1. Introduction

Sensory analyses are fundamental for multiple applications in cheese technology such as classification [

1], quality assurance, new product development, research and investigation of drivers behind consumers’ choice and liking [

2,

3]. In addition, sensory evaluation is extremely important for cheeses with the Protected Denomination of Origin or Protected Geographical Indication whose product specification must include a sensory description useful for controlling production and ripening [

4].

The key outcome of a sensory analysis is the sensory profile, which is defined as the ‘description of the sensory properties of a sample, consisting of the sensory attributes in the order of perception, and with assignment of an intensity value for each attribute’ [

5]. It is determined by descriptive tests, which focus on the differentiation and description of products based on their qualitative and quantitative sensory aspects [

6]. Descriptive methods have been considered the most powerful sensory tool for cheese flavour research [

7], and their application to determine the sensory profile of cheeses is largely documented [

3,

8].

The fundamental element of descriptive techniques is the sensory panel, a group of tasters that have been trained to identify, describe and rate the perceived sensory aspects of a sample [

6]

. The use of reference standards during tasters’ training and calibration procedures is crucial [

9,

10] and required by the international standards [

11]. The ideal reference standard should provide both qualitative and quantitative information, be stable and reproducible over time [

11], be simple in its preparation, identify only one term and not be of commercial origin to avoid production variability or supply difficulties [

12]. Consequently, commercial products and food ingredients are not appropriate as they limit the reproducibility of studies worldwide and over time, although their use as standards for gustatory and olfactory descriptors has been reported in several studies on cheese [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25]. Such a limitation is overcome by pure chemicals, which have been used as reference standards for the gustatory and olfactory descriptors of cheese in several studies [

13,

14,

15,

18,

19,

21,

25,

26,

27,

28,

29,

30]. However, because the assessor must be able to recognise the descriptor among the complex sensations of the stimulus [

11], the use of pure chemicals is not recommended for the panel training. Indeed, the assessors should learn sensory descriptors directly from a medium like the food matrix that is going to be evaluated instead of using external reference standards, as in the case of pure chemical compounds [

31].

A possible solution is represented by food models, which are reconstructed foods that mimic the food structure to be evaluated, but with sensory properties as bland as possible, to include within them compounds representative of the typical sensory descriptors of the product. Such an approach has already been implemented for orange juice [

32], beer [

33], tomatoes [

34], wine [

35,

36,

37,

38,

39,

40,

41], fruit juice [

42] and balsamic vinegar [

43], in which the proposed food models exhibited improved panel performance and the superiority of product-specific training was demonstrated [

31].

In the case of the dairy sector, cheese models (CMs) have been scarcely used as reference standards. Among the reconstructed CMs available in the literature, the one developed by Salles et al. [

44] was described as a potential starting point to create effective and objective standards [

31]. This CM was obtained using a mixture of water, milk fat, milk powder, casein, sodium chloride and glucono-δ-lactone. It was exposed to the action of rennet, and overall, the preparation lasted more than 3 h. However, this study did not focus specifically on the development of reference standards for the descriptive analysis of cheese, and the intensity scales for panel training have not been elaborated [

44].

Some researchers have attempted to harmonise both the lexicon and the reference standards involved in the training process by comparing the terms used by different research groups for the descriptive sensory analysis [

2,

3,

8,

15]; however, the reported reference standards did not include any CM. The lack of homogeneous procedures for the training of tasters, the absence of common validated reference standards for the gustatory and olfactory descriptors of cheese and the need to develop a universal sensory lexicon for cheese have also been highlighted [

3,

8,

31]

. Therefore, this study aimed to develop reference standards that are easily replicable and feasible for panel training procedures. To this end, a tasteless and odourless CM was produced and then added with compounds representative of the typical taste and odour/aroma of cheese. The CM was tested by cheese tasters to collect information on their perceived intensity and recognisability. The implementation of such reference standards in panel management practices is expected to have further potential applications. In particular, it would allow for a uniform sensory lexicon, which is an essential prerequisite for the comparison of the different sensory profiles of cheeses and between different tasting panels, even cross-countries, a procedure that has encountered difficult applications to date [

8]. Furthermore, reference standards are a critical element for cheese products under the EU quality schemes. Their implementation would facilitate the drafting procedures of product specifications and improve conformity verification by producers and authorities [

45,

46].

