Submitted:

07 October 2023

Posted:

07 October 2023

Read the latest preprint version here

Abstract

Keywords:

1. Introduction

2. Materials and Methods

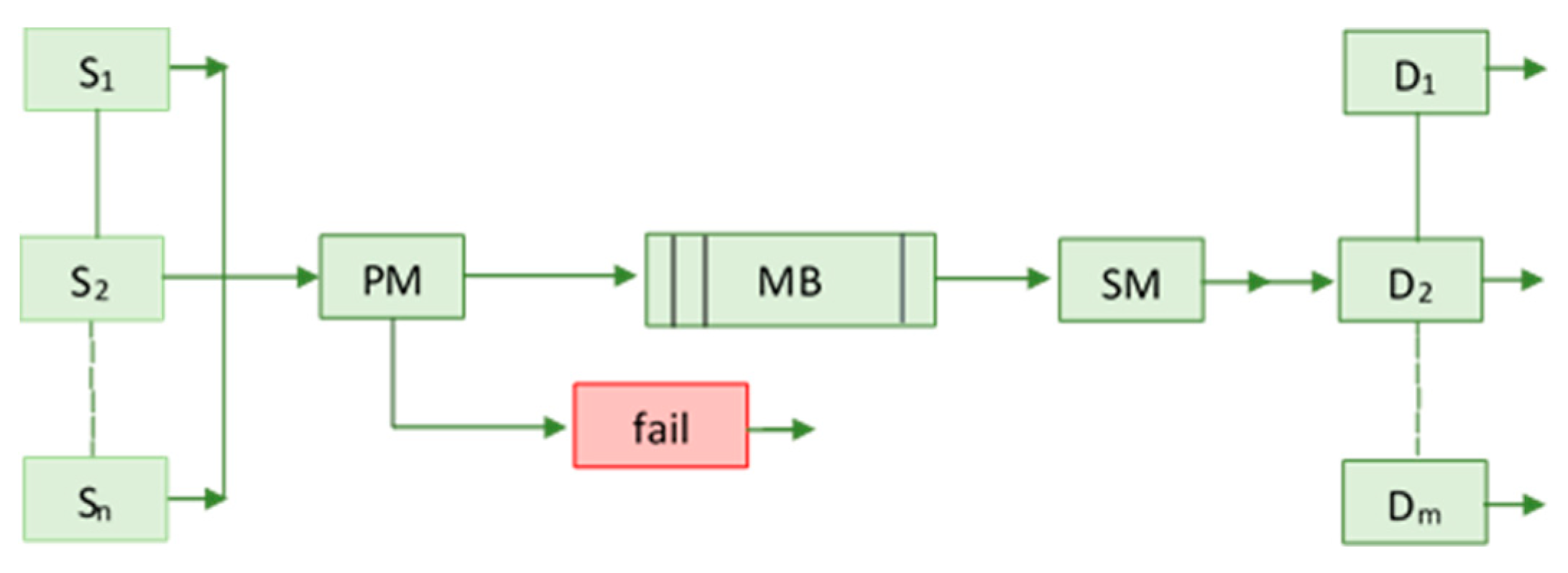

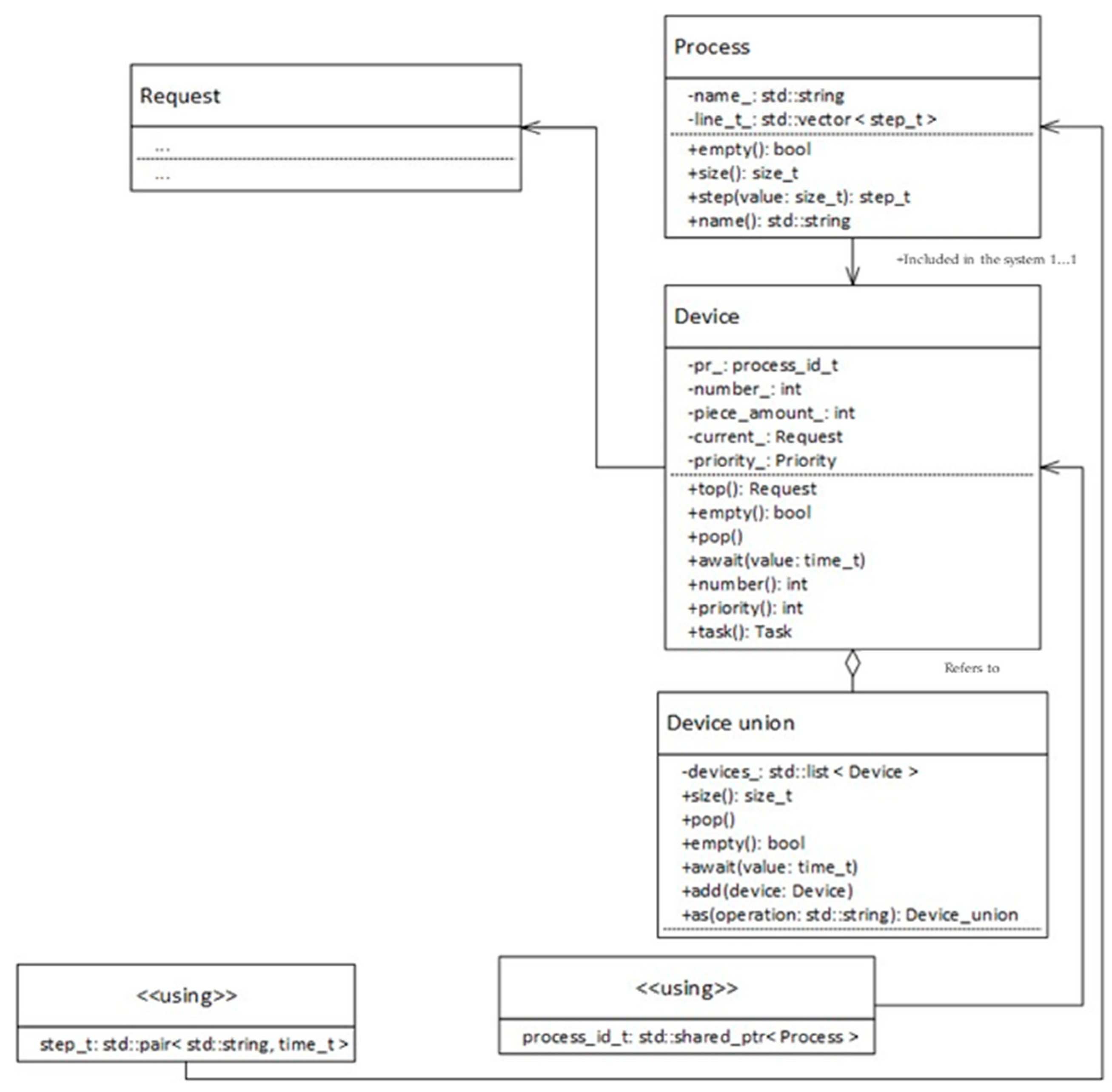

