Submitted:

27 September 2023

Posted:

28 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

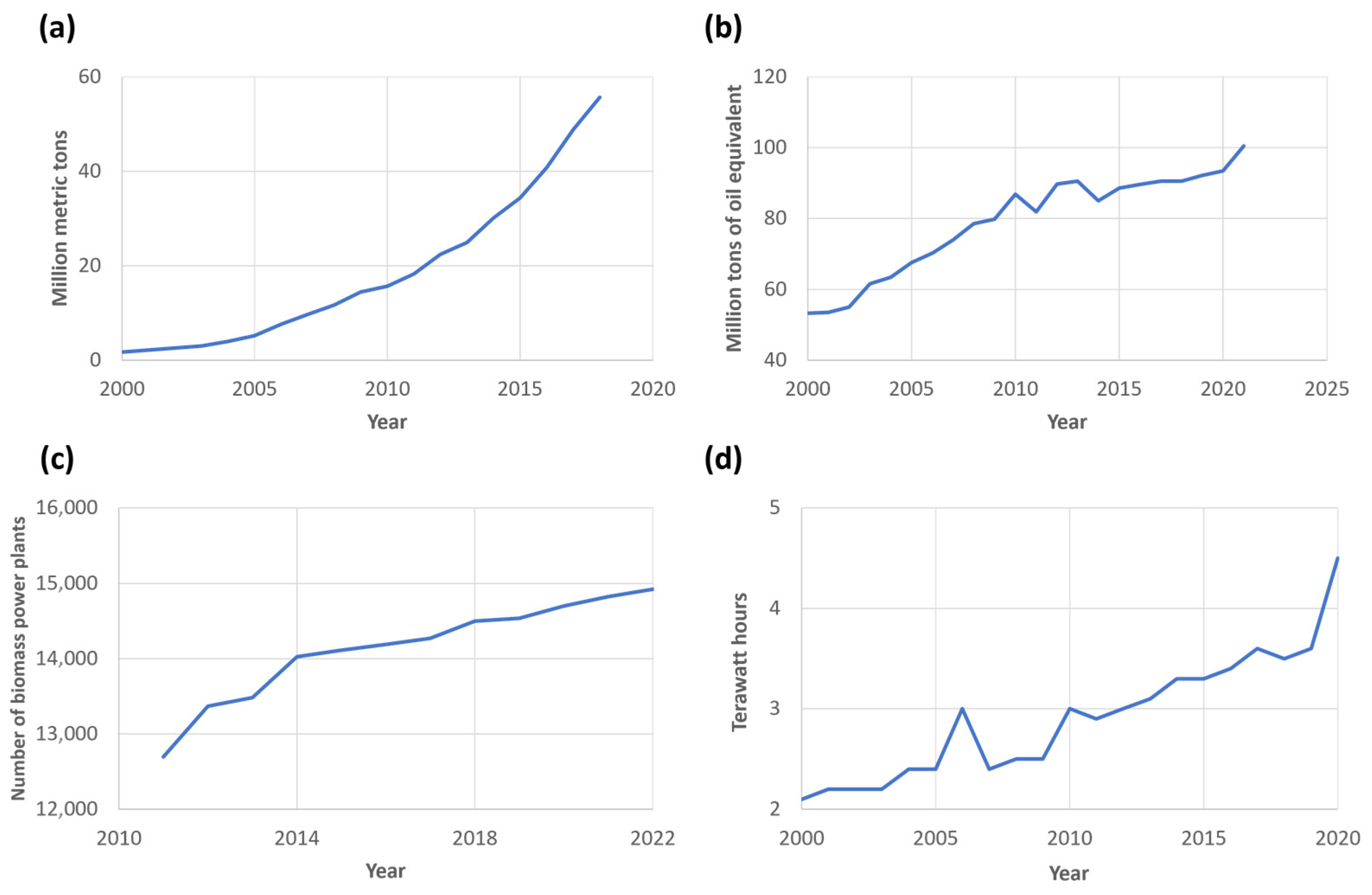

1.1. Global Energy Scenario

1.2. Combustion: Foundations and Optimization

- hh – ha represents the enthalpy change in exhausted fumes.

- mh is the exhausted flow.

- Cph is the average specific heat of fumes.

- Th – Ta is the inlet and outlet temperature (respectively) of fumes and air.

- Vh and ρh are total volume generated and fume density, respectively.

