1. Introduction

Brazil stands out as a prominent global producer and exporter of grains, with a vast planting area of approximately 77 million hectares and an estimated production of 312.2 million tons during the 2022-23 harvest [

1]. However, despite a portion of this production being directly transported from farms to agro-industrial units and ports, a significant amount, around 40%, needs to be stored to address the demands of seasonality and production-consumption dynamics. Inadequate post-harvest processing techniques and deficient storage capacity contribute to losses for grain producers, estimated at approximately 15%, which can escalate to 40% or even higher for small-scale producers. To mitigate these losses, proper handling and processing of the harvested grains is crucial, with drying being the first post-harvest operation that plays a vital role in ensuring effective grain storage. Freshly harvested grains have typically an average moisture content of approximately 30% [

2] and must be reduced to less than 15% for extended storage [

3]. Thermal drying is the preferred method over natural drying techniques because it allows monitoring of operating conditions to achieve standardized and consistent results. However, it is important to note that drying is a highly energy-intensive process that significantly affects the price and quality of the final product. Consequently, studies evaluating drying techniques and their effects on the quality attributes of the grains can contribute to improving the design of drying operations. Moreover, experimental data are essential for developing models aimed at creating effective monitoring and control strategies.

This study focuses on analyzing heat and mass transfer during the hot-air drying of sorghum grains. Sorghum (Sorghum bicolor), a cereal grain plant belonging to the grass family, is widely cultivated in Brazil, Africa, and India, due to its edible starchy seeds that serve as a relevant source of energy and protein. Agronomically classified into four types - grain, sweet, forage, and biomass - sorghum presents several advantages over corn. Notably, it exhibits enhanced resistance to drought and pest attacks, thereby requiring less investment for cultivation. Additionally, sorghum can be employed in biomass production, serving as a source of nutrition for agriculture and livestock, and can even be used as a feedstock for ethanol production [

4,

5]. Projections indicate that Brazil´s sorghum production for the 2022-23 crop is expected to reach approximately 3.9 million tons, representing a substantial increase of 33.9% compared to the previous harvest. The estimated productivity for the 2022-23 season stands at 2,995 kilograms per hectare, reflecting a notable 10.1% improvement over the previous year [

6].

The current study investigates the packed-bed hot-air drying configuration, which is widely employed for drying grains in batch and small-scale processes. In comparison to fluidized, spouted, or vibro-fluidized bed dryers, this configuration better preserves the structure of the grains due to its static nature, avoiding mechanical impacts [

7]. However, the packed-bed drying can result in significant temperature and moisture gradients within the bed as the air flows upwards transferring heat and absorbing moisture, leading to over drying of grains near to the air input and under-drying of grains near the exhaust. Such non-uniformity negatively impacts grain quality. While adding a mechanical mixing device to the dryer is an option to enhance uniformity, it can cause grain damage and increase operating costs [

8]. An alternative approach, proposed by Berbet et al. [

8,

9] and Ratti and Mujumdar [

10], is to periodically reverse the airflow direction.

Berbet et al. [

8,

9] conducted studies on the drying of fresh coffee beans in a fixed bed under air temperatures of 50

oC and 70

oC. They compared the temperature profiles, drying rates, and drying efficiency of the conventional and reversed airflow configurations. The authors observed a significant reduction of temperature difference throughout the bed when the airflow direction was reversed every 3 h, as opposed to a single direct airflow. Ratti and Mujumdar [

10] derived a model to simulate the operation of a batch packed bed dryer under both conventional and reversed airflow configurations. They explored various reversion time intervals and concluded that more uniform drying profiles can be achieved by applying airflow reversal earlier, when the drying kinetics are still affected by the external conditions. Furthermore, the duration of the reversed flow proved to be a crucial adjustable parameter for obtaining optimal conditions.

A model was derived by Ruiz-López et al. [

11] aimed to simulate the operation of a packed-bed dryer with a thick layer using a reversal airflow. The model considered the dryer as a series of interconnected perfectly mixed thanks in a line. The authors emphasized the importance of testing and optimizing the duration of flow reversal periods in thick layer drying to achieve lower average moisture levels.

To tackle the issue of over-drying in the bottom layers of a fixed bed rice dryer and enhance grain quality, Ibrahim et al. [

12] investigated the use of air flow reversal configuration. The results demonstrated that airflow reversal drying increased drying capacity by at least 20% at different bed depths compared to conventional drying. Energy consumption was also reduced by 12% to 32% depending on the grain bed depth and airflow rate.