2. Materials and Methods

2.1. Materials

Milk casein concentrate was purchased from EkoPura (Hoofddorp, Netherlands). Maizena maize starch was provided by Unilever (London, United Kingdom). Kappa-carrageenan was purchased from SaporePuro (Torino, Italy), skimmed milk powder (carbohydrate, 56.0%; protein, 34.0%; fat, 1.2%; salt, 1%) from ProntoFoods (Montichiari, Italy) and natural mineral water from the market (Sant’Anna, Vinadio, Italy). Furthermore, food-grade flavours (almond, ananas, cooked egg yolk, milk, hazelnut, honey, mushroom, olive oil, cooked ham, raw ham, smoked) were furnished by FlavourArt (Oleggio, Italy). Tartaric acid, caffeine anhydrous and glutamic acid monosodium salt were purchased from Fluka Chemie Gmbh (Buchs, Switzerland), sodium chloride from ‘Compagnia Italiana Sali’ (Porto Viro, Italy) and lactose from Carlo Erba Reagents Srl (Cornaredo, Italy). In addition, UHT skimmed milk (carbohydrate, 5.0%; protein, 3.2%; fat, 0.1%; salt, 0.1%) was purchased from Granarolo S.p.a. (Bologna, Italy). Butter ghee was provided by Khanum (Hertford, United Kingdom). Pasteurised fresh cow cream (carbohydrate, 3.0%; protein, 2.0%; fat, 38.0%; salt, 0.07%) was furnished by ‘Centrale del latte d’Italia S.p.a.’ (Torino, Italy). Low-fat yogurt (carbohydrate, 5.6%; protein, 4.3%; fat, 0.1%; salt, 0.1%) was purchased from ‘Cooperativa Latteria Vipiteno’ (Vipiteno, Italy).

2.2. Sensory evaluation

The sensory evaluation (identification of attributes and perceived intensity) was conducted by 60 cheese tasters (men = 53.33%, age range: 24–70 years) from the Italian National Organisation of Cheese Tasters. Each assessor underwent a training in cheese sensory analysis for at least 20 h that included a final exam. Every taster received four cheese standards with different attributes (one for taste and three for odour/aroma) in a randomised, anonymous, and blinded scheme. Therefore, each descriptor was evaluated 12 times by different tasters.

