1. Introduction

High-precision optical components, as the core components of optical systems, are widely used in consumer electronics, astronomy, national defence and military, biomedical, industrial manufacturing and other fields[

1,

2,

3]. The functional realization of an optical imaging system relies on lens design, which requires the optical axis of each optical component or lens to coincide with the ideal axial direction. However, the centre deviation introduced during lens machining and assembly can destroy the coaxial and rotational symmetry of the system, leading to coma, dispersion, aberration, and other aberrations, which seriously affect the final imaging quality of the optical system. Compared with the traditional manual assembly method, centring turning while machining has higher centring accuracy and machining efficiency[

4], so it has attracted much attention. However, centring lathe components will be ageing during the machining process, so considering the time-varying nature of the equipment and accurately monitoring the status of key components, including tools, spindles, feed systems, etc. is the key to ensuring the machining quality and efficiency[

5,

6].

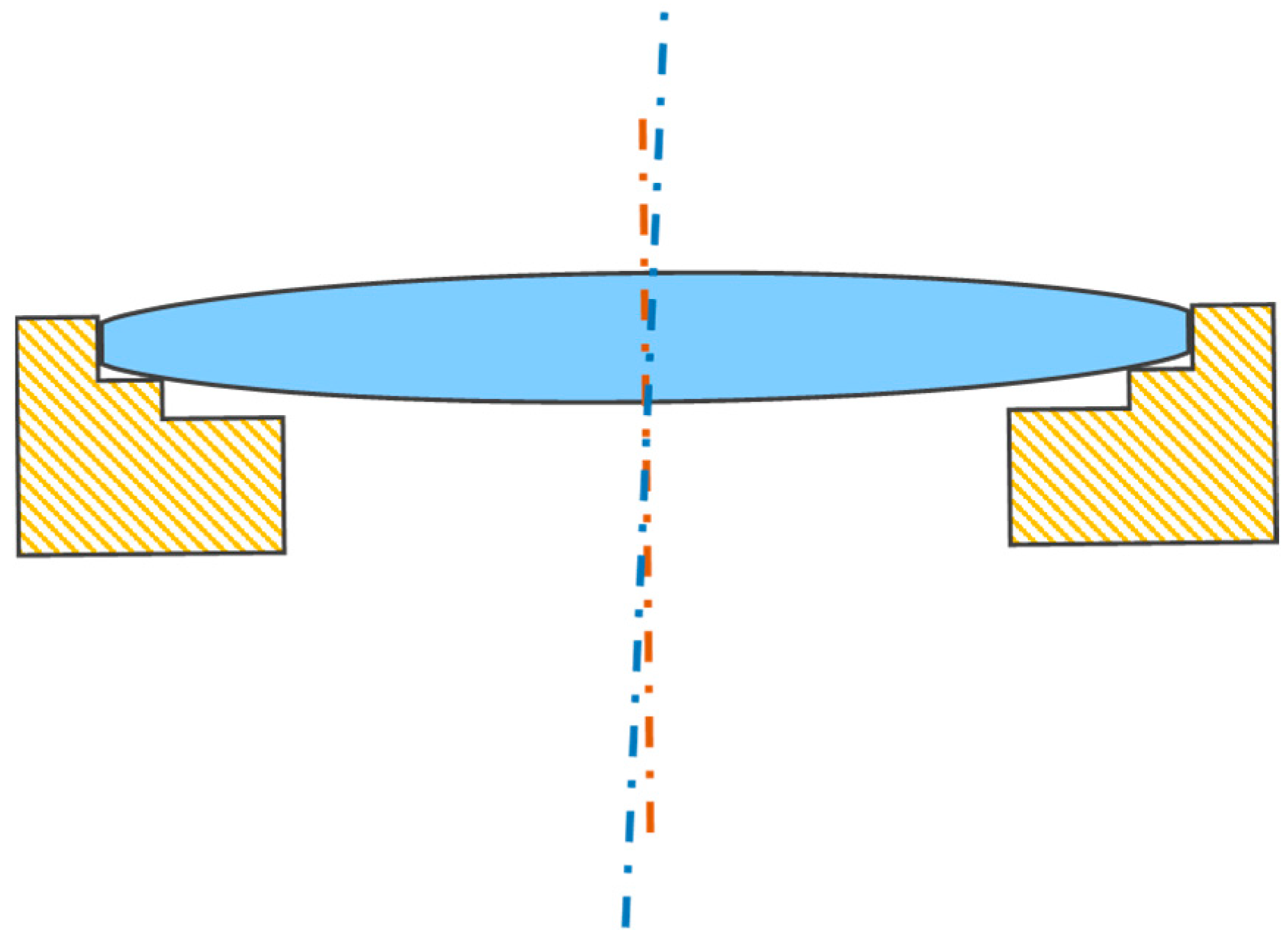

Figure 1.

The diagram of centre error.

Figure 1.

The diagram of centre error.

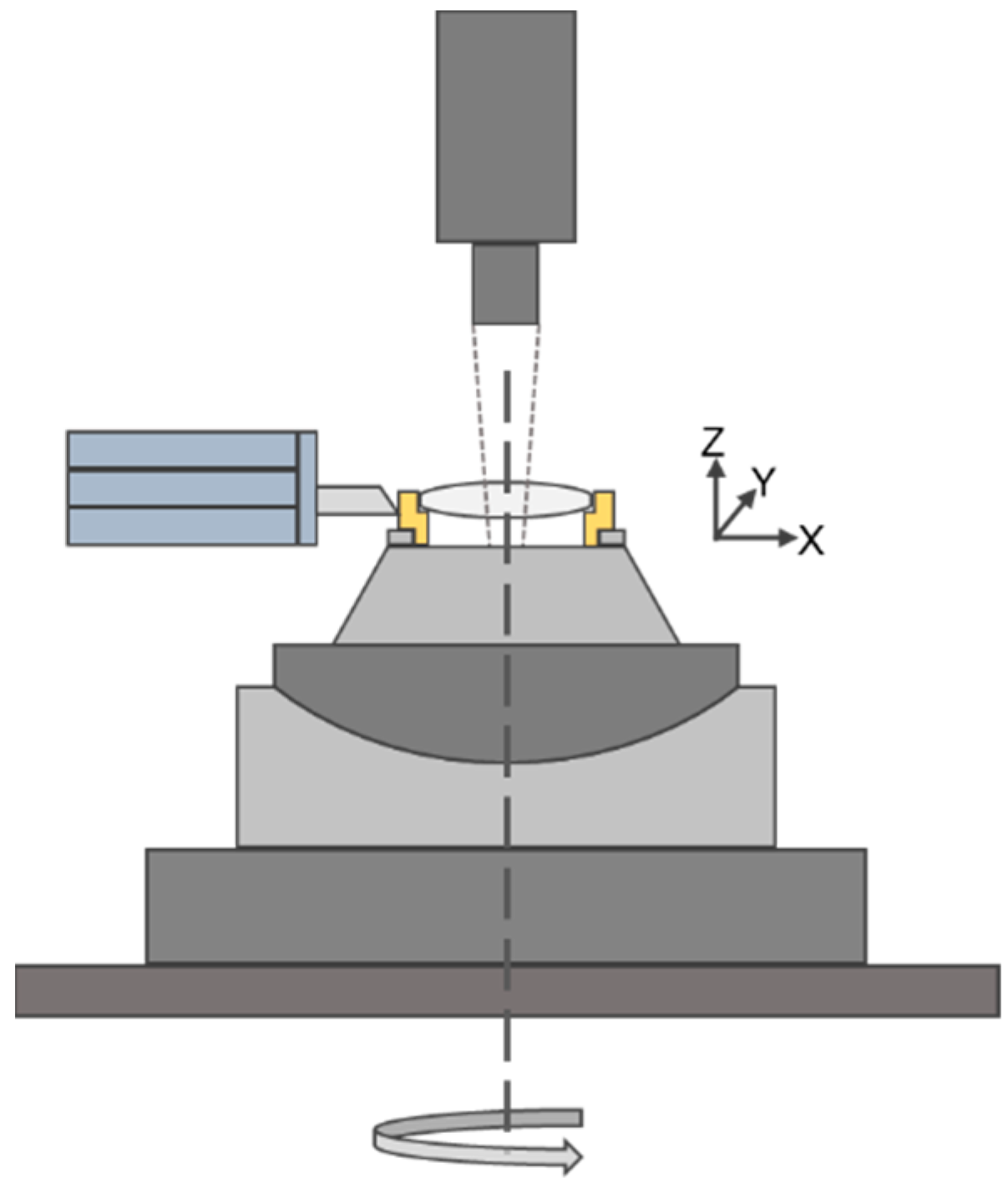

Figure 2.

The diagram of the centre process.

Figure 2.

The diagram of the centre process.

As the key enabling technology of intelligent manufacturing, digital twin technology promotes great changes in manufacturing technology systems and manufacturing modes[

7,

8,

9,

10]. In recent years, the related theoretical system has been improved, and the key technology of digital twin has been developed gradually[

11,

12,

13,

14]; digital twin has been successfully applied in the field of digital machining of complex equipment. Plakhotnik, D. et al.[

15] elaborated on the application of the digital twin concept in digital machining and investigated the digital representations of different objects involved in the machining process. Chao Yang et al.[

16] proposed a framework for the application of digital twin-based extended reality technology in the manufacturing environment, which consists of four layers, including a physical machine and its ROS-based ROS, with a digital twin. The application framework of extended reality technology is based on a digital twin with four layers, including a perception layer with physical machines and their ROS-based simulation models, a machine communication layer, a network layer containing three communication middleware, and a Unity-based service layer for creating XR-based digital applications, improves the efficiency of extended reality application development and the usability of the HMI system.

