Submitted:

22 December 2023

Posted:

26 December 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Types of livestock manure

3. Environmental impact of livestock manure generation

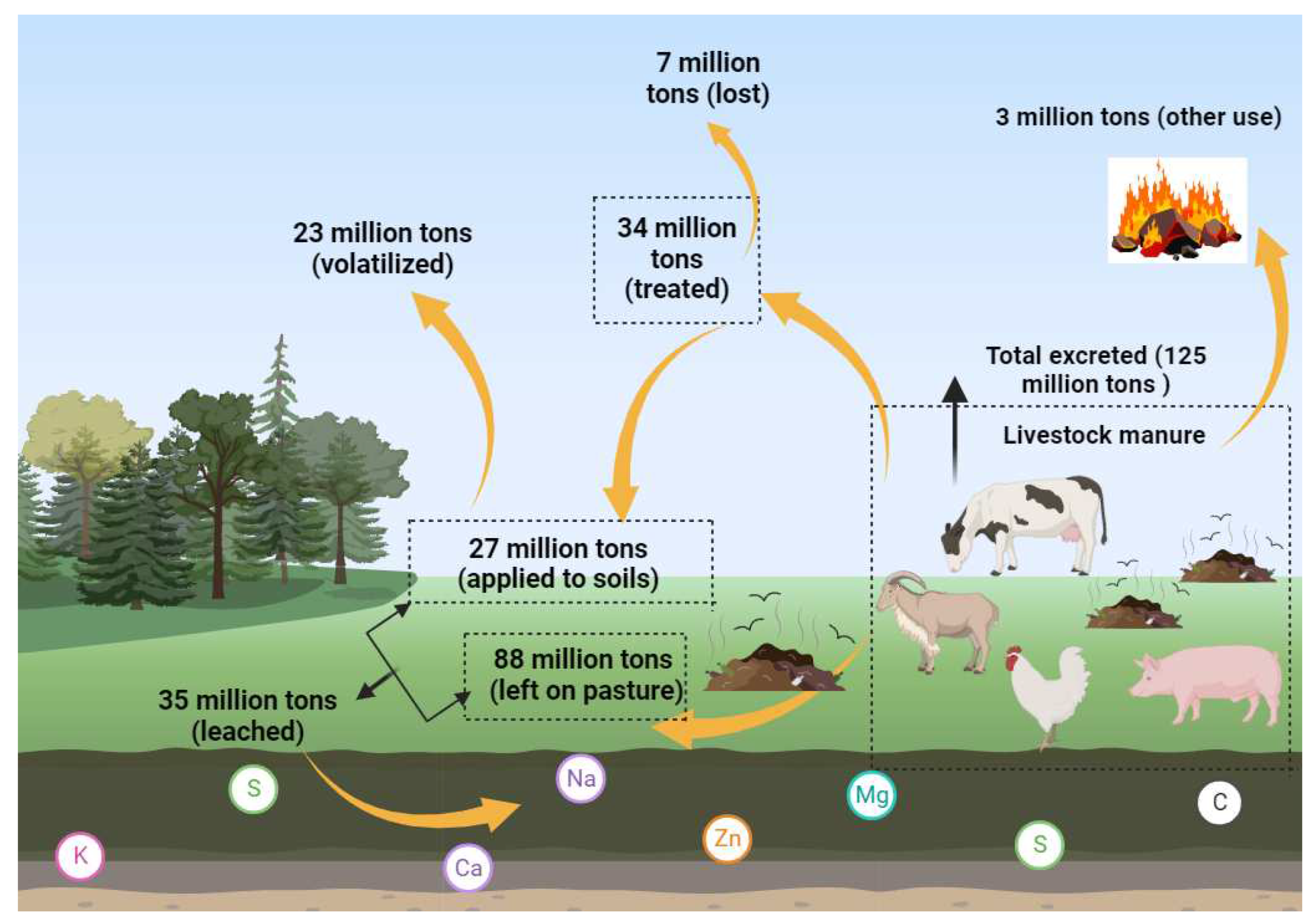

4. Global livestock manure management practices

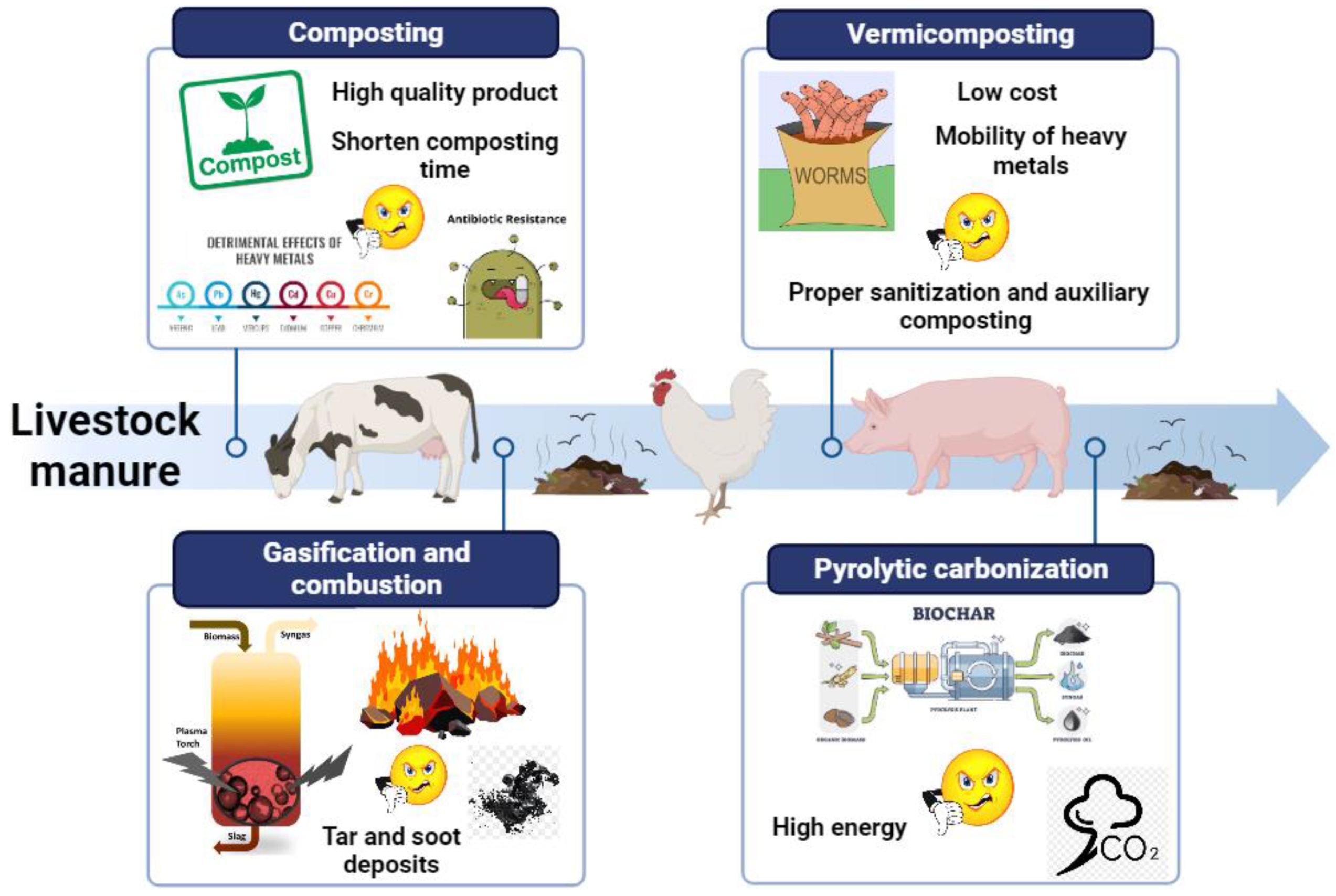

4.1. Composting

4.2. Vermicomposting

4.3. Gasification and combustion

4.4. Pyrolytic carbonization

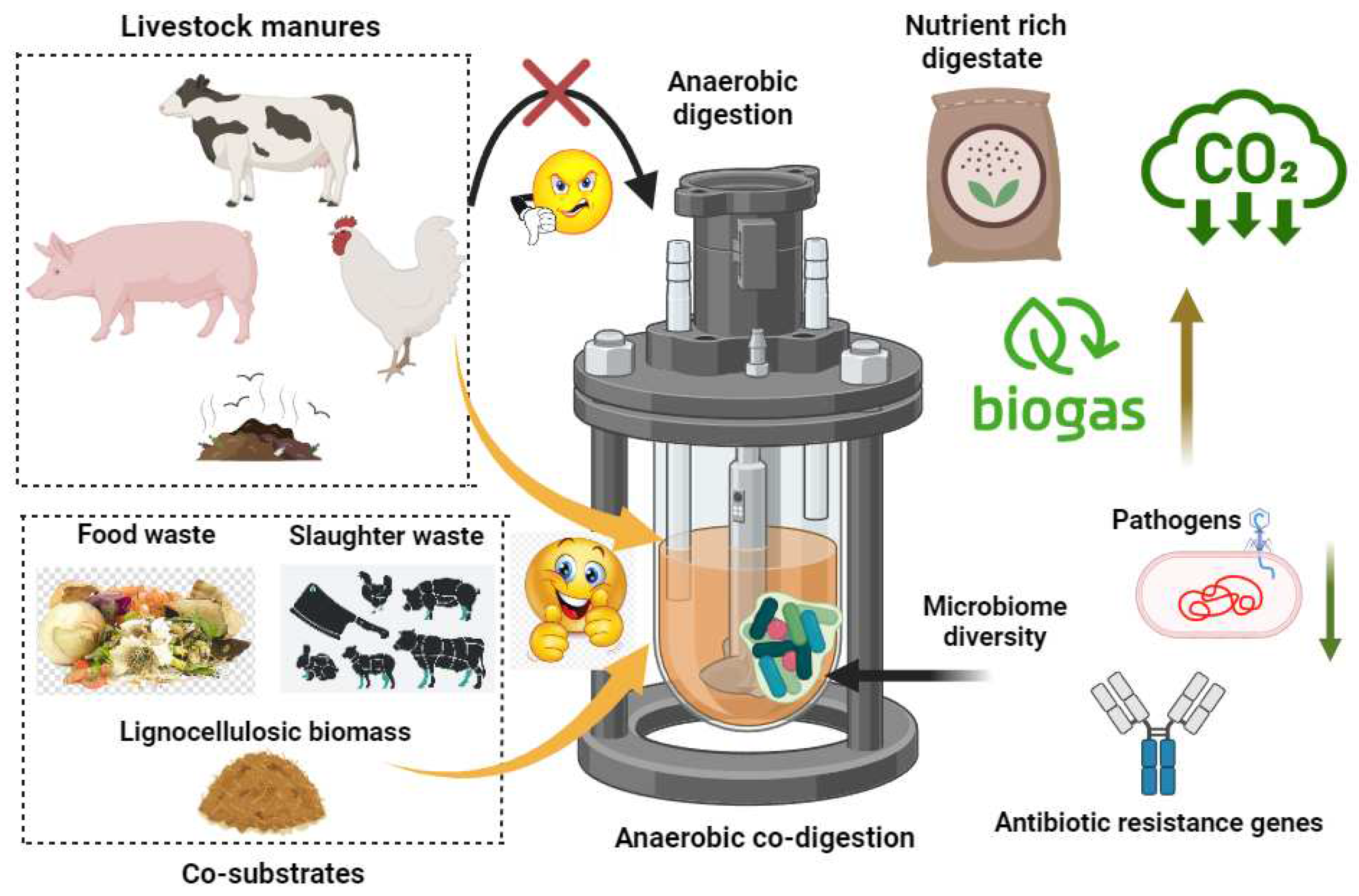

5. Anaerobic digestion of livestock manures

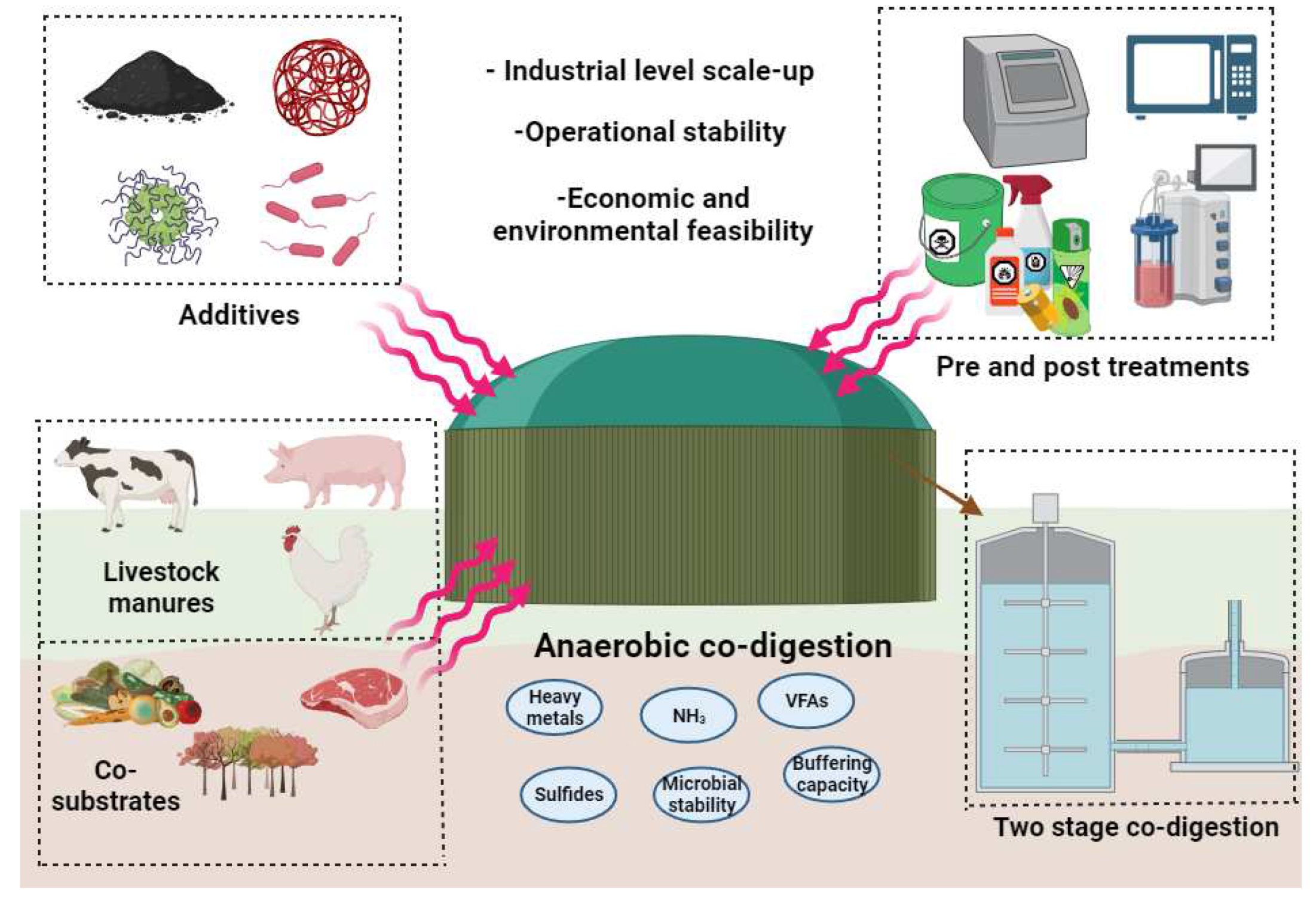

6. Anaerobic co-digestion of livestock manures

7. Synergistic effects of anaerobic co-digestion of livestock manures

8. Progress, challenges, and future direction

9. Conclusion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Haque, M. A.; Kabir, A.; Hashem, M. A.; Azad, M. A. K.; Bhuiyan, M.; Rahman, M. Efficacy of Biogas Production from Different Types of Livestock Manures. International Journal of Smart Grid 2021, 5, 158–166. [Google Scholar]

- Zheng, X.; Zou, D.; Wu, Q.; Wang, H.; Li, S.; Liu, F.; Xiao, Z. Review on fate and bioavailability of heavy metals during anaerobic digestion and composting of animal manure. Waste Management 2022, 150, 75–89. [Google Scholar] [CrossRef] [PubMed]

- Jasińska, A.; Grosser, A.; Meers, E. Possibilities and Limitations of Anaerobic Co-Digestion of Animal Manure—A Critical Review. Energies 2023, 16, 3885. [Google Scholar] [CrossRef]

- Allison, F. E. Soil organic matter and its role in crop production. Elsevier: 1973.

- Hulse, J. H. Sustainable development at risk: Ignoring the past. IDRC: 2007.