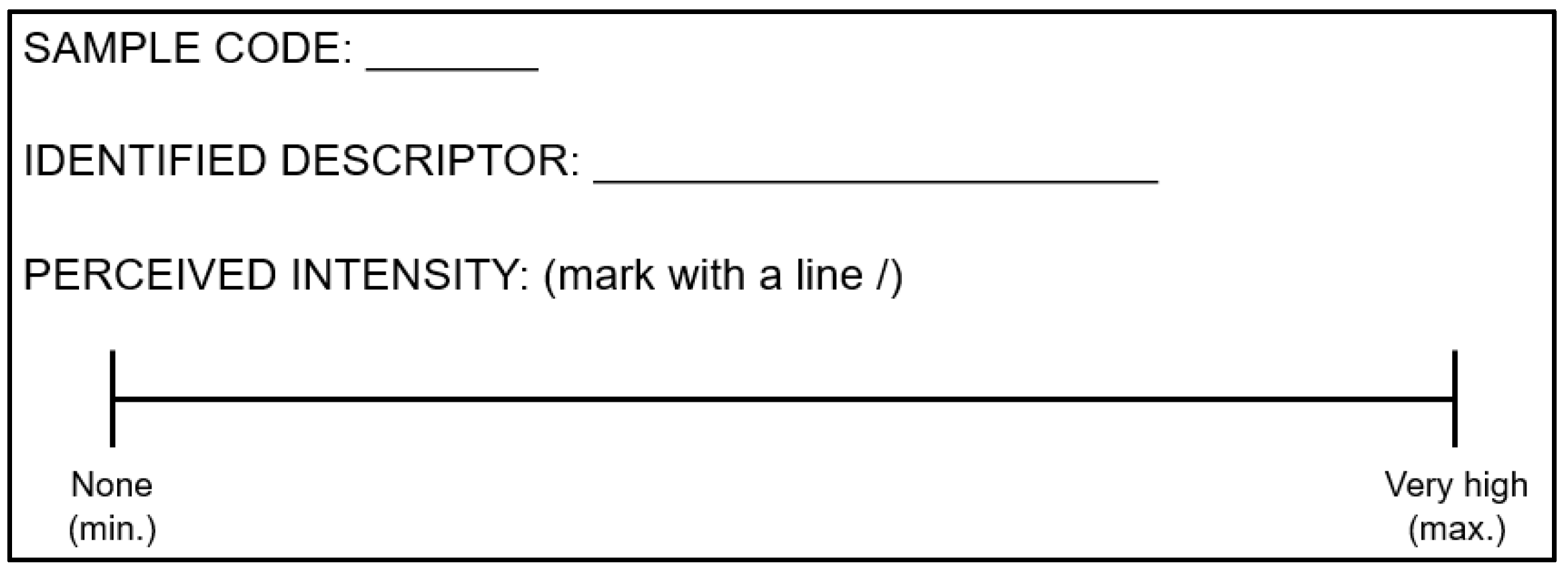

The samples were provided in transparent plastic plates (R.F. Distribuzione Srl, Mercato San Severino, Italy) with no information. For the sensory analysis, a special evaluation sheet was used where the perceived sensory odour/aroma or taste and the intensity were reported (

Figure 1). For the intensity evaluation, a continuous, unipolar 15-cm linear scale with anchors at the two ends (‘none’ and ‘very high’) was used [

6].

The panellists rinsed their mouths with natural mineral water (Sant’Anna, Fonti di Vinadio, Italy) after tasting each sample. The panellists took a 1-min break between sample evaluations. The evaluation was performed in a room with white light at a temperature of 22°C ± 2°C. The samples were prepared in the preceding 2 h and served at 15°C ± 1°C.

When the odour/aroma or taste was correctly identified by the taster, the perceived intensity was manually measured according to the method described by Meilgaard et al. [

6]. The minimum and maximum values of the perceived intensity were determined for each reference standard.

3. Results and Discussion

3.1. Cheese-like base production

To produce a cheese-like base, 8 g of maize starch, 5 g of casein, 4.3 g of powder skimmed milk and 1 g of k-carrageenan were mixed and then added to 81.7 g of water. The obtained mixture was heated to 80 °C using a bain-marie with water pre-heated to 90 °C and stirred for 2 min. Subsequently, the mixture was poured into hemisphere silicone moulds (E-CrossStu Gmbh, Frankfurt am Main, Germany) and allowed to cool at room temperature (20 °C ± 2 °C). A Medidor PH BASIC 20 pH-metre (Hach Lange Srl, Lainate, Italy) was used to evaluate the pH of the samples.

Approximately 110 different formulations were tested, each aimed at achieving a structure resembling fresh cheese, devoid of any distinctive taste or odour. Through a rigorous evaluation, the formulation that exhibited the most accurate mimicry of fresh cheese while lacking discernible taste and odour was selected. Notably, in the trial without carrageenan, a poor structure and a grainy mouthfeel were noted. Furthermore, the sample without starch and with a higher amount of casein felt strong on the palate with an odour of casein, and while it was not completely tasteless, it deviated from the desired characteristics. Although the specific data obtained from these trials were not presented in this manuscript, the final selected formulation was presented in detail above.

The CM obtained through the proposed formulation was comparable to a generic fresh cheese but was odourless and tasteless (

Figure 2). Compared with the study by Salles et al. [

44], the proposed formulation was able to obtain a cheese-like base without sensory properties in a shorter time and with the simplified use of ingredients and equipment.

Coagulation with acids or rennet was avoided to limit their impact on the sensory properties of the standard, to allow greater reproducibility of the production and reduce the preparation time. Alternatively,

k-carrageenan was used owing to its gelling and thickening properties. Indeed, its historical use in combination with milk has been reported [

47] as well as specific interactions with

k-casein and their charged amino acids [

48] and maize starch [

49]. Similarly, maize starch has shown positive interactions with caseins that resulted in a stronger density of the gel network structure [

50,

51]. The temperature range of 70–80 °C, which was selected for the heating process, enabled a complete gelatinisation [

52] and the transfer into the silicone moulds to cool, it firmed up completely to the desired texture.

