1. Introduction

Machine Learning (ML) stands as a pivotal driver in the fourth industrial revolution, commonly referred to as Industry 4.0. ML empowers computer systems to tackle intricate research queries through implicit and automated "learning," which evolves autonomously without explicit preprogramming. From an algorithmic standpoint, the term "machine" alludes to an automated process that progressively enhances its problem-solving prowess through iterative iterations based on external inputs. The concept of ML was pioneered by Samuel [

1], a luminary in modern Artificial Intelligence (AI).

Categorically, ML techniques are segregated into supervised, unsupervised, and reinforcement learning. Supervised learning operates on labeled output with designated input [

2], allowing predictions on novel datasets after training. Unsupervised learning, in contrast, uncovers data patterns devoid of labels [

3], typically applied to clustering tasks. Reinforcement learning, distinctively, doesn’t necessitate a supervisor [

4]; it rewards or penalizes the network based on output acceptability. These methodologies have evolved into various forms, such as deep learning, extreme learning, transfer learning, and reinforcement learning.

Early and prominent ML algorithms encompass Decision Trees (DT), Genetic Algorithms (GA), ANN (ANN), Bayesian Networks, Random Forests (RF), Support Vector Machines (SVM), Regression Analysis, K-Means clustering, Naive Bayes classifier, K-Nearest Neighbor Classifier (kNN), and Principal Component Analysis (PCA). These have evolved into advanced techniques like deep learning, extreme learning, transfer learning, and reinforcement learning. ML’s ubiquity extends across industries, finding application in data mining [

5], process automation [

6], attacks on industrial control systems [

7], predictive maintenance [

8], optimization [

9], process monitoring [

10], and industrial tomography [

11].

ML and the Internet of Things (IoT) offer a dynamic solution for real-time data collection from machinery, enabling proactive problem detection and informed decision-making using well-suited ML algorithms and Wireless Sensor Networks (WSN) [

12]. This approach also facilitates intelligent power management to reduce energy consumption, optimizing machine operations and environmental systems. Moreover, ML-driven prediction algorithms play a crucial role in monitoring production, predicting market trends, and ensuring product quality through computer vision and sensor networks. These tailored solutions, adapted to specific industries and environments, harness live data and reinforcement learning for enhanced efficiency and adaptability, as illustrated in

Figure 1, opening up diverse avenues for research in Industry 4.0.

Control system play pivotal role in industrial sector [

13]. However, they face complex challenges due to numerous variables and nonlinear relationships. Researchers turn to data-driven models and ML techniques, enabling the optimization of these systems efficiently. In Robotics, innovative solutions enhance autonomy through cooperative control and adaptive navigation. Similarly, in SCADA/ICS and the Electric Power Industry, ML aids in PID controller tuning, adaptive algorithms, and fault detection, often validated through simulations. Intrusion detection systems add security, while fault diagnosis enhances maintenance and operation, collectively shaping the future of Industry 4.0.

This article endeavors to bridge this void by presenting a systematic review, poised to answer critical questions pertaining to ML’s role in reactor operations: (i) Which ML techniques dominate the landscape of reactor operations? (ii) In which stages of a reactor’s lifecycle is ML most prominently utilized? (iii) What types of data serve as the bedrock for ML model development in this context? and (iv) What discernible trends surface in terms of input and output variables across various lifecycle stages? The insights unearthed in this comprehensive review hold immense value, catering to both academia and industry professionals engaged in the development of ML-driven solutions that span the multifaceted domains of reactor monitoring, control, and optimization.

This article is structured as follows.

Section 2 describe the in-depth review of ML application in estimation, monitoring, control, and optimization of temperature of reactors. Conclusions and future prospects are outlined in

Section 3.

2. Machine Learning Application in Operation of Reactors

2.1. Estimation and Monitoring

2.1.1. State Estimation

To accurately estimate the sodium temperature in the Intermediate Heat Exchanger (IHE) of a fast breeder test reactor, Patra et al. [

14] developed an ANN model that successfully simulated steady and transient conditions, highlighting the potential of ANN for plant dynamics analysis. Addressing the prediction of temperature fields in a heavy water moderator of a reactor, Starkov and Lavrenkov [

15] proposed a cellular neural network architecture that provides valuable insights into anomalies, moderator flow patterns, and mixing behaviors. To forecast temperature fields within a heavy-water reactor moderator, Starkov and Lavrenkov [

15] utilized a cellular neural network, demonstrating its efficacy through comparative assessments and highlighting the advantages of adaptable network configurations. Addressing the intricate inverse problem associated with optical emission spectroscopy, Dolenko et al. [

16] employed ANN and GMDH techniques to determine gas temperature from optical emission spectra in a DC-discharge Chemical Vapor Deposition (CVD) reactor. Efficiency in non-isothermal continuous stirred tank reactor temperature estimation was evaluated by Apriliani et al. [

17], comparing the reduced rank ensemble Kalman filter to other filters and underscoring the computational superiority and robustness of the ensemble Kalman filter. Addressing reactor monitoring, Leite et al. [

18] proposed a physics-informed Convolutional Neural Network (CNN) to reconstruct temperature fields from constrained boundary measurements, effectively pinpointing complex localized temperature peaks.

2.1.2. Fault Detection and Diagnosis

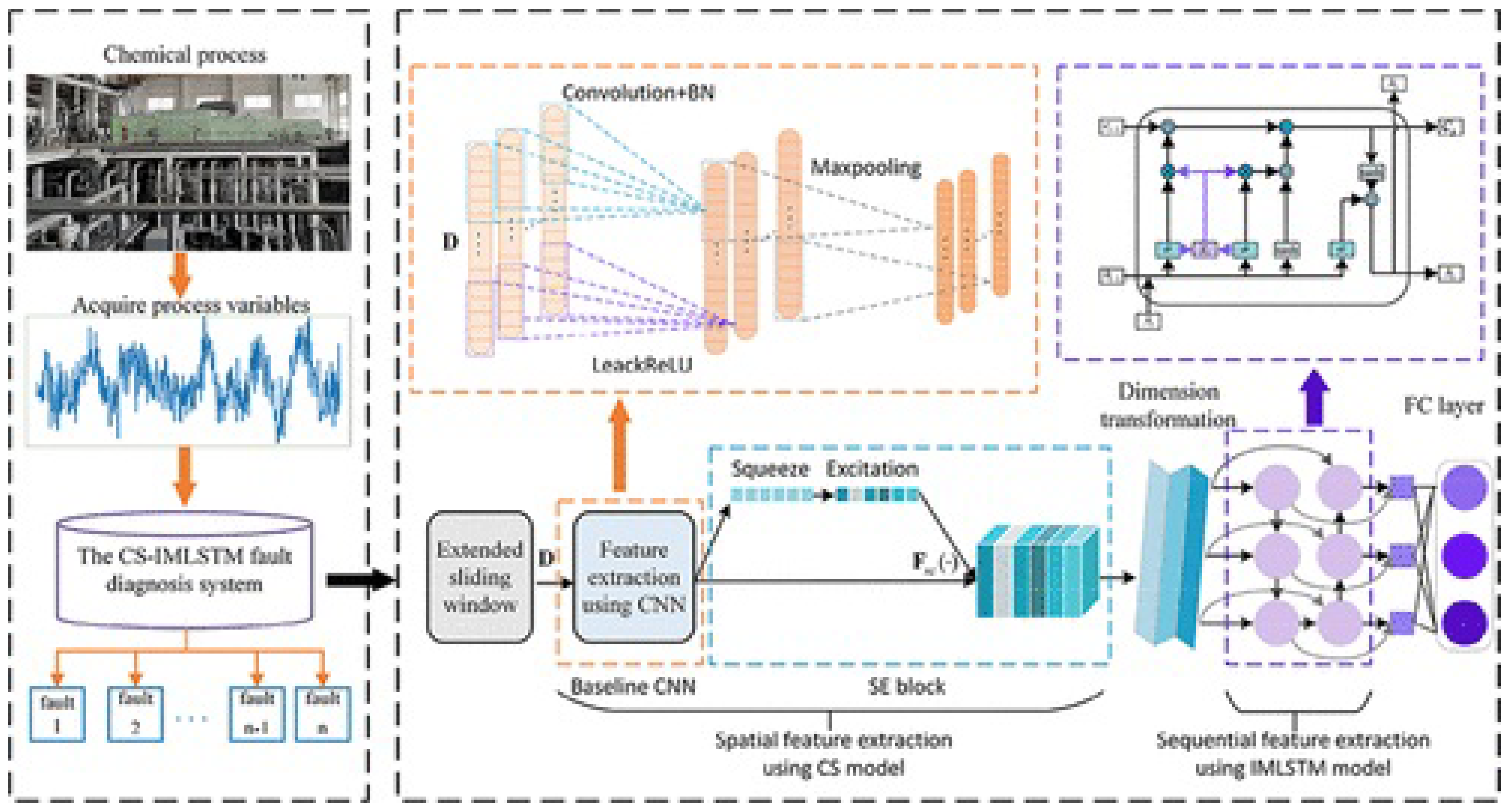

ML techniques, when integrated into fault detection and diagnosis (FDD) methods, offer the advantage of not relying on intricate process mechanisms and enable the extraction of valuable insights from process data.