Combining digital twins with intelligent predictive algorithms for the optimisation of machining processes is an important research idea nowadays. In the field of centring machining, Shiau-Cheng Shiu et al.[

17] researched and developed a digital twin system for process optimisation through experiment-based genetic algorithm (DOE-GA) design, which reduced the process development time from 4 h to 1 h, reduced the full inspection to 10% sampling inspection, and increased the yield by 20%. Lei Wu et al. proposed a hybrid deep learning model driven by digital twins, which combined the signals of motion displacement and speed during machining, accurately estimated the cutting force and predicted the wear state of diamond tools. Lu, QB et al.[

18] proposed a thermal error prediction method based on the digital twin's long and short-term memory (DT-LSTM) and developed a system for the thermal error prediction problem of thermal characterisation of the spindle of CNC machine tools. The Particle Swarm Optimisation (PSO) algorithm was used with the LSTM for thermal error prediction and fusion, which improves the accuracy and robustness of thermal error prediction. Eric J. Tuegel[

19] proposed a high-fidelity digital twin model of aircraft structure, integrating the calculation of structural deflection and temperature response to flight conditions to predict the integrity and lifetime of aircraft structure. Ke Feng et al. [

20]developed a digital twin-driven intelligent health management method for monitoring and evaluating the gear surface degradation process, assessing the surface wear of gearboxes, revealing the gear wear propagation characteristics, and achieving an accurate prediction of the RUL of gearboxes. Hu, WF et al. [

21]address the problem of wind speed prediction and, based on the digital twin technology, propose a hybrid time series prediction model based on the integration of the empirical modal decomposition (EEMD), the long-short-term memory (LSTM) neural network, and the Bayesian optimisation (BO). Forecasting model, which is comprehensively compared with methods including persistence models, ARIMA, LSTM neural networks, BO-LSTM neural networks and EEMD-LSTM neural networks through case studies. At present, experts and scholars have begun to explore the application of digital twin technology in the field of digital processing, but the research content is mainly focused on the level of model definition, system analysis, etc., which is difficult to land and promote. In this regard, this paper establishes the digital twin system architecture for the processing of high-precision optical components, constructs a high-fidelity digital twin model of a centring lathe, carries out a technical exploration of the development process of the twin model and twin data based on Unity3d, and proposes the method of VMD- GRU feature fusion to develop the digital twin intelligent service to intelligently monitor the key components of the centring lathe.

2. Framework of digital twin system for centring process

Tao et al. have studied the guidelines and theories for constructing digital twin systems and proposed the digital twin five-dimensional model, which abstracts the digital twin system into the following five-dimensional model[

22]:

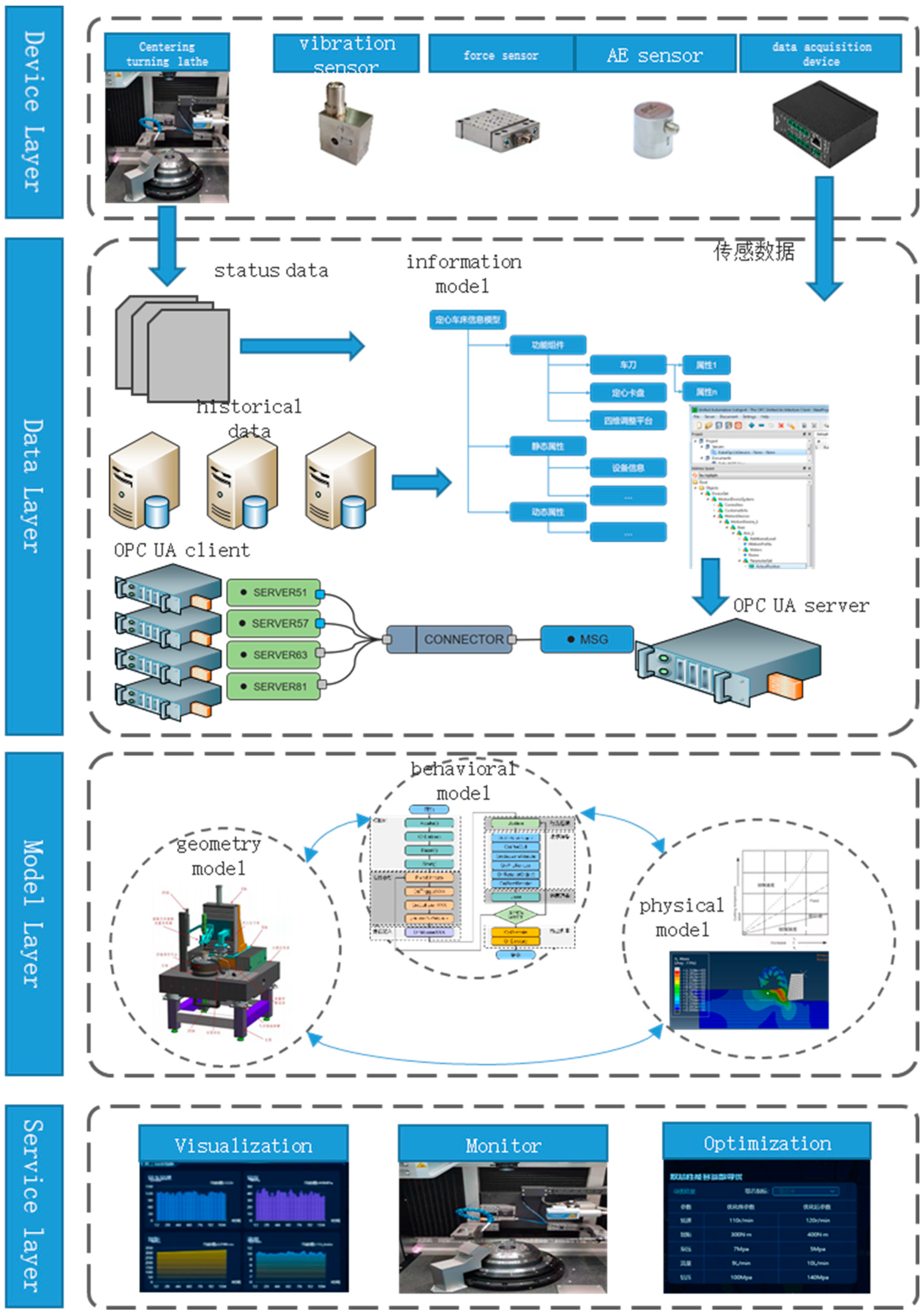

Where PE refers to a physical entity, VE refers to a virtual entity, SS refers to service, DD refers to twin data and CN refers to connection. In this paper, concerning the five-dimensional model of the digital twin, we propose a layered architecture of the digital twin for the centring lathe, as shown in

Figure 3. The first layer is the hardware layer, i.e., hardware such as the device body and various sensors, including vertical turning axis system, axis system for measurement, four-degree-of-freedom adjustment platform, confocal non-contact sensors, force sensors, acceleration sensors, and acoustic emission sensors AE. The second layer is the model layer, i.e. the high-fidelity virtual model of the centring lathe, including the geometric model that portrays the spatial features, the physical model that reflects the thermal, mechanical and motion laws of the object, and the behavioural model that portrays the constraints of the object's movements. The third layer is the data layer, which will include the cutting force, acceleration, acoustic emission and other signals collected by sensors to model the information of the equipment state process data of the centring lathe and transmit the data based on the communication scheme of OPC UA. The fourth layer is the application layer, which develops intelligent services such as machining process visualization, condition monitoring of key components, machining process planning and so on by invoking the data-driven high-fidelity virtual model, oriented to the actual demand and combining various algorithms.

Figure 3.

The digital twin system framework of high-precision lens centring process.

Figure 3.

The digital twin system framework of high-precision lens centring process.

3. High-fidelity digital twin construction methods

Based on the above digital twin architecture, the implementation methods of the data layer, model layer and application layer of the centring processing digital twin system were studied. For the construction of a high-fidelity digital twin virtual model in the model layer, Unity3d[

23,

24] digital twin development tool is used to implement and integrate the geometric model, physical model and behavioural model. For the mapping process of twin data in the data layer, it is analyzed and pointed out that the key to twin data is to solve the problem of information silos in the life cycle of the equipment, the information model is used to standardize the data, and OPC UA technology is used to realize the real-time mapping of twin data[

25]. Finally, the service development of the application layer is carried out, and the intelligent monitoring function of the key components of the centring lathe is achieved based on the VMD-GRU method of feature fusion.

