3.1. First round of tests (2020-2021). Compressive strength.

The tests were carried out separately for clay (229 research scenarios + 17 control scenarios with only cement in the amount of 5% by weight) and for sand (227 research scenarios + 19 control scenarios with only cement in the amount of 5% by weight). The following groups of additives were tested, which were the basis for developing original recipes for hydraulic binders, and their discussion is presented in the following order:

“By-pass” waste ash from the ceramic industry (Nr 2 from

Table 1), the so-called ash from the brickworks bypass, which is an alternative to the popularly used commercial binder GEOSTA (constituting a mixture of salts, i.e. chlorides of magnesium, sodium, potassium, calcium, iron; potassium carbonate and iron, aluminum, sodium sulfates)

Sulfuric acid of waste origin (Nr 6 from

Table 1), which is an alternative to the popularly used Roadbond EN-1

2. Group II EMULSIONS from PYROLYTIC WAXES from the pyrolysis of polyolefins, including:

3. Group III EMULSIONS from CHEWING GUM WASTE, i.e. from waste from the food industry, namely from the production of chewing gum (Nr 3 from Table 1)

4. Group IV HYBRIDS above additives.

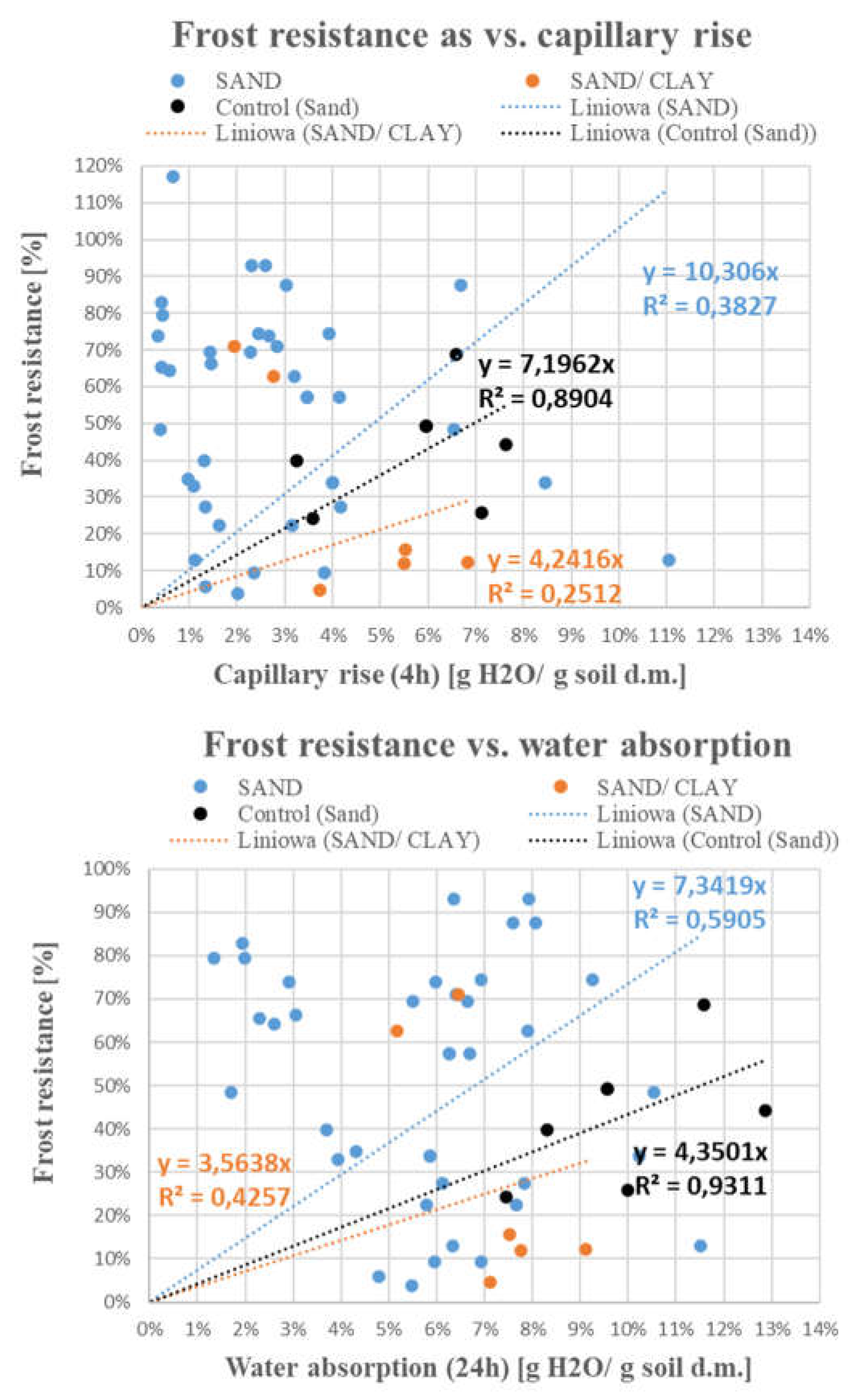

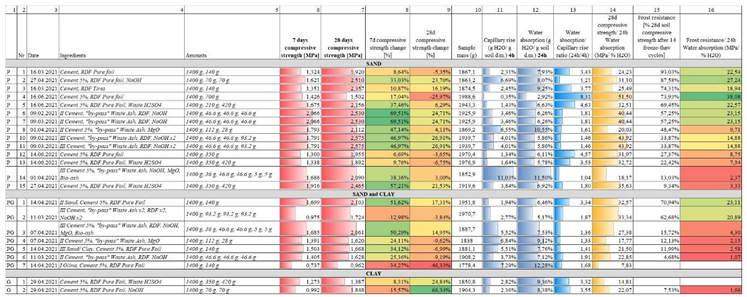

After analyzing the above-mentioned compressive strength results, 15 most promising scenarios with additives on sand, 7 on a mixture of sand and clay and 2 on clay were selected for further tests of water absorption and frost resistance. As a result, several soil parameters were compared and a multi-criteria analysis was performed based on:

Compressive strength after 7 days and 28 days,

Capillary rise after 4 hours and water absorption after 24 hours, expressed as the amount of water absorbed by the soil and expressed in % (g H2O/g dry soil mass)

Frost resistance as compressive strength after 14 frost-thaw cycles, related to the initial compressive strength after 28 days, expressed as a % of the initial strength,

Several parameters recalculated on the basis of the above-measured ones,

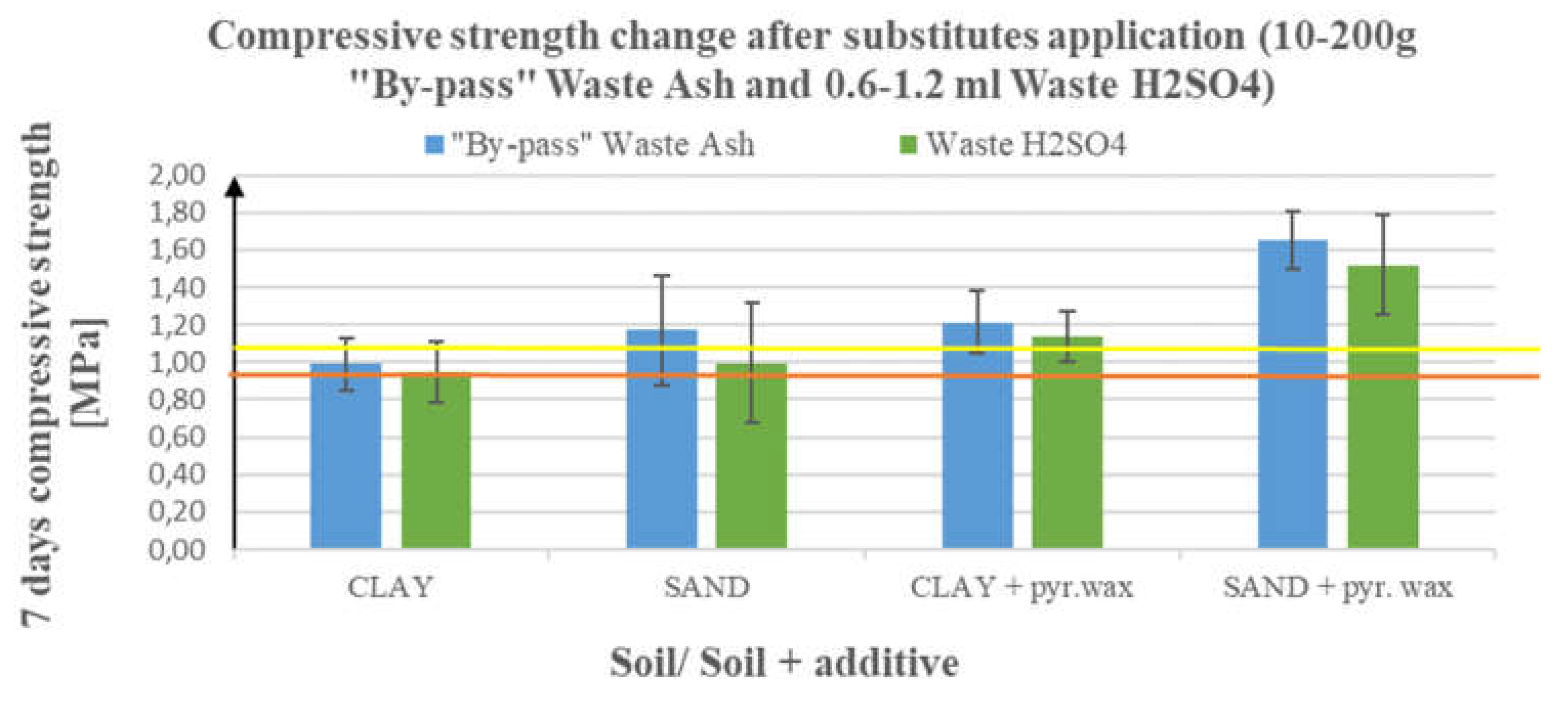

The results of the average values of compressive strength for binders based on the addition of substitutes from GROUP I are presented below. The addition was from 10 to 200 g of the “by-pass” waste ash (Geosta substitute) and from 0.6 to 1.2 ml of the waste sulphuric acid (EN-1 substitute) with 5% cement and 8 kg of soil.

Due to the fact that the addition of the “by-pass” waste ash alone gives a slight improvement in compressive strength (5.7% and 11.1% for clay and sand, respectively) and the use of the waste sulphuric acid (EN-1 substitute) does not affect the strength (

Table 1), it was decided to enrich the binders not only with substitutes from GROUP I, but with the addition of an emulsion of pyrolytic waxes from GROUP II, expecting a hybrid effect of additives from both previously defined groups.