Regardless of whether a conventional or reversal airflow configuration is employed, modelling thick-layer grain drying using the two-fluid model approach is a challenging task. This is mainly due to the substantial changes in the grains and packed bed properties, such as size, shape, porosity, and density, as moisture is removed [

13,

14,

15]. Therefore, it is crucial to investigate the influence of grain´s moisture content on its physical properties and the properties of the packed bed to address this challenge effectively. In addition, changes in the packed bed´s structural properties may significantly affect the model´s heat and mass transfer parameters, requiring more complex and sophisticated modelling approaches to achieve an accurate description of the process.

Aiming at obtaining critical parameters for subsequent modelling of fixed bed drying employing both conventional and reverse airflow approaches, researchers affiliated with the DEQ/UFSCar Drying Center conceived experimental methodologies to obtain reliable temperature and moisture axial distributions during the drying process [

16]. Such methodologies were further applied by Albini et al. [

17] for a comprehensive investigation into the drying of barley seeds within deep packed beds, utilizing both conventional and reverse airflow techniques. Their findings revealed a noteworthy enhancement in moisture bed homogeneity when the airflow direction was alternated every 10 min. However, the conventional approach exhibited superior energy efficiency, attributed to the reduced time required to achieve the desired moisture content.

Subsequently, Genaro et al. [

18] applied a two-phase model to describe the drying behaviour of alumina particles within deep fixed beds and validated the model against experimental data. In contrast to the barley grains of the previous study, which underwent changes in size and shape as moisture levels diminished, the physical properties of alumina remained largely intact throughout the drying process. This characteristic proved highly advantageous for validating the proposed model. The authors concluded that the two-phase mathematical model was suitable to describe the thermal and moisture dynamics of the material during drying with flow reversal and could be useful to address operating aspects, such as the identification of optimal operating conditions to reduce energy consumption and improve moisture homogeneity.

The present study focuses on experimental investigations of deep packed bed layers during hot air drying of sorghum grains under variable conditions using both conventional and reversal airflow approaches. Prior to drying, a comprehensive characterization of the grain´s physical properties, bulk density, and bulk porosity was performed under two moisture content conditions. Subsequently, moisture and temperature axial profiles were obtained along the bed depth in deeply packed bed layers under both conventional and reversal airflow configurations. This analysis aims to provide valuable insights into the drying process in packed beds of grains, enhancing our understanding of the process and improving overall efficiency.

3. Results and Discussion

Table 2 shows the physical properties of sorghum grains. The values shown in

Table 1 are for two different initial moisture contents, such that X = 0.15 kg∙kg-1 (X1) is the moisture of wet grains commercially available by the company Di Solo Seeds and X = 0.43 kg∙kg-1 (X2) is the moisture of grains humidified in the laboratory up to about 30% on a wet basis. The higher the moisture content, the larger the characteristic dimensions of the sorghum grain, although the change was not significant as it was within the standard deviation range of the measurements. The sphericity remained constant, therefore, there were no measurable changes in the shape of the particles. As expected, the apparent specific mass increased with increasing moisture, that is, the increase in the amount of water inside the sorghum grain was more significant than the swelling effect of the solid. Also as expected, the higher the moisture content, the lower the actual specific mass. The specific mass of the bed (bulk density) decreased for the highest moisture content, leading to a more significant increase in mass than the increase in the volume of particles in the fixed bed. The voids between the particles may increase slightly due to the slight increase in particle size.

Instrumentation plays a significant role in providing a better understanding of how the air flow change of direction acts in the drying process. It was necessary to improve the instrumentation available in the Genaro [

19] setup to pay more attention to temperature and relative humidity measurements at the bottom and top of the fixed bed. After all, it is online and real-time measurements that are important for properly monitoring dryer operation.