3.1. High fidelity digital twin construction methods

- 1)

Geometric model

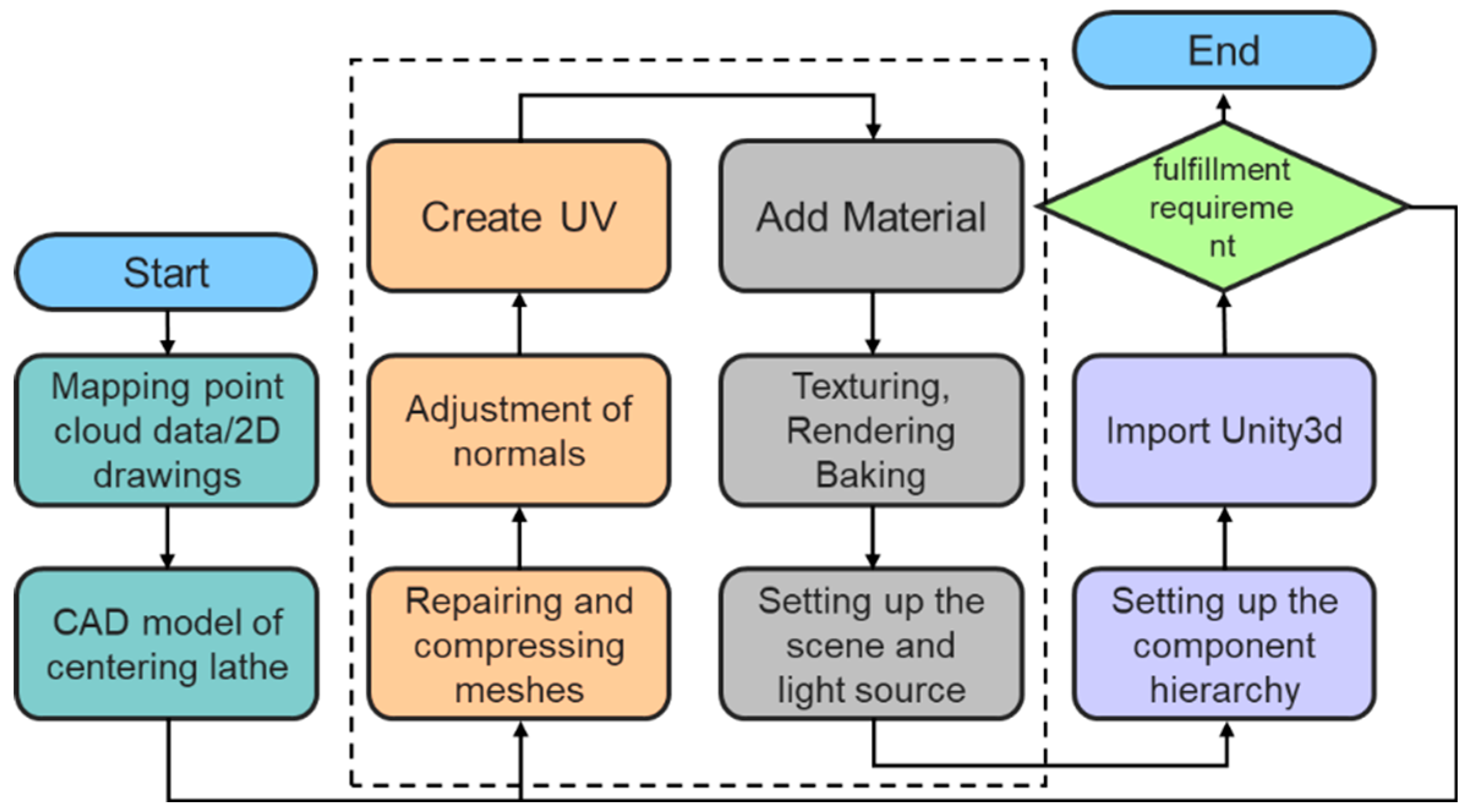

The geometric model of the centring lathe can not only provide a visual display of the structure of the equipment but also provide a basis for the construction of the subsequent physical model and behavioural model. In the process of constructing the geometric model of the centring lathe, not only the accuracy of the model should meet the requirements, but also the model should be compressed and simplified to ensure the operational efficiency of the system. In this paper, a high-fidelity geometric model of centring lathe is constructed by combining the digital twin virtual model development tool, and the process is shown in

Figure 4. First of all, according to the actual geometric dimensions of the parts and the assembly relationship to draw the centring lathe CAD model, with the help of Pixyz tool plug-in import CAD files, mesh size and quality control to optimize the model, including mesh merging, normal adjustment, new UV, create materials, set lighting, and so on, and will be the model output imported into Unity3d, according to the actual relationship between the equipment's movement of the model's hierarchy planning and adjustment. The model output is imported into Unity3d, and the layers of the model are planned and adjusted according to the actual motion relationship of the device.

Figure 4.

The workflow of making a geometry model.

Figure 4.

The workflow of making a geometry model.

- 2)

Behavioral model

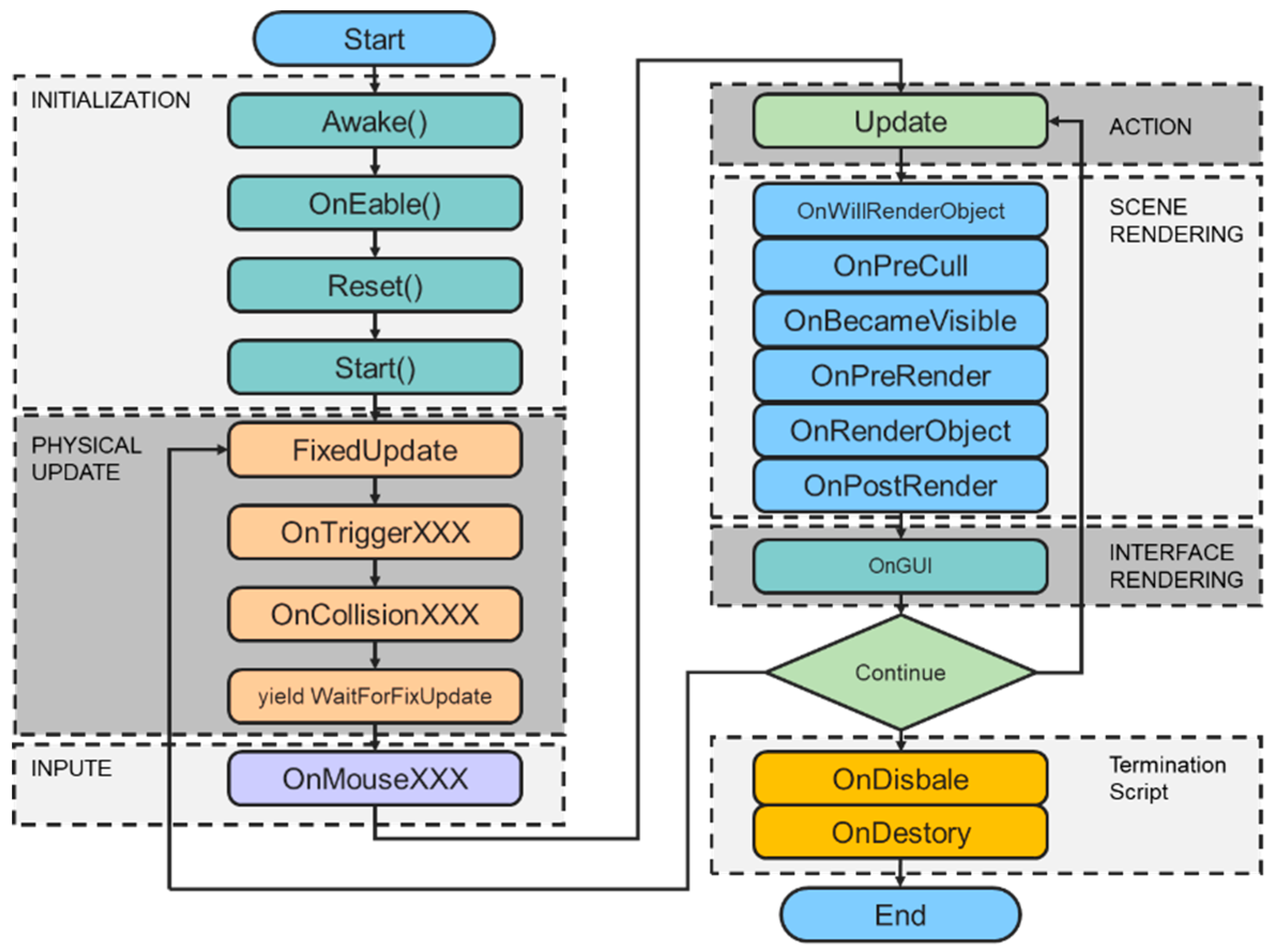

The interactivity of the digital twin model is improved by constructing behavioural models that provide feedback responses to internal events and external inputs[

26]. The key to its construction is to accurately describe the action behaviour and sequence of the device and its components. By establishing a GameObject, the geometric model is coupled by using the Mesh component, and the spatial position and assembly hierarchy of the centring lathe and each component are mapped by using the Transform component. Create a C# script that inherits the MonoBehaviour base class, mounts it to the GameObject object, divides the different phases in the behaviour, and executes the corresponding functions. In the initialization phase, the three functions of Awake(), OnEnable() and Start() are executed sequentially. Among them, Awake() mainly performs some operations including getting components, initializing variables, etc. OnEnable() mainly enables operations such as turning on the helper program, playing sound effects, etc. After the script is instantiated, it calls OnEnable() and Start(). After the script is instantiated, Start() is called to initialize the Gameobject object and play the animation. The physical calculation stage mainly includes the FixedUpdate() function, compared with Update in the later stage; its difference is the interval of calling. FixedUpdate () is called at a fixed interval instead of once per frame, so it is often used to move the rigid body, collision monitoring and other physical functions are executed here. Logic update stage, mainly including update parameters, primarily to achieve the reading of data and the execution of the action, simulation of centring adjustment and turning machining action. Graphics rendering stage, including scene rendering OnRender() and OnGUI () rendering two parts. Finally, the selection judgment of whether to continue updating is carried out; if yes, then return to the physical calculation stage, otherwise execute OnDisable() to disable the script, and finally execute OnDestroy () to deconstruct the script to end the script's life cycle, as shown in

Figure 5.