Unlike the study by Salles et al. [

44], Ultra-Turrax T25 (IKA-Labortechnik, Staufen, Germany) was not used for this preparation as they negatively affected the texture in the preliminary trials.

3.2. Reference standard production

According to the same ‘food-models’ approach already implemented for several food products [

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42,

43,

44], chemicals and food ingredients were added to the cheese-like base to obtain a standard product that has cheese odour/aroma and taste.

According to the descriptors used for the sensory analysis of cheese [

2,

3,

8,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31] 20 reference standards were selected: 5 for taste and 15 for odour/aroma (

Table 1). Although the use of food ingredients may be subjected to the limits of global supply and production changes over time [

12], the ones selected (low-fat yogurt, pasteurised cow cream, butter and UHT skimmed milk) are easily available in different parts of the world [

53], and therefore, the reproducibility of standards is guaranteed.

Solid substances were mixed with the other solid ingredients of the CM, whereas liquid compounds were added to the mix before the heating process.

For the ‘cooked milk’ odour/aroma, the UHT skimmed milk was boiled for 5 min and then added to the mixture before the heating process, whereas for the ‘yogurt’ odour/aroma, the low-fat yogurt was centrifuged at 8000 × g for 15 min at 10°C and then 6 mL of whey was added to the mixture also before the heating process.

Standard concentrations were defined in the preliminary tests to obtain the mean intensity according to the ISO 11035:1994 [

11] to properly train the sensory panel.

The inclusion of these ingredients did not affect the CM structure. Only the standard for acid was less humid and soluble than CM. The reason can be related to the reduction in pH values from 6.64 ± 0.01 of the CM to 5.20 ± 0.03 after the addition of L-tartaric acid. However, the obtained product maintained a solid and stable structure without significant differences from the CM. The alternative use of

k-carrageenan with maize starch, casein and skimmed milk in an aqueous medium to obtain a solid matrix similar to a fresh cheese was effective and the obtained products is adaptable to a different shape. This provides a solid standard to train tasters, allowing mastication with an improved retro-olfactory aroma perception [

54,

55]

, compared with liquid pure chemicals currently used as cheese reference standards. The versatility of the base matrix in including substances representative of the 20 gustatory and olfactory descriptors developed would also allow future use of this formulation for additional attributes not involved in this study.

3.3. Sensory evaluation

Among the 240 obtained evaluation sheets, only for 27 of these the sensory descriptor was not identified. The results indicate that the tasters had difficulty identifying some descriptors such as ‘Umami’, ‘Almond’, ‘Cooked egg yolk’ and ‘Mushroom’, which were correctly identified by only 2 out of 12 tasters (

Table 2). Contrarily, other descriptors, such as ‘Acid’, ‘Bitter’, ‘Fresh milk’ and ‘Fresh cream’ were correctly identified by about two-thirds of the tasters since these descriptors are more known and largely used for the sensory analysis of cheese. The low number of correct identification can also be attributed to the lack of a list of the sensory descriptors supplied with the samples to simplify the identification.

Regarding the intensity for some descriptors, such as ‘Salty’, ‘Sweet’, ‘Umami’, ‘Almond’, ‘Ananas’, ‘Butter’, ‘Hazelnut’, ‘Honey’ and ‘Raw ham’, the reported values were very narrow, whereas the other descriptors showed a very high variability (

Table 2).

Actually, it is impossible to define an intensity value for the reported attributes and concentration then it is necessary to modify the concentration for each attribute and train the panellist in order to define the extreme values for each of it as required by the ISO 11035:1994 [

11]. A direct comparison of the performance of these new reference standards with that of the traditional ones (commercial products and pure chemicals) will be useful for a definitive validation and to improve the formulation. The potential approaches for this purpose are the ones followed by Meilgaard et al. [

56] and Noble et al. [

36] for beer and wine as well as also by Hunter and McEwan [

57] and Nielsen and Zannoni [

58] for different sensory panels, even across different countries.

