Submitted:

23 October 2023

Posted:

25 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

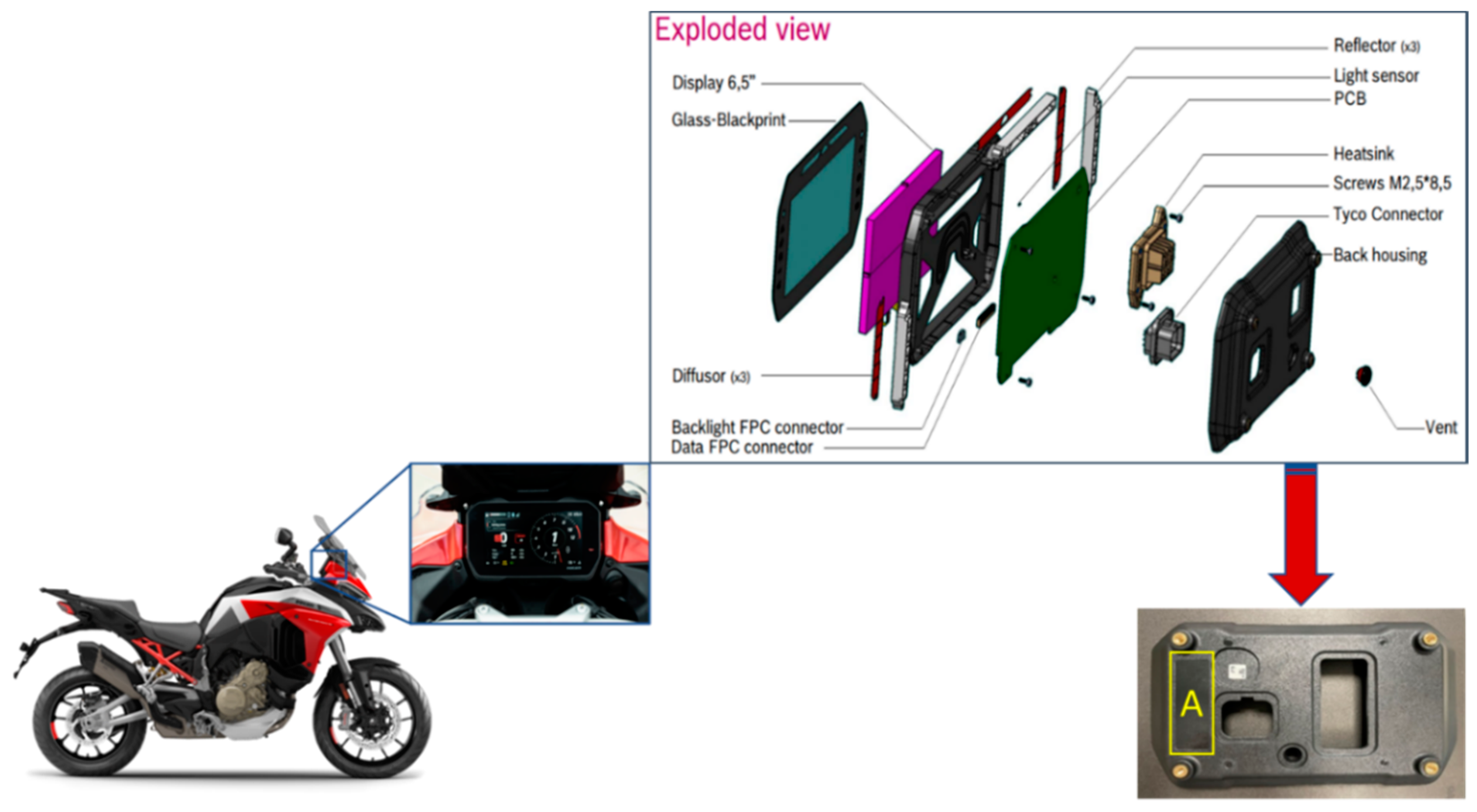

2.1. Material

2.2. Sample Analyses and Preparation before the Laser Marking Process

2.3. Laser Marking Equipment and Parameters

2.4. Quality Assurance of Laser-Marked Codes

2.5. Code Surface Analyses by SEM

3. Results and Discussion

