Submitted:

25 October 2023

Posted:

25 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

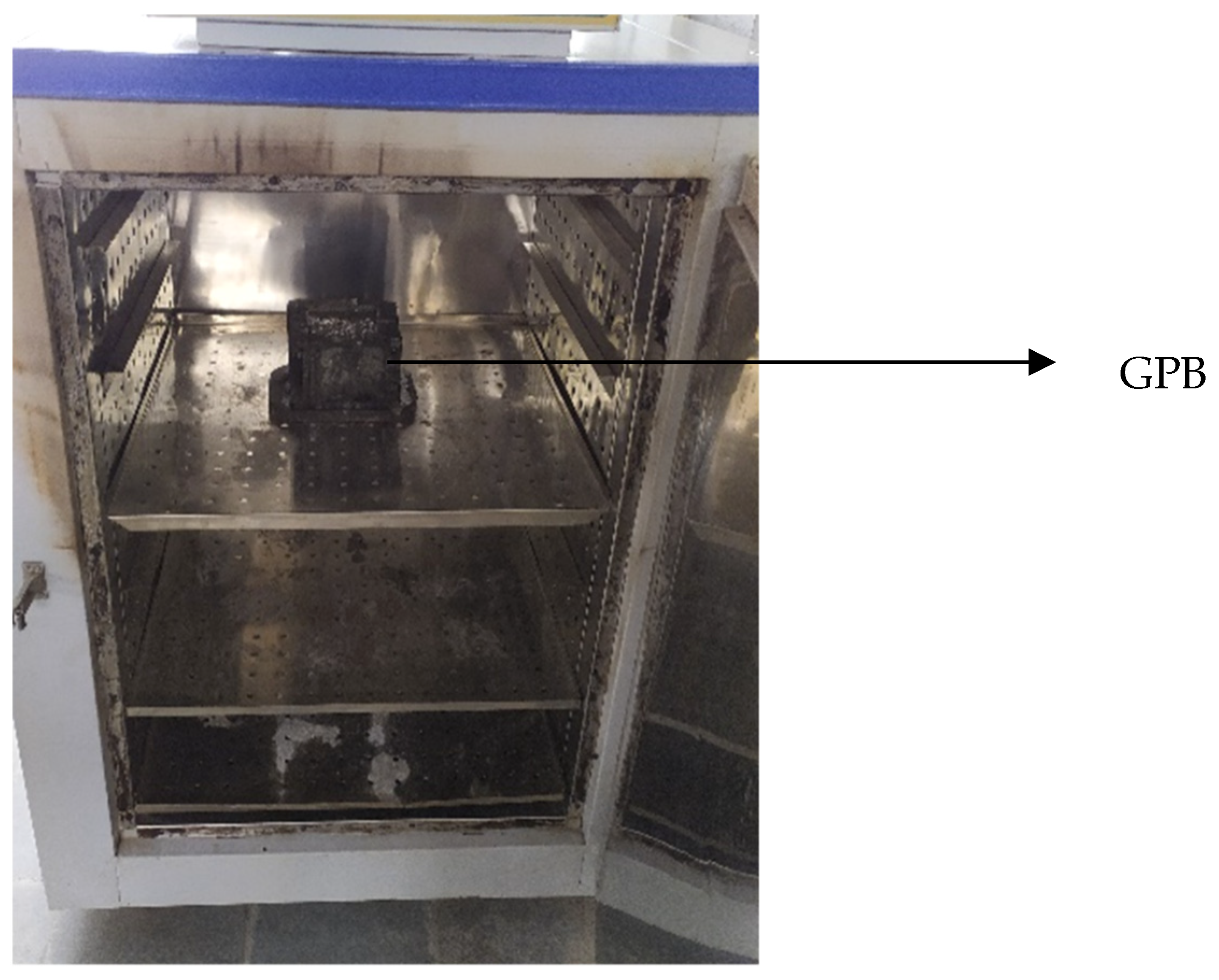

2.1. Electrical Oven Drying

2.2. Solar Drying without PCM

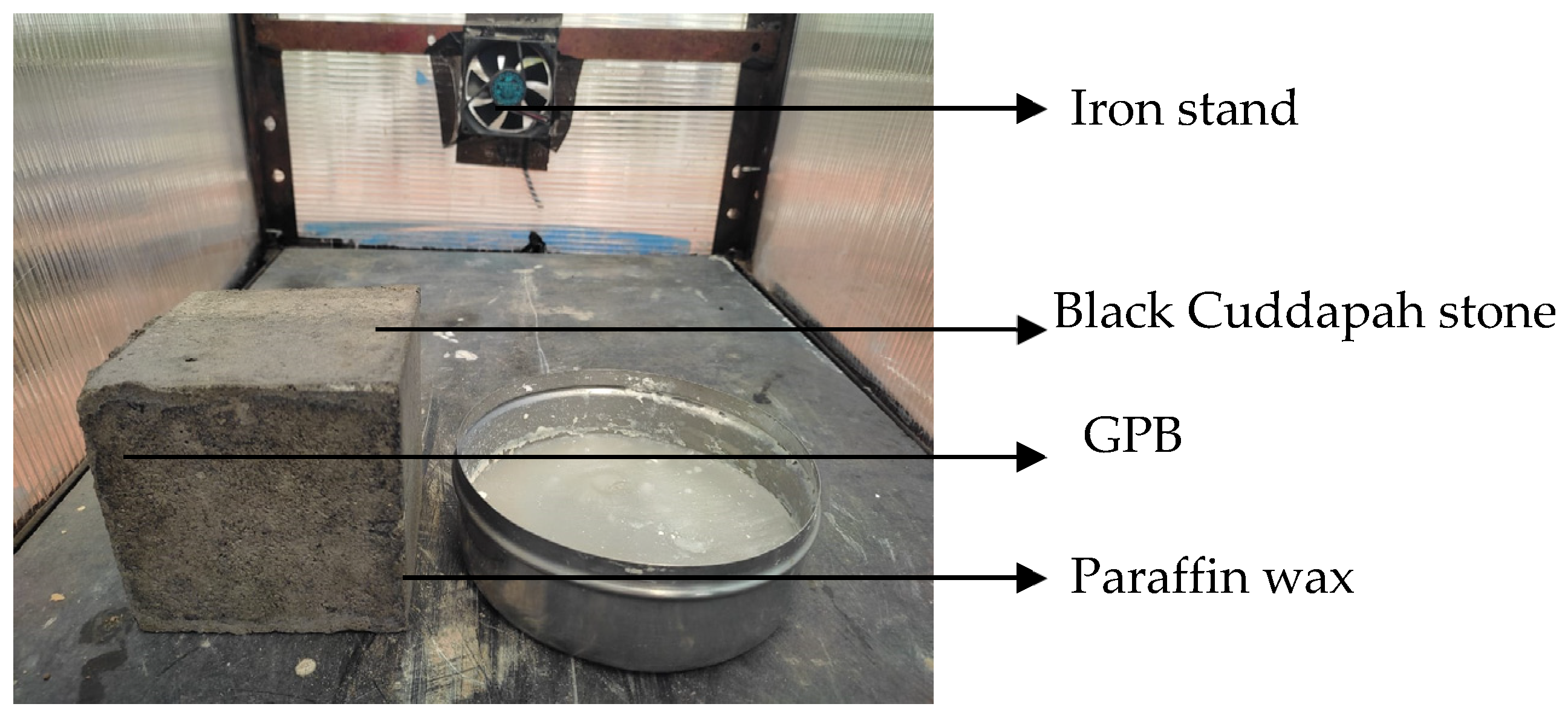

2.3. Solar Drying with PCM

2.4. Open Sun Drying