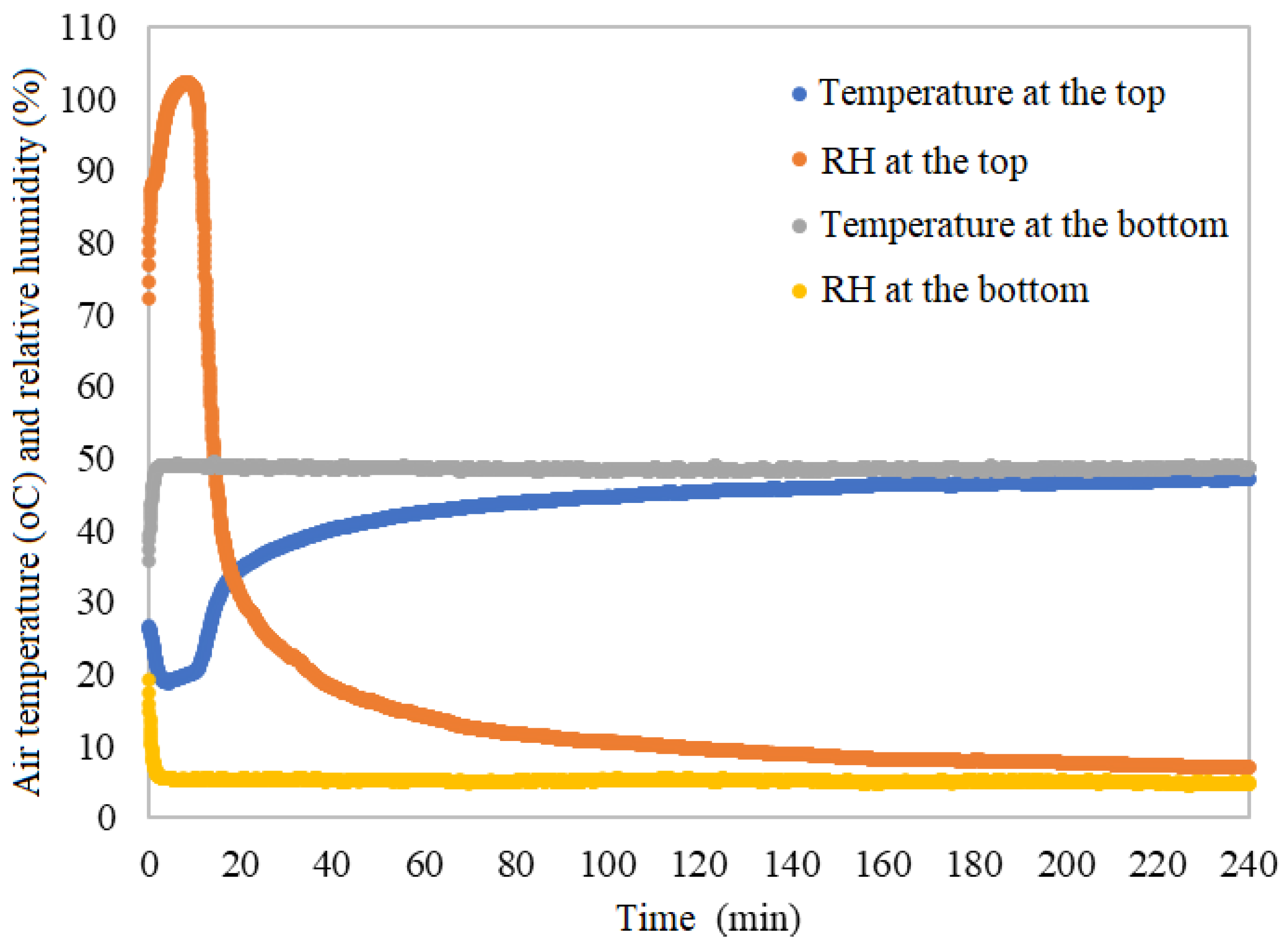

Figure 1 shows the temperature and relative humidity measurements at the bottom and top of the fixed bed throughout the sorghum drying experiment at 50°C without changing the direction of the air flow.

The results in

Figure 1 show that right at the beginning of drying, the exhaust air at the top of the bed becomes saturated (RH = 100%), then decreases quickly until it reaches steady state, approaching the relative humidity of the air at the bottom of the bed. This is due to the fact that, at the beginning of drying, sorghum grains have a high moisture content that is more weakly linked to the structure of the grains, thus, the dry air that percolates through the porous medium becomes saturated before reaching the dryer exhaust.