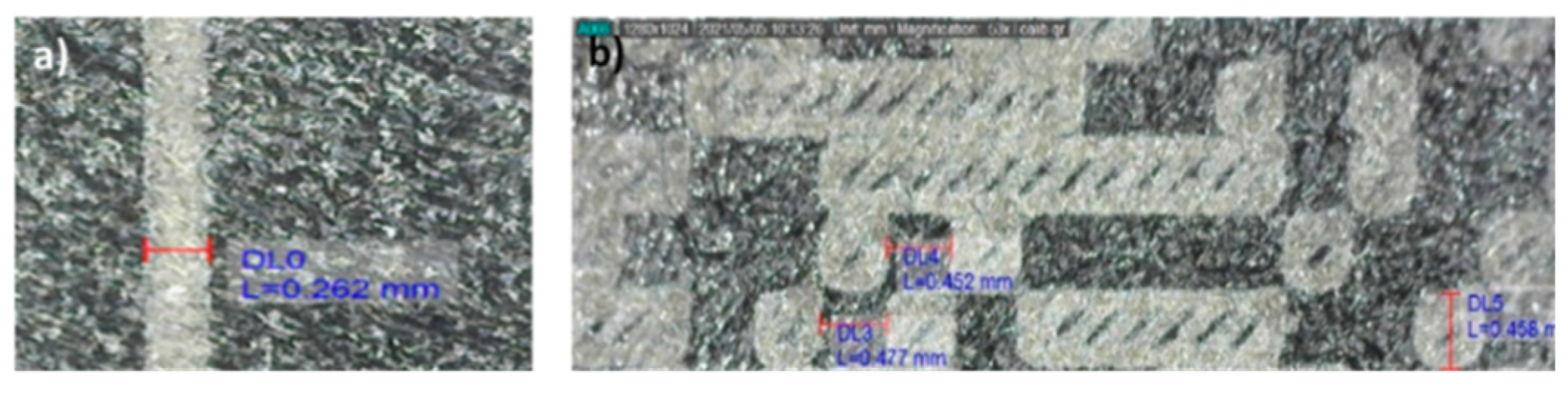

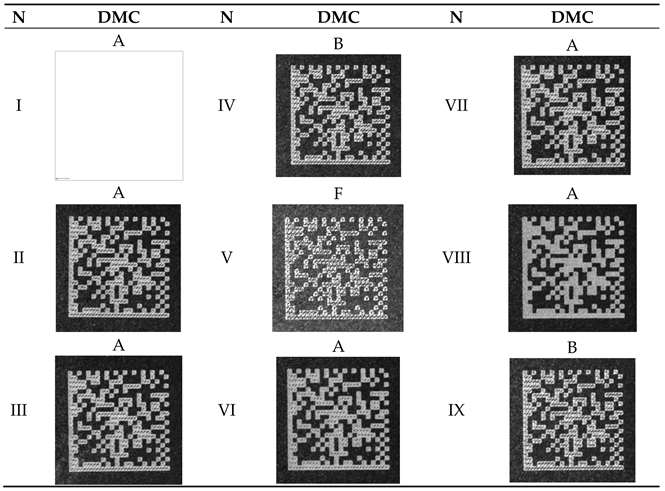

3.1. Quality Analysis of the Codes

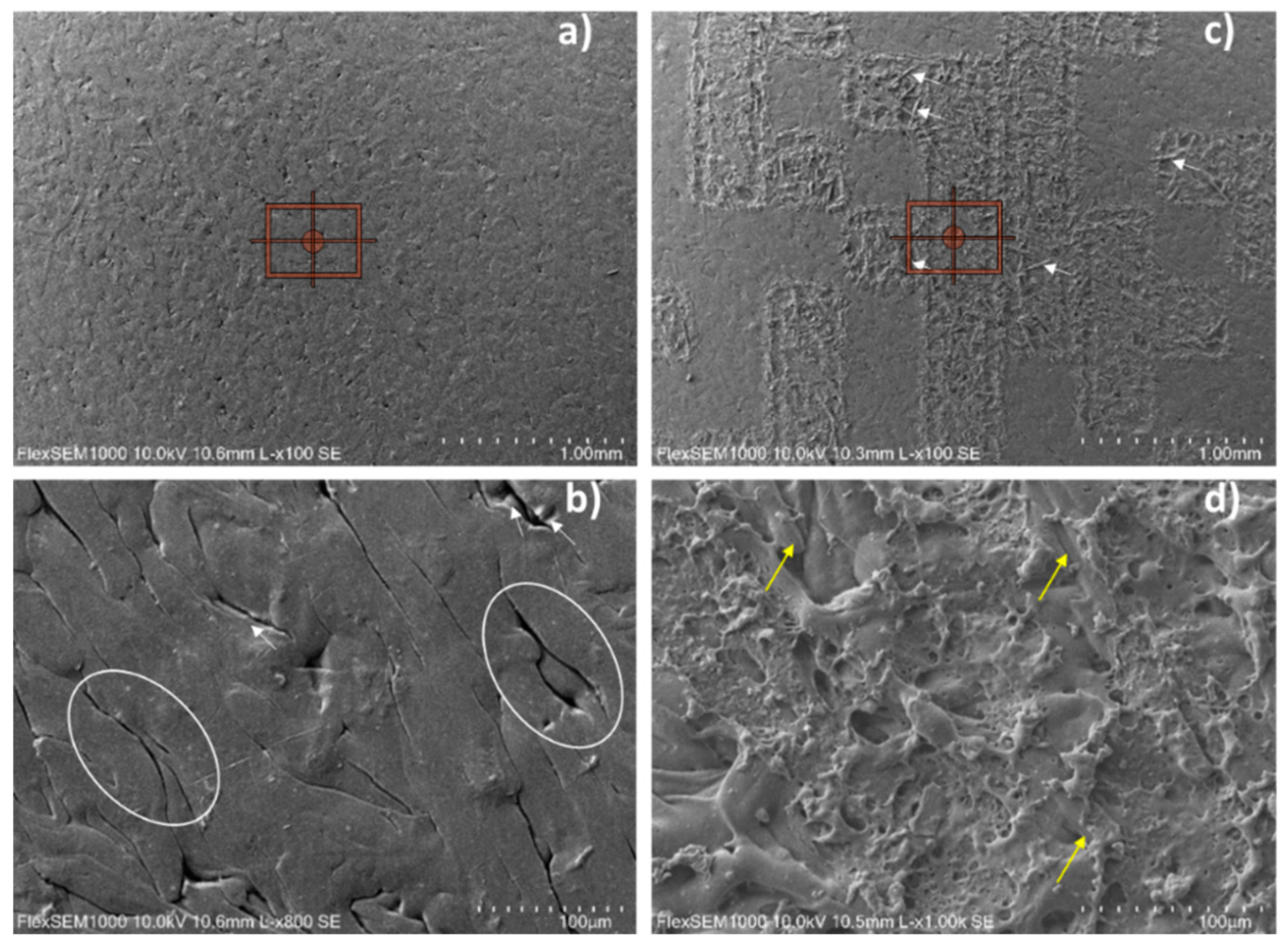

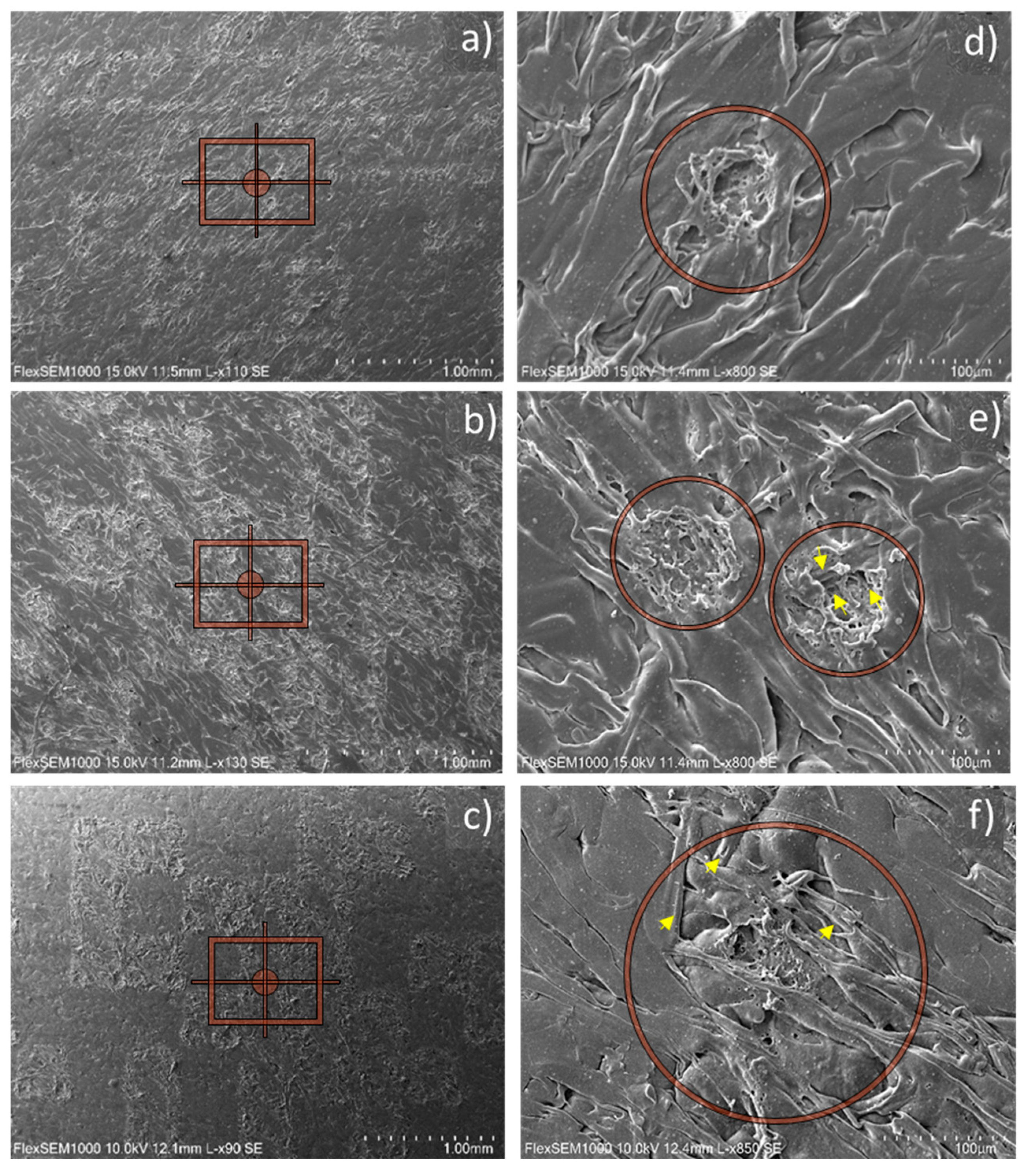

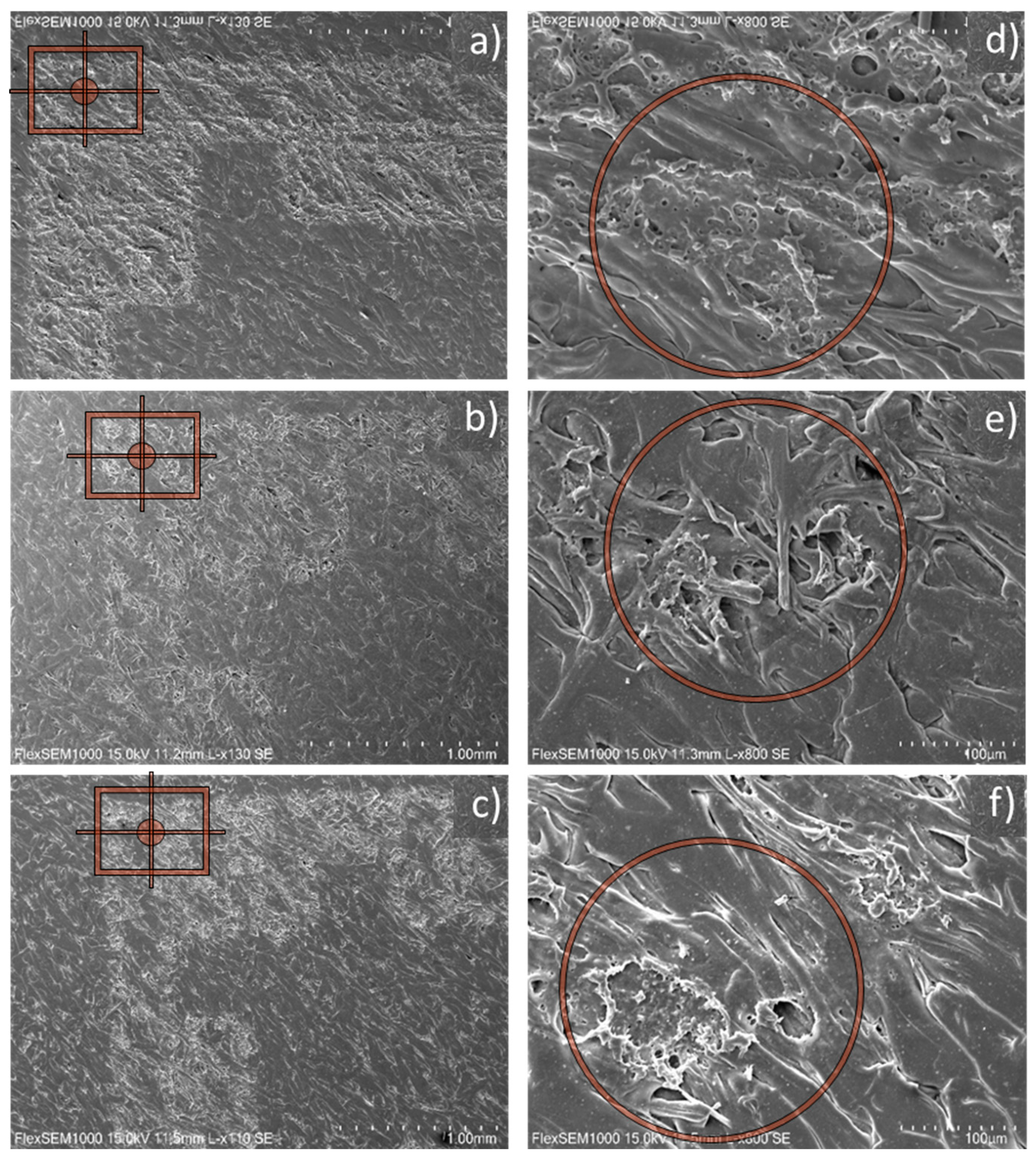

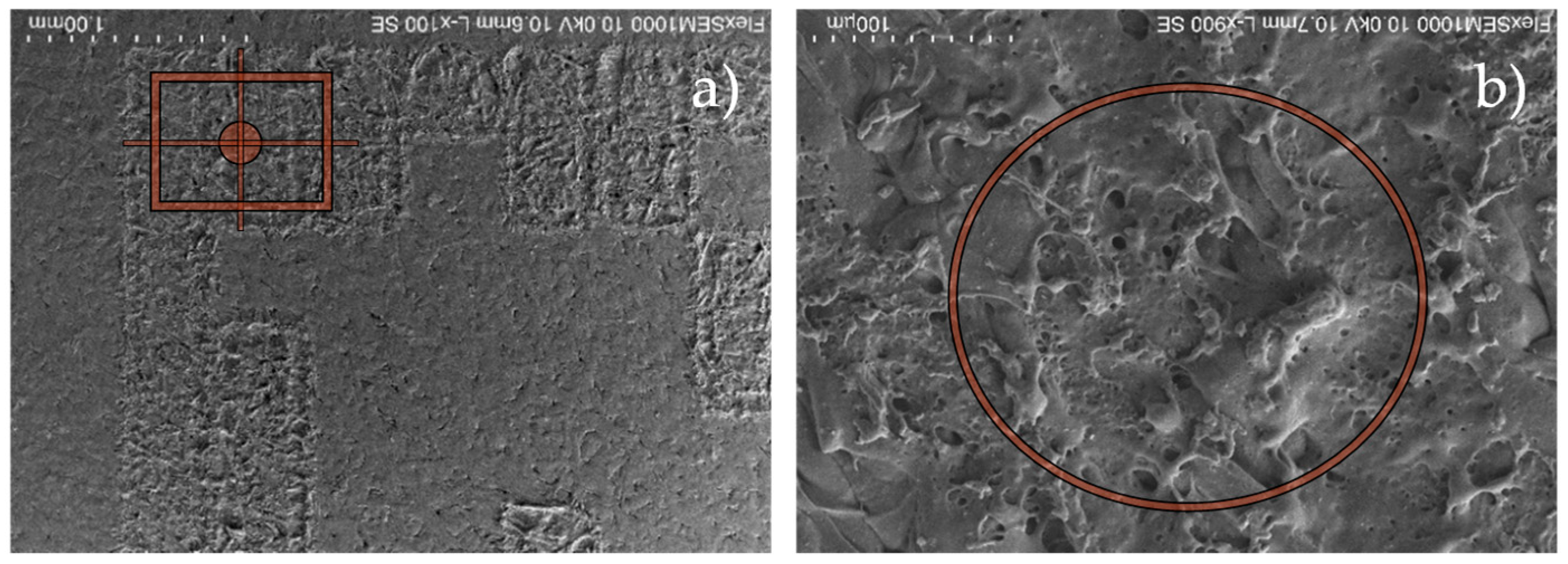

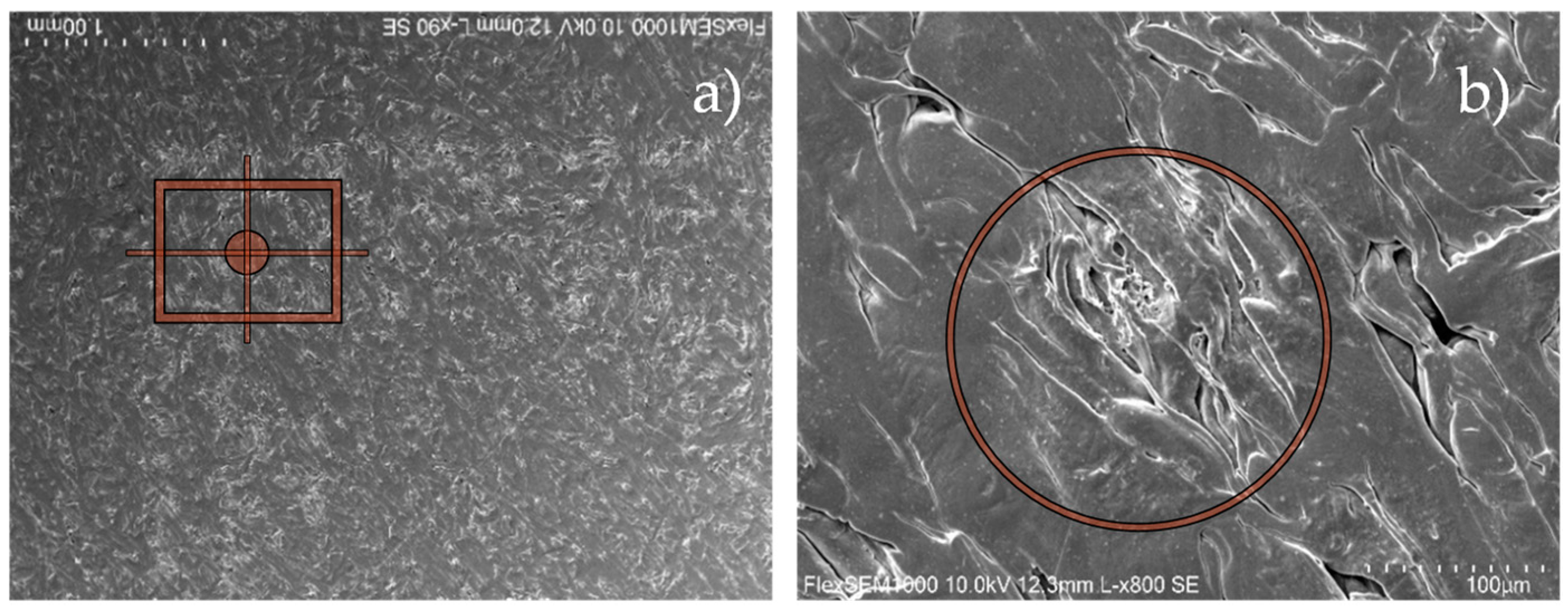

3.2. Analysis of the marked surface on samples

