Submitted:

29 November 2023

Posted:

30 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

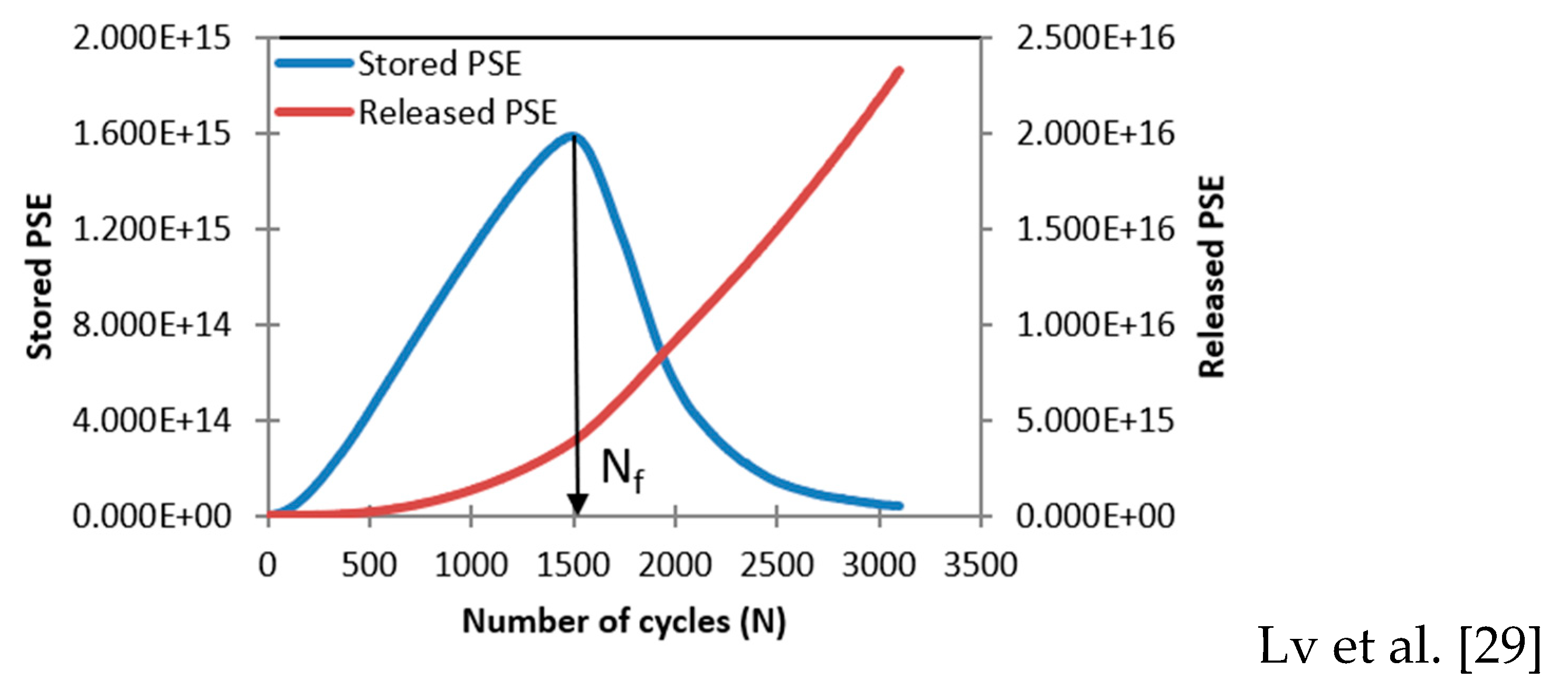

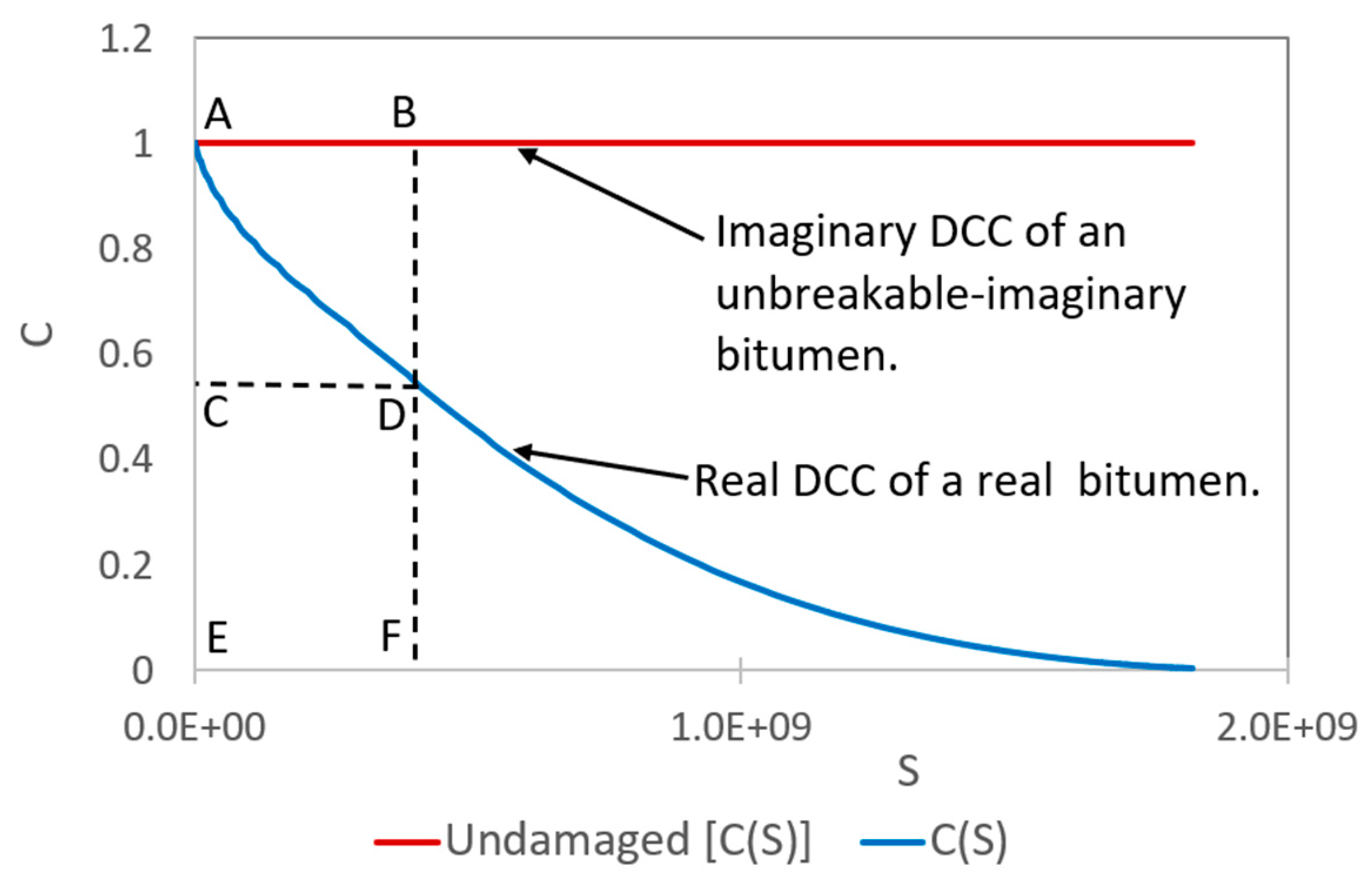

1.1. Failure definition of bitumen

1.2. Failure criterion of bitumen

1.3. Summary and objectives

- Propose a new framework to address the ranking inconsistency between the failure definition and DCC analysis.

- Verify the usefulness of the proposal of a new framework to evaluate bitumen fatigue cracking performance.

- Test in this study NA and PMBs, including SPMB to test the capability of the proposal to accommodate the performance of any types of asphalt binders.

2. Materials and Methods

2.1. Materials.

2.1.1. Neat asphalt binder (NA)

2.1.2. SBS modified bitumen (SBSB)

2.1.3. Self-healing elastomers

Self-healing thermoplastic polyurethane

Self-healing IPA1w (IPA1w)