- Daniel, J.; Sharpley, A.; Stewart, B.; Smith, S. Environmental impact of animal manure management in the southern plains. 1993.

- Cheng, M.; McCarl, B.; Fei, C. Climate change and livestock production: a literature review. Atmosphere 2022, 13, 140. [Google Scholar] [CrossRef]

- Burg, V.; Bowman, G.; Haubensak, M.; Baier, U.; Thees, O. Valorization of an untapped resource: Energy and greenhouse gas emissions benefits of converting manure to biogas through anaerobic digestion. Resources, Conservation and Recycling 2018, 136, 53–62. [Google Scholar] [CrossRef]

- Kim, S.; Lee, C.; Kim, J.; Kim, J. Y. Feasibility of thermal hydrolysis pretreatment to reduce hydraulic retention time of anaerobic digestion of cattle manure. Bioresource Technology 2023, 129308. [Google Scholar] [CrossRef]

- Tufaner, F.; Avşar, Y. Effects of co-substrate on biogas production from cattle manure: a review. International journal of environmental science and technology 2016, 13, 2303–2312. [Google Scholar] [CrossRef]

- Lymperatou, A.; Rasmussen, N. B.; Gavala, H. N.; Skiadas, I. V. Improving the anaerobic digestion of swine manure through an optimized ammonia treatment: process performance, digestate and techno-economic aspects. Energies 2021, 14, 787. [Google Scholar] [CrossRef]

- Jiang, Y.; McAdam, E.; Zhang, Y.; Heaven, S.; Banks, C.; Longhurst, P. Ammonia inhibition and toxicity in anaerobic digestion: A critical review. Journal of Water Process Engineering 2019, 32, 100899. [Google Scholar] [CrossRef]

- Estevez, M. M.; Sapci, Z.; Linjordet, R.; Schnürer, A.; Morken, J. Semi-continuous anaerobic co-digestion of cow manure and steam-exploded Salix with recirculation of liquid digestate. Journal of Environmental Management 2014, 136, 9–15. [Google Scholar] [CrossRef]