The results of average compressive strength values for binders based on hybrids, i.e. the addition of substitutes from GROUP I and the addition of emulsions from pyrolytic waxes from GROUP II, are summarized below. The addition of substitutes was from 10 to 200 g of “by-pass” waste ash and from 0.6 to 1.2 ml of waste sulphuric acid, and the emulsion was from 10 to 40 g with 5% cement and 8 kg of soil.

As shown on Table 3 and

Figure 1 the addition of wax emulsion (data averaged for waxes from HDPE, RDF, Foil) significantly improved the compressive strength of soils where only substitutes were used (

Table 2). Thus, the strength on clay increased by almost 30% and 22% (for the Geosta and EN-1 substitutes, respectively), and on sand by as much as 57% and 44% (for the Geosta and EN-1 substitutes, respectively). Standard deviations were greater for sand results (up to 30%) and smaller for clay results (up to 15%), which would mean that sand showed greater heterogeneity than clay and, in practice, that the influence of the above-mentioned additives and their hybrids will be more visible in this soil.

Table 2.

The average soil compressive strength values for substitutes of commercial stabilizers.

Table 2.

The average soil compressive strength values for substitutes of commercial stabilizers.

| Additive |

"By-pass" Waste Ash |

Waste H2SO4

|

| Soil |

CLAY |

SAND |

CLAY |

SAND |

| Samples |

63 |

63 |

24 |

23 |

| MPa |

0,99 |

1,17 |

0,95 |

0,99 |

| SD/2 |

0,14 |

0,29 |

0,16 |

0,32 |

| Change (%)1 |

5,67% |

11,08% |

1,36% |

-5,63% |

Table 3.

The average soil compressive strength values for substitutes of commercial stabilizers with the addition of pyrolytic wax from various polyolefines (HDPE, RDF, pure foil)

Table 3.

The average soil compressive strength values for substitutes of commercial stabilizers with the addition of pyrolytic wax from various polyolefines (HDPE, RDF, pure foil)

| Additive |

"By-pass" Waste Ash + pyrolytic wax |

Waste H2SO4 + pyrolytic wax |

| Soil |

CLAY |

SAND |

CLAY |

SAND |

| Samples |

14 |

14 |

8 |

9 |

| MPa |

1,21 |

1,66 |

1,14 |

1,52 |

| SD/2 |

0,16 |

0,15 |

0,13 |

0,27 |

| Change (%)1 |

29,67% |

57,12% |

21,87% |

44,14% |

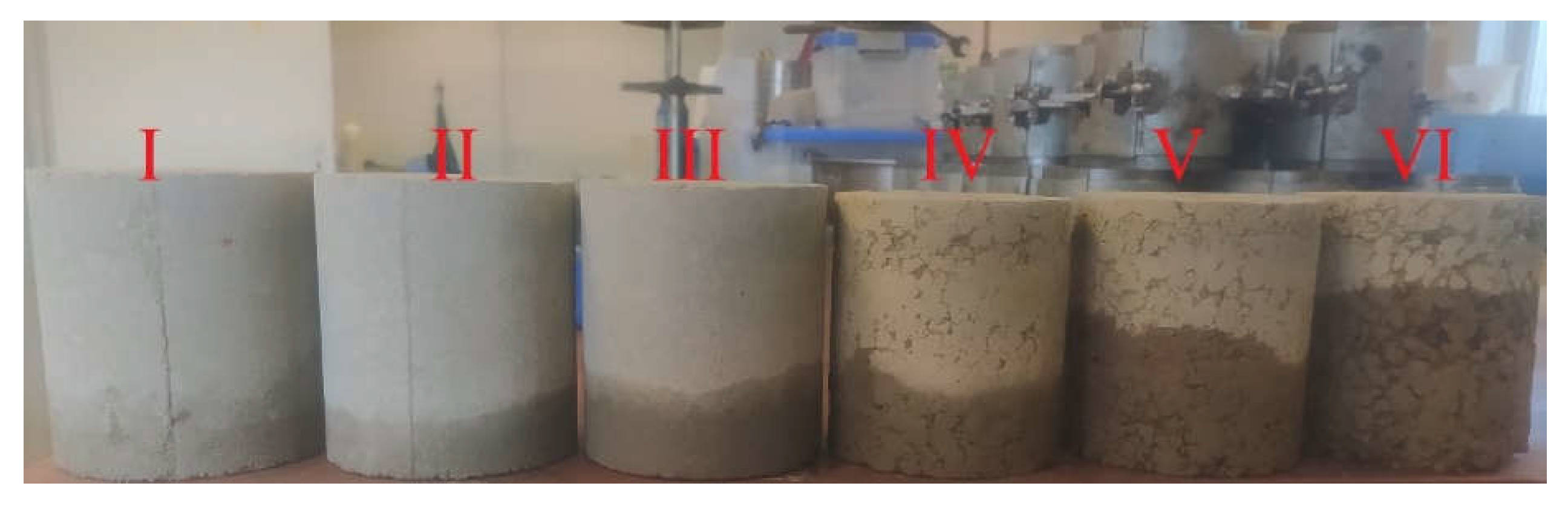

Figure 1.

View of the samples during capillary rise test.

Figure 1.

View of the samples during capillary rise test.

