Introduction

Metallurgical production is technologically accompanied by the formation of a significant amount of various waste accounting for up to 30% of steel production. Approximately 80% of this amount is slag, and approximately 20% is dust and other waste. The processing and disposal of man-made waste is important not only for its use as an alternative source of raw materials but also from the point of view of environmental protection. However, despite its considerable resource potential, mining waste, both in Russia and Kazakhstan, is used mainly as raw material for the construction industry, but even as such, no more than 10% of the annual volume of its formation is processed. The environmental legislation of Russia and Kazakhstan regulates the activities of the metallurgical complex at a fairly high level however, the principles of a waste-free economy and resource-saving technologies based on waste disposal lag behind the implementation of environmental protection measures. For example, the recycling of pulverized iron ore waste, in which the iron content reaches 60%. For Russia and Kazakhstan, which produce a significant share of the world's mineral products and have powerful mining and metallurgical potential, the problem of recycling accumulated waste is of paramount importance. This is especially true under conditions of increased demand for iron. Metallurgy in the countries of the former USSR is characterized by high resource and energy intensity - 1.5–3 times higher than that in developed countries [

1], which leads to a high level of specific waste generate on per unit of metal products. Currently, the volume of accumulated solid waste from metallurgical enterprises is estimated to be billions of tons [

2]. Moreover, some types of metallurgical waste, such as iron-containing sludge, do not need to be enriched and can be equated to iron ore concentrates. The most significant man-made deposits in terms of volume are hydraulic dumps and tailings ponds [

3]. The annual increase in waste in individual industries is millions of tons: coal industry -1960; ferrous metallurgy - 630; non-ferrous metallurgy – 374; chemical industry - 270 and production of building materials – 265 [

4]. More than billion tons of wastes have accumulated in the dumps and sludge storage facilities of the metallurgical enterprises of the Russian Federation. Of these, approximately 360 million tons of ferrous metallurgy waste and more than 800 tons of nonferrous metallurgy waste exist. In particular, billions of cubic meters of waste have accumulated in the Urals over a 300-year period of intensive mining and metallurgical production [

5]. All of the above applies to highly moist iron-containing sludge from metallurgical production.

Owing to the lack of effective dewatering and caking technologies, they are usually stored in ash and slag storage facilities, where they are mixed with other slurries and dust, and their metallurgical value is lost. For Kazakhstan's metallurgical enterprises, for example, “ArcelorMittal Temirtau” JSC (now “Garmet” JSC) annually generates approximately 95-100 thousand tons). tons of iron-containing blast furnace and oxygen converter gas treatment sludge containing 35-40% iron and other elements important for metallurgical processes (calcium, magnesium), which are not used and are stored in ash and sludge accumulators and dumps. The increase in iron-containing sands with a content of 50-75% iron at JSC “Aluminium in Kazakhstan” is approximately 100 thousand tons, which are also stored in slurry fields.

Considering the tendency toward a constant decrease in the iron content in natural iron ore concentrates (45-50%), the iron-containing calcification material obtained from highly moist iron-containing sludge and pulverized waste from lime production and the firing of raw dolomite can serve as an alternative secondary material for the partial replacement of iron ore concentrate. This will reduce the need for natural iron ore raw materials and fluxing materials, which is possible with the availability of technology for preparing iron-containing sludge for metallurgical processing.

On the other hand, at full-cycle metallurgical enterprises, which include ArcelorMittal Temirtau JSC, when calcareous and raw dolomite are fired, a large amount of finely dispersed calcium and magnesium-containing dust is formed in the form of lime and dolomite dust, which have excellent dehydrating and astringent properties, which, as a rule, are not in demand and are stored in ash and sludge storage facilities.

The development of technology for the dewatering of highly moist finely dispersed ferruginous sludge, as well as the creation of complex composite self-healing materials as alternative sources of raw materials, can serve as the basis for the creation of resource-saving, low-waste, closed environmentally safe and waste-free metallurgical processes that solve not only the issues of raw materials with maximum involvement of production waste in economic turnover, but also the environmental problems of the region.

In world practice, technologies for the production of iron-containing briquettes are known, but they differ from our proposed technology in that they use expensive and complex (thermal, vacuum) pre dewatering and multistage caking technologies, which are energy-intensive and expensive [

6,

7,

8,

9].