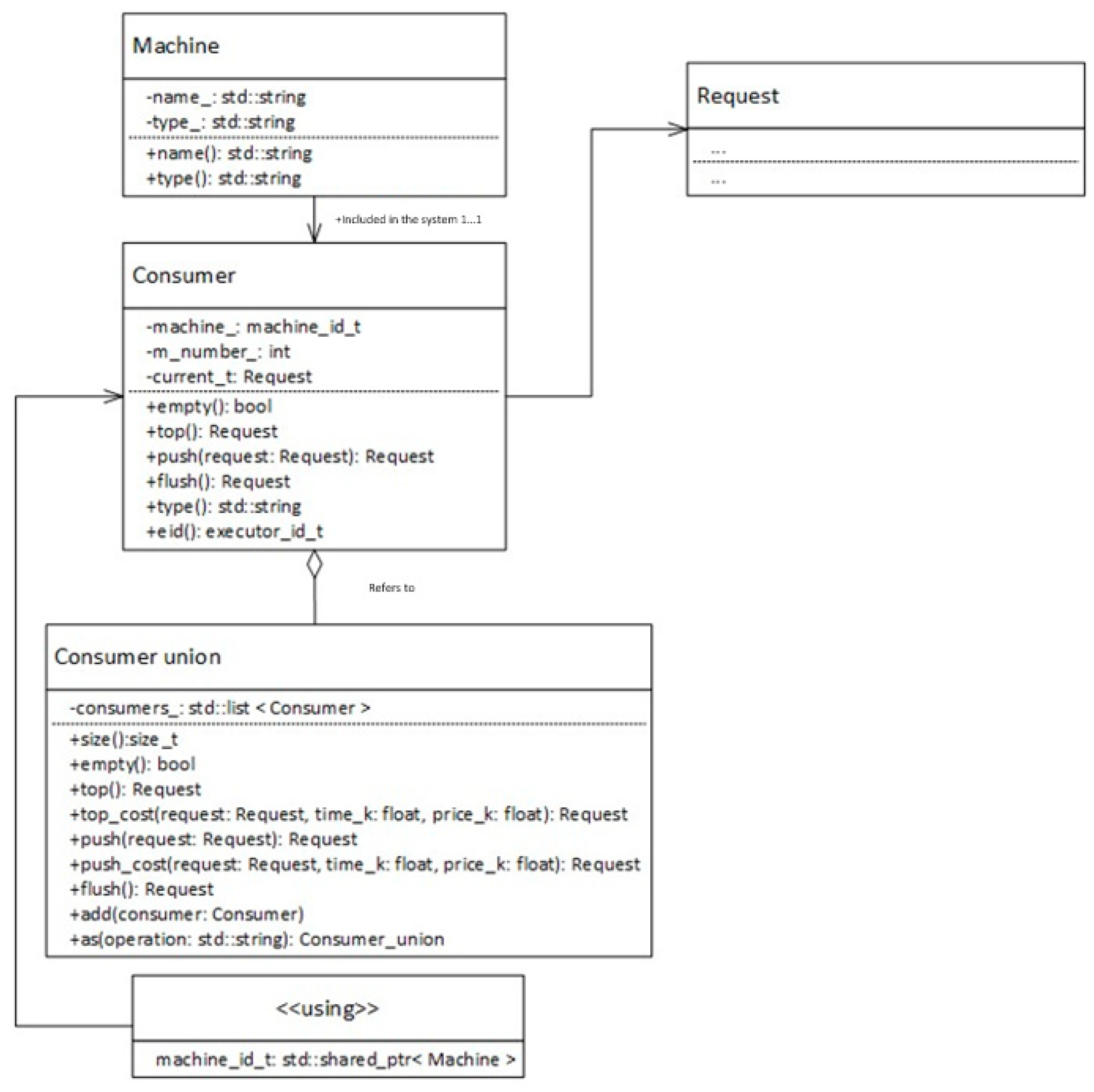

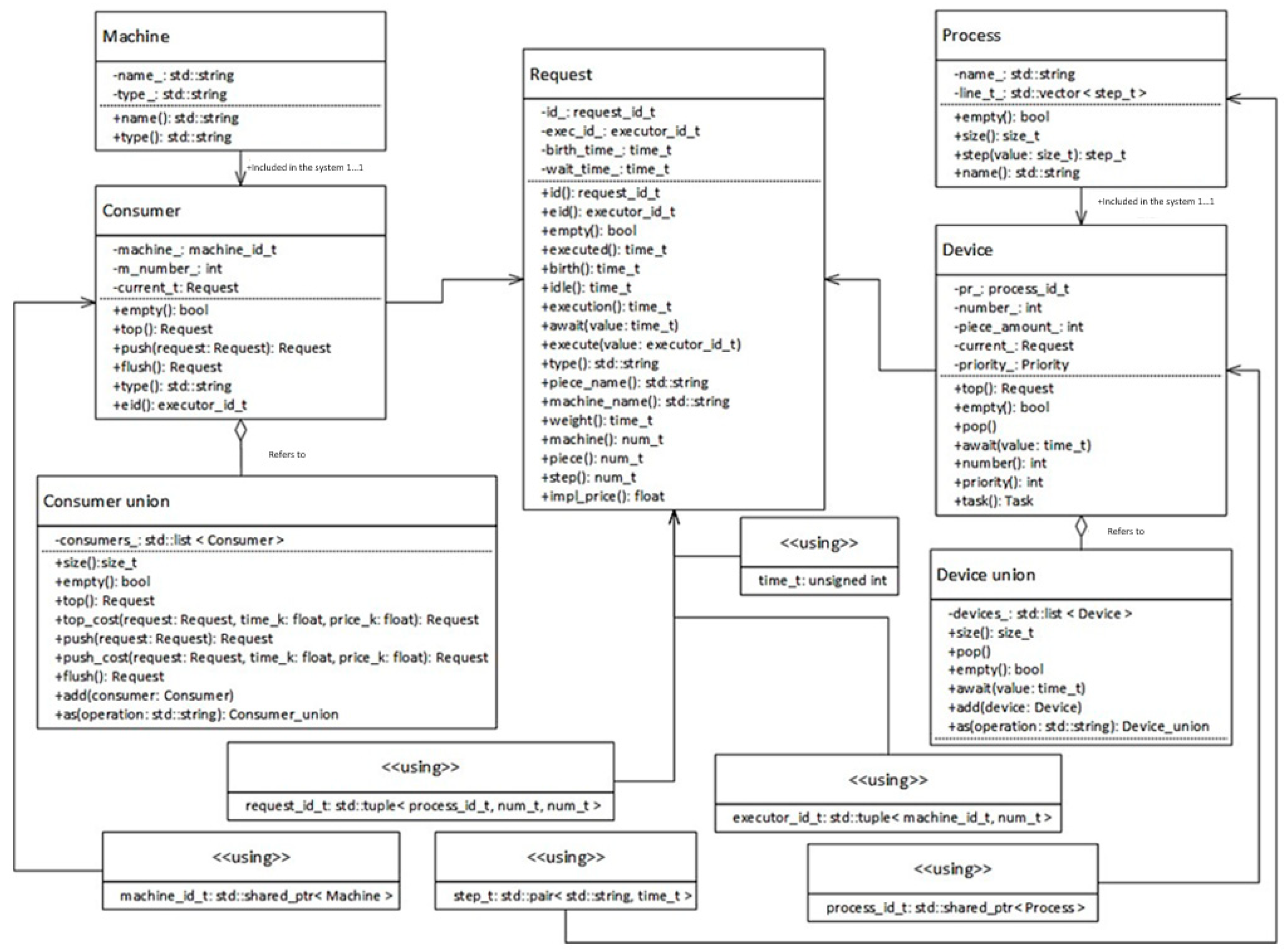

2.1. Structure of the simulation model and description of the simulation process

3. Result

3.1. Structure of the simulation model and description of the simulation process

