1. Introduction

Today, a public service building is designed to fulfill a defined function, such as a hospital, education, police station, courthouse, museum theatre, cinema, social service, library, pharmacy, place of worship, and banking. Such service buildings should allow people with disabilities, especially those using wheelchairs, orthopedic crutches, canes, or assistive devices, to move safely in any footwear [

1,

2]. Apart from their basic aesthetic value, the number of steps, width, and design of these buildings, stairs, and corridors serving the public space should meet the specific needs of older and disabled people [

3,

4,

5].

Slips and trips are common in daily life and in the workplace [

6,

7]. Accidents caused by slipping have increased in importance, especially in industrial areas, restaurants, shops, and public buildings [

8,

9,

10]. The surface of the flooring materials used in buildings should be non-slip [

11,

12]. It has become crucial to determine the slip risk assessment of material surfaces used as floor coverings [

13,

14]. Slip resistance is caused by the interaction between the shoe sole and the surface of the floor covering material. The slip resistance of the floor surface is influenced by ambient conditions, color contrast, lighting type, and angle of incidence [

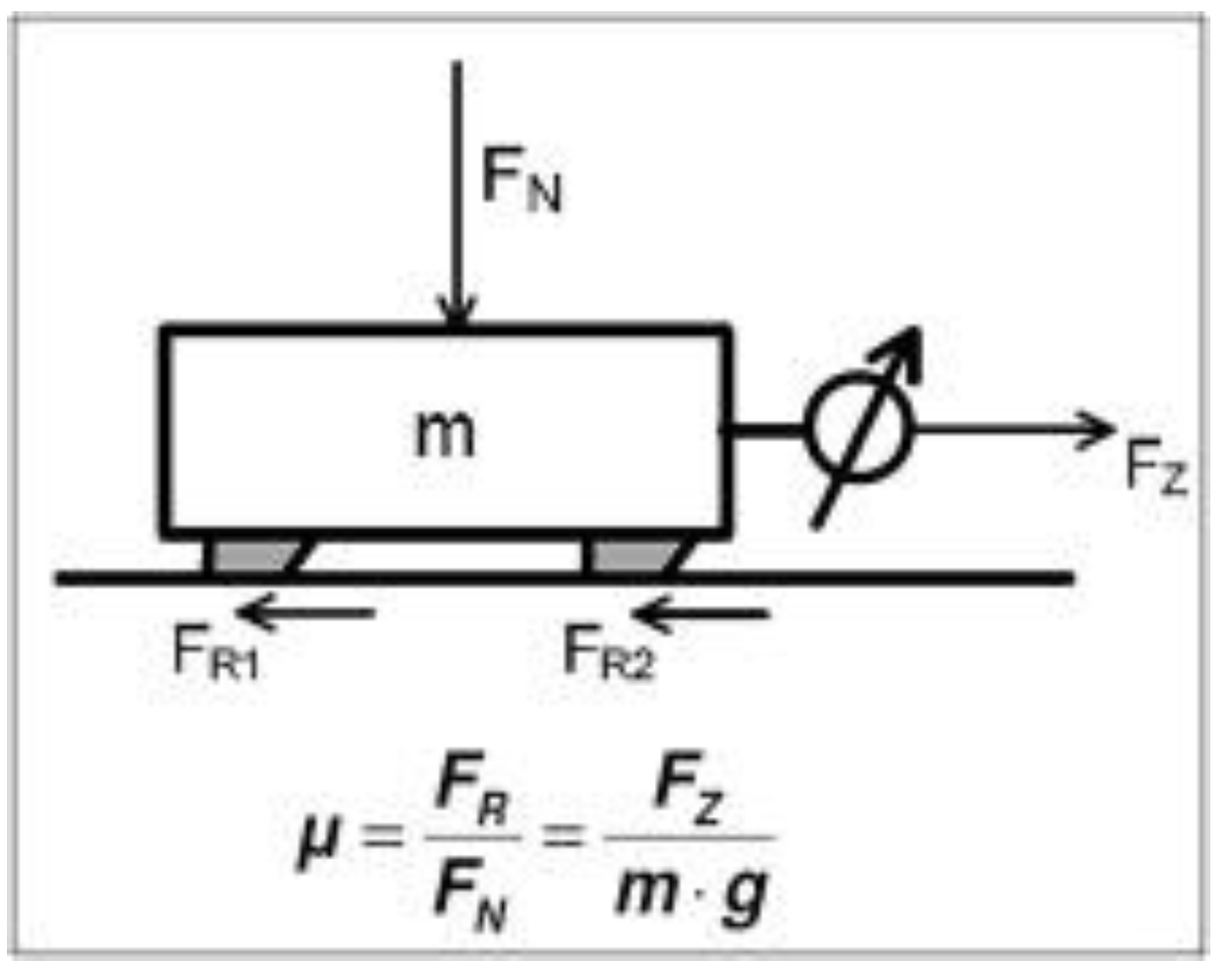

15]. The extent of slip safety and resistance is assessed by users by measuring the static and dynamic coefficient of friction (COF) [

16,

17,

18].