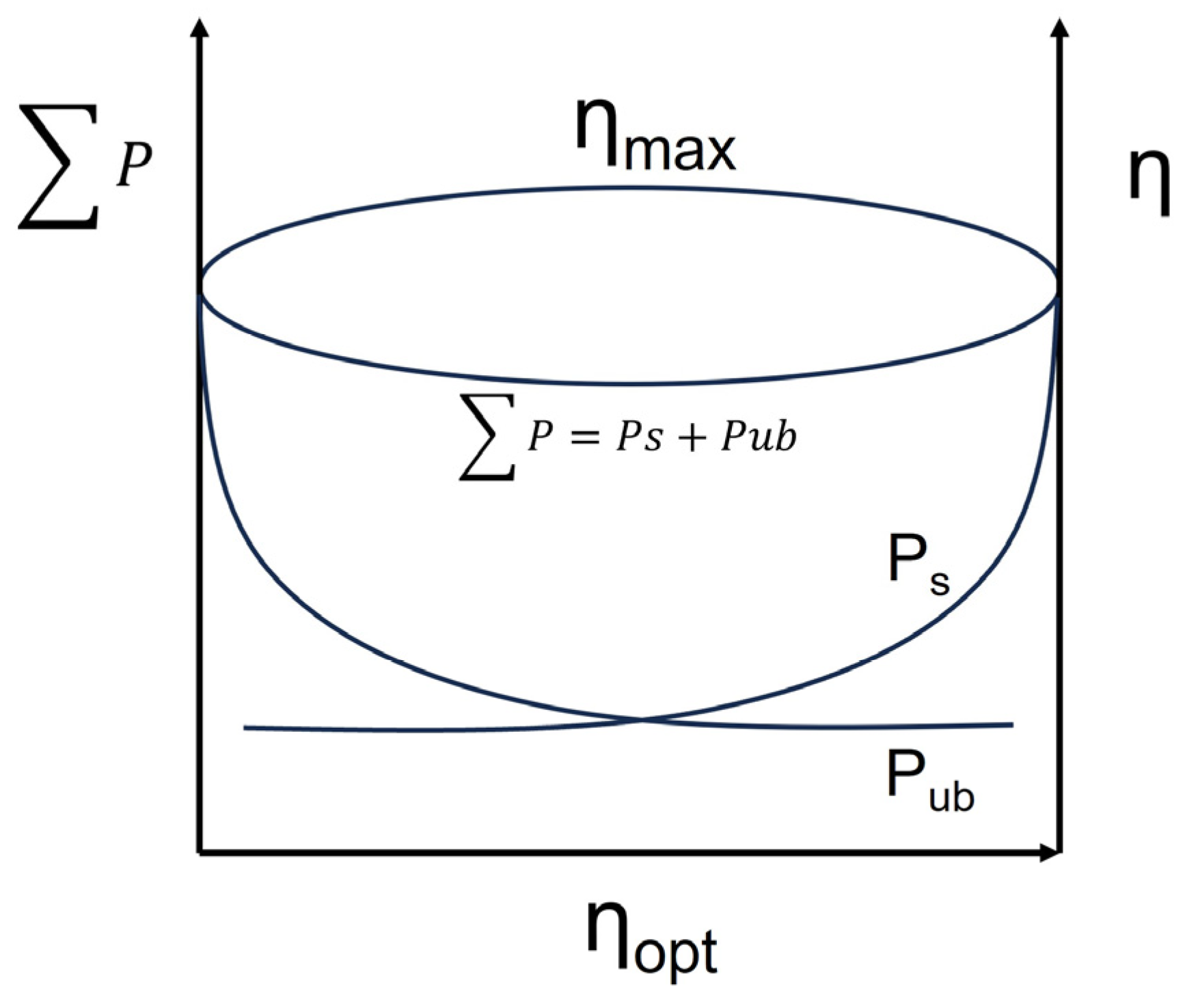

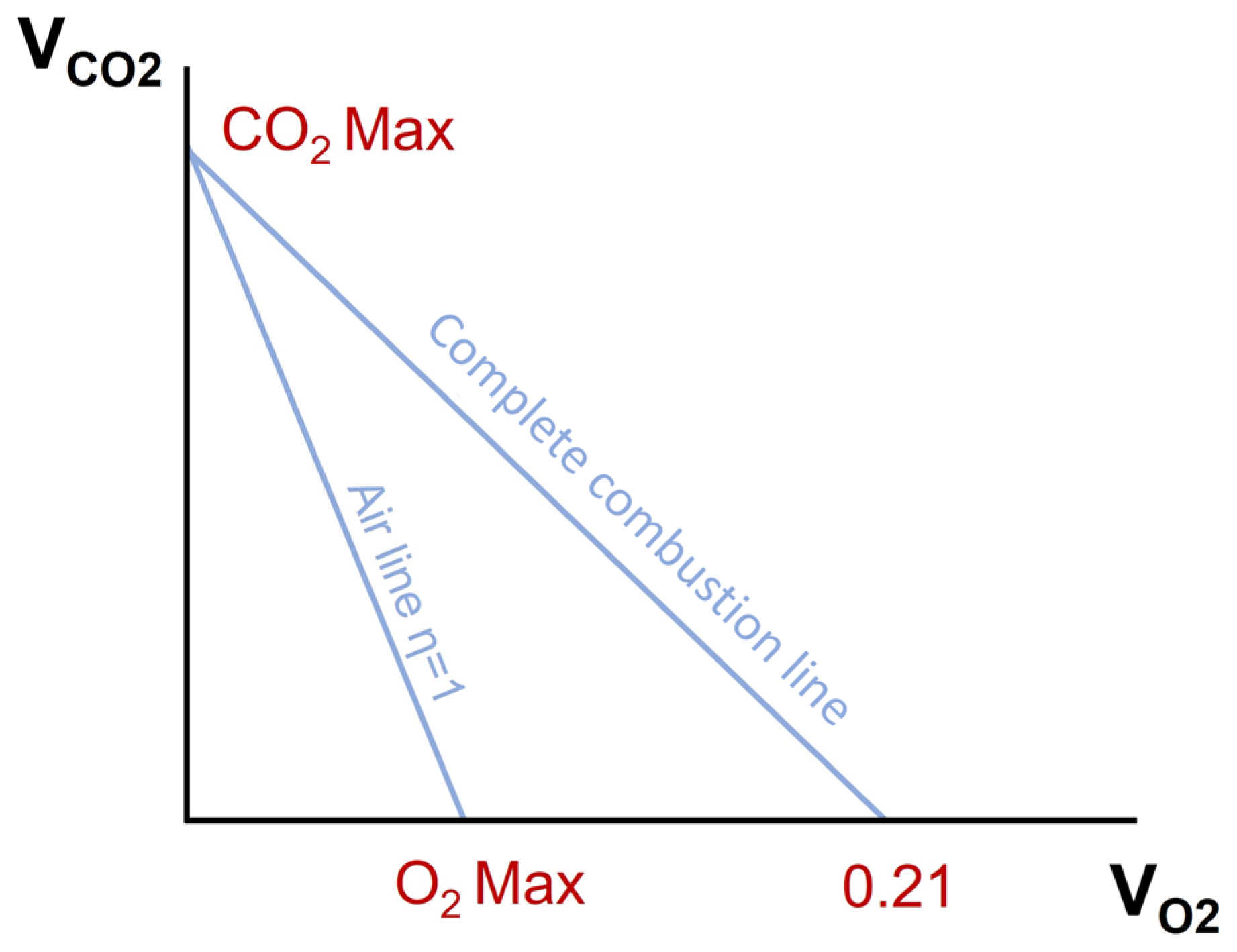

1.3. Ostwald Diagram: Theoretical Foundations

1.4. Novelty and Aim of This Work

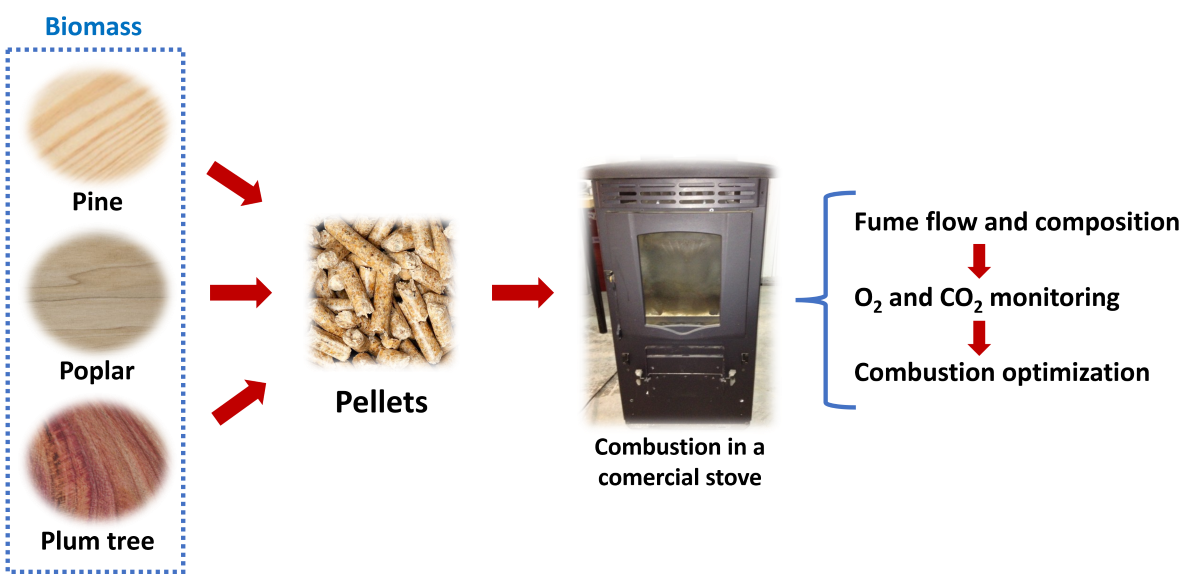

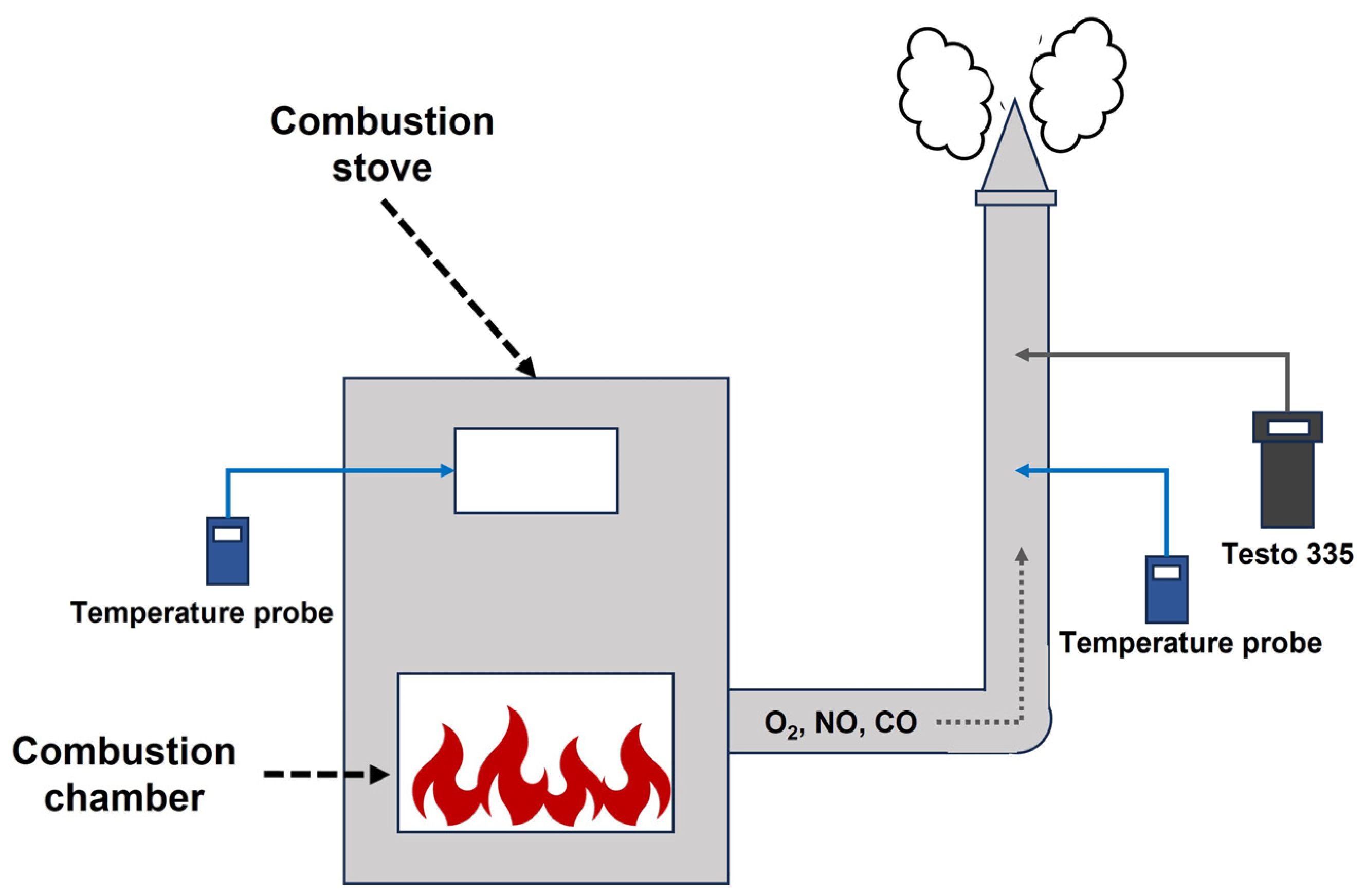

2. Materials and Methods

2.1. Facilities, Raw Materials and Their Characterization

2.2. Combustion System and Equipment

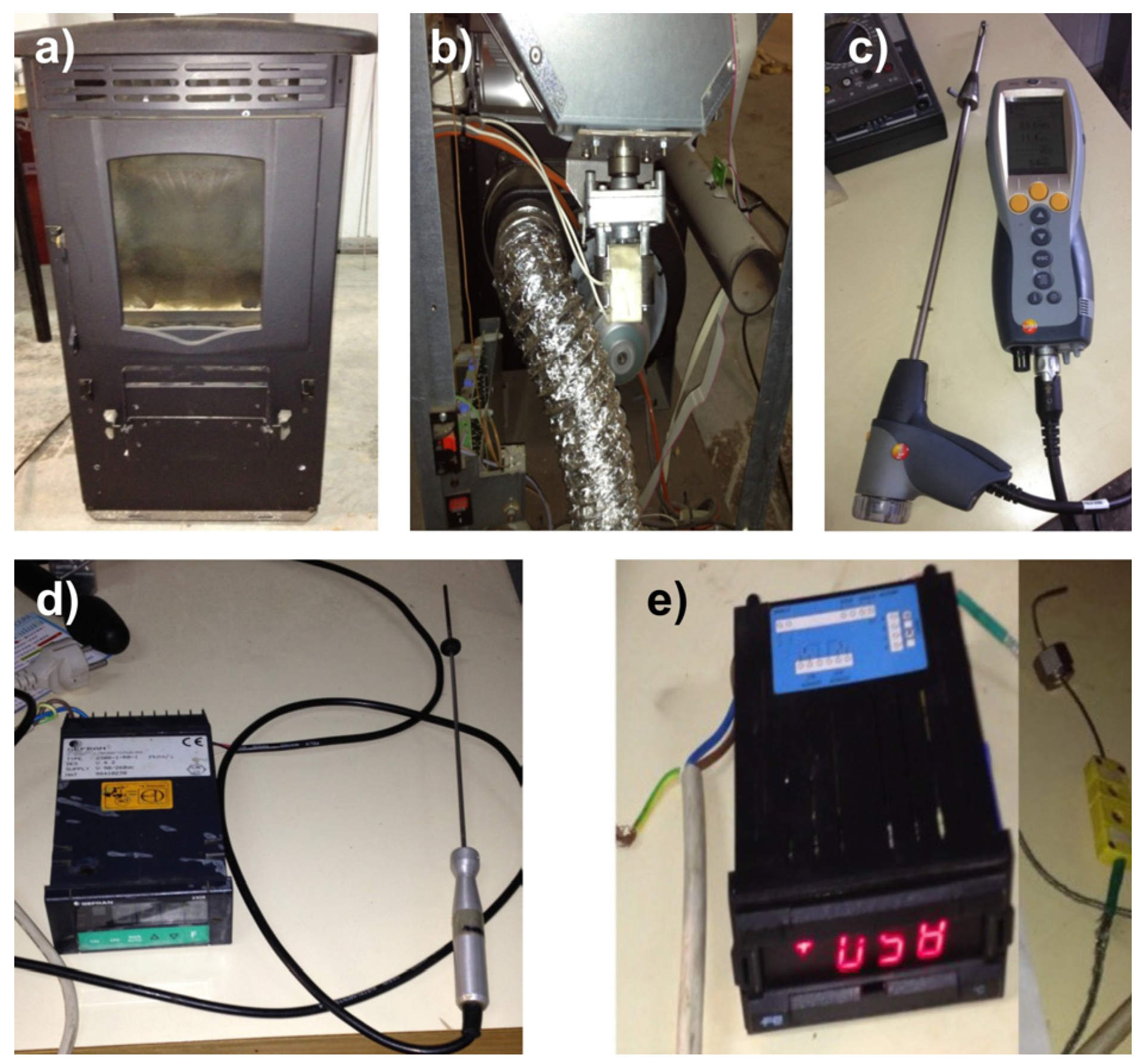

- Pellet stove, where the different biomass pellets were fed to carry out their combustion at different feed ratios and power.

- Gas analyzer for combustion fumes (Testo 335), placed in the chimney once to analyze the main components included in combustion fumes such as O2, CO2 or CO.

- Temperature probe for fumes.

- Temperature probe for inlet air.