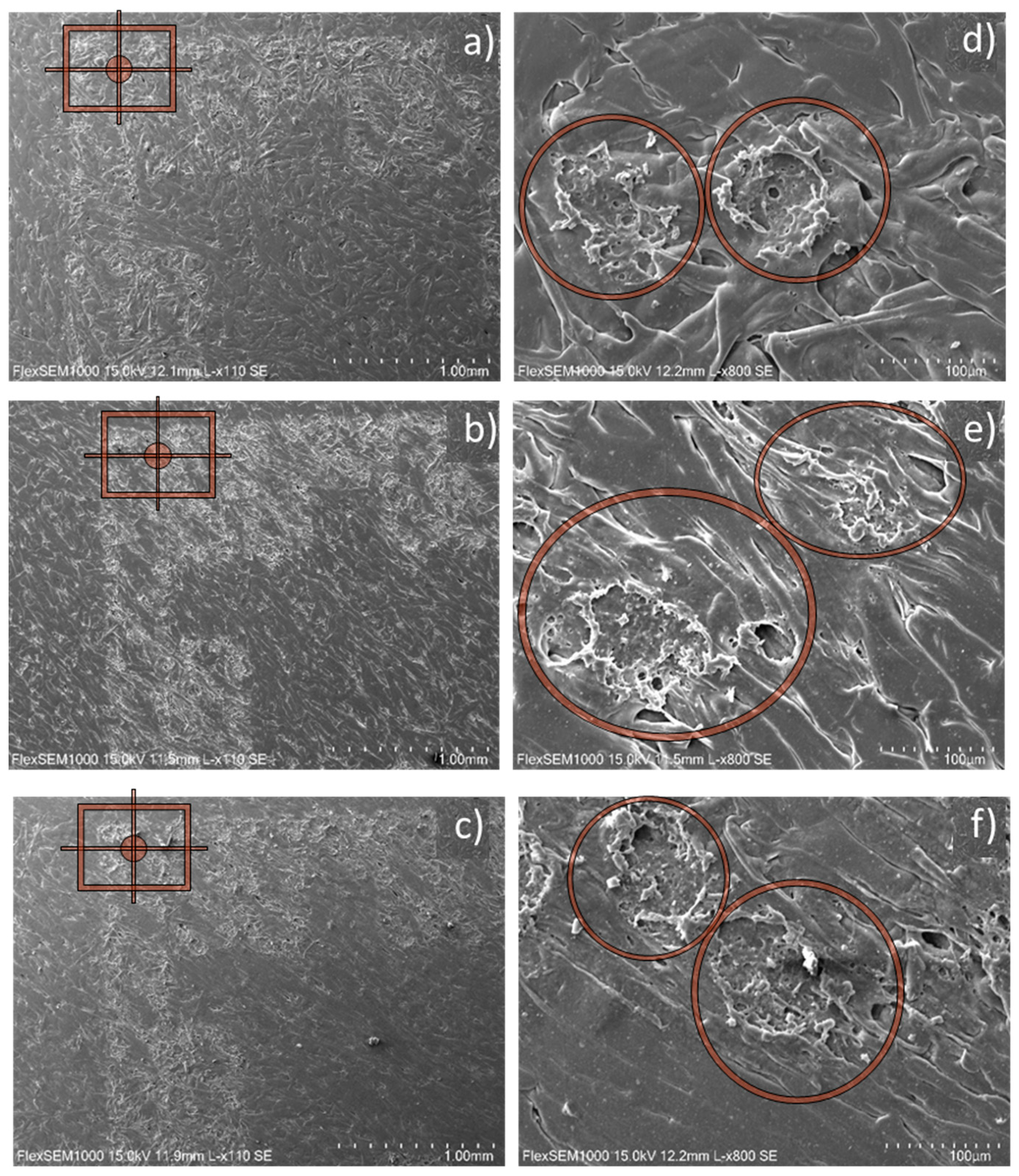

3.3. Effect of Different Values of Radiation Power

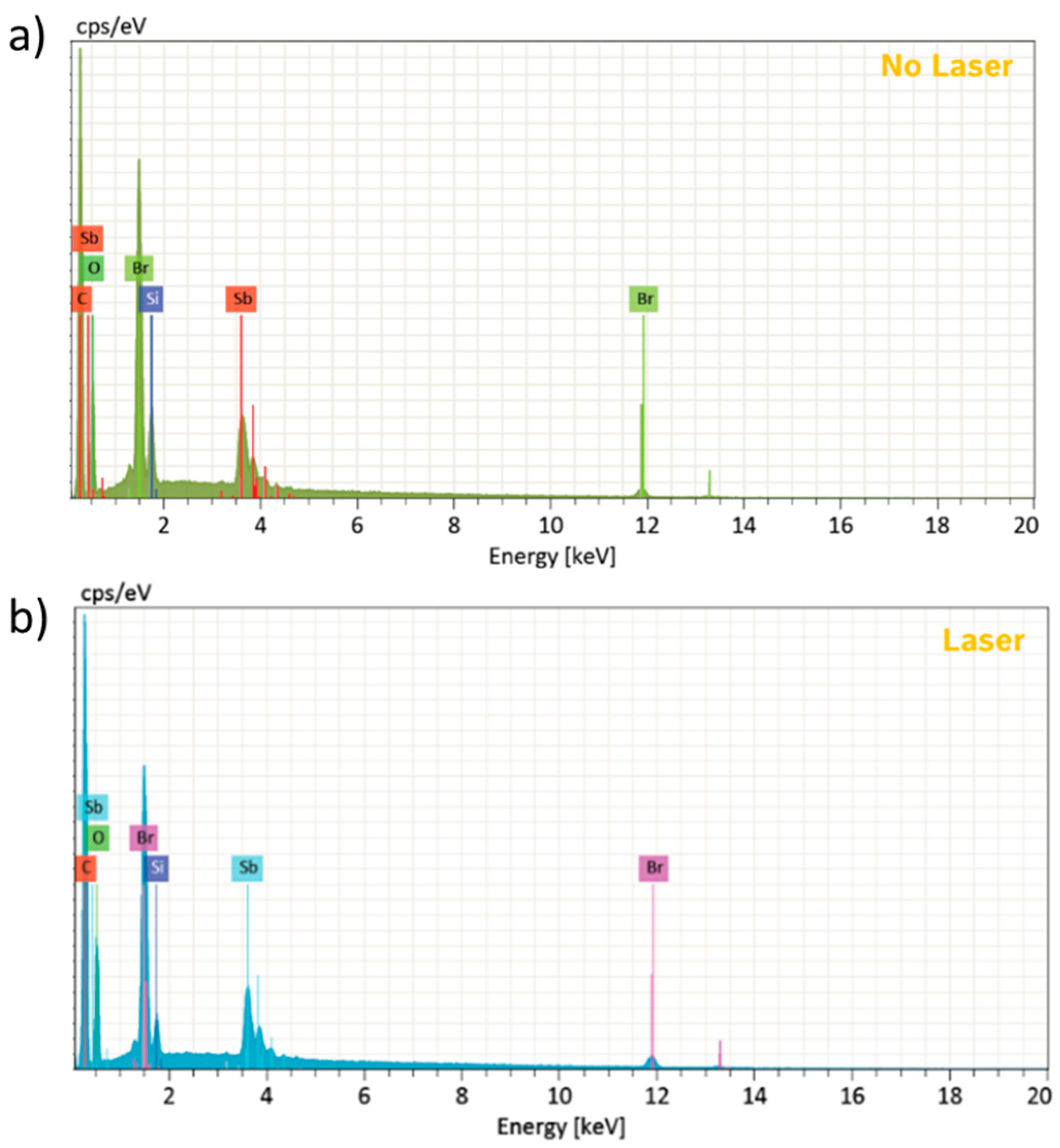

3.4. Analysis of Chemical Properties after the Laser Marking Process

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marin-Garcia, J.A., Pardo del Val, M. and Bonavía Martín, T. Longitudinal study of the results of