Surface slip resistance must be minimal in industries producing surface coating materials. In addition to the decorative and aesthetic qualities of the surface coating materials used on floors, great importance is attached to their mechanical properties. Ceramic tiles and natural stones tested under dry, wet, and oily conditions are used on raw, polished, honed, and aged surfaces [

19,

20]. Research has also been conducted under various ambient conditions (oil, milk, wine, water, glycerol, and diesel industrial oil) [

21].

A new slip safety risk scale for safer movement of pedestrians on ground surfaces has been identified [

14]. Slip safety was determined by analyzing the slip resistance of floor coverings in health-related tests [

22]. Footwear manufacturers also demand to determine the slip resistance properties on different floor surfaces. Because slip friction occurs between the shoe and the floor surface, research has been conducted on the slip resistance of shoe soles [

23,

24]. In addition, slip resistance assessment inside and outside buildings forms part of the slip safety scope [

15]. It is assessed in terms of compliance with regulations and tests conducted as part of cheques by independent organizations [

25].

Research into the reduction of slip risk remains essential to improve slip safety. Research to improve this parameter is carried out in the field of surface and footwear design and the development of measurement methods that consider the effect of wear on the surface [

26,

27,

28]. This study employs the K-means method to categorize floor surfaces utilized within Public Service Buildings (PSB), specifically in pedestrian zones characterized by high foot traffic. The analysis is conducted under diverse conditions, encompassing various slip test methodologies and environmental factors. The primary objective is to discern and evaluate the slip safety risks associated with the different floor surfaces present in these bustling areas, where multiple pedestrians traverse regularly.

2. Materials and Methods

2.1. Materials used in experimental studies

Natural stone, ceramic, laminate, and PVC floor coverings of different types and properties, especially natural stone, are used as floor coverings in public and closed areas, especially in public buildings. Especially in PSB, polished surfaces, and glossy materials are used and preferred as floor coverings to be attractive and look more beautiful. Dynamic friction coefficients should be determined to minimize accidents caused by slipping, and safety classification should be made. For this purpose, in situ dynamic friction coefficients of floor surfaces were measured in thirty different public institutions in Sivas Province and six different locations in each institution under dry and wet conditions.

Table 1 identifies public service buildings, zones, environmental conditions, surface materials and portable test methods.