2.3. Experimental Procedure

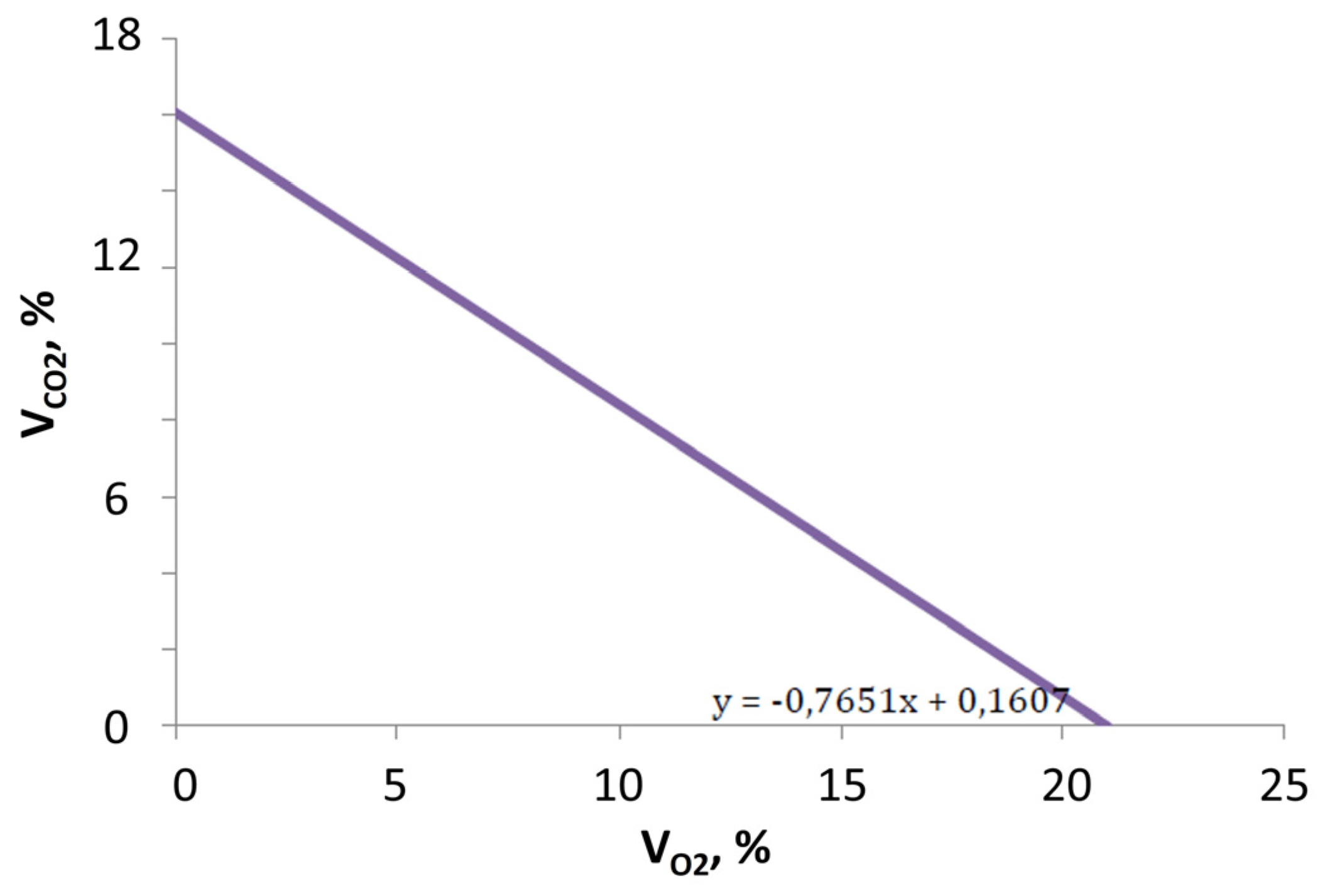

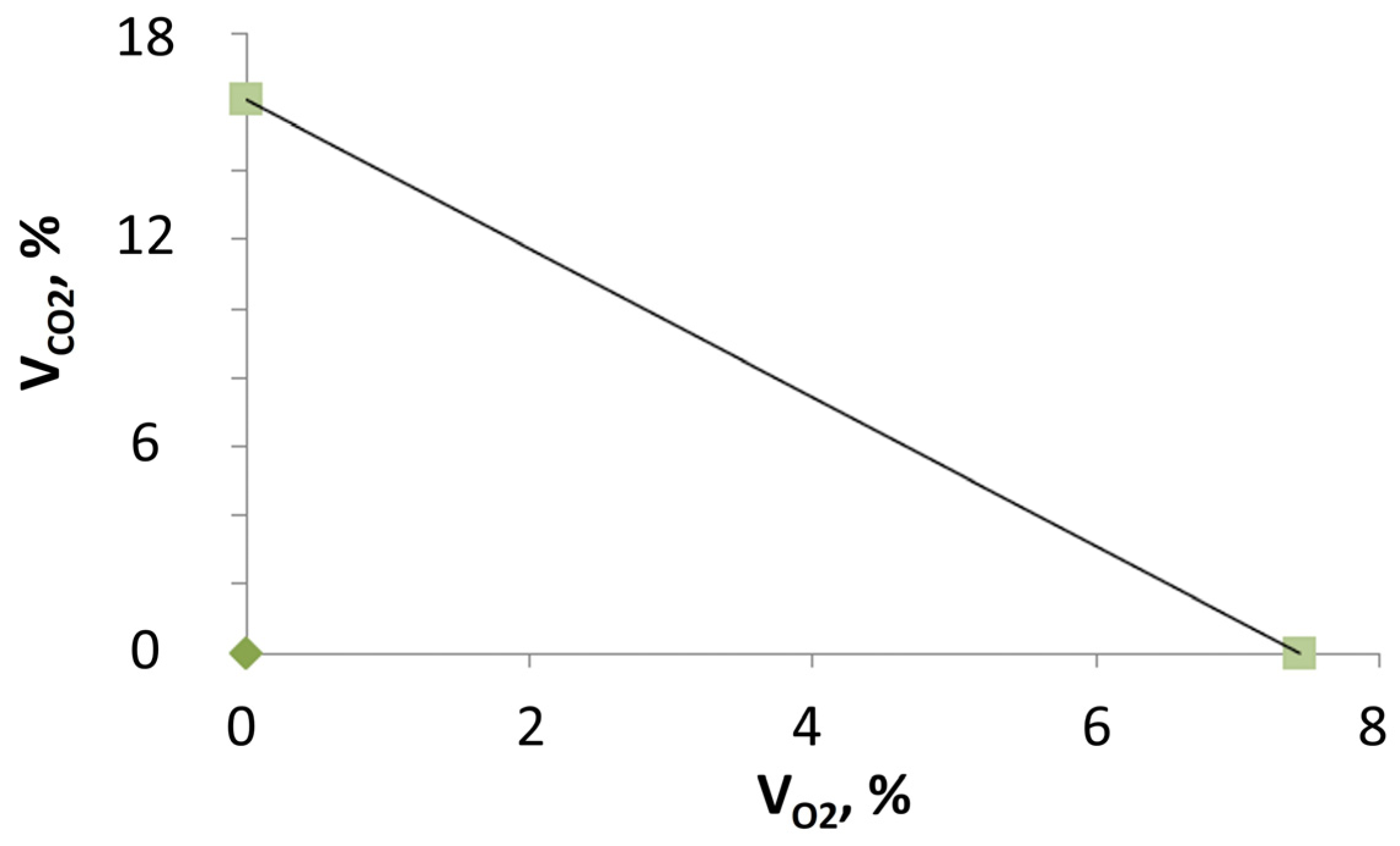

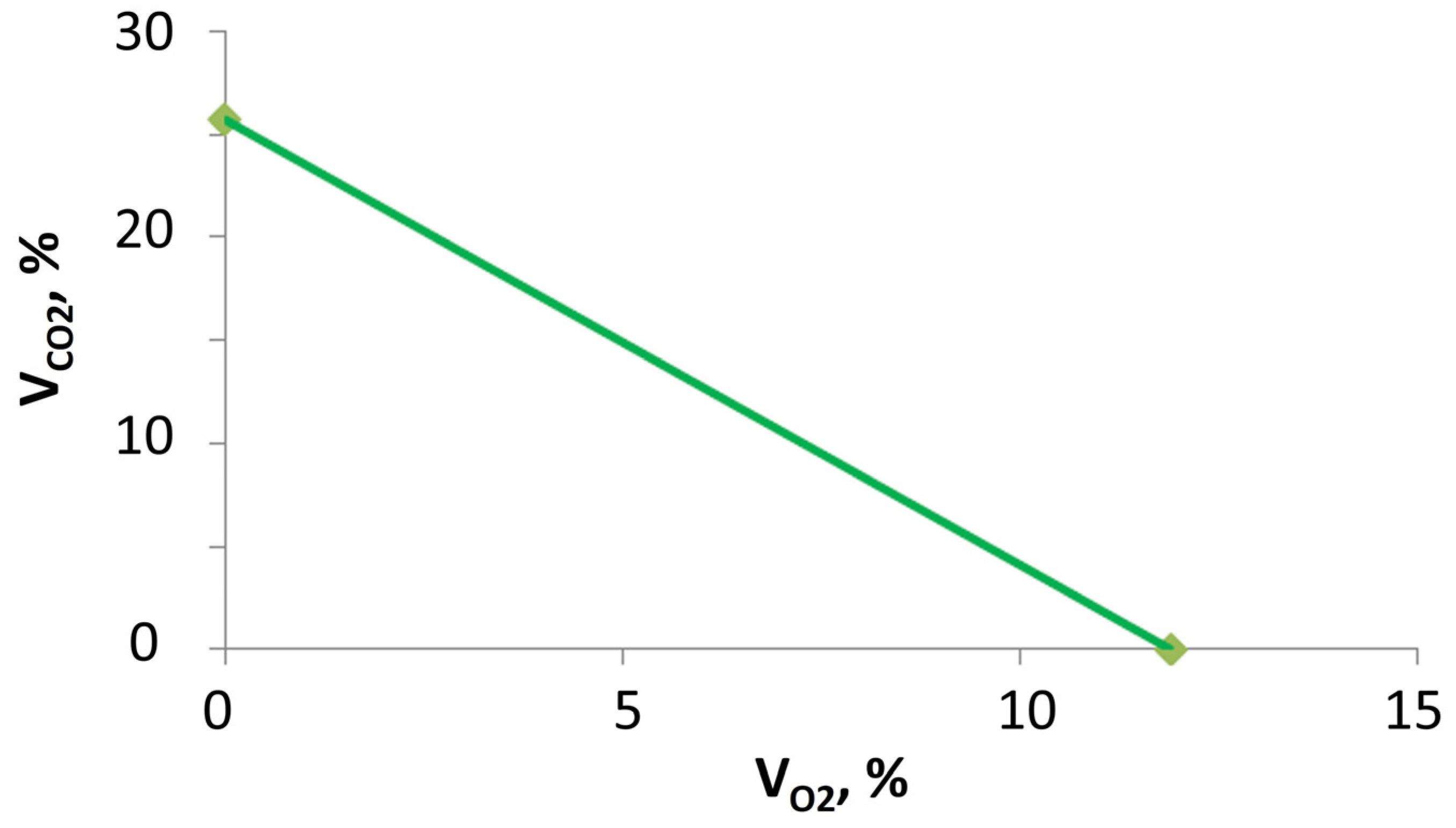

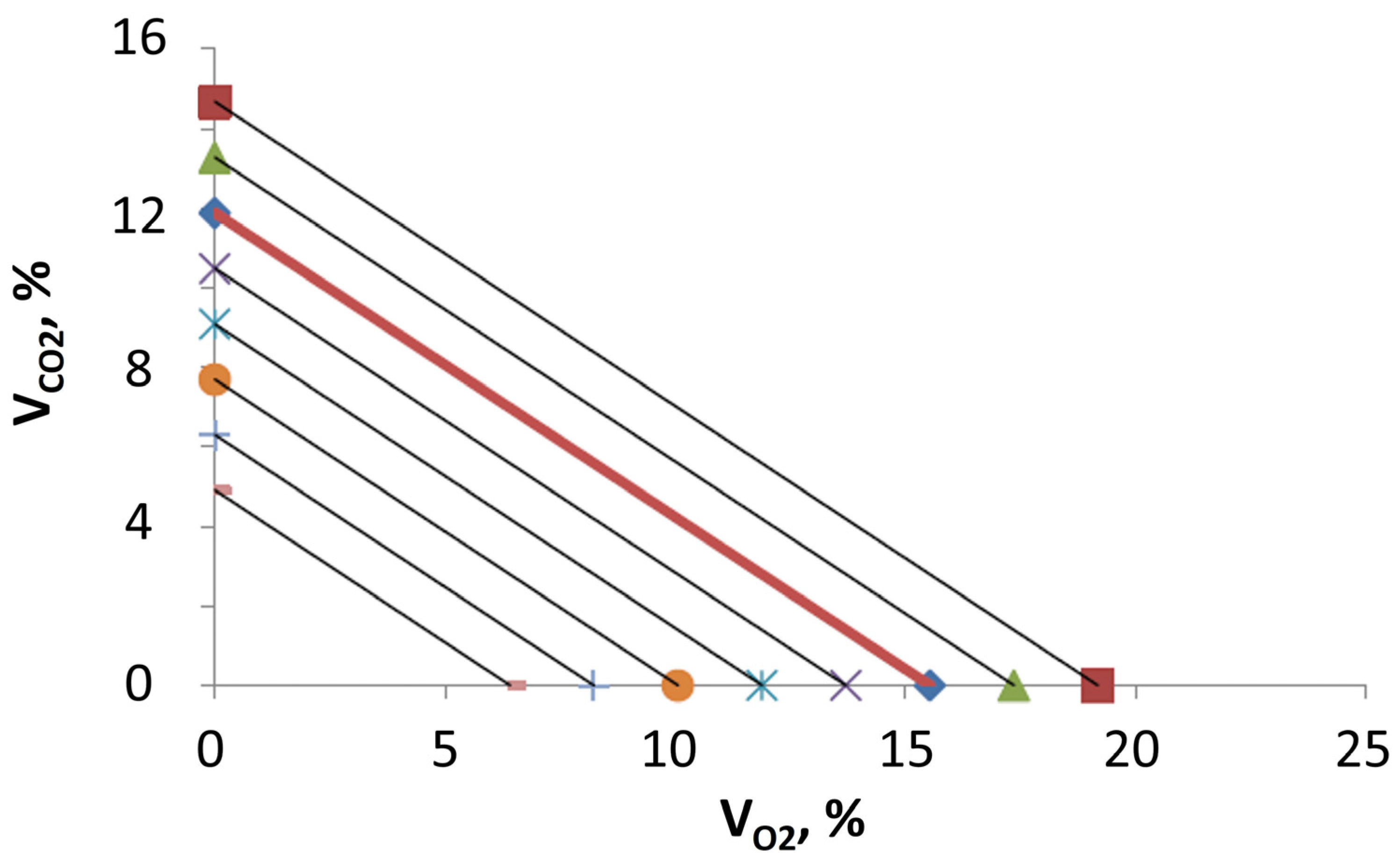

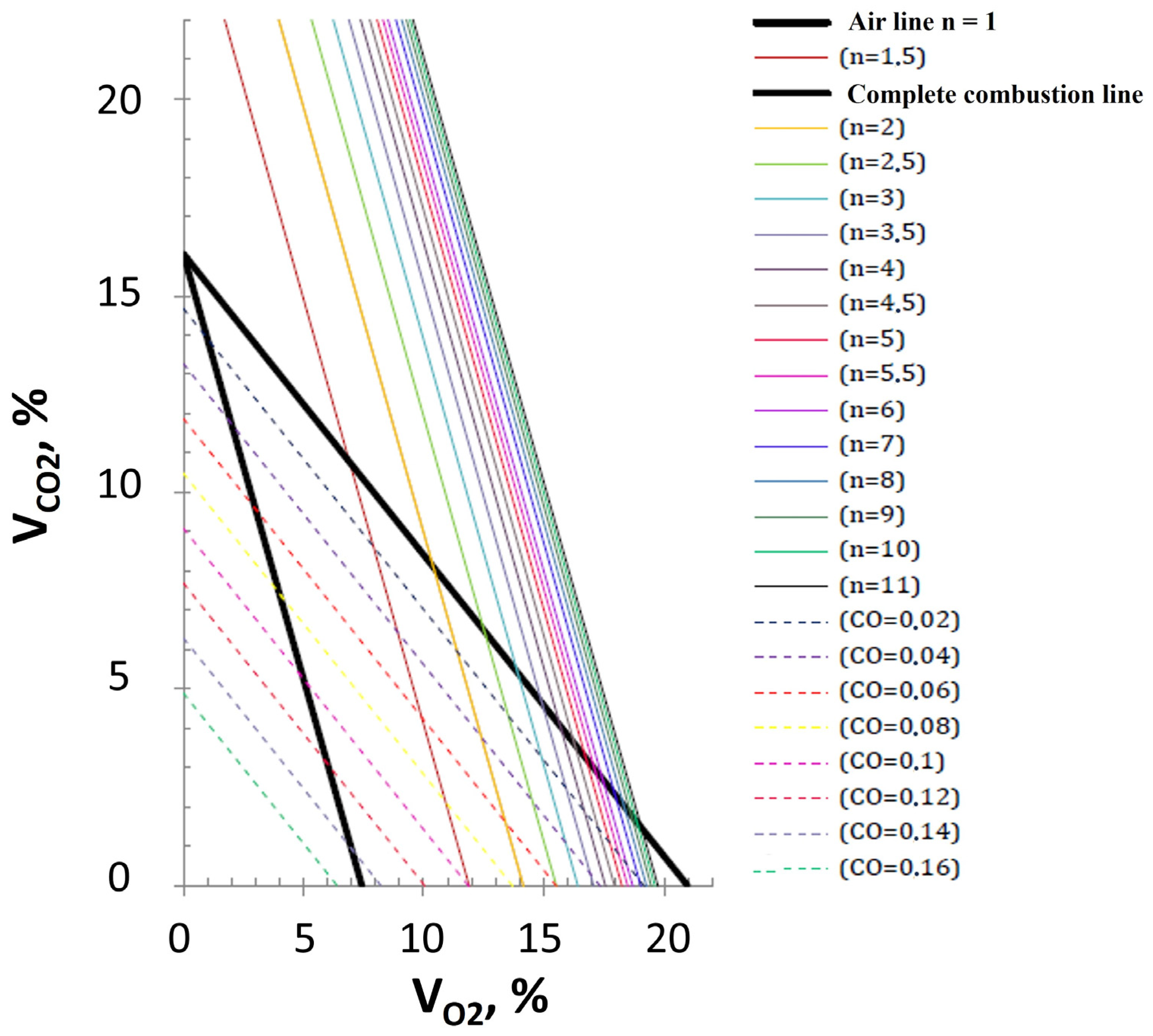

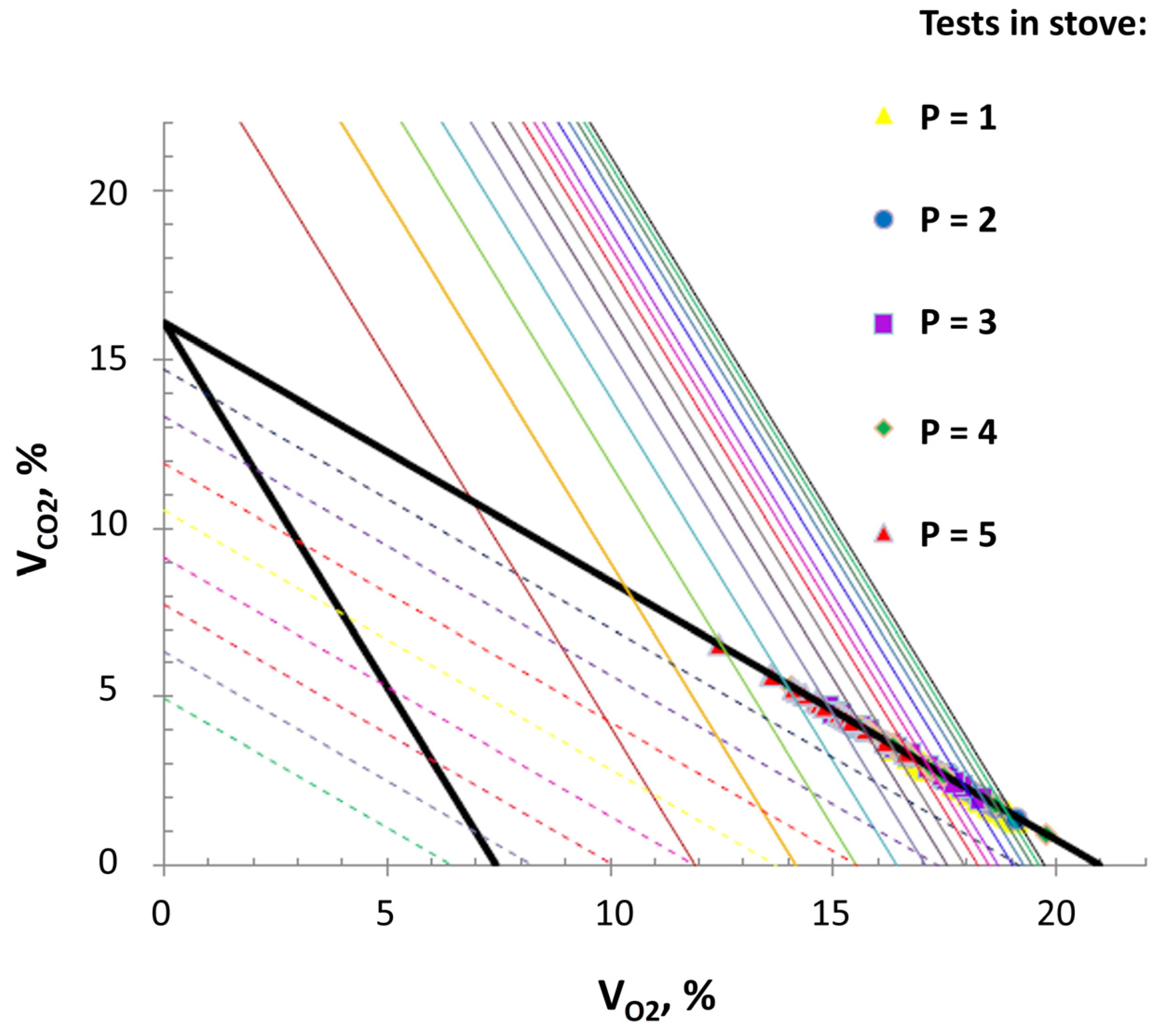