The technology closest to the proposed technology is the production of metallurgical self-healing briquettes of the Russian company Ecomashgio. In contrast to the proposed technology, iron-containing sludge with a moisture content of 15-20% is used, which is suitable for storing stale sludge. Moreover, the proposed technological scheme of Ecomashgio does not exclude the transportation of iron-containing pulp through a multikilometer slurry pipeline and storage in sludge accumulators. In addition, cement is used as a binder and reinforcing material in Ecomashgio technology, which increases the cost of metallurgical briquettes [

10,

11].

The prerequisites for the development of this project were the establishment of new patterns of processing highly moist iron-containing sludge and calcium and magnesium-containing materials (lime, dolomite dust) for chemical dewatering of sludge, hardening of the mixture, and mixing of cement with water to obtain a stone-like material in the form of fine sand. When highly moist sludge is mixed with dehydrating materials due to the exothermic reaction of active calcium and magnesium oxides with sludge moisture, the system temperature increases to 95-110°C, and some of the moisture evaporates and is removed as steam [

12,

13,

14,

15]. This variant of the technology was introduced at “Garmet” JSC (Republic of Kazakhstan) in a water supply workshop for dewatering oil scale using pulverized lime and dolomite waste to obtain a limited scale for agglomeration production [

14].

Research Methodology

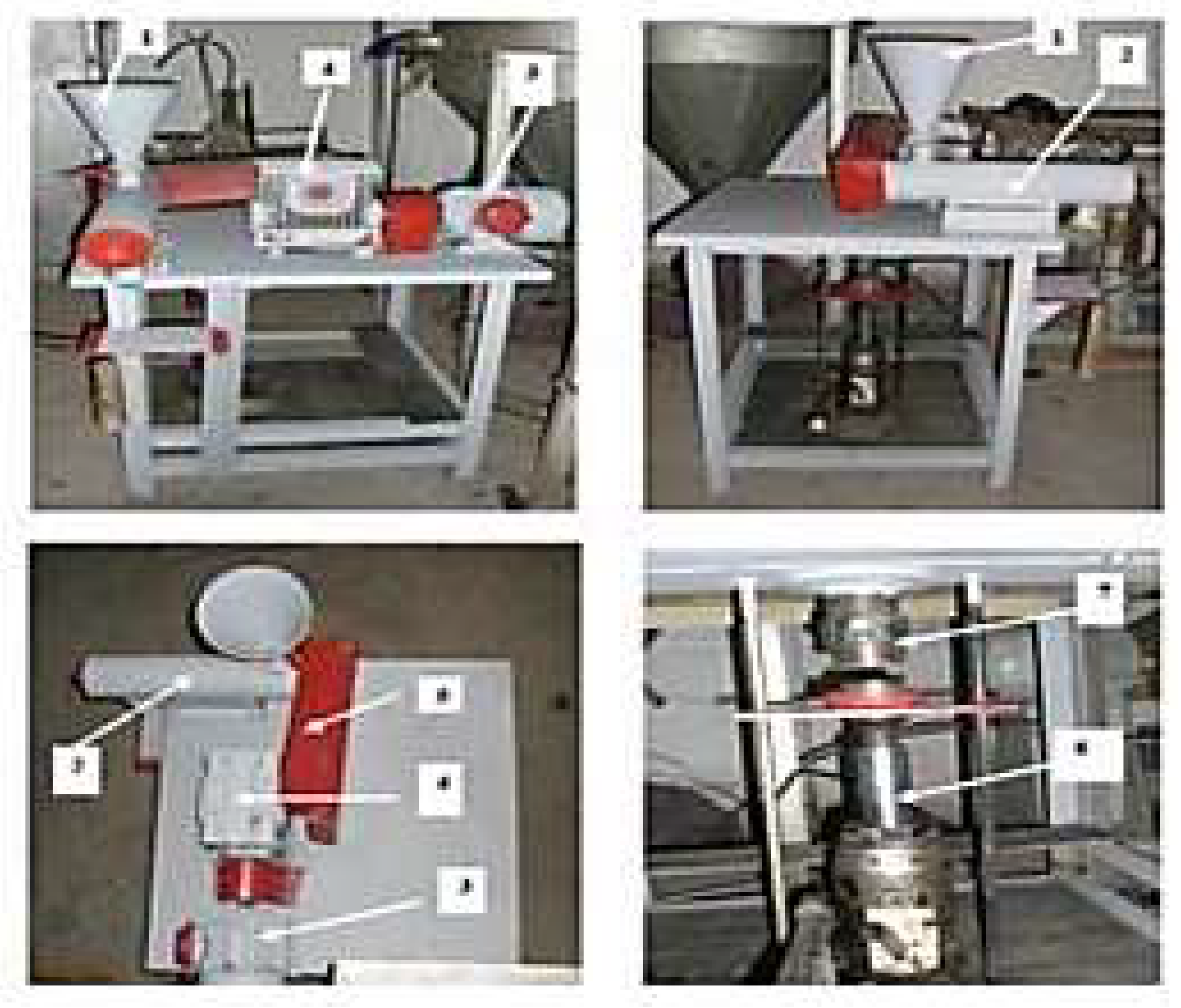

To study the processes of combining the operations of dewatering, hardening and caking of iron-containing sludge, a laboratory installation was developed (

Figure 1) and experiments were conducted to study the conditions for obtaining iron-containing briquettes suitable for steelmaking [