Figure 2 illustrates the utilization of deep learning in an FDD mechanism for a chemical process. Subsequently, an overview of the specific application of ML in FDD related to reactor temperature control is provided.

Investigating fault diagnosis in a 10 MW High-Temperature Gas-Cooled Reactor, Li et al. [

20] devised a compound system by employing two Backpropagation (BP) networks—one trained on tendency values and the other on real values during accidents—resulting in improved accuracy and adaptability for fault detection. To improve fault diagnosis accuracy in a 10 MW High-Temperature Gas-Cooled Reactor, Hui et al. [

21] adopted a dual Back Propagation (BP) network approach. They combined tendency and real data values from accidents, demonstrating the superiority of a compound system for enhanced diagnostic accuracy. Detecting anomalies in temperature sensors of a research pool reactor, Penha and Hines [

22] utilized Principal Component Analysis (PCA). They demonstrated the model’s effectiveness by showcasing its resilience to artificial drifts and its capability to monitor the reactor’s temperature sensors. To address the challenges of anomaly detection and non-measurable signal estimation in a nuclear power plant, Ayaz et al. [

23] investigated the application of ANN . They utilized feed-forward and recurrent neural networks to process simulated data from Japan’s high-temperature engineering testing reactor (HTTR). Introducing a method for fault detection in Resistance Temperature Detectors (RTD) sensors, Messai et al. [

24] combined an ANN with discrete wavelet transform (DWT) noise reduction, achieving accurate fuel rod temperature estimation with enhanced noise handling capabilities. Comparing neural network algorithms for real-time monitoring of the High Temperature Engineering Testing Reactor (HTTR), Çeker et al. [

24] highlighted the exceptional performance of recurrent neural networks in detecting anomalies and estimating unmeasured signals.

2.1.3. Uncertainty and Lon-linearity Detection

By introducing a novel model that tackles nonlinearity challenges, Tan, Liu, and Wei [

25] harnessed ML to enhance cross-section calculation accuracy within the high-temperature gas-cooled reactor engineering simulator system (HTR-ESS). Addressing the uncertainty in ductile-to-brittle transition temperature (DBTT) of reactor pressure vessel steels, Takamizawa et al. [

26] proposed a Bayesian method that estimates credible intervals through a hyperbolic tangent model with incorporated uncertainties and Monte Carlo sampling. Addressing core power modeling of the High-Temperature Engineering Test Reactor (HTTR), Istiqomah and Subiantoro [

27] utilize the nonlinear least squares method for parameter estimation. They establish a nonlinear mathematical model for the reactor core based on fundamental principles, estimating unknown parameters through physics equations and the nonlinear least squares curve fitting technique.

2.1.4. Decay in heat Removal

Addressing decay heat removal in high-temperature gas-cooled reactors, Wu et al. [

28] employed a ML approach to handle intricate radiative heat transfer issues at the particle scale, effectively predicting obstructed view factors between pebble pairs using artificial intelligence techniques. Using ML, Wu et al. [

28] tackled the challenge of modeling decay heat removal in high-temperature gas-cooled reactors, successfully addressing complex radiative heat transfer at the particle scale and predicting obstructed view factors to maintain transient results within acceptable design limits.

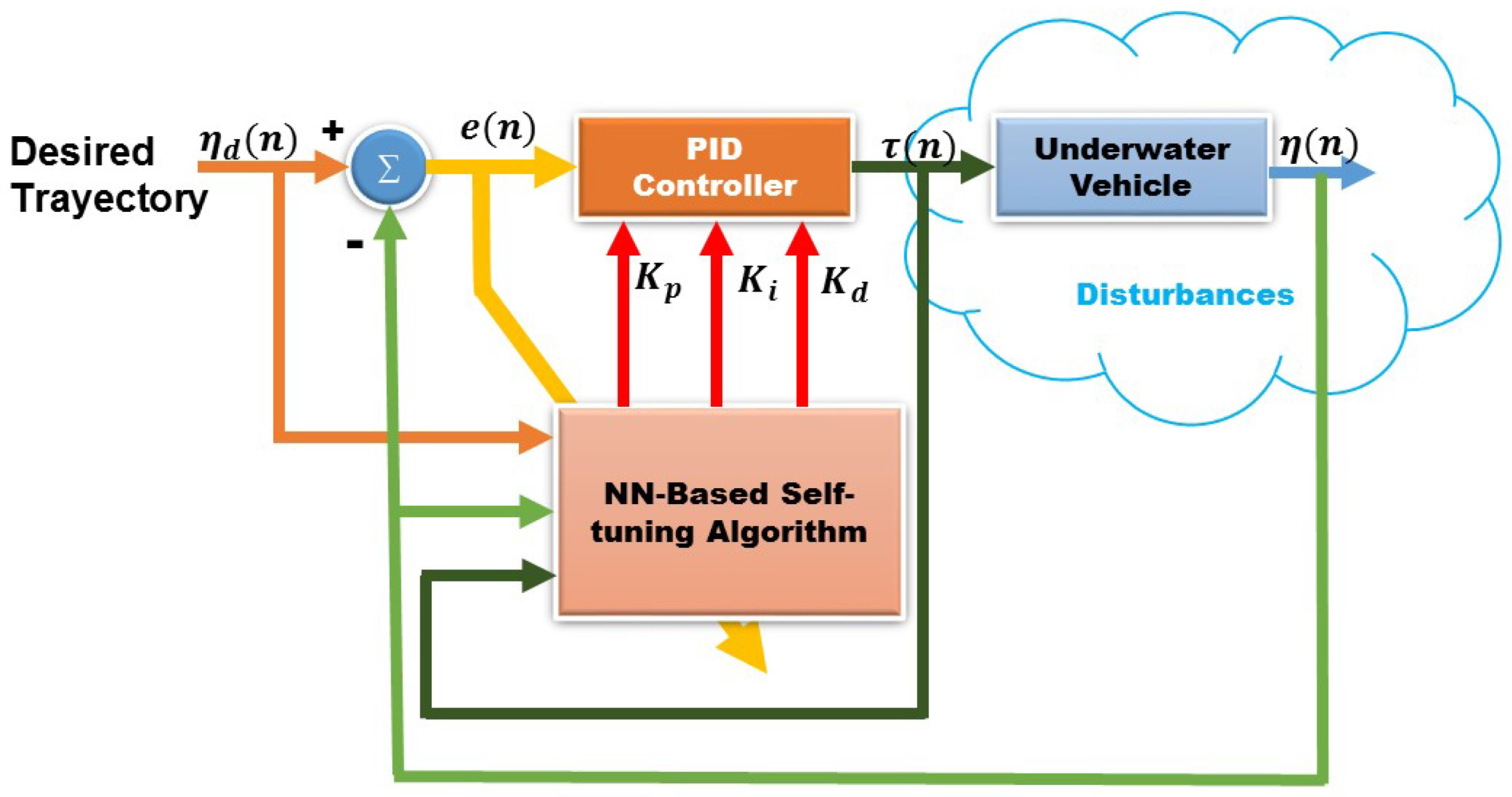

2.2. Temperature Control

ML has emerged as a powerful tool in process control, offering data-driven insights and adaptive strategies to optimize industrial processes. By harnessing ML algorithms, industries can enhance efficiency, reduce costs, and improve product quality, paving the way for more sustainable and competitive manufacturing operations. From predictive maintenance to real-time anomaly detection, ML empowers process engineers to make informed decisions and drive continuous improvements in production and resource management. A Block diagram of an auto-tuned PID with artificial NN control is shown in

Figure 3. The reactors’ temperature control specific applications of ML methods is shown in

Figure 2.