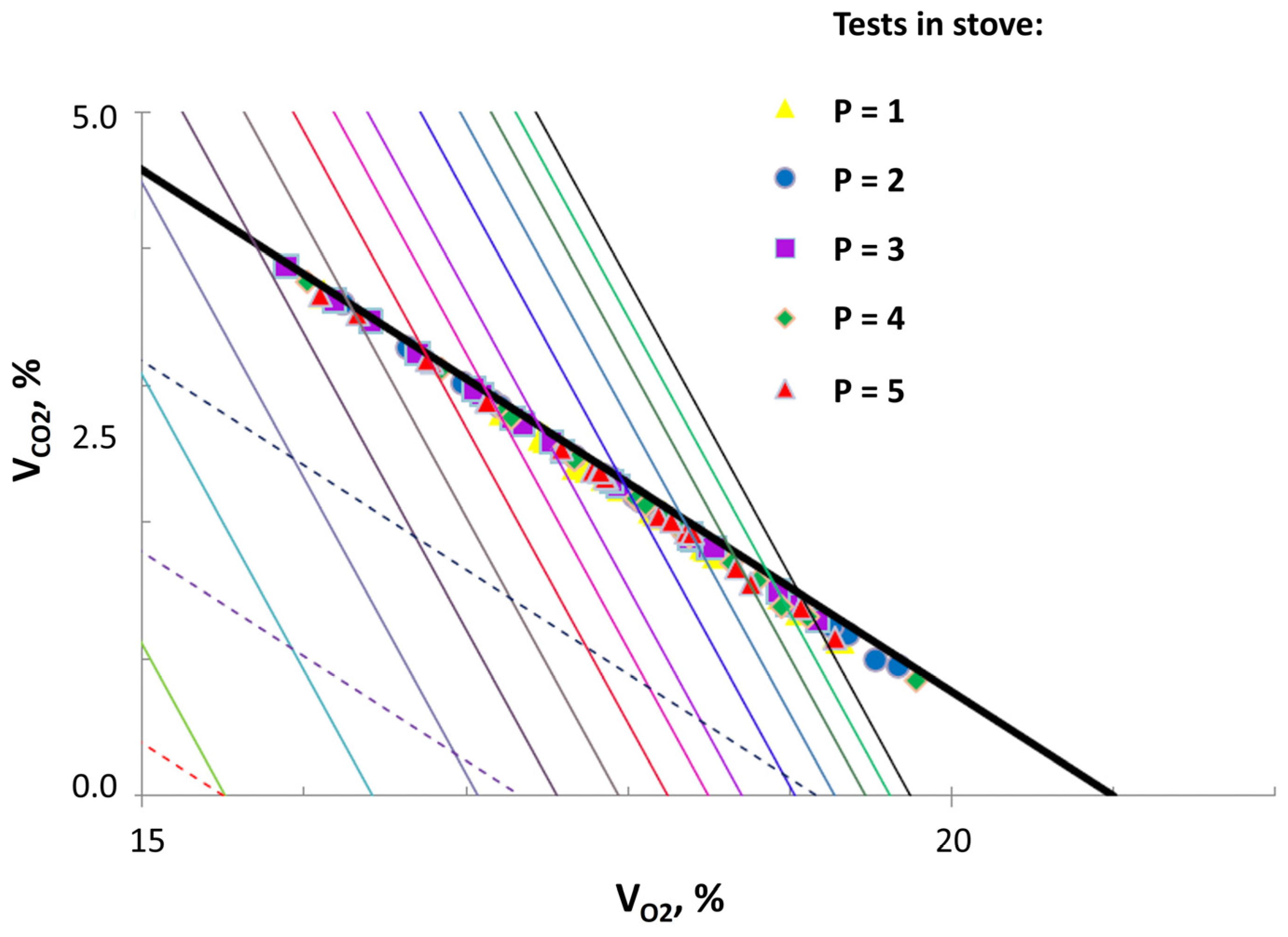

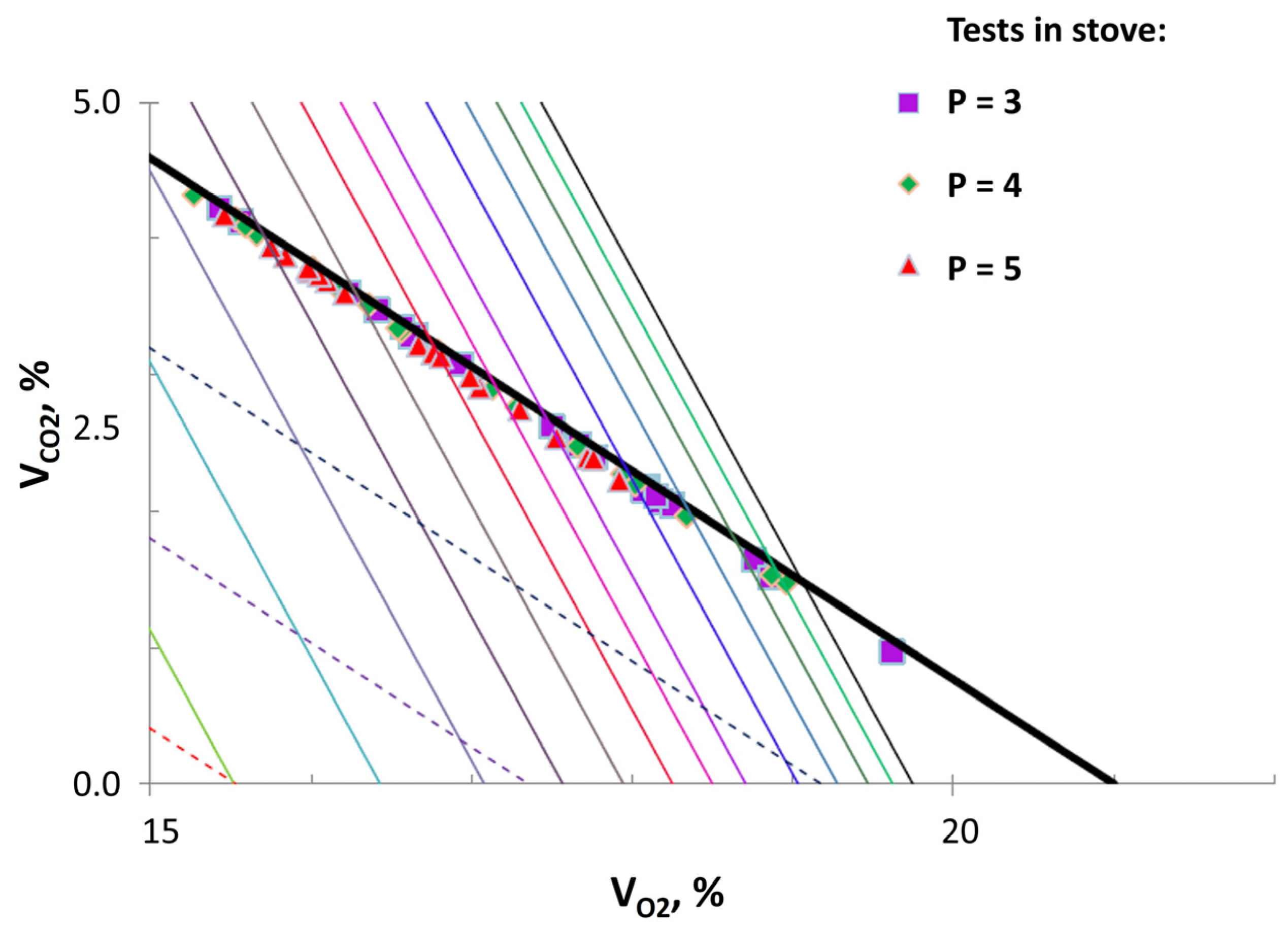

2.4. Ostwald Diagram

- VCO2max, VO2=0: with n=1 and x=1. VCO2 max is obtained from Equation 10, obtaining a value of 0.161.

- VCO2=0, VO2max: with n=1 and x=1. VO2 max is obtained from Equation 11, obtaining a value of 0.074.