Figure 5.

The workflow of the behavioural model.

Figure 5.

The workflow of the behavioural model.

- 3)

Physical Model

The physics model describes the mechanism of motion, heat transfer, stress-strain, and processing deformation.Unity3D provides excellent management mode, i.e. Physics Manager. Physical models describe the mechanisms of motion, heat transfer, stress-strain, and processing deformation.Unity3D provides an excellent management mode, namely Physics Manager. Through the Rigidbody component in Unity3d, set the object's mass, drag, Drag, angular drag, and use gravity, and other parameters to realize the simulation of object dynamics. In addition, the physical model is constructed by combining industrial-grade simulation software. Taking Matlab as an example, the engine instance is created by determining the communication data format and protocol, then using Matlab's COM interface to create an engine instance, and then using C# to call the Matlab function in Unity to carry out the simulation calculation. According to the simulation results, the data is mapped to texture mapping, and the colours attribute is assigned a value through MeshFiltercolors to visualize the simulation results.

3.2. Digital Twin Data Mapping Methods

The ultimate goal of the digital twin is to provide real-time, efficient, and intelligent services such as monitoring, diagnosis, and decision-making, which require a large amount of data. In addition, the digital twin model is also a dynamic rather than static model and requires access to data to dynamically update the model. That is, twin data is the key to the digital twin system. In the process of constructing a digital twin system, due to the diversity of devices in hardware, software, connection mode, and communication protocols, i.e., data acquisition mode, the data has the characteristics of multi-source heterogeneity, which is eventually manifested in the phenomenon of data silo including physical level and logical level. The so-called physical data silos, that is, in the data at different stages, different departments independently of each other to store and maintain, the formation of the physical sense of the island. The logical data silo refers to the same data in the definition, and understanding will be different because of different stages, equipment, departments and different; that is, the data in the logical semantics can not interact. To solve the data silo problem of industrial equipment, this paper is based on the OPC UA information model[

27] and proposes to instantiate the information model of centring turning processing according to specific application scenarios, represent the events and data of the processing process as an object, and give the object variables, events, and methods, and realize the interconnection between the objects through the referencing, and ultimately form a set of standard data parsing and organization models to realize the semantic interoperability of multi-source and heterogeneous data. Semantic interoperability of heterogeneous data. OPC UA technology is used to map the information objects to the address space, and the description and access to process data is realized through OPC DA, the description and access to vertical data is realized through OPC HAD, and OPC A&E provides the information interface of running events and alarms.

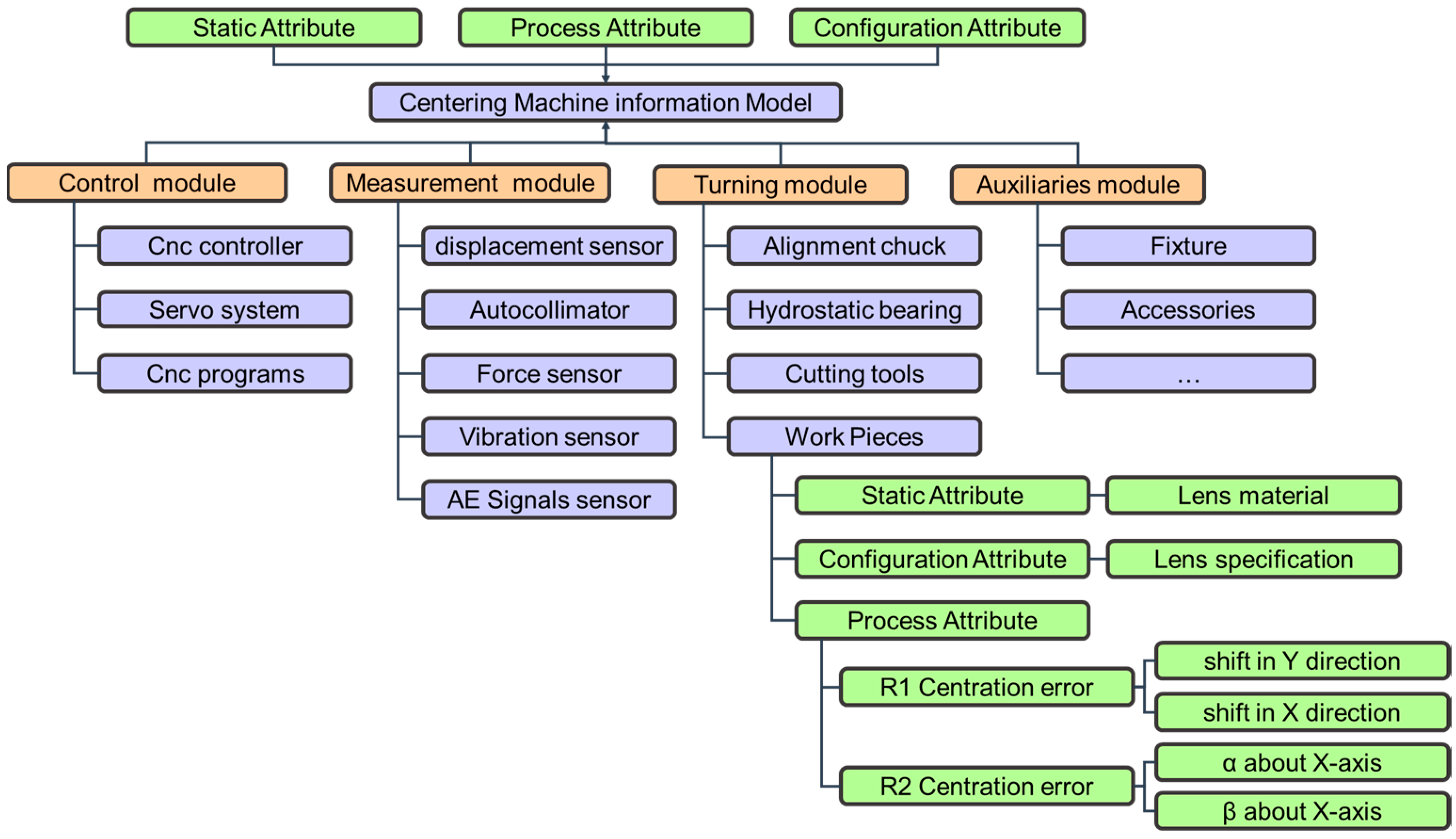

- 1)

Centring process information model

In this paper, based on the standard machine tool manufacturing information model is modified and extended to propose the information model of the centring turning machining process, and the tree structure is used to describe it, as shown in Figure XX. The information model has three elements: information object, attribute and attribute set. Among them, information objects are conceptualized descriptions of real or abstract entities of the machining process, such as spindles, chucks, and process documents. Attributes are textualized or digitized descriptions of the nature and characteristics of information objects. An attribute set is a collection of attributes. The information model is instantiated according to the above definition to get the centring machining system information model with practical significance, as shown in

Figure 6.

Figure 6.

The information model of a digital twin for high-precision lens centring process.

Figure 6.

The information model of a digital twin for high-precision lens centring process.

- 2)

Data communication scheme based on OPC UA

OPC UA is a new generation of service-oriented communication solution for cross-platform transmission and transmission process security in the manufacturing field developed based on OPC Classic, which supports a wide variety of data semantics and information models and can unify the communication mechanism and data interaction mode of different industrial devices and solve the problem of data transmission and communication of the machining process. OPC UA mainly consists of three parts. OPC UA specifically includes three parts: OPC DA, i.e. OPC Data Access, defines the value, event and quality information of the data exchange process, which is the most important function in OPC, and is mainly used for the transmission and communication of production data, process data and factual state of the equipment; OPC HDA, i.e. OPC Historical Data Access, defines methods for querying and analyzing the data which can be applied to the historical data and time data; OPC HDA, i.e. OPC Historical Data Access, defines methods for querying and analyzing the data which can be applied to the historical data and time data. OPC HDA, OPC Historical Data Access, defines the methods that can be applied to the query and analysis of historical data and time data; OPC AE, OPC Alarms & Events, defines the exchange of alarms and event-type message information, as well as variable state and state management. C/S, i.e. Client/server architecture is used to realize the construction of the OPC UA system. The OPC UA Client includes the OPC UA client application, communication stack, and client API, and can send and receive OPC UA service requests to and from the OPC UA server side. the OPC UA Server includes the OPC UA server application, communication stack, address space, publish/subscribe entity, and server interface API. The OPC UA C/S OPC UA C/S architecture through the publish/subscribe machine to realize the interaction between the client and the server, the process is, through the client-side communication stack request to generate a session release queue, the server-side communication stack to set up the monitoring items for subscription monitoring, after accepting the session, call request the corresponding service, and in the node of the address space to perform the tasks specified in the request after sending notifications and publish the answer, as shown in

Figure 7.