2.2.1. Polymerization Reactors

The challenge of precise temperature control in a polystyrene polymerization reactor is addressed by Etike et al. [

30] through the use of a Neural Network Model Predictive Algorithm and an ANN model to capture system responses, aiming to achieve desired temperature profiles in batch polymerization. Experimental implementation demonstrates the superiority of the Neural Network Model Predictive Control (NN-MPC) algorithm over conventional PID control for effective temperature tracking. In addressing the need for precise temperature regulation in a polymerization reactor, Vasanthi et al. [

31] introduce a self-tuning cascade control concept. Their approach utilizes an ANN to estimate essential parameters for accurate control and calculates a cooling jacket temperature trajectory based on these estimates. This approach effectively improves temperature control performance compared to the conventional cascade controller, ensuring that the reactor temperature remains within specified tolerances. In addressing the challenge of temperature regulation in a Polymerase Chain Reaction (PCR) reactor, Zhang et al. [

32] introduce a fuzzy neural network controller. Their approach involves dynamically tuning parameters online to achieve an improved response rate and stability compared to a conventional PID controller. The experimental results validate the enhanced dynamic performance of their method, which overcomes limitations associated with traditional PID control.

2.2.2. Catalytic-bed Reactors

To tackle the challenge of hot-spot temperature control in a fixed-bed catalytic reactor, Mazana and Nzama [

33] present a self-tuning PID control approach that incorporates ANN . Their method combines an online ANN process identifier with a non-predictive PID controller, aiming to adaptively control the reactor while directly addressing nonlinearity based on historical data, thus demonstrating its applicability to real-world control challenges. To address the challenge of controlling medium temperature in a fluidized bed synthesis reactor for vinyl acetate production, Meng et al. [

34] utilized an adaptive learning rate BP neural network to establish a control model. Their approach successfully achieved accurate temperature control within the reactor, highlighting the effectiveness of ANN modeling with the adaptive learning rate BP learning algorithm. To stabilize the temperature of a packed bed tubular reactor engaged in highly exothermic reactions, Onderwater et al. [

35] introduce the development of an inner loop controller utilizing a self-tuning regulator. Their study emphasizes the importance of nonlinear transformations of the reactor’s hot-spot temperature and demonstrates the efficacy of adjusting input constraints to achieve desired controller properties. This research underscores the advantages of applying model identification and self-tuning regulators in improving control performance for challenging reactor systems. To address temperature trajectory tracking in a fixed bed reactor, Pundir and Singh introduced a novel approach [

36]. They combined Chattering Free Sliding Mode Control (CFSMC) with an observer-based adaptive Radial Basis Function Neural Network (RBFNN). This hybrid controller effectively reduced chattering behavior associated with Sliding Mode Control (SMC) and demonstrated enhanced performance in temperature tracking and disturbance rejection compared to a PID controller. Their findings were validated through simulation studies.

2.2.3. Nuclear Reactors

Addressing the need for improved nuclear reactor temperature control, Ku et al. [

37] introduce an innovative approach that utilizes diagonal recurrent neural networks (DRNNs) with adaptive learning rates. Their method demonstrates improved convergence and practical effectiveness in various scenarios, ultimately enhancing reactor temperature regulation compared to traditional feedforward neural networks. To address the challenge of controlling reactor temperature in pressurized water reactors (PWR) within nuclear power plants, Haoran et al. [

38] propose a method that employs a Radial Basis Function (RBF) Neural Network. Their study assesses control system characteristics through simulation and utilizes experimental data to analyze a transfer function for the reactor temperature. By combining RBF neural networks with traditional PID control, they develop a composite strategy that demonstrates enhanced control performance compared to conventional PID and fuzzy PID control methods. Addressing the challenge of mitigating rotor imbalance-induced periodic vibration in active magnetic bearing systems of primary helium circulators, Zheng et al. [

39] introduce a novel iterative learning control (ILC-2) method. Their approach incorporates system information from previous iterations and a parallel control mechanism, effectively suppressing vibration while maintaining real-time control requirements. This contributes to enhancing the safety and stability of primary helium circulators.

2.2.4. Continuous Stirred Tank Reactor (CSTR)

Addressing the challenge of temperature control in a CSTR, Xu et al. [

40] introduce an intelligent method that utilizes the Asynchronous Advantage Actor-Critic (A3C) reinforcement learning algorithm. Their approach effectively achieves temperature control by guiding the CSTR to explore the A3C network and learn a control law through a motivating function, thus demonstrating the capability of the A3C algorithm for temperature regulation in CSTR systems. In addressing temperature control challenges in continuously stirred tank reactor (CSTR) processes, Ouyang, Wang, Wu, and Lin propose an innovative approach [

41]. They introduce an Improved Sparrow Search Algorithm (ISSA) to optimize PID parameters, enhancing control performance. Their ISSA-PID temperature controller exhibits improved transient and steady-state performance, demonstrating enhanced accuracy and robustness in reactor temperature control, as evidenced by simulations and experiments.

2.2.5. Batch, Semi-Batch Reactors

To address temperature trajectory control in an exothermic batch reactor, Shukla et al. [

42] implement a recursive algorithm that relies on an energy balance approach, without the need for detailed process kinetics. Their algorithm’s successful application in the hydrolysis of acetic anhydride demonstrates its versatility and potential for achieving isothermal operation and desired temperature profiles in various systems. To improve temperature control in batch reactors used in various industries, Balaton, Nagy, and Szeifert propose a model-based split-range algorithm [

43]. This algorithm is specifically designed for systems with three temperature levels, offering enhanced control performance and simplifying PID controller design. Their contribution aims to enhance the efficiency and quality of batch reactor processes. In addressing the need for precise temperature regulation in a semi-batch chemical reactor, Mezghani et al. [

44] showcase an experimental application of iterative learning control (ILC). Their approach, which is based on Batch Model Predictive Control (BMPC), successfully achieves desired temperature profiles with enhanced tracking performance. This study highlights the potential of ILC for improving control in challenging industrial processes. In the context of managing the temperature of a pilot-plant reactor with a challenging monofluid heating-cooling system, Dirion et al. [

45] introduce a neural network-based controller for semi-batch reactor temperature regulation. Their study emphasizes the potential of neural controllers for setpoint-tracking and disturbance rejection, showcasing practical applicability in industries where automation has traditionally been challenging.

2.2.6. Miscellaneous Studies on Robustness

In addressing the complexities of reactor temperature control, Li and Yu [

46] introduce a predictive control algorithm, specifically an improved dynamic matrix control (DMC) algorithm. This approach effectively handles system uncertainties and showcases superior dynamic and stable-state performance compared to conventional PID control. The study highlights the effectiveness of their proposed approach in enhancing control precision and dynamic performance for industrial reactor temperature control applications. In addressing reactor temperature control challenges, Zhou et al. propose a PID control method based on a BP neural network [

47]. This approach effectively handles nonlinearity, strong coupling, and uncertainty in the system. Their introduced method combines self-learning and nonlinear approximation capabilities, achieving precise and adaptable control in complex systems. Simulation results demonstrate its superiority over conventional PID algorithms. In addressing reactor temperature control, Ai and Pan [

48] introduce a unique approach that utilizes a self-optimizing fuzzy algorithm. This algorithm dynamically adjusts factors based on error and change rate, resulting in an enhanced controller output by combining performance indicators with artificial inputs. Consequently, this approach improves the robustness, flexibility, and tracking ability of the temperature control system. In the context of regulating the temperature of a chemical reactor in the presence of disturbances, Siddikov et al. [

49] introduce an algorithm that utilizes a fuzzy-logical proportional-integral-differential (PID) controller. Their approach combines fuzzy logic and neural networks, providing stability against external noise and parameter variations, thus ensuring effective temperature regulation and qualitative control of the reactor’s process.

In addressing the challenge of controlling reactor transients during start-up, Jouse and Williams [

50] introduce a neural network application that emphasizes simultaneous control of temperature and pressure. Their expanded neural architecture incorporates proportional control, highlighting the practical potential of the network for control tasks and effective system control through internal connectivities.