continuous improvement in an industrial company, Team Perform. Manag. 2008;14, 1-2, 56-69. [CrossRef]

- Grütter, A. W., Field, J. M., Faull, N. H. B., Work team performance over time: Three case studies of South African manufacturers, J. Oper. Manag., 2002; 20:5:641–657, . [CrossRef]

- Bosch, Manual BPS. Publicação Interna, 2021.

- Barad, M. Design of Experiments (DoE)—A Valuable Multi-Purpose Methodology, Appl. Math. 2014; 5: 14: 2120–2129. [CrossRef]

- Loh, S.H., The, P.C., Sim, J.J., Tai, C.K., Yeap, K.H., Lee, Y.J, Mazlan, A.U. Decoding Dot Peen Data Matrix Code with Deep Learning Capability for Product Traceability. Appl. of Model. and Simul. 2023; 7: 38-48. Available at: http://arqiipubl.com/ojs/index.php/AMS_Journal/article/view/385.

- Li, C., Lu, C., Li, J., Research on the quality of laser marked Data Matrix symbols, Key Eng. Mater. 2018; 764: 1: 219–224. [CrossRef]

- Sobotova, L., Demec, P. Laser marking of metal materials. MM Sci. J. 2015; 808-812. [CrossRef]

- Javale V., Nair, V. A Review on Laser marking by Nd-Yag Laser and Fiber Laser, Int. J. Sci. Res. Dev. 2013; 1: 9: 95–97.