16,

17]. During mixing and subsequent exposure, the temperature of the mass, the rate of dehydration, and the chemical composition were measured. The forming process was carried out on a laboratory hydraulic press with forces of 125, 180 and 280 kN. Cylindrical briquettes made under laboratory conditions with a diameter of 50 mm and a height of 60 mm had strengths of 94, 265 and 505 kN/cm

2, respectively, and a density of 2.7 kg/cm

3. The amount of fines of less than 5 mm when dropped onto a steel plate from a height of 2 m was 0.6%.

Research Results

This research established new patterns that made it possible to develop an annealing-free method for producing iron-containing materials and self-healing briquettes, which became one of the main provisions of scientific novelty. The essence of this method combines the processes of dehydration and self-curing of the mixture with the process of shaping by applying external pressure to the hardening mixture in molds to obtain a lumped material in the form of briquettes. The proposed technology does not require drying and firing, and a set of strength properties occurs in the air as the material cools during the day. Innovative patents of the Republic of Kazakhstan were obtained for the proposed technical solution [

18,

19]. As a result of additional research, a new efficient resource-saving technological scheme for the production of carbonized iron-carbon-containing materials for metallurgical production has been developed. The innovative technologies developed for the preparation of wet sludge for processing were presented in the Catalogue of the Exhibitory of Industrial Achievements "Development of the Mining, Metallurgical and Coal industries" [

20] and reflected in the materials of the All-Russian Conference "Research in the field of processing and disposal of man-made formations and waste" [

21].

