1. Introduction

The performance of reinforced concrete structures built and served in marine environments are often degraded due to chloride-induced corrosion. Chloride ion penetration into concrete depends on a number of variables, such as chloride ion concentration, concrete’s microstructures and properties, and the magnitude of hydrostatic pressure [

1,

2,

3,

4,

5,

6]. On the one hand, concrete structures are unavoidably cracked due to internal deformation and external loadings during their service life. The presence of cracks in the concrete accelerates the corrosion process of the steel reinforcement. On the other hand, water pressure affects substantially the chloride penetration process into concrete with cracks whose hydraulic properties are heavily stress dependent. Therefore, understanding the behaviour of chloride diffusion in concrete with cracks under various hydrostatic pressure is critical to assess and predict the long-term durability of marine concrete structures, particularly for those built in the deep-sea environments [

6,

7,

8].

The effect of cracks on the chloride penetration of concrete has attracted numerous investigations recently [

6,

9,

10,

11,

12,

13,

14,

15,

16,

17]. Aldea et al. [

15] reported that the chloride permeability increased with increased crack widths and the water permeability was much more sensitive than that of chlorides. Olga and Hooton [

17], however, reported that chloride diffusion was independent of both crack width and crack wall roughness. François et al. [

16] reported that the chloride diffusion perpendicular to the crack walls with wide cracks (width ≥205 μm) was similar to that of the surface. For the cracks running through the specimens, the diffusion coefficient in the crack under steady-state conditions was assumed to equal the diffusion coefficient in free solution [

18,

19]. Therefore, it is apparent that cracks in concrete greatly affect the durability of reinforced concrete structures with some inconsistent findings from previous literature. Moreover, Liu et al. [

20,

21,

22,

23] studied the migration mechanism of chloride in cracked concrete by numerical simulation, which provided a new idea for the durability design of concrete. In theory, stability of deep-sea concrete-made engineering infrastructures is closely associated with the concrete durability under a high hydrostatic pressure environment. However, the effect of hydrostatic pressure on the penetration of chloride in cracked concrete has been rarely explored.

This paper reports experimental studies on chloride diffusion in the pre-cracked concrete with different degrees of hydrostatic pressure. The crack of a desired width in the concrete specimen was manually created using a controlled splitting tensile apparatus and maintained during the chloride penetration process in cracked concrete. The average crack widths varied from 20 μm to about 100 μm. Moreover, the effect of hydrostatic pressure on the diffusion coefficient values of the cracked concrete was also examined.