After that, the grains become increasingly dry, especially at the solid-fluid interface, in which case the air tends to leave the dryer progressively less rich in moisture. The results also show that the relative humidity in the exhaust decreases rapidly between 10 and 20 minutes of drying, then decreases more slowly until it approaches the input humidity values. In this case, most of the moisture content of the grain is strongly linked to the porous structure, therefore, the resistance to mass transfer is predominantly diffusive, that is, water has to migrate from the interior of the solid to its surface. The fixed bed inlet temperature measurements are at the steady state value of 50oC from the beginning of drying, while the outlet temperature decreases rapidly in the first 4 minutes, slowly increases again for up to 10 minutes and then increases rapidly up to 20 minutes, when it reaches a steady state close to 50°C. The heat exchanged between the air and the solid in the first 4 minutes removes most of the loosely bound moisture from the sorghum grain, then until about 10 minutes in, the temperature in the dryer exhaust increases very slowly because the saturated air in thermodynamic equilibrium tends to maintain constant conditions. Then, the temperature increases rapidly for up to 20 minutes because, as the porous medium becomes drier, less heat is exchanged to carry out evaporation. In the following minutes, the temperature of the exhaust air increases slowly, exchanging sensible heat with the grain.

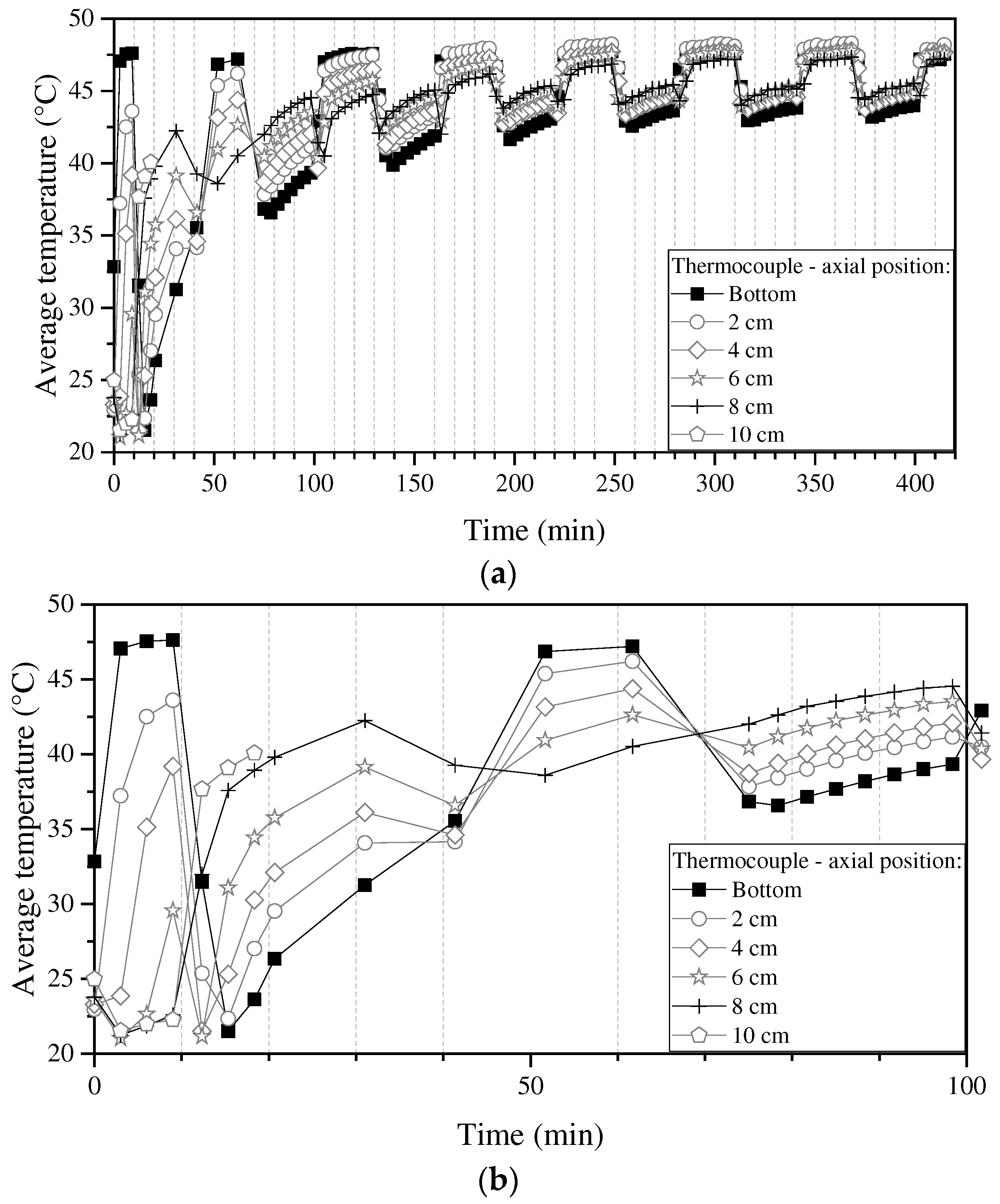

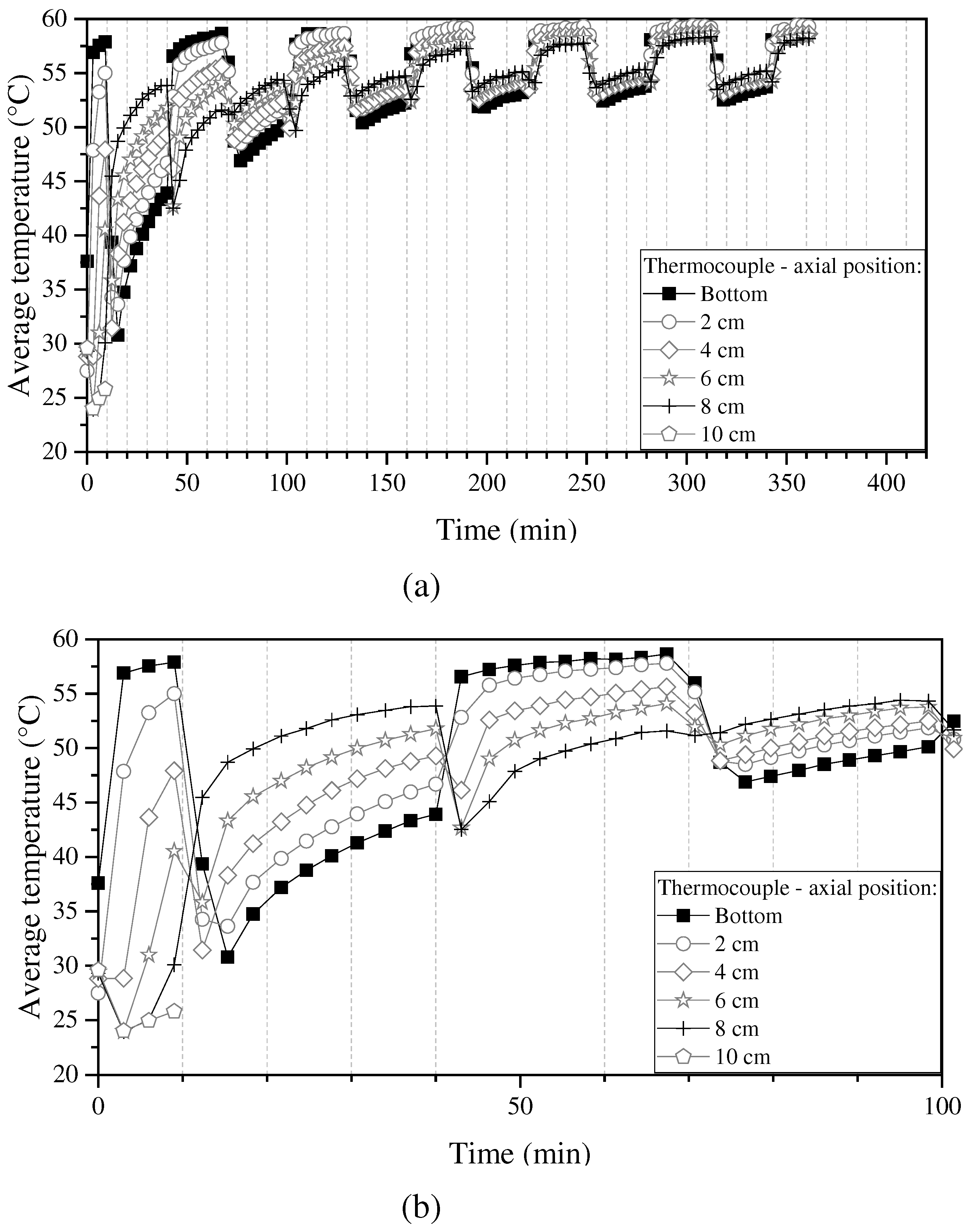