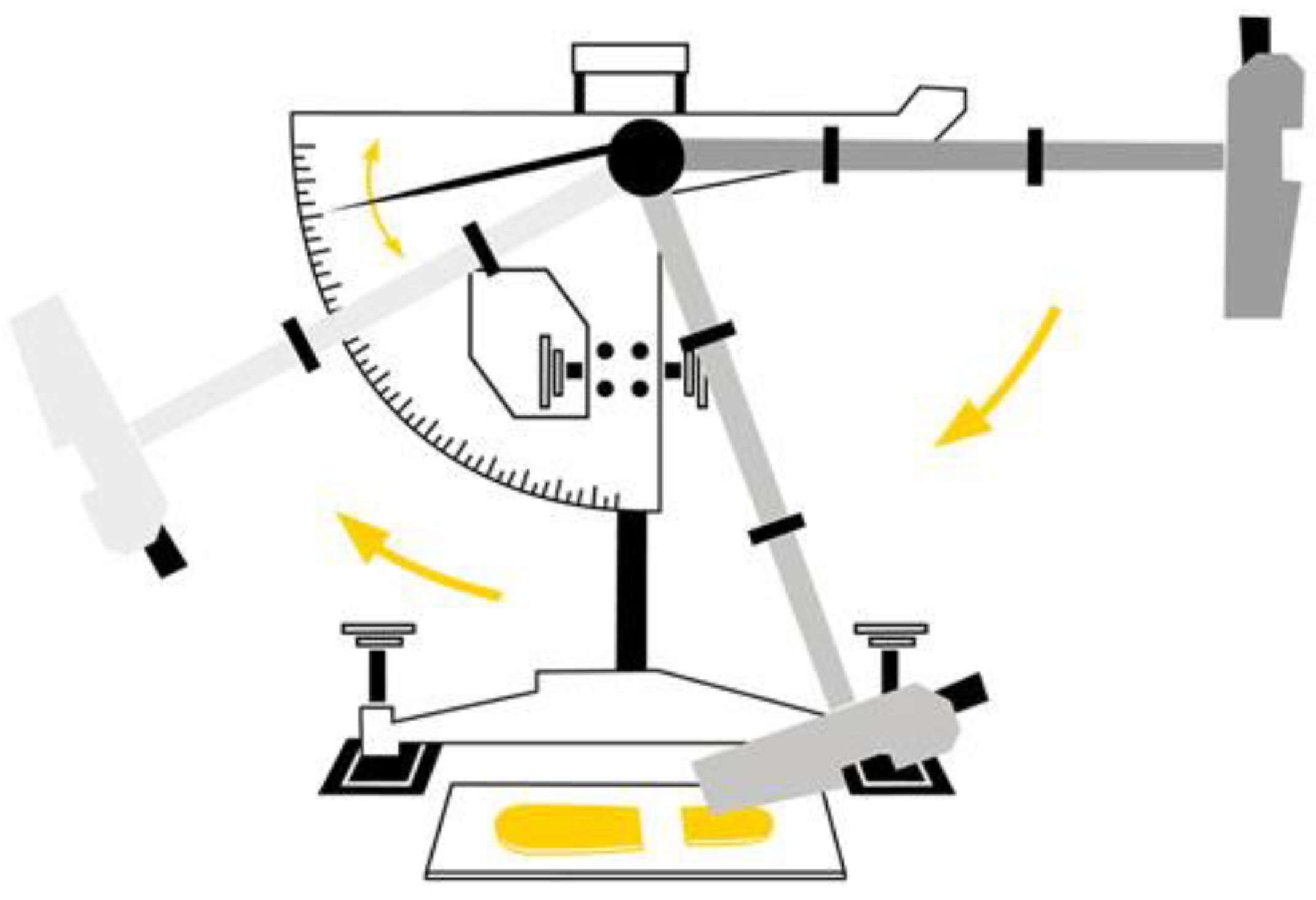

2.2. Portable slip meter

In this study, slip resistance measurements were conducted utilizing the GMG 200 and Pendulum testers. The GMG 200 tester, designed and manufactured by the German GTE company in accordance with the DIN 51131 standard [

29], was employed for its widespread use in numerous European countries owing to its portability and incorporation of advanced mechanical and electronic measurement techniques, as depicted in

Figure 1.

The GMG 200 tester determines the dynamic coefficient of friction of the floor by utilizing a measuring apparatus that simulates a shoe pad. The device automatically recognizes the coded measuring apparatus, and the measurement value is recorded through the integrated control unit, as illustrated in

Figure 2

Furthermore, the slip resistance of the floor coverings was evaluated using WESSEX's S885 pendulum testers, adhering to the specifications outlined in TS EN 14231 standards [

30]. This particular tester, displayed in

Figure 3, gauges the friction force between the floor surface and a specialized measuring apparatus.

The deployment of these two distinct testing methodologies allows for a comprehensive assessment of the slip resistance characteristics of the floor surfaces under investigation. The GMG 200 tester, recognized for its portability and versatility, offers a dynamic coefficient of friction measurement, while the WESSEX pendulum tester, designed in compliance with international standards, provides a reliable evaluation of friction forces. The integration of these testing devices enhances the robustness and reliability of the slip resistance measurements conducted in this study.

2.3. Statistical analysis

In this study, the K-Means Clustering (KMC) methodology was implemented, employing DCOF values derived from slip tests. K-Means, a non-hierarchical clustering technique, offers distinct advantages when confronted with a substantial volume of units necessitating classification. Within this framework, a predetermined number of clusters is established [

31]. The KMC method emerges as one of the most widely employed algorithms for organizing geometric points, involving an iterative redefinition of centers until achieving algorithmic stability. The K-Means algorithm in R

d categorizes a set of X points in n into k clusters. Initially, the clustering center is positioned in R

d. Subsequently, each data point is assigned to the cluster with the closest center. The recalculated position of a center is determined as the mean of the points assigned to it [

32].

3. Results

Slip test measurements were performed in 30 public institutions with a portable GMG 200 and pendulum tester. DCOF values were determined on floor surfaces such as natural stone, PVC, ceramic, and laminate in six regions in dry and wet environments. DCOF values were analyzed using the K-means method and classified into five clusters. Because of this analysis, a safety slip risk scale was determined (

Table 2).

In the slip tests conducted, the floor surfaces commonly preferred within PSB were selected for evaluation. Subsequently, the DCOF values obtained from these tests underwent statistical analysis through the application of Analysis of Variance (ANOVA). The outcomes of the ANOVA for DCOF values, stratified by PSB, are presented in

Table 3. The DCOF measurements conducted on portable test devices employed a one-way analysis of variance, incorporating a randomized experimental design with a comprehensive factorial structure (30 PSB x 2 Environmental Conditions x 6 Zones x 2 Slip Test Methods x 4 Floor Surfaces x 5 Replicate Data). This experimental design yielded a total dataset of 14,400 data points from the slip tests. Statistical analyses revealed a significant difference (p < 0.001) in the DCOF values among different PSB. In other words, the DCOF values exhibited variations across PSB, emphasizing the influence of the specific institutional context on slip resistance. This statistical distinction underscores the importance of considering the unique characteristics of individual state institutions when assessing and implementing measures to enhance floor slip safety.

There was a difference (p<0.001) in the DCOF values according to usage areas, environmental conditions, slip test methods, and surface materials. In other words, the DCOF values differ among usage areas, environmental conditions, slip test methods, and surface materials. The results of the analysis of the variance of DCOF values according to regions, environmental conditions, slip test methods, and surface materials are given in

Table 4. A statistically significant effect exists between the DCOF values of floor coverings used by PSB and regions, environmental conditions, slip test methods, and floor surfaces.

