Submitted:

06 October 2023

Posted:

06 October 2023

You are already at the latest version

Abstract

Keywords:

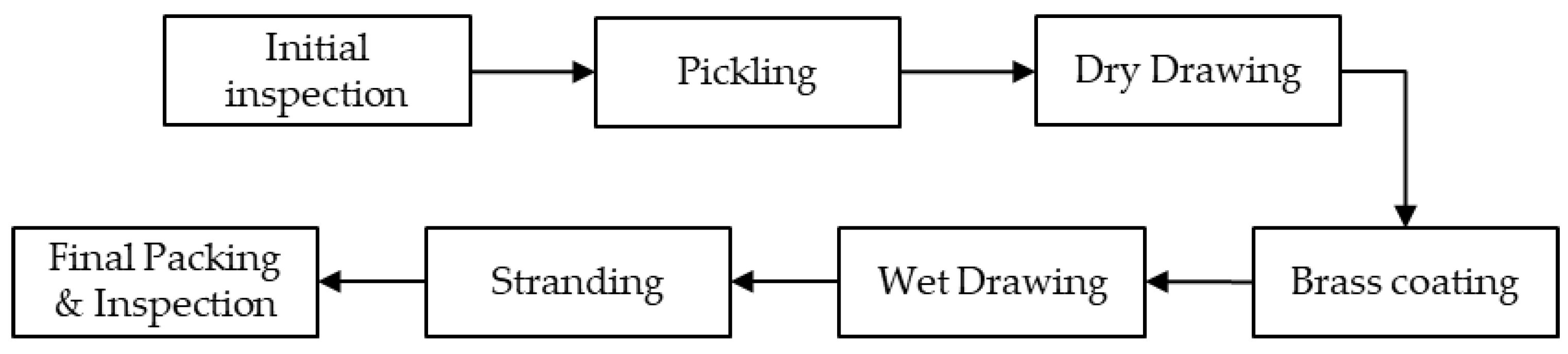

1. Introduction

2. Research methodology

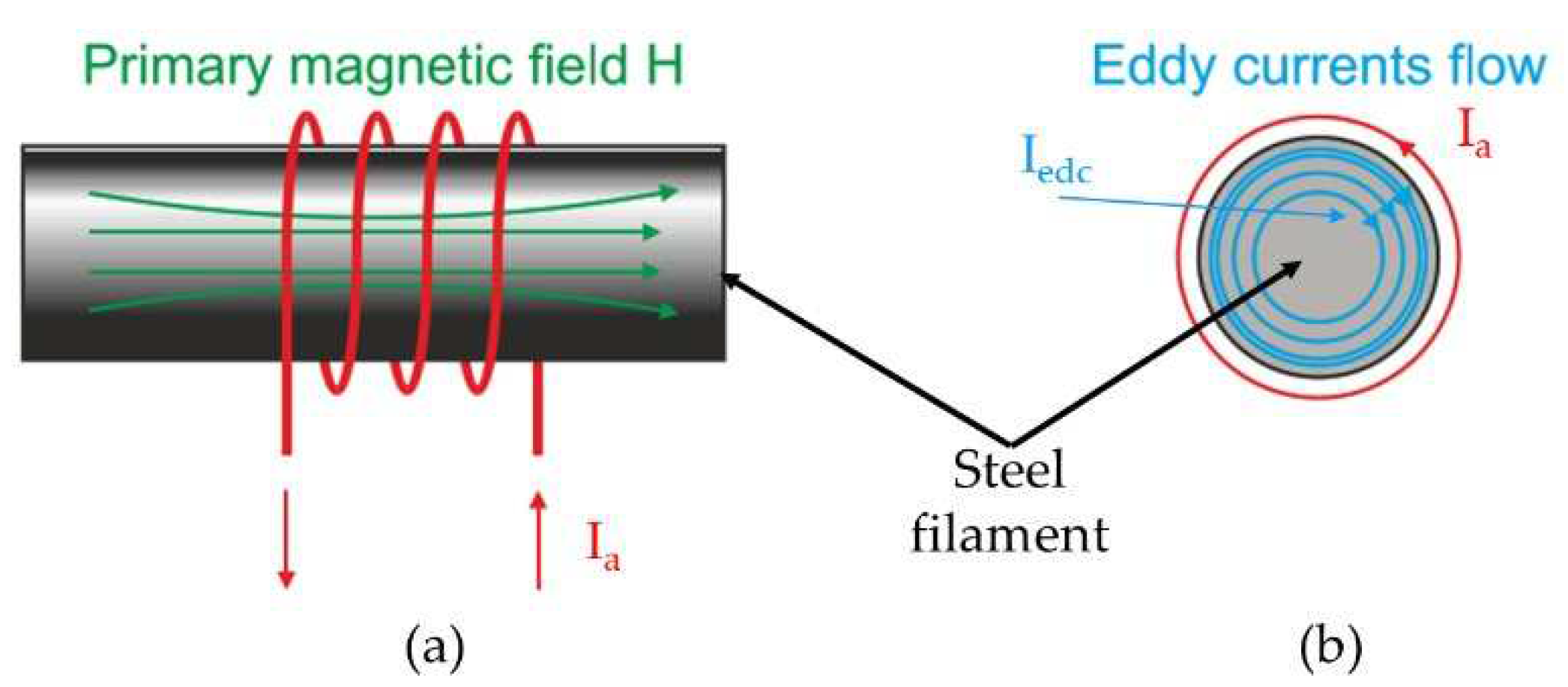

2.1. Eddy current princile

2.2. Standard penetration depth and defect’s depth

3. Experiment