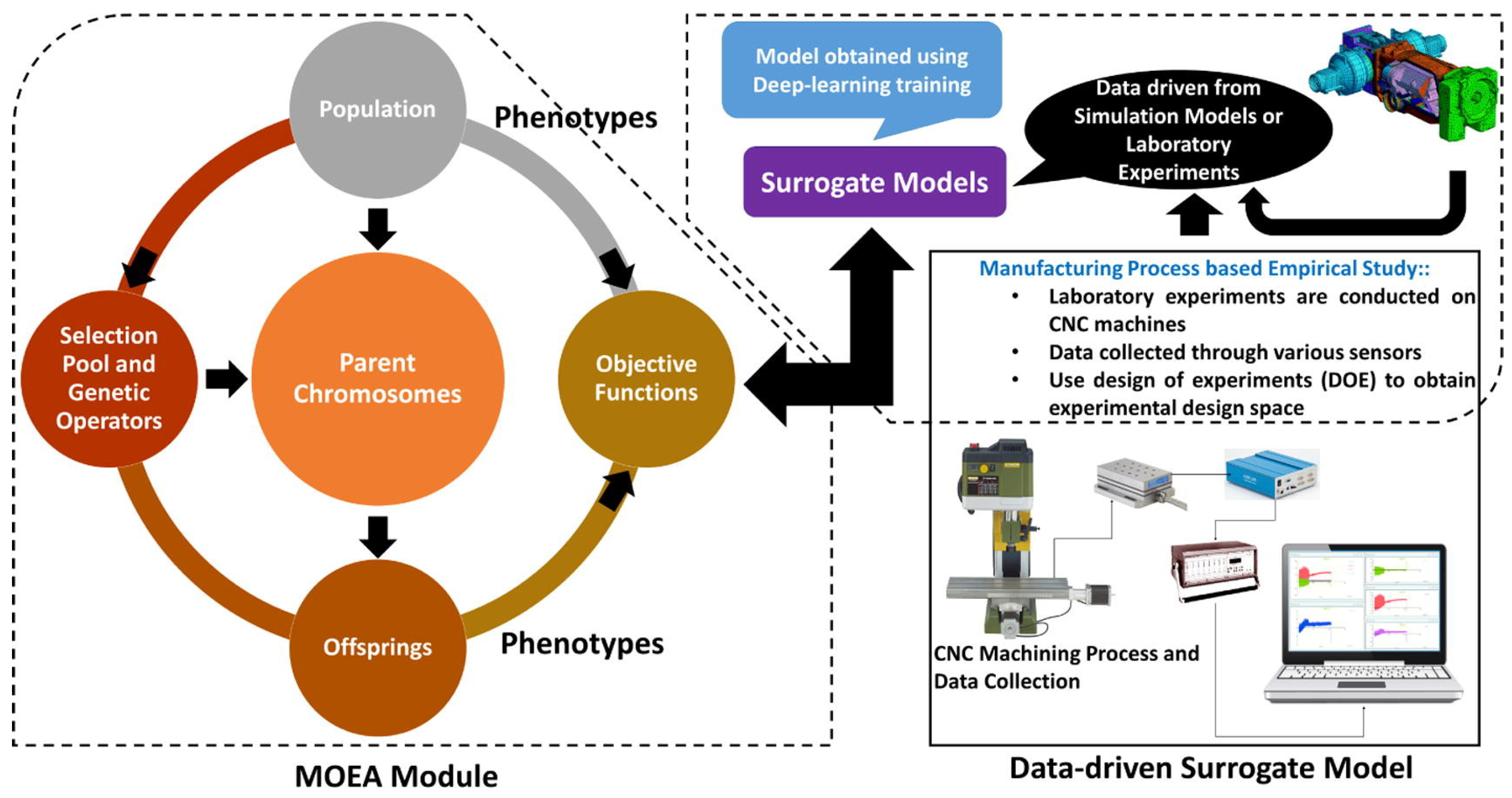

2.3. Optimization

In the context of manufacturing process optimization, dealing with complex and multi-variable systems can be challenging. To address this, ML techniques, such as data-driven surrogate models and Multi-Objective Evolutionary Algorithms (MOEAs), are recommended. These models facilitate optimization by approximating relationships among variables and reducing the need for computationally complex mathematical modeling. A Data-Driven multi-objective evolutionary algorithm MOEA Framework is shown in

Figure 4. The literature reported on reactors temperature optimization through ML assistance is discussed afterwards.

2.3.1. Fluctuations and Uncertainties

Huang and Pan [

52] tackle the challenges of lag, non-linearity, and complex reactions in batch reactors. To address these issues, they introduce a predictive control algorithm that combines Generalized Predictive Control (GPC) with Particle Swarm Optimization (PSO) for predictive parameter optimization. This approach efficiently controls reactor temperature, demonstrating effective handling of temperature complexities in batch reactors using the PSO-GPC combination. Yadav et al. [

53] address the inherent nonlinearities in a pilot plant batch reactor by developing a data-driven model and introducing a nonlinear model predictive controller (NMPC). Their NMPC approach demonstrates enhanced temperature tracking and energy efficiency in simulations and real-time experiments, highlighting its potential for optimizing batch reactor processes. Future work aims to refine this approach through first-principle-based models and online optimization methods. In addressing the challenges of nonlinearity and limited training data in hydrogen-producing reactor temperature prediction, Pan, Zeng, and Xu propose a novel approach utilizing Support Vector Machine (SVM) regression with PSO [

54]. Their method harnesses the regression capability of SVM and the hyper-parameter optimization of PSO to create a highly accurate forecasting model for hydrogen-producing reactor temperatures, surpassing other methods. Facing the challenge of real-time temperature control in an advanced microwave biodiesel reactor characterized by high nonlinearity and operational uncertainties, the study by Wali et al. [

55] aimed to develop an effective control solution. In response to this problem, the researchers designed an online genetic-ANFIS controller using LabVIEW. This controller was compared to an error-based adaptive controller, with the results demonstrating the genetic-ANFIS controller’s robust performance in maintaining temperature control in the biodiesel microwave reactor during nonlinear real-time scenarios, ultimately improving reactor efficiency and performance. The challenge of regulating reactor temperature with minimal overshoot and effective handling of load disturbances in a pilot plant continuous stirred tank reactor scenario is addressed by Wahab et al. in their work [

56]. To tackle this problem, they utilize a GA to design an optimal model-based controller, demonstrating the GA’s effectiveness in achieving these objectives. Investigating the challenge of reactor temperature regulation, Khairi Abdul Wahab et al. [

57] utilize a GA to develop an optimal model-based controller. Their research demonstrates that the mathematical model controller evolved through GA effectively achieves the regulation of reactor temperature with minimal overshoot and the capability to reject load disturbances, highlighting the method’s applicability in controlling pilot plant chemical reactors.

2.3.2. Controllers Tuning

Addressing the issue of temperature control in a chemical reactor, Areed et al. [

58] introduce a novel GA. This research highlights the effectiveness of GAs in identifying and controlling plants. The study includes a comparison between the GA-based approach and conventional P, PI, and PID controllers, showcasing the superior performance of the GA controller. Particularly noteworthy is its ability to handle nonlinearities, demonstrating its applicability in controlling nonlinear systems such as Continuous Stirred Tank Reactors (CSTR) while minimizing steady-state error. Addressing the optimization of PID controller parameters for continuous stirred tank reactors (CSTRs, Begum [

59] introduces innovative control techniques. She employs the coot bird optimization algorithm (CBOA) to optimize PID parameters, resulting in improved time domain response parameters for the controllers. This approach demonstrates its effectiveness in enhancing CSTR temperature control, offering a promising avenue for real-time process improvements.

2.3.3. Reactors’ Safety

In their research on the Advanced High-Temperature Reactor (AHTR), He Liaoyuan et al. employ a Hybrid Adaptive Genetic Annealing Algorithm to address the challenge of reducing the reactor core’s high power peak factor [

60]. By utilizing different enrichment fuel assemblies and an adaptive intelligent algorithm, their approach successfully achieves a substantial 25.02% reduction in the power peak factor, contributing to enhanced safety and economy while improving temperature distribution in the core. In addressing the optimization of the Fluoride-Salt-Cooled High-Temperature Reactor (AHTR), Chee’s PhD thesis [

61] introduces a distinctive generative design approach using evolutionary algorithms. The study highlights the potential of leveraging additive manufacturing to optimize reactor core geometries, overcoming conventional manufacturing constraints. This approach has the potential to reduce costs, deployment times, and enhance safety while showcasing the significance of generative design in exploring innovative design possibilities beyond classical input parameters. Addressing the optimization of Very High Temperature Pebble-Bed Reactors (VHTR) for electricity and hydrogen production, Gougar et al. employ GA [

63]. Their approach yields enhanced fuel economy and passive safety in both 300 MW and 600 MW designs. By optimizing core characteristics, this method enhances computational efficiency and design flexibility, ultimately proving effective in achieving improved safety through accident analysis in pebble-bed reactors.