Discussion of Research Results

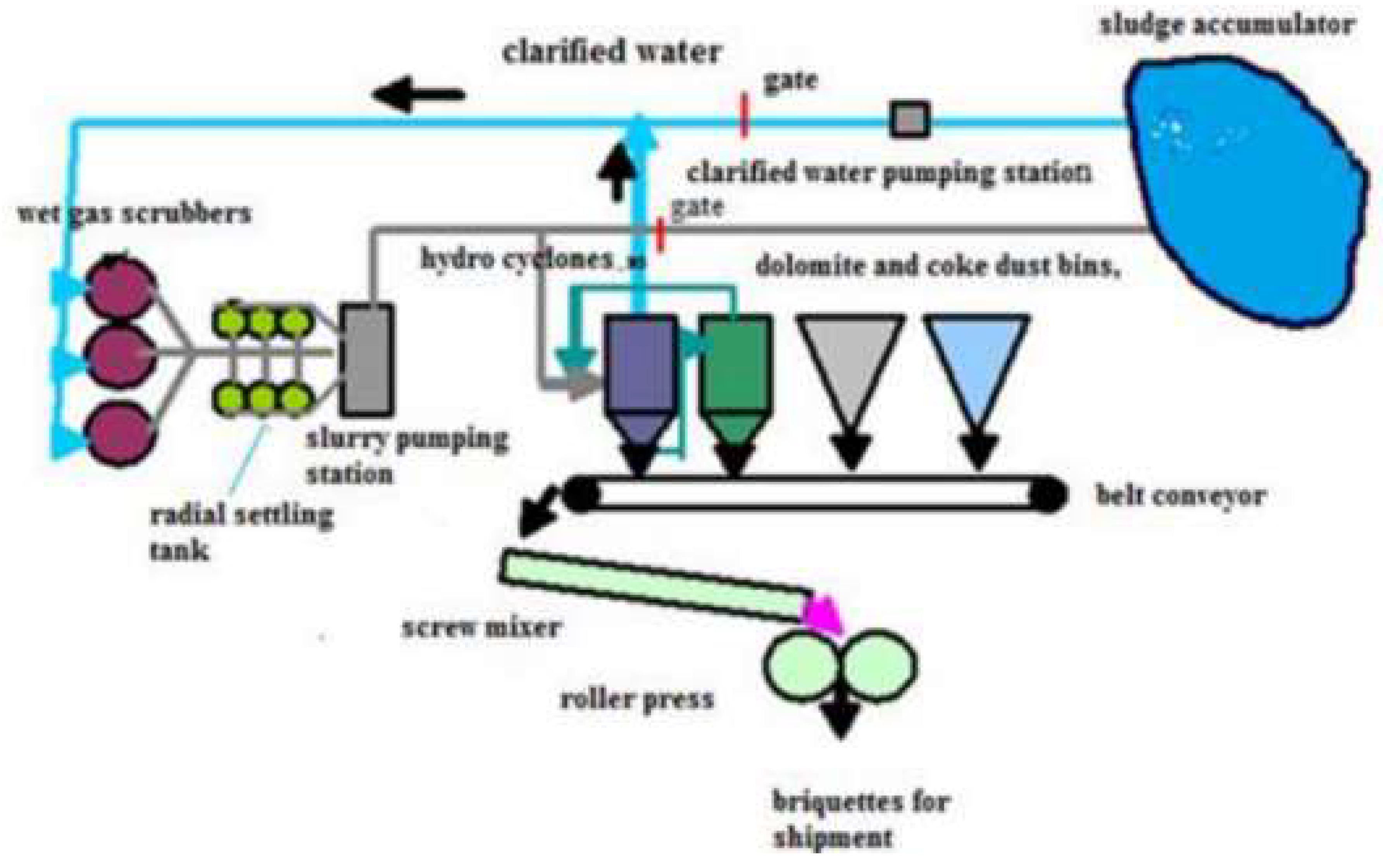

Slurry from the technological cycle or wet gas purification systems is pumped directly to the proposed installation (

Figure 2), where the pulp is condensed in pressure hydrocyclones to a humidity of 40-50%, and the condensed sludge is sent to a conveyor, where pulverized lime and/or pulverized dolomite are also loaded from metering bunkers, as well as screening of coke fines or pulverized coal.

The materials are fed from the conveyor to the screw mixer-activator, where the chemical dewatering process is underway. From the mixer, the dehydrated heated slurry-lime mixture is fed to a roller or vibrating press, where a calcified material with a residual moisture content of 5-9% is formed. The briquettes are stored on pallets for cooling and aging at ambient temperature. The spent clarified water from the hydrocyclone is pumped and returned to the general technological cycle. In general, this technology allows one to create a closed water supply system through the proposed installation (department), excluding a pond separator (sludge storage), which significantly reduces water consumption, labor and energy costs for transporting pulp through a multikilometer slurry pipeline to the sludge storage and clarified water back for the technology, as well as the maintenance costs of slurry pumps, sludge pipelines and sludge storage. Thus, iron ore sludge in the form of a caked composite material can be used as a substitute for iron ore concentrate in the end-to-end technology of steel and cast iron smelting, which does not require allocation of land for sludge storage for sludge storage and ensures more complete utilization of man-made production waste.

The proposed project is the basis for the creation of resource-saving, low-waste, closed and environmentally friendly waste-free processes that solve not only the problems of raw materials and the maximum involvement of waste in circulation, but also the environmental problems of production. The competitiveness of the proposed technology in comparison with similar Western analogues is as follows:

- -

- exclusion of transportation and storage of sludge in a sludge storage facility and sludge processing in the immediate vicinity of the source of education;

- -

- reduction of labour and energy costs for the transportation and storage of sludge, maintenance of slurry pumps, slurry pipelines and sludge accumulators;

- -

- elimination of the need for sludge drying before the production of iron ore briquettes;

- -

- processing consists of a single–stage process of dewatering, self-curing and shaping to obtain complex iron-carbon-containing granular material in one production cycle;

- -

- and the use of calcium - and magnesium containing dust (pulverized waste) as a dehydrating and binding material and coke or coal production as a reducing agent. As a result of the project, commercial products will be obtained in the form of secondary iron-carbon-containing material and an iron-carbon alloy as a substitute for iron ore raw materials and scrap for the production of steel, iron and alloys.