3. Results

4. Discussion

5. Conclusion

- ➢

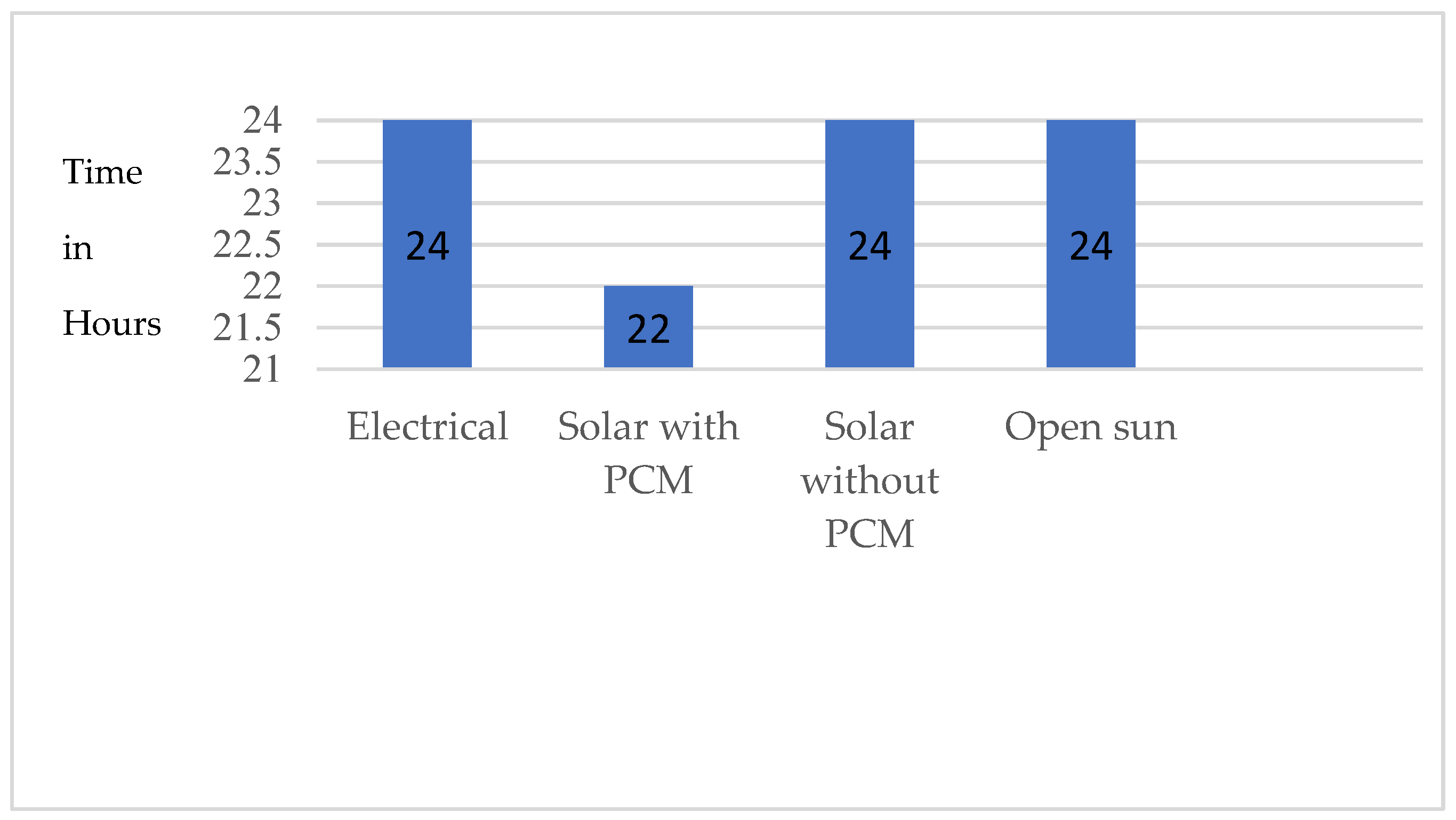

- From Fly ash waste and other ingredients the constructed GPB undergoes full curing in all the four methods.

- ➢

- Solar dryer with PCM consumes 2 hours less curing time when compared to all other methods.