3. Results and Discussion

3.1. Pellet Characterization and Experiments Selected for Combustion Tests

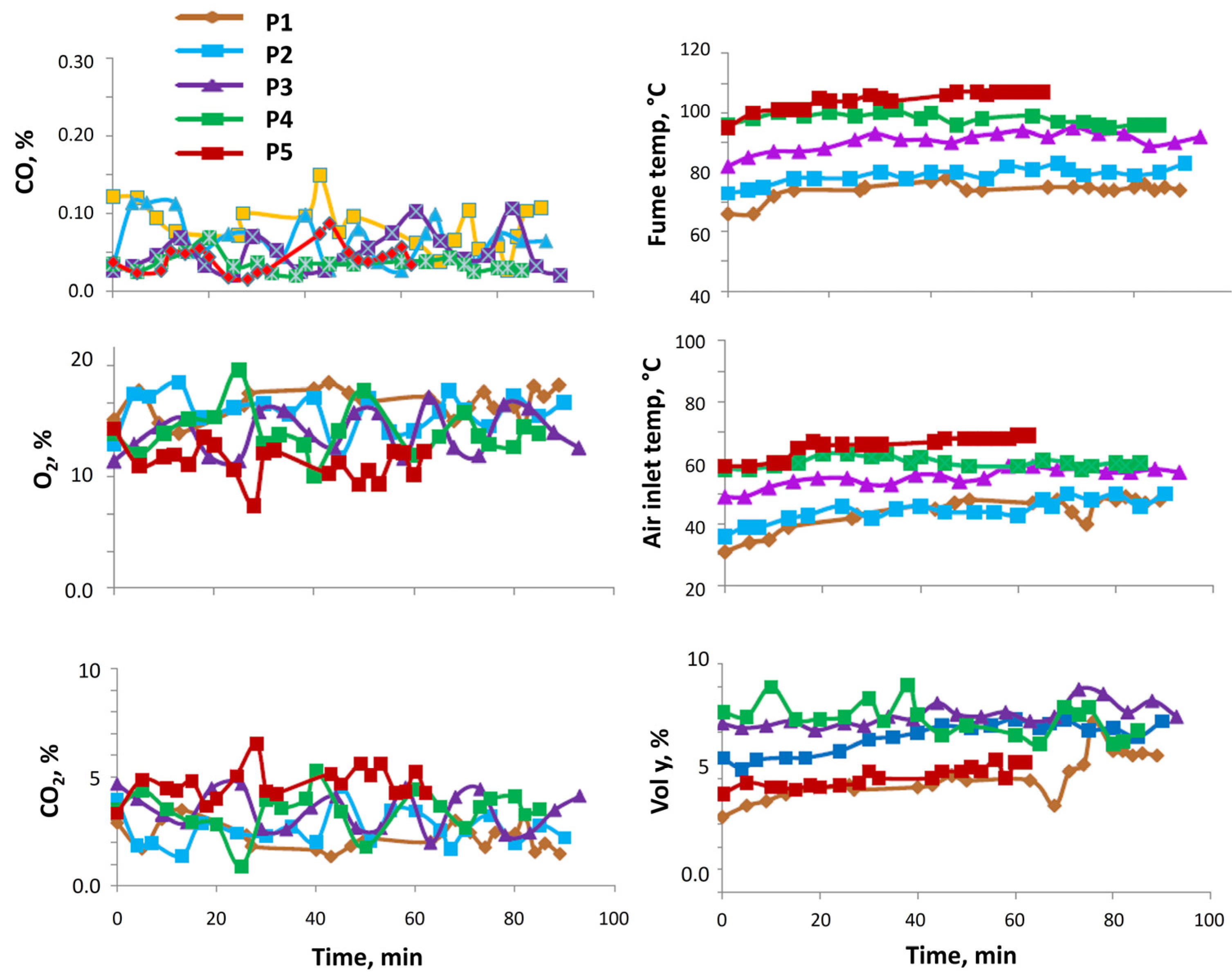

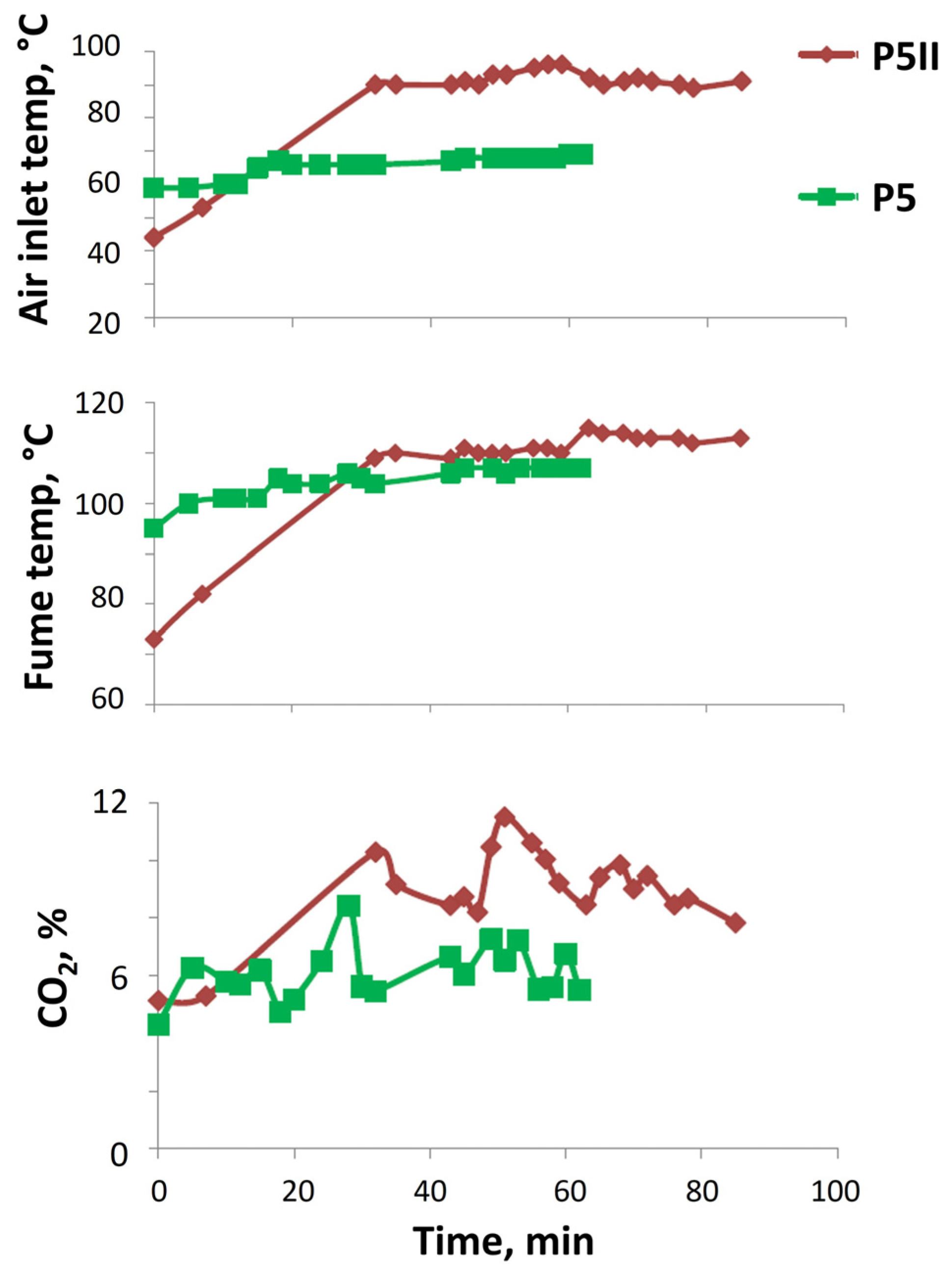

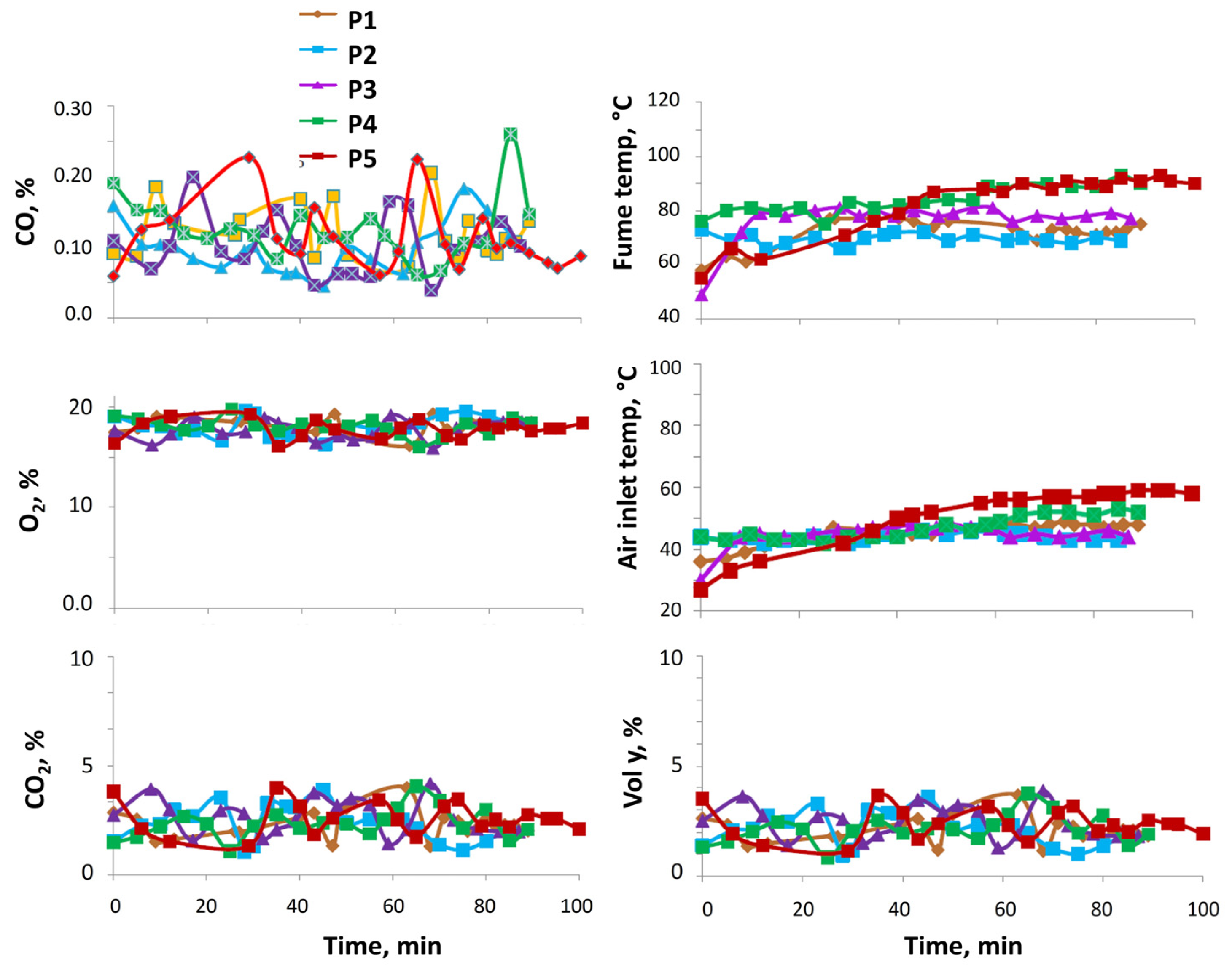

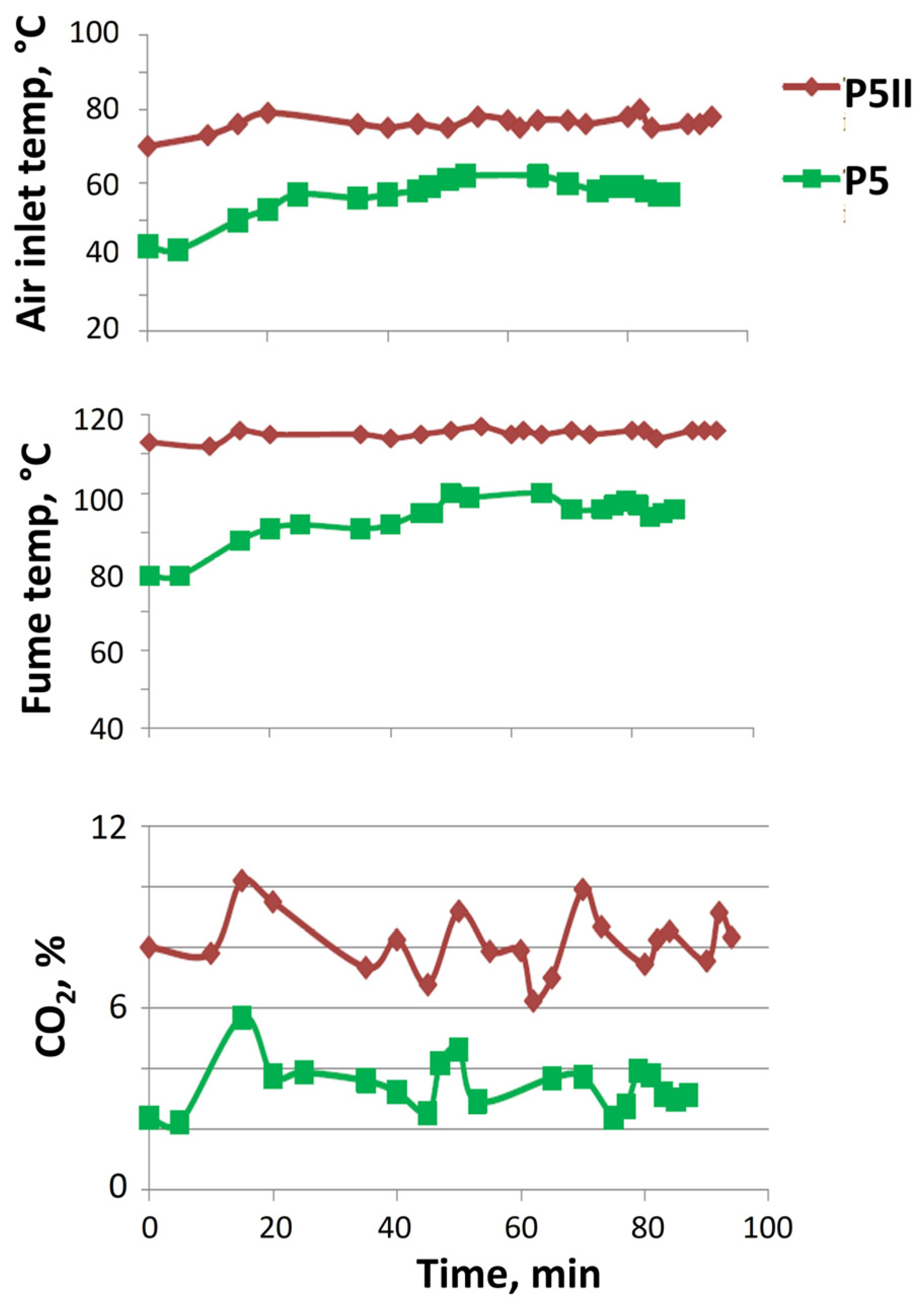

3.2. Pine Pellet Combustion

3.3. Plum Tree Pellet Combustion

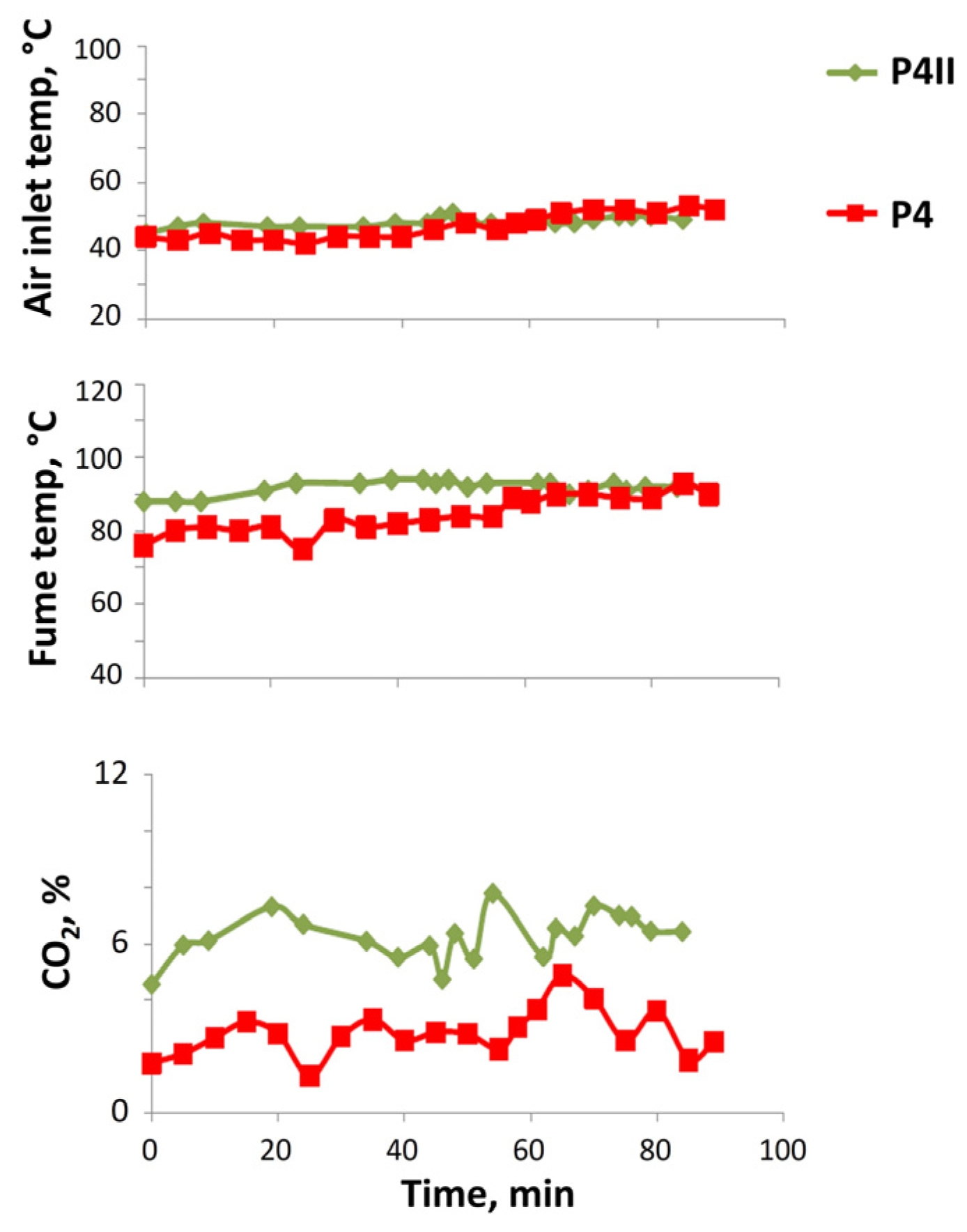