- Abouelenien, F.; Namba, Y.; Kosseva, M. R.; Nishio, N.; Nakashimada, Y. Enhancement of methane production from co-digestion of chicken manure with agricultural wastes. Bioresource technology 2014, 159, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Borowski, S.; Weatherley, L. Co-digestion of solid poultry manure with municipal sewage sludge. Bioresource technology 2013, 142, 345–352. [Google Scholar] [CrossRef] [PubMed]

- El-Mashad, H. M.; Zhang, R. Biogas production from co-digestion of dairy manure and food waste. Bioresource technology 2010, 101, 4021–4028. [Google Scholar] [CrossRef] [PubMed]

- Monou, M.; Pafitis, N.; Kythreotou, N.; Smith, S. R.; Mantzavinos, D.; Kassinos, D. Anaerobic co-digestion of potato processing wastewater with pig slurry and abattoir wastewater. Journal of Chemical Technology & Biotechnology: International Research in Process, Environmental & Clean Technology 2008, 83, 1658–1663. [Google Scholar]

- Tyagi, V. K.; Fdez-Güelfo, L.; Zhou, Y.; Álvarez-Gallego, C.; Garcia, L. R.; Ng, W. J. Anaerobic co-digestion of organic fraction of municipal solid waste (OFMSW): Progress and challenges. Renewable and Sustainable Energy Reviews 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Ma, G.; Ndegwa, P.; Harrison, J. H.; Chen, Y. Methane yields during anaerobic co-digestion of animal manure with other feedstocks: A meta-analysis. Science of the Total Environment 2020, 728, 138224. [Google Scholar] [CrossRef] [PubMed]

- Shober, A. L.; Maguire, R. O. Manure management. 2018.

- FAO Livestock systems. https://www.fao.org/livestock-systems/global-distributions/en/.