- ➢

- ➢

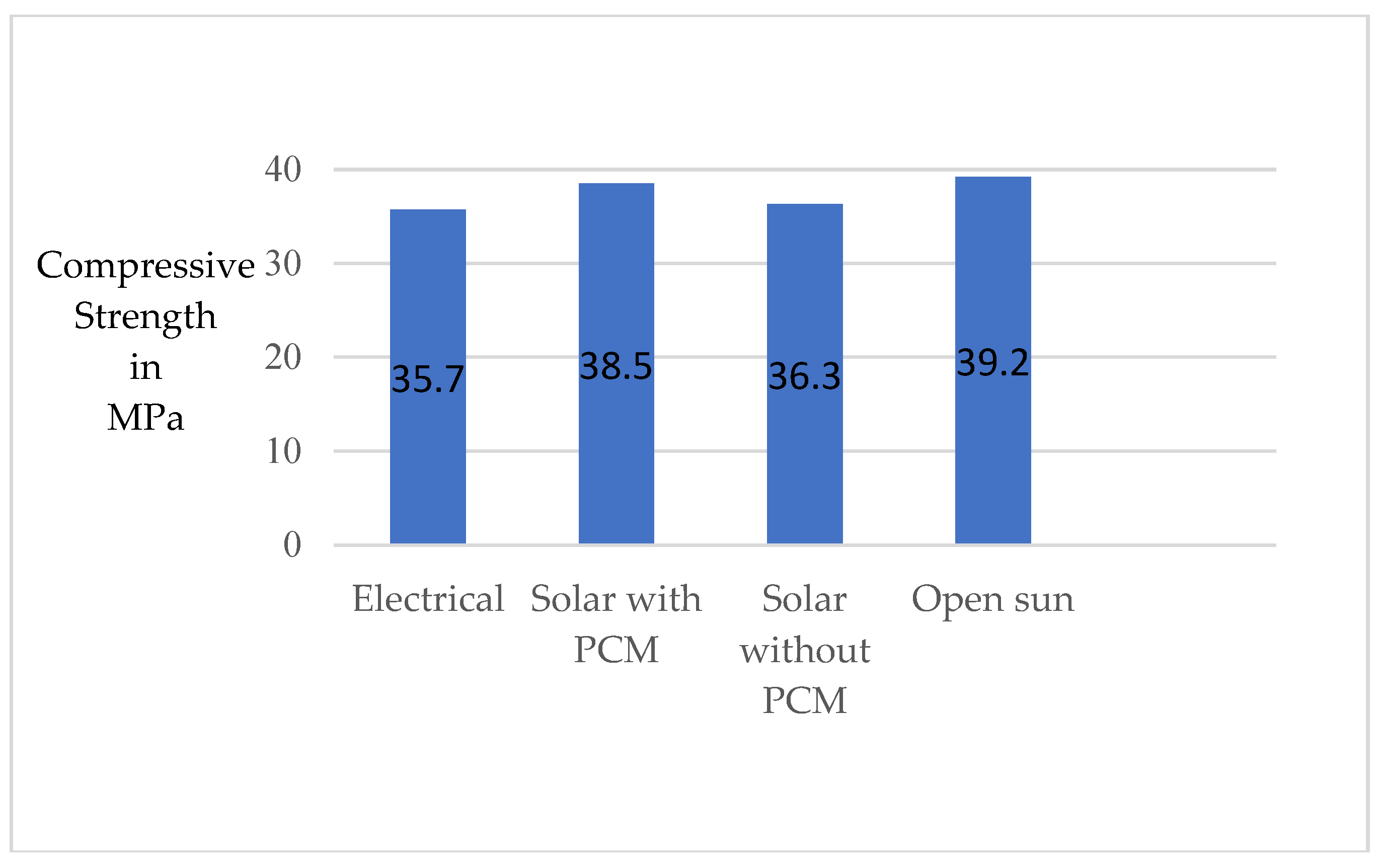

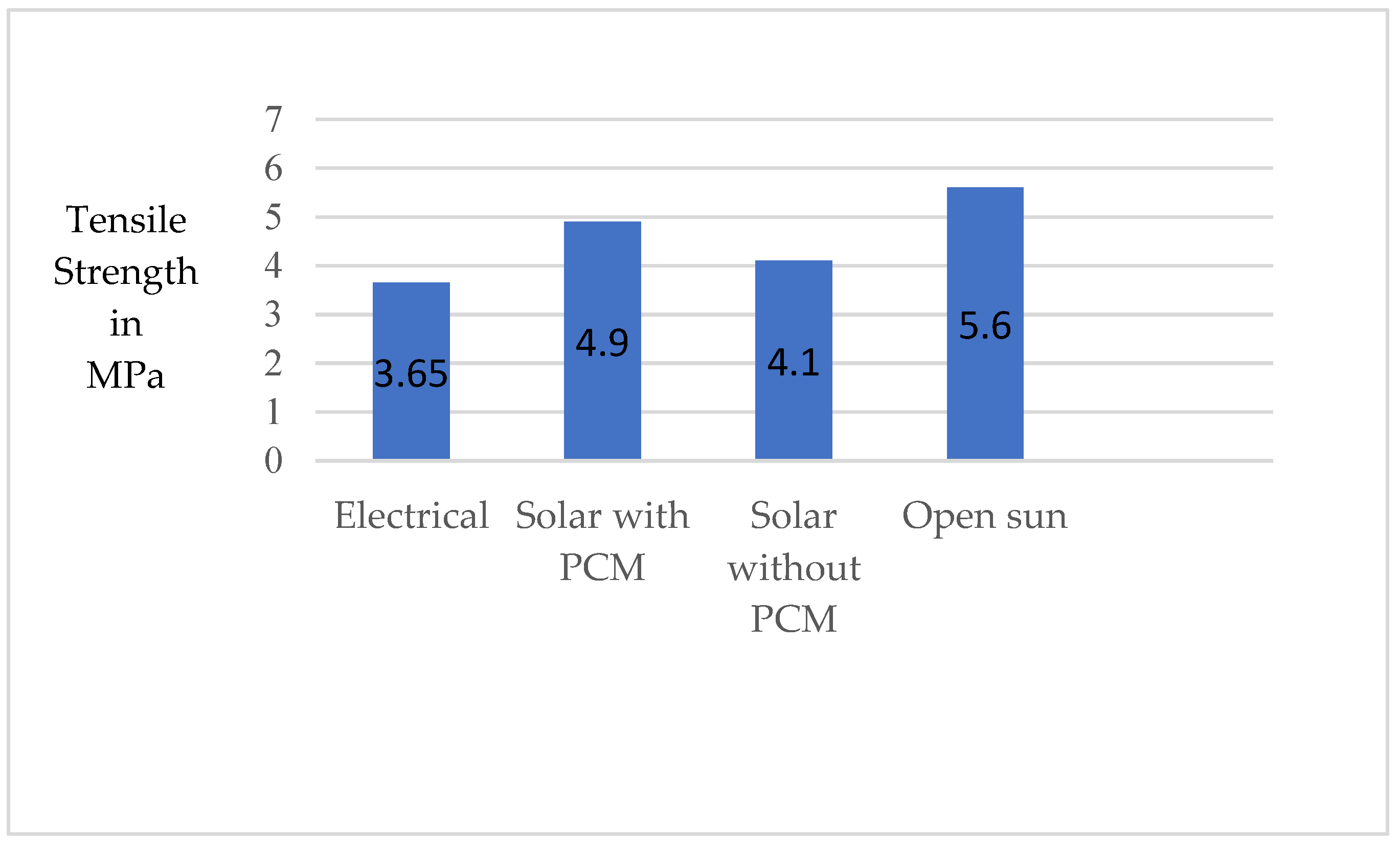

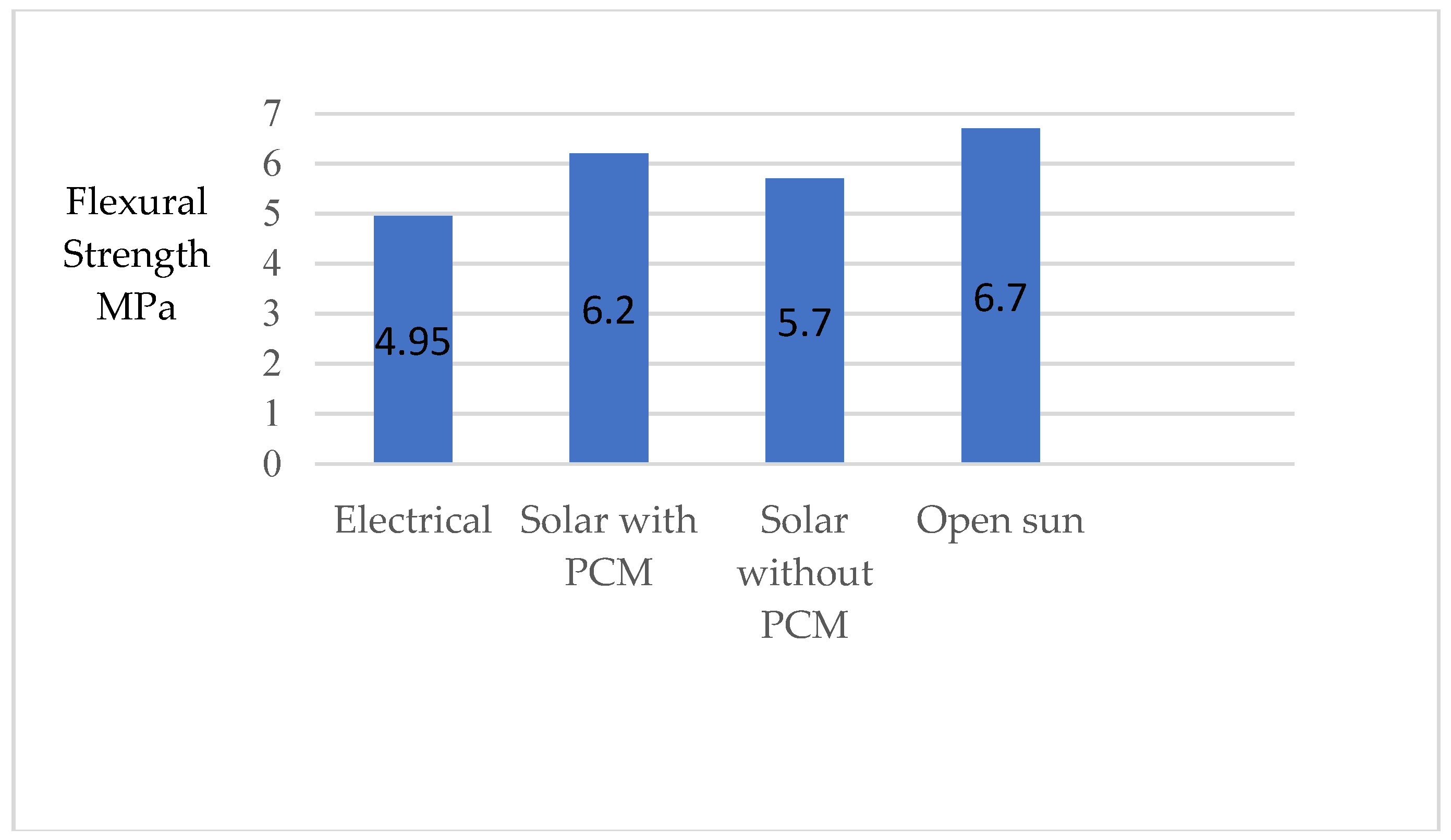

- Solar dried brick with PCM and without PCM exhibits 7.84% and 1.7% higher compressive strength, 34.2% and 12.3 % higher tensile split strength, 25.25% and 15.15% higher flexural strength when compared to electrical oven dried brick respectively.

- ➢

- Also Solar drying with PCM shows 6.1 % higher compressive strength, 19.5 % higher tensile split strength and 8.1 % higher flexural strength when compared to solar drying without PCM.

- ➢

- At the same time open sun drying shows 1.8 %, 8 %, 9.8 %, higher compressive strength, 14.3 %, 36.5 %, 53.4 % higher tensile split strength and 8.1 %, 17.5 %, 35.35 % higher flexural strength properties when compared to solar drying with PCM, solar drying without PCM and electrical drying respectively.

- ➢

- But open sun drying may cause degradation of materials of GPB which may lead to extreme dry conditions inside GPB which may not be suitable from application point of view.

- ➢

- Use of PCM like paraffin wax in solar dryer has pronounced effect on curing time and mechanical properties of GPB.