4. Conclusions

The results of this study indicated that the developed CM can be used for panellist training on odour/aroma and taste attributes. The use of standardised and very simple ingredients as well as the easy method for production make it simple to obtain. The absence in this product of taste, odour and aroma but the presence of a structure similar to a fresh cheese simplifies the training of panellist.

Also the products used in this study in order to reproduce odour/aroma and taste attributes of cheeses are very simple and standardized then could be the starting point of a list for panellist training. In the future, it is necessary to evaluate new products/ingredients in order to define other attributes.

Similarly, the quantity of each product/ingredient used in this study determined very different perceived sensations in the panellists then are needed new researches in order to define well the range of intensity for each attribute, to define the standardised intensity values and above all to define the extreme values of each.

Author Contributions

Conceptualization, G.Z. and P.R.; Methodology, P.R. N.S.Z. and G.Z.; Formal analysis, P.R. N.S.Z. and G.Z.; Data curation, P.R. and G.Z.; Writing—original draft preparation, P.R.; Writing—review and editing, G.Z., N.S.Z, and P.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors are grateful to FlavourArt for the support in the supply of chemical aromas and to the National Organization of Cheese Tasters (ONAF) - Turin delegation for their collaboration in the sensory evaluation of the reference standards.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Almena-Aliste, M.; Mietton, B. Cheese Classification, Characterization, and Categorization: A Global Perspective. Microbiol. Spectrum 2014, 2. [Google Scholar] [CrossRef]

- Clark, S.; Costello, M.; Drake, M.A.; Bodyfelt, F. The Sensory Evaluation of Dairy Products, 2nd ed.; Springer: New York, USA, 2009; pp. 38–42. [Google Scholar]

- Drake, M.A.; Delahunty, C.M. Sensory Character of Cheese And its Evaluation. In Cheese: Chemistry, Physics and Microbiology, 4th ed.; McSweeney, P.L.H., Fox, P.F., Cotter, P.D., Everett, D.W., Eds.; Academic Press: San Diego, USA, 2017; pp. 517–545. [Google Scholar]

- European Union (EU). Regulation No 1151/2012 of the European Parliament and of the Council of 21 November 2012 on quality schemes for agricultural products and foodstuffs. Off. J. Eur. Union. 2012, L343, 1–29. Available online: https://eur-lex.europa.eu/legal-content/IT/ALL/?uri=celex:32012R1151 (accessed on 10 March 2023).

-

5492:2008; ISO Standard 5492:2008 Sensory analysis. Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2017; p. 86. Available online: https://www.iso.org/obp/ui/#iso:std:iso:5492:ed-2:v1:en (accessed on 12 March 2023).

- Meilgaard, M.C.; Civille, G.V.; Thomas Carr, B. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, USA, 2015; pp. 1–223. ISBN 9781482216912. [Google Scholar]

- Kilcawley, K.; O’Sullivan, M. Cheese Flavour Development and Sensory Characteristics. In Global cheesemaking technology: cheese quality and characteristics, 1st ed.; Papademas, P., Bintsis, T., Eds.; John Wiley & Sons Ltd.: Hoboken, USA, 2017; pp. 45–70. ISBN 9781119046158. [Google Scholar]

- Italian Society of Sensory Sciences (SISS). Atlante sensoriale dei prodotti alimentari, 1st ed.; New Technical Editions: Milan, Italy, 2012; pp. 193–241. ISBN 9788848128414. [Google Scholar]

- Rainey, B.A. Importance of Reference Standards in Training Panelists. J. Sens. Stud. 1986, 1, 149–154. [Google Scholar] [CrossRef]

- Civille, G.V.; Lawless, H.T. The Importance of Language in Describing Perceptions. J. Sens. Stud. 1986, 1, 203–215. [Google Scholar] [CrossRef]

-

11035:1994; ISO Standard 11035:1994 Sensory Analysis. Identification and Selection of Descriptors for Establishing a Sensory Profile by a Multidimensional Approach. International Organization for Standardization: Geneva, Switzerland, 1994. Available online: https://www.iso.org/obp/ui/#iso:std:iso:11035:ed-1:v1:en (accessed on 13 March 2023).