2.2. Methods

2.2.1. Preparation of STP modified bitumen (STPB)

2.2.2. Preparation of IPA1w modified bitumen (IPAB)

2.2.3. Aging procedure.

2.2.4. Performance Grade (PG) characterization.

2.2.5. LAS test

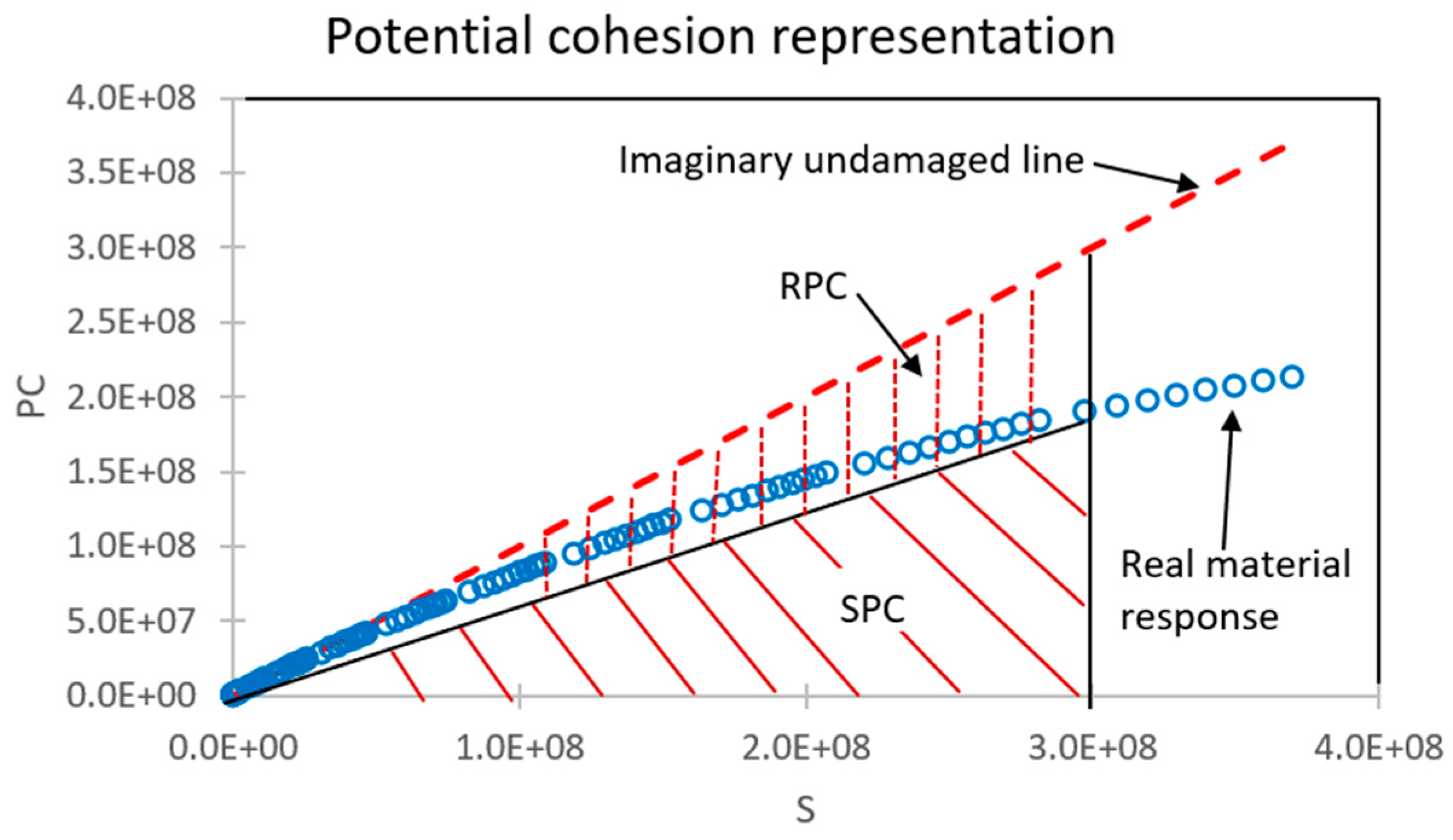