2.3.4. Computational Time

In the context of optimizing spatial temperature trajectories for a tubular reactor model, Patel et al. [

62] tackled the problem of computational expense associated with traditional approaches. To address this issue, they employed a Physics Informed Neural Network (PINN) framework, leveraging the analytical form of PINNs to develop a computationally efficient method for online optimization and control, ultimately providing a solution to the problem of costly computational resources in this context. In the context of batch reactor temperature control, the article introduces a Hybrid Fuzzy Predictive Control (HFPC) strategy utilizing a GA [

63]. The study evaluates HFPC-GA against other hybrid predictive control methods, showcasing its capability for effective temperature regulation while reducing computational time. This approach holds promise for tackling complex control problems involving both discrete and continuous manipulated variables. In addressing the optimization of reloading patterns in block-type high-temperature gas-cooled reactors, Jie et al. [

64] employ a GA. Their study overcomes the limitations of traditional methods by efficiently handling a vast search space. The research showcases GA’s adaptive optimization in reloading pattern design, which is supported by parallel processing to manage computational complexity. Furthermore, it demonstrates significant improvements in core physics accuracy and stability.

2.3.5. Production Rate

To enhance carbon dioxide (CO

2) utilization in Lurgi type methanol synthesis, Alarifi et al. tackle the problem through dynamic optimization [

65]. Their approach involves a hybrid GA-GPS algorithm that takes into account catalyst deactivation and process constraints. By optimizing the shell coolant temperature and CO

2 recycle ratio, the study achieves a significant increase in methanol production, leading to economic benefits and reduced CO

2 emissions.

To enhance methanol production efficiency in a Lurgi type methanol reactor using CO

2 as a feedstock, Abdulaziz et al. introduced a dynamic optimization challenge [

66]. The problem involved finding the optimal settings for shell coolant temperature and CO

2 recycle ratio to maximize methanol production while considering process constraints. In response, they proposed a hybrid GA-GPS algorithm, combining GA and generalized pattern search (GPS), to address this challenge effectively. This approach aimed to overcome the limitations of traditional methods and efficiently explore the search space for optimal solutions. Through this research, they sought to contribute to the field of methanol production by improving its efficiency and sustainability.

The challenge of optimizing reactor temperature in a Catalytic Microreactor for hydrogen production is addressed in the work by E. Ardeshiri-Gilani and A. M. Astaraki [

67]. To tackle this problem, they utilize Aspen Plus for simulation and Matlab with GA. By considering various kinetics and investigating the effects of temperature, feed composition, feed rate, and reactor size, their study effectively employs GA to maximize hydrogen yield through reactor temperature optimization. This research offers valuable insights into the influencing factors and demonstrates the practical application of GA in optimization.

Omata and Yamada [

68] faced the challenge of optimizing the temperature profile in a temperature gradient reactor (TGR) for dimethyl ether synthesis. To address this challenge, they employed an ANN and grid search approach. Through strategic catalyst bed division, tailored catalysts, and

-alumina, they achieved a high one-pass CO conversion rate of 82°C, effectively overcoming equilibrium and catalyst activity challenges. This work showcases the advantage of ANN-based optimization in complex reactor systems.

2.3.6. Design and Economic Feasibility

In the context of nuclear reactor core design, Kianpour, Ansarifar, and Fathi [

69] undertake research to optimize a VVER-1000 reactor core with dual cooled annular fuel. Their approach, which leverages ANN and GA, aims to determine the optimal fuel geometry while considering reactivity temperature coefficients. The study demonstrates the feasibility of this approach through thorough thermal hydraulic and neutronic analysis. Highlighting the potential of dual-cooled annular fuel, the study offers valuable insights into reactor core optimization. In the context of dimethyl ether (DME) synthesis from syngas, Sha [

70] underscores the significance of a temperature gradient reactor (TGR). The comment emphasizes the effective use of the synergy between GA (GA) and neural networks to optimize temperature profiles, resulting in improved CO conversion and addressing the equilibrium and catalyst activity challenges associated with TGR operation. Addressing Generation IV nuclear reactor optimization for cost reduction, Mansilla [

71] presents a technoeconomic optimization approach applied to the power conversion system of a very high-temperature reactor (VHTR). The utilization of GA within Vizir software effectively optimizes the VHTR’s helium loop, taking into account factors such as pressure, constraints, cooling water temperature changes, and the impact of compressor parameters on production costs. This approach provides valuable insights for managing investment and operational expenses in high-capital systems.

To optimize temperature control in a non-isothermal tubular reactor, Agrawal et al. [

72] utilize a GA. They leverage GA’s stochastic, population-based approach to prevent getting trapped in local optima. The study highlights the industrial applicability of GA, particularly in an industrial tubular reactor. It demonstrates that GA-based optimization efficiently determines the optimal feed temperature at the reactor inlet to achieve the desired outlet product temperature. Additionally, the research analyzes the impact of mutation and selection on optimization iterations.

2.4. Summary of the ML Application

2.4.1. Estimation and Monitoring

The literature review on ML applications in Estimation and Monitoring of Reactors highlights the widespread use of ML methods such as ANN , BP Networks, Cellular Neural Networks (CNN), Principal Component Analysis (PCA), Bayesian Methods, Nonlinear Least Squares Methods, Novel ML Models, and the Discrete Wavelet Transform (DWT) to address a variety of complex problems, including temperature estimation, gas temperature determination, reactor monitoring, fault diagnosis, anomaly detection, and uncertainty handling in reactor engineering.An overview of the findings is given below:

In the realm of reactor technology, ML techniques have taken center stage, with ANN emerging as a prominent player, deployed in various roles. ANN, harnessed fourfold, prove their versatility by tackling temperature estimation, determining gas temperatures, and overseeing reactor monitoring. They serve as the backbone of innovation in this domain, empowering engineers and researchers to make more informed decisions.

Not far behind, BP Networks, a type of ANN make their presence felt, appearing twice in the narrative. These networks specialize in fault diagnosis, elevating diagnostic accuracy to new heights. Their ability to pinpoint issues within reactor systems adds an extra layer of confidence in their application.

Cellular Neural Network (CNN), a two-time participant, uniquely suited to predict temperature fields and address anomalies and flow patterns. Their utilization signifies a shift towards more holistic and predictive reactor management.

In the quest for anomaly detection, Principal Component Analysis (PCA) emerges as a key tool, singularly dedicated to identifying irregularities in temperature sensors. Its role in ensuring the integrity of sensor data is paramount.

However, innovation knows no bounds, as evidenced by the application of a Bayesian Method. In addressing uncertainty surrounding the ductile-to-brittle transition temperature (DBTT), this method offers a novel approach to tackling complex challenges in reactor engineering.

Nonlinear Least Squares Methods, featured twice, prove indispensable in core power modeling and parameter estimation. They contribute to a deeper understanding of reactor dynamics, guiding decisions that impact both safety and efficiency.

A unique addition to the ensemble, the introduction of a Novel ML Model signifies the continuous quest for improvement. This model, dedicated to enhancing cross-section calculation accuracy, showcases the relentless pursuit of excellence in reactor technology.

The story wouldn’t be complete without the mention of the Discrete Wavelet Transform (DWT), a critical player when combined with ANN for fault detection in sensors. This combination reflects the synergy between traditional signal processing and cutting-edge ML.

In this ever-evolving landscape of reactor technology, these ML techniques and methods form a vibrant tapestry, enabling us to unlock the full potential of these complex systems and drive innovation in the pursuit of safer, more efficient, and environmentally conscious reactor operations.

2.4.2. Control

The literature review on ML applications in Control of Reactors reveals the extensive utilization of ML methods, encompassing ANN , BP Networks, Neural Network Model Predictive Control (NN-MPC) Algorithm, Self-Tuning PID Control with ANN , Fuzzy Neural Network Controller, Chattering Free Sliding Mode Control (CFSMC) with Radial Basis Function Neural Network (RBFNN), Asynchronous Advantage Actor-Critic (A3C) Reinforcement Learning Algorithm, and the Improved Sparrow Search Algorithm (ISSA). These diverse ML techniques collectively empower engineers and researchers to enhance reactor operations, foster innovation, and ensure safety and efficiency in this ever-evolving field.

