Submitted:

15 October 2023

Posted:

17 October 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

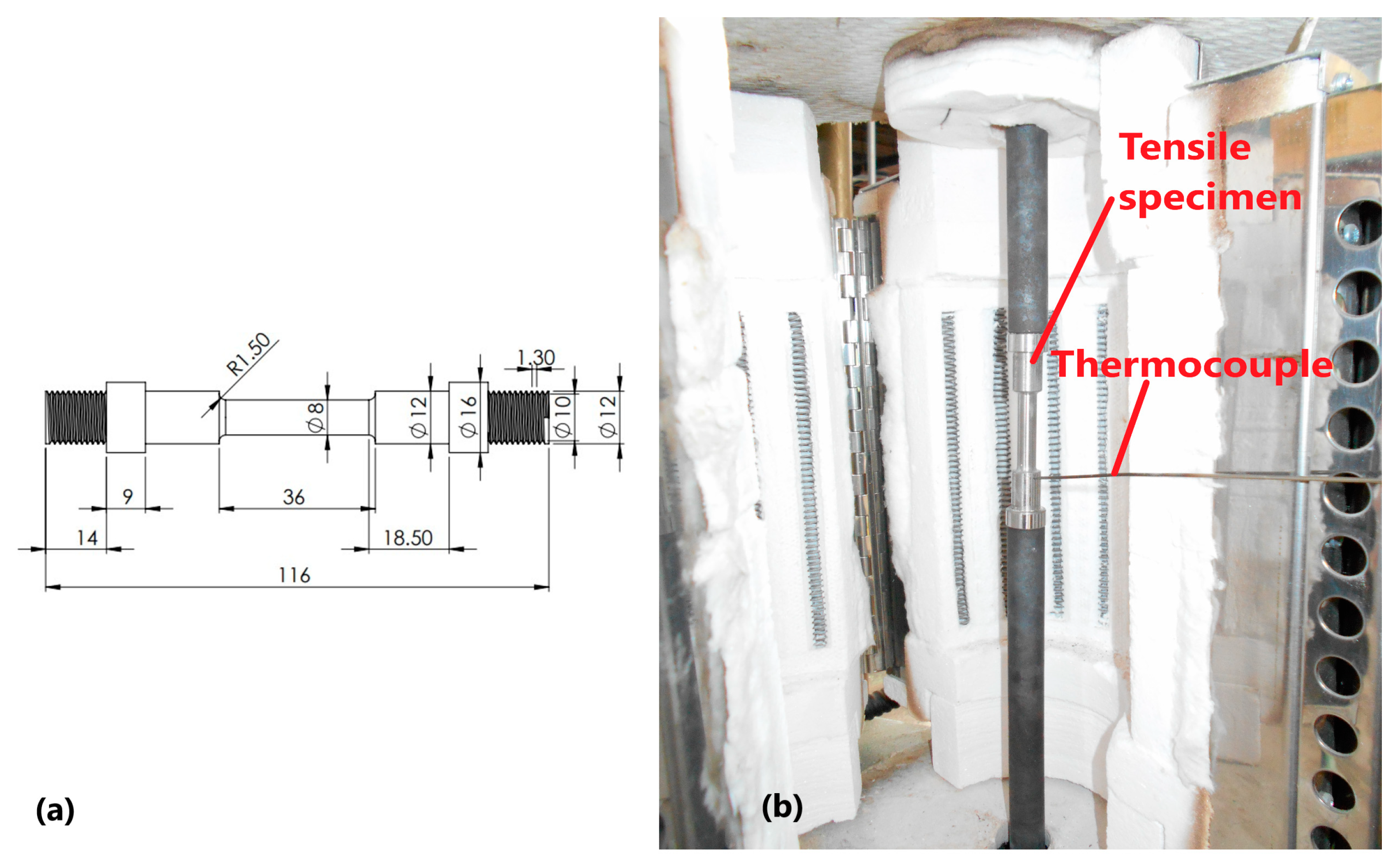

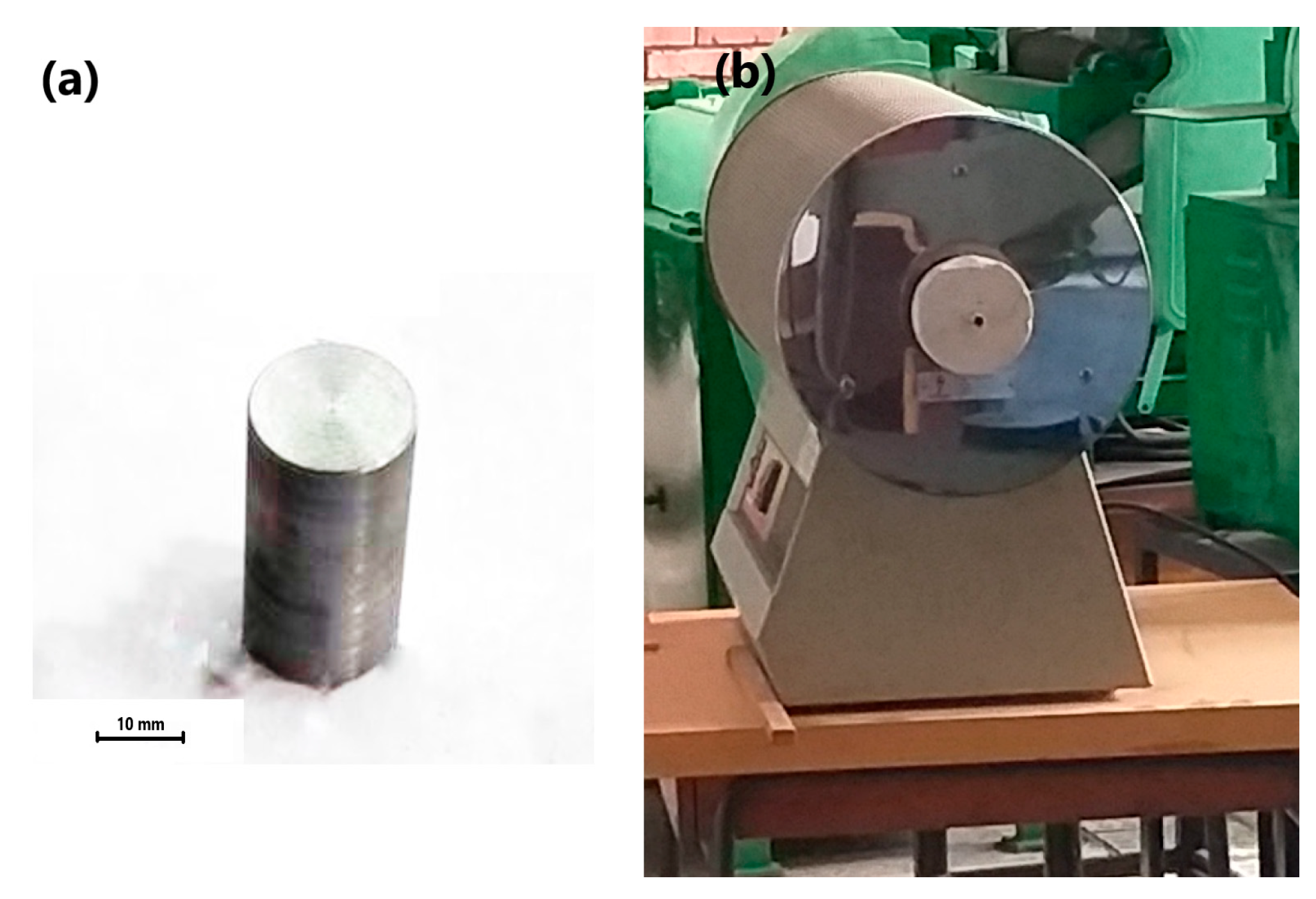