- Porretta, S. Analisi Sensoriale & Consumer Science, 1st ed.; Chiriotti: Pinerolo, Italy, 2000; pp. 170–174. ISBN 8885022685. [Google Scholar]

- Heisserer, D.M.; Chambers IV, E. Determination of the Sensory Flavor Attributes of Aged Natural Cheese. J. Sens. Stud. 1993, 8, 121–132. [Google Scholar] [CrossRef]

- Stampanoni, C.R. The Use of Standardized Flavor Languages and Quantitative Flavor Profiling Technique for Flavored Dairy Products. J. Sens. Stud. 1994, 9, 383–400. [Google Scholar] [CrossRef]

- Berodier, F.; Lavanchy, P.; Zannoni, M.; Casals, J.; Herrero, L.; Adamo, C. Guide to the Smell, Aroma and Taste Evaluation of Hard and Semi-Hard Cheeses. LWT 1997, 30, 653–664. [Google Scholar]

- Pagliarini, E.; Monteleone, E. Sensory Profile Description of Mozzarella Cheese and Its Relationship with Consumer Preference. J. Sens. Stud. 1997, 12, 285–301. [Google Scholar] [CrossRef]

- Bárcenas, P.; Pérez Elortondo, F.J.; Salmerón, J.; Albisu, M. Development of a Preliminary Sensory Lexicon and Standard References of Ewes Milk Cheeses Aided by Multivariate Statistical Procedures. J. Sens. Stud. 1999, 14, 161–179. [Google Scholar] [CrossRef]

- Murray, J.M.; Delahunty, C.M. Selection of Standards to Reference Terms in a Cheddar-type Cheese Flavor Language. J. Sens. Stud. 2000, 15, 179–199. [Google Scholar] [CrossRef]

- Drake, M.A.; Mcingvale, S.C.; Gerard, P.D.; Cadwallader, K.R.; Civille, G.V. Development of a Descriptive Language for Cheddar Cheese. J. Food Sci. 2001, 66, 1422–1427. [Google Scholar] [CrossRef]

- Rétiveau, A.; Chambers, D.H.; Esteve, E. Developing a Lexicon for the Flavor Description of French Cheeses. Food Qual. Prefer. 2005, 16, 517–527. [Google Scholar] [CrossRef]

- Elortondo, F.J.P.; Ojeda, M.; Albisu, M.; Salmerón, J.; Etayo, I.; Molina, M. Food quality certification: An approach for the development of accredited sensory evaluation methods. Food Qual. Prefer. 2007, 18, 425–439. [Google Scholar] [CrossRef]

- Talavera-Bianchi, M.; Chambers, D.H. Simplified Lexicon to Describe Flavor Characteristics of Western European Cheeses. J. Sens. Stud. 2008, 23, 468–484. [Google Scholar] [CrossRef]

- Deegan, K.C.; Holopainen, U.; McSweeney, P.L.H.; Alatossava, T.; Tuorila, H. Characterisation of the Sensory Properties and Market Positioning of Novel Reduced-Fat Cheese. Innov. Food Sci. Emerg. Technol. 2014, 21, 169–178. [Google Scholar] [CrossRef]

- Giaccone, D.; Revello-Chion, A.; Galassi, L.; Bianchi, P.; Battelli, G.; Coppa, M.; Tabacco, E.; Borreani, G. Effect of Milk Thermisation and Farming System on Cheese Sensory Profile and Fatty Acid Composition. Int. Dairy J. 2016, 59, 10–19. [Google Scholar] [CrossRef]

- Salum, P.; Govce, G.; Kendirci, P.; Bas, D.; Erbay, Z. Composition, Proteolysis, Lipolysis, Volatile Compound Profile and Sensory Characteristics of Ripened White Cheeses Manufactured in Different Geographical Regions of Turkey. Int. Dairy J. 2018, 87, 26–36. [Google Scholar] [CrossRef]

- Issanchou, S.; Lesschaeve, I.; Köster, E.P. Screening Individual Ability to Perform Descriptive Analysis of Food Products: Basic Statements and Application to a Camembert Cheese Descriptive Panel. J. Sens. Stud. 1995, 10, 349–368. [Google Scholar] [CrossRef]