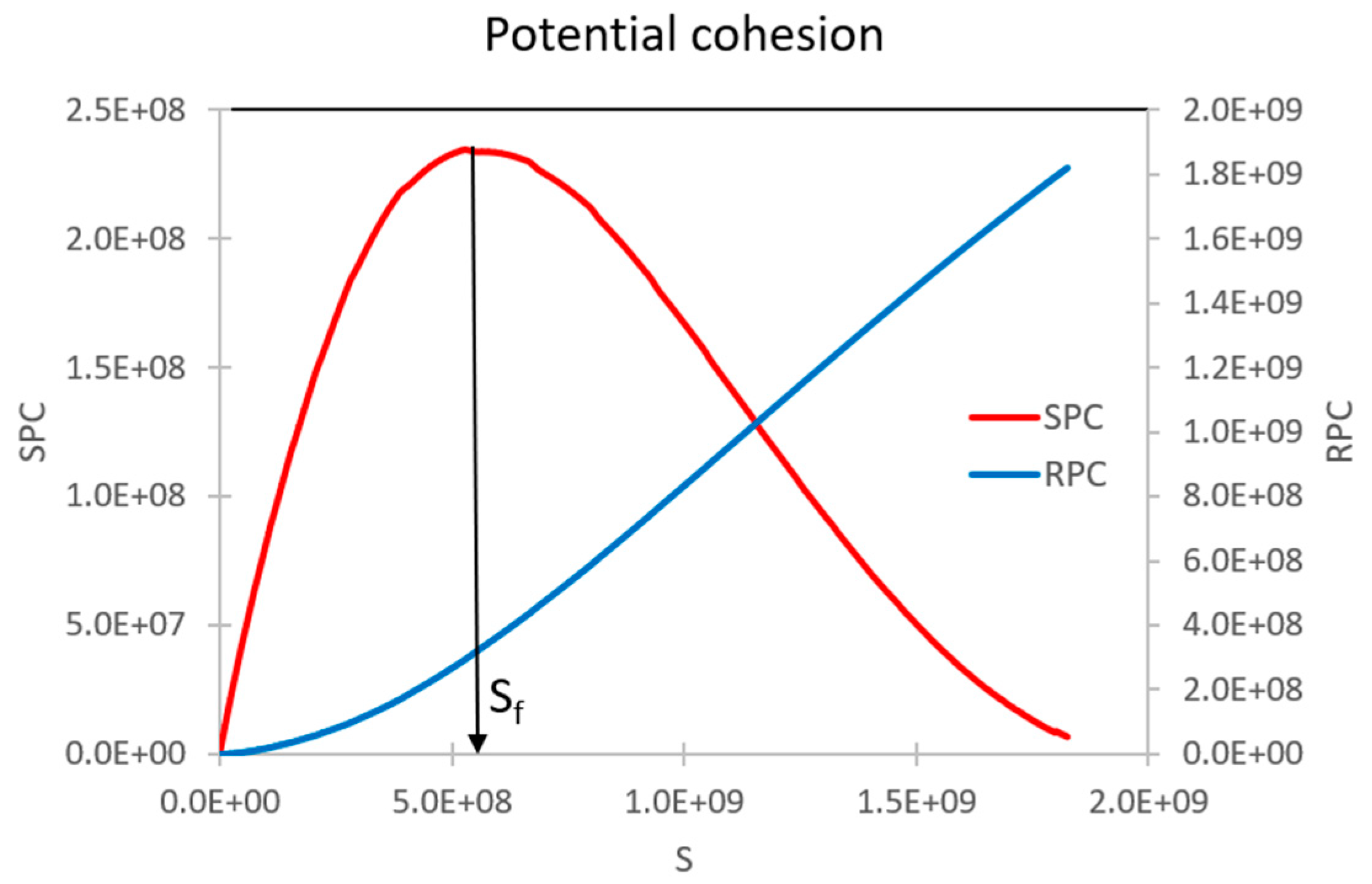

2.2.6. S-VECD

2.2.7. Proposal of new framework to determine failure definition and criterion

3. Results

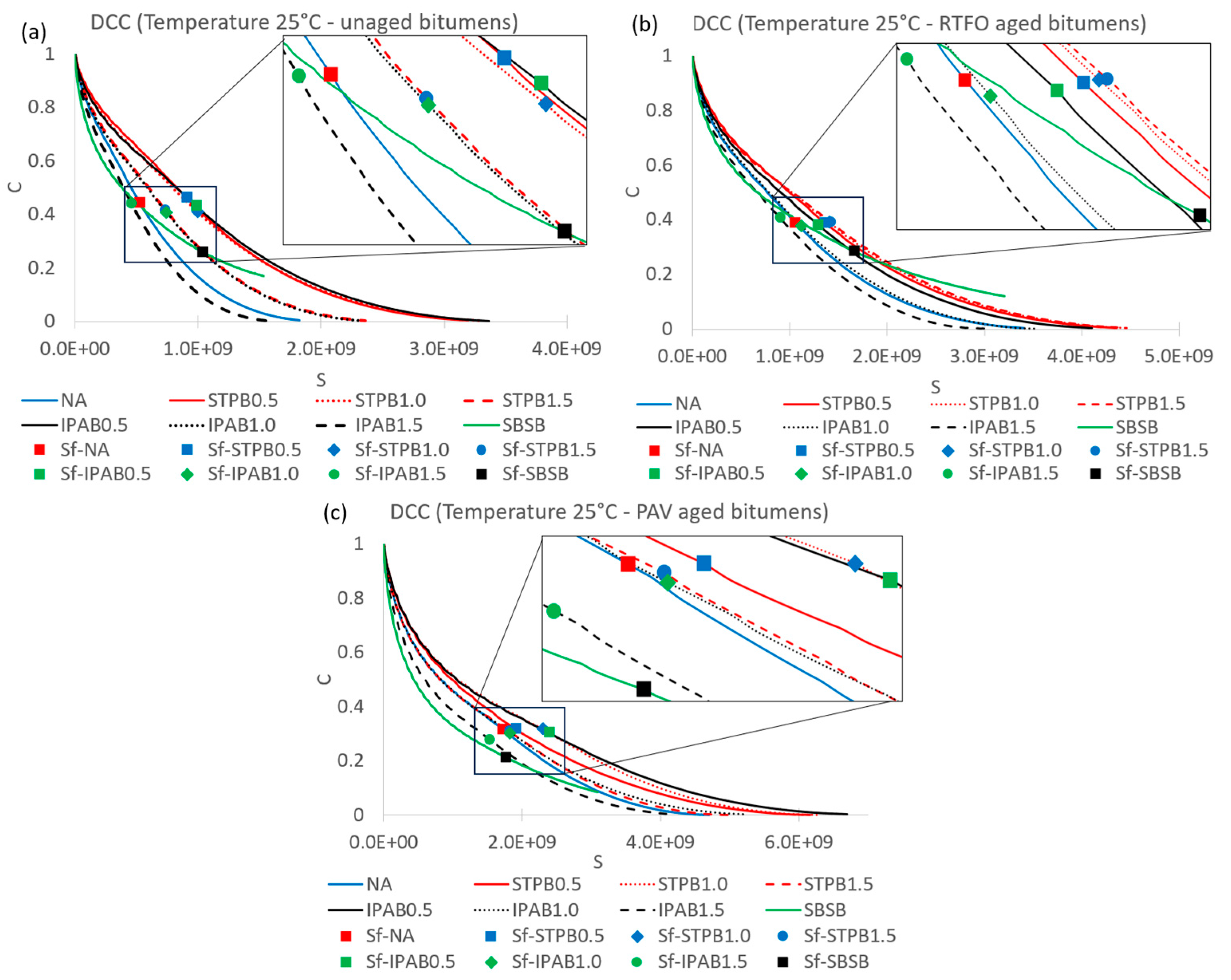

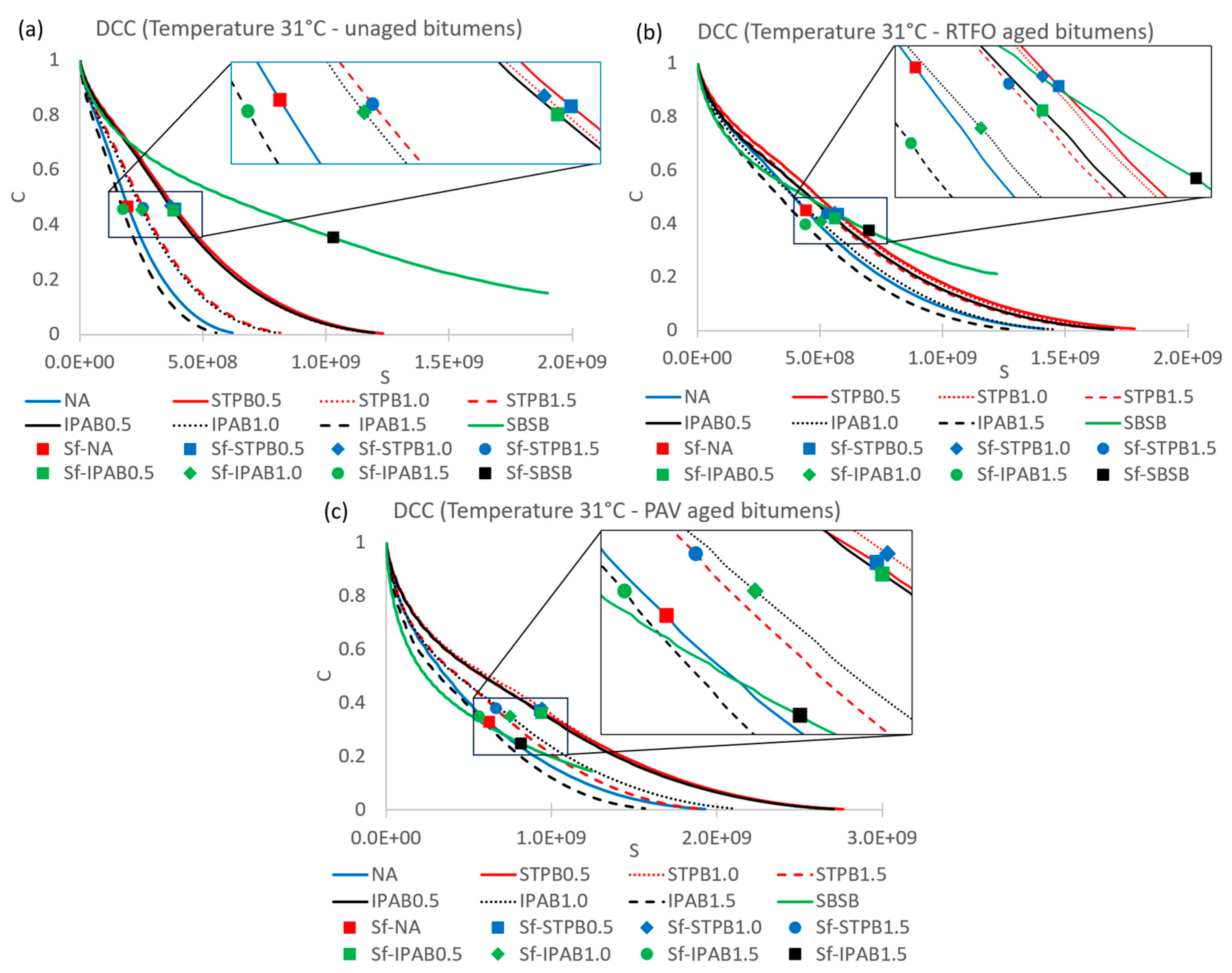

3.1. Failure definition evaluation