3.4. Poplar Pellet Combustion

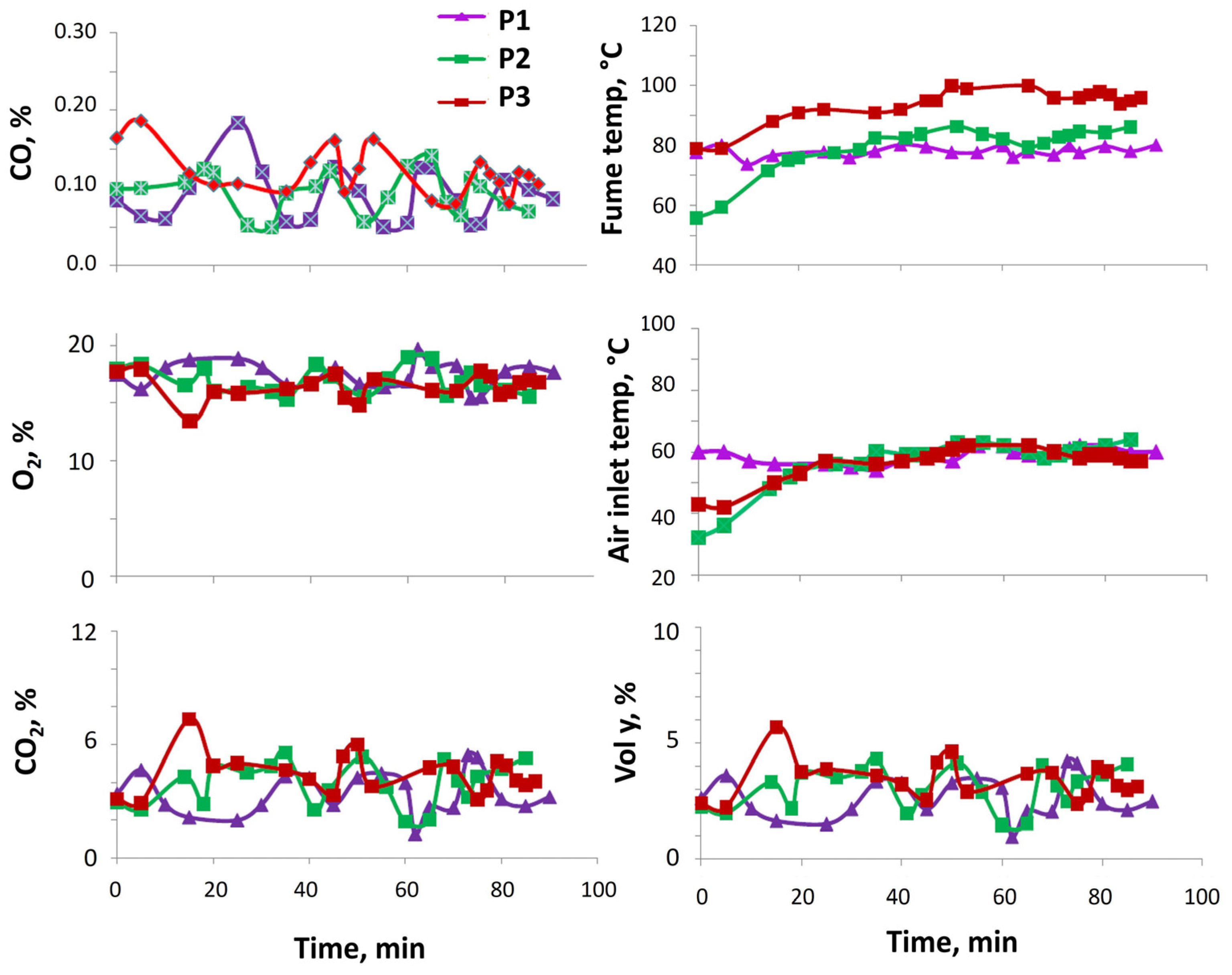

4. Conclusions

- In general, when power increased, combustion was more efficient except for poplar pellets. Also, when pellet feed flow increased, combustion was more efficient, with a special positive effect in plum tree pellets. Thus, carbon monoxide emissions were reduced, except for poplar pellets.