- Preininger, M.; Warmke, R.; Grosch, W. Identification of the Character Impact Flavour Compounds of Swiss Cheese by Sensory Studies of Models. ZLUF 1996, 202, 30–34. [Google Scholar] [CrossRef]

- Kubı́cková, J.; Grosch, W. Evaluation of Flavour Compounds of Camembert Cheese. Int. Dairy J. 1998, 8, 11–16. [Google Scholar] [CrossRef]

- Talavera-Bianchi, M.; Chambers, D.H. Flavor Lexicon and Characteristics of Artisan Goat Cheese from the United States. J. Sens. Stud. 2016, 31, 492–506. [Google Scholar] [CrossRef]

- Braghieri, A.; Zotta, T.; Morone, G.; Piazzolla, N.; Majlesi, M.; Napolitano, F. Starter Cultures and Preservation Liquids Modulate Consumer Liking and Shelf Life of Mozzarella Cheese. Int. Dairy J. 2018, 85, 254–262. [Google Scholar] [CrossRef]

- Murray, J.M.; Delahunty, C.M.; Baxter, I.A. Descriptive Sensory Analysis: Past, Present and Future. Food Res. Int. 2001, 34, 461–471. [Google Scholar] [CrossRef]

- Sulmont, C.; Lesschaeve, I.; Sauvageot, F.; Issanchou, S. Comparative Training Procedures to Learn Odor Descriptors: Effects on Profiling Performance. J. Sens. Stud. 1999, 14, 467–490. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Dalgliesh, C.E.; Clapperton, J.F. Beer Flavour Terminology. J. Inst. Brew. 1979, 85, 38–42. [Google Scholar] [CrossRef]

- Petró-Turza, M.; Teleky-Vámossy, G. Study on taste substances of tomato Part 3. Sensory evaluations. In Proceedings of the 2nd Wartburg Aroma Symposium, Eisenach, GDR, 16th-19th November 1987. [Google Scholar]

- Selfridge, T.B.; Amerine, M.A. Odor thresholds and interactions of ethyl acetate and diacetyl in an artificial wine medium. Am. J. Enol. Vitic. 1978, 29, 1–6. [Google Scholar] [CrossRef]

- Noble, A.C.; Arnold, R.A.; Masuda, B.M.; Pecore, S.D.; Schmidt, J.O.; Stern, P.M. Progress towards a standardized system of wine aroma terminology. Am. J. Enol. Vitic. 1984, 35, 107–109. [Google Scholar] [CrossRef]

- Edwards, T.L.; Singleton, V.L.; Boulton, R. Formation of ethyl esters of tartaric acid during wine aging: chemical and sensory effects. Am. J. Enol. Vitic. 1985, 36, 118–124. [Google Scholar] [CrossRef]

- Noble, A.C.; Arnold, R.A.; Buechsenstein, J.; Leach, E.J.; Schmidt, J.O.; Stern, P.M. Modification of a standardized system of wine flavour terminology. Am. J. Enol. Vitic. 1987, 38, 143–146. [Google Scholar] [CrossRef]

- Etiévant, P.; Issanchou, I.; Marie, S.; Ducruet, V.; Flanzy, C. Sensory impact of volatile phenols on red wine aroma: influence of carbonic maceration and time of storage. Sci Aliments 1989, 9, 19–33. [Google Scholar]

- Maga, J.A. Sensory and stability properties of added methoxypyrazines to model and authentic wines. In Development in food science. Flavors and off-flavors, 1st ed.; Charalambous, G., Ed.; Elsevier: Amsterdam, Netherlands, 1990; Volume 24, pp. 61–70. [Google Scholar]

- Martin, B.; Etiévant, P.; Le Quéré, J.L. More clues of the occurrence and flavor impact of Solerone in wine. J. Agric. Food. Chem. 1991, 39, 1501–1503. [Google Scholar] [CrossRef]

- Casimir, D.J.; Whitfield, F.B. Flavour impact values: a new concept for assigning numerical values for the potency of individual flavour components and their contribution to the overall flavour profile. Ber. Int. Fruchtsafrunion 1978, 15, 325–345. [Google Scholar]