In the intricate world of reactor control, ANN emerge as a dominant force, making their presence felt a remarkable thirteen times. These adaptable networks prove their mettle across a spectrum of functions, from the precision of temperature control to the finesse of trajectory tracking and the intricacies of control system optimization. ANN are the linchpin in the quest for more efficient and precise reactor operation.

A standout in this narrative is the Neural Network Model Predictive Control (NN-MPC) Algorithm, which shines in its role of ensuring precise temperature control within a polymerization reactor. Its superiority over conventional PID control methods signals a significant leap forward in temperature regulation, enhancing the performance and stability of these critical systems.

Equally noteworthy are the Self-Tuning PID Control approaches, employed three times. These methods leverage the power of ANN to not only control temperature but also grapple with the inherent nonlinearity found in various reactor types. Their adaptability is a testament to the ongoing quest for versatile and efficient control strategies.

The introduction of the Fuzzy Neural Network Controller adds a unique dimension, addressing the specific challenge of temperature regulation in Polymerase Chain Reaction (PCR) reactors. This innovation exemplifies the tailored solutions that ML can provide in highly specialized domains.

For the intricate task of temperature trajectory tracking in a fixed bed reactor, the Chattering Free Sliding Mode Control (CFSMC) with Radial Basis Function Neural Network (RBFNN) steps up. Its application signifies the fusion of advanced control techniques and ML, paving the way for more precise and stable reactor operation.

Meanwhile, the Asynchronous Advantage Actor-Critic (A3C) Reinforcement Learning Algorithm proves its worth by intelligently handling temperature control in a CSTR. This foray into reinforcement learning showcases the adaptability of AI in complex real-time scenarios.

Last but not least, the Improved Sparrow Search Algorithm (ISSA) takes center stage as it optimizes PID parameters for temperature control in a fluidized bed synthesis reactor. This novel approach reflects the growing reliance on optimization techniques to fine-tune control strategies, ensuring efficient and stable reactor performance.

In this dynamic landscape of reactor control, these ML methods and algorithms serve as the guiding stars, illuminating the path to more precise, efficient, and adaptive control strategies. They underpin the drive for innovation in the realm of reactor technology, ensuring that these complex systems operate at their best while meeting the demands of modern industry.

2.4.3. Optimization

The literature review on ML applications in Optimization of Reactors reveals the extensive utilization of ML methods, encompassing GA, PSO, Neural Networks, Hybrid Genetic Algorithm-Generalized Pattern Search (GA-GPS) approaches, Physics Informed Neural Network (PINN), and ANN . These diverse ML and optimization techniques collectively empower engineers and researchers to enhance reactor operations, foster innovation, and ensure safety and efficiency in this ever-evolving field.

GA emerge as a powerful and versatile force, making their presence felt an impressive thirteen times across a myriad of applications. From the realm of temperature control to the intricacies of controller tuning, GAs stand as a robust tool for achieving optimization. They also play a pivotal role in safety optimization, reducing computational time, maximizing production rates, and optimizing reactor designs. GAs are the backbone of a holistic approach to reactor management.

In the pursuit of precision, PSO steps onto the stage, showcasing its prowess through strategic combinations. Collaborating with Generalized Predictive Control (GPC) and Support Vector Machine (SVM) regression, PSO proves its mettle in temperature control and forecasting hydrogen-producing reactor temperatures. This synergy between optimization methods underscores the versatility of ML techniques.

Neural Networks, appearing twice, bring their computational intelligence to bear on optimization challenges. They dive into the intricate world of temperature profiles in tubular reactors and the art of dimethyl ether (DME) synthesis, proving to be indispensable tools for fine-tuning complex processes.

The Hybrid Genetic Algorithm-Generalized Pattern Search (GA-GPS) duo, making a noteworthy double appearance, tackles the optimization of methanol production from CO2 feedstock and the temperature control in Catalytic Microreactors for hydrogen production. This hybrid approach exemplifies the power of combining optimization strategies to address multifaceted challenges.

The introduction of the Physics Informed Neural Network (PINN) marks a pivotal moment in the quest for precision. This novel approach optimizes spatial temperature trajectories in tubular reactor models, showcasing the fusion of physics-based knowledge and ML techniques.

ANN make a cameo appearance in optimizing the temperature profile within a temperature gradient reactor (TGR) for dimethyl ether synthesis, further highlighting their adaptability in intricate optimization scenarios.

Not to be overlooked is the Hybrid Fuzzy Predictive Control (HFPC) with GA, which excels in the realm of batch reactor temperature control. This hybrid strategy represents the intersection of advanced control methods and optimization, enhancing reactor operation.

Last but certainly not least, the Hybrid Genetic Algorithm-Generalized Pattern Search (GA-GPS) trio emerges as a robust player in the optimization of PID controller parameters within continuous stirred tank reactors (CSTRs) and the overarching task of optimizing reactor temperature control. This versatile approach brings together the power of GAs and pattern search techniques, ensuring that complex control systems operate at their peak efficiency.

In this dynamic landscape of reactor optimization, these techniques and algorithms stand as pillars of innovation, driving the quest for precision, efficiency, and adaptability in the operation of critical reactor systems. They symbolize the intersection of advanced computational intelligence and the challenges of modern industry, shaping the future of reactor technology.

3. Conclusions and and Future Work

In conclusion, the review of research pertaining to reactor monitoring, control, and optimization highlights the significant and growing influence of ML and optimization techniques in enhancing reactor performance and safety. ANN emerge as a dominant and versatile tool, serving multifaceted roles across all aspects of reactor operations. These ANNs are employed for temperature estimation, fault diagnosis, precise control, and trajectory tracking, underlining their adaptability to a wide range of reactor systems. Furthermore, other ML methods, such as BP networks and Cellular Neural Networks (CNNs), prove instrumental in addressing specific challenges, from enhancing diagnostic accuracy to predicting temperature fields and flow patterns.

On the optimization front, GA shine as a go-to choice, facilitating improvements in temperature control, safety optimization, and design considerations across various reactor types. Complementary methods like PSO and hybrid approaches further enhance optimization efforts, notably in forecasting hydrogen-producing reactor temperatures and achieving methanol production efficiency. These techniques optimize critical parameters, contributing to higher reactor efficiency and performance while minimizing resource consumption.

These trends underscore the vital role of ML and optimization strategies in advancing reactor technology. The interdisciplinary nature of this research, bridging traditional engineering and cutting-edge computational methods, promises ongoing innovations in reactor design, operation, and safety. As technology continues to evolve, these techniques are poised to play an even more pivotal role in meeting the ever-growing demands for cleaner and more efficient energy production and chemical processes.

References

- Samuel, A.L. Some Studies in Machine Learning Using the Game of Checkers. IBM Journal of Research and Development 1959, 3, 210–229. [Google Scholar] [CrossRef]

- Shobha, G.; Rangaswamy, S. Computational analysis and understand of natural languages: principles, methods and applications. Handbook of Statistics 2018. [Google Scholar]

- El Bouchefry, K.; de Souza, R.S. Learning in big data: Introduction to machine learning. In Knowledge Discovery in Big Data from Astronomy and Earth Observation; Elsevier, 2020; pp. 225–249.

- Popovic, D. Intelligent Control with Neural Networks. In Soft Computing and Intelligent Systems; Elsevier, 2000; pp. 419–467.

- Ge, Z.; Song, Z.; Ding, S.X.; Huang, B. Data mining and analytics in the process industry: The role of machine learning. Ieee Access 2017, 5, 20590–20616. [Google Scholar] [CrossRef]

- De, R.; Rajan, A.; Govindaraj, K.; Kinage, A.; Ramamurthy, R.K.; Schreder, J.; Peters, C. System and method for industrial process automation controller farm with flexible redundancy schema and dynamic resource management through machine learning, 2019. US Patent 10,416, 630.