Conclusions

The proposed project and technology will make it possible to organize production for the processing of highly moist iron-containing sludge and the production of complex iron-containing material as a secondary metal-containing raw material for metallurgical plants for the production of steel and rolled metal. The technology will completely recycle not only iron-containing sludge from current production, but also pulverized waste from calcining limestone and dolomite (limestone and dolomite dust of dry gas cleaners) as dehydrating and binding materials, as well as from screening coke and coal as reducing agents. The proposed technology also removes the problems of environmental pollution and the allocation of land for the storage of industrial waste. The described project and technology will make it possible to eliminate the storage of iron-containing sludge in ash and sludge storage facilities and sludge fields, obtain new marketable products, reduce the consumption of natural iron ore and fluxing materials, and solve not only technological but also environmental issues of metallurgical production. The proposed technological scheme of recycling will reduce environmental charges for waste storage and reduce the amount of off-balance sheet water and groundwater pollution.

Author Contributions

Ibraev I.K.: Conceptualization, Methodology, Software , Investigation.; Bludova D. I. Data curation, Writing - Original draft pre pa ration, Visualization; Ibraeva O.T.: Supervision, Software , Validation, Writing- Reviewing and Editing; Aitkenov N. B: Methodology, Rocks Writing-Possibility Original University draft greatest preparation, Charge visualization. The final manuscript was read and approve d by all authors.

Conflict of interest

The authors declare that the y have no conflict of interest in relation to this research, whether financial, personal, authorship or otherwise , that could affect the research and its results presented in this paper.

References

- Volinkina E. P. Development of the waste management concept and development of a methodology for its implementation at a metallurgical enterprise : spec. 05.16.07 "Metallurgy of technogenic and secondary resources" : diss. ... Doctor of Technical Sciences /E. P. Volinkina. Novokuznetsk, 2007. 589 p. (in Russian).

- Kozlovsky E. A. The state and directions of development of the mineral resource base of Russia/ E. A. Kozlovsky/ Mining Journal, 2003, No. 10, pp. 4-9. rudmet.ru›journal/1085/article/17817/.

- Anisimov V. N., Bulgakov I. S., Gasiev G. K. Solving geoecological problems of safety and deep processing of natural and man-made deposits/ Mining industry. – 2012. – № 6 (106). – pp. 64-68. elibrary.ru›item.asp?id=18329410.

- Granovskaya N.V. Technogenic mineral deposits. N. V. Granovskaya, A.V. Mentochkin, F. V. Meshchaninov. – Rostov-on-Don : SFU. 2013. 93 p. – URL: http://nauka.xpdf.ru/17raznoe/461906-1-granovskaya-nastavkin-meschaninov-tehnogenniemestorozhdeniya-poleznih-iskopaemih-rostov-na-donu-nauchno-obrazovatelniy-ku.php.

- Ignatyeva M. N., Yurak V. V., Dushin A. V., Strovsky V. E. Technogenic mineral accumulations: problems of transition to circular economy. Mining Science and Technology (Russia). 2021;6(2):73–89. https://doi.org/10.17073/2500-0632-2021-2-73-89. [CrossRef]

- Gonik I. L. Features of the use of briquetable iron-containing waste/ I. L. Gonik, V. P. Lyamkin, N. A. Novitsky/ Metallurg, 2011, No. 5, pp. 25-27. https://link.springer.com/article/10.1007/s11015-011-9443-1. [CrossRef]

- Belkin A. S. The use of iron–coke briquettes on a cement bond in blast furnace melting/A. S. Belkin et al. Metallurgist. - 2003. – No. 4. – pp. 39-41. link.springer.com›article/10.1023/A:1024907130762. [CrossRef]

- Anyashiki T. Development of Carbon Iron Composite Process /T. Anyashiki, K. Fukada, H. Fujimoto. JFE GIHO. – 2008. – No. 22. – P. 20-24. nipponsteel.com›en/tech/report/pdf/123-14.pdf.