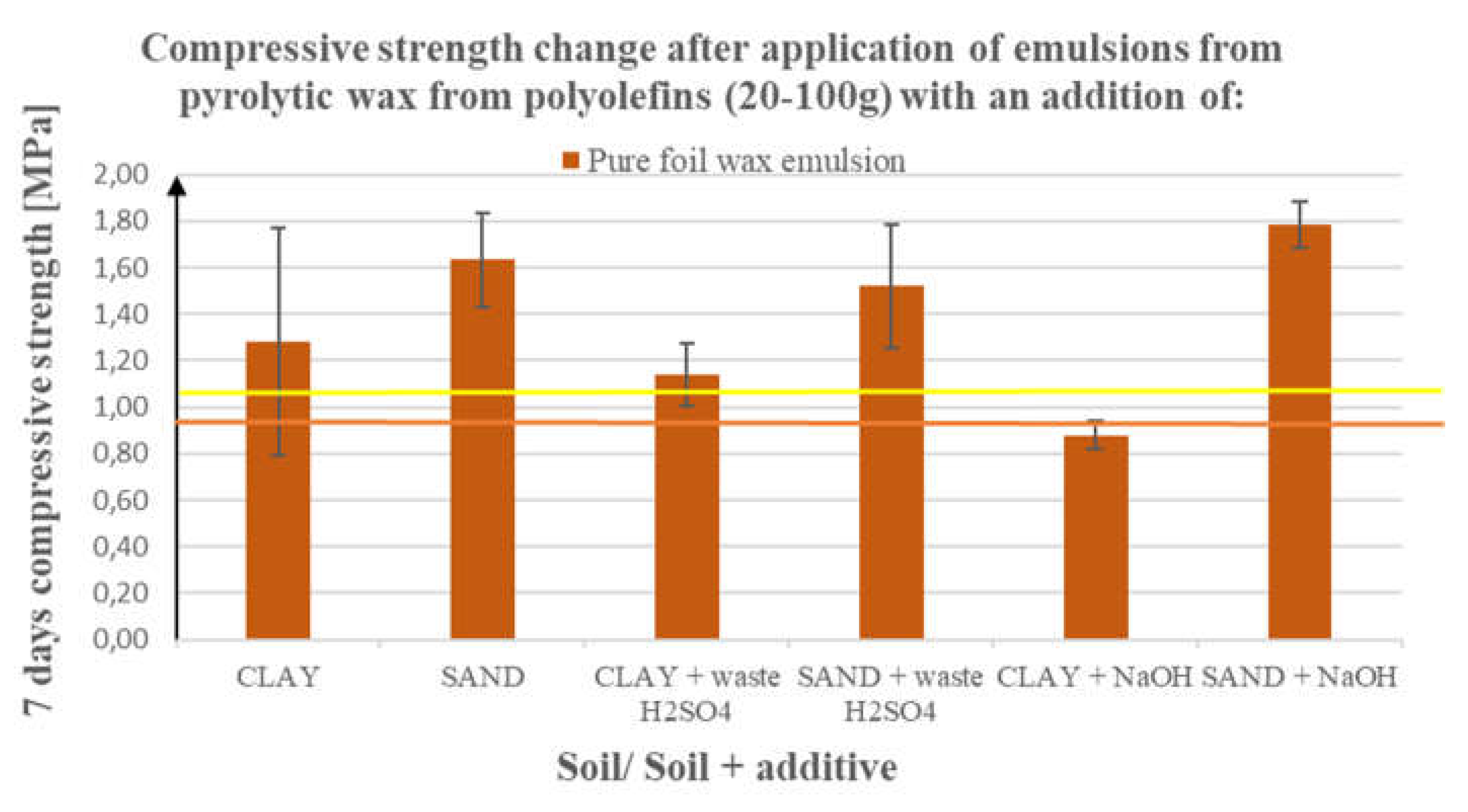

Figure 2.

Average effect of the addition of substitutes on compressive strength (first 4 bars) and average effect of the addition of substitutes enriched with pyrolytic wax emulsions (next 4 bars). The yellow line represents the control value (average compressive strength using only cement without additives) for sand and the brown line for clay.

Figure 2.

Average effect of the addition of substitutes on compressive strength (first 4 bars) and average effect of the addition of substitutes enriched with pyrolytic wax emulsions (next 4 bars). The yellow line represents the control value (average compressive strength using only cement without additives) for sand and the brown line for clay.