Figure 7.

The workflow of OPC UA Client and Server.

Figure 7.

The workflow of OPC UA Client and Server.

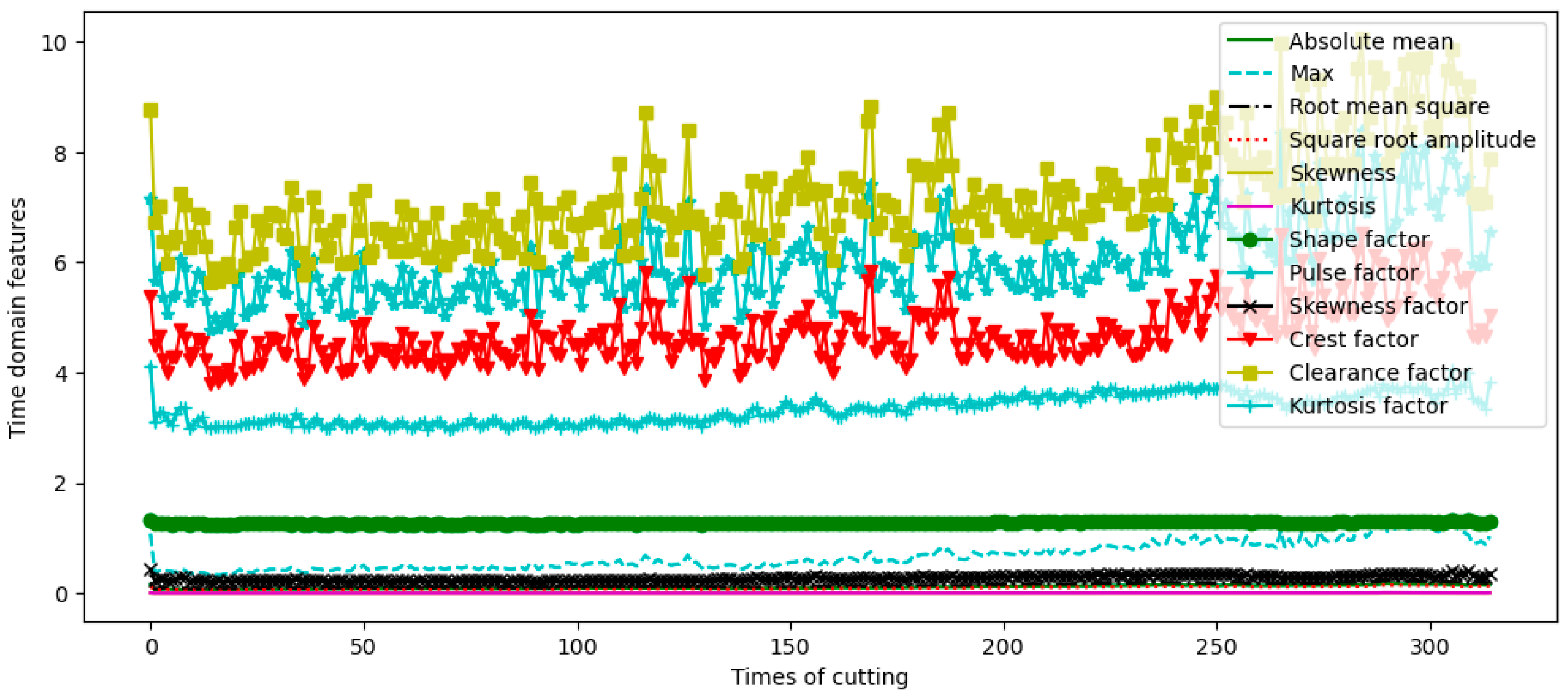

3.3. VMD-GRU Intelligent Monitoring Approach

The digital twin system provides accurate and reliable intelligent services for the stages of manufacturing, operation and maintenance, to optimise the machining and manufacturing process to achieve intelligent manufacturing. Current research on digital twins focuses on the level of model frameworks and less on the development of actual intelligent services, which is an important reason why digital twins are difficult to promote on the ground. With the machining process, the key components of the equipment change, in the wear of the tool has an important impact on the quality of the workpiece, so it is important to achieve the monitoring of the status of the tool to ensure the quality of machining and improve productivity. Tool condition monitoring methods have direct and indirect methods, while the implementation of the direct method of high cost and affects the continuity of machining, so the application has been limited, while the indirect method is through the sensor acquisition of displacement, force, acoustic emission, spindle power and other signals to indirectly monitor the amount of tool wear. In this paper, for the centring machining process, based on the digital twin system mentioned above, an intelligent monitoring service for the state of the tool, a key component of the machining system, is developed. Firstly, the time-frequency domain eigencomponents of the sensed data are extracted using the VMD variational modal decomposition, and then the input eigenvectors are constructed by normalising them, and finally the wear amount is predicted using the GRU's sequential model to predict the wear amount.

Sensor data have a low data value density due to the presence of a large amount of random background noise and repetitive redundant data, and also due to the complex coupling relationship between various signals. Therefore, the sensed data must be processed to accurately extract the effective components to construct suitable features as model inputs, which is crucial for the final effect of monitoring.

Firstly, suitable signal processing methods are chosen to convert the signals. In time series signal analysis, there are three main extraction methods commonly used, the method of time domain analysis, the method of frequency domain analysis, and the method of time-frequency domain analysis. Among them, the method of time domain analysis and frequency domain analysis is to decompose the signal in time domain and frequency domain respectively, which is suitable for dealing with smooth signals. In this paper, the monitoring of the components, due to the damage process of the components will change the frequency domain characteristics, which belong to the typical non-smooth signal. Therefore, this paper adopts the time-frequency domain analysis method commonly used for non-smooth signals. The vibration signal's inherent modal component IMF component is extracted using the variational modal decomposition VMD method[

28]. The basic idea is to assume that all IMFs are bandwidth-limited components near their centre frequencies so that the sum of the estimated bandwidths is minimised, which translates into the following constrained variational problem:

It is realised as follows.

initialise the parameters.

2. update the parameters cyclically

3. judge whether the convergence condition is satisfied, then end and output the result, otherwise repeat step 2.

Then through the extraction of the statistical characteristics of the signal in the time domain, frequency domain, and geometric features, information features, to achieve the initial screening of the features of the data, to complete the dimensionality reduction of the data. Finally, the features are selected for splicing.

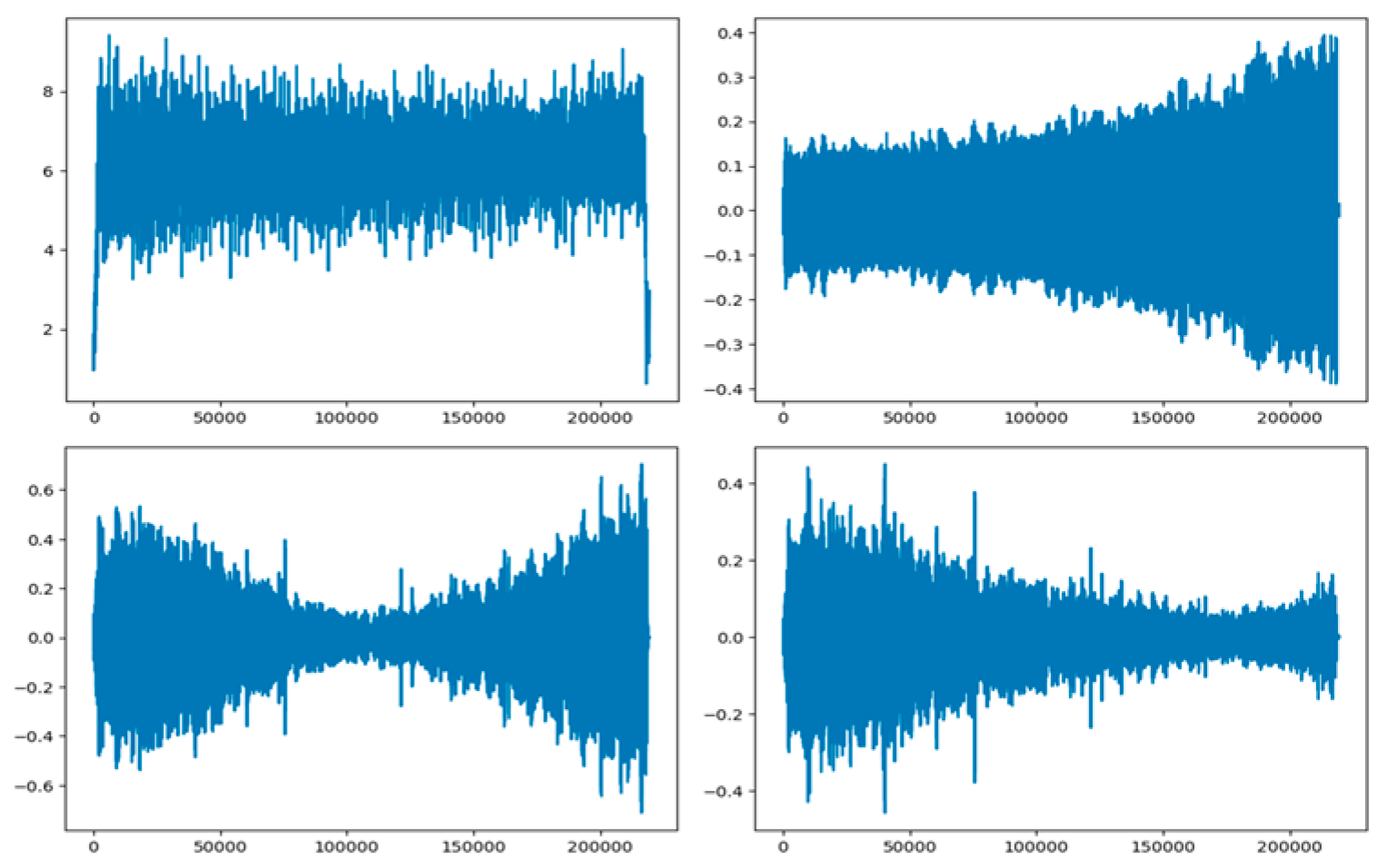

Figure 8.