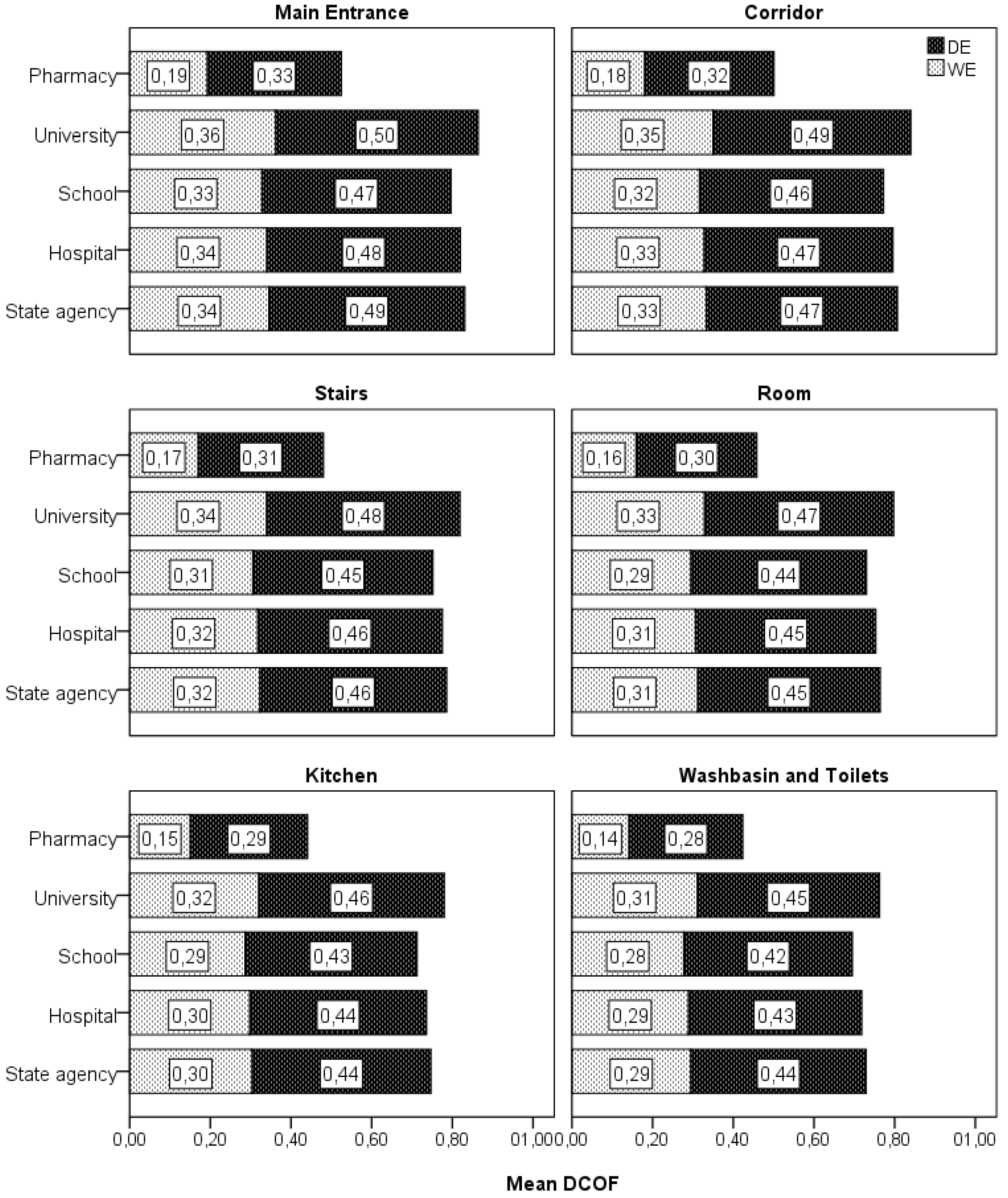

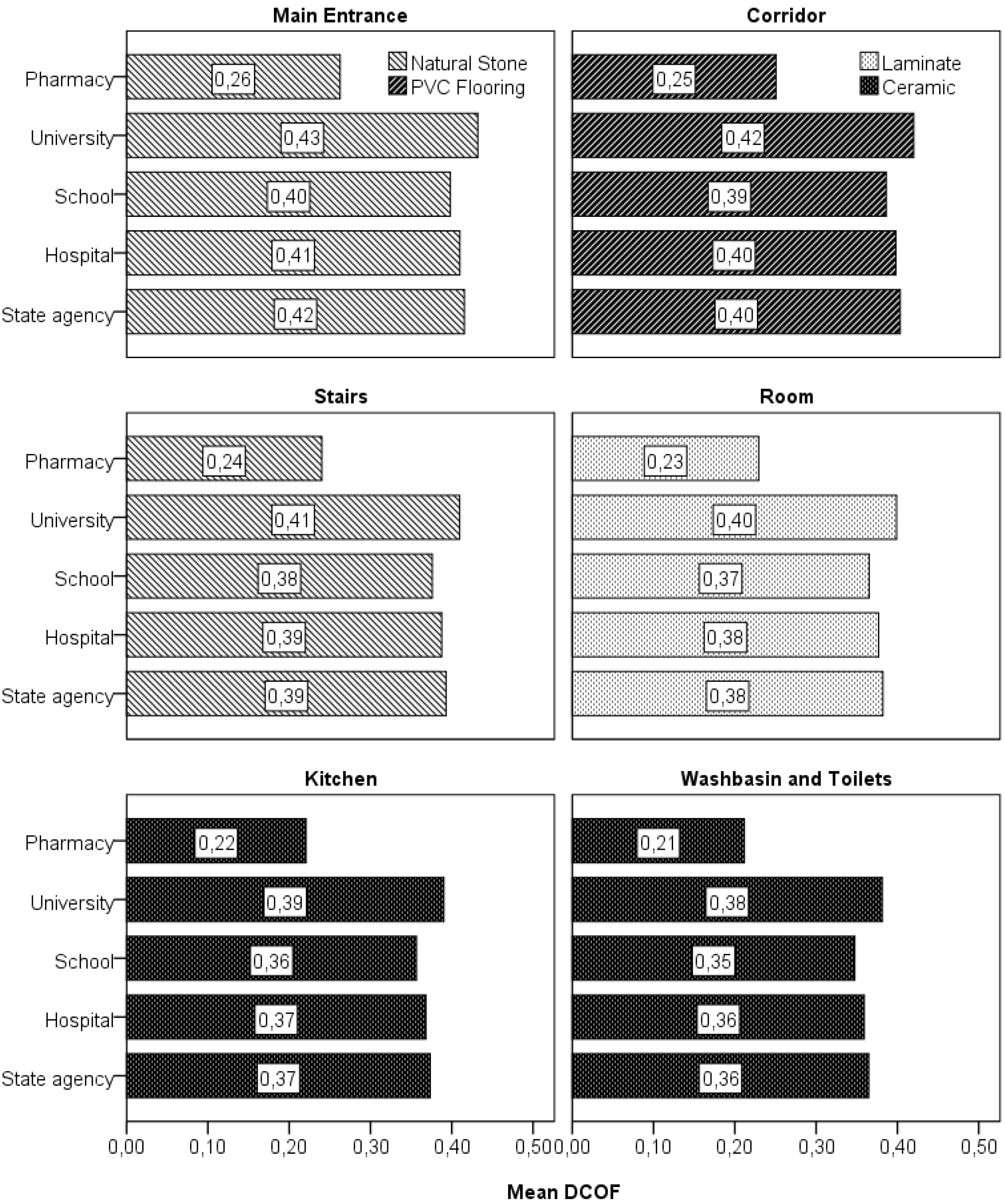

Measurements were made at the main entrance, corridor, stairs, rooms, kitchens, sinks, and toilets in dry and wet environments using slip test equipment in PSB.

Figure 4 shows the mean values of DCOF (μ) in dry and wet conditions according to different occupancy areas for PSB. The mean standard deviation for dry and wet conditions and areas of use was in the range of 0.001–0.13 μ. In the pharmacy room, the lowest DCOF was obtained with a value of 0.14 μ in wet conditions. The highest DCOF was obtained with a value of 0.50 μ in the dry environment at the university entrance. The lowest DCOF value was obtained at the pharmacy in wet environments, whereas the highest values were obtained at the university in dry environments.