- ➢

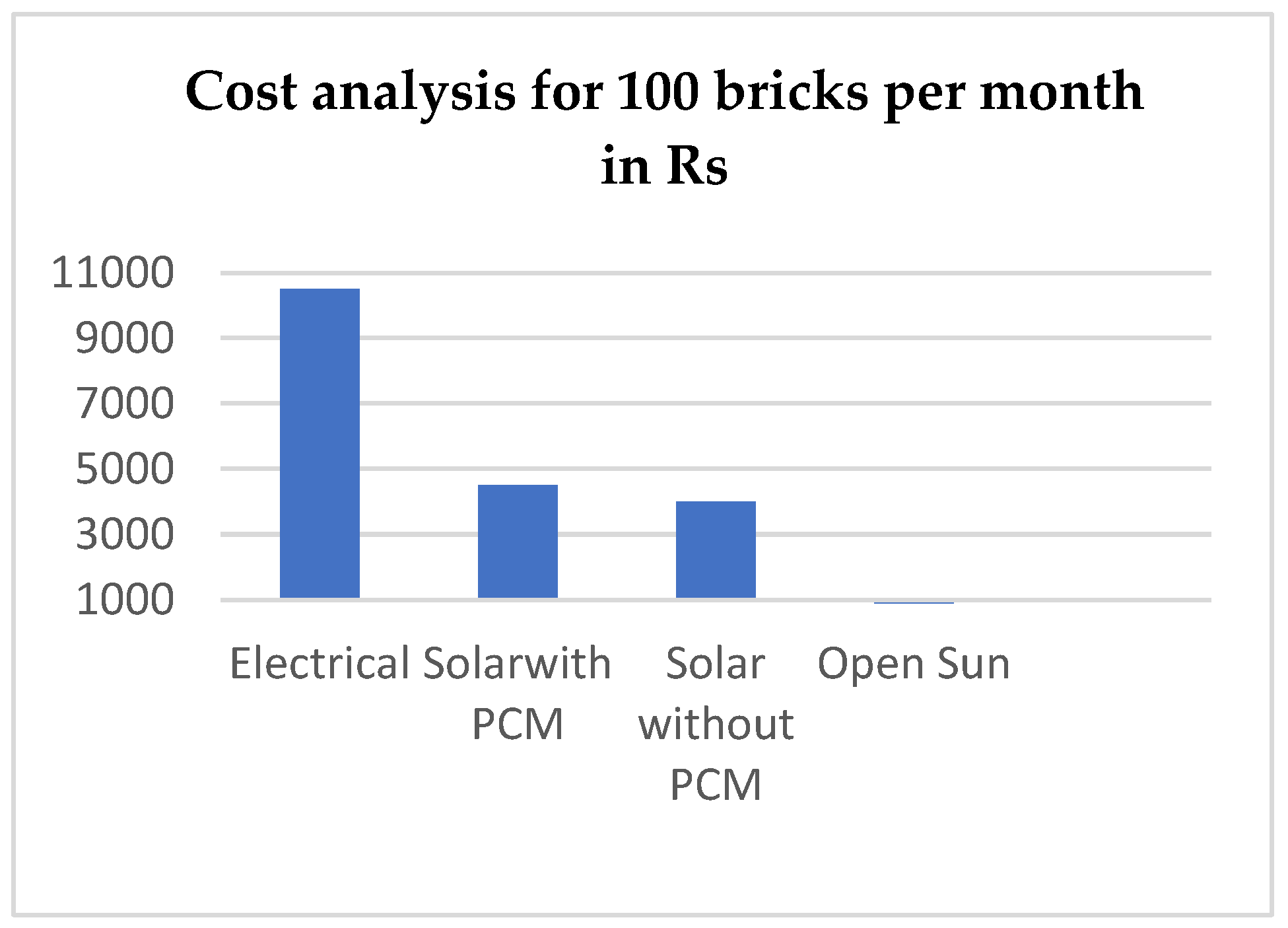

- When sustainability goals are concerned solar energy is a better performer when compared to electrical energy. From this research work we conclude that by using solar energy in drying applications we can save high grade electrical energy from energy and economy point of view.

- ➢

- GPBs are finding their application in construction sectors as their properties are in accordance with concrete design standards.

- ➢

- Newer PCMs (organic or inorganic) may be tested inside solar dryer for curing of GPB which forms the scope for future work. Along with, in what way PCMs can influence the mechanical properties of GPB can be studied. Also a thermal degradation study of PCMs is suggested as scope for future study to have an idea of entropy changes occurring inside PCMs so that the correlation between degradation and life of PCMs for solar dryer application can be established.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- G.R. Gopinath, S. Muthuvel, M. Muthukannan, R. Sudhakarapandian, B. Praveen Kumar, Ch.Santhan Kumar, Sudhakar Babu Thanikanti. Design, development, and performance testing of thermal energy storage based solar dryer system for seeded grapes. Sustainable Energy Technologies and Assessments, Volume 51, June 2022, 101923. [CrossRef]

- IS 10262 (2009) Guidelines for Concrete Mix Design, Proportioning [CED2 Cement and Concrete], Bureau of Indian Standards.

- Anuradha Ramachandran, R. Venkatasubramani, Srividya Venkataraman, B.V. Rangan. Modified guidelines for geopolymer concrete mix design using Indian standard Article in Asian Journal of Civil Engineering· January 2012. https://www.researchgate.net/publication/286998254.

- Zaineb Azaizia, Sami Kooli, Ilhem Hamdi, Wissem Elkhal, Amen Allah Guizani Experimental study of a new mixed mode solar green house drying system with and without thermal energy storage for pepper. Renewable Energy, Volume 145, January 2020, Pages 1972-1984. [CrossRef]

- Santanu Malakar, Vinkel Kumar Arora. Development of phase change material assisted evacuated tube solar dryer: Investigation of thermal profile, drying characteristics and functional properties of pumpkin slices. [CrossRef]

- Langov´a R, Jůzl M, Cwikov´a O, Kos. Effect of Different Method of Drying of Five Varieties Grapes (Vitisvinifera, L.) on the Bunch Stem on Physicochemical, Microbiological, and Sensory Quality. Foods 2020; 9(9):1183. [CrossRef]

- Nicola De Simone, Vittorio Capozzi, Maria Lucia Valeria de Chiara, Maria Luisa Amodio, Samira Brahimi, Giancarlo Colelli, Djamel Drider, Giuseppe Spanoand Pasquale Russo. Screening of Lactic Acid Bacteria for the Bio-Control of Botrytis cinerea and the Potential of Lactic plant bacillus plantarum for Eco-Friendly Preservation of Fresh-Cut Kiwifruit. Journals/Microorganisms/Volume9/Issue4/10.3390/ microorganisms 9040773. [CrossRef]

- Bharani Priya A, Dinesh kumar M, Naveen Romi J, Vijay Nepolean A, Kirubakaran V. Solar Dryer Integrated with Thermal Energy Storage Systems for the Preparation of Dry Grapes in the Farmyard. Sustainable Rural Farming Approach. Research Journal of Chemistry and Environment. Vol.24 (Special Issue I), (2020).