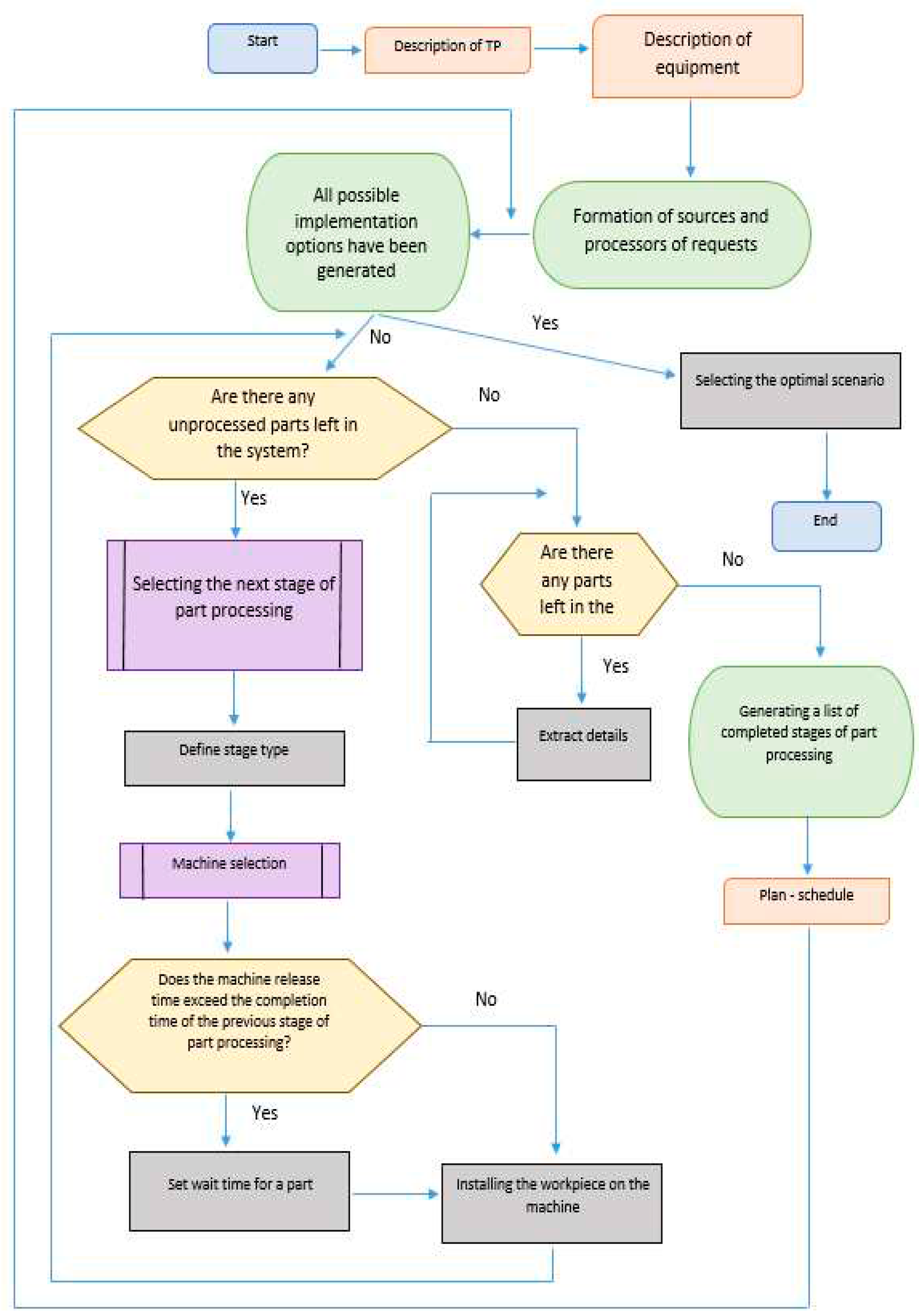

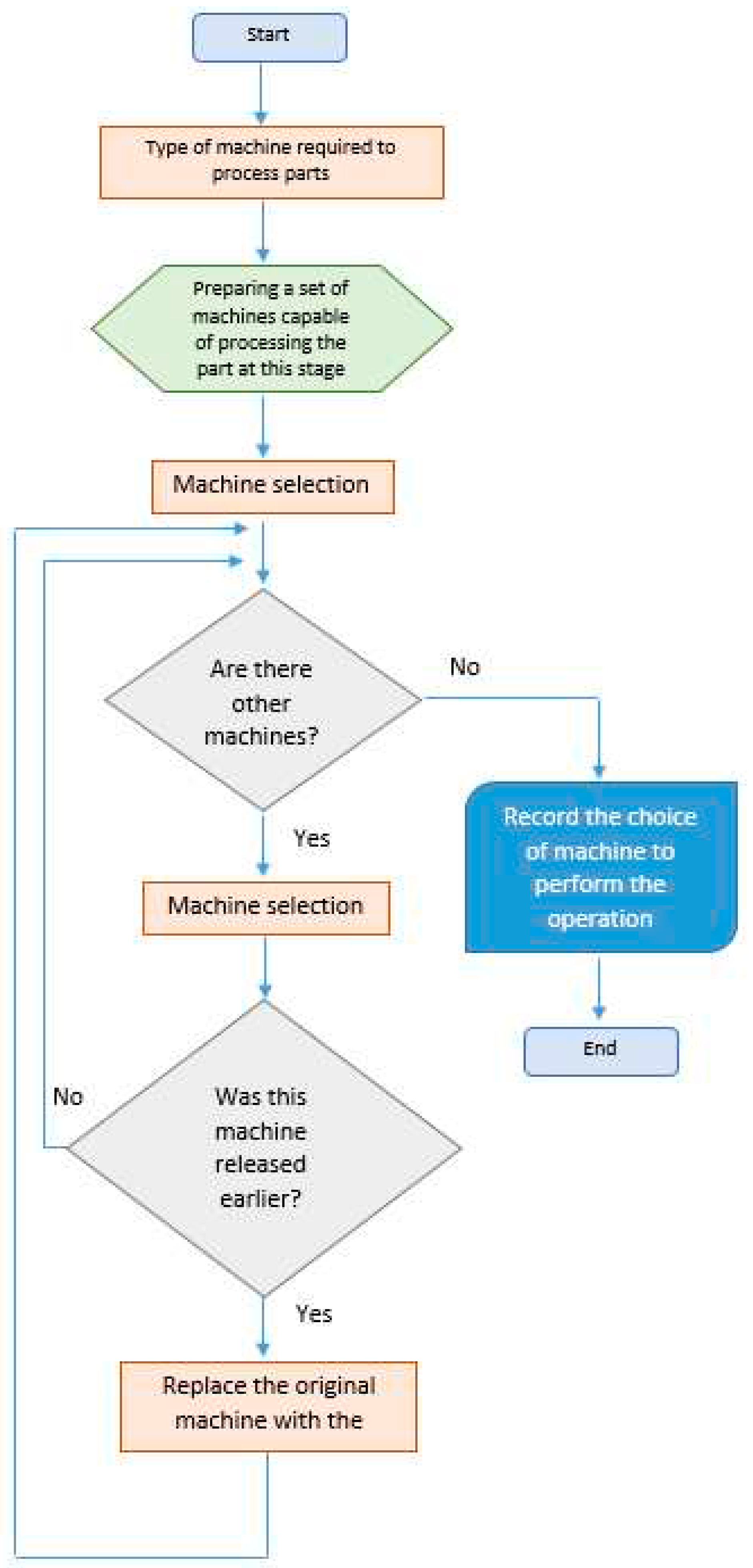

3.2. Algorithmization of simulation modeling

- Dimensions: maximum diameter 24mm, length 26mm;

-

Exact dimensions:

- -

- outer diameter 𝜙 24ℎ6 with roughness Ra 0.8;

- -

- internal diameter 𝜙 11𝐻8 with roughness Ra 1.6;

- -

- internal threaded surface M8-7H, roughness Ra 3.2.

- General tolerances for other dimensions: H14, h14, ±IT14/2.