2. Experimental Study

2.1. Sample Preparation

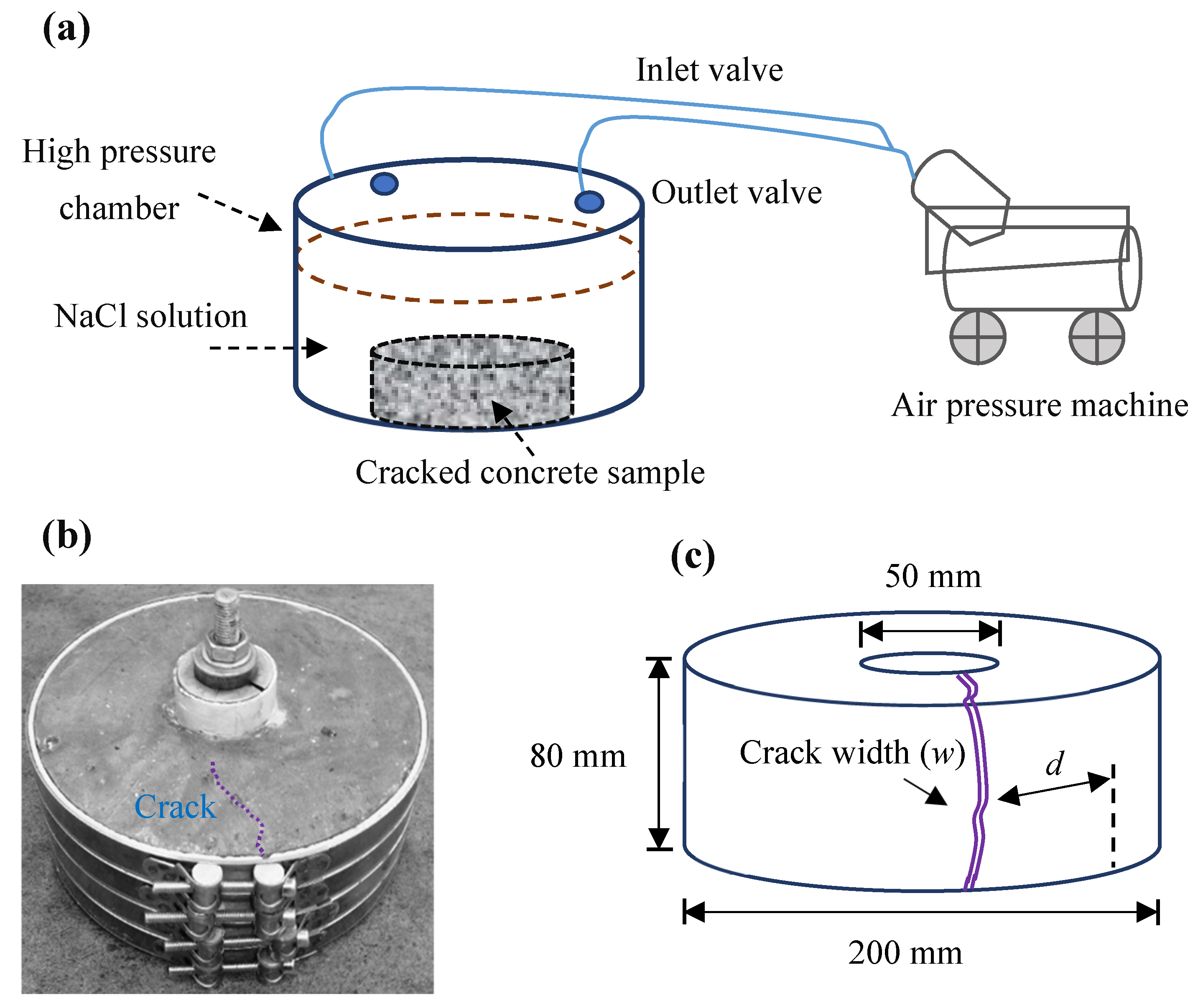

Figure 1 illustrates the experimental configuration for exploring the chloride transport into the cracked concrete samples under various magnitudes of hydrostatic pressure. An air pressure machine was employed to apply four different hydrostatic pressures of 0 MPa, 0.1 MPa, 0.3 MPa and 0.5 MPa on the cracked concrete, and the highest hydrostatic pressure simulated the marine environment in depth up to 50m [

24]. The concrete specimen exhibited a ring profile with an inner radius of 50 mm, outer radius of 200 mm, and height of 80 mm (

Figure 1b). The concrete mixture consisted of cement, water, sand, aggregates, and water reduction agent in the ratio of 1:0.38:1.56:2.66:0.012 by mass, which complied with the Chinese Standard, JGJ55-2011 [

25]. The cement type was P.II 52.5, with an apparent density of 3150 kg/m

3. The size of coarse aggregate ranged from 5 mm to 20 mm with continuous grading, and its apparent density was 2630 kg/m

3. The apparent density of sand was 2.64 g/cm

3 with a water proportion of 3.7%. The type of the water reducing agent was HP4000A with a water reduction ratio of 27.5%. The uniaxial compressive strength of the concrete was 50.5 ± 0.5 MPa and 59.1 ± 0.3 MPa after 14 and 28 days of curing, respectively. The tensile strength of the concrete was respectively 5.36 ± 0.44 MPa and 6.87 ± 0.27 MPa after 14 and 28 days. Twenty concrete samples were prepared from a single batch for the concrete mixtures after 14 and 28 days of curing, respectively. The concrete mixtures were cast in steel molds and compacted using a mechanical vibrator.

2.2. Sample Pre-Cracking

Cracks with five different widths of 20 μm, 40 μm, 60 μm, 80 μm, and 100 μm in the ring concrete sample was created by a controlled splitting tensile apparatus. A crack width gauge, i.e., DJCK-2 Type, was used to measure the crack width. After cutting, the lateral surfaces of ring concrete sample were sealed with two epoxy resin coats to ensure that the chlorides flow through the ring concrete crack in radial direction (

Figure 1c).

3. Results and Analysis

3.1. Chloride Concentration Quantification

The chloride concentration in concrete is estimated through the Volhard method. The powdered concrete samples normal to the crack surface are used to extract acid-soluble chloride contents, as shown in

Figure 1c. The chloride diffusion is calculated by fitting the experimentally-measured curves. The penetration of chloride into concrete is assumed one-dimensional in a semi-infinite medium complying with Fick’s second law of pure diffusion [

26,

27]:

Solve Eq. (1):

where

is the chloride concentration at distance

x from the exposed surface,

is the surface chloride concentration,

is the apparent chloride diffusion coefficient,

is the exposure time, and

is the error function [

26,

28]. The values of

and

are determined from fitting the measured chloride profile.