- Scarlat, N.; Fahl, F.; Dallemand, J.-F.; Monforti, F.; Motola, V. A spatial analysis of biogas potential from manure in Europe. Renewable and Sustainable Energy Reviews 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Jurgutis, L.; Slepetiene, A.; Volungevicius, J.; Amaleviciute-Volunge, K. Biogas production from chicken manure at different organic loading rates in a mesophilic full scale anaerobic digestion plant. Biomass and Bioenergy 2020, 141, 105693. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, Y.; Wang, S.; Wang, Z.; Liu, Y.; Hu, Z.; Zhan, X. Environmental sustainability assessment of pig manure mono-and co-digestion and dynamic land application of the digestate. Renewable and Sustainable Energy Reviews 2021, 137, 110476. [Google Scholar] [CrossRef]

- Chávez-Fuentes, J.; Capobianco, A.; Barbušová, J.; Hutňan, M. Manure from our agricultural animals: A quantitative and qualitative analysis focused on biogas production. Waste and Biomass Valorization 2017, 8, 1749–1757. [Google Scholar] [CrossRef]

- Baek, G.; Kim, D.; Kim, J.; Kim, H.; Lee, C. Treatment of cattle manure by anaerobic co-digestion with food waste and pig manure: Methane yield and synergistic effect. International Journal of Environmental Research and Public Health 2020, 17, 4737. [Google Scholar] [CrossRef] [PubMed]

- Cheong, D.-Y.; Harvey, J. T.; Kim, J.; Lee, C. Improving biomethanation of chicken manure by co-digestion with ethanol plant effluent. International Journal of Environmental Research and Public Health 2019, 16, 5023. [Google Scholar] [CrossRef] [PubMed]

- Daramy, M. A.; Kawada, R.; Oba, S. Alterations of the chemical compositions, surface functionalities, and nitrogen structures of cage layer chicken manure by carbonization to improve nitrogen bioavailability in soil. Agronomy 2020, 10, 1031. [Google Scholar] [CrossRef]

- Pelster, D. E.; Gisore, B.; Goopy, J.; Korir, D.; Koske, J.; Rufino, M. C.; Butterbach-Bahl, K. Methane and nitrous oxide emissions from cattle excreta on an East African grassland. Journal of environmental quality 2016, 45, 1531–1539. [Google Scholar] [CrossRef] [PubMed]

- Tawfik, A.; Eraky, M.; Osman, A. I.; Ai, P.; Zhou, Z.; Meng, F.; Rooney, D. W. Bioenergy production from chicken manure: a review. Environmental Chemistry Letters 2023, 1–21. [Google Scholar]

- IPCC EMISSIONS FROM LIVESTOCK AND .

- MANURE MANAGEMENT; USA, 2006; p 87.

- FAO Livestock and environment statistics: manure and greenhouse gas emissions. https://www.fao.org/food-agriculture-statistics/data-release/data-release-detail/fr/c/1329440/.

- Khoshnevisan, B.; Duan, N.; Tsapekos, P.; Awasthi, M. K.; Liu, Z.; Mohammadi, A.; Angelidaki, I.; Tsang, D. C.; Zhang, Z.; Pan, J. A critical review on livestock manure biorefinery technologies: Sustainability, challenges, and future perspectives. Renewable and Sustainable Energy Reviews 2021, 135, 110033. [Google Scholar] [CrossRef]

- Lee, J.; Febrisiantosa, A. In Improvement of nitrogen balance (land budget) in South Korea in terms of livestock manure: a review, IOP Conference Series: Earth and Environmental Science, 2020; IOP Publishing: 2020; p 012011.

- Bernal, M. P.; Alburquerque, J.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresource technology 2009, 100, 5444–5453. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M. K.; Ren, X.; Zhao, J.; Li, R.; Wang, Z.; Chen, H.; Wang, M.; Zhang, Z. Comparison of biochar, zeolite and their mixture amendment for aiding organic matter transformation and nitrogen conservation during pig manure composting. Bioresource technology 2017, 245, 300–308. [Google Scholar] [CrossRef] [PubMed]

- Tiquia, S. Microbial transformation of nitrogen during composting. In Microbiology of composting, Springer: 2002; pp 237-245.

- Parkinson, R.; Gibbs, P.; Burchett, S.; Misselbrook, T. Effect of turning regime and seasonal weather conditions on nitrogen and phosphorus losses during aerobic composting of cattle manure. Bioresource technology 2004, 91, 171–178. [Google Scholar] [CrossRef]

- Wang, Q.; Awasthi, M. K.; Ren, X.; Zhao, J.; Li, R.; Wang, Z.; Wang, M.; Chen, H.; Zhang, Z. Combining biochar, zeolite and wood vinegar for composting of pig manure: The effect on greenhouse gas emission and nitrogen conservation. Waste management 2018, 74, 221–230. [Google Scholar] [CrossRef]

- Awasthi, M. K.; Duan, Y.; Awasthi, S. K.; Liu, T.; Zhang, Z. Effect of biochar and bacterial inoculum additions on cow dung composting. Bioresource Technology 2020, 297, 122407. [Google Scholar] [CrossRef]

- Yuan, J.; Chadwick, D.; Zhang, D.; Li, G.; Chen, S.; Luo, W.; Du, L.; He, S.; Peng, S. Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting. Waste Management 2016, 56, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Garg, V. Vermicomposting of waste: a zero-waste approach for waste management. In Sustainable resource recovery and zero waste approaches, Elsevier: 2019; pp 133-164.

- Hanc, A.; Enev, V.; Hrebeckova, T.; Klucakova, M.; Pekar, M. Characterization of humic acids in a continuous-feeding vermicomposting system with horse manure. Waste Management 2019, 99, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Lv, B.; Xing, M.; Yang, J. Speciation and transformation of heavy metals during vermicomposting of animal manure. Bioresource Technology 2016, 209, 397–401. [Google Scholar] [CrossRef]

- Anukam, A.; Mamphweli, S.; Reddy, P.; Meyer, E.; Okoh, O. Pre-processing of sugarcane bagasse for gasification in a downdraft biomass gasifier system: A comprehensive review. Renewable and Sustainable Energy Reviews 2016, 66, 775–801. [Google Scholar] [CrossRef]

- Dalólio, F. S.; da Silva, J. N.; de Oliveira, A. C. C.; Tinôco, I. d. F. F.; Barbosa, R. C.; de Oliveira Resende, M.; Albino, L. F. T.; Coelho, S. T. Poultry litter as biomass energy: A review and future perspectives. Renewable and Sustainable Energy Reviews 2017, 76, 941–949. [Google Scholar] [CrossRef]

- Rout, P. R.; Pandey, D. S.; Haynes-Parry, M.; Briggs, C.; Manuel, H. L. C.; Umapathi, R.; Mukherjee, S.; Panigrahi, S.; Goel, M. Sustainable valorisation of animal manures via thermochemical conversion technologies: an inclusive review on recent trends. Waste and Biomass Valorization 2023, 14, 553–582. [Google Scholar] [CrossRef]

- Moradian, F.; Pettersson, A.; Svärd, S. H.; Richards, T. Co-combustion of animal waste in a commercial waste-to-energy BFB boiler. Energies 2013, 6, 6170–6187. [Google Scholar] [CrossRef]

- Lang, T.; Jensen, A. D.; Jensen, P. A. Retention of organic elements during solid fuel pyrolysis with emphasis on the peculiar behavior of nitrogen. Energy & fuels 2005, 19, 1631–1643. [Google Scholar]

- Yu, X.; Zhang, C.; Qiu, L.; Yao, Y.; Sun, G.; Guo, X. Anaerobic digestion of swine manure using aqueous pyrolysis liquid as an additive. Renewable Energy 2020, 147, 2484–2493. [Google Scholar] [CrossRef]