- Thun – universal lathes

- Tchpu – lathes with numerical control

- TFNC – turning and milling machines with numerical control

- KSh – cylindrical grinding machines

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chernorutsky, I.; Kotlyarov, V.; Shyamasundar, R.; Tolstoles, A.; Voinov, N. Implementation of reliable net-centric management of IoT industrial workshop for small-scale production. IOP Conference Series: Materials Science and Engineering, 21–22 November. [CrossRef]

- Manzei, C. , Schleupner L., Heinze R. Industrie 4.0 im internationalen Kontext: Kernkonzepte, Ergebnisse, Trends; VDE VERLAG GmbH: Berlin, Germany, 2016; ISBN 3-8007-3671-3. [Google Scholar]

- Marcos, M.P.; Pitarch, J.L.; de Prada, C. Integrated Process Re-Design with Operation in the Digital Era: Illustration through an Industrial Case Study. Processes 2021, 9, 1203. [Google Scholar] [CrossRef]

- Bako, B.; Božek, P. Trends in simulation and planning of manufacturing companies. International Conference on Manufacturing Engineering and Materials, Novy Smokovec, Slovakia, 6-, Volume 149, pp 571-575. 10 June. [CrossRef]

- Chlebus, E.; Krot, K. CAD 3D models decomposition in manufacturing processes. Archives of Civil and Mechanical Engineering 2016, 16, 20–29. [Google Scholar] [CrossRef]

- Adam, R.; Kotze, P.; Van der Merwe, A. Acceptance of enterprise resource planning systems by small manufacturing Enterprises. ICEIS 2011 - Proceedings of the 13th International Conference on Enterprise Information Systems, Volume 1, Beijing, China, 8-. 11 June. [CrossRef]

- Browne, J.; O'Kelly, M.E.J.; Davies, B.J. Scheduling in a batch or job shop production environment. Engineering Management International 1982, Issue 3, 173–184. [Google Scholar] [CrossRef]

- Burdo, G.B. Improving the technological preparations for manufacturing production. Russian Engineering Research volume 2017, 37, 49–56. [Google Scholar] [CrossRef]

- Siderska, J. Application of tecnomatix plant simulation for modeling production and logistics processes. Business, Management and Education, 2016. [Google Scholar] [CrossRef]

- Dong, S.; Medeiros, D.J. Minimising schedule cost via simulation optimisation: an application in pipe manufacturing. International journal of production research 2012, 50, 831–841. [Google Scholar] [CrossRef]

- 11, J. San Cristobal, J.R. Critical Path Definition Using Multicriteria Decision Making: Promethee Method. Journal of Construction Engineering and Management. [CrossRef]

- Jato-Espino, D.; Castillo-Lopez, E.; Rodriguez-Hernandez, J.; Canteras-Jordana, J. A review of application of multi-criteria decision making methods in construction. Automation in Construction 2014, 45. 151–162. [CrossRef]

- Rosova, A.; Behun, M.; Khouri, S. Case study: the simulation modeling to improve the efficiency and performance of production process. Wireless Networks 2022, 28, 863–872. [Google Scholar] [CrossRef]

- Pompeev, K.P.; Timofeeva, O.S.; Yablochnikov, E.I.; Volosatova, E.E. Methods of Parts Digital Models Design for Problems Resolving in Technological Preparation of Production. In: Evgrafov, A.N. (eds) Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Cham: Saint-Petersburg, Russian Federation, 2022, 129–139. [CrossRef]

- Torres-Jimenez, J.; Rangel-Valdez, N.; De-la-Torre, M.; Avila-George, H. An Approach to Aid Decision-Making by Solving Complex Optimization Problems Using SQL Queries. Appl. Sci. 2022, 12, 4569. [Google Scholar] [CrossRef]

- Sipser, M. Introduction to the Theory of Computation, 2 edition; Thomson: Boston, USA, 2006; ISBN 0-534-95097-3. [Google Scholar]

- Abramov, S.A. Lectures on the complexity of algorithms, ed. 3rd, rev. and additional; MTsNMO: Moscow, Russia, 2020; ISBN 978-5-443-91464-0. [Google Scholar]

- Pompeev, K.P.; Timofeeva, O.S.; Yablochnikov, E.I.; Volosatova, E.E. Methods of Parts Digital Models Design for Problems Resolving in Technological Preparation of Production. In: Evgrafov, A.N. (eds) Advances in Mechanical Engineering. Lecture Notes in Mechanical Engineering. Springer, Cham: Saint-Petersburg, Russian Federation, 2022, 129–139. [CrossRef]

- Kalyakulin, S.Yu.; Kuzmin, V.V.; Mitin, E.V.; Suldin, S.P.; Tyurbeeva, T.B. Designing the Structure of Technological Processes Based on Synthesis. Mordovia University Bulletin 2018, 28, 77–84. [Google Scholar] [CrossRef]

- Khrustaleva, I.N.; Lyubomudrov, S.A.; Chernykh, L.G.; Stepanov, S.N.; Larionova, T.A. Automating production engineering for custom and small-batch production on the basis of simulation modeling. Journal of Physics: Conference Series, 0120. [Google Scholar] [CrossRef]

- Ivanov, V.; Botko, F.; Kolos, V.; Pavlenko, I.; Hatala, M.; Antosz, K.; Trojanowska, J. Locating Chart Choice Based on the Decision-Making Approach. Materials 2022, 15, 3557. [Google Scholar] [CrossRef]

- Trojanowska, J.; Kolinski, A.; Galusik, D.; Rocha Varela, L. A methodology of improvement of manufacturing productivity through increasing operational efficiency of the production process. Advances in Manufacturing 2018. Springer International Publishing 2018, 1, 23–32. [Google Scholar] [CrossRef]

- Araujo, A.F. et al. Development of an intelligent and automated system for lean industrial production, adding maximum productivity and efficiency in the production process. Advances in manufacturing, Springer International Publishing 2018, 1, 131-140. [CrossRef]