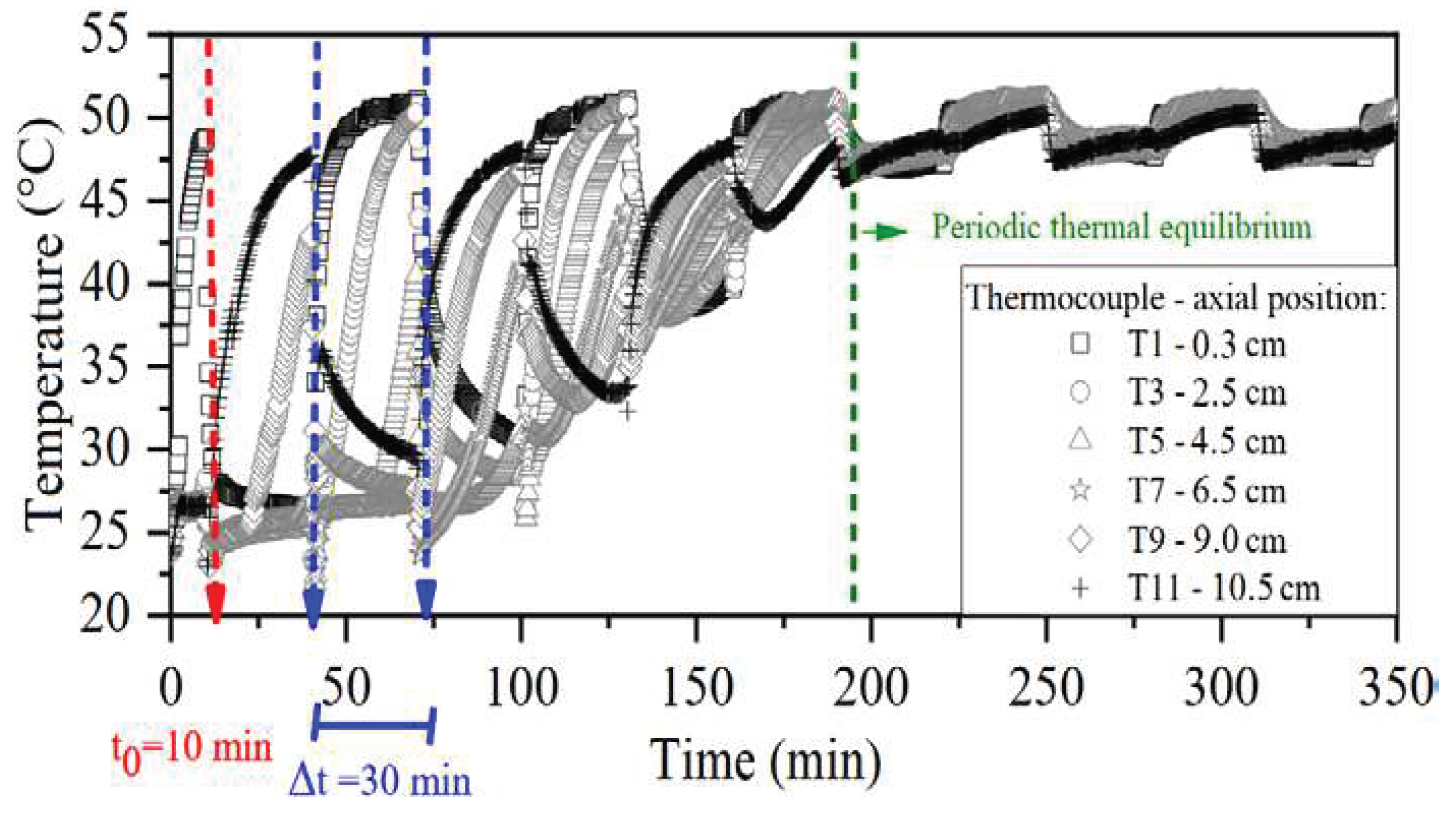

Figure 2 and

Figure 3 show the temperatures of sorghum grains at different axial positions for air temperatures of 50 and 60°C and air flow velocity of 2.1 m∙s

-1, with the first change in the direction of flow at t

0 = 10 min, switched subsequently every ∆t = 30 min. As expected, the results show that the average temperature along the axial positions gets progressively larger, the increase being faster at the bottom where the heated air enters at the beginning of the experiment. It is worth mentioning that in

Figure 2b and

Figure 3b, after 20 and 10 min, respectively, the average temperature measurements of positions above 8 cm were interrupted, as the sorghum grains shrank significantly, leaving the highest areas of the dryer empty.