- Zeppa, G.; Gambigliani Zoccoli, M.; Nasi, E.; Masini, G.; Meglioli, G.; Zappino, M. Descriptive sensory analysis of Aceto Balsamico Tradizionale di Modena DOP and Aceto Balsamico Tradizionale di Reggio Emilia DOP. J. Sci. Food Agric. 2013, 15, 3737–3742. [Google Scholar] [CrossRef] [PubMed]

- Salles, C.; Dalmas, S.; Septier, C.; Issanchou, S.; Noël, Y.; Etiévant, P.; Le Quéré, J.L. Production of a cheese model for sensory evaluation of flavour compounds. Lait 1995, 75, 535–549. [Google Scholar] [CrossRef]

- Pérez-Elortondo, F.J.; Barcenas, P.; Casas, Carmen. ; Salmeron, J.; Albisu, M. Development of standardized sensory methodologies: some applications to Protected Designation of Origin cheeses. Sci. Aliment. 1999, 19, 543–558. [Google Scholar]

- Pérez-Elortondo, F.J.; Zannoni, M. Guidelines for Sensory Analysis of Protected Designation of Origin Food Products and Wines, 1st ed.; Editorial Acribia: Zaragoza, Spain, 2021; pp. 11–23. ISBN 9788420012582. [Google Scholar]

- Bates, M. Chapter 4. Creamy milk puddings, junkets and custards. In Talking about puddings, 1st ed.; Pergamon Press: Oxford, United Kingdom, 1968; pp. 27–37. ISBN 978-0080036007. [Google Scholar]

- Imeson, A.P. Chapter 7. Carrageenan and furcellaran. In Handbook of hydrocolloids, 2nd ed.; Philipps, G.O., Williams, P.A., Eds.; Woodhead Publishing Limited: Cambridge, United Kingdom, 2009; pp. 164–185. ISBN 978-1-84569-414-2. [Google Scholar]

- Lascombes, C.; Agoda-Tandjawa, G.; Boulenguer, P.; Le Garnec, C.; Gilles, M.; Mauduit, S.; Barey, P.; Langerndorff, V. Starch-carrageenan interactions in acqueous media: Role of each polysaccharide chemical and macromolecular characteristics. Food Hydocoll. 2017, 66, 176–189. [Google Scholar] [CrossRef]

- Considine, T.; Noisuwan, A.; Hemar, Y.; Wilkinson, B.; Bronlund, J.; Kasapis, S. Rheological investigations of the interactions between starch and milk proteins in model dairy systems: a review. Food Hydrocoll. 2011, 25, 2008–2017. [Google Scholar] [CrossRef]

- Sun, N.; Liang, Y.; Yu, B.; Tan, C.; Cui, B. Interaction of starch and casein. Food Hydrocoll. 2016, 60, 572–579. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Gelatinization and Solubility of Corn Starch during Heating in Excess Water: New Insights. J. Agric. Food Chem. 2006, 54, 3712–3716. [Google Scholar] [CrossRef]

- OECD/FAO. Chapter 7. Dairy and dairy products. In OECD-FAO Agricultural Outlook 2023-2032; OECD Publishing: Paris, France, 2023; pp. 202–212. [Google Scholar]

- Pionnier, E.; Chabanet, C.; Mioche, L.; Le Quéré, J.L.; Salles, C. In Vivo Aroma Release during Eating of a Model Cheese: Relationships with Oral Parameters. J. Agric. Food Chem. 2004, 52, 557–564. [Google Scholar] [CrossRef]

- Tarrega, A.; Yven, C.; Sémon, E.; Salles, C. In-mouth aroma compound release during cheese consumption: Relationship with food bolus formation. Int. Dairy J. 2011, 21, 358–364. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Reid, D.S.; Wyborski, K.A. Reference Standards for Beer Flavor Terminology System. J. Am. Soc. Brew. Chem. 1982, 40, 119–128. [Google Scholar] [CrossRef]

- Hunter, E.A.; McEwan, J.A. Evaluation of an international ring trial for sensory profiling of hard cheese. Food Qual. Prefer. 1998, 9, 343–354. [Google Scholar] [CrossRef]

- Nielsen, R.G.; Zannoni, M. Progress in developing an international protocol for sensory profiling of hard cheese. Int. J. Dairy Technol. 1998, 51, 57–64. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).