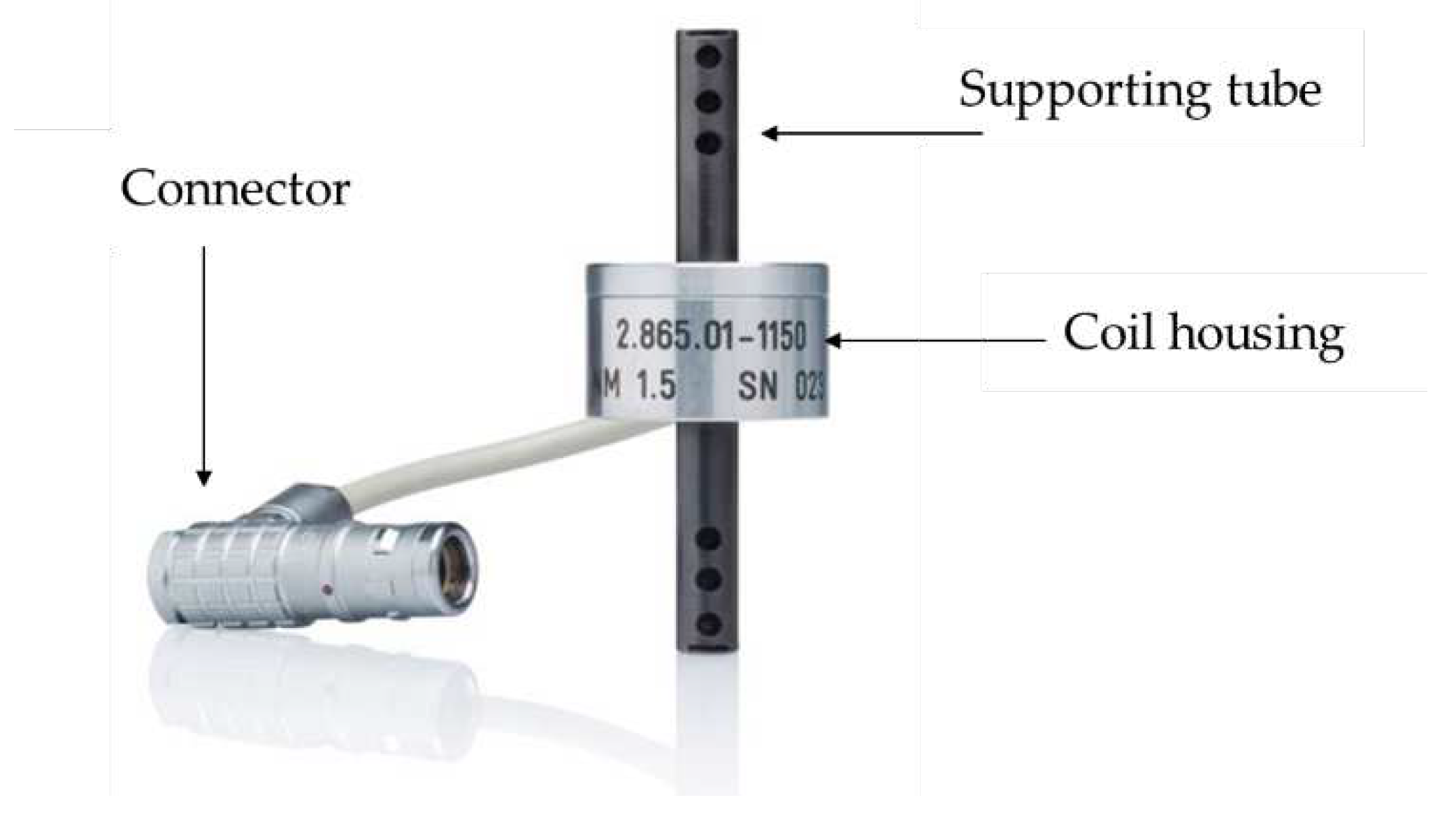

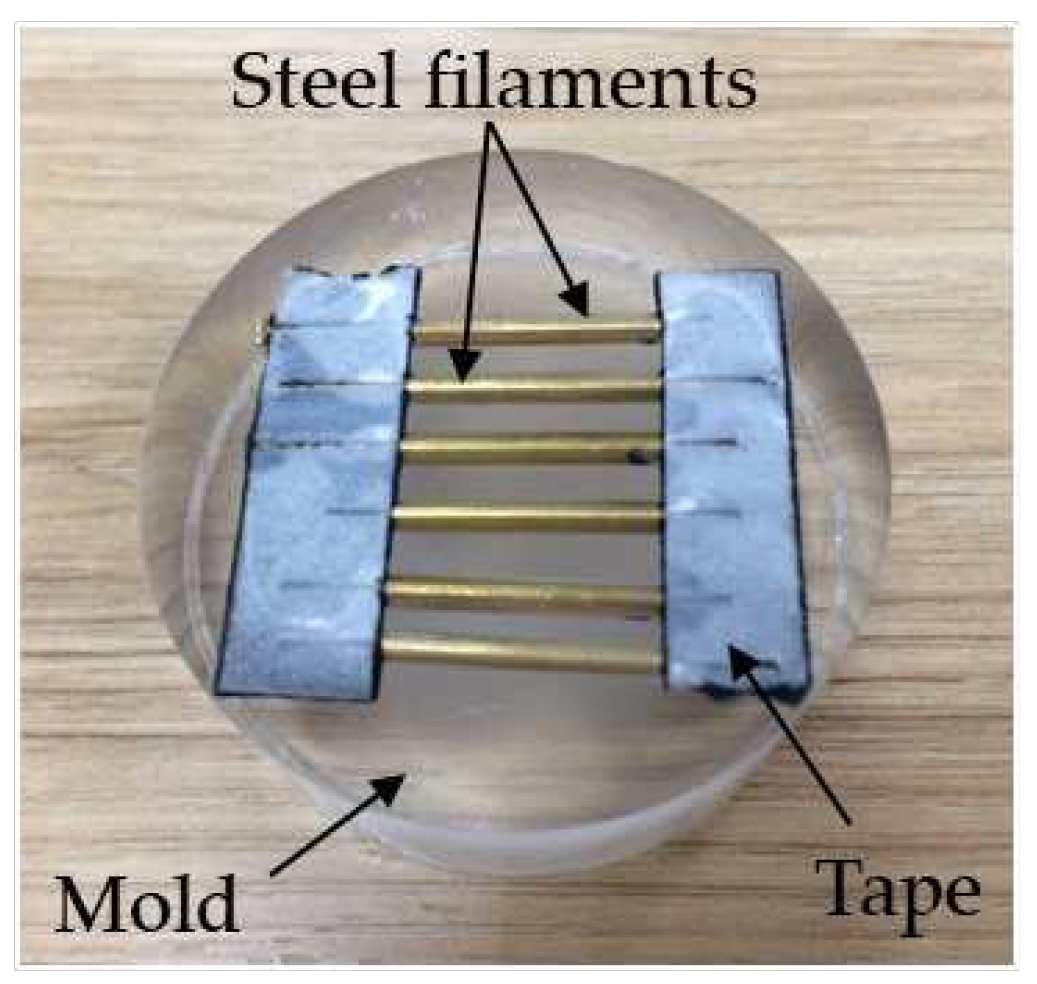

3.1. Sensor coil configuration

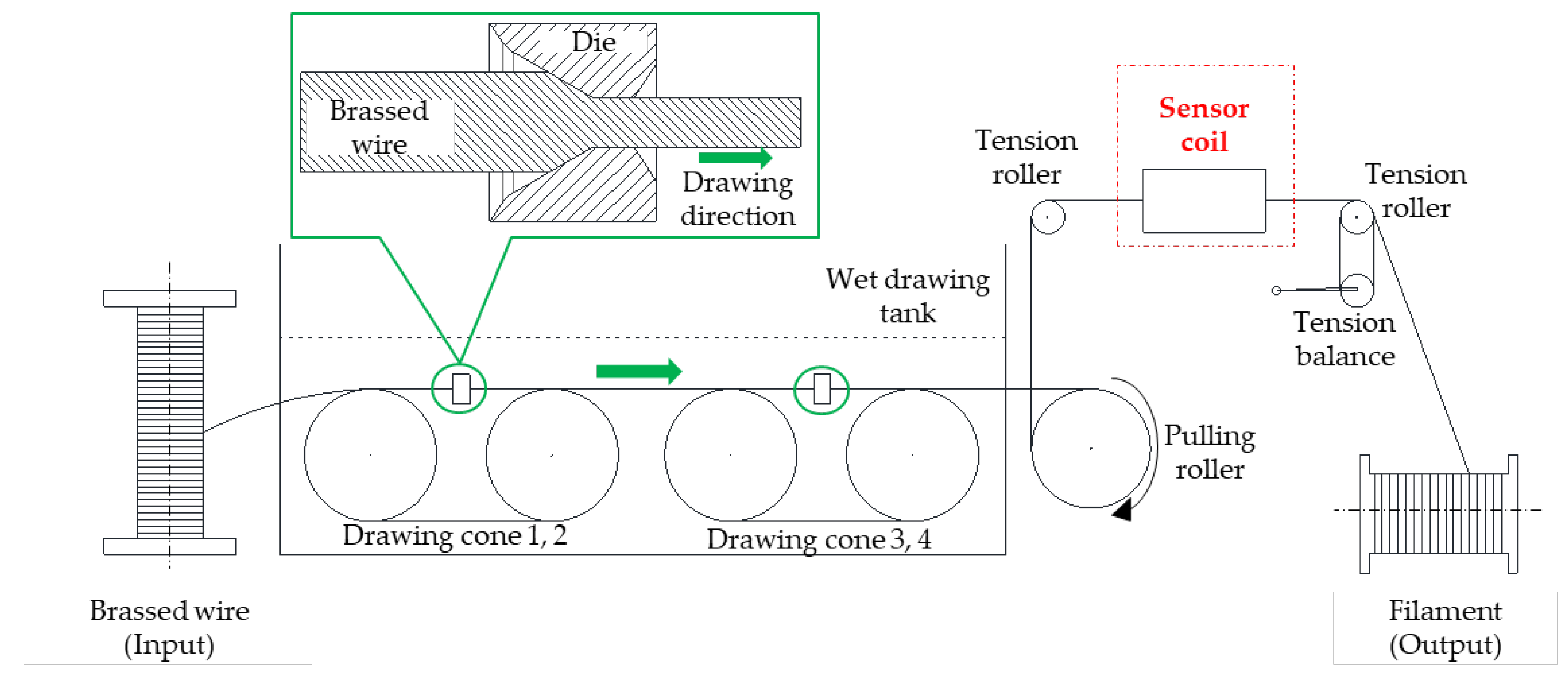

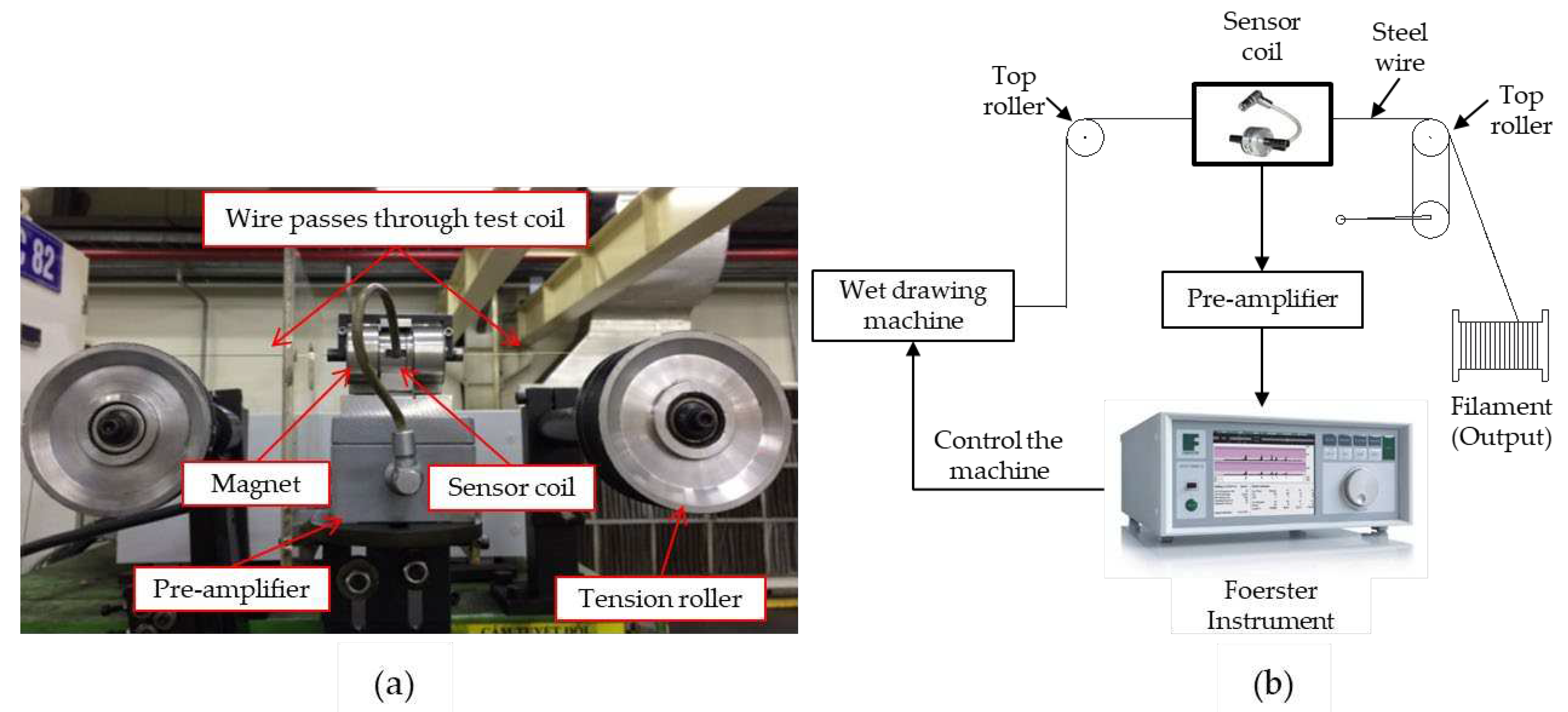

3.2. Experimental setup

3.3. Establish working condition

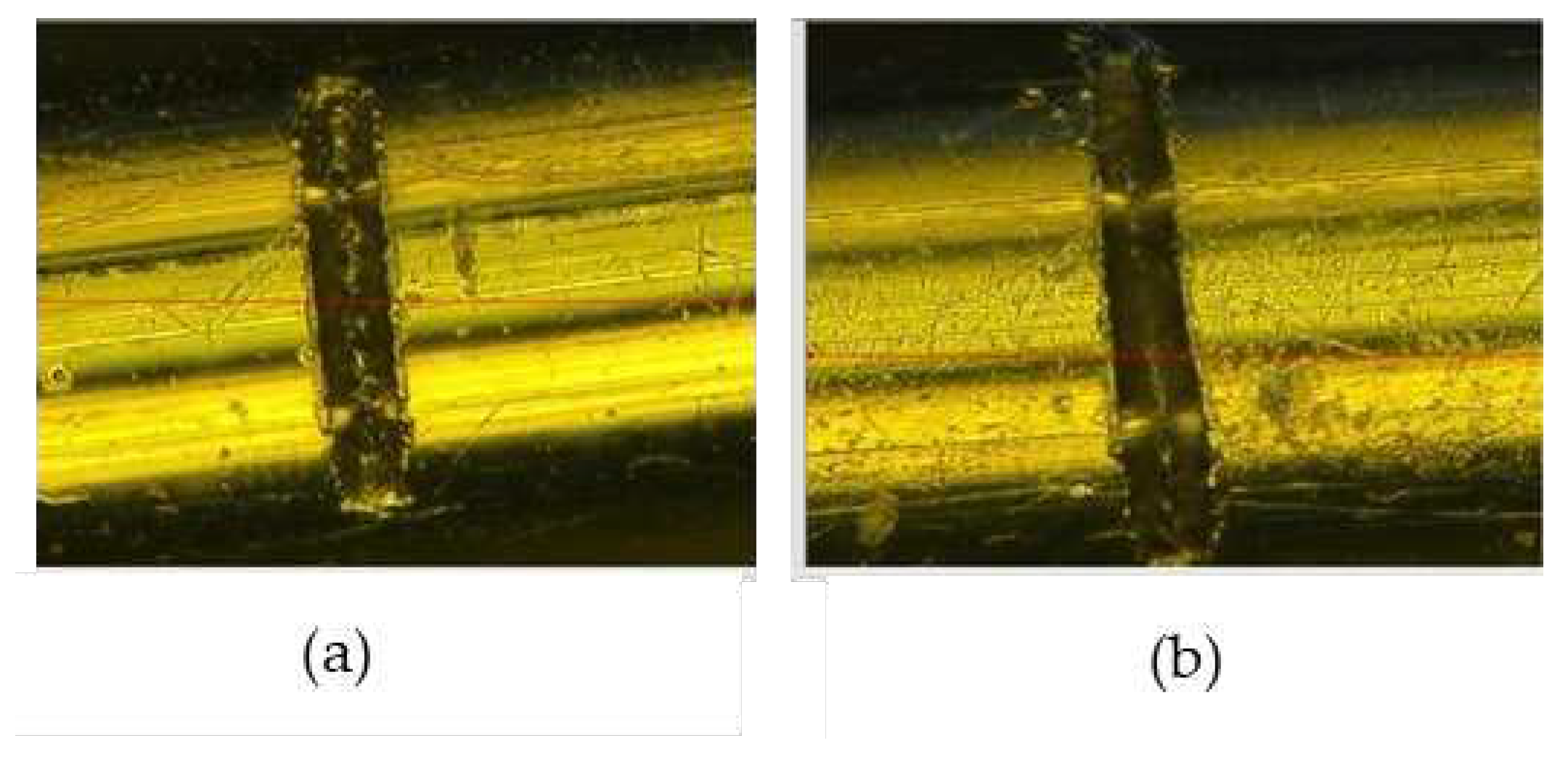

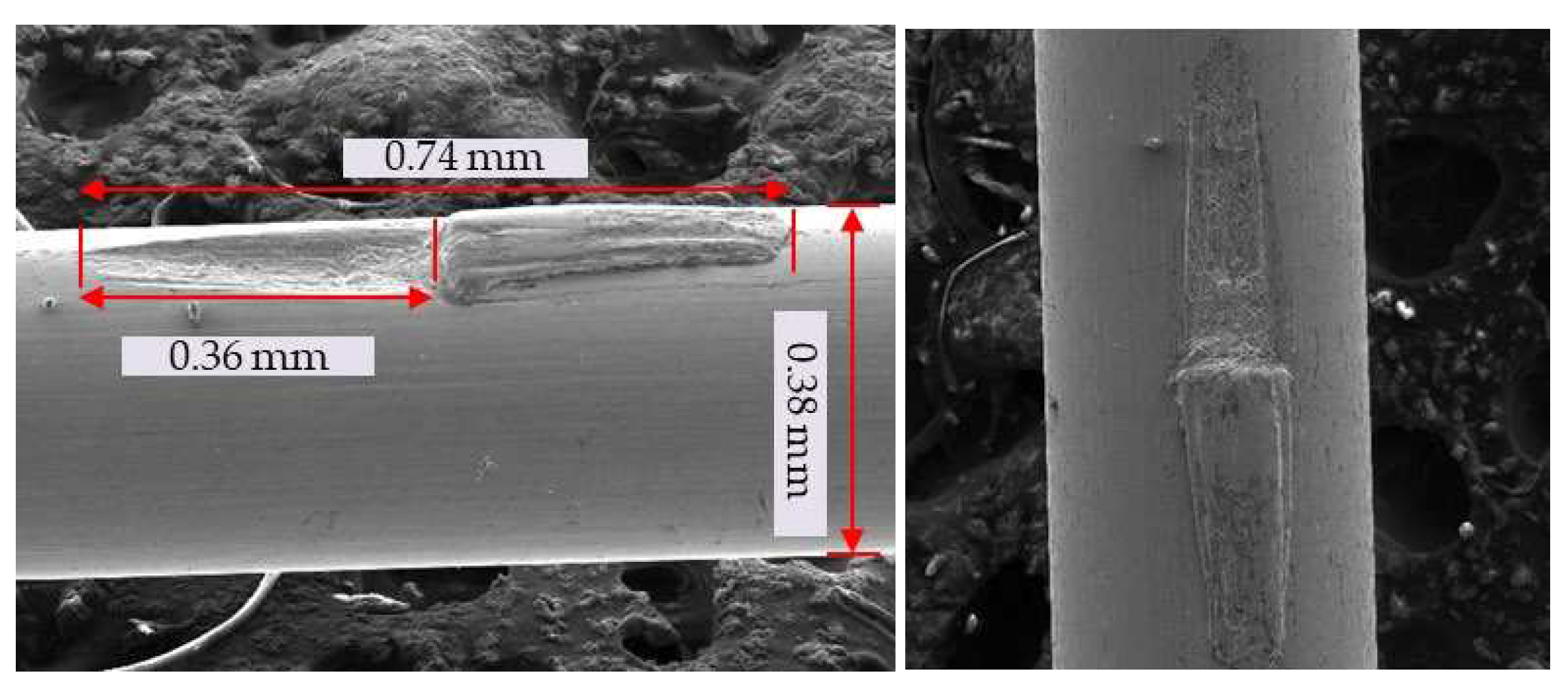