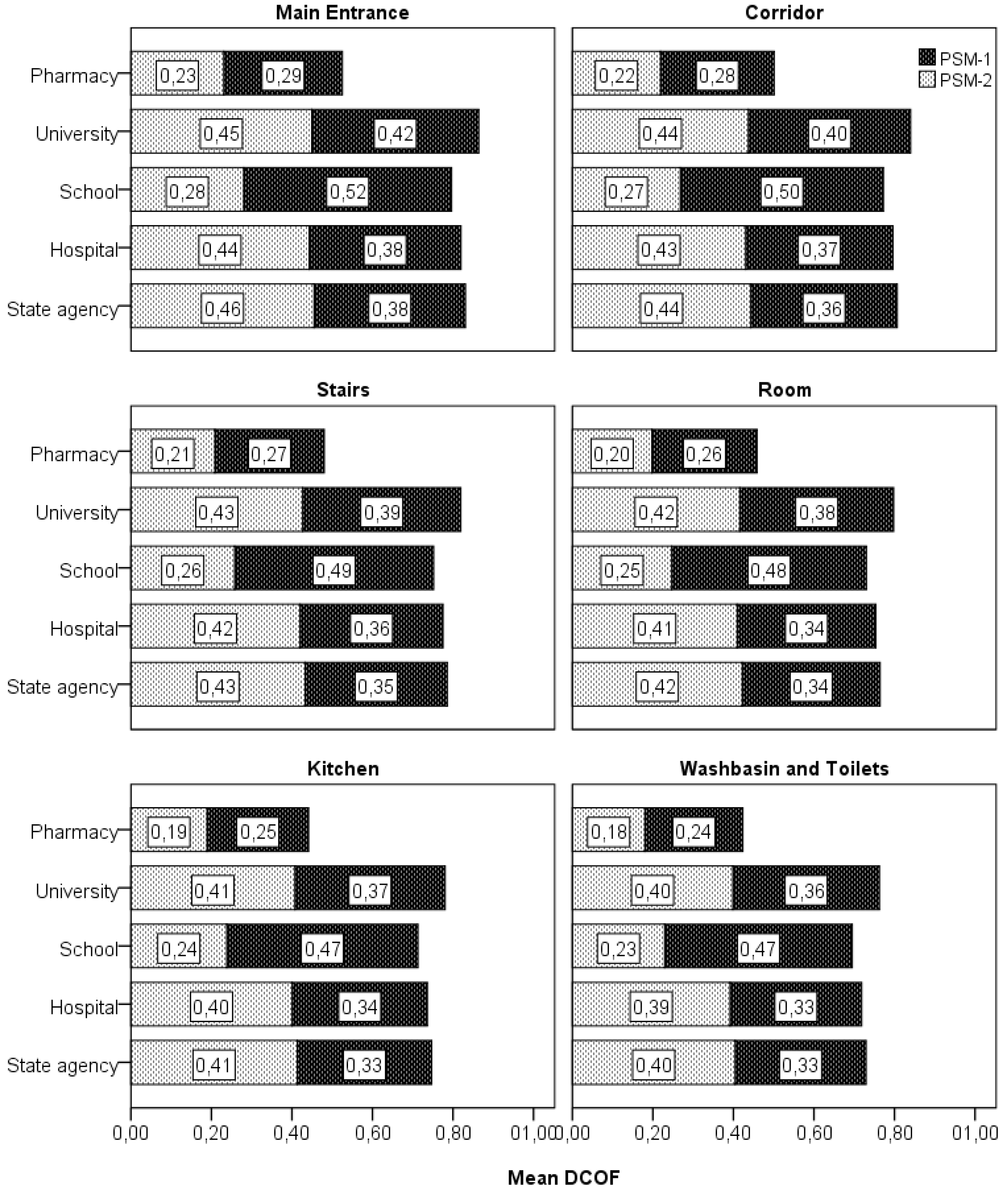

The mean values of DCOF (μ) in the slip test methods according to different areas of use for PSB are given in

Figure 5. The reproducibility of these mean, and standard deviation values in the areas of use with slip test methods was found to be in the range of 0.001–0.14 μ. The lowest DCOF was obtained with a value of 0.18 μ in the PSM-2 method in pharmacies' bathrooms and toilets. The highest DCOF was obtained at the school entrance with a value of 0.52 μ in the PSM-1 method. The lowest DCOF value was obtained in pharmacies using the PSM-2 method, whereas the highest values were obtained in schools using the PSM-1 method.

The mean values of DCOF (μ) in surface materials according to different usage areas for PSB are shown in

Figure 6. The reproducibility of these mean and standard deviation values of surface materials and usage areas were found to be in the range of 0.001–0.13 μ. The lowest DCOF was obtained with a value of 0.21 μ for ceramic surface materials in pharmacies' bathrooms and toilet areas. The highest DCOF was obtained with a value of 0.43 μ in natural stone surface materials at the university entrance. The lowest DCOF value was obtained in the pharmacy for ceramic surface materials from PSB, whereas the highest values were obtained in the university for natural stone surface materials.

The DCOF values were determined according to DIN 51131 and TS EN 14231 standards in dry and wet environments on different floor surfaces in PSB. While there is no safety classification according to the DCOF values obtained in the DIN 51131 standard, there is a safety class according to the slip resistance values in the TS EN 14231 standard. Only the Wuppertal classification is accepted by the German Accident Insurance Association as a safety class. This study will consider both standards and a new classification will be made according to the DCOF values.

According to the portable testing machine, the slip risk in the Wuppertal classification was determined in five clusters. Using the K-means method, the slip safety risk scale was classified into five clusters ranging from 0.11 to 0.59.

Table 5 shows the slip safety risk classification according to the DCOF values.

Table 5 shows that the floor surfaces used in pharmacies and schools are classified as hazardous due to DCOF values less than 0.20 μ in wet environments and the PSM-2 method. In PSB, it is generally classified as conditionally safe because of DCOF values ranging between 0.33 and 0.45 μ in wet environments and unsafe because of DCOF values ranging between 0.20 and 0.33 μ. In PSB, it is generally classified as safe in dry environments because of DCOF values between 0.45 and 0.58 μ.

4. Discussion

In this study, DCOF values were assessed under both dry and wet conditions through various slip-test methodologies applied to the flooring surfaces employed in PSB. The DCOF values obtained from diverse floor surfaces were subjected to analysis using the K-means method, leading to their classification into five distinct clusters. Subsequently, a novel slip safety risk scale was established based on these findings.

The soil surfaces were categorized based on their slip resistance, considering the DCOF values in accordance with the established slip risk scale. Natural stone slabs were subject to classification concerning their slip resistance values on various surfaces, employing the risk scale advocated by the ramp tester DIN 51131 standard and the pendulum tester TS EN 14231 standard [

29,

30]. The study results revealed that natural stone slabs exhibit diminished slip resistance and heightened slip potential in dry environments, particularly on polished surfaces as opposed to wet environments. Consequently, it was recommended to utilize honed and aged surfaces, characterized by lower slip resistance, in wet environments [

33,

34,

35]. Researchers further devised a novel safety slip scale based on COF (Coefficient of Friction) values derived from ramp and pendulum tests, employing the K-means method [

36].

In this investigation, a novel slip safety risk scale was established, taking into account slip test apparatus, the K-means method, and DCOF values. Consequently, measurements conducted on natural stone, laminate, PVC, and ceramic floor surfaces within PSB indicated that DCOF values were lower, and slip risk was higher in wet environments compared to dry environments across six distinct regions. Previous research has demonstrated the substantial influence of diverse surface treatments and environmental conditions on the slip resistance values of natural stone slabs within laboratory settings. In light of these findings, the utilization of honed, patinated, and aged surfaces on natural stones has been recommended to enhance slip safety [

26,

37].