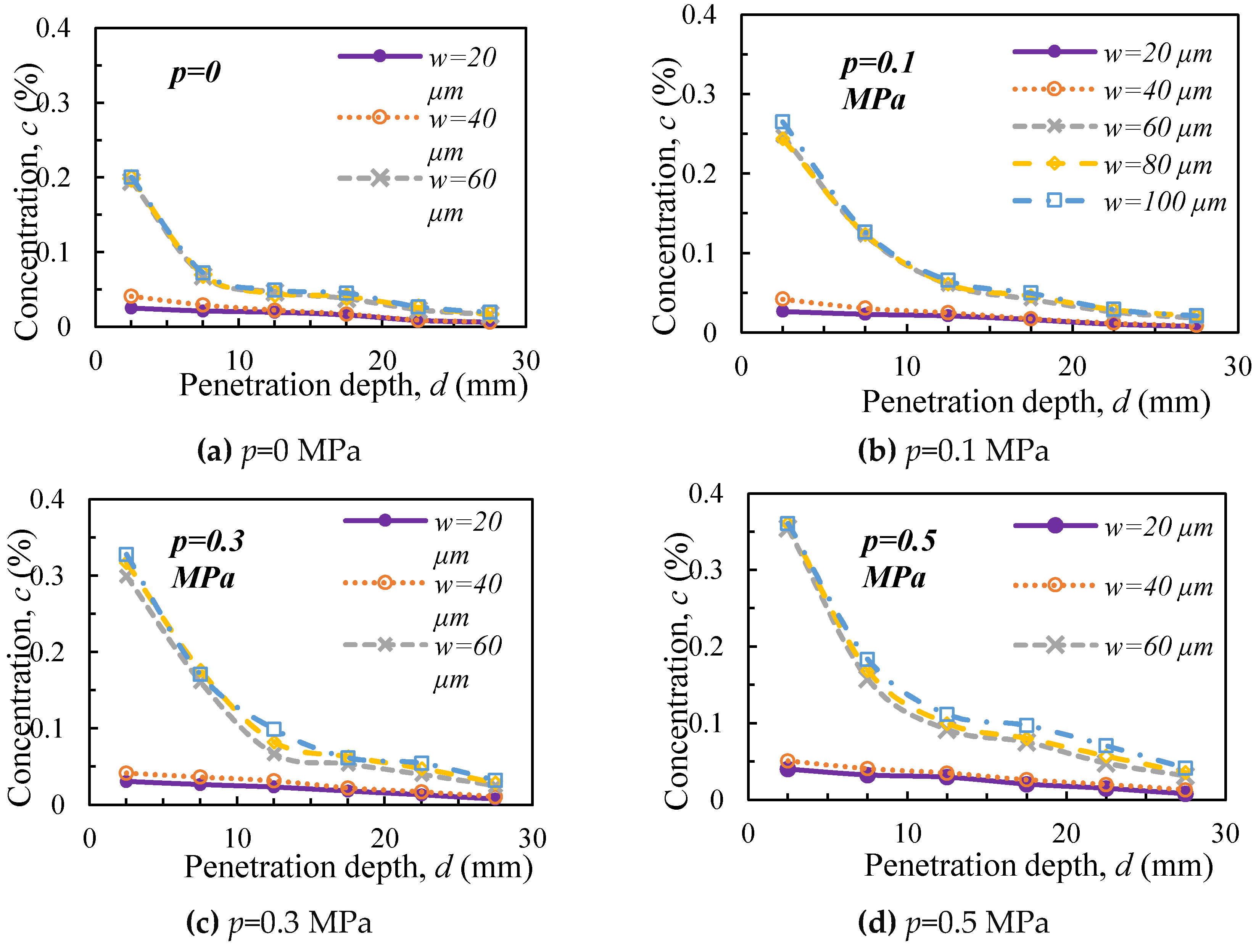

3.2. Effect of Crack Width on Chloride Diffusion

Figure 2 shows the chloride concentration of the ring concrete sample with different crack widths under four magnitudes of hydrostatic pressure. As the hydrostatic pressure grows from 0 to 0.5 MPa, remarkable difference in chloride concentration (

) occurs between the crack width increasing from 20 µm to 40 µm and that from 60 µm to 100 µm. The chloride concentration (

) (0.025% to 0.041%) for the crack width of 20 µm to 40 µm is substantially lower than that of 60 µm to100 µm (0.19% to 0.36%), particularly for those close to the crack surface. The discrepancy decreases gradually as the penetration depth (

d) from the crack surface increases. This indicates that the crack width remarkably affects the chloride transport in concrete and the influence degree decreases with the increasing penetration depth. The effect of the crack width is much less pronounced when the width is around 20 µm to 40 µm. Similarly, minor difference is found given the crack width ranging between 60 µm and 100 µm. Therefore, a critical crack width exists beyond which the chloride transportation in concrete is significantly influenced. The results are consistent with the findings reported from other studies [

14,

29,

30]. In the study carried out by Wang et al. [

11], it was also found that the chloride diffusion depth increased significantly when the crack width was 0.05 mm or greater, compared to that when the crack width was 0.03 mm or less. In that case, the threshold (the critical crack width) was about 0.03 -0.05 mm, close to the result from this research (40-60 µm). When the crack width is greater, there are more capillary pores available on the surface of cracks, making the ingress of water easier, and thus the chloride concentration was also higher.