3.4. Detection of surface defects

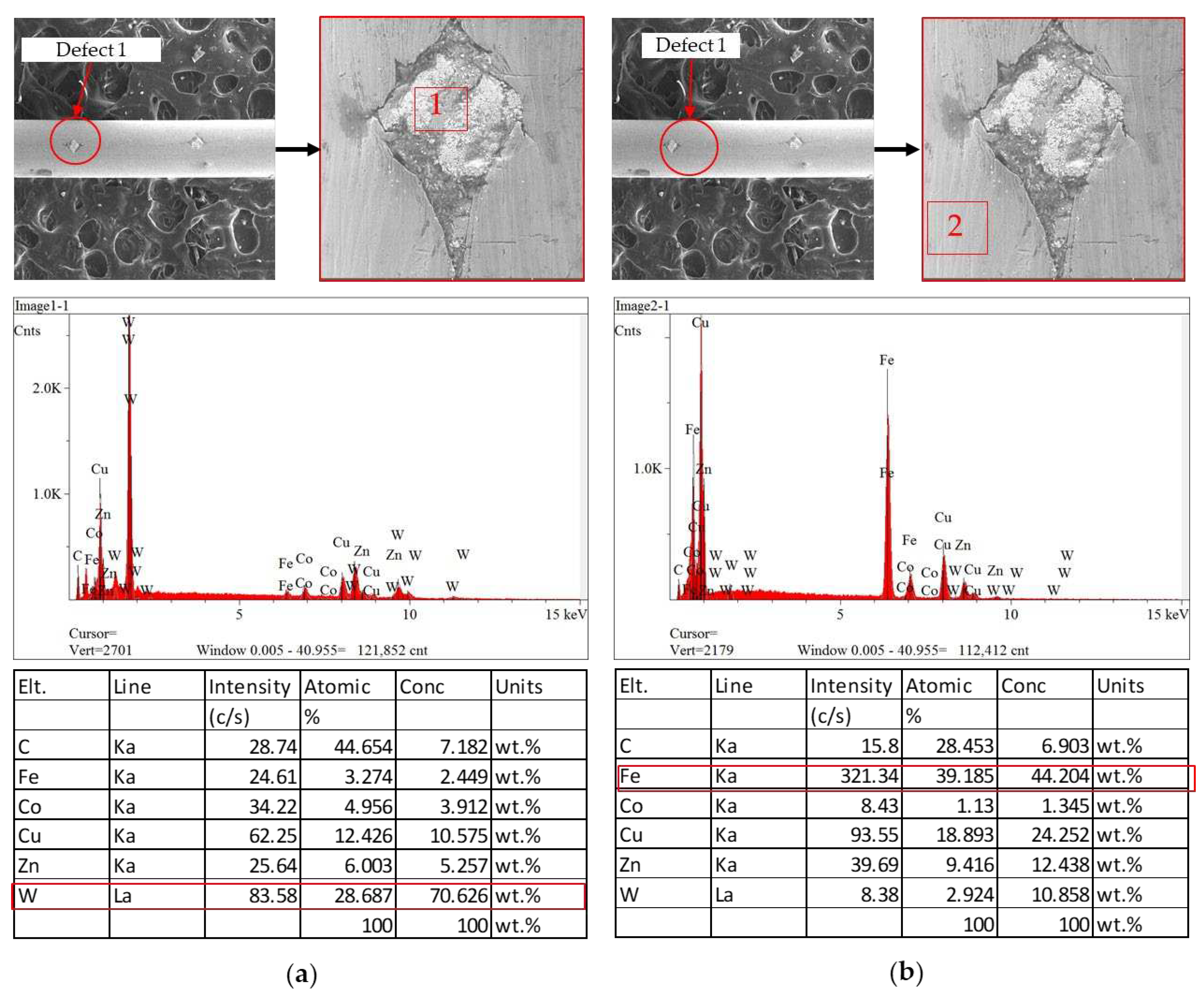

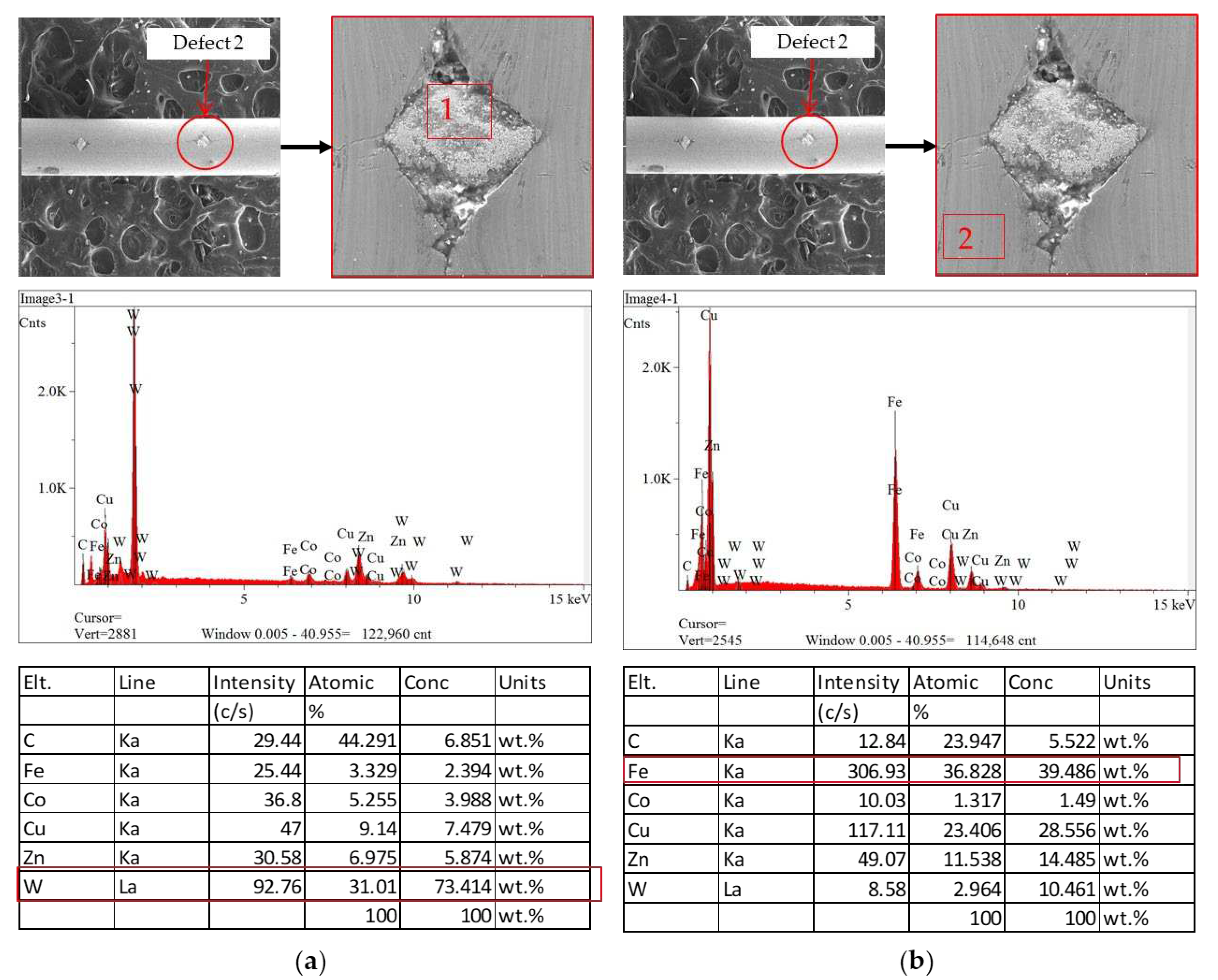

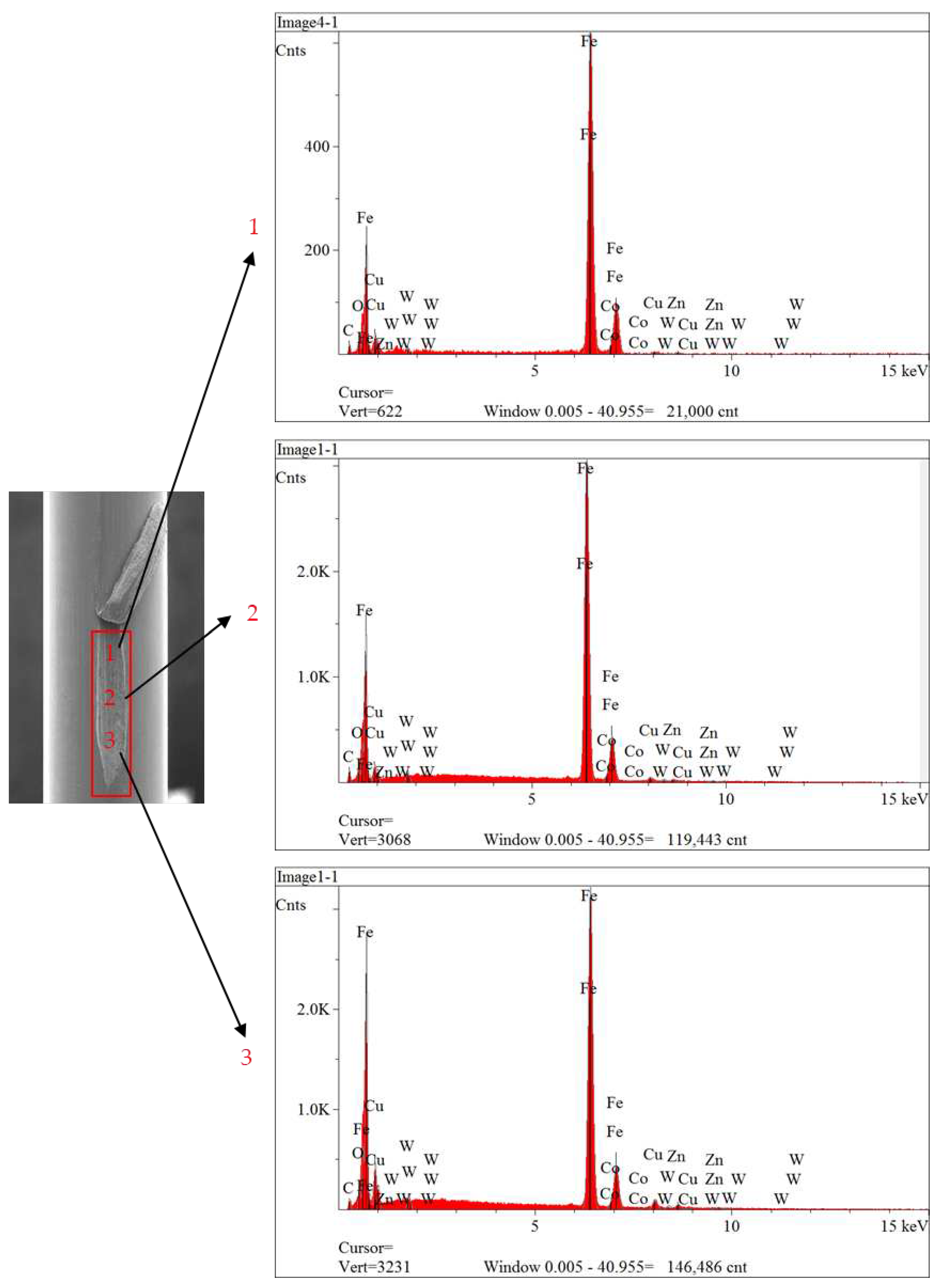

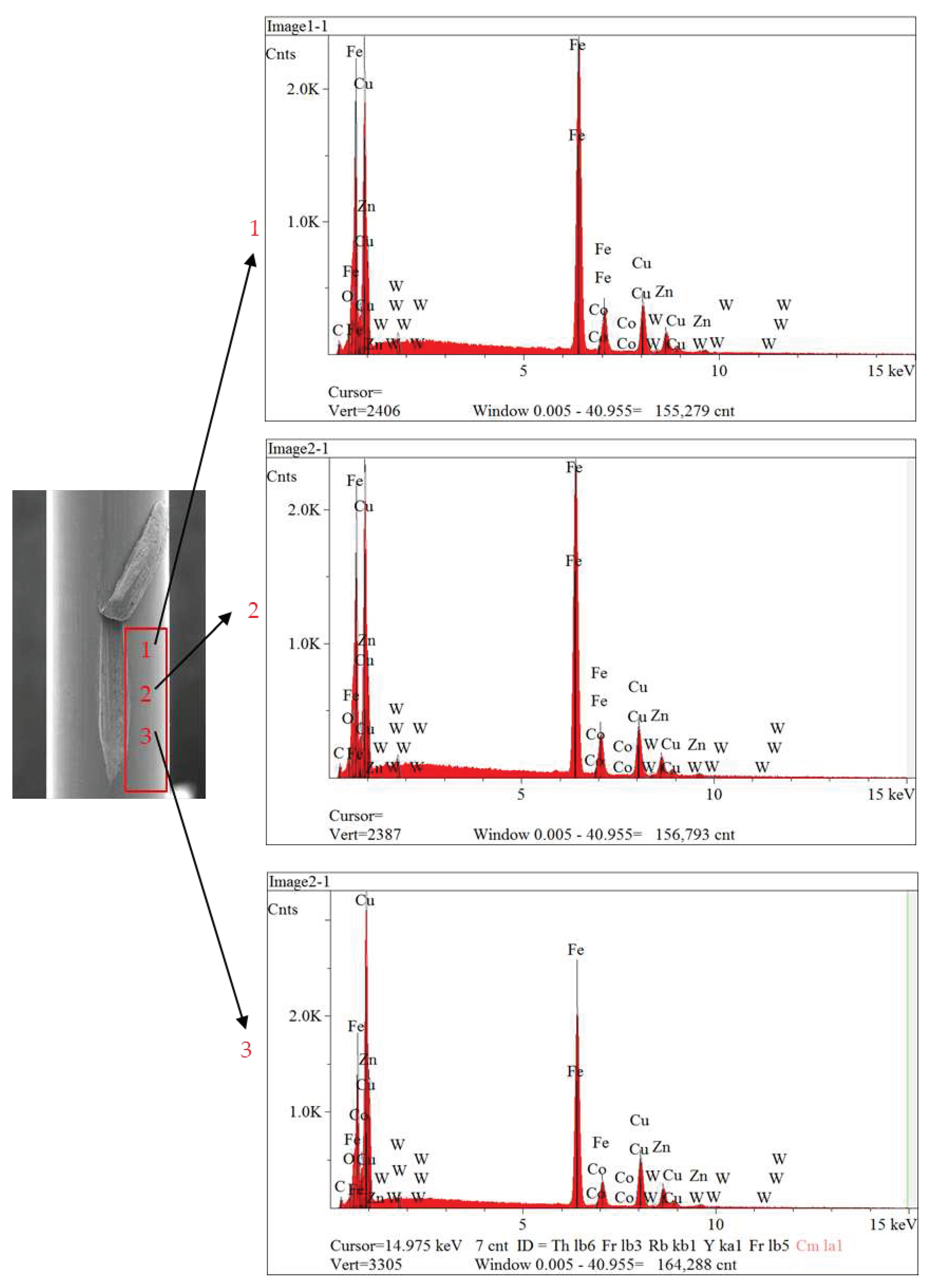

3.5. Verification of surface defects

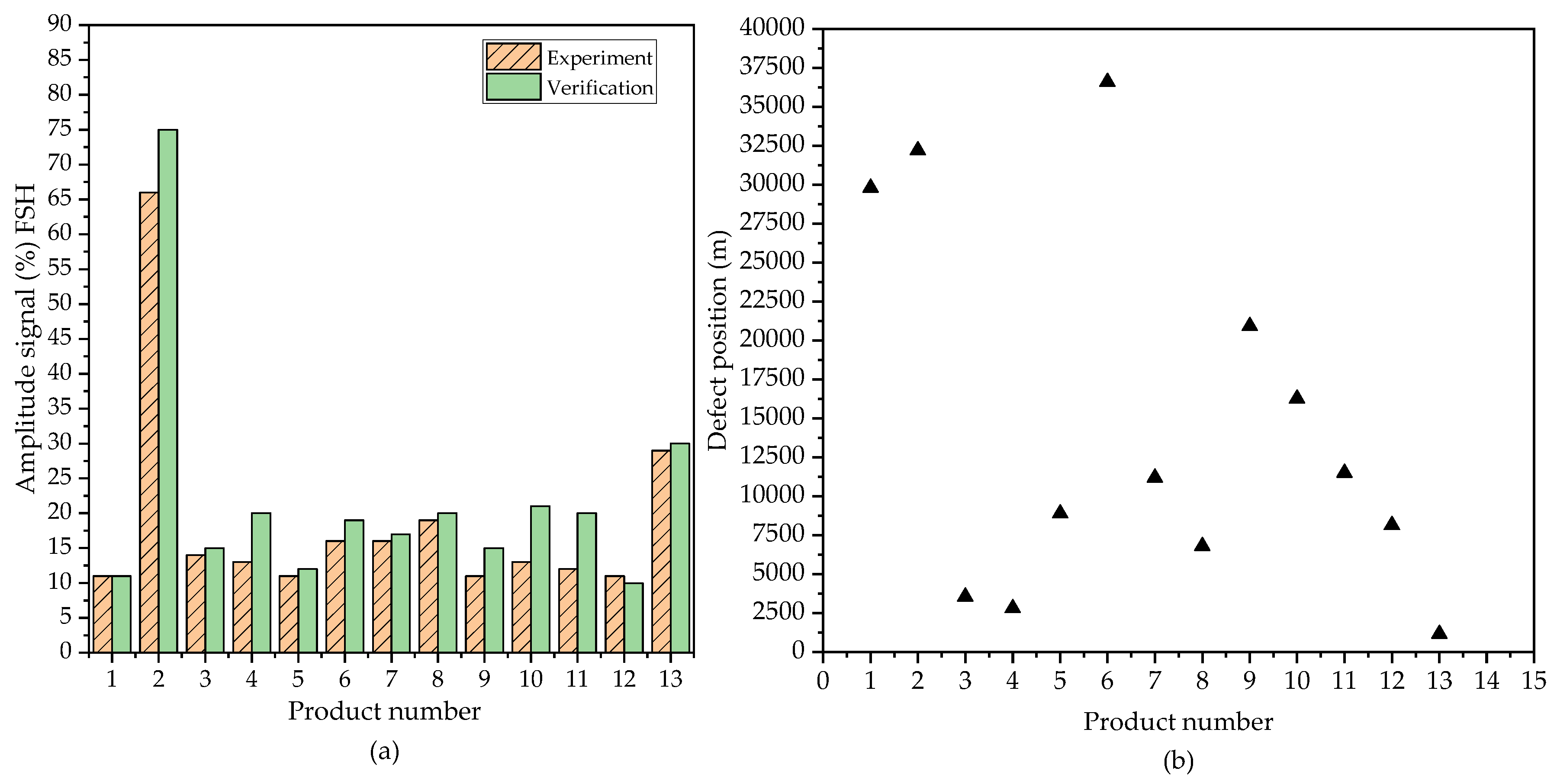

4. Experimental Results

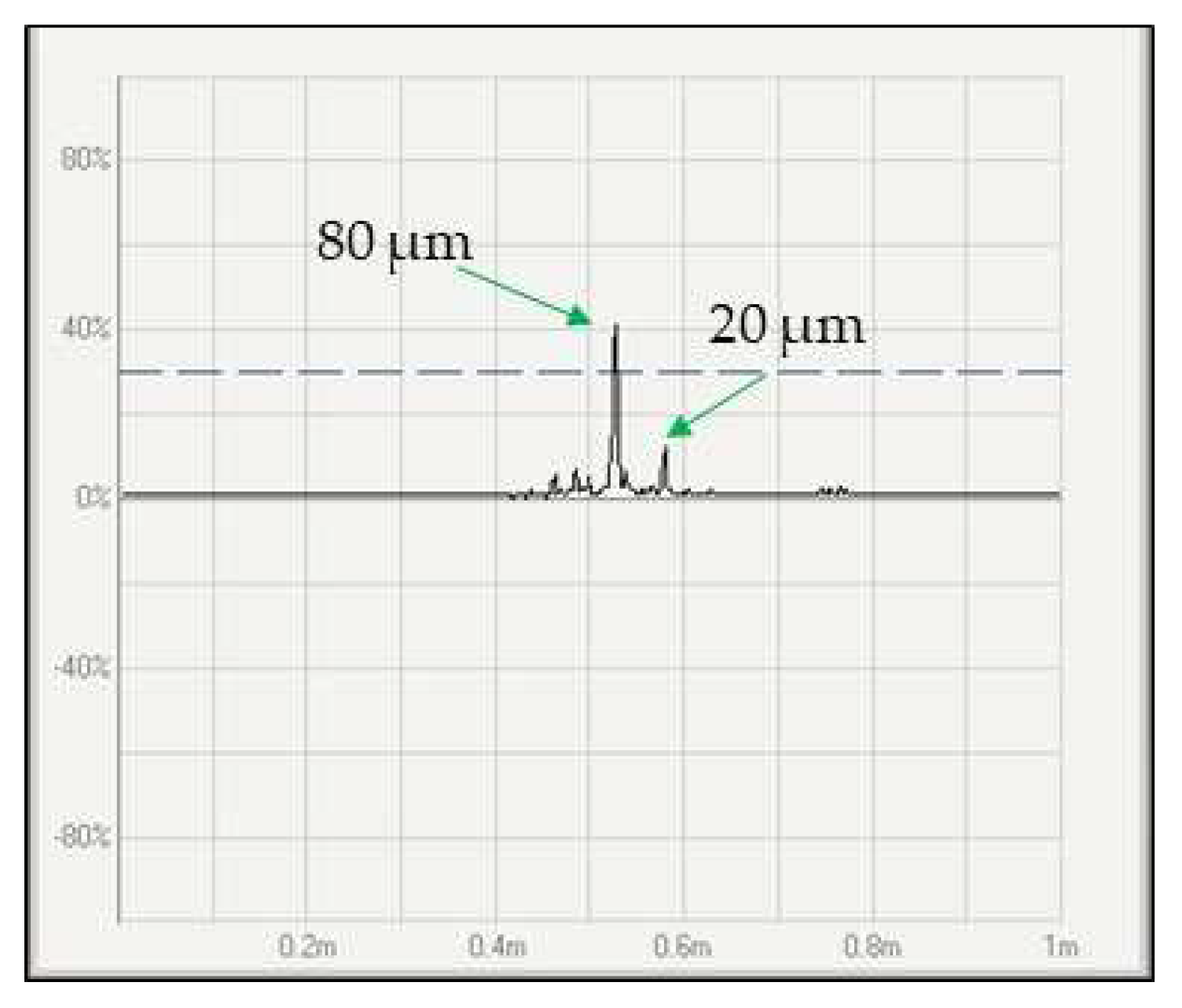