- TROTEC, A comprehensive guide to industrial laser applications, Handbook to Industrial Laser Applications, 2019. Available at: https://www.troteclaser.com/static/images/News/EN_US/2016-11-Industrial-application-guide/Industrial_Application_guide.pdf. Accessed on April 15th, 2022.

- Qi J., Wang K., Zhu Y., A study on the laser marking process of stainless steel, J. Mater. Process. Technol. 2003; 139: 1–3: 273–276. [CrossRef]

- Jangsombatsiri, W., Porter, J. D. Laser direct-part marking of data matrix symbols on carbon steel substrates, J. Manuf. Sci. Eng. Trans. ASME 2007; 129: 3: 583–591. [CrossRef]

- Zelenska, K.S., Zelensky, S.E., Poperenko, L.V., Kanev, K., Mizeikis, V., Gnatyuk, V.A., Thermal mechanisms of laser marking in transparent polymers with light-absorbing microparticles, Optics & Laser Techn. 2016; 76: 96-100. [CrossRef]

- Czyzewski, P.; Sykutera, D.; Rojewski, M. The Impact of Selected Laser-Marking Parameters and Surface Conditions on White Polypropylene Moldings. Polym. 2022; 14: 1879. [CrossRef]

- Lu, G., Wu, Y., Zhang, Y., Wang, K, Gao, H., Luo, K., Cao, Z., Cheng, J., Liu, C., Zhang, L., Qi, J., Surface Laser-Marking and Mechanical Properties of Acrylonitrile- Butadiene-Styrene Copolymer Composites with Organically Modified Montmorillonite, ACS Omega 2020; 5: 19255−19267. [CrossRef]

- Narica, P., Fedotovs J., Marking of a Small Sized QR Code on a Plastic Surface, 19th International Conference on Reliability and Statistics in Transportation and Communication, RelStat’19, 2019; pp. 16–19, Riga, Latvia Springer. https://link.springer.com/chapter/10.1007/978-3-030-44610-9_41.

- Li, W.H., Preparation of laser markable polyamide compounds, 2nd International Conference on Graphene and Novel Nanomaterials (GNN), J. of Phys: Conference Series, IOP Publishing, 2021; 012003. [CrossRef]

- Chen, M. F., Hsiao, W. T., Huang, W. L., Hu, C. W., Y. P. Chen, Laser coding on the eggshell using pulsed-laser marking system, J. Mater. Process. Technol. 2009; 209:2: 737–744. [CrossRef]

- Cheng, J., Zhou, J., Zhang, C., Cao, Z., Wu, D., Liu, C., Zou, H. . Enhanced laser marking of polypropylene induced by “core-shell” ATO@PI laser-sensitive composite, Polym. Degrad. and Stab. 2019; 167: 77e85.

- Yang, J., Xiang, M., Zhu, Y. et al. Influences of carbon nanotubes/polycarbonate composite on enhanced local laser marking properties of polypropylene. Polym. Bull. 2023; 80:1321–1333 (2023). [CrossRef]

- Zhong, W., Cao, Z., Qiu, P., Wu, D., Liu, C., Li, H., Zhu, H., Laser-Marking Mechanism of Thermoplastic Polyurethane/Bi2O3 Composites. ACS Appl. Mater. Interf. 2015: 7: 24142−24149. [CrossRef]

- Cao, Z., Hu, Y., Lu, U., Xiong, Y., Zhou, A., Zhang, C., Wu, D., Liu, C., Laser-induced blackening on surfaces of thermoplastic polyurethane/ BiOCl composites, Polym. Degrad. and Stab. 2017; 141: 33-40. [CrossRef]

- Ng, T.W., Yeo, S.C., Aesthetic laser marking assessment, Optics & Laser Techn. 2000; 32: 187-191. [CrossRef]

- Ng, T.W., Yeo, S.C., Aesthetic laser marking assessment using luminance ratios, Optics and Lasers in Eng., 2001; 35: 177-186. [CrossRef]

- Li, W.H., Preparation of laser markable polyamide compounds, 2nd International Conference on Graphene and Novel Nanomaterials (GNN), J. of Phys: Conference Series, IOP Publishing, 2021; 012003. [CrossRef]

- Arai, S., Tsunoda, S., Yamaguchi, A., Ougizawa, T. Effect of anisotropy in the build direction and laser-scanning conditions on characterization of short-glass-fiber-reinforced PBT for laser sintering. Opt. and Laser Techn. 2019; 113: 345–356. [CrossRef]

- Greiner, S., Wudy, K., Lanzl, L., Drummer, D. Selective laser sintering of polymer blends: Bulk properties and process behaviour. Polym, Test. 2017; 64: 136–144. [CrossRef]

- Silva, L.R.R., Marques, E.A.S., Carbas, R.J.C., Akhavan-Safar, A., da Silva, L.F.M. Study of the optical, thermal, morphological and mechanical characteristics of a laser weldable fibre reinforced polymer, Polym. Compos. 2002; 43: 4038–4055, . [CrossRef]

- Ng, T.W., Yeo, S.C., Aesthetic laser marking assessment using spectrophotometers, J. of Mat. Proc. Techn. 2000; 104: 280-283. [CrossRef]

- BASF. Product Data Sheet Ultradur® B 4406 G6 05/2023 PBT-GF30 FR(17). Available at: https://download.basf.com/p1/8a8081c57fd4b609017fd64d909d71c4/en/ULTRADUR%3Csup%3E%C2%AE%3Csup%3E_B4406_G6_Product_Data_Sheet_Asia_PacificEurope_English.pdf Accessed on: July 29th, 2023.

- ISO/IEC 29158, Information technology - Automatic identification and data capture techniques - Direct Part Mark (DPM) Quality Guideline. 2020.