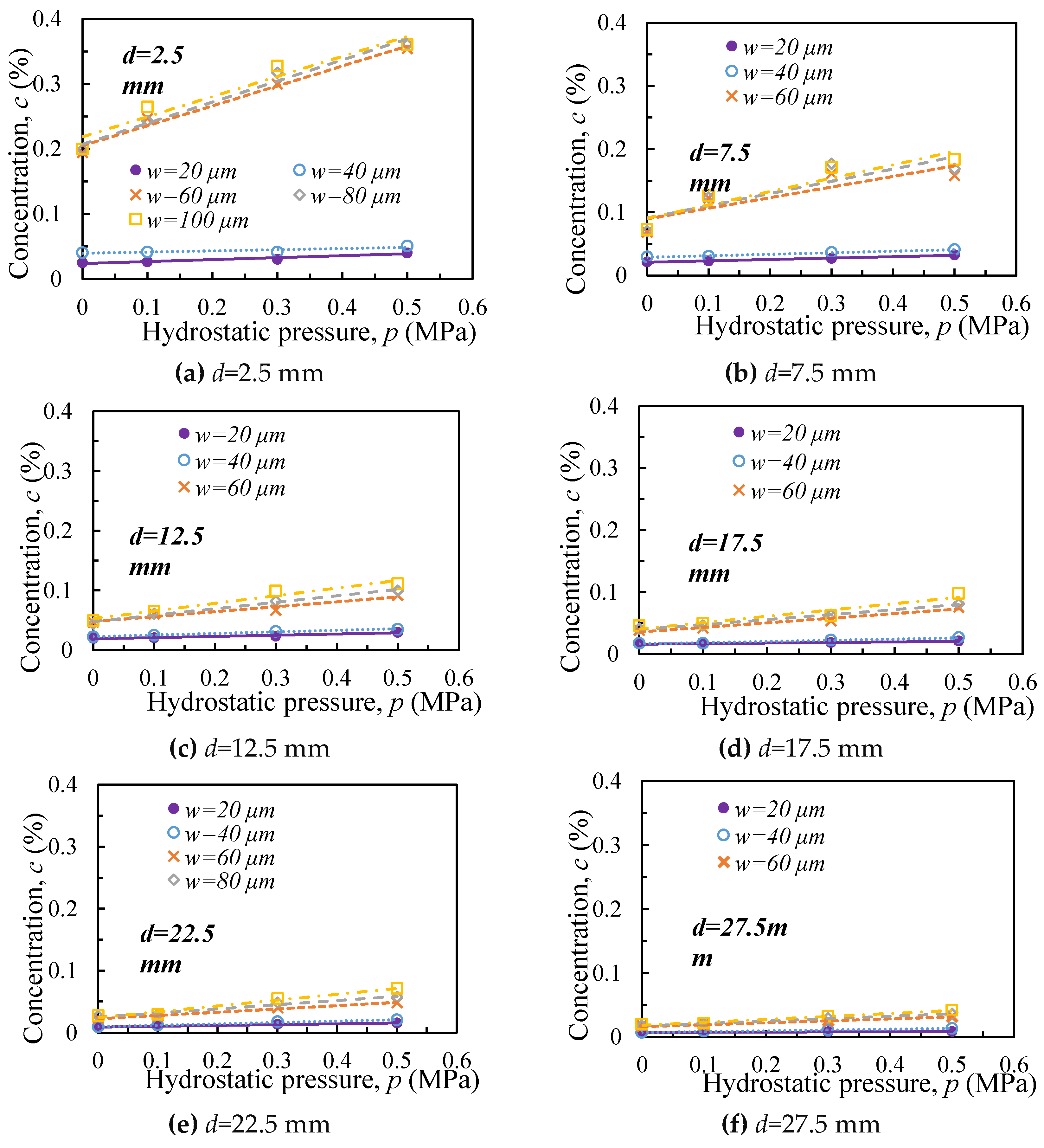

3.3. Effect of Hydrostatic Pressure on Chloride Diffusion

Figure 3 shows the effect of hydrostatic pressure on the chloride transport in concrete with different crack width. Appreciable difference can be found between the chloride concentration for the crack width from 20 µm to 40 µm and that for the crack width from 60 µm to 100 µm. The hydrostatic pressure only slightly affects the chloride transport in the concrete with the crack width from 20 µm to 40 µm, whereas the chloride concentration in concrete with crack width from 60 µm to 100 µm is strongly affected. Besides, it is obvious that the chloride concentration increases as the hydrostatic pressure increases, particularly for the region near the crack. This phenomenon can be explained by considering the fact that when there is an external hydraulic pressure applied to the crack, the water infiltration depth increases and thus the corresponding rate of chloride penetration becomes higher, leading to higher concentration of chlorides at a certain depth [