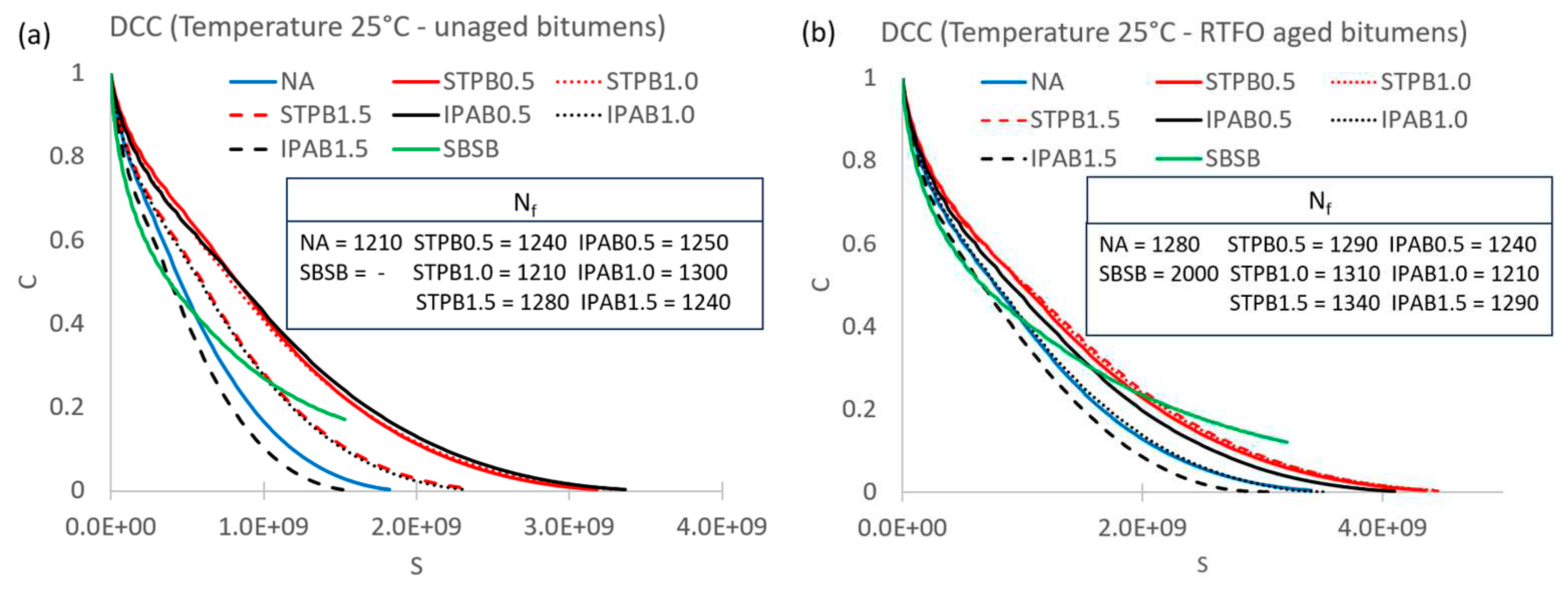

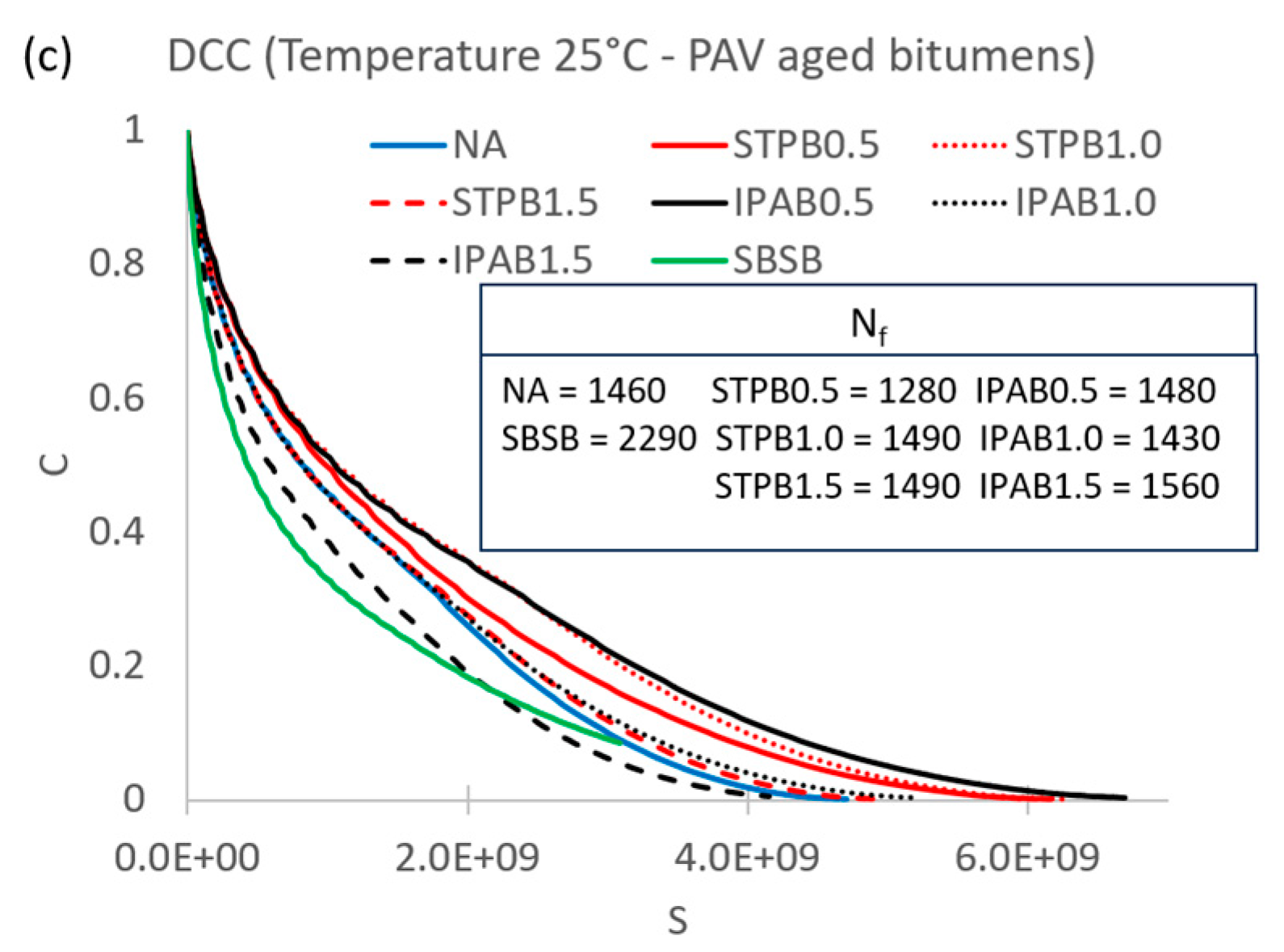

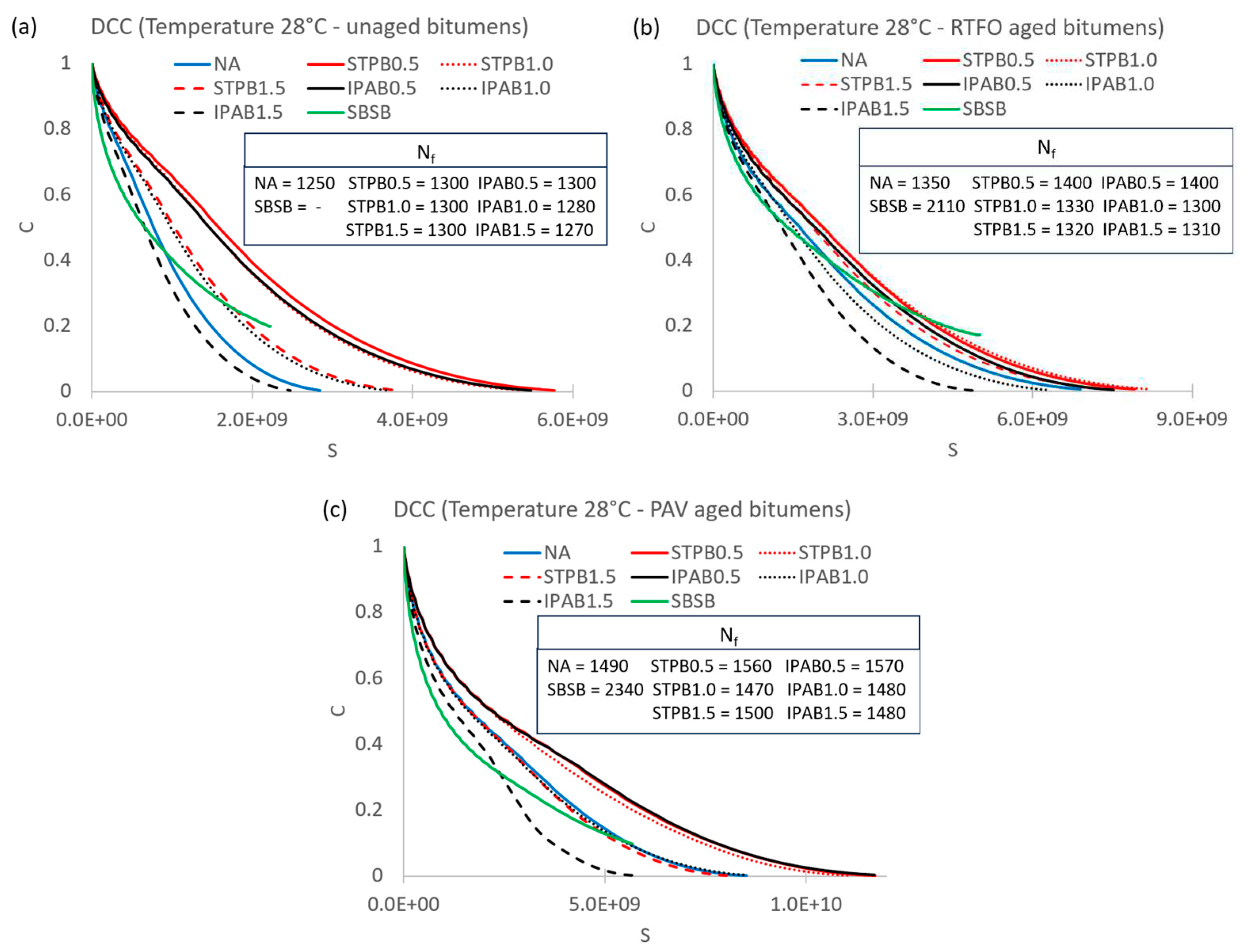

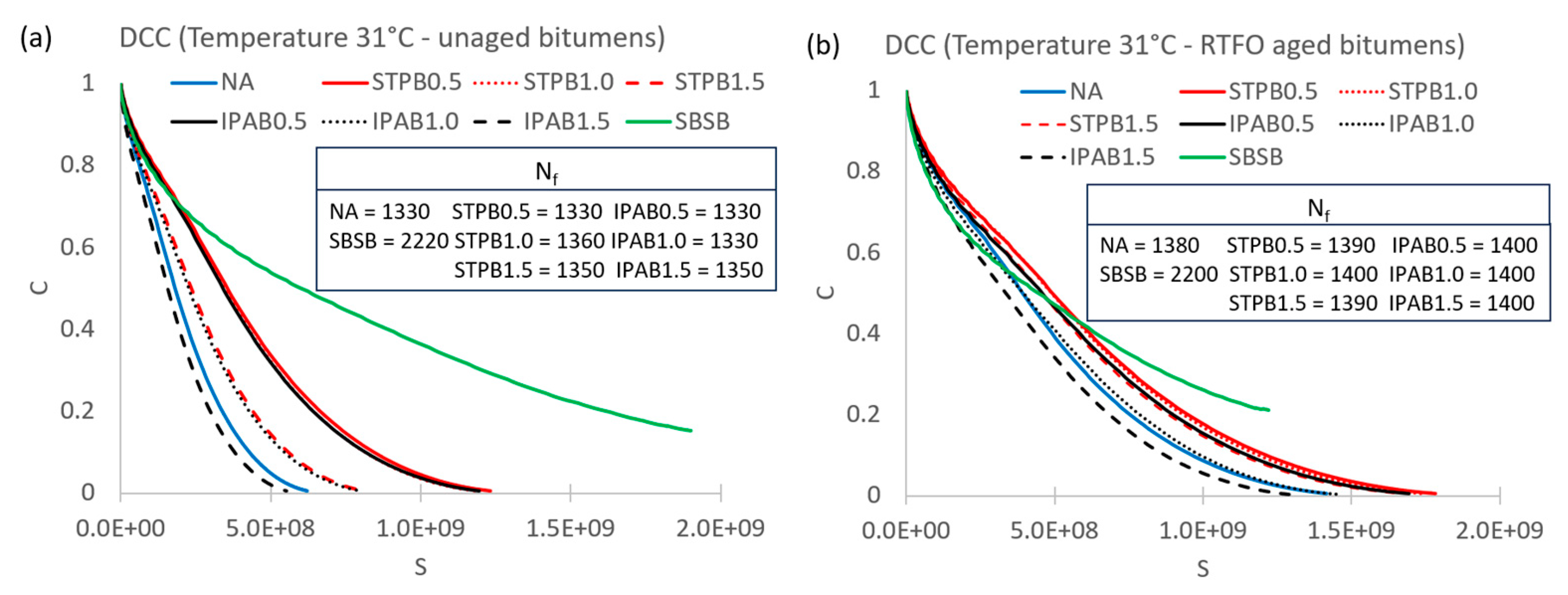

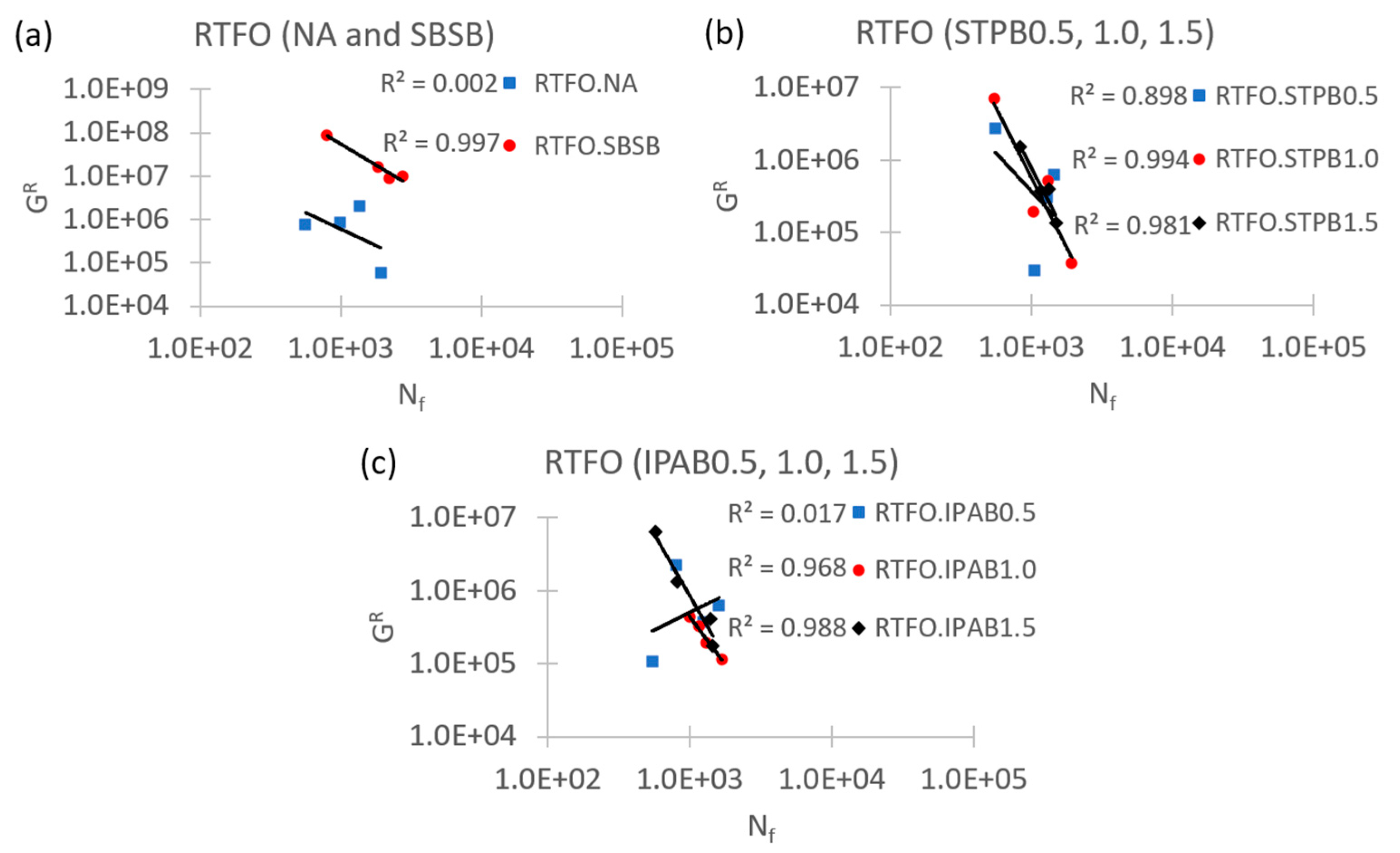

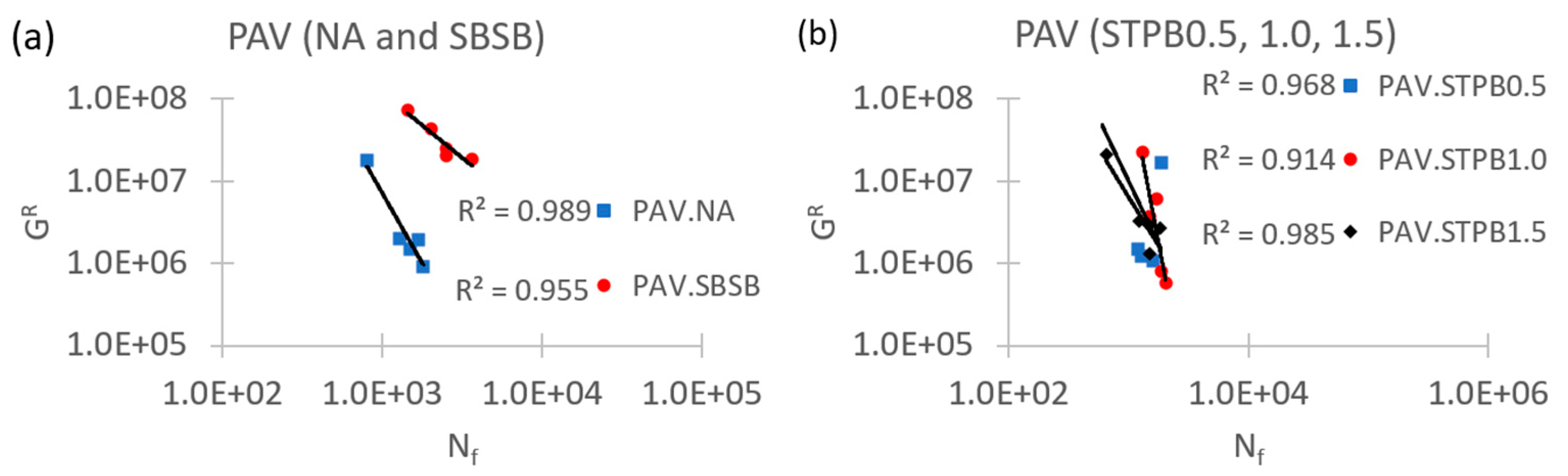