Partial time-domain features obtained by VMD extraction.

Figure 8.

Partial time-domain features obtained by VMD extraction.

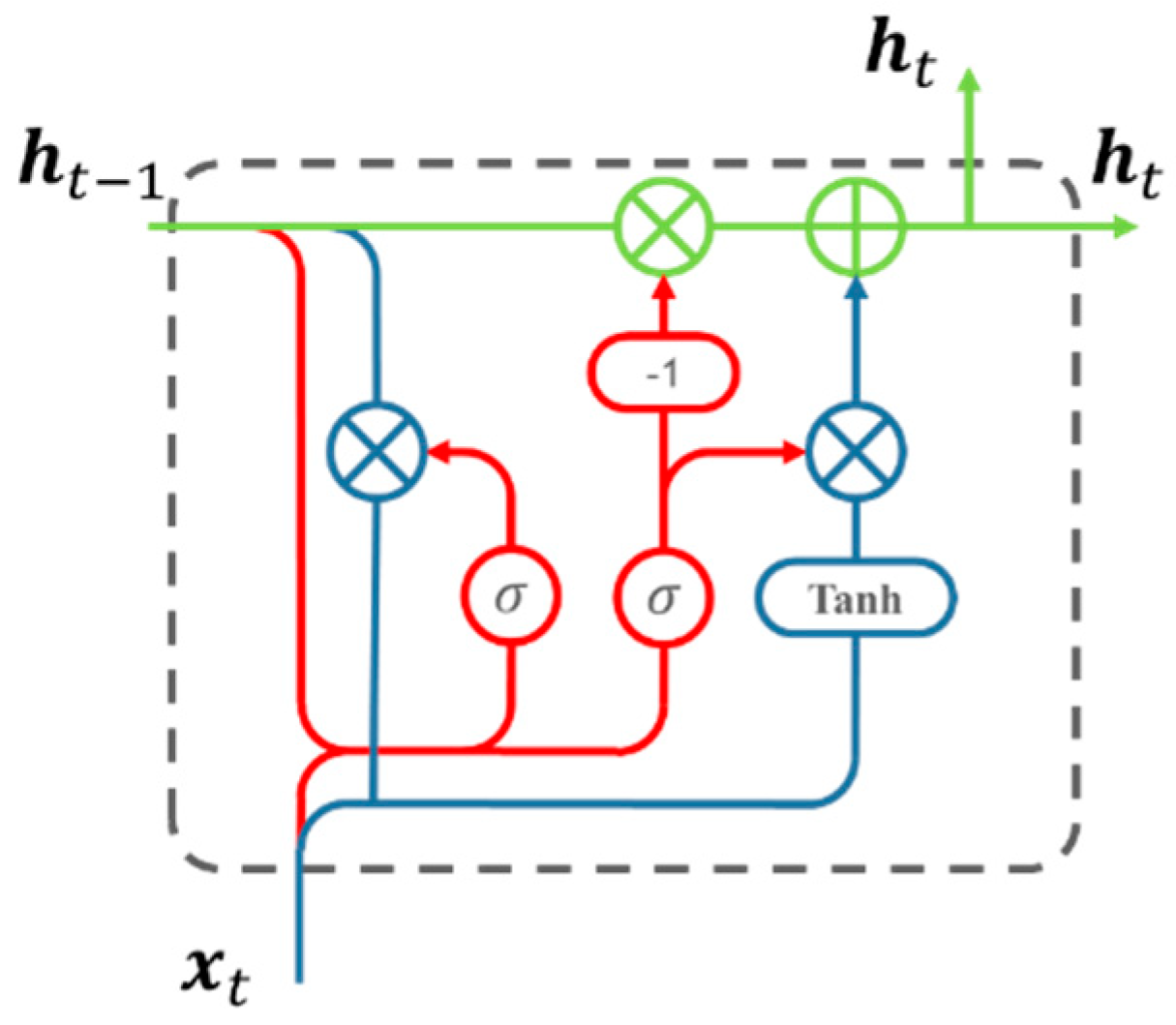

Figure 9.

Structure diagram of GRU.

Figure 9.

Structure diagram of GRU.

Recurrent neural networks can effectively capture the time-varying nature of equipment by passing the output and state of the current moment as input to the next moment and thus are widely used in the state prediction of equipment. To improve the representation ability of the model, the number of layers of the RNN is usually superimposed, but the increase of the computational depth will lead to a series of gradient problems and thus make it difficult or even impossible to train the model.LSTM uses the gating mechanism, which solves the problem of gradient to a certain extent. However, the large number of parameters in LSTM leads to a large amount of computation in the training process, and there are limitations in the real-time training and computation of the model.GRU replaces the forgetting gate and input gate in LSTM with a single forgetting gate and adds some other minor changes, which is a simplified variant of LSTM.GRU has a faster convergence speed with fewer parameters than LSTM, and the effect of GRU is not as good as that of LSTM on different tasks and datasets. and datasets are not significantly different. Therefore, GRU is used as an alternative to LSTM in this paper. The structure of GRU is shown in Fig and the calculation formula is as follows[

29]:

4. System implementation and verification

This paper takes the centring machining system as the application object and carries out the digital twin system design based on the above digital twin system framework, and the configuration information of the system operation platform is shown in

Table 1.

Table 1.

Development Platform Configuration Information.

Table 1.

Development Platform Configuration Information.