To ensure pedestrian slip safety and mitigate slip-and-fall incidents, the authors conducted measurements on various floor surfaces within fifteen public institutions using the GMG 200 tester. In this study, a safety slip risk scale was established by employing the K-means method on DCOF data, aiming to facilitate secure pedestrian movement across floor surfaces. Subsequently, safety classifications were assigned to diverse floor surfaces based on their DCOF values and the determined slip safety risk scale. The analysis revealed that, across all six regions, dry environments were consistently safer than wet environments, with hospital floors being conditionally safe when dry but posing a risk when wet. Consequently, recommendations were made for rendering hospital floors less slippery to enhance pedestrian safety [

14,

22].

This entails an examination of human locomotion on the slip resistance of corridor and stair surfaces within a public service building, employing rubber-soled shoes and a rubber-tipped testing apparatus. The objective of this research is to contribute to the design of devices and the formulation of floor surface evaluation criteria tailored for individuals with mobility impairments within buildings [

38].

Unlike existing literature, the present study devised a novel scale by assessing DCOF values across two environments and six regions within thirty PSB. Various floor surfaces were examined using a portable GMG 200 and a pendulum tester in order to establish this scale.

5. Conclusion

This study assessed the DCOF values on various ground surfaces through slip tests conducted using a portable GMG 200 and pendulum testers. The slip safety risk scale was derived by applying the K-means method to the DCOF values obtained from different ground surfaces. Based on the acquired DCOF values, the floor surfaces were categorized according to their respective safe usage areas.

At the main entrance, corridors, stairs, rooms, kitchens, sinks, and toilet areas of the state institution, portable floor slip testers were employed to assess slip resistance in both dry and wet conditions. The study revealed that the floor surfaces within the PSB exhibit statistically significant variations in DCOF values, influenced by usage areas, environmental conditions, slip test methodologies, and surface materials. Pharmacies and schools were classified as safe, with DCOF values ranging between 0.45 and 0.58 μ in dry environments using the PSM-2 method, whereas they were deemed hazardous in wet environments due to DCOF values falling below 0.20 μ.

The floor surfaces, namely natural stone, PVC, ceramic, and laminate, commonly utilized in main entrances, corridors, staircases, classrooms, patient rooms, administrative areas, and polyclinics, are advised against being polished, particularly in spaces with high human traffic such as kitchens, sinks, and toilets. In lieu of polished and honed surfaces, safer alternatives like patinated and aged surfaces are recommended in high-risk areas. If the objective is to achieve a decorative, flexible, and non-slippery surface, opting for a honed finish is suggested for natural stones and ceramics.

References

- Shahraki, AA. Urban planning for physically disabled people’s needs with case studies. Spatial Information Research 2021;29(2): 173-184.

- Badawy UI, Jawabrah MQ, Jarada A. Adaptation of accessibility for people with disabilities in private and public buildings using appropriate design checklist. International Journal for Modern Trends in Science and Technology 2020.

- Stanojević A, Keković A. Functional and aesthetic transformation of industrial into housing spaces. Facta Universitatis, Series: Architecture and Civil Engineering 2019; 401-416.

- Arslan M, Erkan I. A model for evaluating the user satisfaction of human movements on stairs through the ergonomic design approach. Theoretical Issues in Ergonomics Science 2020;22(6): 651-672.

- Vesela, L. Staircase-dimensions of stair steps and their deviations of geometrical accuracy. In IOP Conference Series: Materials Science and Engineering 2019; 471(2): 022012.

- Sarkar S, Raj R, Vinay S, Maiti J, Pratihar DK. An optimizationbased decision tree approach for predicting slip-trip-fall accidents at work. Safety science 2019:118, 57-69.

- Atlas R. What Is The Role Of Design And Architecture In Slip, Trip, And Fall Accidents. In Proceedings of the Human Factors and Ergonomics Society Annual Meeting 2019; 63(1):531-536. Sage CA: Los Angeles, CA: SAGE Publications.

- Yu LX, Hon CY. Safety Climate Within Ontario Restaurants. Professional Safety, 2020; 65(11): 39-44.

- Weber A, Nickel P, Hartmann U, Friemert D, Karamanidis K. Contributions of Training Programs Supported by VR Techniques to the Prevention of STF Accidents. In International Conference on Human-Computer Interaction 2020:276-290. Springer, Cham.

- Larue GS, Popovic V, Legge M, Brophy C, Blackman R. Safe trip: Factors contributing to slip, trip and fall risk at train stations. Applied ergonomics 2021:92, 103316.

- Sato T, Nakajima M, Murano R, Kato M, Nakajima K. Relationship of Floor Material and Fall Risk Assessment During Descending Stairs. In Congress of the International Ergonomics Association 2021:171-174. Springer, Cham.

- Namdari N, Mohammadian B, Jafari P, Mohammadi R, Sojoudi H, Ghasemi H, Rizvi R. Advanced functional surfaces through controlled damage and instabilities. Materials Horizons, 2020:7(2); 366-396.

- Çoşkun G, Sarıışık G, Sarıışık A. Classification of parameters affecting slip safety of limestones. Cogent Engineering 2016: 3(1);1217821.