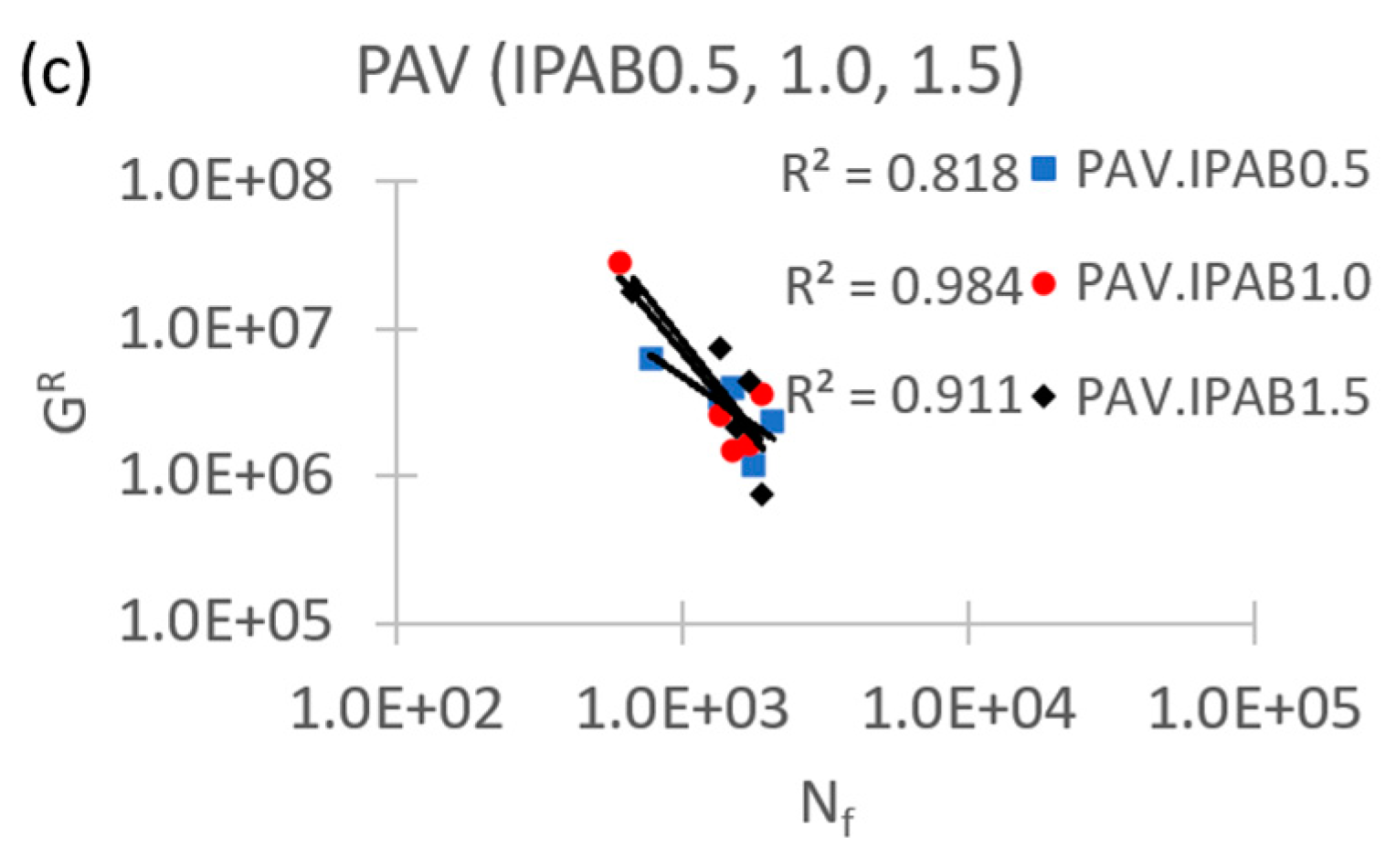

3.2. Failure criterion evaluation

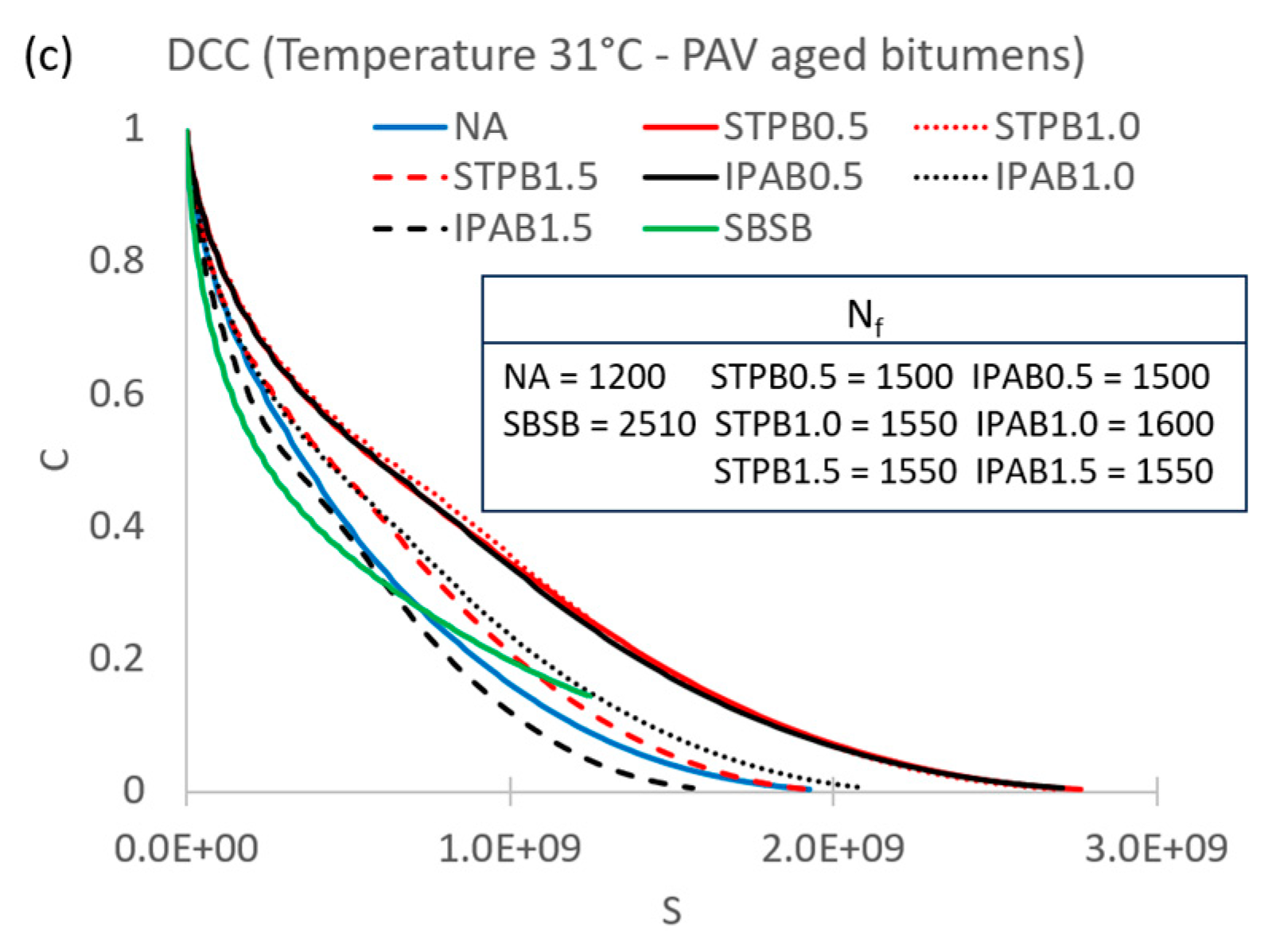

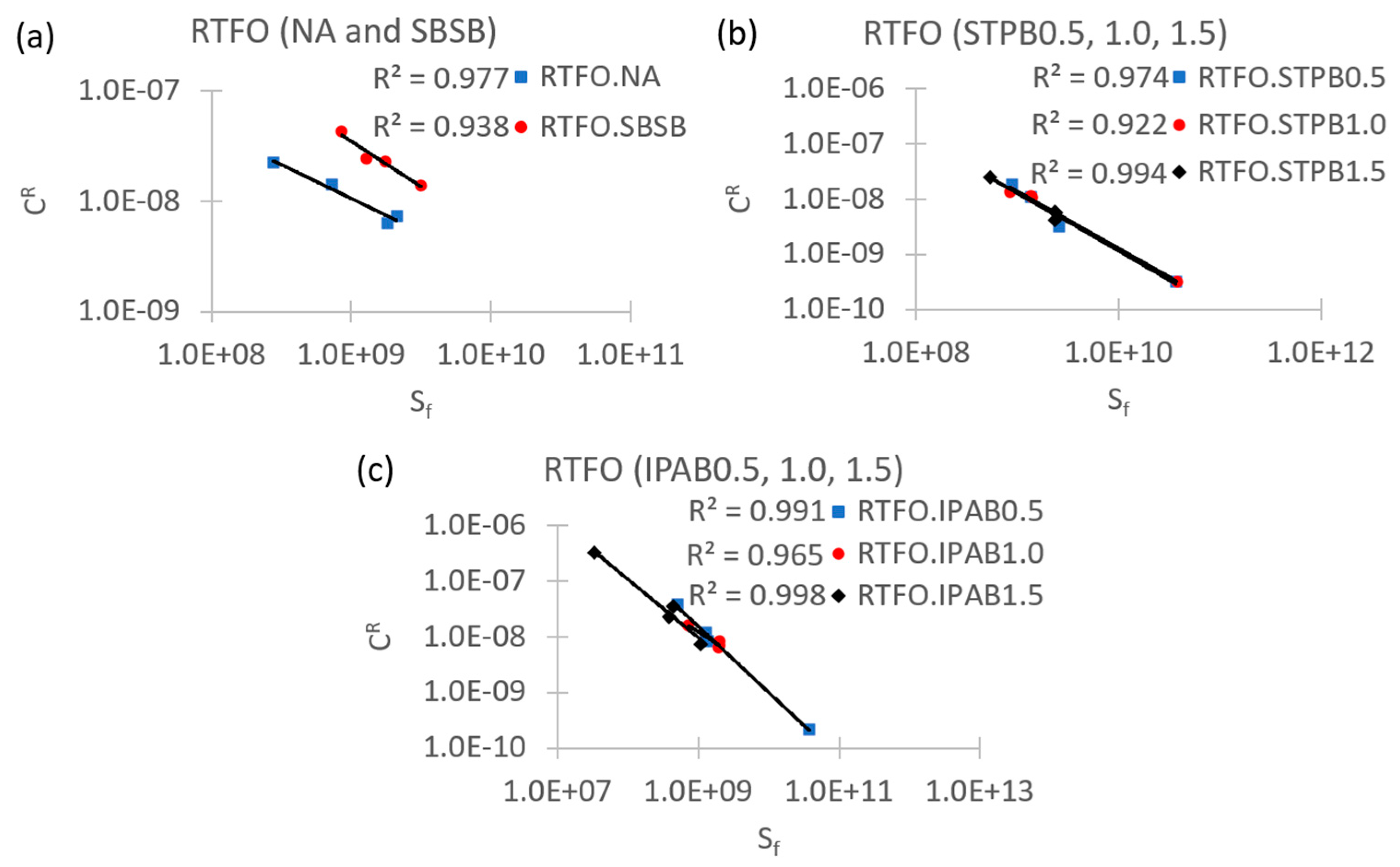

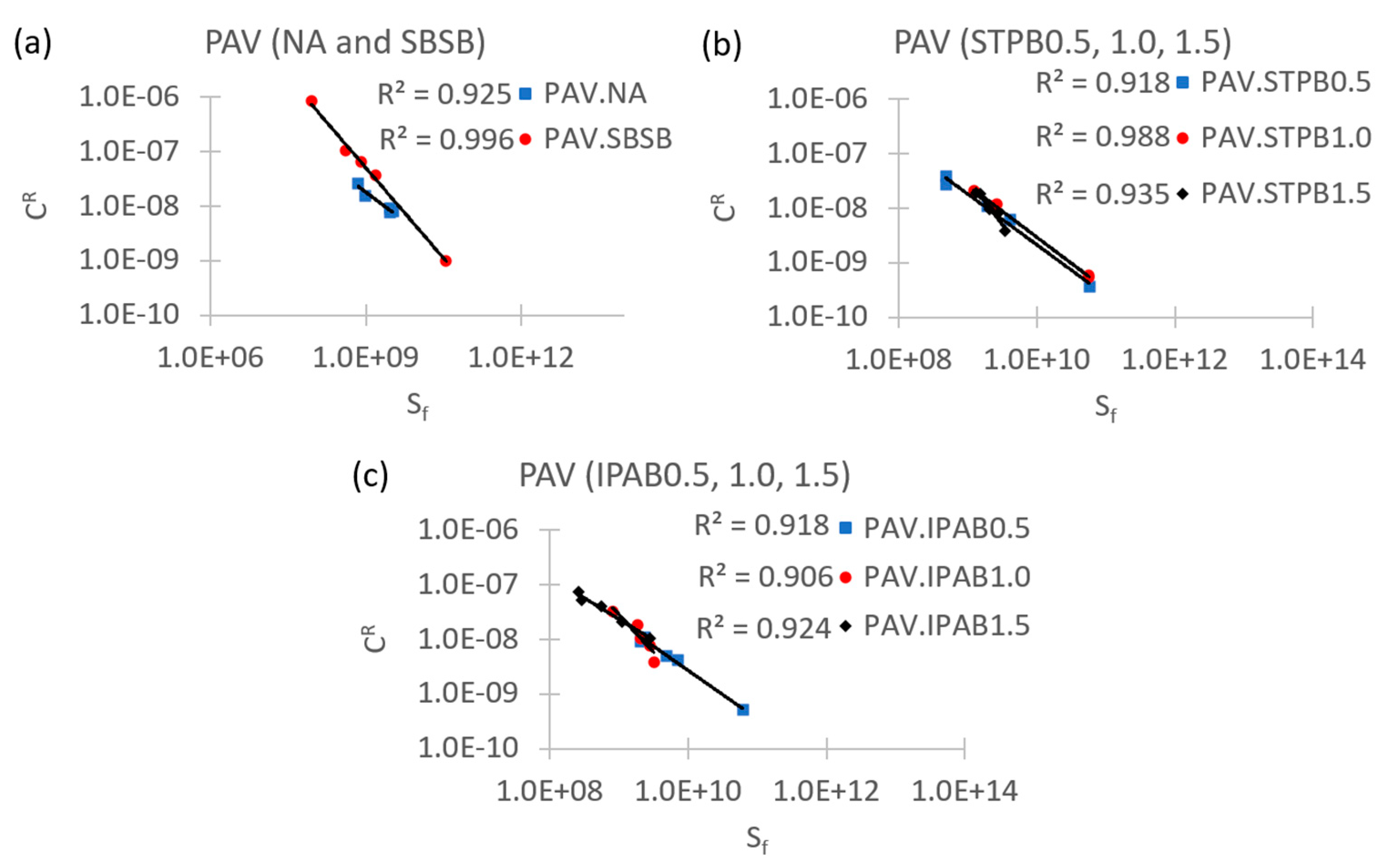

3.3. Failure definition evaluation (new proposal)

3.4. Failure criterion evaluation (proposal)

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wen, H.; Kim, Y.R. Simple performance test for fatigue cracking and validation with WesTrack mixtures. Transp. Res. Rec. 2002, 1789, 66–72. [Google Scholar] [CrossRef]