- Keliris, A.; Salehghaffari, H.; Cairl, B.; Krishnamurthy, P.; Maniatakos, M.; Khorrami, F. Machine learning-based defense against process-aware attacks on industrial control systems. 2016 IEEE International Test Conference (ITC). IEEE, 2016, pp. 1–10. [CrossRef]

- Kanawaday, A.; Sane, A. Machine learning for predictive maintenance of industrial machines using IoT sensor data. 2017 8th IEEE International Conference on Software Engineering and Service Science (ICSESS). IEEE, 2017, pp. 87–90. [CrossRef]

- Weichert, D.; Link, P.; Stoll, A.; Rüping, S.; Ihlenfeldt, S.; Wrobel, S. A review of machine learning for the optimization of production processes. The International Journal of Advanced Manufacturing Technology 2019, 104, 1889–1902. [Google Scholar] [CrossRef]

- Lahdhiri, H.; Said, M.; Abdellafou, K.B.; Taouali, O.; Harkat, M.F. Supervised process monitoring and fault diagnosis based on machine learning methods. The International Journal of Advanced Manufacturing Technology 2019, 102, 2321–2337. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Kozłowski, E.; Kłosowski, G.; Niderla, K. Logistic Regression for Machine Learning in Process Tomography. Sensors 2019, 19, 3400. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.S.; Ghosh, T.; Aurna, N.F.; Kaiser, M.S.; Anannya, M.; Hosen, A.S. Machine Learning and internet of things in industry 4.0: A review. Measurement: Sensors, 1008. [Google Scholar] [CrossRef]

- Pinto, R.; Gonçalves, G. Application of artificial immune systems in advanced manufacturing. Array, 1002. [Google Scholar] [CrossRef]

- Patra, S.R.; Jehadeesan, R.; Rajeswari, S.; Banerjee, I.; Murty, S.V.S.; Padmakumar, G.; Baba, M.S. Neural network modeling for evaluating sodium temperature of intermediate heat exchanger of fast breeder reactor. Internal Journal in advances in computing 2012, 2, 16–22. [Google Scholar]

- Starkov, S.; Lavrenkov, Y. Prediction of the moderator temperature field in a heavy water reactor based on a cellular neural network. Nuclear Energy and Technology 2017, 3, 133–140. [Google Scholar] [CrossRef]

- Dolenko, S.; Filippov, A.; Pal, A.; Persiantsev, I.; Serov, A. Determination of Gas Temperature in a CVD Reactor from Optical Emmission Spectra with the Help of Artificial Neural Networks and Group Method of Data Handling (GMDH). Adaptive Computing in Design and Manufacture: The Integration of Evolutionary and Adaptive Computing Technologies with Product/System Design and Realisation. Springer, 1998, pp. 345–353. [CrossRef]

- Apriliani, E.; Adzkiya, D.; Baihaqi, A. The reduced rank of ensemble Kalman filter to estimate the temperature of non isothermal continue stirred tank reactor. Jurnal Teknik Industri 2011, 13, 107–112. [Google Scholar] [CrossRef]

- Leite, V.C.; Merzari, E.; Ponciroli, R.; Ibarra, L. Convolutional Neural Network–Aided Temperature Field Reconstruction: An Innovative Method for Advanced Reactor Monitoring. Nuclear Technology 2023, 209, 645–666. [Google Scholar] [CrossRef]

- Chen, H.; Cen, J.; Yang, Z.; Si, W.; Cheng, H. Fault diagnosis of the dynamic chemical process based on the optimized CNN-LSTM network. ACS omega 2022, 7, 34389–34400. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, R.; Hu, S. Application of artificial neural networks in fault diagnosis for 10MW high-temperature gas-cooled reactor. Nuclear Power Engineering 2003, 24, 563–567. [Google Scholar]

- Hui, L.; Ruipian, W.; Shouyin, H. Application of artificial neural networks in fault diagnosis for 10MW high-temperature gas-cooled reactor. Nuclear Power Engineering 2003, 24. [Google Scholar]

- Penha, R.; Hines, J.W. Using principal component analysis modeling to monitor temperature sensors in a nuclear research reactor. Maintenance and reliability conference (MARCON 2001), 2001.

- Ayaz, E.; Seker, S.; Barutcu, B.; Tuerkcan, E. Neural networks for monitoring of high temperature gas cooled reactor from simulated power operation. Annual meeting on nuclear technology 2001. Proceedings, 2001.

- Şeker, S.; Türkcan, E.; Ayaz, E.; Barutçu, B. Artificial neural networks for dynamic monitoring of simulated-operating parameters of high temperature gas cooled engineering test reactor (HTTR). Annals of Nuclear Energy 2003, 30, 1777–1791. [Google Scholar] [CrossRef]

- Tan, K.; Liu, M.; Wei, C. Application of Machine Learning in Crosssection Calculation for High-Temperature Gas-Cooled Reactor Engineering Simulator System. Available at SSRN 419 9183. [CrossRef]

- Takamizawa, H.; Nishiyama, Y.; Hirano, T.

- Istiqomah, A.; Subiantoro, A. Core power modelling of high-temperature engineering test reactor (HTTR) using nonlinear least squares method for parameter estimation. 2021 International Conference on Artificial Intelligence and Mechatronics Systems (AIMS). IEEE, 2021, pp. 1–6. [CrossRef]

- Wu, H.; Yu, L.; Niu, F.; Tu, J.; Jiang, S. Machine Learning Modelling of Decay Heat Removal in High Temperature Gas-Cooled Reactor. International Conference on Nuclear Engineering. American Society of Mechanical Engineers, 2022, Vol. 86427, p. V07BT07A019. [CrossRef]

- Hernández-Alvarado, R.; García-Valdovinos, L.G.; Salgado-Jiménez, T.; Gómez-Espinosa, A.; Fonseca-Navarro, F. Neural network-based self-tuning PID control for underwater vehicles. sensors 2016, 16, 1429. [Google Scholar] [CrossRef]

- Etike, E.; Özkan, G.; Hapoglu, H. Temperature Control in Polystyrene Polymerization Reactor by Using Neural Network Model Predictive Algorithm. J. Indian Chem. Soc 2020, 97, 2031–2036. [Google Scholar]

- Vasanthi, D.; Pranavamoorthy, B.; Pappa, N. Artificial Neural Network tuned cascade control for temperature control of polymerization reactor. 2011 IEEE International Symposium on Intelligent Control. IEEE, 2011, pp. 1367–1372. [CrossRef]

- Zhang, S.; Liu, Y.; Cheng, M.; Zhao, X. The fuzzy neural network temperature control in PCR reactor. 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing. IEEE, 2008, pp. 1–4. [CrossRef]

- Mazana, N.; Nzama, M. Neural Network Self-Tuning Control Of Hot-Spot Temperature In A Fixed-Bed Catalytic Reactor. WIT Transactions on Information and Communication Technologies 1970, 19. [Google Scholar]

- Meng, H.; Ma, J.; Bao, S.F.; Wei, S.Q. Based on the BP Neural Network VAc Synthesis Reactor in Temperature Control. Applied Mechanics and Materials 2013, 313, 1389–1392. [Google Scholar] [CrossRef]

- Onderwater, D.; Macgregor, J.; Wright, J. Use of nonlinear transformations and a self-tuning regulator to develop an algorithm for catalytic reactor temperature control. The Canadian Journal of Chemical Engineering 1988, 66, 478–484. [Google Scholar] [CrossRef]

- Pundir, A.S.; Singh, K. Chattering Free Sliding Mode Control with Observer Based Adaptive Radial Basis Function Neural Network for Temperature Tracking in a Fixed Bed Reactor. International Journal of Chemical Reactor Engineering 2019, 17, 20180256. [Google Scholar] [CrossRef]

- Ku, C.C.; Lee, K.Y.; Edwards, R. Improved nuclear reactor temperature control using diagonal recurrent neural networks. IEEE Transactions on Nuclear Science 1992, 39, 2298–2308. [Google Scholar] [CrossRef]

- Haoran, L.; Xuhong, Y.; Hui, W. The Reactor Temperature Control of Pressurized Water Reactor in Nuclear Power Plant Based on RBF Neural Network. Computer Science and Engineering Technology (CSET2015) & Medical Science and Biological Engineering (MSBE2015) Proceedings of the 2015 International Conference on CSET & MSBE. World Scientific, 2016, pp. 99–105. [CrossRef]

- Zheng, Y.; Liu, X.; Zhao, J.; Mo, N.; Shi, Z. A novel iterative learning control method and control system design for active magnetic bearing rotor imbalance of primary helium circulator in high-temperature gas-cooled reactor. Measurement and Control 2020, 53, 474–484. [Google Scholar] [CrossRef]

- Xu, J.; Yu, L.; Yang, Z.; Shao, G.; Yan, X. Intelligent temperature control for continuous stirred tank reactor system based on reinforcement learning algorithm. International Conference on Intelligent Systems, Communications, and Computer Networks (ISCCN 2023). SPIE, 2023, Vol. 12702, pp. 176–181. [CrossRef]

- Ouyang, M.; Wang, Y.; Wu, F.; Lin, Y. Continuous Reactor Temperature Control with Optimized PID Parameters Based on Improved Sparrow Algorithm. Processes 2023, 11, 1302. [Google Scholar] [CrossRef]

- Shukla, P.K.; Pushpavanam, S.; Khanna, A.; Harmon, J.L. Experimental implementation of a recursive algorithm to control the temperature trajectory of an exothermic batch reactor. Industrial & engineering chemistry research 1997, 36, 122–129. [Google Scholar]

- Balaton, M.G.; Nagy, L.; Szeifert, F. Model-based split-range algorithm for the temperature control of a batch reactor 2012.