- Shiva Gorjian, Behnam Hosseing holilou , Laxmikant D. Jathar, Haniyeh Samadi, Samiran Samanta, Atul A. Sagade, Karunesh Kant and Ravi shankar Sathyamurthy. Recent Advancements in Technical Design and Thermal Performance Enhancement of Solar Green house Dryers. Journals/Sustainability/Volume13/Issue13/10.3390/su13137025. [CrossRef]

- Ankit Srivastava, Abhishek Anand, Amritanshu Shukla, Anil Kumar, D. Buddhi, Atul Sharma. A comprehensive overview on solar grapes drying: Modeling, energy, environmental and economic analysis. Sustainable Energy Technologies and Assessments. Volume 47, October 2021, 101513. [CrossRef]

- Edidiong Joseph EJ Bassey, JH Cheng, DW Sun. Novel non thermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables- Trends in Food Science & Technology, 2021 – Elsevier. [CrossRef]

- K Sridhar, AL Charles. Mathematical Modeling to Describe Drying Behavior of Kyoho (Vitis labruscana) Skin Waste: Drying Kinetics and Quality Attributes. Processes, 2022 - mdpi.com. [CrossRef]

- E Elavarasan,Y kumar, R Mouresh, Sendhil Kumar Nataraja. Experimental investigation of drying tomato in a double slope solar dryer under natural convection.. Advances in Mechanical and Materials Technology: Select Proceedings of EMSME 2020, 179- 190, 2022. [CrossRef]

- D Saikia, PK Nayak, KR Krishnan. Development of indirect type solar dryer and experiments for estimation of drying parameters of dhekia (Diplazium esculentum). Materials Today /proceedings. Volume 56, Part 2, 2022, Pages 774-780. [CrossRef]

- Ouassila Badaoui,Salah Hanini, Ahmed Djebli, Brahim Haddad, Amina Benhamou Experimental and modelling study of tomato pomace waste drying in a new solar greenhouse: Evaluation of new drying models. Renewable Energy, Volume 133,April 2019, Pages 144-155. [CrossRef]

- Sukhmeet Singh, R.S.Gill, V.S.Hans, T.C.Mittal. Experimental performance and economic viability of evacuated tube solar collector assisted greenhouse dryer for sustainable development. Energy Volume 241, 15 February 2022, 122794, Elsevier. [CrossRef]

- Yanying Bai, Weichao Guo, Jianwei Wang, Zehua Xu, Shuai Wang, Qingxin Zhao, Jinman Zhou. Geo polymer bricks prepared by MSWI fly ash and other solid wastes: Moulding pressure and curing method optimization. Chemosphere, Volume 307, Part 3, 2022, 135987,ISSN0045-6535. [CrossRef]

- Hao Shi, Hongwen Ma, Linan Tian, Jing Yang, Jiangyan Yuan. Effect of microwave curing on metakaolin-quartz-based geo polymer bricks, Construction and Building Materials. Volume 258, 2020,120354, ISSN 0950-0618. [CrossRef]

- Mohammed Rihan Maaze, Sandeep Shrivastava. Design development of sustainable brick-waste geo polymer brick using full factorial design methodology, Construction and Building Materials., Volume 370, 2023, 130655,ISSN 0950-0618. [CrossRef]

- Juan Pablo Capossio, María Paula Fabani, Andrés Reyes-Urrutia, Rodrigo Torres- Sciancalepore, Yimin Deng, Jan Baeyens, Rosa Rodriguez and Germán Mazz. Sustainable Solar Drying of Brewer’s Spent Grains : A Comparison with Conventional Electric Convective Drying. Process_Design_Development/Journals/Processes/Volume 10/Issue 2/10.3390/pr10020339. [CrossRef]

- Chithambar Ganesh, M. Muthukannan. Development of high performance sustainable optimized fibre reinforced geo polymer concrete and prediction of compressive strength. Journal of Cleaner Production, Volume 282, 2021, 124543, ISSN 0959-6526. [CrossRef]

- Vigneshwaran Shanmugam, Deepak Joel Johnson Rajendran, Karthik Babu, Sundarakannan Rajendran, Arumugaprabu Veerasimman, Uthayakumar Marimuthu, Sunpreet Singh, Oisik Das, Rasoul Esmaeely Neisiany, Mikael S. Hedenqvist, FilippoBerto, Seeram Ramakrishna. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing, Polymer Testing, Vol93, 2021, 106925, ISSN0142-9418. [CrossRef]

- Ammar Saliby, Béla Kovács. Minimization of annual energy consumption by incorporating phase change materials into building components: a comprehensive review, Volume 54, Issue 13, 2023, pp. 65-91. [CrossRef]

- Pranav Mehta, Nilesh Bhatt, Gurmitsingh Bassan, Abd Elnaby Kabeel. Performance improvement and advancement studies of mixed-mode solar thermal dryers: a review Environmental Science and Pollution Research 29 (42), 62822-62838, 2022. [CrossRef]

- Mall P, Singh D. Comparative study of performance of indirect mode with PCM and mixed mode solar dryer for coriander leaves. Int J Appl Eng Res 2018;13(8): 5909–19.