6]. The slope of the curves for the crack width from 20 µm to 40 µm is around 0.01 to 0.03 whereas it increases to around 0.03 to 0.3 for the crack width from 60 µm to 100 µm. The slope approaches the maximum value of 0.3 at the depth of 2.5 cm. The hydrostatic pressure has a great effect on the chloride transport in concrete with the crack width from 60 µm to 100 µm. The relationship between the chloride concentration and the hydrostatic pressure is linear, which can be expressed as the following equation:

where

is the chloride concentration in concrete,

is the chloride concentration without hydrostatic pressure,

is the curve slope, and

is the hydrostatic pressure.

Table 1 shows the values of the correlation parameters of the linear relationship.

3.4. Diffusion Coefficient

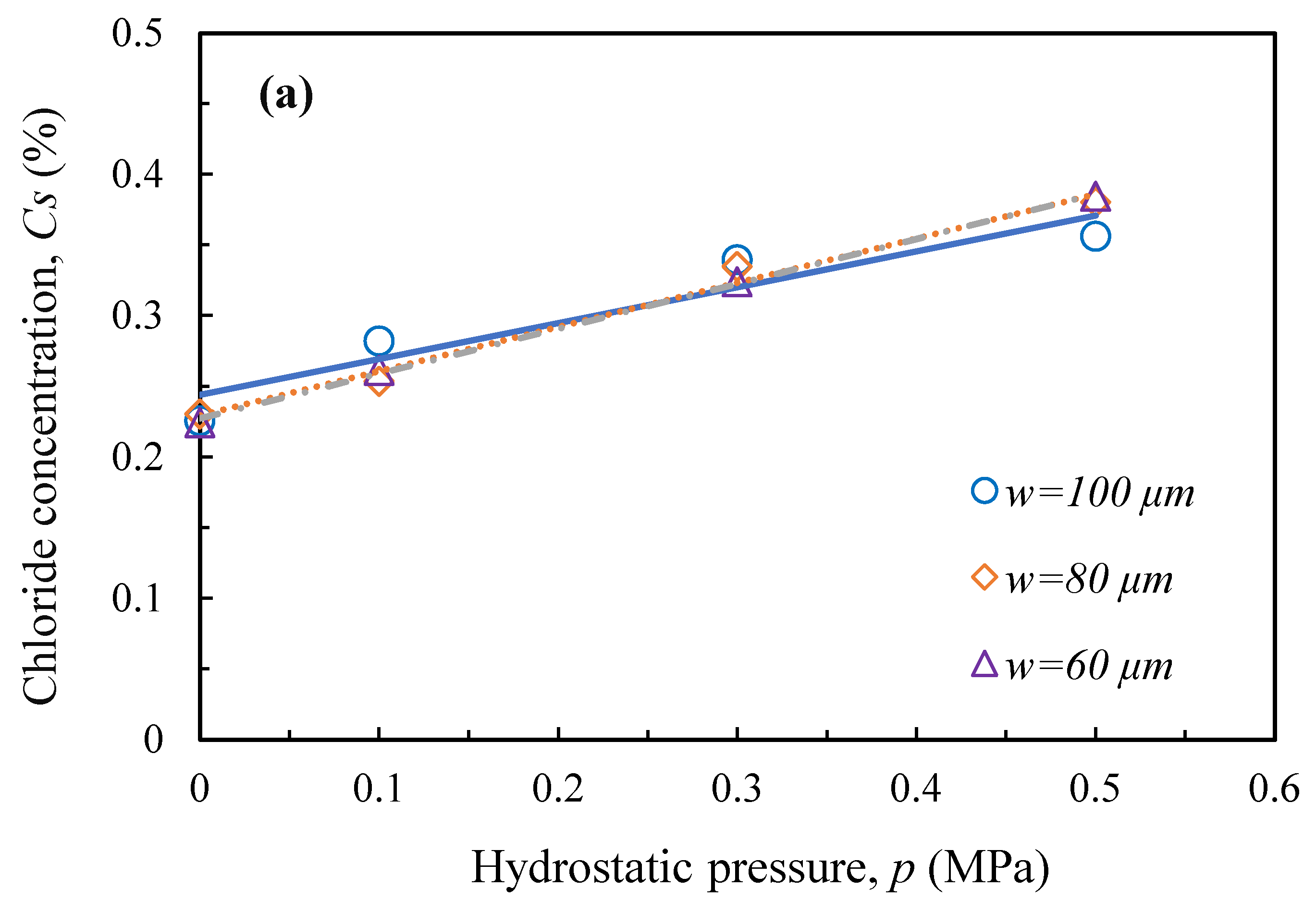

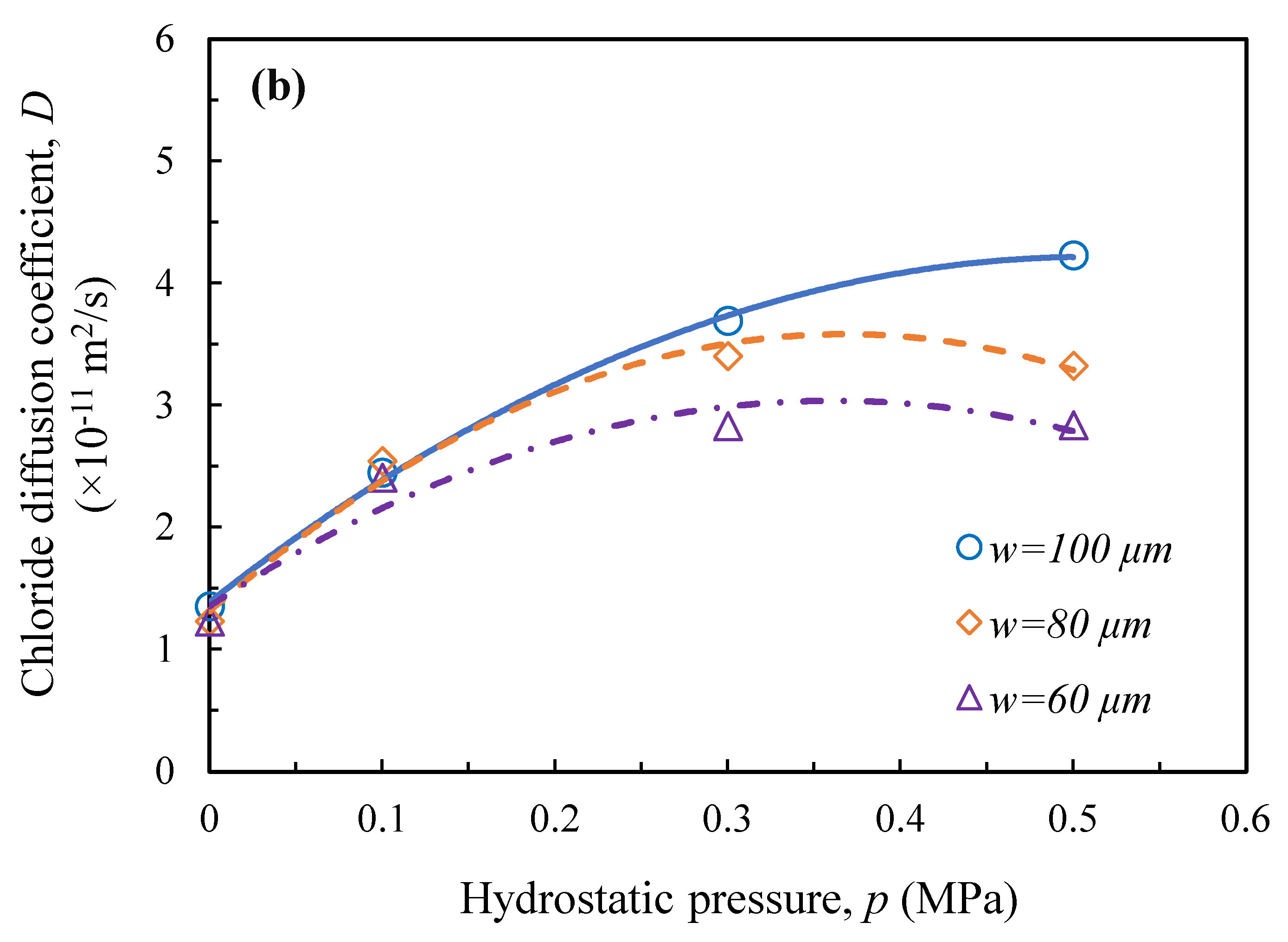

Figure 4a and

Figure 4b show the calculated apparent chloride diffusion coefficient

and the corresponding surface chloride concentration

based on Eq. (2), respectively. The chloride concentration (

) for the crack width from 60 µm to 100 µm increases almost linearly with increasing hydrostatic pressure. The value of

at

p=0 MPa is 0.22 and reaches around 0.38 at

p=0.5 MPa. The effect of hydrostatic pressure on the chloride diffusion into concrete is probably due to the increase of the surface chloride concentration (

) in the cracks given the same chloride concentration in solution, which shows the similar trend to that illustrated in

Figure 3. Similarly, the chloride diffusion coefficient (

) initially increases over the increase in hydrostatic pressure, then keeps constant when the hydrostatic pressure exceeds 0.3 MPa, particularly for the crack width ranging from 60 µm to 80 µm. The results for the crack width at 20 and 40 µm are not presented here because very little change was found between these two lines and the corresponding diffusion coefficient was quite small. For the crack width of 100 µm,

continuously increases as the hydrostatic pressure rises from 0 to 0.5 MPa. This suggests that the crack width promotes chloride diffusion under high hydrostatic pressure when the value exceeds 0.1 MPa. Both the calculated apparent chloride diffusion coefficient (

) and the surface chloride concentration (

) are influenced dramatically by the hydrostatic pressure which results in the evolution of chloride diffusion as the hydrostatic pressure varies.