- Zeiada, W.A.; Souliman, M.I.; Kaloush, K.E.; Mamlouk, M.; Underwood, B.S. Comparison of fatigue damage, healing, and endurance limit with beam and uniaxial fatigue tests. Transp. Res. Rec. 2014, 2447, 32–41. [Google Scholar] [CrossRef]

- Motamed, A.; Bhasin, A.; Izadi, A. Evaluating Fatigue-Cracking Resistance of Asphalt Binders in a Standardized Composite Using Continuum Damage Theory. J. Mater. Civ. Eng. 2013, 25, 1209–1219. [Google Scholar] [CrossRef]

- Safaei, F.; Castorena, C.; Kim, Y.R. Linking asphalt binder fatigue to asphalt mixture fatigue performance using viscoelastic continuum damage modeling. Mech. Time-Depend. Mater. 2016, 20, 299–323. [Google Scholar] [CrossRef]

- Zhang, Z.; Oeser, M. Energy dissipation and rheological property degradation of asphalt binder under repeated shearing with different oscillation amplitudes. Int. J. Fatigue 2021, 152, 106417. [Google Scholar] [CrossRef]

- AASHTO, TP 101-14. Estimating Damage Tolerance of Asphalt Binders Using the Linear Amplitude Sweep. Washington, DC, 2014.

- Hintz, C.; Bahia, H. Simplification of Linear Amplitude Sweep Test and Specification Parameter. Transp. Res. Rec. 2013, 2370, 10–16. [Google Scholar] [CrossRef]

- Hintz, C.; Velasquez, R.; Johnson, C.; Bahia, H. Modification and validation of linear amplitude sweep test for binder fatigue specification. Transp. Res. Rec. 2011, 2207, 99–106. [Google Scholar] [CrossRef]

- Wang, C.; Castorena, C.; Zhang, J.; Kim, Y.R. Unified failure criterion for asphalt binder under cyclic fatigue loading. Road Mater. Pavement Des. 2015, 16, 1–25. [Google Scholar] [CrossRef]

- Wang, C.; Castrorena, C.; Zhang, J.; Kim, Y.R. Application of Time-Temperature Superposition Principle on Fatigue Failure Analysis of Asphalt Binder. J. Mater. Civ. Eng. 2017, 29, 1–9. [Google Scholar] [CrossRef]

- Ameri, M.; Mansourkhaki, A.; Daryaee, D. Evaluation of fatigue behavior of asphalt binders containing reclaimed asphalt binder using simplified viscoelastic continuum damage approach. Constr. Build. Mater. 2019, 202, 374–386. [Google Scholar] [CrossRef]

- Roque, R.; Yan, Y.; Lopp, G. Cracking Performance Evaluation of Asphalt Binders At Intermediate Temperature. University of Florida and Florida Department of Transportation. Contract No. BDV31-977-83. Final Report., 2020.

- Schapery, R.A. Correspondence principles and a generalized J integral for large deformation and fracture analysis of viscoelastic media. Int. J. Fract. 1984, 25, 195–223. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, Y.R.; Schapery, R.A. A viscoelastic continuum damage model and its application to uniaxial behavior of asphalt concrete. Mech. Mater. 1996, 24, 241–255. [Google Scholar] [CrossRef]

- Cao, W.; Wang, C. A new comprehensive analysis framework for fatigue characterization of asphalt binder using the Linear Amplitude Sweep test. Constr. Build. Mater. 2018, 171, 1–12. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Ayar, P.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Exploring the recovery of fatigue damage in bituminous mixtures at macro-crack level: the influence of temperature, time, and external loads. Road Mater. Pavement Des. 2017, 18, 293–303. [Google Scholar] [CrossRef]

- Babadopulos, L.F.d.A.L.; Orozco, G.; Sauzéat, C.; Di Benedetto, H. Reversible phenomena and fatigue damage during cyclic loading and rest periods on bitumen. Int. J. Fatigue 2019, 124, 303–314. [Google Scholar] [CrossRef]

- Hicks, R.G.; Finn, F.N.; Monismith, C.L.; Leahy, R.B. Validation of SHRP binder specification through mix testing. J. Assoc. Asph. Paving Technol. 1993, 62, 565–614. [Google Scholar]

- Kim, Y.R.; Lee, H.J.; Little, D.N. Fatigue characterization of asphalt concrete using viscoelasticity and continuum damage theory. J. Assoc. Asph. Paving Technol. 1997, 66, 520–569. [Google Scholar]

- Bonnetti, K.S.; Nam, K.; Bahia, H.U. Measuring and defining fatigue behavior of asphalt binders. Transp. Res. Rec. 2002, 1810, 33–43. [Google Scholar] [CrossRef]

- Johnson, C.M. Estimating Asphalt Binder Fatigue Resistance Using an Accelerated Test Method. Ph.D. Dissertation, University of Wisconsin—Madison, Madison, WI, USA, 2010. [Google Scholar]

- Safaei, F.; Lee, J.; Nascimento, L.A.H.D.; Hintz, C.; Kim, Y.R. Implications of Warm-Mix asphalt on long term oxidative aging and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement Des. 2014, 15, 45–61. [Google Scholar] [CrossRef]

- Reese, R. Properties of aged asphalt binder related to asphalt concrete fatigue life. J. Assoc. Asph. Paving Technol. 1997, 66, 604–632. [Google Scholar]

- Masad, E.; Castelo Branco, V.T.F.; Little, D.N.; Lytton, R. A unified method for the analysis of controlled-strain and controlled-stress fatigue testing. Int. J. Pavement Eng. 2008, 9, 233–246. [Google Scholar] [CrossRef]

- Sabouri, M.; Kim, Y.R. Development of a failure criterion for asphalt mixtures under different modes of fatigue loading. Transp. Res. Rec. 2014, 2447, 117–125. [Google Scholar] [CrossRef]

- Zhou, F.; Karki, P.; Im, S. Development of a Simple Fatigue Cracking Test for Asphalt Binders. Transp. Res. Rec. 2017, 2632, 79–87. [Google Scholar] [CrossRef]

- Zhang, R.; Sias, J.E.; Dave, E.V. Development of new performance indices to evaluate the fatigue properties of asphalt binders with ageing. Road Mater. Pavement Des. 2020, 23, 377–396. [Google Scholar] [CrossRef]

- Yan, Y.; Hernando, D.; Park, B.; Allen, C.; Roque, R. Understanding asphalt binder cracking characterization at intermediate temperatures: Review and evaluation of two approaches. Constr. Build. Mater. 2021, 312. [Google Scholar] [CrossRef]

- Cabrera, M.B.; Lv, S.; Ge, D.; Wang, Z.; Wang, J.; Liu, J.; Ju, Z.; Peng, X.; Fan, X.; Cao, S.; et al. Performance Assessment of Self-Healing Polymer-Modified Bitumens by Evaluating the Suitability of Current Failure Definition, Failure Criterion, and Fatigue-Restoration Criteria. Materials 2023, 16, 2488. [Google Scholar] [CrossRef] [PubMed]

- Safaei, F.; Castorena, C. Temperature effects of linear amplitude sweep testing and analysis. Transp. Res. Rec. 2016, 2574, 92–100. [Google Scholar] [CrossRef]

- Zhang, J. Development of Failure Criteria for Asphalt Concrete Mixtures under Fatigue Loading. Master’s Thesis, North Carolina State University, Raleigh, NC, USA, 2012. [Google Scholar]

- Zhang, J.; Sabouri, M.; Guddati, M.N.; Kim, Y.R. Development of a failure criterion for asphalt mixtures under fatigue loading. J. Assoc. Asph. Paving Technol. 2013, 82, 1–22. [Google Scholar] [CrossRef]

- Wang, C.; Xie, W.; Chen, Y.; Diab, A.; You, Z. Refining the Calculation Method for Fatigue Failure Criterion of Asphalt Binder from Linear Amplitude Sweep Test. J. Mater. Civ. Eng. 2018, 30, 1–11. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.; Bahia, H.U. Estimating asphalt binder fatigue at multiple temperatures using a simplified pseudo-strain energy analysis approach in the LAS test. Constr. Build. Mater. 2021, 266. [Google Scholar] [CrossRef]

- Sun, G.; Ma, J.; Sun, D.; Li, B.; Ling, S.; Lu, T. Influence of thermal oxidative aging on temperature induced self-healing transition of polymer modified bitumens Mater. Design 2020, 192. [Google Scholar] [CrossRef]

- Zhang, T.; Gao, S.; Yu, J.; He, Y.; Han, X.; Zhuang, R. Preparation and performance of self-healing SBS modified bitumen based on dynamic disulfide bonds. Constr. Build. Mater. 2023, 397. [Google Scholar] [CrossRef]

- Yousif, R.A.; Tayh, S.A.; Al-Saadi, I.F.; Jasim, A.F. Physical and Rheological Properties of Asphalt Binder Modified with Recycled Fibers. Adv. Civ. Eng. 2022, 2022. [Google Scholar] [CrossRef]