- Inlet air and outlet fume temperatures increased with the working level (that is, power), except for poplar pellets in the case of inlet air temperature.

- Combustion is more complete when power and feed increased, decreasing energy loss except for poplar pellets. Regarding pine and plum tree pellets, yield increased with a rise in pellet feed and power, except for poplar pellets where this yield improved by modifying excess air.

- Thus, some solutions to energy loss according to these results were proposed, such as sample homogenization to make feeding rate more stable, a reduction in excess air coefficient and the implementation of an economizer (in order to reduce fume temperature, which is a good step from environmental and economic points of view).

- In particular, the optimum combustion conditions for pine pellets were obtained by selecting Position 5 and +25 % biomass feed, with a highest yield of 92.34 % for an excess air coefficient of 2.23, a burned gas ratio of 0.994 and fumes and inlet air temperatures of 113.14 °C and 90.57 °C, respectively.

- Regarding plum tree pellets, Position 4 and +25 % biomass feed were selected for the optimum conditions in the commercial combustion stove, with a highest yield of 91.58 % for an excess air coefficient of 2.91, a burned gas ratio of 0.993 and fumes and inlet air temperatures of 91.71 °C and 49.14 °C, respectively.

- Concerning poplar pellets, optimum conditions were found when P = 3 and +25 % biomass supply were selected, with a highest yield of 91.1 % for an excess air coefficient of 3.18, and fumes and inlet air temperatures of 87.66 °C and 84.66 °C, respectively.

- To sum up, for this combustion chamber, it can be concluded that the three fuels studied are suitable for this facility in order to achieve optimum conditions, that is, an efficient combustion process, not showing considerable differences among them to be selected as an ideal biomass for this experience.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Högselius, P.; Kaijser, A. Energy Dependence in Historical Perspective: The Geopolitics of Smaller Nations. Energy Policy 2019, 127, 438–444. [Google Scholar] [CrossRef]

- Vakulchuk, R.; Overland, I.; Scholten, D. Renewable Energy and Geopolitics : A Review. Renewable and Sustainable Energy Reviews 2020, 122, 109547. [Google Scholar] [CrossRef]

- Bricout, A.; Slade, R.; Staffell, I.; Halttunen, K. From the Geopolitics of Oil and Gas to the Geopolitics of the Energy Transition: Is There a Role for European Supermajors? Energy Res Soc Sci 2022, 88. [Google Scholar] [CrossRef]

- Scholten, D.; Bosman, R. The Geopolitics of Renewables; Exploring the Political Implications of Renewable Energy Systems. Technol Forecast Soc Change 2016, 103, 273–283. [Google Scholar] [CrossRef]

- Carfora, A.; Pansini, R.V.; Scandurra, G. Energy Dependence, Renewable Energy Generation and Import Demand: Are EU Countries Resilient? Renew Energy 2022, 195, 1262–1274. [Google Scholar] [CrossRef]

- UN Sustainable Development Goals. 2019.

- Singh, A.; Christensen, T.; Panoutsou, C. Policy Review for Biomass Value Chains in the European Bioeconomy. Glob Transit 2021, 3, 13–42. [Google Scholar] [CrossRef]

- Vitoussia, T.; Leyssens, G.; Trouvé, G.; Brillard, A.; Kemajou, A.; Njeugna, E.; Brilhac, J.F. Analysis of the Combustion of Pellets Made with Three Cameroonian Biomass in a Domestic Pellet Stove. Fuel 2020, 276. [Google Scholar] [CrossRef]

- Bioenergy Europe Wood Pellet Production Worldwide from 2000 to 2018. Available online: https://www.statista.com/statistics/509075/global-wood-pellet-production/ (accessed on 18 September 2023).

- EurObserv’ER Solid Biomass Primary Energy Production in the European Union 2000-2021. Available online: https://www.statista.com/statistics/799329/solid-biomass-energy-production-european-union-eu/ (accessed on 18 September 2023).

- Federal Network Agency Number of Biomass Power Plants in Germany from 2011 to 2022. Available online: https://www.statista.com/statistics/457781/biomass-plants-in-germany/ (accessed on 18 September 2023).

- Energy Information Administration Electricity Generation from Biomass and Waste in Africa from 2000 to 2020. Available online: https://www.statista.com/statistics/1276088/electricity-generation-from-biomass-and-waste-in-africa/ (accessed on 18 September 2023).

- EurObserv’ER Biomass Energy Production and Consumption in Finland 2015-2016. Available online: https://www.statista.com/statistics/799434/solid-biomass-production-consumption-finland/ (accessed on 18 September 2023).

- EurObserv’ER Biomass Energy Production and Consumption in Sweden 2016-2021. Available online: https://www.statista.com/statistics/799426/solid-biomass-production-consumption-sweden/ (accessed on 18 September 2023).

- EurObserv’ER Biomass Energy Production and Consumption in Portugal 2016-2021. Available online: https://www.statista.com/statistics/799491/solid-biomass-production-consumption-portugal/ (accessed on 18 September 2023).

- EurObserv’ER Biomass Energy Production and Consumption in Italy 2016-2018. Available online: https://www.statista.com/statistics/799429/solid-biomass-production-consumption-italy/ (accessed on 18 September 2023).

- EurObserv’ER Biomass Energy Production and Consumption in Spain 2015-2021. Available online: https://www.statista.com/statistics/799448/solid-biomass-production-consumption-spain/ (accessed on 18 September 2023).

- Moayedi, H.; Aghel, B.; Abdullahi, M.M.; Nguyen, H.; Safuan A Rashid, A. Applications of Rice Husk Ash as Green and Sustainable Biomass. J Clean Prod 2019, 237, 117851. [Google Scholar] [CrossRef]

- Lewandowski, W.M.; Ryms, M.; Kosakowski, W. Thermal Biomass Conversion: A Review. Processes 2020, 8. [Google Scholar] [CrossRef]

- Hustad, J.E.; Wnju, O.K. BIOMASS COMBUSTION IN II3A COUNTRES; 1992; Vol. 2. [Google Scholar]

- Oladosu, K.O.; Babalola, S.A.; Kareem, M.W.; Ajimotokan, H.A.; Kolawole, M.Y.; Issa, W.A.; Olawore, A.S.; Ponle, E.A. Optimization of Fuel Briquette Made from Bi-Composite Biomass for Domestic Heating Applications. Sci Afr 2023, 21. [Google Scholar] [CrossRef]

- Pokhrel, R.P.; Gordon, J.; Fiddler, M.N.; Bililign, S. Determination of Emission Factors of Pollutants From Biomass Burning of African Fuels in Laboratory Measurements. Journal of Geophysical Research: Atmospheres 2021, 126. [Google Scholar] [CrossRef]

- Labbé, R.; Paczkowski, S.; Knappe, V.; Russ, M.; Wöhler, M.; Pelz, S. Effect of Feedstock Particle Size Distribution and Feedstock Moisture Content on Pellet Production Efficiency, Pellet Quality, Transport and Combustion Emissions. Fuel 2020, 263. [Google Scholar] [CrossRef]

- Brandelet, B.; Rose, C.; Landreau, J.; Druette, L.; Rogaume, Y. Toward a Cleaner Domestic Wood Heating by the Optimization of Firewood Stoves? J Clean Prod 2021, 325. [Google Scholar] [CrossRef]

- Han, J.; Liu, X.; Hu, S.; Zhang, N.; Wang, J.; Liang, B. Optimization of Decoupling Combustion Characteristics of Coal Briquettes and Biomass Pellets in Household Stoves. Chin J Chem Eng 2023. [Google Scholar] [CrossRef]

- Shaisundaram, V.S.; Chandrasekaran, M.; Sujith, S.; Praveen Kumar, K.J.; Shanmugam, M. Design and Analysis of Novel Biomass Stove. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd, 2020; Vol. 46, pp. 4054–4058. [Google Scholar]

- Zhang, H.; Zhang, X.; Wang, Y.; Bai, P.; Hayakawa, K.; Zhang, L.; Tang, N. Characteristics and Influencing Factors of Polycyclic Aromatic Hydrocarbons Emitted from Open Burning and Stove Burning of Biomass: A Brief Review. Int J Environ Res Public Health 2022, 19. [Google Scholar] [CrossRef]

- Qi, J.; Liu, L.; Wu, J. Improving Combustion Technology for Cooking Activities for Pollutant Emission Reduction and Carbon Neutrality. Atmosphere (Basel) 2022, 13. [Google Scholar] [CrossRef]

- Huang, Y.; Partha, D.B.; Harper, K.; Heyes, C. Impacts of Global Solid Biofuel Stove Emissions on Ambient Air Quality and Human Health. Geohealth 2021, 5. [Google Scholar] [CrossRef]

- Lustenberger, D.; Strassburg, J.; Strebel, T.; Mangold, F.; Griffin, T. Simulation Tool for the Development of a Staged Combustion Pellet Stove Controller. Energies (Basel) 2022, 15. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Coelho, P.; García-Sanz-Calcedo, J.; Moral, F.J.; Al-Karany, R.K.; Yusaf, T. An Experimental Technology of Drying and Clean Combustion of Biomass Residues. Applied Sciences (Switzerland) 2018, 8. [Google Scholar] [CrossRef]

- Maxwell, D.; Gudka, B.A.; Jones, J.M.; Williams, A. Emissions from the Combustion of Torrefied and Raw Biomass Fuels in a Domestic Heating Stove. Fuel Processing Technology 2020, 199. [Google Scholar] [CrossRef]

- Prapas, J.; Baumgardner, M.E.; Marchese, A.J.; Willson, B.; DeFoort, M. Influence of Chimneys on Combustion Characteristics of Buoyantly Driven Biomass Stoves. Energy for Sustainable Development 2014, 23, 286–293. [Google Scholar] [CrossRef]

- Sungur, B.; Basar, C.; Kaleli, A. Multi-Objective Optimisation of the Emission Parameters and Efficiency of Pellet Stove at Different Supply Airflow Positions Based on Machine Learning Approach. Energy 2023, 278. [Google Scholar] [CrossRef]

- Schmidt, G.; Trouvé, G.; Leyssens, G.; Schönnenbeck, C.; Genevray, P.; Cazier, F.; Dewaele, D.; Vandenbilcke, C.; Faivre, E.; Denance, Y.; et al. Wood Washing: Influence on Gaseous and Particulate Emissions during Wood Combustion in a Domestic Pellet Stove. Fuel Processing Technology 2018, 174, 104–117. [Google Scholar] [CrossRef]

- Vicente, E.D.; Duarte, M.A.; Calvo, A.I.; Nunes, T.F.; Tarelho, L.; Alves, C.A. Emission of Carbon Monoxide, Total Hydrocarbons and Particulate Matter during Wood Combustion in a Stove Operating under Distinct Conditions. Fuel Processing Technology 2015, 131, 182–192. [Google Scholar] [CrossRef]

- Toscano, G.; Duca, D.; Amato, A.; Pizzi, A. Emission from Realistic Utilization of Wood Pellet Stove. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- UNE Normalización Española. Solid Mineral Fuels. Determination of Ash.

- UNE Normalización Española. Hard Coal and Anthracite. Determination of Total Moisture.

- UNE Normalización Española. Hard Coal and Coke. Determination of Volatile Matter Content.