4. Conclusions

This study showed that hydrostatic pressure affected the chloride diffusion in the pre-cracked concrete with different crack widths. The effect of hydrostatic pressure should be considered carefully when estimating the chloride diffusion in cracked concrete and thus the chloride-induced corrosion, by which the service time of the corresponding concrete structure can be accurately predicted, and effective protective actions could be taken. The main conclusions of the study are listed below.

(1) Under the hydrostatic pressure from 0 MPa to 0.5 MPa, chloride concentration in the concrete increased as the crack width incremented. The chloride concentration in the concrete exhibited similar trends for the crack width ranging from 60 µm to 100 µm and for the crack width from 20 µm to 40 µm, respectively. A critical crack width seemingly exists beyond which the effect of hydrostatic pressure on the chloride diffusion in concrete is significantly stronger.

(2) For the concrete sample with a crack of width from 20 µm to 100 µm, chloride concentration increased almost linearly as the hydrostatic pressure became higher, particularly for the crack width ranging from 60 µm to 100 µm. Moreover, the increased crack width enhances the effect of hydrostatic pressure on chloride diffusion, as evidenced by the increased slope of the chloride concentration-hydrostatic pressure curve given the increase in the crack width.

(3) The calculated chloride diffusion coefficient and the surface chloride concentration of the cracked samples increased with increasing crack width and hydrostatic pressure.

Acknowledgements

The authors gratefully acknowledge the financial support provided by the National Natural Science Foundation of China (No. 42177141). The corresponding author would like to express great thanks to the Internal funding (INCB2437) from the Interdisciplinary Research Center for Construction and Building Materials in King Fahd University of Petroleum & Minerals.

References

- R. Wattanapornprom, T. Ishida, Comprehensive Numerical System for Predicting Airborne Chloride Generation and Its Ingress in Concrete under Actual Environmental Conditions. Journal of Advanced Concrete Technology 2018, 16, 18–35. [Google Scholar] [CrossRef]

- H. Sun, S. Liu, F. Yu, X. Zhang, C. Wu, F. Xing, J. Ren, Behaviour of cement binder exposed to semi-immersion in chloride-rich salt solutions and seawater with different RH levels. Cement and Concrete Composites 2022, 131, 104606. [Google Scholar] [CrossRef]

- K. Pasupathy, J. K. Pasupathy, J. Sanjayan, P. Rajeev, D. Law, The effect of chloride ingress in reinforced geopolymer concrete exposed in the marine environment. Journal of Building Engineering (.

- L. Basheer, J. Kropp, D. Cleland, Assessment of the durability of concrete from its permeation properties: a review. Construction and Building Materials 2001, 15, 93–103. [Google Scholar] [CrossRef]

- J. Bao, J. Wei, P. Zhang, Z. Zhuang, T. Zhao, Experimental and theoretical investigation of chloride ingress into concrete exposed to real marine environment. Cement and Concrete Composites 2022, 130, 104511. [Google Scholar] [CrossRef]

- M. -Y. Chen, R.-P. Chen, Y.-Q. Chen, X. Kang, Chloride ion transport in unsaturated ultra-high performance concrete cracks under high hydraulic pressures. Construction and Building Materials 2023, 409, 133810. [Google Scholar] [CrossRef]

- F. Chuanqing, J. Xianyu, Y. Hailong, J. Nanguo, Theoretical and Experimental Investigation of Loading Effects on Chloride Diffusion in Saturated Concrete. Journal of Advanced Concrete Technology 2015, 13, 30–43. [Google Scholar] [CrossRef]

- Z. He, C. He, X. Kang, X. Huang, S. Wang, Assessment of structural performance of super large cross-section subsea RC shield tunnels: Emphasis on the combined effects of highly hydrostatic pressure and corrosion-induced deterioration. Ocean Engineering 2023, 288, 116134. [Google Scholar] [CrossRef]

- M. B. Otieno, M.G. Alexander, H.D. Beushausen, Corrosion in cracked and uncracked concrete - influence of crack width, concrete quality and crack re-opening. Magazine of Concrete Research 2010, 62, 393–404. [Google Scholar] [CrossRef]