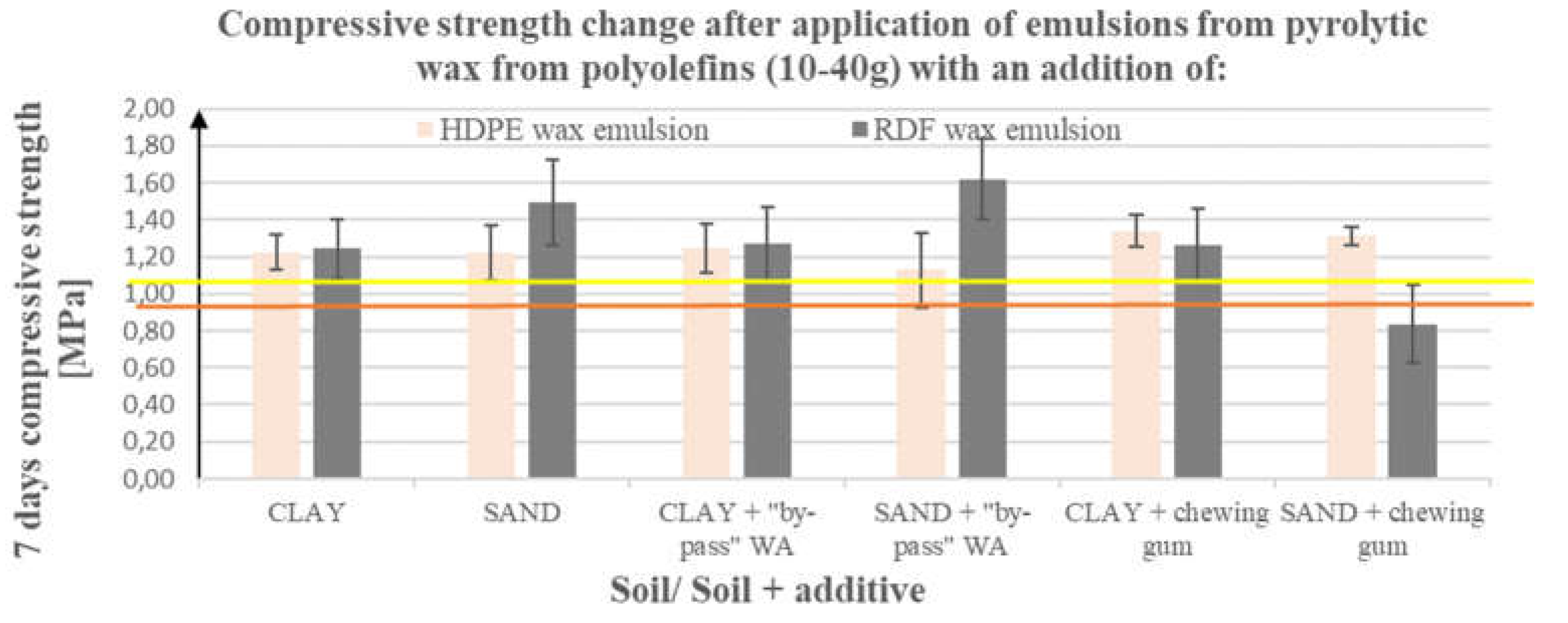

The results of average compressive strength values for binders based on the addition of emulsions from GROUP II are summarized below. The addition was from 10 to 40 g with 5% cement and 8 kg of soil.

Table 4.

The average soil compressive strength values with the addition of emulsions from pyrolytic waxes from particular polyolefines (HDPE, RDF, pure foil).

Table 4.

The average soil compressive strength values with the addition of emulsions from pyrolytic waxes from particular polyolefines (HDPE, RDF, pure foil).

| Additive |

HDPE wax emulsion |

RDF wax emulsion |

Pure foil wax emulsion |

| Soil |

CLAY |

SAND |

CLAY |

SAND |

CLAY |

SAND |

| Samples |

7 |

8 |

13 |

14 |

17 |

20 |

| MPa (7d) |

1,23 |

1,22 |

1,24 |

1,49 |

1,28 |

1,63 |

| SD/2 |

0,10 |

0,15 |

0,16 |

0,23 |

0,49 |

0,20 |

| Change (%)1 |

30,77% |

15,67% |

32,75% |

41,75% |

36,77% |

54,84% |

The results indicate a positive effect of the use of wax emulsions, with the best results observed for foil emulsions (37% increase for clay and 55% increase for sand), but RDF emulsions were slightly worse (33% for clay and 42% for sand). In contrast, the effect of using HDPE emulsion turned out to be two times better on clay than on sand. Any differences are probably due to inevitable impurities contained in thermally processed waste polyolefins. The good news is that RDF, much more polluted than foil, does not pose a threat to a significant reduction in the bearing capacity of the soil compared to a cleaner material such as foil. Standard deviations reached approximately 15-20%.

Despite the good results of the increase in compressive strength after using an emulsion made of post-pyrolytic waxes of waste polyolefins, the results for binders, where the addition of wax emulsion was also enriched with a substitute (Geosta or EN-1), are presented separately below on

Table 5. The effect of this addition compared to the use of the emulsion itself turned out to be small for the HDPE emulsion (from 31 to 33% for clay), slightly more significant for the RDF emulsion (from 42 to 54% for sand) and decreased for the emulsion with pure foil (from 37% to 22% for clay and from 55% to 44% for sand). Therefore, taking into account the results from

Table 1 and

Table 2, it is suggested to use pyrolytic wax emulsions as an additive as a priority, and temporarily, depending on the soil and situation, to use emulsion hybrids with substitutes which gave the highest results for the combination of emulsions with Geosta substitute (up to 30% on clay and 57% on sand). Standard deviations reached approximately 15-20%.

The compressive strength results for hybrids in the form of pyrolysis wax emulsions (HDPE and RDF) + chewing gum emulsion and pyrolysis wax emulsions (pure foil) + NaOH are listed below in

Table 6. The best results using chewing gum waste were achieved for HDPE emulsion, i.e. up to 43% growth on clay and up to 24% on sand and up to 35% on clay when using RDF emulsion. The addition of NaOH to the foil emulsion had no effect on the results on clay, and on sand it increased the compressive strength by up to almost 70%.