- Yao, W.; Zhao, Y.; Chen, R.; Wang, M.; Song, W.; Yu, D. Emissions of Toxic Substances from Biomass Burning: A Review of Methods and Technical Influencing Factors. Processes 2023, 11. [Google Scholar] [CrossRef]

- Deng, M.; Li, P.; Shan, M.; Yang, X. Optimizing Supply Airflow and Its Distribution between Primary and Secondary Air in a Forced-Draft Biomass Pellet Stove. Environ Res 2020, 184. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Zhou, Y.; Dong, R. The Influences of Various Testing Conditions on the Evaluation of Household Biomass Pellet Fuel Combustion. Energies (Basel) 2018, 11. [Google Scholar] [CrossRef]

- Holubčík, M.; Čajová Kantová, N.; Jandačka, J.; Čaja, A. The Performance and Emission Parameters Based on the Redistribution of the Amount of Combustion Air of the Wood Stove. Processes 2022, 10. [Google Scholar] [CrossRef]

- Wang, X.; Niu, B.; Deng, S.; Liu, Y.; Tan, H. Optimization Study on Air Distribution of an Actual Agriculture Up-Draft Biomass Gasification Stove. In Proceedings of the Energy Procedia; Elsevier Ltd, 2014; Vol. 61, pp. 2335–2338. [Google Scholar]

- Lasek, J.A.; Matuszek, K.; Hrycko, P.; Głód, K.; Li, Y.H. The Combustion of Torrefied Biomass in Commercial-Scale Domestic Boilers. Renew Energy 2023, 216. [Google Scholar] [CrossRef]

- Costa, M.A.M.; Schiavon, N.C.B.; Felizardo, M.P.; Souza, A.J.D.; Dussán, K.J. Emission Analysis of Sugarcane Bagasse Combustion in a Burner Pilot. Sustain Chem Pharm 2023, 32. [Google Scholar] [CrossRef]

- Kougioumtzis, M.A.; Kanaveli, I.P.; Karampinis, E.; Grammelis, P.; Kakaras, E. Combustion of Olive Tree Pruning Pellets versus Sunflower Husk Pellets at Industrial Boiler. Monitoring of Emissions and Combustion Efficiency. Renew Energy 2021, 171, 516–525. [Google Scholar] [CrossRef]

| Authors | Details and findings | Reference |

|---|---|---|

| Maxwell et al. | Analysis of the emissions of three different biomass and their torrefied counterparts in a domestic wood stove. After torrefaction, lower emissions (CO and CH4) were found. | [32] |

| Prapas et al. | Study of the influence of a chimney on the combustion characteristics of a stove, observing changes in CO production. | [33] |

| Sungur et al. | Optimization of the effect of burner pot design by changing supply airflow position in a pellet stove through machine learning. | [34] |

| Schmidt et al. | Influence of wood washing on emissions during wood combustion in a domestic pellet stove, with a decrease in pollutants. | [35] |

| Vicente et al. | Wood combustion experiments were carried out to determine the effect of different factors like biomass load. | [36] |

| Toscano et al. | Combustion tests were carried out simulating domestic utilization conditions of a pellet stove. Higher emissions (for instance, CO) were found in steady state condition. | [37] |

| Parameter | Details |

|---|---|

| Proximate analysis | It consists of biomass composition regarding ash, moisture, volatile content, and fixed carbon. |

| Ash content | It is the solid waste after incineration. High-quality fuels present low ash content. Determination according to UNE 32004:1984 standard [38] |

| Moisture content | High moisture reduces energy potential as some energy will be used to evaporate and remove moisture. According to UNE 32001:1981 standard [39] |

| Volatile matter | Weight loss of a fuel during heating in absence of oxygen (apart from moisture content). According to UNE 32019:1984 standard [40] |

| Fixed carbon | It is obtained according to the previous values, as follows: Fixed carbon = 100 – (% ash + % moisture + % volatile matter). |

| Ultimate analysis | It is the qualitative and quantitative determination of certain chemical elements such as C, H, N, S and O, mainly. |

| Parameter | Result |

|---|---|

| Weight, kg | 110 |

| Height, mm | 864 |

| Width, mm | 453 |

| Depth, mm | 497 |

| Fume pipe diameter, mm | 80 |

| Air suction pipe diameter, mm | 50 |

| Maximum heating volume, m3 | 115 |

| Maximum thermal power, kW | 5.8 |

| Maximum useful thermal power, kW | 5.0 |

| Minimum useful thermal power, kW | 2.5 |

| Maximum hourly fuel consumption, kg/h | 1.2 |

| Minimum hourly fuel consumption, kg/h | 0.6 |

| Tank capacity, kg | 11 |

| Nominal electric power, W | 300 |

| Recommended flue gas pressure, Pa | 10 |

| Flue gas pressure at maximum thermal power, Pa | 12 |

| Flue gas pressure at minimum thermal power, Pa | 10 |

| Raw material | Position or level selected | Pellet feed |

|---|---|---|

| Pine | ||

| Poplar | 1, 2, 3, 4 and 5 | Normal (100 %) Extra (125 %) |

| Plum tree |

| VO2, % (X) | VCO2, % (Y) | VO2, % (X) | VCO2, % (Y) |

|---|---|---|---|

| 0.00 | 0.161 | 0.11 | 0.077 |

| 0.01 | 0.153 | 0.12 | 0.069 |

| 0.02 | 0.145 | 0.13 | 0.061 |

| 0.03 | 0.138 | 0.14 | 0.054 |

| 0.04 | 0.130 | 0.15 | 0.046 |

| 0.05 | 0.122 | 0.16 | 0.038 |

| 0.06 | 0.115 | 0.17 | 0.031 |

| 0.07 | 0.107 | 0.18 | 0.023 |

| 0.08 | 0.099 | 0.19 | 0.015 |

| 0.09 | 0.092 | 0.20 | 0.008 |

| 0.10 | 0.084 | 0.21 | 0.000 |

| Proximate analysis | |||||

| Sample | Ash, % | Moisture, % | Volatile matter, % | Fixed carbon, % | |

| Pine | 0.50 | 6.42 | 84.01 | 15.49 | |

| Poplar | 1.79 | 6.61 | 78.24 | 13.36 | |

| Plum tree | 0.83 | 6.90 | 78.37 | 13.90 | |

| Ultimate analysis | |||||

| Sample | C, % | H, % | N, % | S, % | O, % |

| Pine | 47.70 | 6.12 | 0.33 | 0.004 | 45.85 |

| Poplar | 46.40 | 6.01 | 0.52 | 0.028 | 47.04 |

| Plum tree | 47.50 | 6.23 | 0.38 | 0.093 | 45.80 |

| Pine | Poplar | Plum tree |

|---|---|---|

| P1I vs P5I | P3I vs P5I | P2I vs P4I |

| P1I vs P5II | P3I vs P5II | P2I vs P4II |

| P1II vs P5II | P3II vs P5II | P2II vs P4II |

| P5I vs P5II | P5I vs P5II | P4I vs P4II |

| P1 | P5 | |||

|---|---|---|---|---|

| Parameter | Average | Average deviation | Average | Average deviation |

| O2, % | 0.18 | 0.01 | 0.148 | 0.006 |

| Air supply temperature, °C | 46.7 | 1.9 | 68.4 | 0.4 |

| Fume temperature, °C | 74.7 | 0.5 | 107 | 0.3 |

| Ambient temperature, °C | 20.9 | 0.6 | 20.5 | 0.2 |

| CO, ppm | 700.1 | 214.1 | 445.2 | 126.4 |

| CO, % | 0.00070 | 0.00021 | 0.00045 | 0.00013 |

| y, % | 0.0227 | 0.0046 | 0.0475 | 0.0044 |

| CO2, % | 0.0293 | 0.0058 | 0.0612 | 0.0056 |

| Λ | 7.19 | 1.38 | 3.36 | 0.29 |

| η, % | 85.82 | 3.00 | 89.74 | 0.78 |

| qA, % | 14.18 | 3.00 | 10.26 | 0.78 |

| NO, ppm | 17.9 | 6.7 | 43.2 | 6.0 |

| Calculated n | 6.94 | 1.33 | 3.26 | 0.28 |

| X (x = [VCO2/(VCO2+VCO)]-n) | 0.966 | 0.016 | 0.991 | 0.002 |

| Test parameter | Pine pellet (P = 1, 100 % feed) |

Pine pellet (P = 5, 125 % feed) |

Comparison |

|---|---|---|---|

| O2, % | 0.18 | 0.119 | |

| Air supply temperature, °C | 46.7 | 90.6 | |

| Fume temperature, °C | 74.7 | 113.1 | |

| Ambient temperature, °C | 20.9 | 20.8 | Constant |

| CO, ppm | 700.1 | 364.4 | |

| CO, % | 0.00070 | 0.00036 | |

| y, % | 0.0227 | 0.0696 | |

| CO2, % | 0.0293 | 0.0896 | |

| Λ | 7.19 | 2.29 | |

| η, % | 85.82 | 92.34 | |

| qA, % | 14.18 | 7.66 | |

| NO, ppm | 17.9 | 65.1 | Negligible |

| Calculated n | 6.94 | 2.24 | |

| x (x = [VCO2/(VCO2+VCO)]-n) | 0.966 | 0.995 |

| P2 | P4 | |||

|---|---|---|---|---|

| Parameter | Average | Average deviation | Average | Average deviation |

| O2, % | 0.189 | 0.004 | 0.180 | 0.007 |

| Air supply temperature, °C | 43.6 | 0.7 | 52 | 0.4 |

| Fume temperature, °C | 69.2 | 0.6 | 90.2 | 1.1 |

| Ambient temperature, °C | 18.8 | 0.4 | 18.7 | 0.5 |

| CO, ppm | 1378.0 | 240.8 | 1372.6 | 533.1 |

| CO, % | 0.00138 | 0.00024 | 0.00137 | 0.00053 |

| y, % | 0.0150 | 0.0035 | 0.0222 | 0.0057 |

| CO2, % | 0.0198 | 0.0045 | 0.0291 | 0.0073 |

| Λ | 10.05 | 1.92 | 7.06 | 1.46 |

| η, % | 79.98 | 4.42 | 81.26 | 4.69 |

| qA, % | 20.02 | 4.42 | 18.74 | 4.69 |

| NO, ppm | 40 | 11.2 | 61.4 | 12.9 |

| Calculated n | 9.72 | 1.87 | 6.82 | 1.42 |

| X (x = [VCO2/(VCO2+VCO)]-n) | 0.908 | 0.029 | 0.932 | 0.038 |

| Test parameter | Plum tree pellet (P = 2, 100 % feed) |

Plum tree pellet (P = 4, 125 % feed) |

Comparison |

|---|---|---|---|

| O2, % | 0.189 | 0.141 | |

| Air supply temperature, °C | 43.6 | 49.1 | |

| Fume temperature, °C | 69.2 | 91.7 | |

| Ambient temperature, °C | 18.8 | 18.9 | Constant |

| CO, ppm | 1378 | 329.3 | |

| CO, % | 0.00138 | 0.00033 | |

| y, % | 0.0150 | 0.0526 | |

| CO2, % | 0.0198 | 0.0671 | |

| Λ | 10.05 | 3.01 | |

| η, % | 79.98 | 91.53 | |

| qA, % | 20.02 | 8.41 | |

| NO, ppm | 40 | 115.9 | Negligible |

| Calculated n | 9.72 | 2.92 | |

| x (x = [VCO2/(VCO2+VCO)]-n) | 0.908 | 0.994 |

| P3 | P5 | |||

|---|---|---|---|---|

| Parameter | Average | Average deviation | Average | Average deviation |

| O2, % | 0.171 | 0.011 | 0.166 | 0.006 |

| Air supply temperature, °C | 60.7 | 1.0 | 58.8 | 1.1 |

| Fume temperature, °C | 78.8 | 1.2 | 96.6 | 1.3 |

| Ambient temperature, °C | 14.2 | 0.5 | 18.9 | 0.5 |

| CO, ppm | 806.7 | 182.4 | 1047.1 | 158.5 |

| CO, % | 0.00081 | 0.00018 | 0.00105 | 0.00016 |

| y, % | 0.0290 | 0.0085 | 0.0328 | 0.0045 |

| CO2, % | 0.0376 | 0.0109 | 0.0426 | 0.0057 |

| Λ | 5.76 | 1.33 | 4.77 | 0.61 |

| η, % | 85.62 | 3.46 | 85.47 | 1.85 |

| qA, % | 14.38 | 3.46 | 14.57 | 1.85 |

| NO, ppm | 73.7 | 15.6 | 114.7 | 13.6 |

| Calculated n | 5.56 | 1.28 | 4.62 | 0.58 |

| x (x = [VCO2/(VCO2+VCO)]-n) | 0.969 | 0.012 | 0.968 | 0.009 |

| Test parameter | Pine pellet (P = 3, 100 % feed) |

Pine pellet (P = 5, 125 % feed) |

Comparison |

|---|---|---|---|

| O2, % | 0.171 | 0.125 | |

| Air supply temperature, °C | 60.7 | 77 | |

| Fume temperature, °C | 78.8 | 115.6 | |

| Ambient temperature, °C | 14.2 | 21 | |

| CO, ppm | 806.7 | 1058.6 | Constant |

| CO, % | 0.00081 | 0.00106 | Constant |

| y, % | 0.0290 | 0.0640 | |

| CO2, % | 0.0376 | 0.0828 | |

| Λ | 5.76 | 2.45 | |

| η, % | 85.62 | 90.53 | |

| qA, % | 14.38 | 9.47 | |

| NO, ppm | 73.7 | 165.4 | Negligible |

| Calculated n | 5.56 | 2.39 | |

| x (x = [VCO2/(VCO2+VCO)]-n) | 0.969 | 0.984 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).