- Vukelic, D.; Zuperl, U.; Hodolic, J. Complex system for fixture selection, modification, and design. The International Journal of Advanced Manufacturing Technology 2009, 45, 731–748. [Google Scholar] [CrossRef]

- Abouel Nasr, E. Al-Ahmari, A.; Khan A.A.; Mian S.H. Integrated system for automation of process, fixture and inspection planning. Journal of the Brazilian Society of Mechanical Sciences and Engineering. [CrossRef]

- Liu, M.; Zhou, B.; Li, J.; Li, X.; Bao, J. A Knowledge Graph-Based Approach for Assembly Sequence Recommendations for Wind Turbines. Machines 2023, 11, 930. [Google Scholar] [CrossRef]

- Chen, Z. Assembly information model based on knowledge graph. Journal of Shanghai Jiaotong University (Science) 2020, 25, 578–588. [Google Scholar] [CrossRef]

- Li, X. Structured modeling of heterogeneous CAM model based on process knowledge graph. The International Journal of Advanced Manufacturing Technology 2018, 96, 4173–4193. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, H.; Li, J.; Zhang, Q.; Tang, Y. CKGAT: Collaborative Knowledge-Aware Graph Attention Network for Top-N Recommendation. Appl. Sci. 2022, 12, 1669. [Google Scholar] [CrossRef]

- Han, Z.; Mo, R.; Hao, L. Clustering and retrieval of mechanical CAD assembly models based on multi-source attributes information. Robotics and Computer-Integrated Manufacturing. [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Sabatakakis, K. Data Attributes in Quality Monitoring of Manufacturing Processes: The Welding Case. Appl. Sci. 2023, 13, 10580. [Google Scholar] [CrossRef]

- Wang, X.; Liu, M.; Zhong, P.; Zhang, C.; Zhang, D. A Discrete Cooperative Control Method for Production Scheduling Problem of Assembly Manufacturing System. Sustainability 2023, 15, 13785. [Google Scholar] [CrossRef]

- Xiong, H.; Shi, Sh.; Ren, D.; Hu, J. A survey of job shop scheduling problem: The types and models. Computers & Operations, 1057. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hasani, A. An energy-efficient multi-objective optimization for flexible job-shop scheduling problem, Computers & Chemical Engineering 2017, 104, 339-352. [CrossRef]

- Ciurana, J.; Garcia-Romeu, M.L.; Ferrer, I.; Casadesus, M. A model for integrating process planning and production planning and control in machining processes. Robotics and Computer-Integrated Manufacturing. [CrossRef]

- García-Leon, A.A.; Dauzère-Pérès, S.; Mati, Ya. An efficient Pareto approach for solving the multi-objective flexible job-shop scheduling problem with regular criteria. Computers & Operations Research. [CrossRef]

- Knopp, S.; Dauzère-Pérès, S.; Yugma, C. A batch-oblivious approach for Complex Job-Shop scheduling problems. European Journal of Operational Research 2017, 263(1), 50–61. [Google Scholar] [CrossRef]

- Azzouz, A.; Ennigrou, M.; Ben Said, L. A self-adaptive hybrid algorithm for solving flexible job-shop problem with sequence dependent setup time. Procedia Computer Science 2017, 112, 457–466. [Google Scholar] [CrossRef]

- Xing, LN.; Chen, YW.; Yang, KW. An efficient search method for multi-objective flexible job shop scheduling problems. Journal of Intelligent Manufacturing 2009, 20, 283–293. [Google Scholar] [CrossRef]

- Shen, X.N.; Han, Y.; Fu, J.Z. Robustness measures and robust scheduling for multi-objective stochastic flexible job shop scheduling problems. Soft Computing 2017, 21, 6531–6554. [Google Scholar] [CrossRef]

- Fernández Pérez, M.A.; Raupp, F.M.P. A Newton-based heuristic algorithm for multi-objective flexible job-shop scheduling problem. Journal of Intelligent Manufacturing 2016, 27, 409–416. [Google Scholar] [CrossRef]

- Moslehi, G.; Mahnam, M. A Pareto approach to multi-objective flexible job-shop scheduling problem using particle swarm optimization and local search. International Journal of Production Economics 2011, 129(1), 14–22. [Google Scholar] [CrossRef]

- Kacem, I.; Hammadi, S.; Borne, P. Pareto-optimality approach for flexible job-shop scheduling problems: hybridization of evolutionary algorithms and fuzzy logic. Mathematics and Computers in Simulation. [CrossRef]

- Ondov, M.; Rosova, A.; Sofranko, M.; Feher, J.; Cambal, J.; Feckova Skrabulakova, E. Redesigning the Production Process Using Simulation for Sustainable Development of the Enterprise. Sustainability 2022, 14, 1514. [Google Scholar] [CrossRef]

- Iassinovski, S.; Artiba, A.; Fagnart, C. A generic production rules-based system for on-line simulation, decision making and discrete process control. International journal of production economics 2008, 112(1), 62–76. [Google Scholar] [CrossRef]

- Bernard, A.; Perry, N. Fundamental concepts of product/technology/process informational integration for process modelling and process planning. International Journal of Computer Integrated Manufacturing. [CrossRef]

- Shah, D.; Shin, J. Randomized scheduling algorithm for queueing networks. Ann. Appl. Probab. [CrossRef]

- Bathaee, M.; Nozari, H.; Szmelter-Jarosz, A. Designing a New Location-Allocation and Routing Model with Simultaneous Pick-Up and Delivery in a Closed-Loop Supply Chain Network under Uncertainty. Logistics 2023, 7, 3. [Google Scholar] [CrossRef]

- Malega, P.; Gazda, V.; Rudy, V. Optimization of production system in plant simulation. SIMULATION 2022, 98(4), 295–306. [Google Scholar] [CrossRef]