- Kök, B.V.; Çolak, H. Laboratory comparison of the crumb-rubber and SBS modified bitumen and hot mix asphalt. Constr. Build. Mater. 2011, 25, 3204–3212. [Google Scholar] [CrossRef]

- Sun, P.; Zhang, K.; Xiao, Y.; Liang, Z. Analysis of Pavement Performance for Nano-CaCO3/SBS Modified Asphalt Mixture. J. Phys. Conf. Ser. 2022, 2329. [Google Scholar] [CrossRef]

- Li, X.; Guo, D.; Xu, M.; Guo, C.; Wang, D. REOB/SBS Composite-Modified Bitumen Preparation and Modification Mechanism Analysis. Buildings 2023, 13, 1601. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, L.; Chen, F.; Yang, C.; Li, Y.; Yan, X.; Zang, J.; Liu, J. Evaluation method of storage stability of SBS modified bitumen based on dynamic rheological properties. Constr. Build. Mater. 2022, 323. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Sun, A.; Jing, M.; Liu, X.; Wei, L.; Wu, K.; Fu, Q. A self-reinforcing and self-healing elastomer with high strength, unprecedented toughness and room-temperature reparability. Mater. Horiz. 2020, 8, 267–275. [Google Scholar] [CrossRef]

- Wang, D.P.; Zhao, Z.H.; Li, C.H. Universal Self-Healing Poly(dimethylsiloxane) Polymer Crosslinked Predominantly by Physical Entanglements. ACS Appl. Mater. Interfaces 2021, 13, 31129–31139. [Google Scholar] [CrossRef]

- Yang, S.; Ji, J.; Tao, H.; Muhammad, Y.; Huang, J.; Wang, S.; Wei, Y.; Li, J. Fabrication of urea formaldehyde–epoxy resin microcapsules for the preparation of high self-healing ability containing SBS modified asphalt. Polym. Compos. 2021, 42, 4128–4137. [Google Scholar] [CrossRef]

- Aurilio, R.M.; Aurilio, M.; Baaj, H. The effect of a chemical warm mix additive on the self-healing capability of bitumen. J. Test. Eval. 2022, 50. [Google Scholar] [CrossRef]

- Xie, W.; Castorena, C.; Wang, C.; Kim, Y.R. A framework to characterize the healing potential of asphalt binder using the linear amplitude sweep test. Constr. Build. Mater. 2017, 154, 771–779. [Google Scholar] [CrossRef]

- Chen, H.; Bahia, H.U. Modelling effects of aging on asphalt binder fatigue using complex modulus and the LAS test. Int. J. Fatigue 2021, 146. [Google Scholar] [CrossRef]

| Test | Standard value | Measured value | Standard test |

|---|---|---|---|

| Penetration (25°C, 5s, 100g) (0.1mm) | 60 ~ 80 | 64.0 | T0604 |

| PI | -1.5 ~ 1.0 | -1.2 | T0604 |

| Softening point (°C) | ≥ 46 | 48.5 | T0606 |

| Viscosity (60°C) (Pa*s) | ≥ 180 | 237 | T0620 |

| Ductility (10°C) | ≥ 15 | 25 | T0605 |

| Ductility (15°C) | ≥ 100 | >150 | T0605 |

| Wax content (%) | ≤ 2.2 | 1.8 | T0615 |

| Flash point (°C) | ≥ 260 | >300 | T0611 |

| Solubility (%) | ≥99.5 | 99.91 | T0607 |

| Density (15°C) (g/cm3) | - | 1.040 | T0603 |

| After the RTFO: Mass change Residual penetration ratio (%) Residual ductility (10°C) (cm) |

≤ ±0.8 ≥ 61 ≥ 6 |

-0.034 63.6 6.3 |

T0609 T0604 T0605 |

| Test | Standard value | Measured value | Standard test |

|---|---|---|---|

| Penetration (25°C, 5s, 100g) (0.1mm) | 30 ~ 60 | 52.0 | T0604 |

| PI | ≥ 0 | 0.15 | T0604 |

| Softening point (°C) | ≥ 76 | 83.2 | T0606 |

| Viscosity (135°C) (Pa*s) | ≤ 3 | 2.45 | T0625 |

| Ductility (5°C) | ≥ 25 | 35 | T0605 |

| Flash point (°C) | ≥ 230 | 310 | T0611 |

| Solubility (%) | ≥99.0 | 99.78 | T0607 |

| After the RTFO: Mass change Residual penetration ratio (%) Residual ductility (10°C) (cm) |

≤ ±1.0 ≥ 65 ≥ 20 |

-0.04 78 22 |

T0610 T0604 T0605 |

| Parameters | STP Values |

|---|---|

| Tensile strength (MPa) | 13.5±2.2 |

| Elongation [dried state] (%) | 1460±87 |

| Density (g/cm3) | 1.07 |

| Melting point (°C) | 120 a |

| Parameters | STP Values |

|---|---|

| Tensile strength (MPa) | 1.61±0.15 |

| Elongation [dried state] (%) | 1700 |

| Young’s modulus (MPa) | 0.59±0.02 |

| Toughness (MJ m-3) | 17.89±0.18 |

| Set | Material name (MN) | PG | Aging condition (AC) | CSR (%/cycle) | T (°C) | Note |

|---|---|---|---|---|---|---|

| 1a | NA, STPB1.5, IPAB1.0 | 64-16 | U, R, RP | 0.010 | 25 | VFD |

| STPB0.5, STPB1.0, IPAB0.5 | 64-22 | U, R, RP | 0.010 | 25 | VFD | |

| IPAB1.5 | 64-10 | U, R, RP | 0.010 | 25 | VFD | |

| SBSB | 76-22 | U, R, RP | 0.010 | 25 | VFD | |

| 1b | NA, STPB1.5, IPAB1.0 | 64-16 | U, R, RP | 0.010 | 28 | VFD |

| STPB0.5, STPB1.0, IPAB0.5 | 64-22 | U, R, RP | 0.010 | 28 | VFD | |

| IPAB1.5 | 64-10 | U, R, RP | 0.010 | 28 | VFD | |

| SBSB | 76-22 | U, R, RP | 0.010 | 28 | VFD | |

| 1c | NA, STPB1.5, IPAB1.0 | 64-16 | U, R, RP | 0.010 | 31 | VFD |

| STPB0.5, STPB1.0, IPAB0.5 | 64-22 | U, R, RP | 0.010 | 31 | VFD | |

| IPAB1.5 | 64-10 | U, R, RP | 0.010 | 31 | VFD | |

| SBSB | 76-22 | U, R, RP | 0.010 | 31 | VFD |

| Set | MN | PG | AC | CSR (%/cycle) | T (°C) | Note |

|---|---|---|---|---|---|---|

| 2a | NA | 64-16 | R | 0.0101, 0.0302, 0.0153, 0.0064 | 281, 322, 263, 304 | VFC |

| 2b | NA | 64-16 | RP | 0.0101, 0.00852, 0.00753, 0.0204, 0.0125 | 281, 2, 3, 244, 315 | VFC |

| 3a | STPB0.5 | 64-22 | R | 0.0101, 0.0302, 0.00853, 0.0154 | 251, 262, 243, 274 | VFC |

| 3b | STPB0.5 | 64-22 | RP | 0.0101, 0.0302, 0.00753, 0.0154, 0.00855 | 251, 222, 3, 274, 285 | VFC |

| 4a | STPB1.0 | 64-22 | R | 0.0101, 0.0152, 0.0063, 0.0304 | 251, 272, 293, 244 | VFC |

| 4b | STPB1.0 | 64-22 | RP | 0.0101, 0.00852, 0.00753, 0.00664, 0.0125 | 251, 2, 273, 4, 235 | VFC |

| 5a | STPB1.5 | 64-16 | R | 0.0101, 0.0202, 0.0123, 0.00854 | 281, 2, 263, 314 | VFC |

| 5b | STPB1.5 | 64-16 | RP | 0.0101, 0.00662, 0.00853, 0.0304, 0.0155 | 281, 252, 3, 284, 305 | VFC |

| 6a | IPAB0.5 | 64-22 | R | 0.0101, 0.0202, 0.00663, 0.0304 | 251, 2, 233, 274 | VFC |

| 6b | IPAB0.5 | 64-22 | RP | 0.0101, 0.0202, 0.00853, 0.0124, 0.0065 | 251, 2, 273, 284, 235 | VFC |

| 7a | IPAB1.0 | 64-16 | R | 0.0101, 0.0122, 0.00663, 0.0154 | 281, 3, 302, 264 | VFC |

| 7b | IPAB1.0 | 64-16 | RP | 0.0101, 0.0122, 0.00853, 0.0304, 0.00665 | 281, 302, 313, 264, 255 | VFC |

| 8a | IPAB1.5 | 64-10 | R | 0.0101, 0.0302, 0.0203, 0.00854 | 311, 3, 292, 344 | VFC |

| 8b | IPAB1.5 | 64-10 | RP | 0.0101, 0.0302, 0.0123, 0.00854, 0.00755 | 311, 332, 293, 284, 345 | VFC |

| 9a | SBSB | 76-22 | R | 0.0101, 0.0122, 0.00663, 0.0304 | 311, 302, 283, 334 | VFC |

| 9b | SBSB | 76-22 | RP | 0.0101, 0.00662, 0.00853, 0.0154, 0.0205 | 311, 342, 293, 324, 275 | VFC |

| Bitumen | Ranking of CWDCC and CWSPC | Sum of Rankings | |||

|---|---|---|---|---|---|

| T (25 °C) | T (28 °C) | T (31 °C) | |||

| PAV-STPB1.0 | 1 | 3 | 1 | 3 | 8 |

| PAV-STPB0.5 | 3 | 1 | 2 | 1 | 7 |

| PAV-IPAB0.5 | 2 | 2 | 3 | 2 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).