- Bociga, E., Jaruga, T. Experimental investigation of polymer flow in injection mould. Arch. of Mater. Sci. and Eng. 2007; 28: 3: 165-172.

- Wang G., Zhao G., Wang X., Effects of cavity surface temperature on reinforced plastic part surface appearance in rapid heat cycle moulding, Mater. Des. 2013; 44: 509–520. [CrossRef]

- Gim, J., Turng, L.S. A review of current advancements in high surface quality injection moulding: Measurement, influencing factors, prediction, and control, Polym. Test. 2022; 115: 107718. [CrossRef]

- Mercan, S.U.M., Uzun, L. Serial number restoration on polymer surfaces: A survey of recent literature, Forensic Chem. 2020; 20: 100267. [CrossRef]

- Katterwe H., The recovery of erased numbers in polymers, J. Forensıc Sci. 1994; 34: 1: 11-16. [CrossRef]

- Young R.J., Lovell P.A., Introduction to Polymers, CRC Press, 2011.

- Aly A.A., Heat treatment of polymers: a review, Int. J. Mater. Chem. Phys. 2015; 1: 2: 132–140. https://api.semanticscholar.org/CorpusID:53342231.

- Pieretti, E.F., Costa, I. Surface characterisation of ASTM F139 stainless steel marked by laser and mechanical techniques. Electrochimica Acta 2013; 114: 838-843. [CrossRef]

- Lu, G., Wu, Y., Zhang, Y., Wang, K., Gao, H., Luo, K., Cao, Z., Cheng, J., Liu, C., Zhang, L., Juan Q. Surface Laser-Marking and Mechanical Properties of Acrylonitrile Butadiene-Styrene Copolymer Composites with Organically Modified Montmorillonite. ACS Omega, 2020; 5: 19255−19267. [CrossRef]

- Man H.C., Li M., Yue T.M., Surface treatment of thermoplastic composites with an excimer laser, Int. J. of Adhes. and Adhesiv. 1998; 18: 3: 151-157, ISSN 0143-7496. [CrossRef]

- Cao, Z., Hu, Y., Yu, Q., Lu, Y., Wu, D., Zhou, A., Ma, W., Xia, Y., Liu, C. and Loos, K., Facile Fabrication, Structures, and Properties of Laser-Marked Polyacrylamide/Bi2O3 Hydrogels. Adv. Eng. Mater. 2017; 19: 1600826. [CrossRef]

- Obilor, A.F., Pacella, M., Wilson, A. et al. Micro-texturing of polymer surfaces using lasers: a review. Int J Adv Manuf Technol. 2022; 120: 103–135. [CrossRef]

- Margolis, J.M. Engineering Plastic Handbook, p. 463, McGraw-Hill, New York, 2006. [CrossRef]

- Cheng J., Li H., Zhou J., Cao, Z., Wu, D., Liu, C. Influences of diantimony trioxide on laser-marking properties of thermoplastic polyurethane. Polym. Degrad. and Stab. 2018; 154: 149-156. [CrossRef]

| Sample | Radiation Power (W) | Pulse Frequency (kHz) | Marking Speed (mm/s) | Pass overlap (%) |

|---|---|---|---|---|

| I | 15 | 25 | 2000 | 15 |

| II | 19 | 25 | 2000 | 15 |

| III | 17 | 30 | 2000 | 15 |

| IV | 17 | 25 | 3000 | 15 |

| V | 15 | 15 | 3000 | 0 |

| VI | 17 | 25 | 1000 | 15 |

| VII | 17 | 25 | 2000 | 15 |

| VIII | 19 | 30 | 1000 | 30 |

| IX | 17 | 15 | 2000 | 15 |

| Factor | Name | Level | Level values | ||

|---|---|---|---|---|---|

| A | Radiation Power (W) | 3 | Pi | Pn | Ps |

| 15 | 17 | 19 | |||

| B | Pulse Frequency (kHz) | 3 | Fi | Fn | Fs |

| 15 | 25 | 30 | |||

| C | Marking Speed (mm/s) | 3 | Vi | Vn | Vs |

| 1000 | 2000 | 3000 | |||

| D | Pass overlap (%) | 3 | Si | Sn | Ss |

| 0 | 15 | 30 | |||

| Factor | Name | Level | Level values | ||

|---|---|---|---|---|---|

| A | Radiation Power (W) | 3 | Pi | Pn | Ps |

| 15 | 17 | 19 | |||

| B | Pulse Frequency (kHz) | 3 | Fi | Fn | Fs |

| 15 | 25 | 30 | |||

| C | Marking Speed (mm/s) | 3 | Vi | Vn | Vs |

| 1000 | 2000 | 3000 | |||

| D | Pass overlap (%) | 3 | Si | Sn | Ss |

| 0 | 15 | 30 | |||

| Sample | Radiation Power (W) | Pulse Frequency (kHz) | Marking Speed (mm/s) | Pass overlap (%) |

|---|---|---|---|---|

| I | 15 | 25 | 2000 | 15 |

| II | 19 | 25 | 2000 | 15 |

| III | 17 | 30 | 2000 | 15 |

| IV | 17 | 25 | 3000 | 15 |

| V | 15 | 15 | 3000 | 0 |

| VI | 17 | 25 | 1000 | 15 |

| VII | 17 | 25 | 2000 | 15 |

| VIII | 19 | 30 | 1000 | 30 |

| IX | 17 | 15 | 2000 | 15 |

| Sample Area | Normalised mass concentration [%] | ||||

|---|---|---|---|---|---|

| Area without laser marking | C | O | Si | Br | Sb |

| 59.53 | 21.08 | 1.59 | 10.68 | 7.12 | |

| Area with laser marking | C | O | Si | Br | Sb |

| 59.32 | 21.15 | 0.89 | 11.38 | 7.26 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).