- Shakoor, A.; Shahzad, S. M.; Chatterjee, N.; Arif, M. S.; Farooq, T. H.; Altaf, M. M.; Tufail, M. A.; Dar, A. A.; Mehmood, T. Nitrous oxide emission from agricultural soils: Application of animal manure or biochar? A global meta-analysis. Journal of Environmental Management 2021, 285, 112170. [Google Scholar] [CrossRef] [PubMed]

- Kiran, Y. K.; Barkat, A.; CUI, X.-q.; Ying, F.; PAN, F.-s.; Lin, T.; YANG, X.-e. Cow manure and cow manure-derived biochar application as a soil amendment for reducing cadmium availability and accumulation by Brassica chinensis L. in acidic red soil. Journal of integrative agriculture 2017, 16, 725–734. [Google Scholar] [CrossRef]

- Bai, M.; Impraim, R.; Coates, T.; Flesch, T.; Trouve, R.; van Grinsven, H.; Cao, Y.; Hill, J.; Chen, D. Lignite effects on NH3, N2O, CO2 and CH4 emissions during composting of manure. Journal of Environmental Management 2020, 271, 110960. [Google Scholar] [CrossRef] [PubMed]

- Nasir, I. M.; Mohd Ghazi, T. I.; Omar, R. Anaerobic digestion technology in livestock manure treatment for biogas production: a review. Engineering in Life Sciences 2012, 12, 258–269. [Google Scholar] [CrossRef]

- Neshat, S. A.; Mohammadi, M.; Najafpour, G. D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renewable and Sustainable Energy Reviews 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S. K. Anaerobic co-digestion: Current status and perspectives. Bioresource Technology 2021, 330, 125001. [Google Scholar] [CrossRef]

- Hong, J.; Chae, C.; Kim, H.; Kwon, H.; Kim, J.; Kim, I. Investigation to Enhance Solid Fuel Quality in Torrefaction of Cow Manure. Energies 2023, 16, 4505. [Google Scholar] [CrossRef]

- Kougias, P. G.; Angelidaki, I. Biogas and its opportunities—A review. Frontiers of Environmental Science & Engineering 2018, 12, 1–12. [Google Scholar]

- Dehhaghi, M.; Tabatabaei, M.; Aghbashlo, M.; Panahi, H. K. S.; Nizami, A.-S. A state-of-the-art review on the application of nanomaterials for enhancing biogas production. Journal of environmental management 2019, 251, 109597. [Google Scholar] [CrossRef]

- Sillero, L.; Solera, R.; Perez, M. Improvement of the anaerobic digestion of sewage sludge by co-digestion with wine vinasse and poultry manure: Effect of different hydraulic retention times. Fuel 2022, 321, 124104. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S.; Moneti, M. Biogas production from poultry manure and cheese whey wastewater under mesophilic conditions in batch reactor. Energy Procedia 2015, 82, 811–818. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, K.; Liu, P.; Khan, A.; Xiong, J.; Tian, F.; Li, X. A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresource technology 2018, 247, 1119–1127. [Google Scholar] [CrossRef]

- Zhou, S.; Nikolausz, M.; Zhang, J.; Riya, S.; Terada, A.; Hosomi, M. Variation of the microbial community in thermophilic anaerobic digestion of pig manure mixed with different ratios of rice straw. Journal of bioscience and bioengineering 2016, 122, 334–340. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, R.; He, Y.; Zhang, C.; Liu, X.; Chen, C.; Liu, G. Anaerobic co-digestion of chicken manure and corn stover in batch and continuously stirred tank reactor (CSTR). Bioresource technology 2014, 156, 342–347. [Google Scholar] [CrossRef]

- Omar, R.; Harun, R. M.; Mohd Ghazi, T.; Wan Azlina, W.; Idris, A.; Yunus, R. In Anaerobic treatment of cattle manure for biogas production, Proceedings Philadelphia, annual meeting of American institute of chemical engineers, 2008; 2008; pp 1-10.

- MarañóN, E.; Castrillón, L.; Vázquez, I.; Sastre, H. The influence of hydraulic residence time on the treatment of cattle manure in UASB reactors. Waste management & research 2001, 19, 436–441. [Google Scholar]

- Ahring, B. K.; Ibrahim, A. A.; Mladenovska, Z. Effect of temperature increase from 55 to 65 C on performance and microbial population dynamics of an anaerobic reactor treating cattle manure. Water research 2001, 35, 2446–2452. [Google Scholar] [CrossRef]

- Harikishan, S.; Sung, S. Cattle waste treatment and Class A biosolid production using temperature-phased anaerobic digester. Advances in Environmental Research 2003, 7, 701–706. [Google Scholar] [CrossRef]

- Andara, A. R. g.; Esteban, J. L. Kinetic study of the anaerobic digestion of the solid fraction of piggery slurries. Biomass and bioenergy 1999, 17, 435–443. [Google Scholar] [CrossRef]

- Chae, K.; Jang, A.; Yim, S.; Kim, I. S. The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresource technology 2008, 99, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Masse, D. I.; Masse, L.; Croteau, F. The effect of temperature fluctuations on psychrophilic anaerobic sequencing batch reactors treating swine manure. Bioresource Technology 2003, 89, 57–62. [Google Scholar] [CrossRef]

- Ferrer, I.; Gamiz, M.; Almeida, M.; Ruiz, A. Pilot project of biogas production from pig manure and urine mixture at ambient temperature in Ventanilla (Lima, Peru). Waste Management 2009, 29, 168–173. [Google Scholar] [CrossRef] [PubMed]

- Bujoczek, G.; Oleszkiewicz, J.; Sparling, R.; Cenkowski, S. High solid anaerobic digestion of chicken manure. Journal of Agricultural Engineering Research 2000, 76, 51–60. [Google Scholar] [CrossRef]

- Atuanya, E. I.; Aigbirior, M. Mesophilic biomethanation and treatment of poultry waste-water using pilot scale UASB reactor. Environmental monitoring and assessment 2002, 77, 139–147. [Google Scholar] [CrossRef] [PubMed]

- Abouelenien, F.; Fujiwara, W.; Namba, Y.; Kosseva, M.; Nishio, N.; Nakashimada, Y. Improved methane fermentation of chicken manure via ammonia removal by biogas recycle. Bioresource technology 2010, 101, 6368–6373. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M. J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. International journal of molecular sciences 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed]

- Orlando, M.-Q.; Borja, V.-M. Pretreatment of animal manure biomass to improve biogas production: A review. Energies 2020, 13, 3573. [Google Scholar] [CrossRef]

- Li, K.; Liu, R.; Sun, C. Comparison of anaerobic digestion characteristics and kinetics of four livestock manures with different substrate concentrations. Bioresource technology 2015, 198, 133–140. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Zhao, C.; Liu, Y.; Zhang, R.; Liu, G.; Chen, C. Biogas production from anaerobic co-digestion of durian shell with chicken, dairy, and pig manures. Energy Conversion and Management 2019, 198, 110535. [Google Scholar] [CrossRef]

- Millati, R.; Wikandari, R.; Ariyanto, T.; Putri, R. U.; Taherzadeh, M. J. Pretreatment technologies for anaerobic digestion of lignocelluloses and toxic feedstocks. Bioresource technology 2020, 304, 122998. [Google Scholar] [CrossRef]