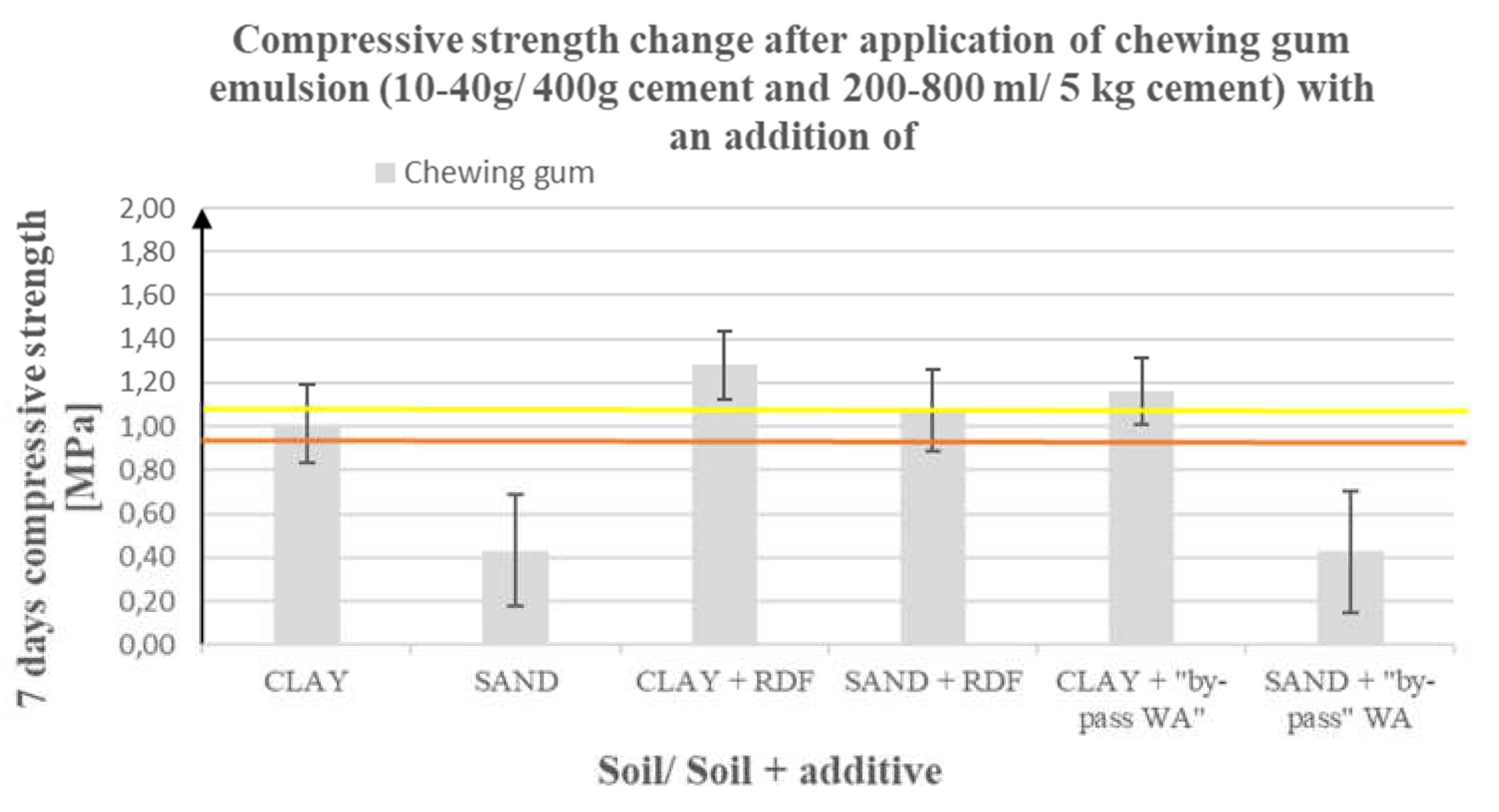

Group III EMULSIONS from CHEWING GUM WASTE

+ Emulsions from pyrolytic waxes of plastic waste

+ “By-pass” waste ash from ceramic industry

As shown in

Table 7 and its graphical interpretation on

Figure 3, the effect of using chewing gum emulsion on sand is negative, while on clay only in hybrids with RDF emulsion (37% increase) and with the Geosta substitute (24% increase) is observed significant improvement in the compressive strength of the soil. Standard deviations for increases reached 15-20% and even up to 50% for decreases.

Table 7.

Average effect of the addition of an emulsion from chewing gum waste and additionally with (1) an emulsion from pyrolytic waxes and (2) a Geosta substitute, on the soil compressive strength.

Table 7.

Average effect of the addition of an emulsion from chewing gum waste and additionally with (1) an emulsion from pyrolytic waxes and (2) a Geosta substitute, on the soil compressive strength.

| Additive |

Chewing gum |

Chewing gum + RDF |

Chewing gum + "by-pass" Waste Ash |

| Soil |

CLAY |

SAND |

CLAY |

SAND |

CLAY |

SAND |

| Samples |

48 |

32 |

13 |

8 |

22 |

12 |

| MPa (7d) |

1,01 |

0,43 |

1,28 |

1,07 |

1,16 |

0,43 |

| SD/2 |

0,18 |

0,26 |

0,16 |

0,19 |

0,16 |

0,28 |

| Change (%) |

7,92% |

-58,99% |

36,67% |

1,77% |

23,97% |

-59,60% |

Figure 3.

Average effect of the addition of emulsion from chewing gum waste (first 2 bars) and additionally with (1) emulsion from pyrolytic waxes (next 2 bars) and (2) Geosta substitute (last 2 bars) on soil compressive strength. The yellow line represents the base value (average compressive strength using only cement without additives) for sand and the brown line for clay.

Figure 3.

Average effect of the addition of emulsion from chewing gum waste (first 2 bars) and additionally with (1) emulsion from pyrolytic waxes (next 2 bars) and (2) Geosta substitute (last 2 bars) on soil compressive strength. The yellow line represents the base value (average compressive strength using only cement without additives) for sand and the brown line for clay.