- Mezghani, M.; Le Lann, M.; Roux, G.; Cabassud, M.; Dahhou, B.; Casamatta, G. Experimental application of the iterative learning control to the temperature control of batch reactor. IFAC Proceedings Volumes 2002, 35, 283–288. [Google Scholar] [CrossRef]

- Dirion, J.L.; Ettedgui, B.; Cabassud, M.; Le Lann, M.; Casamatta, G. Elaboration of a neural network system for semi-batch reactor temperature control: an experimental study. Chemical Engineering and Processing: Process Intensification 1996, 35, 225–234. [Google Scholar] [CrossRef]

- Li, M.Q.; Yu, Y.X. Study on Predictive Control Algorithm of Reactor Temperature. Applied Mechanics and Materials 2013, 273, 631–635. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, Y.; Li, J.; Wang, F. PID control in the reactor temperature control system based on BP neural network. 2009 International Conference on Intelligent Human-Machine Systems and Cybernetics. IEEE, 2009, Vol. 1, pp. 245–248.

- Ai, L.; Pan, H. The reactor temperature control based on self-optimizing and self-adjustment fuzzy algorithm. 2011 Eighth International Conference on Fuzzy Systems and Knowledge Discovery (FSKD). IEEE, 2011, Vol. 1, pp. 300–304. [CrossRef]

- Isamiddin, S.; Mamasodikova, N.; Rayimdjanova, O.; Khalmatov, D.; Mirzaaxmedova, X. Algorithms for synthesis of a fuzzy control system chemical reactor temperature 2021.

- Jouse, W.; Williams, J.G. Neural control of temperature and pressure during pwr [pressurized water reactor] start-up. Transactions of the American Nuclear Society 1990, 61. [Google Scholar]

- Ghosh, T.; Martinsen, K. Generalized approach for multi-response machining process optimization using machine learning and evolutionary algorithms. Engineering Science and Technology, an International Journal 2020, 23, 650–663. [Google Scholar] [CrossRef]

- Huang, C.; Pan, H. Reactor temperature predictive control algorithm research based on the PSO. Proceedings of the 32nd Chinese Control Conference. IEEE, 2013, pp. 4073–4076.

- Yadav, E.S.; Shettigar J, P.; Poojary, S.; Chokkadi, S.; Jeppu, G.; Indiran, T. Data-Driven Modeling of a Pilot Plant Batch Reactor and Validation of a Nonlinear Model Predictive Controller for Dynamic Temperature Profile Tracking. ACS omega 2021, 6, 16714–16721. [Google Scholar] [CrossRef] [PubMed]

- Minqiang, P.; Dehuai, Z.; Gang, X. Temperature prediction of hydrogen producing reactor using SVM regression with PSO. Journal of computers 2010, 5, 388–393. [Google Scholar]

- Wali, W.; Al-Shamma’a, A.; Hassan, K.H.; Cullen, J. Online genetic-ANFIS temperature control for advanced microwave biodiesel reactor. Journal of Process Control 2012, 22, 1256–1272. [Google Scholar] [CrossRef]

- Wahab, A.K.A.; Hussain, M.A.; Omer, R. Temperature control of a pilot plant reactor system using a genetic algorithm model-based control approach. Asia-Pacific Journal of Chemical Engineering 2007, 2, 526–535. [Google Scholar] [CrossRef]

- Khairi Abdul Wahab, A.; Azlan Hussain, M.; Omar, R. Temperature control of a pilot plant reactor system using a genetic algorithm model-based control approach. Asia-Pacific Journal of Chemical Engineering 2007, 2, 526–535. [Google Scholar] [CrossRef]

- Areed, F.; El-Hosseini, M.A.; Saraya, M. Temperature control for a chemical reactor using a new Genetic Algorithm.

- Begum, K.G. Coot bird optimization algorithm for the temperature control of continuous stirred tank reactor process. Asia-Pacific Journal of Chemical Engineering 2023, 18, e2787. [Google Scholar] [CrossRef]

- Liaoyuan, H.; Rui, Y.; Yang, Z.; Wei, G.; Guimin, L.; others. Optimization of Core of Advanced High-Temperature Reactor Based on Hybrid Adaptive Genetic Annealing Algorithm. 核动力工程 2019, 40, 56–60. [Google Scholar]

- Chee, G.J.Y. Fluoride-salt-cooled high-temperature reactor generative design optimization with evolutionary algorithms. PhD thesis, 2022.

- Patel, R.; Bhartiya, S.; Gudi, R. Optimal temperature trajectory for tubular reactor using physics informed neural networks. Journal of Process Control 2023, 128, 103003. [Google Scholar] [CrossRef]

- Causa, J.; Karer, G.; Núnez, A.; Sáez, D.; Škrjanc, I.; Zupančič, B. Hybrid fuzzy predictive control based on genetic algorithms for the temperature control of a batch reactor. Computers & chemical engineering 2008, 32, 3254–3263. [Google Scholar] [CrossRef]

- Jie, H.; Wenqiang, L.; Ming, D. Block-type high temperature gas cooled reactor reloading pattern optimization using genetic algorithm. 强激光与粒子束 2017, 29, 016002. [Google Scholar] [CrossRef]

- Alarifi, A.; Liu, Z.; Erenay, F.S.; Elkamel, A.; Croiset, E. Dynamic optimization of lurgi type methanol reactor using hybrid GA-GPS algorithm: the optimal shell temperature trajectory and carbon dioxide utilization. Industrial & Engineering Chemistry Research 2016, 55, 1164–1173. [Google Scholar]

- Abdulaziz, A.; Zhefu, L.; Safa, E.F.; Ali, E.; Eric, C. Dynamic Optimization of Lurgi Type Methanol Reactor Using Hybrid GA-GPS Algorithm: The Optimal Shell Temperature Trajectory and Carbon Dioxide Utilization 2016.

- Ardeshiri-Gilani, E.; Astaraki, A. Production and purification of hydrogen in Catalytic Micro reactor with Aspen plus software and optimization of reactor temperature with genetic algorithms in Matlab software.

- Omata, K.; Yamada, M. Artificial neural network and grid search aided optimization of temperature profile of temperature gradient reactor for dimethyl ether synthesis from syngas. Industrial & Engineering Chemistry Research 2009, 48, 844–849. [Google Scholar]

- Kianpour, R.; Ansarifar, G.; Fathi, M. Optimal design of a VVER-1000 nuclear reactor core with dual cooled annular fuel based on the reactivity temperature coefficients using thermal hydraulic and neutronic analysis by implementing the genetic algorithms. Annals of Nuclear Energy 2020, 148, 107682. [Google Scholar] [CrossRef]

- Sha, W. Comment on “Optimization of the temperature profile of a temperature gradient reactor for DME synthesis using a simple genetic algorithm assisted by a neural network” by Kohji Omata, Toshihiko Ozaki, Tetsuo Umegaki, Yuhsuke Watanabe, Noritoshi Nukui, and Muneyoshi Yamada. Energy & Fuels 2007, 21, 379–380. [Google Scholar]

- Mansilla, C. Using genetic algorithms to optimize the helium loop of a very high temperature reactor. Nuclear technology 2008, 162, 323–332. [Google Scholar] [CrossRef]

- Agrawal, G.; Chaudhary, A.; Pani, A.K. Temperature Optimization in Non-isothermal Tubular Reactor using Genetic Algorithm. 2020 3rd International Conference on Communication System, Computing and IT Applications (CSCITA). IEEE, 2020, pp. 23–26. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).