- Kuznetsov, P.M.; Khoroshko, L.L. Digitalization of Multi-Object Technological Projecting in Terms of Small Batch Production. Inventions 2020, 5, 38. [Google Scholar] [CrossRef]

- Simunovic, G.; Majdandzic, N.; Simunovic, K.; Lujic, R. Applying of the Typical Technological Operations in the Single Production. AMST’02 Advanced Manufacturing Systems and Technology, 437, 275–281; eds Kulianic, E., Ed.; International Centre for Mechanical Sciences, Springer: Vienna, Austria, 2002. [Google Scholar] [CrossRef]

| № | Machine type | Machine type designation | Processing method | Designation of processing method |

|---|---|---|---|---|

| 1 | Тun | mach1 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| 2 | ТCNC | mach2 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| 3 | ТFCNC | mach3 | tapping threads | op1 |

| drilling | op2 | |||

| semi-finish turning | op3 | |||

| rough turning | op4 | |||

| finishing turning | op5 | |||

| Pre- | op6 | |||

| grinding | ||||

| 4 | KS | mach4 | Tapping threads | op1 |

| Equipment |

|---|

| (:consumer 0:worker (:machine "mach1":line ( "op1" "op2" "op3" "op4" "op5" ):factor 1.0:):) |

| (:consumer 1:worker (:machine "mach2":line ( "op1" "op2" "op3" "op4" "op5" ) :factor 1.2:):) |

| (:consumer 2:worker (:machine "mach3":line ( "op1" "op2" "op3" "op4" "op5" ) :factor 1.3:):) |

| (:consumer 3:worker (:machine "mach4":line ( "op6" ) :factor 1.0:):) |

| № | Block of surfaces |

DTE | Processing method | Designation of processing method | |

|---|---|---|---|---|---|

| 1 | MB(1/2) | 1 | DTE(1Н-1)2 | rough turning | op4 |

| 2 | DTE(2Н/1-4)1 | re-grinding | op6 | ||

| rough turning | op4 | ||||

| semi-finish turning | op3 | ||||

| finishing turning | op5 | ||||

| 2 | MB(2/1) | 1 | DTE(2В/1-2)1 | drilling | op2 |

| semi-finish turning | op3 | ||||

| 2 | DTE(2В/1-1)2 | drilling | op2 | ||

| 3 | DTE(2В/2-1)1 | drilling | op2 | ||

| 4 | DTE(1В-1)1 | rough turning | op4 | ||

| 3 | MB(1/1) | 1 | DTE(1Н-1)1 | rough turning | op4 |

| 2 | DTE(2Н/2-1)2 | rough turning | op4 | ||

| 3 | DTE(2Н/1-1)2 | rough turning | op4 | ||

| 4 | DTE(2Н/2-1)1 | rough turning | op4 | ||

| 4 | MB(2/2) | 1 | DTE(2В/1-2)3 | drilling | op2 |

| semi-finish turning | op3 | ||||

| 2 | DTE(2В/1-3)4 | drilling | op2 | ||

| semi-finish turning | op3 | ||||

| rough turning | op5 | ||||

| 3 | DTE(2В/2-2)2 | drilling | op2 | ||

| semi-finish turning | op3 | ||||

| 4 | DTE(1В-1)2 | rough turning | op4 | ||

| 5 | DTE(1В-2)3 | rough turning | op4 | ||

| semi-finish turning | op3 | ||||

| 5 | MB(4/1) | 1 | DTE(4В/1-2)1 | drilling | op2 |

| thread cutting | op1 | ||||

| № | Designation of processing method | Processing method | Processing time (working hours) | Amount of costs (conventional units) |

|---|---|---|---|---|

| 1 | op1 | tapping threads | 32 | 4800 |

| 2 | op2 | drilling | 18 | 5600 |

| 3 | op3 | semi-finish turning | 12 | 8200 |

| 4 | op4 | rough turning | 20 | 6800 |

| 5 | op5 | finishing turning | 16 | 7400 |

| 6 | op6 | re-grinding | 29 | 5800 |

| Technological process |

|---|

| (:device 0:task ( (:process "TP-T":line ( ( "op4" (:time 40:price 13600:) ) ( "op3" (:time 12:price 8200:) ) ( "op5" (:time 16:price 7400:) ) ( "op6" (:time 29:price 5800:) ) ( "op2" (:time 18:price 5600:) ) ( "op3" (:time 12:price 8200:) ) ( "op2" (:time 36:price 11200:) ) ( "op4" (:time 100:price 34000:) ) ( "op2" (:time 18:price 5600:) ) "op3" (:time 12:price 8200:) ) ( "op2" (:time 18:price 5600:) ) ( "op3" (:time 12:price 8200:) ) ( "op5" (:time 16:price 7400:) ) ( "op2" (:time 18:price 5600:) ) ( "op3" (:time 12:price 8200:) ) ( "op4" (:time 40:price 13600:) ) ( "op3" (:time 12:price 8200:) ) ( "op2" (:time 18:price 5600:) ) ( "op1" (:time 32:price 4800:) ) ):) 1 ):) |