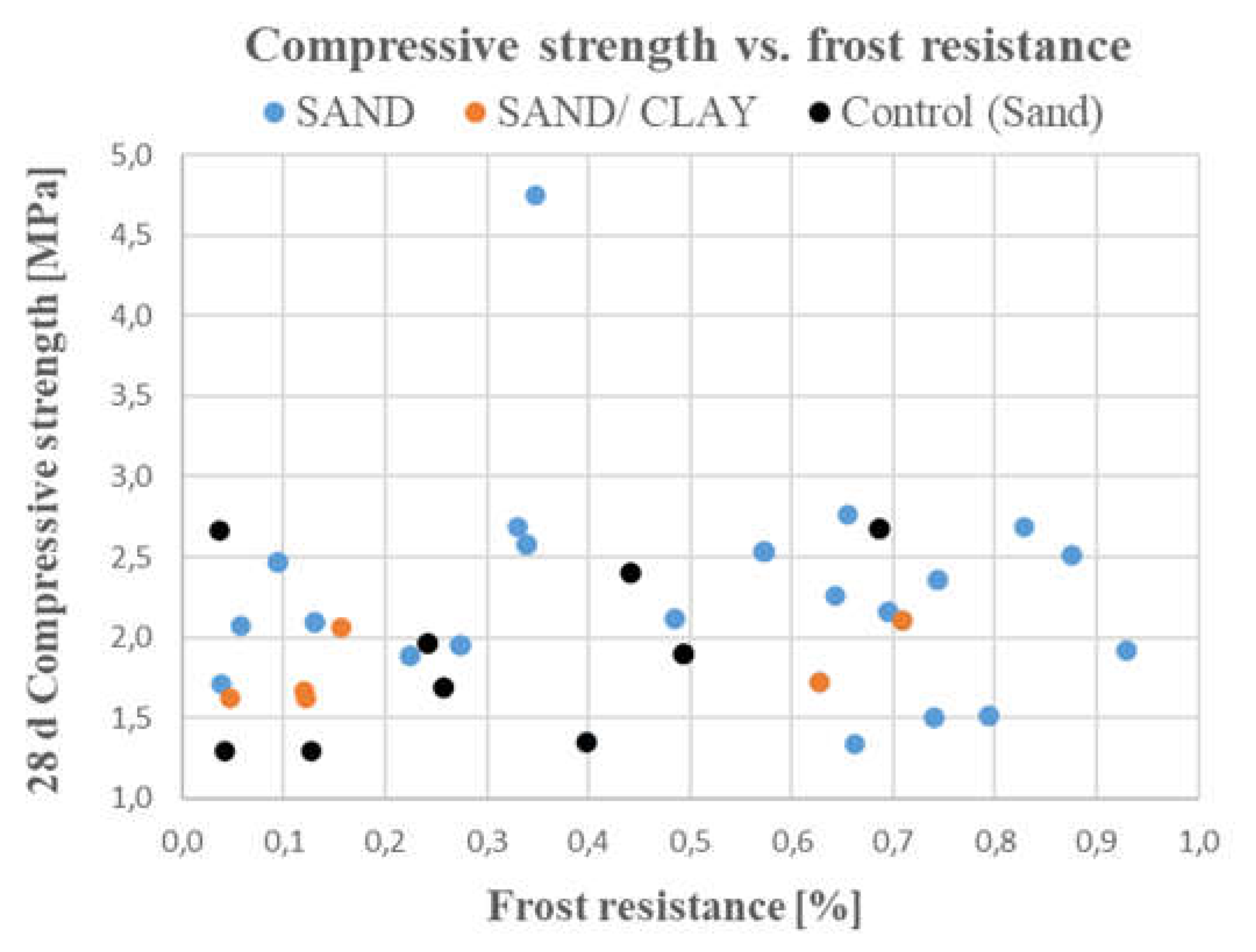

3.3. Second round of tests (2021-2022). Soil compressive strength, water absorption and frost resistance.

SAND

Best sealing materials – sorted by the frost resistance

All results from studied materials were sorted by frost resistance value. Only results higher than 35.6% are presented, which is the average value for the control scenario with cement only. Advantages: + The highest frost resistance values, i.e. above 80% (excluding the result above 100%), were achieved for the following additives: Pure foil, RDF Pure foil + NaOH, ProRoad Waterproof + Water Glass. + For these scenarios, capillary rise and water absorption values were mainly below 3% and below 8%, respectively. Disadvantages: - The disadvantage of using these additives is only a slight increase in compressive strength after 7 days (15-40%) and after 28 days (26-36%).

Subjective assessment of additives: + + -

All results from studied materials were sorted by the capillary rise value (water absorption over 4 hours). Only results better (lower) than 2% are presented (the control value is 6% for the binder only with cement). Advantages: + The lowest capillary rise values i.e. less than 1% were achieved for the following additives: Pure foil, RDF, Sodium Stearate, waste from Nivea cream production and RDF Mixture, ProRoad Waterproof, Nivea Soap, RDF Sulfonated, waste from Nivea cream production, waste from washing powder production, + For these scenarios frost resistance values (if measured) ranged from 22% to 74%. Disadvantages: +- The uncertainty of using these additives is the unstable change in compressive strength after 7 days (-80 +231%) and - rather, the decrease in compressive strength after 28 days to -25% (if measured).