- Mario Palacio, Camilo Ramírez, Mauricio Carmona, Cristóbal Cortés. Effect of phase change materials in the performance of a solar air heater Solar Energy 247, 385-396, 2022. [CrossRef]

- Shanghai Huakeer Wang, Wei Lu, Zhigen Wu, Guanhua Zhang. Parametric analysis of applying PCM wallboards for energy saving in high-rise lightweight buildings Renewable Energy 145, 52-64, 2020. [CrossRef]

- Hajar Essalhi, Mohammed Benchrifa, Rachid Tadili. Effect of Natural and Forced Ventilation on Drying of Kiwi in an Indirect Solar Dryer Sustainable Energy Development and Innovation: Selected Papers from the World Renewable Energy Congress (WREC) 2020, 177-180, 2022. [CrossRef]

- López-Vidaña Erick César, César-Munguía Ana Lilia, García-Valladares Octavio, Pilatowsky Figueroa Isaac, Brito Orosco Rogelio. Thermal performance of a passive, mixed-type solar dryer for tomato slices (Solanum lycopersicum) Renewable Energy 147, 845-855, 2020. [CrossRef]

- Atalay H, Coban MT, Kıncay O. Modeling of the drying process of apple slices: Application with a solar dryer and the thermal energy storagesystem. Energy 2017; 134:382–91. [CrossRef]

| PCM | Melting Temperature (℃) | Density (kg/m3 ) |

Specific Heat (J/kg.K) | Thermal Conductivity (W/m.K) |

Latent Heat of Fusion (kJ/kg) | |||

|---|---|---|---|---|---|---|---|---|

| Solid | Liquid | Solid | Liquid | Solid | Liquid | |||

| Paraffin Wax | 58 | 910 | 810 | 2000 | 2100 | 0.228 | 0.25 | 204 |

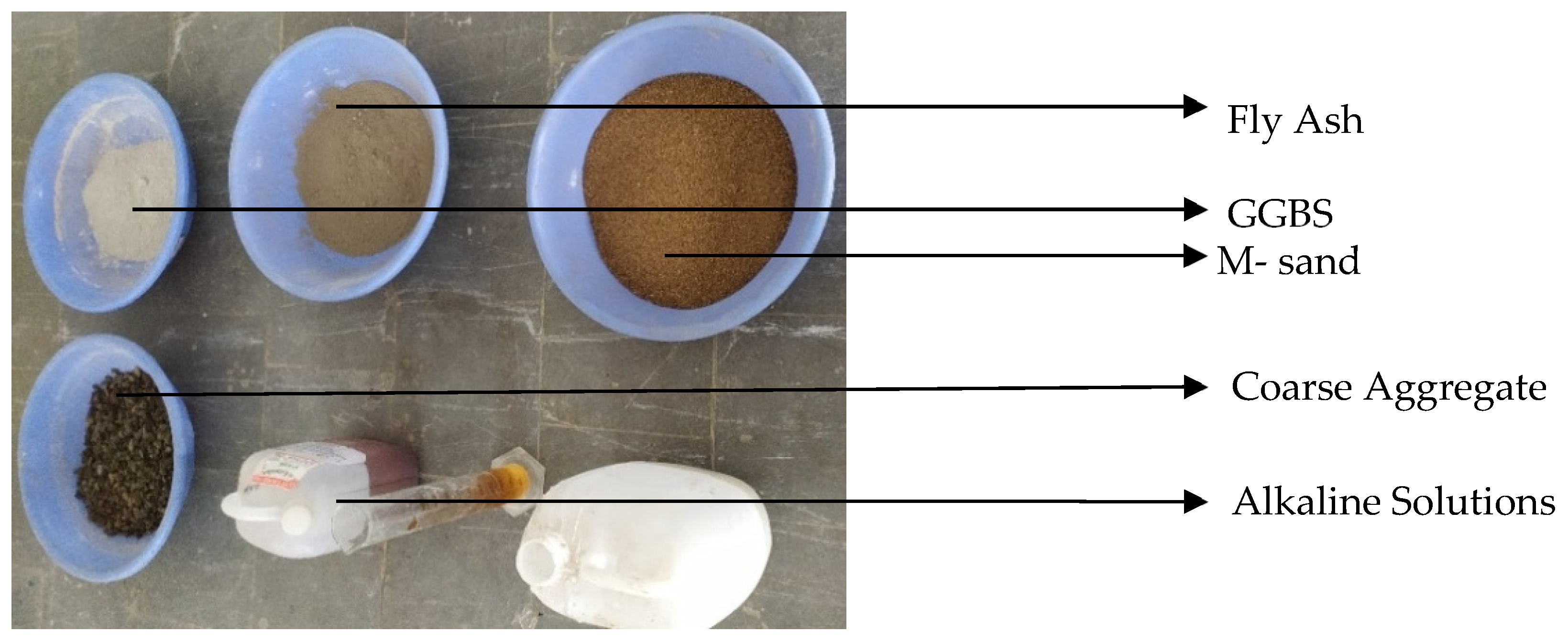

| Materials | Weight in kg/m3 |

|---|---|

| Fly ash | 385 |

| GGBS – Ground Granulated Blast furnace Slag | 165 |

| M sand | 579.64 |

| Coarse Aggregate 20mm | 864.12 |

| AAS Alkaline Activated solution | 335.5 |

| SSS sodium silicate solution Na2SiO3 | 239.64 |

| NaOH | 95.86 |

| NaOH Molarity | 12 |

| Alkaline /binder ratio | 0.61 |

| Drying Methods |

Compressive Strength (MPa) | Tensile Split Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|---|

| Electrical dryer | 35.70 | 3.65 | 4.95 |

| Solar dryer with PCM | 38.50 | 4.90 | 6.20 |

| Solar dryer without PCM | 36.30 | 4.10 | 5.70 |

| Open sun dryer | 39.20 | 5.60 | 6.70 |

| Sustainability Development Goals | Description |

|---|---|

| SDG 7 | Clean and affordable Energy – Usage of Solar energy |

| SDG 8 | Economic Growth – Cheaper than Electric energy |

| SDG 13 | Climate action and its impact –Free from fossil fuels and emissions |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).