- Coşkun G, Sarıışık G. Analysis of slip safety risk by portable floor slipperiness tester in state institutions. Journal of Building Engineering 2020:7, 100953.

- Enkhjargal OE, Li KW. Subjective Ratings of Floor Slippery on Common Indoor and Outdoor Floors. International Journal of Engineering and Technology 2019:11(4);241-244.

- Li KW, Chen Y, Zou F, Li N, Duan T. Perception of risk of tripping under lighting and obstacle conditions. Hum. Factors Man. 2019:(29); 529– 536.

- Khaday S, Li KW. Friction Measurement on Common Floor Using a Horizontal Pull Slip Meter, International Journal of Environmental Science and Development 2019:10(9);275-279.

- Chang WR, Li KW, Huang YH, Filiaggi A, Courtney TK, Objective and subjective measurements of slipperiness in fast-food restaurants in the USA and their comparison with the previous results obtained in Taiwan, Safety Science 2006:44(10); 891-903.

- Sariisik, A. Safety analysis of slipping barefoot on marble covered wet areas. Safety Science 2009: 47(10);1417-1428.

- Terjék A, Dudás A. Ceramic Floor Slipperiness Classification–A new approach for assessing slip resistance of ceramic tiles. Construction and Building Materials 2018:164; 809-819.

- Barreca F, Cardinali G, Fichera CR. Assessment of flooring slipperiness for food industry buildings. Agricultural Engineering International: The CIGR Journal 2015:17(2); 23-30.

- Çoşkun G, Bendak S. Safety of hospital floor coverings: a mixed method study. Safety science 2023:163;106145.

- Norlander A, Miller M, Gard G. Perceived risks for slipping and falling at work during wintertime and criteria for a slip-resistant winter shoe among Swedish outdoor workers. Safety Science 2015:73;52-61.

- Yamaguchi T, Umetsu T, Ishizuka Y, Kasuga K, Ito T, Ishizawa S, Hokkirigawa K. Development of new footwear sole surface pattern for prevention of sliprelated falls. Safety Science 2012:50(4); 986-994.

- Jhou SY, Hsu WC, Hsu CC. A New Numerical Simulation Process for Footwear Slip Resistance Analysis. In: Lin KP., Magjarevic R., de Carvalho P. (eds) Future Trends in Biomedical and Health Informatics and Cybersecurity in Medical Devices. ICBHI 2019. IFMBE Proceedings 2020:74. Springer, Cham.

- Çoşkun, G. A new slip safety risk scale of natural stones with statistical Kmeans clustering analysis. Arabian Journal of Geosciences 2018:11(24); 1-14.

- Karataş F, Sarıışık A, Çoşkun G. Evaluation of the Safety Coefficients of Floor Coverings Used in Wet and Dry Environments by K-Means and Decision Tree Methods. Dicle University Journal of Engineering 2021:12(5);16.

- Sudol E, Malek M, Jackowski M, Czarnecki M, Strąk, C. What makes a floor slippery? A brief experimental study of ceramic tiles slip resistance depending on their properties and surface conditions. Materials 2021:14(22); 7064.

- German Institute for Standardization (DIN) Prüfung von Bodenbelägen - Bestimmung der rutschhemmenden Eigenschaft - Verfahren zur Messung des Gleitreibungskoeffizienten [Testing of floor coverings - Determination of the anti-slip property - Method for measurement of the sliding friction coefficient] DIN, Berlin (2014) Standard No. DIN 51131: 2014. German.

- Turkish Standards Institute (TSI) Doğal Taşlar Deney Metotları - Pandül Deney Donanımıyla Kayma Direncinin Tayini [Natural Stone Test Methods - Determination of the Slip Resistance by Means of the Pendulum Tester] TSI, Ankara (2004) Standard No. TS EN 14231: 2004. Turkish.

- Hair JFJ, Black WC, Babin BJ, Anderson RE. Multivariate Data Analysis, seventh ed., Prentice Hall, 2010.

- Vattani, A. K-means requires exponentially many iterations even in the plane, Discrete Comput. Geom. 2011:45 (4); 596–616.

- Sarıısık A, Sarıısık G. Analysis of the parameters affecting the slip angle of surface-processed natural stones, Min. J. 2010:49;17–30 (in Turkish).

- Sariisik A, Sariisik G, Akdaş H. Slip analysis of surface-processed limestones. Proceedings of the Institution of Civil Engineers-Construction Materials 2012:165(5);279-296.

- Sariisik A, Akdas H, Sariisik G, Coskun G. Slip safety analysis of differently surface processed dimension marbles. Journal of Testing and Evaluation 2011:39(5);1.

- Çoşkun G, Sarıışık G, Sarıışık A. Classification of parameters affecting slip safety of limestones. Cogent Engineering 2016:3(1);1217821.

- Çoşkun G, Sarıışık G, Sarıışık A. Slip safety risk analysis of surface properties using the coefficients of friction of rocks. International journal of occupational safety and ergonomics 2017:1–15.

- Waluś KJ, Warguła Ł, Wieczorek B, Krawiec P. Slip risk analysis on the surface of floors in public utility buildings. Journal of Building Engineering 2022:104643.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).