- X. Xu, D. He, S. Zeng, W. He, H. Tan, Z. Yu, Effect of concrete cracks on the corrosion of headed studs in steel and concrete composite structures. Construction and Building Materials 2021, 293, 123440. [Google Scholar] [CrossRef]

- X. Wang, M. Ba, B. Yi, J. Liu, Experimental and numerical investigation on the effect of cracks on chloride diffusion and steel corrosion in concrete. Journal of Building Engineering 2024, 86, 108521. [Google Scholar] [CrossRef]

- F. Du, Z. Jin, W. She, C. Xiong, G. Feng, J. Fan, Chloride ions migration and induced reinforcement corrosion in concrete with cracks: A comparative study of current acceleration and natural marine exposure. Construction and Building Materials 2020, 263, 120099. [Google Scholar] [CrossRef]

- S. Wang, X. Guo, Z. Guo, C. He, X. Duan, W. Hu, K. Zhuang, Direct characterization of steel fibre corrosion in pre-cracked ultra-high performance concrete (UHPC) with different crack widths. Construction and Building Materials 2022, 315, 125769. [Google Scholar] [CrossRef]

- Djerbi, S. Bonnet, A. Khelidj, V. Baroghel-bouny, Influence of traversing crack on chloride diffusion into concrete. Cement and Concrete Research 2008, 38, 877–883. [Google Scholar] [CrossRef]

- C. M. Aldea, S.P. Shah, A. Karr, Effect of Cracking on Water and Chloride Permeability of Concrete. Journal of Materials in Civil Engineering 1999, 11, 181–187. [Google Scholar] [CrossRef]

- M. Ismail, A. Toumi, R. François, R. Gagné, Effect of crack opening on the local diffusion of chloride in cracked mortar samples. Cement and Concrete Research 2008, 38, 1106–1111. [Google Scholar] [CrossRef]

- Rodriguez, R.D. Hooton, Influence of cracks on chloride ingress into concrete. Aci Materials Journal 2003, 100, 120–126. [Google Scholar]

- B. Gérard, J. Marchand, Influence of cracking on the diffusion properties of cement-based materials. Part I: Influence of continuous cracks on the steady-state regime. Cement & Concrete Research 2000, 30, 37–43. [Google Scholar]

- S. Jacobsen, J. Marchand, L. Boisvert, Effect of cracking and healing on chloride transport in OPC concrete. Cement and Concrete Research 1996, 26, 869–881. [Google Scholar] [CrossRef]

- Q. -f. Liu, M.F. Iqbal, J. Yang, X.-y. Lu, P. Zhang, M. Rauf, Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Construction and Building Materials 2021, 268, 121082. [Google Scholar] [CrossRef]

- L. -j. Li, Q.-f. Liu, L. Tang, Z. Hu, Y. Wen, P. Zhang, Chloride penetration in freeze–thaw induced cracking concrete: A numerical study. Construction and Building Materials 2021, 302, 124291. [Google Scholar] [CrossRef]

- C. -l. Zhang, W.-k. Chen, S. Mu, B. Šavija, Q.-f. Liu, Numerical investigation of external sulfate attack and its effect on chloride binding and diffusion in concrete. Construction and Building Materials 2021, 285, 122806. [Google Scholar] [CrossRef]

- Q. -f. Liu, J. Yang, J. Xia, D. Easterbrook, L.-y. Li, X.-Y. Lu, A numerical study on chloride migration in cracked concrete using multi-component ionic transport models. Computational Materials Science 2015, 99, 396–416. [Google Scholar] [CrossRef]

- T. Yamazaki, Y. T. Yamazaki, Y. Kajitani, Deep-sea environment and impact experiment to it, (1999).

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. JGJ55-2011. Specification for mix proportion design of ordinary concrete, China Architecture & Building Press (2011-12-01).

- J.M. Frederiksen, L. J.M. Frederiksen, L. Mejlbro, L.-O. Nilsson, Fick’s 2 nd law-Complete solutions for chloride ingress into concrete, Report TVBM-3146, Lund Institute of Technology, Sweden (2008).

- J. -C. Park, H.-J. Jung, Finite element method-based numerical study utilizing experimental data on chloride solution transport in concrete under hydraulic pressure. Construction and Building Materials 2024, 418, 135270. [Google Scholar] [CrossRef]

- S. Chatterji, On the applicability of Fick’s second law to chloride ion migration through portland cement concrete. Cement and Concrete Research 1995, 25, 299–303. [Google Scholar] [CrossRef]

- N. Gowripalan, V. Sirivivatnanon, C.C. Lim, Chloride diffusivity of concrete cracked in flexure. Cement & Concrete Research 2000, 30, 725–730. [Google Scholar]

- L. Marsavina, K. Audenaert, G. De Schutter, N. Faur, D. Marsavina, Experimental and numerical determination of the chloride penetration in cracked concrete. Construction and Building Materials 2009, 23, 264–274. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).