- Angelidaki, I.; Ahring, B. K. Methods for increasing the biogas potential from the recalcitrant organic matter contained in manure. Water science and technology 2000, 41, 189–194. [Google Scholar] [CrossRef]

- Paudel, S. R.; Banjara, S. P.; Choi, O. K.; Park, K. Y.; Kim, Y. M.; Lee, J. W. Pretreatment of agricultural biomass for anaerobic digestion: Current state and challenges. Bioresource Technology 2017, 245, 1194–1205. [Google Scholar] [CrossRef]

- Rafique, R.; Poulsen, T. G.; Nizami, A.-S.; Murphy, J. D.; Kiely, G. Effect of thermal, chemical and thermo-chemical pre-treatments to enhance methane production. Energy 2010, 35, 4556–4561. [Google Scholar] [CrossRef]

- Liu, M.; Ni, H.; Yang, L.; Chen, G.; Yan, X.; Leng, X.; Liu, P.; Li, X. Pretreatment of swine manure containing β-lactam antibiotics with whole-cell biocatalyst to improve biogas production. Journal of Cleaner Production 2019, 240, 118070. [Google Scholar] [CrossRef]

- Raju, C. S.; Sutaryo, S.; Ward, A. J.; Møller, H. B. Effects of high-temperature isochoric pre-treatment on the methane yields of cattle, pig and chicken manure. Environmental technology 2013, 34, 239–244. [Google Scholar] [CrossRef]

- Costa, J.; Barbosa, S.; Alves, M.; Sousa, D. Thermochemical pre-and biological co-treatments to improve hydrolysis and methane production from poultry litter. Bioresource technology 2012, 111, 141–147. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renewable and sustainable energy reviews 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Zieliński, M.; Dębowski, M.; Kisielewska, M.; Nowicka, A.; Rokicka, M.; Szwarc, K. Cavitation-based pretreatment strategies to enhance biogas production in a small-scale agricultural biogas plant. Energy for Sustainable Development 2019, 49, 21–26. [Google Scholar] [CrossRef]

- Chuenchart, W.; Logan, M.; Leelayouthayotin, C.; Visvanathan, C. Enhancement of food waste thermophilic anaerobic digestion through synergistic effect with chicken manure. Biomass and bioenergy 2020, 136, 105541. [Google Scholar] [CrossRef]

- Wei, L.; Qin, K.; Ding, J.; Xue, M.; Yang, C.; Jiang, J.; Zhao, Q. Optimization of the co-digestion of sewage sludge, maize straw and cow manure: microbial responses and effect of fractional organic characteristics. Scientific reports 2019, 9, 2374. [Google Scholar] [CrossRef]

- Yuan, Y.; Bian, A.; Zhang, L.; Chen, Z.; Zhou, F.; Ye, F.; Jin, T.; Pan, M.; Chen, T.; Yan, J. Thermal-alkali and enzymes for efficient biomethane production from co-digestion of corn straw and cattle manure. BioResources 2019, 14, 5422–5437. [Google Scholar] [CrossRef]

- Mao, C.; Zhang, T.; Wang, X.; Feng, Y.; Ren, G.; Yang, G. Process performance and methane production optimizing of anaerobic co-digestion of swine manure and corn straw. Scientific reports 2017, 7, 9379. [Google Scholar] [CrossRef]

- Agayev, E.; Ugurlu, A. Biogas production from co-digestion of horse manure and waste sewage sludge. TechConnect Briefs 2011, 3, 657–660. [Google Scholar]

- Astals, S.; Nolla-Ardèvol, V.; Mata-Alvarez, J. Anaerobic co-digestion of pig manure and crude glycerol at mesophilic conditions: Biogas and digestate. Bioresource technology 2012, 110, 63–70. [Google Scholar] [CrossRef]

- Glanpracha, N.; Annachhatre, A. P. Anaerobic co-digestion of cyanide containing cassava pulp with pig manure. Bioresource Technology 2016, 214, 112–121. [Google Scholar] [CrossRef]

- de Oliveira Paranhos, A. G.; Adarme, O. F. H.; Barreto, G. F.; de Queiroz Silva, S.; de Aquino, S. F. Methane production by co-digestion of poultry manure and lignocellulosic biomass: Kinetic and energy assessment. Bioresource Technology 2020, 300, 122588. [Google Scholar]

- Silvestre, G.; Gómez, M.; Pascual, A.; Ruiz, B. Anaerobic co-digestion of cattle manure with rice straw: economic & energy feasibility. Water Science and Technology 2013, 67, 745–755. [Google Scholar]

- Han, G.; Deng, J.; Zhang, S.; Bicho, P.; Wu, Q. Effect of steam explosion treatment on characteristics of wheat straw. Industrial Crops and Products 2010, 31, 28–33. [Google Scholar] [CrossRef]

- Li, R.; Chen, S.; Li, X.; Saifullah Lar, J.; He, Y.; Zhu, B. Anaerobic codigestion of kitchen waste with cattle manure for biogas production. Energy & Fuels 2009, 23, 2225–2228. [Google Scholar]

- Lehtomäki, A.; Huttunen, S.; Rintala, J. Laboratory investigations on co-digestion of energy crops and crop residues with cow manure for methane production: effect of crop to manure ratio. Resources, conservation and recycling 2007, 51, 591–609. [Google Scholar] [CrossRef]

- Rico, C.; Muñoz, N.; Fernández, J.; Rico, J. L. High-load anaerobic co-digestion of cheese whey and liquid fraction of dairy manure in a one-stage UASB process: Limits in co-substrates ratio and organic loading rate. Chemical Engineering Journal 2015, 262, 794–802. [Google Scholar] [CrossRef]

- Cuetos, M. J.; Fernández, C.; Gómez, X.; Morán, A. Anaerobic co-digestion of swine manure with energy crop residues. Biotechnology and Bioprocess Engineering 2011, 16, 1044–1052. [Google Scholar] [CrossRef]

- Cheng, X.-Y.; Zhong, C. Effects of feed to inoculum ratio, co-digestion, and pretreatment on biogas production from anaerobic digestion of cotton stalk. Energy & Fuels 2014, 28, 3157–3166. [Google Scholar]

- Aboudi, K.; Álvarez-Gallego, C. J.; Romero-García, L. I. Semi-continuous anaerobic co-digestion of sugar beet byproduct and pig manure: effect of the organic loading rate (OLR) on process performance. Bioresource technology 2015, 194, 283–290. [Google Scholar] [CrossRef] [PubMed]

- Bayrakdar, A.; Molaey, R.; Sürmeli, R. Ö.; Sahinkaya, E.; Çalli, B. Biogas production from chicken manure: Co-digestion with spent poppy straw. International Biodeterioration & Biodegradation 2017, 119, 205–210. [Google Scholar]

- Dahunsi, S.; Osueke, C.; Olayanju, T.; Lawal, A. Co-digestion of Theobroma cacao (Cocoa) pod husk and poultry manure for energy generation: Effects of pretreatment methods. Bioresource technology 2019, 283, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Optimizing feeding composition and carbon–nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresource technology 2012, 120, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Jiang, Y.; Wang, S.; Zhang, Y.; Hu, Y.; Hu, Z.-h.; Wu, G.; Zhan, X. Impact of total solids content on anaerobic co-digestion of pig manure and food waste: Insights into shifting of the methanogenic pathway. Waste Management 2020, 114, 96–106. [Google Scholar] [CrossRef] [PubMed]