| Machine name |

DESKTOP-I58VE5J |

| Operation system |

Windows 10 64-bit |

| Processor |

Intel(R) Core(TM) i5-9400F CPU @ 2.90GHz (6 CPUs), ~2.9GHz |

| Memory |

32768MB RAM |

| Video card |

NVIDIA GeForce GTX 1050 Ti |

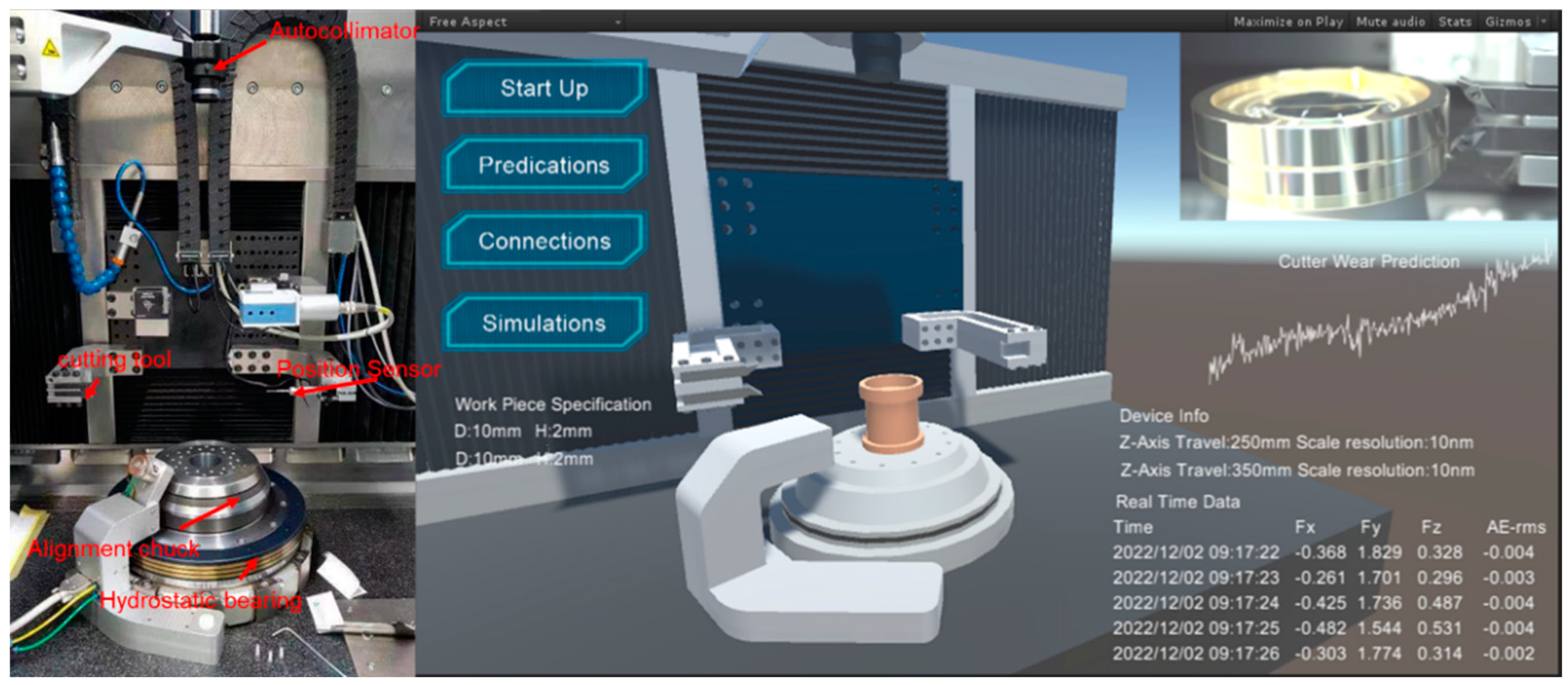

PixyzStudio and other tools were used to develop a digital twin system for centring and machining lathes for high-precision optical components. The development process is as follows: draw a high-fidelity CAD model that reflects the spatial features of the centring lathe according to the actual drawings through Solidworks2019, then import the model into PixyzStudio, simplify the non-critical features to reduce the rendering consumption, triangulate the CSG model using the Tessellate method, merge the parts, unify the pivot, create UVs and export them to Unity3D, create a digital twin of a high precision optical component. , create UVs and export as FBX model. Then the FBX model is imported into Unity, the digital twin scene is created, objects and textures are added, the physics engine provided by Unity is used to add components, physical and motion simulation is performed, and a script is written in C# to control the simulation and interaction, OPC UA is registered and the socket object is created in the script to complete the TCP connection, and the interface is connected through the OPC UA transfer protocol to get the centring Lathe including spindle position coordinates, spindle speed, spindle power and other equipment state information to complete the data connection, and will accept the data by the information model into a crude such as a database, the use of C# scripts to call MySQL for data interaction connection. The centring lathe digital twin system is shown in Fig 10.

Figure 10.

The main interface of the digital twin system for the high-precision lens-centring process

Figure 10.

The main interface of the digital twin system for the high-precision lens-centring process

This paper uses the public dataset PHM2010 to construct the VMD-GRU deep learning model to verify the prediction effect of the equipment machining state. Repeat six trials under the above cutting conditions to obtain six sets of data, C1, C2, C3,..., C6. In this paper, C1 is selected as the training data and C4 is selected as the test data. Each group of data consists of two parts with 316 files, including 1 prediction output file and 315 prediction input files. The input files include 315 groups of tool wear values in X, Y and Z directions respectively, and each input file includes 7 signal channels: force signal, vibration signal and acoustic emission signal in XYZ direction. Some of the VMD decomposition results are shown in Fig 11.

Figure 11.

The result VMD Decomposition.

Figure 11.

The result VMD Decomposition.

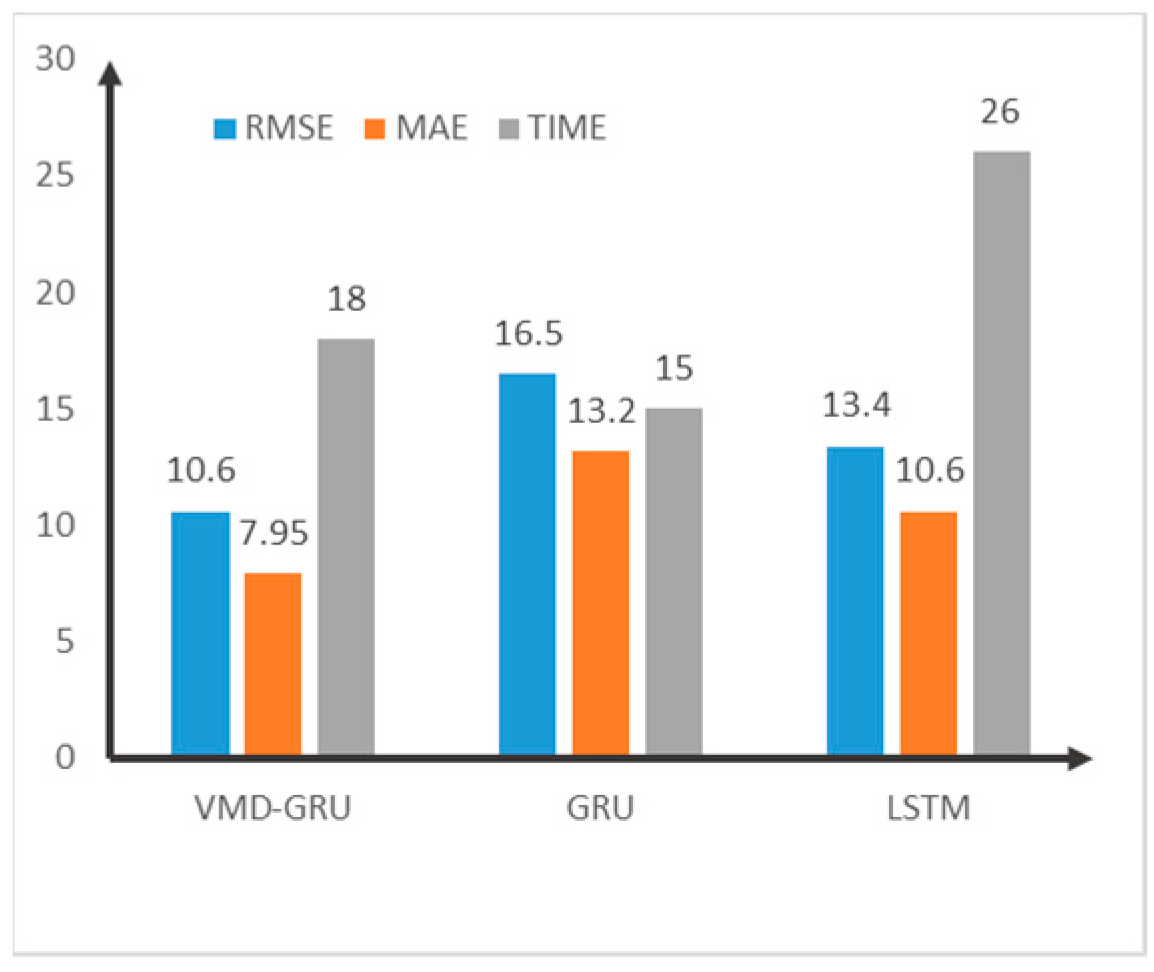

Figure 12.

Evaluation results.

Figure 12.

Evaluation results.

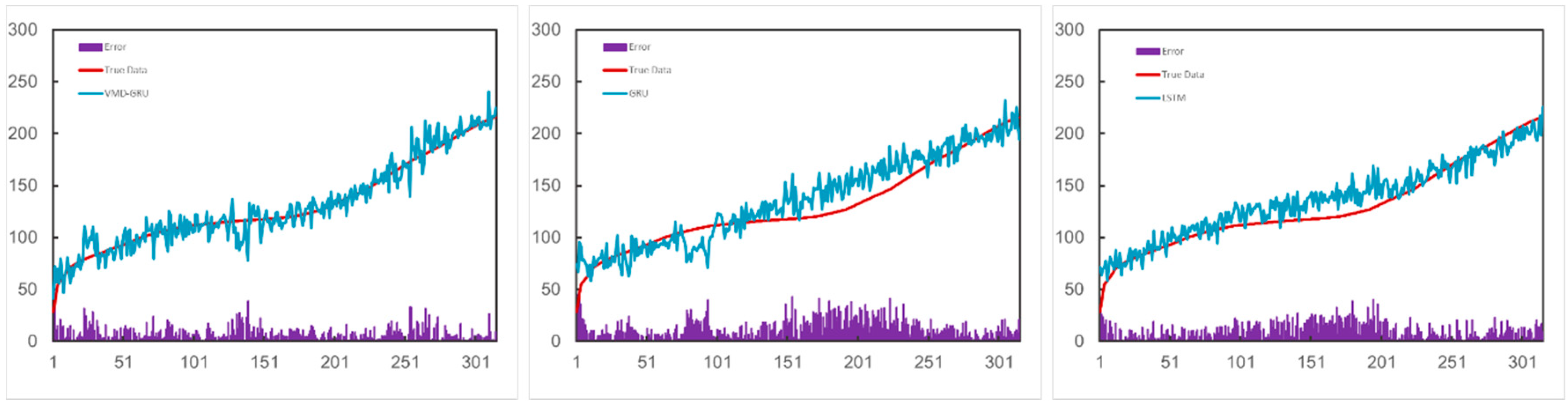

The prediction results are shown in Fig 13.

Figure 12 shows the RMSE and MAE of the different models in the three experiments, and it is easy to see that the VMD-GRU method proposed in this paper exhibits good prediction performance, although the LSTM has more parameters than the GRU to capture more temporal features and learn more complex patterns, and thus exhibits better performance, it requires more data and computational resources, and in the case of sequence relatively short, its performance is not stable enough, while it is prone to overfitting. The VMD-GRU method can mine more sequence information through VMD signal decomposition and effectively suppresses the influence of noise in the original signal to obtain more relevant features, so it shows better prediction performance, and at the same time, in terms of training time, it achieves a performance superior to that of the LSTM and close to that of the GRU, which meets the real-time requirements of the system's intelligent monitoring.

Figure 13.

The result of the VMD-GRU Intelligent Monitoring Approach.

Figure 13.

The result of the VMD-GRU Intelligent Monitoring Approach.