| Simulation Listing |

|---|

| (:id (:name TP-T:num 0:step 0:type op4:):birth 0:price 13600:wait 0:executor (:name mach1:num 0:execution 40:impl_price 13600:):) (:id (:name TP-T:num 0:step 1:type op3:):birth 40:price 8200:wait 40:executor (:name mach1:num 0:execution 52:impl_price 8200:):) (:id ():birth 0:price 0:wait 0:executor ():) (:id (:name TP-T:num 0:step 2:type op5:):birth 52:price 7400:wait 52:executor (:name mach1:num 0:execution 68:impl_price 7400:):) (:id (:name TP-T:num 0:step 4:type op2:):birth 97:price 5600:wait 97:executor (:name mach1:num 0:execution 115:impl_price 5600:):) (:id (:name TP-T:num 0:step 5:type op3:):birth 115:price 8200:wait 115:executor (:name mach1:num 0:execution 127:impl_price 8200:):) (:id (:name TP-T:num 0:step 6:type op2:):birth 127:price 11200:wait 127:executor (:name mach1:num 0:execution 163:impl_price 11200:):) (:id (:name TP-T:num 0:step 7:type op4:):birth 163:price 34000:wait 163:executor (:name mach1:num 0:execution 263:impl_price 34000:):) (:id (:name TP-T:num 0:step 8:type op2:):birth 263:price 5600:wait 263:executor (:name mach1:num 0:execution 281:impl_price 5600:):) (:id (:name TP-T:num 0:step 9:type op3:):birth 281:price 8200:wait 281:executor (:name mach1:num 0:execution 293:impl_price 8200:):) (:id (:name TP-T:num 0:step 10:type op2:):birth 293:price 5600:wait 293:executor (:name mach1:num 0:execution 311:impl_price 5600:):) (:id (:name TP-T:num 0:step 11:type op3:):birth 311:price 8200:wait 311:executor (:name mach1:num 0:execution 323:impl_price 8200:):) (:id (:name TP-T:num 0:step 12:type op5:):birth 323:price 7400:wait 323:executor (:name mach1:num 0:execution 339:impl_price 7400:):) (:id (:name TP-T:num 0:step 13:type op2:):birth 339:price 5600:wait 339:executor (:name mach1:num 0:execution 357:impl_price 5600:):) (:id (:name TP-T:num 0:step 14:type op3:):birth 357:price 8200:wait 357:executor (:name mach1:num 0:execution 369:impl_price 8200:):) (:id (:name TP-T:num 0:step 15:type op4:):birth 369:price 13600:wait 369:executor (:name mach1:num 0:execution 409:impl_price 13600:):) (:id (:name TP-T:num 0:step 16:type op3:):birth 409:price 8200:wait 409:executor (:name mach1:num 0:execution 421:impl_price 8200:):) (:id (:name TP-T:num 0:step 17:type op2:):birth 421:price 5600:wait 421:executor (:name mach1:num 0:execution 439:impl_price 5600:):) (:id (:name TP-T:num 0:step 18:type op1:):birth 439:price 4800:wait 439:executor (:name mach1:num 0:execution 471:impl_price 4800:):) (:id (:name TP-T:num 0:step 3:type op6:):birth 68:price 5800:wait 68:executor (:name mach4:num 3:execution 97:impl_price 5800:):) (:id (:name TP-T:num 0:step 0:type op4:):birth 0:price 13600:wait 0:executor (:name mach1:num 0:execution 40:impl_price 13600:):) (:id (:name TP-T:num 0:step 1:type op3:):birth 40:price 8200:wait 40:executor (:name mach1:num 0:execution 52:impl_price 8200:):) (:id (:name TP-T:num 0:step 2:type op5:):birth 52:price 7400:wait 52:executor (:name mach1:num 0:execution 68:impl_price 7400:):) (:id (:name TP-T:num 0:step 4:type op2:):birth 97:price 5600:wait 97:executor (:name mach1:num 0:execution 115:impl_price 5600:):) (:id (:name TP-T:num 0:step 5:type op3:):birth 115:price 8200:wait 115:executor (:name mach1:num 0:execution 127:impl_price 8200:):) (:id (:name TP-T:num 0:step 6:type op2:):birth 127:price 11200:wait 127:executor (:name mach1:num 0:execution 163:impl_price 11200:):) (:id (:name TP-T:num 0:step 7:type op4:):birth 163:price 34000:wait 163:executor (:name mach1:num 0:execution 263:impl_price 34000:):) (:id (:name TP-T:num 0:step 8:type op2:):birth 263:price 5600:wait 263:executor (:name mach1:num 0:execution 281:impl_price 5600:):) (:id (:name TP-T:num 0:step 9:type op3:):birth 281:price 8200:wait 281:executor (:name mach1:num 0:execution 293:impl_price 8200:):) (:id (:name TP-T:num 0:step 10:type op2:):birth 293:price 5600:wait 293:executor (:name mach1:num 0:execution 311:impl_price 5600:):) (:id (:name TP-T:num 0:step 11:type op3:):birth 311:price 8200:wait 311:executor (:name mach1:num 0:execution 323:impl_price 8200:):) (:id (:name TP-T:num 0:step 12:type op5:):birth 323:price 7400:wait 323:executor (:name mach1:num 0:execution 339:impl_price 7400:):) (:id (:name TP-T:num 0:step 13:type op2:):birth 339:price 5600:wait 339:executor (:name mach1:num 0:execution 357:impl_price 5600:):) (:id (:name TP-T:num 0:step 14:type op3:):birth 357:price 8200:wait 357:executor (:name mach1:num 0:execution 369:impl_price 8200:):) (:id (:name TP-T:num 0:step 15:type op4:):birth 369:price 13600:wait 369:executor (:name mach1:num 0:execution 409:impl_price 13600:):) (:id (:name TP-T:num 0:step 16:type op3:):birth 409:price 8200:wait 409:executor (:name mach1:num 0:execution 421:impl_price 8200:):) (:id (:name TP-T:num 0:step 17:type op2:):birth 421:price 5600:wait 421:executor (:name mach1:num 0:execution 439:impl_price 5600:):) (:id (:name TP-T:num 0:step 18:type op1:):birth 439:price 4800:wait 439:executor (:name mach1:num 0:execution 471:impl_price 4800:):) (:id (:name TP-T:num 0:step 3:type op6:):birth 68:price 5800:wait 68:executor (:name mach4:num 3:execution 97:impl_price 5800:):) Res_price:175000 Res_time: 471 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).