.1 | 1.50 | Rutting beginning tracks deforming |

| Bentonite | 15 | 0.1 | 2.40 | Deep rutting, tracks digging in |

| Bentonite | 20 | 0.1 | 2.70 | Severe rutting, tracks stuck |

| Bentonite | 25 | 0.1 | 3.20 | Severe track deformation and sinking |

| Bentonite | 30 | 0.1 | 3.80 | Increased track slippage |

| Diatom | 5 | 0.1 | 0.55 | Normal wear and tear on tracks |

| Diatom | 10 | 0.1 | 0.80 | Minor rutting |

| Diatom | 15 | 0.1 | 0.83 | Rutting |

| Diatom | 20 | 0.1 | 0.90 | Deep Rutting |

| Diatom | 25 | 0.1 | 1.21 | very soft soil, tracks dug in |

| Diatom | 30 | 0.1 | 1.30 | Severe track deformation and sinking |

| Soil Type | Speed (m/s) | Moisture Content (±%) | Ground Pressure (kPa) | Sinkage (cm) |

|---|---|---|---|---|

| Bentonite | 0.1 | 10 | 23 | 1.5 |

| Bentonite | 0.1 | 20 | 25 | 2.7 |

| Bentonite | 0.1 | 30 | 27 | 3.8 |

| Bentonite | 0.2 | 10 | 21 | 2.6 |

| Bentonite | 0.2 | 20 | 23 | 3.7 |

| Bentonite | 0.2 | 30 | 25 | 4.3 |

| Bentonite | 0.3 | 10 | 19 | 3.2 |

| Bentonite | 0.3 | 20 | 21 | 4.4 |

| Bentonite | 0.3 | 30 | 23 | 5.2 |

| Diatom | 0.1 | 10 | 29 | 0.8 |

| Diatom | 0.1 | 20 | 31 | 0.9 |

| Diatom | 0.1 | 30 | 33 | 1.3 |

| Diatom | 0.2 | 10 | 27 | 0.6 |

| Diatom | 0.2 | 20 | 29 | 1.8 |

| Diatom | 0.2 | 30 | 31 | 1.6 |

| Diatom | 0.3 | 10 | 25 | 1.9 |

| Diatom | 0.3 | 20 | 27 | 1.7 |

| Diatom | 0.3 | 30 | 29 | 2.8 |

| Soil Type | Moisture Content (± %) | Sinkage Exponent | Cohesive Modulus (kPa) |