From the moment there is the first change in direction of the flow, the temperature at the top tends to rise above the other temperatures, leading to an inversion in the gradient such that the heights close to the top have the highest temperatures while those close to the bottom have the lowest temperatures. After 30 min of the first change in the direction of air flow, there is a new change such that the air flows once again in an upward direction, from the base to the top. Successive changes in the air flow direction are then made every 30 min. Over time, there is, therefore, a change in the drying front towards the intermediate height of the dryer, thus reducing the internal gradients. It is interesting to note that despite changes in the direction of air flow, the temperatures of all axial positions tend to increase. This is due to the fact that the air that passes through the dryer in alternate directions has not yet reached hygroscopic equilibrium with the moist grains. This dynamic equilibrium is reached after 310 min, for the experiment at 50°C, and after 250 min for the experiment at 60°C.

When the air flow is in a downward direction, as in the intervals 10-40 min and 70-100 min, in addition to the inversion of the temperature gradient there is also an abrupt decrease in the temperature increase. Some bed heights had a more pronounced temperature drop before heating up again, as seen in the base temperature at 70 min (

Figure 3b).

This is due to the fact that when the air flow changes in a downward direction it passes through a pipe 0.8 m longer than when it is flowing in an upward direction. Despite efforts to thermally isolate the piping, there is more heat loss in the longer piping, that is, less heat enters the dryer downwards from the top. That's why the heights close to the top do not experience abrupt changes in temperature because in the previous cycle they already received less heat from the upward flow. The opposite can be said for heights neighbouring the bottom of the dryer. In short, there are greater temperature oscillations at lower bed heights and smaller temperature oscillations at higher bed heights due to the experimental setup.

Figure 4 shows the average moisture content of sorghum grains along the heights of the fixed bed for drying with changing direction of air flow at 50°C. As previously mentioned, the reversion causes drying to be more uniform throughout the bed and the air does not reach saturation.

Figure 4 shows that the moisture content decreases more markedly in the first 60 min than in the remainder of the drying time. After this period of time there is a less pronounced decrease in the average overall moisture content with small changes in the concavity of the curves at times 60, 120 and 180 min. In the intervals of 70 to 100 min and 130 to 160 min, the air flows downwards, from the top towards the bottom, therefore resulting in less energy input. Drying lasted a total of 240 min, bringing the sorghum grains to an average overall moisture content of 0.13 on a dry basis.

A comparison between the results obtained in this work and those of Genaro [

19] reveals interesting aspects of the air flow reversal technique. As it is a standard particulate solid, which maintains its physical structure and properties constant during drying, alumina has the role of establishing limits for the process. Even though they do not share exactly the same operating conditions, there are clear trends that distance both drying systems with air flow reversal. From the temperature results of the alumina spheres shown in

Figure 5 for operating conditions close to those of the experiment with sorghum grains at 50°C, it can be seen that the oscillations were much greater for drying alumina than sorghum. In the case of alumina, the excess water weakly bound to the structure of the solid is first removed at a constant temperature and only then does the bed actually heat up. The further away from the inlet of heated air, the greater this effect as the temperatures of the two phases tend to get closer. It is important to note that both transferring excess water out and into the alumina spheres involves latent heat, that is, constant temperatures. This is not significant when drying sorghum grains as diffusion is the main drying mechanism and, therefore, there is greater resistance to rehumidification. In other words, there is more sensible heat transfer.

There was significant shrinkage during drying of sorghum grains, which resulted in a decrease in bed height of up to 1.5 cm. Along with the shrinkage, there were also changes over drying time of key parameters for heat and mass transfer. It is known that changing the direction of drying airflow from time to time requires some level of automation for the technique to be suitable on an industrial scale. Therefore, a more comprehensive understanding of the flow direction reversal technique in a thick fixed bed must take into account, in some way, the presence of important time-varying parameters. Future work will be done to better understand the cause-and-effect relationships of shrinkage and time-varying parameters in the drying of sorghum grains.