- Preparation of coal briquettes based on non standard Kazakh coal with various additives and determination of their quality.-M. Tulepov, L. Sassykova, A. Kerimkulova, [et al.] /Journal of Chemical Technology and Metallurgy. – 2021. – 56 (1). kaznu.kz›content/files/pages/folder7387/….

- Preparation of metallurgical raw materials for blast furnace and non–blast metallurgy of iron : in 2 volumes Vol.1. Theory, technology and practice of preparing components and charges for pelletizing : textbook /F. M. Zhuravlev, V. P. Lyalyuk, N. I. Stupnik [et al.]. - Moscow ; Vologda : Infra-Engineering, 2021. – 300 p. – ISBN 978-5-9729- 0704-5, 978-5-9729-0706-9 (vol. 1). – Text : electronic /Digital educational resource IPR SMART : [website]. – URL: https://www.iprbookshop.ru/115157.html .

- Han H. Binders and Bonding Mechanism for RHF Briquette Made from Blast Furnace Dust / H. Han, D. Duan, P. Yuan. ISIJ International. – 2014. – Vol. 54. – No. 8. – P. 1781-1789. https://doi.org/10.2355/isijinternational.54.1781. [CrossRef]

- Investigation of the processes of dehydration and preparation of iron-containing sludge for disposal / I. K. Ibraev, V. K. Golovkin, S. N. Klimushkin, V. G. Sadovsky [et al.] // Steel. - 1996. – No. 11. – pp. 71-74. chermetinfo.elpub.ru›jour/article/download/1650/….

- The patent of the Republic of Kazakhstan. № 4005. (51)702 11/12,21 5/36. The sludge dewatering method / Industrial property. The official bulletin. – 1996. – No. 12, published on 12/15/2000. URL: https://kzpatents.com/5-4005-sposob-obezvozhivaniya-shlama.html.

- Innovation patent of the Republic of Kazakhstan No. 21208. The method of disposal of oil-iron-containing waste from rolling production / Industrial property. Official Bulletin, 2009, No. 5, published on 05/15/2009.

- Ibraeva O. T. Energy-saving technology of waste processing of metallurgical production / O. T. Ibraeva, I. K. Ibraev. Almaty : SIC "Gylym", 2011. 292 p.

- Ibraev I. K. Development of a complex for the preparation of secondary raw materials from metallurgical waste for use in through–metal rolling technologies / I. K. Ibraev, I. S. Vishnev /Republican Scientific Journal "Technology of production of metals and secondary materials". Temirtau, 2009, No. 2, pp. 18-21.

- Utility model Patent № 586. (2009.01) 28 5/12 (2009.01) 10 5/06 (2009.01) 10 7/06 (2009.01) A complex for briquetting bulk materials /Industrial property. The official bulletin. – 2011. – No. 10, published on 10/15/2010. kz.patents.su›4-ip21208-sposob-utilizacii-….

- Innovation Patent of the Republic of Kazakhstan N 25103. A4 (11) C22B 1/243 (2009.01) C22B 1/24 (2009.01) 2010/0670.1 05/24/2010. Astringent for nonbinding coating Industrial property. The official bulletin. – 2011. – No. 12 a, published on 12/15/2011. 153 kz.patents.su›patents/c22b-1-243.

- Innovation Patent of the Republic of Kazakhstan N 23987. A4 (11) C22B 1/243 (2010.01) C22B 1/24 (2010.01) 2010/0623.1 was published on 14/05/2010. The method of non-ignition caulking // Industrial property. The official bulletin. – 2011. – № 5, 16.05.2011. kz.patents.su›patents/c22b-1-243.

- Ibraev I. K. Innovative technologies for preparing high-moisture sludge for burial /I. K. Ibraev, O. T. Ibraeva, M. M. Suyundikov. //Catalogue of the exhibition of achievements of the domestic industry "Development of the mining and metallurgical complex and the coal industry". "– Karaganda, 2010. – pp. 32-36.

- Ibraev IK, Ibraeva OT, Aitkenov NB. An annealing-free method for processing high-moisture iron-containing sludge of metallurgical production. Kompleksnoe Ispolzovanie Mineralnogo Syra = Complex Use of Mineral Resources.2025; 333(2):59-70. https://doi.org/10.31643/2025/6445.18. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).