5. Conclusion

This paper takes the centring process of high-precision optical components as the research object, based on the proposed digital twin system for high-precision optical components, based on the five-dimensional model of the digital twin, designing the four-layer architecture including hardware layer, data layer, model layer, and application layer, respectively, and carrying out research and case development validation on the method of constructing high-fidelity digital twins, the mapping of the twin data, and the intelligent monitoring of key components.

The VMD-GRU intelligent monitoring method proposed in this paper is compared with the prediction results of other methods in a comparison experiment, and the results show that: the method proposed in this paper is better than GRU and LSTM in terms of the evaluation indexes of RMSE and MAE and other accuracy indexes, and the efficiency indexes are better than LSTM and close to GRU, which verifies the feasibility and effectiveness of the proposed method.

This study has made a useful exploration for accelerating the application of digital twin technology in the manufacturing field, and ultimately realizing the visualization and intelligence of the processing of high-precision optical components, and optimizing the development process of digital twins to improve the accuracy, real-time and stability of intelligent monitoring services is the focus of the subsequent research.

Author Contributions

Conceptualization, S.F.; methodology, S.F, and C.L.; validation, S.F., C.L., and Y.L.; formal analysis, S.F.; investigation, S.F. and Z.W.; resources, Y.L.; data curation, S.F., X.B., C.Z.; writing—original draft preparation, S.F.; writing—review and editing, S.F., C.L. and Y.L.; visualization, S.F.; supervision, Y.L.; project administration, Z.W.; funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the financial support from the National Key R&D Program of China (2022YFB3706604、2022YFB3706605); and Sichuan Provincial Science and Technology Achievement Transfer and Transformation Demonstration Project (2023ZHCG0029); and Sichuan Science and Technology Program (2022YFG0064).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Raw or processed data required to reproduce these findings cannot be shared at this time, as the data also form part of an ongoing study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mcguire, James P.; Bentley, J.; Gupta, A.; Youngworth, R.N. Manufacturable Mobile Phone Optics: Higher Order Aspheres Are Not Always Better. Proceedings of SPIE - The International Society for Optical Engineering 2010, 7652, 76521O–76521O.

- Wang, Y.Q.; Liu, W.Q.; Meng, X.X.; Fu, H.Y.; Zhang, D.L.; Kang, Y.S.; Feng, R.; Wei, Z.L.; Zhu, X.Q.; Jiang, G.H. Development of an immersive virtual reality head-mounted display with high performance. Appl. Optics 2016, 55, 6969–6977. [Google Scholar] [CrossRef]

- Yang, J.-P.; Chen, L.; Gu, X.-B.; Zhao, Z.-Y.; Fu, C.-H.; Yang, D.-S.; Tian, D.-Z.; Chen, Z.-S.; Xie, H.-P. Hollow glass microspheres/silicone rubber composite materials toward materials for high performance deep in-situ temperature-preserved coring. Petroleum Science 2022, 19, 309–320. [Google Scholar] [CrossRef]

- Gebhardt, A.; Schmidt, E.; Hertel, T.; Kirschstein, S.; Gebhardt, E.; Rendel, T.; Gawronski, U.; Wand, V. Alignment turning and assembly of the Sentinel 4 optical modules. Proceedings of SPIE 2021, 11852, 118522X–118511. [Google Scholar] [CrossRef]

- Huiyong, L.; Song, Z.; Jianfeng, L.; Xiaona, L. Tool Wear Condition Monitoring Using Improved CNN-BiLSTM Modeling. China Mechanical Engineering 2022, 033. [Google Scholar]

- Wu, L.; Leng, J.; Ju, B. Digital Twins-Based Smart Design and Control of Ultra-Precision Machining: A Review. Symmetry-Basel 2021, 13. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber-Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. In Proceedings of the 16th IFAC Symposium on Information Control Problems in Manufacturing (INCOM), Bergamo, ITALY, 2018, 2018 Jun 11-13; pp. 1016–1022. [Google Scholar]

- Grieves, M. Digital Twin Certified: Employing Virtual Testing of Digital Twins in Manufacturing to Ensure Quality Products. Machines 2023, 11, 808. [Google Scholar] [CrossRef]

- Guo, D.; Xie, H.-P.; Chen, L.; Zhou, Z.-Y.; Lu, H.-P.; Dai, L.; Wang, D.-M.; Wang, T.-Y.; Li, J.; He, Z.-Q.; et al. In-situ pressure-preserved coring for deep exploration: Insight into the rotation behavior of the valve cover of a pressure controller. Petroleum Science 2023, 20, 2386–2398. [Google Scholar] [CrossRef]

- Tekinerdogan, B. On the Notion of Digital Twins: A Modeling Perspective. Systems 2023, 11, 15. [Google Scholar] [CrossRef]

- Costantini, A.; Di Modica, G.; Ahouangonou, J.C.; Duma, D.C.; Martelli, B.; Galletti, M.; Antonacci, M.; Nehls, D.; Bellavista, P.; Delamarre, C.; et al. IoTwins: Toward Implementation of Distributed Digital Twins in Industry 4.0 Settings. Computers 2022, 11. [Google Scholar] [CrossRef]

- Chen, L.; Stahl, J.-E.; Zhao, W.; Zhou, J. Assessment on abrasiveness of high chromium cast iron material on the wear performance of PCBN cutting tools in dry machining. Journal of Materials Processing Technology 2018, 255, 110–120. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, J.; Bushlya, V.; Gutnichenko, O.; Stahl, J.-E. Performance assessment of pCBN and bCBN tools in machining of high-chromium white cast iron. International Journal of Advanced Manufacturing Technology 2015, 79, 635–644. [Google Scholar] [CrossRef]

- Plakhotnik, D.; Curutiu, A.; Zhulavskyi, A.; Beudaert, X.; Munoa, J.; Stautner, M. FRAMEWORK FOR COUPLED DIGITAL TWINS IN DIGITAL MACHINING. Mm Science Journal 2021, 2021, 5093–5097. [Google Scholar] [CrossRef]

- Yang, C.; Tu, X.; Autiosalo, J.; Ala-Laurinaho, R.; Mattila, J.; Salminen, P.; Tammi, K. Extended Reality Application Framework for a Digital-Twin-Based Smart Crane. Applied Sciences-Basel 2022, 12. [Google Scholar] [CrossRef]

- Shiu, S.-C.; Tang, K.-E.; Liu, C.W. Digital twin-driven centring process optimization for high-precision glass lens. Journal of Manufacturing Systems 2023, 67, 122–131. [Google Scholar] [CrossRef]

- Lu, Q.; Zhu, D.; Wang, M.; Li, M. Digital Twin-Driven Thermal Error Prediction for CNC Machine Tool Spindle. Lubricants 2023, 11. [Google Scholar] [CrossRef]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. International Journal of Aerospace Engineering 2011, 154798. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Zhang, Y.; Ni, Q.; Liu, Z.; Beer, M. Digital twin-driven intelligent assessment of gear surface degradation. Mechanical Systems and Signal Processing 2023, 186. [Google Scholar] [CrossRef]

- Hu, W.; He, Y.; Liu, Z.; Tan, J.; Yang, M.; Chen, J.; Amer Soc Mech, E. A HYBRID WIND SPEED PREDICTION APPROACH BASED ON ENSEMBLE EMPIRICAL MODE DECOMPOSITION AND BO-LSTM NEURAL NETWORKS FOR DIGITAL TWIN. In Proceedings of the ASME Power Conference (POWER), Electr Network, 2020., 2020 Aug 03-06. [Google Scholar]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Hui, X.; Huang, Z.; et al. Digital twin five-dimensional model and ten domain applications. computer-integrated manufacturing system 2019, 25, 1–18. [Google Scholar] [CrossRef]

- Tian, X. Research and realization of virtual simulation monitoring system for machine tool machining process based on digital twins. Master, University of Electronic Science and Technology of China, 2021. [Google Scholar]

- Szalai, M.; Varga, B.; Tettamanti, T.; Tihanyi, V. Szalai, M.; Varga, B.; Tettamanti, T.; Tihanyi, V.; Ieee. Mixed reality test environment for autonomous cars using Unity 3D and SUMO. In Proceedings of the 18th IEEE World Symposium on Applied Machine Intelligence and Informatics (SAMI), Herlany, SLOVAKIA, 2020 Jan 23-25; 2020; pp. 73–78. [Google Scholar]

- Arestova, A.; Martin, M.; Hielscher, K.-S.J.; German, R. A Service-Oriented Real-Time Communication Scheme for AUTOSAR Adaptive Using OPC UA and Time-Sensitive Networking. Sensors 2021, 21. [Google Scholar] [CrossRef] [PubMed]

- Gardner, P.; Dal Borgo, M.; Ruffini, V.; Hughes, A.J.; Zhu, Y.; Wagg, D.J. Towards the Development of an Operational Digital Twin. Vibration 2020, 3, 235–265. [Google Scholar] [CrossRef]

- Shin, I.-J.; Song, B.-K.; Eom, D.-S. Auto-Mapping and Configuration Method of IEC 61850 Information Model Based on OPC UA. Energies 2016, 9. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational Mode Decomposition. Ieee Transactions on Signal Processing 2014, 62, 531–544. [Google Scholar] [CrossRef]

- Graupe, D. Deep Learning Neural Networks — Methodology and Scope; DEEP LEARNING NEURAL NETWORKS:Design and Case Studies.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).