4.1. Detection of micro surface defects

4.2. Defects analysis

5. Conclusions

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yilmaz, M.; Ertunc, H.M. The prediction of mechanical behavior for steel wires and cord materials using neural networks. Materials & design 2007, 28, 599–608. [Google Scholar]

- Lee, S.W.; Jeong, K.M.; Kim, K.W.; Kim, J.H. Numerical estimation of the uneven wear of passenger car tires. World Journal of Engineering and Technology 2018, 6, 780. [Google Scholar] [CrossRef]

- Polyakova, M.; Stolyarov, A. Automobile Tires’ High-Carbon Steel Wire. Encyclopedia 2021, 1, 859–870. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Y.J.; Liu, X.C.; He, C.F. A novel TMR-based MFL sensor for steel wire rope inspection using the orthogonal test method. Smart Materials and Structures 2015, 24. [Google Scholar] [CrossRef]

- Tran, K.S. Detection of Micro-scratch Found on Surface of Steel Filament Using Eddy Current Sensor. In Proceedings of the 1st Australian International Conference on Industrial Engineering and Operations Management 2022. [Google Scholar] [CrossRef]

- Zapata, J.; Vilar, R.; Ruiz, R. Performance evaluation of an automatic inspection system of weld defects in radiographic images based on neuro-classifiers. Expert Systems with Applications 2011, 38, 8812–8824. [Google Scholar] [CrossRef]