- Dennehy, C.; Lawlor, P.; McCabe, M.; Cormican, P.; Sheahan, J.; Jiang, Y.; Zhan, X.; Gardiner, G. Anaerobic co-digestion of pig manure and food waste; effects on digestate biosafety, dewaterability, and microbial community dynamics. Waste Management 2018, 71, 532–541. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Chen, Y.; Zhang, D.; Yi, J. High-solid anaerobic co-digestion of sewage sludge and cattle manure: the effects of volatile solid ratio and pH. Sci. Rep. 6. In 2016. [CrossRef]

- Lim, J.-S.; Yang, S. H.; Kim, B.-S.; Lee, E. Y. Comparison of microbial communities in swine manure at various temperatures and storage times. Asian-Australasian journal of animal sciences 2018, 31, 1373. [Google Scholar] [CrossRef]

- Li, X.; Zhao, X.; Yang, J.; Li, S.; Bai, S.; Zhao, X. Recognition of core microbial communities contributing to complex organic components degradation during dry anaerobic digestion of chicken manure. Bioresource Technology 2020, 314, 123765. [Google Scholar] [CrossRef]

- Ozbayram, E. G.; Ince, O.; Ince, B.; Harms, H.; Kleinsteuber, S. Comparison of rumen and manure microbiomes and implications for the inoculation of anaerobic digesters. Microorganisms 2018, 6, 15. [Google Scholar] [CrossRef] [PubMed]

- Kupper, T.; Bürge, D.; Bachmann, H. J.; Güsewell, S.; Mayer, J. Heavy metals in source-separated compost and digestates. Waste Management 2014, 34, 867–874. [Google Scholar] [CrossRef] [PubMed]

- Montoro, S.; Lucas Jr, J.; Santos, D.; Costa, M. Anaerobic co-digestion of sweet potato and dairy cattle manure: A technical and economic evaluation for energy and biofertilizer production. Journal of cleaner production 2019, 226, 1082–1091. [Google Scholar] [CrossRef]

- Kataki, S.; Hazarika, S.; Baruah, D. Assessment of by-products of bioenergy systems (anaerobic digestion and gasification) as potential crop nutrient. Waste Management 2017, 59, 102–117. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.-G.; Chen, Q.-L.; Hu, H.-W.; He, J.-Z. Fate of antibiotic resistance genes during high-solid anaerobic co-digestion of pig manure with lignite. Bioresource technology 2020, 303, 122906. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Gu, J.; Wang, X.; Zhang, R.; Tuo, X.; Guo, A.; Qiu, L. Fate of antibiotic resistance genes and mobile genetic elements during anaerobic co-digestion of Chinese medicinal herbal residues and swine manure. Bioresource technology 2018, 250, 799–805. [Google Scholar] [CrossRef] [PubMed]

- Choong, Y. Y.; Norli, I.; Abdullah, A. Z.; Yhaya, M. F. Impacts of trace element supplementation on the performance of anaerobic digestion process: A critical review. Bioresource technology 2016, 209, 369–379. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J. H.; Labatut, R. A.; Lodge, J. S.; Williamson, A. A.; Trabold, T. A. Anaerobic co-digestion of commercial food waste and dairy manure: Characterizing biochemical parameters and synergistic effects. Waste management 2016, 52, 286–294. [Google Scholar] [CrossRef]

- Kim, J.; Baek, G.; Kim, J.; Lee, C. Energy production from different organic wastes by anaerobic co-digestion: Maximizing methane yield versus maximizing synergistic effect. Renewable energy 2019, 136, 683–690. [Google Scholar] [CrossRef]

- Xavier, C. A.; Moset, V.; Wahid, R.; Møller, H. B. The efficiency of shredded and briquetted wheat straw in anaerobic co-digestion with dairy cattle manure. Biosystems Engineering 2015, 139, 16–24. [Google Scholar] [CrossRef]

- Andriamanohiarisoamanana, F. J.; Saikawa, A.; Tarukawa, K.; Qi, G.; Pan, Z.; Yamashiro, T.; Iwasaki, M.; Ihara, I.; Nishida, T.; Umetsu, K. Anaerobic co-digestion of dairy manure, meat and bone meal, and crude glycerol under mesophilic conditions: Synergistic effect and kinetic studies. Energy for Sustainable Development 2017, 40, 11–18. [Google Scholar] [CrossRef]

- Ning, J.; Zhou, M.; Pan, X.; Li, C.; Lv, N.; Wang, T.; Cai, G.; Wang, R.; Li, J.; Zhu, G. Simultaneous biogas and biogas slurry production from co-digestion of pig manure and corn straw: Performance optimization and microbial community shift. Bioresource Technology 2019, 282, 37–47. [Google Scholar] [CrossRef]

- Li, D.; Liu, S.; Mi, L.; Li, Z.; Yuan, Y.; Yan, Z.; Liu, X. Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and cow manure. Bioresource Technology 2015, 189, 319–326. [Google Scholar] [CrossRef]

- Hassan, M.; Umar, M.; Ding, W.; Mehryar, E.; Zhao, C. Methane enhancement through co-digestion of chicken manure and oxidative cleaved wheat straw: Stability performance and kinetic modeling perspectives. Energy 2017, 141, 2314–2320. [Google Scholar] [CrossRef]

- Li, K.; Liu, R.; Cui, S.; Yu, Q.; Ma, R. Anaerobic co-digestion of animal manures with corn stover or apple pulp for enhanced biogas production. Renewable Energy 2018, 118, 335–342. [Google Scholar] [CrossRef]

- Møller, H. B.; Sørensen, P.; Olesen, J. E.; Petersen, S. O.; Nyord, T.; Sommer, S. G. Agricultural biogas production—climate and environmental impacts. Sustainability 2022, 14, 1849. [Google Scholar] [CrossRef]

- Siddique, M. N. I.; Wahid, Z. A. Achievements and perspectives of anaerobic co-digestion: A review. Journal of cleaner production 2018, 194, 359–371. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, T.; Wan, H.; Chen, Y.; Wang, X.; Yang, G.; Ren, G. Anaerobic co-digestion of animal manure and wheat straw for optimized biogas production by the addition of magnetite and zeolite. Energy Conversion and Management 2015, 97, 132–139. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.; Abdel-Hadi, M.; Hassan, H.; Badr, Y. Effects of Co and Ni nanoparticles on biogas and methane production from anaerobic digestion of slurry. Energy Conversion and Management 2017, 141, 108–119. [Google Scholar] [CrossRef]

- Parawira, W. Enzyme research and applications in biotechnological intensification of biogas production. Critical reviews in biotechnology 2012, 32, 172–186. [Google Scholar] [CrossRef] [PubMed]

- Dahunsi, S.; Oranusi, S.; Efeovbokhan, V. Pretreatment optimization, process control, mass and energy balances and economics of anaerobic co-digestion of Arachis hypogaea (Peanut) hull and poultry manure. Bioresource Technology 2017, 241, 454–464. [Google Scholar] [CrossRef] [PubMed]