|---|---|---|---|

| Bentonite | 5 | 0.3 | 150 |

| Bentonite | 10 | 0.5 | 100 |

| Bentonite | 15 | 0.7 | 75 |

| Bentonite | 20 | 0.9 | 50 |

| Bentonite | 25 | 1.1 | 25 |

| Bentonite | 30 | 1.3 | 12.5 |

| Diatom | 5 | 0.1 | 75 |

| Diatom | 10 | 0.3 | 50 |

| Diatom | 15 | 0.5 | 37.5 |

| Diatom | 20 | 0.7 | 25 |

| Diatom | 25 | 0.9 | 12.5 |

| Diatom | 30 | 1.1 | 6.25 |

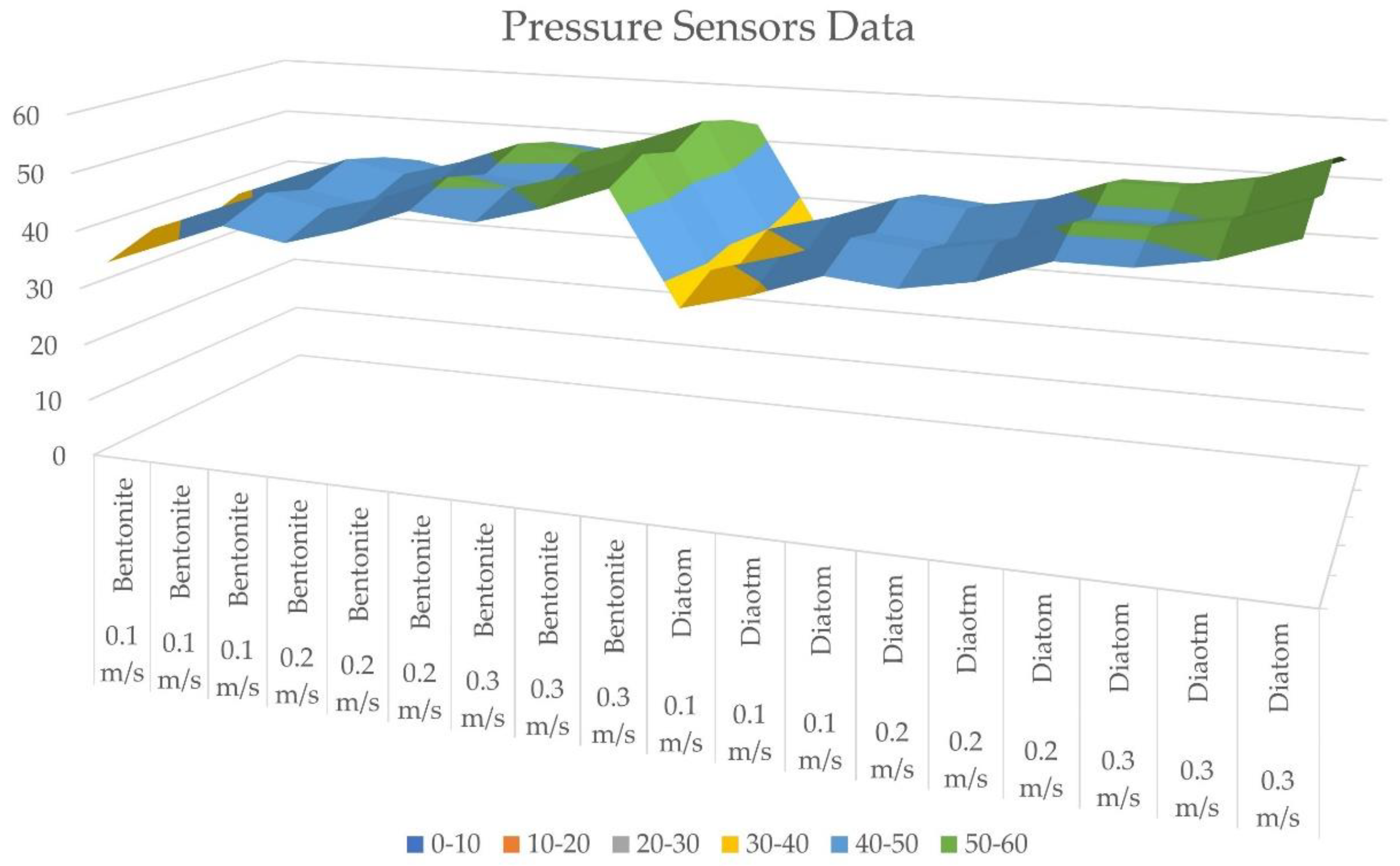

| Soil Type | Moisture Level (±%) | Speed (m/sec) | Sensor 1 (kPa) | Sensor 2 (kPa) | Sensor 3 (kPa) | Sensor 4 (kPa) | Sensor 5 (kPa) | Sensor 6 (kPa) |

|---|---|---|---|---|---|---|---|---|

| Bentonite | 10 | 0.1 | 35 | 38 | 36 | 39 | 37 | 34 |

| Bentonite | 20 | 0.1 | 39 | 42 | 40 | 43 | 41 | 38 |

| Bentonite | 30 | 0.1 | 43 | 46 | 44 | 47 | 45 | 42 |

| Diatom | 10 | 0.1 | 36 | 39 | 37 | 40 | 38 | 35 |

| Diatom | 20 | 0.1 | 39 | 42 | 40 | 43 | 41 | 38 |

| Diatom | 30 | 0.1 | 43 | 46 | 44 | 47 | 45 | 42 |

| Bentonite | 10 | 0.2 | 41 | 44 | 42 | 45 | 43 | 40 |

| Bentonite | 20 | 0.2 | 44 | 47 | 45 | 48 | 46 | 43 |

| Bentonite | 30 | 0.2 | 48 | 51 | 49 | 52 | 50 | 47 |

| Diatom | 10 | 0.2 | 42 | 45 | 43 | 46 | 44 | 41 |

| Diatom | 20 | 0.2 | 44 | 47 | 45 | 48 | 46 | 43 |

| Diatom | 30 | 0.2 | 48 | 51 | 49 | 52 | 50 | 47 |

| Bentonite | 10 | 0.3 | 47 | 50 | 48 | 51 | 49 | 46 |

| Bentonite | 20 | 0.3 | 50 | 53 | 51 | 54 | 52 | 49 |

| Bentonite | 30 | 0.3 | 54 | 57 | 55 | 58 | 56 | 53 |

| Diatom | 10 | 0.3 | 48 | 51 | 49 | 52 | 50 | 47 |

| Diatom | 20 | 0.3 | 50 | 53 | 51 | 54 | 52 | 49 |

| Diatom | 30 | 0.3 | 54 | 57 | 55 | 58 | 56 | 53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).