- Shirinzadeh, B.; Alici, G.; Foong, C.W.; Cassidy, G. Fabrication process of open surfaces by robotic fibre placement. Robotics and Computer-Integrated Manufacturing 2004, 20, 17–28. [Google Scholar] [CrossRef]

- Batty, T.; Ehrampoosh, A.; Shirinzadeh, B.; Zhong, Y.; Smith, J. A transparent teleoperated robotic surgical system with predictive haptic feedback and force modelling. Sensors 2022, 22, 9770. [Google Scholar] [CrossRef]

- García-Martín, J.; Gómez-Gil, J.; Vázquez-Sánchez, E. Non-destructive techniques based on eddy current testing. Sensors 2011, 11, 2525–2565. [Google Scholar] [CrossRef]

- Zhao, P.; Shirinzadeh, B.; He, X.; Guo, J.; Shi, K.; Qiang, B.; Jin, Q.; Li, F. Predicting and Improving Interlaminar Bonding Uniformity during the Robotic Fiber Steering Process. Polymers 2022, 15, 19. [Google Scholar] [CrossRef]

- Zhang, G.; Tang, Z.; Fan, Y.; Liu, J.; Jahanshahi, H.; Aly, A.A. Steel Wire Rope Surface Defect Detection Based on Segmentation Template and Spatiotemporal Gray Sample Set. Sensors (Basel) 2021, 21. [Google Scholar] [CrossRef]

- Su, S.; Ma, X.; Wang, W.; Yang, Y. Stress-Dependent Magnetic Charge Model for Micro-Defects of Steel Wire Based on the Magnetic Memory Method. Research in Nondestructive Evaluation 2019, 31, 24–47. [Google Scholar] [CrossRef]

- Shirinzadeh, B.; Teoh, P.L.; Tian, Y.; Dalvand, M.M.; Zhong, Y.; Liaw, H.C. Laser interferometry-based guidance methodology for high precision positioning of mechanisms and robots. Robotics and Computer-Integrated Manufacturing 2010, 26, 74–82. [Google Scholar] [CrossRef]

- Ammar, M.M.; Shirinzadeh, B. Evaluation of robotic fiber placement effect on process-induced residual stresses using incremental hole-drilling method. Polymer Composites 2022, 43, 4417–4436. [Google Scholar] [CrossRef]

- Saludes-Rodil, S.; Baeyens, E.; Rodriguez-Juan, C.P. Unsupervised classification of surface defects in wire rod production obtained by eddy current sensors. Sensors (Basel) 2015, 15, 10100–10117. [Google Scholar] [CrossRef]

- Yoshida, K.; Norasethasopon, S.; Shinohara, T.; Ido, R. Influence of flaws of wire rod surface, inclusions and voids on wire breaks in superfine wire drawing. JSME International Journal Series A Solid Mechanics and Material Engineering 2003, 46, 365–370. [Google Scholar] [CrossRef]

- Verpoest, I.; Aernoudt, E.; Deruyttere, A.; De Bondt, M. The fatigue threshold, surface condition and fatigue limit of steel wire. International Journal of Fatigue 1985, 7, 199–214. [Google Scholar] [CrossRef]

- Tran, K.; Phan, H.; Lee, H.; Kim, Y.; Park, H. Blocking force of a piezoelectric stack actuator made of single crystal layers (PMN-29PT). Smart Materials and Structures 2016, 25, 095038. [Google Scholar] [CrossRef]

- Tran, K.; Lee, H.; Kim, Y.; Park, H. Resonant frequency and hysteresis of a stack actuator made of single crystal (PMN-29PT) layers. Smart Materials and Structures 2016, 25, 125009. [Google Scholar] [CrossRef]

- Ammar, M.M.A.; Shirinzadeh, B.; Zhao, P.; Shi, Y. An approach for damage initiation and propagation in metal and carbon fiber hybrid composites manufactured by robotic fiber placement. Composite Structures 2021, 268. [Google Scholar] [CrossRef]

- Shinohara, T.; Yoshida, K. Deformation analysis of surface flaws in stainless steel wire drawing. Journal of Materials Processing Technology 2005, 162-163, 579–584. [Google Scholar] [CrossRef]

- Yun, J.P.; Choi, D.-c.; Jeon, Y.-j.; Park, C.; Kim, S.W. Defect inspection system for steel wire rods produced by hot rolling process. The International Journal of Advanced Manufacturing Technology 2013, 70, 1625–1634. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Wang, S.; Wang, H.; He, Z.; Yan, X. Visual Sensing Inspection for the Surface Damage of Steel Wire Ropes With Object Detection Method. IEEE Sensors Journal 2022, 22, 22985–22993. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, Y.; Zhai, J.; Tian, L.; Chen, L.; Chen, L. Prediction of surface wrinkle defect of welding wire steel ER70S-6 in hot bar rolling process using finite element method and experiments. Metals 2020, 10, 1559. [Google Scholar] [CrossRef]

- Heo, T.; Cho, S.W.; Cho, S.H.; Ahn, B.; Lim, Z.S. Detection of an axial surface microcrack in steel wire rods with noncontact ultrasonic reverberation spectroscopy. Journal of Mechanical Science and Technology 2017, 31, 5921–5927. [Google Scholar] [CrossRef]

- Jasper, W.J.; Potlapalli, H. Image analysis of mispicks in woven fabric. Textile Research Journal 1995, 65, 683–692. [Google Scholar] [CrossRef]

- Conci, A.; Proença, C. A computer vision approach for textile inspection. Textile Research Journal 2000, 70, 347–350. [Google Scholar] [CrossRef]

- Lane, J.S. Textile fabric inspection system. 1998.

- Daugman, J.G. Uncertainty relation for resolution in space, spatial frequency, and orientation optimized by two-dimensional visual cortical filters. JOSA A 1985, 2, 1160–1169. [Google Scholar] [CrossRef]

- Sari-Sarraf, H.; Goddard, J.S. Vision system for on-loom fabric inspection. In Proceedings of the 1998 IEEE Annual Textile, 1998, Fiber and Film Industry Technical Conference (Cat. No. 98CH36246); pp. 8–810. [Google Scholar]

- Filipovic, M. Evolution of artificial defects during shape rolling. KTH, 2007.

- Yun, J.P.; Choi, S.; Kim, S.W. Vision-based defect detection of scale-covered steel billet surfaces. Optical Engineering 2009, 48, 037205–037205. [Google Scholar] [CrossRef]

- Park, C.; Choi, S.; Won, S. Vision-based inspection for periodic defects in steel wire rod production. Optical Engineering 2010, 49, 017202–017202. [Google Scholar]

- Zhang, W.; Bu, J.; Li, D.; Zhang, K.; Zhou, M. Coupling Interference between Eddy Current Sensors for the Radial Displacement Measurement of a Cylindrical Target. Sensors 2022, 22, 4375. [Google Scholar] [CrossRef]

- Ramos, H.G.; Postolache, O.; Alegria, F.C.; Ribeiro, A.L. Using the skin effect to estimate cracks depths in mettalic structures. In Proceedings of the 2009 IEEE instrumentation and measurement technology conference; 2009; pp. 1361–1366. [Google Scholar]

| Crack No. | Depth | Width |

|---|---|---|

| 1 | 20 | 73 |

| 2 | 80 | 73 |

| Categories | Number of samples | Pass/Fail |

|---|---|---|

| Without defect | 134 | Pass |

| With defect | 48 | Fail |

| Total samples | 182 | |

| Defective ratio | 26.37 % |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).