Subjective assessment of additives: + + + - -

All results from studied materials were sorted by the water absorption value (during 24 hours). Only results better (lower) than 5.1% were presented, which is twice as low as for the control scenario with cement only (9.9%). Advantages: + The lowest absorption values, i.e. below 3%, were achieved for the following additives: Tequant, ProRoad Waterproof, RDF, Pure foil, Sodium Stearate, waste from Nivea cream production, waste from washing powder production, vaseline. Disadvantages: +- Frost resistance values were not measured for these scenarios. - The disadvantage of using these additives is a very unstable change in compressive strength after 7 days (from -79% to +231.6%) and, here and there, a decrease in compressive strength after 28 days.

Subjective assessment of additives: + + - - -

All results from studied materials were sorted by the compressive strength value after 7 days. Only results that are better (higher) by 50% or more compared to the control scenario with cement only (1.15 MPa) are presented. Advantages: + The highest compressive strength values above 2 MPa (change of 75% and more) were achieved for the following additives: waste from Nivea cream production and RDF mixture, waste from washing powder production, waste from Nivea cream production + RDF + waste from washing powder production, Concrete additive, Water glass + NaOH, RDF sulfonated, waste from Nivea cream production + RDF. For these scenarios, frost resistance and compressive strength values after 28 days were not measured (apart from two visible ones from 9/02/21 and 9/03/21). + Capillary rise values for these scenarios were mostly below 3% (with 6% for the control scenario).

Subjective assessment of additives: + + +

All results from studied materials were sorted by the compressive strength value after 28 days. Only results that are better (higher) by 14% or more compared to the control scenario with cement only (1.98 MPa) are presented. Advantages: + The highest compressive strength values above 2.2 MPa were achieved for the following additives: waste from washing powder production, Proroad Waterproof, Prorad Waterproof + Water Glass, Sodium stearate, “by-pass” waste ash + RDF + NaOH x2 and x1, Pure foil + NaOH, Pure foil + waste sulphuric acid, RDF from waste tires. + For these scenarios, frost resistance values ranged from 34 to 88% and + compressive strength after 7 days was increased by 56-80% for waste additives (RDF-based) and unfortunately - decreased by 27-65% for commercial additives. ++ The capillary rise and water absorption values for these scenarios were mainly below 4% and 10%, respectively.

Subjective assessment of additives: + + + - + +

The tests failed due to samples disintegrating during freezing-thawing cycles.

All results from studied materials were sorted by the capillary rise value (water absorption over 4 hours). Only results better (lower) than 4.2% are presented (the control value is 4.24% for the binder with cement only). Advantages: + The lowest capillary rise values, i.e. below 3%, were achieved for the following additives: Tequant, ROKAmin, Pure foil + NaOH, Pure foil + EN-1 Substitute, Concrete Additive, ProRoad Waterproof, Disadvantages: - The uncertainty of using these additives is the unstable change in compressive strength after 7 days (-42 +81%) where a significant (>40%) increase in compressive strength after their use occurred only for 3 scenarios: Pure foil + NaOH, Pure foil + EN-1 Substitute, Concrete Additive, + Compressive Strength after 28 days, measured for 3 scenarios, it varied from -38% to 119%.

Subjective assessment of additives: + - +

All results from studied materials were sorted by the water absorption value (water absorption during 24 hours). Only results better (lower) than 11% are presented (the control value is 11.14% for the binder only with cement). Advantages: + The lowest water absorption values, i.e. below 10%, were achieved for the following additives: Tequant, ROKAmin, Pure foil + NaOH, Pure foil + EN-1 substitute, Pure foil + ROKAmin + NaOH, ProRoad Waterproof, Concrete additive (these are also the same additives that ensured the lowest capillary rise), - The uncertainty of using these additives is the unstable change in compressive strength after 7 days (-41 +81%) where a significant (>40%) increase in compressive strength after their use occurred only for 3 scenarios: Pure foil + NaOH, RDF ure foil + EN-1 Substitute, Concrete Additive, + Compressive strength after 28 days measured for 3 scenarios varied from -38% to 119%.

Subjective assessment of additives: + - + (the same additives had a relatively even effect on both capillary rise and water absorption).

All results from studied materials were sorted by the compressive strength value after 7 days. Only results better (higher) than 10% and more compared to the control scenario with cement only (0.7 MPa) are presented. Advantages: + The highest compressive strength values above 0.9 MPa (change of 30% and more) were achieved for the following additives: Pure foil + EN-1 Substitute, Pure foil, Concrete Additive, chewing gum waste + Pure fil + NaOH, Pure foil + NaOH, Glass Water + NaOH, RDF with pyrolytic oil. + For these scenarios, the compressive strength values after 28 days were not measured (apart from the two from 28/04/21 where these values improved significantly, i.e. by 64 and 119%). Disadvantages: +- the capillary rise values for these scenarios were mostly in the range of 2.3%-10% for the best scenarios, 10%-12% for the moderate scenarios with two exceptions of 12% and 14.8%. (at 4.2% for the control scenario).

Subjective assessment of additives: + + + -

All results from studied materials were sorted by the compressive strength value after 28 days. All results are presented relative to the control scenario with cement only (0.84 MPa). Disadvantages: - The highest compressive strength values above 1 MPa were achieved only for the following additives: RDF Foil + NaOH, Pure foil + EN-1 Substitute. Disadvantages: - For the first scenario, frost resistance was only 7.53% and + Compressive strength after 7 days was increased by 41-81%. The + capillary rise and + water absorption values for these scenarios were mainly below 3% and 10%, respectively (with reference values of 4.2% and 11.1%, respectively).

Subjective assessment of additives: - - + + +