- Naran, E.; Toor, U. A.; Kim, D.-J. Effect of pretreatment and anaerobic co-digestion of food waste and waste activated sludge on stabilization and methane production. International Biodeterioration & Biodegradation 2016, 113, 17–21. [Google Scholar]

- Zhen, G.; Lu, X.; Kato, H.; Zhao, Y.; Li, Y.-Y. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renewable and Sustainable Energy Reviews 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Jurado, E.; Antonopoulou, G.; Lyberatos, G.; Gavala, H. N.; Skiadas, I. V. Continuous anaerobic digestion of swine manure: ADM1-based modelling and effect of addition of swine manure fibers pretreated with aqueous ammonia soaking. Applied Energy 2016, 172, 190–198. [Google Scholar] [CrossRef]

- Tugtas, A. E.; Cavdar, P.; Calli, B. Bio-electrochemical post-treatment of anaerobically treated landfill leachate. Bioresource technology 2013, 128, 266–272. [Google Scholar] [CrossRef] [PubMed]

- Muha, I.; Zielonka, S.; Lemmer, A.; Schönberg, M.; Linke, B.; Grillo, A.; Wittum, G. Do two-phase biogas plants separate anaerobic digestion phases?–A mathematical model for the distribution of anaerobic digestion phases among reactor stages. Bioresource technology 2013, 132, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.-F.; Xu, X.-H.; Dai, M.; Yuan, X.-Z.; Guo, R.-B. Hydrogen and methane production from vinasse using two-stage anaerobic digestion. Process Safety and Environmental Protection 2017, 107, 81–86. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.-c. A bench scale study of fermentative hydrogen and methane production from food waste in integrated two-stage process. International journal of hydrogen energy 2009, 34, 245–254. [Google Scholar] [CrossRef]

| Parameter | Cattle manure | Pig manure | Chicken manure |

|---|---|---|---|

| TS (g/kg) | 310 | 70.6 | 132-171 |

| VS(g/kg) | 235.3 | 56.5 | 55-75 |

| TSS (g/kg) | 280 | 58.5 | NA |

| VSS (g/kg) | 230 | 46.8 | NA |

| pH | 8.0 | 7.6 | 6.9-7.4 |

| TCOD (g/kg) | 290.8 | 134.5 | 87-130 |

| SCOD(g/kg) | 22.5 | 39.4 | 32-97 |

| TVFAs (g COD/kg) | 1.5 | 22.3 | 10-50 |

| TN (g/kg) | 9.1 | 6.1 | 4 |

| TP (g/kg) | 1.0 | 1.8 | 8.1 |

| C | 38.8 | 46.4 | 30.92 |

| H | 4.9 | 5.9 | 3.89 |

| O | 29.3 | 34.5 | 32.08 |

| N | 1.6 | 2.1 | 7.74 |

| Alkalinity (g caCO3/kg) | 32.7 | 13.8 | NA |

| Livestock manure | Reactor type | Temperature (0c) | OLR (kg VS m-3 day-1) | HRT (d) | CH4 yield (m3 kg-1 VS) | Biogas yield (m3 kg-1 VS) | CH4 content (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| Cattle | Batch | 53 | NA | 17 | 0.184 | 0.159 | 65 | [65] |

| Cattle | UASB | 37 | 2.35 | 22.5 | NA | 0.200 | 64 | [66] |

| Cattle | CSTR | 55 | 3 | 15 | 0.202 | NA | NA | [67] |

| Cattle | TPAD | 35 | 5.8 | 14 | 0.210 | NA | 60 | [68] |

| Pig | Stirred batch | 35 | 12.39 | 0.9-3.6 | 0.176 | NA | 50 | [69] |

| Pig | Batch | 25 | NA | 20 | 0.317 | NA | 44 | [70] |

| Pig | ASBR | 20 | 1.1 | 15 | 0.266 | NA | 75 | [71] |

| Pig | Batch | 22.6 | NA | 80 | NA | 0.207 | 22 | [72] |

| Pig | batch | 35 | NA | 15 | 0.548 | NA | 70 | [73] |

| Chicken | batch | 35 | NA | 33 | 0.473 | NA | 41 | [73] |

| Chicken | UASB | 34 | 2.9 | 13.2 | 0.26 | NA | NA | [74] |

| Chicken | Batch | 55 | NA | 10 | 0.195 | NA | 67 | [75] |

| Livestock manure | Type of pretreatment | CH4 (mL/g VS) | CH4 enhancement (%) | Reference |

|---|---|---|---|---|

| Cattle | Physical (maceration and pressurized at 100 atm. pressure | 276 | 20 | [81] |

| Chemical (peracetic acid) | 182.4 | 39 | [82] | |

| Biological (Incubation with B4 bacteria) | 300 | 30 | [81] | |

| Pig | Physiochemical (1000C) for 1 hour | 237.5 | 28 | [83] |

| Chemical, Ca (OH)2, 1h (700C) | 345 | 72 | [83] | |

| Biological (cell biocatalyst) | 98.7 | 93.2 | [84] | |

| Chicken | Physiochemical (High pressure and temperature) | 518 | 54.6 | [85] |

| Chemical, Ca (OH)2, at 900C and 1.27 bar pressure | 137 | NA | [86] | |

| Biological (Clostridium saccharolyticum and Clostridium thermocellum as bioaccumulation strains) | 102 | 15 | [86] |

| Livestock manure | Co-substrate | Reactor configuration | Biogas or CH4 production increase | Methane (%) | Reference |

|---|---|---|---|---|---|

| Cattle | Wheat straw | Batch | Sp. CH4 yield0.460 m3/kg VSadd (+24.6%) | 53 (1.3%) | [88] |

| Food waste | CSTR | Sp. CH4 yield0.6-0.8 m3/kg VSadd +88.6%) | 61.34-65.89(+4.7%) | [89] | |

| Maize straw | Batch | Sp. CH4 yield0.534-0.614 m3/kg VSadd (39.8%) | 51.21-58.66 (+39.5%) | [90] | |

| Corn straw | Batch | Sp. CH4 yield0.290 m3/kg VSadd(+31.82%) | NA | [91] | |

| Pig | Corn straw | Batch | CH4 yield220 (mL/g VSadd)At PM:CS-70:30 | [92] | |

| Sewage sludge | Batch | Biogas yield410 mL/g VSadd at TS 2% | 65% at TS 2% | [93] | |

| Glycerol | CSTR | Biogas production5.44-5.58 L/g VSadd | NA | [94] | |

| Cassava pulp | Semi-continuous reactor | Sp. Methane yield380 mL/g VSadd | NA | [95] | |

| Chicken | Agricultural waste | 500 mL anaerobic vials | CH4 yield695 mL/g VS | NA | [14] |

| Rice straw | Batch | Sp. CH4 yield0.123-270 m3/kg VSadd | NA | [96] | |

| Corn cob | Batch | Sp. CH4 yield0.131-0.291m3/kg VSadd | NA | [96] | |

| Sugar cane bagasse | Batch | Sp. CH4 yield0.140-230 m3/kg VSadd | NA | [96] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).