2. Experimental Details

3. Experimental Results

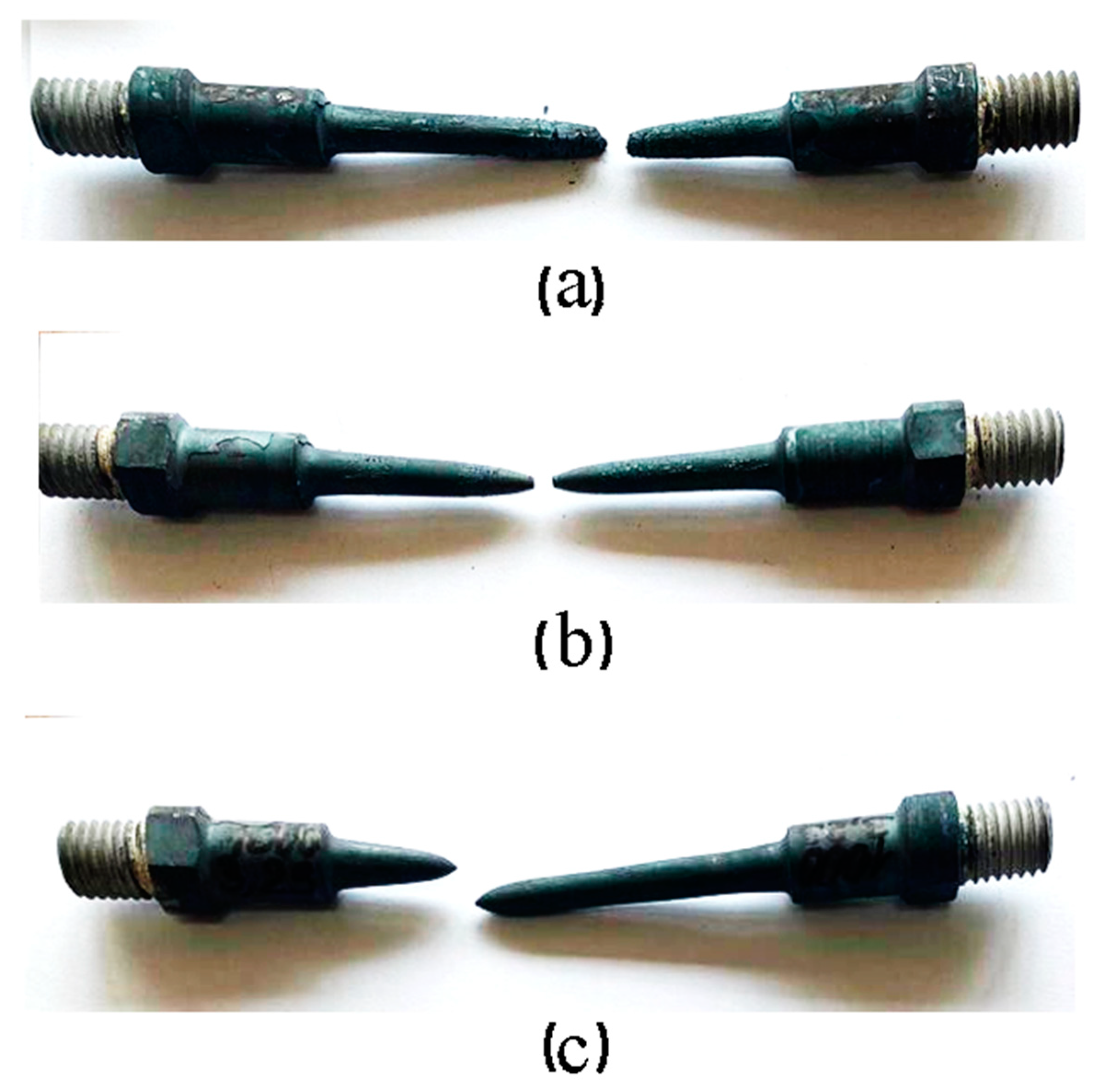

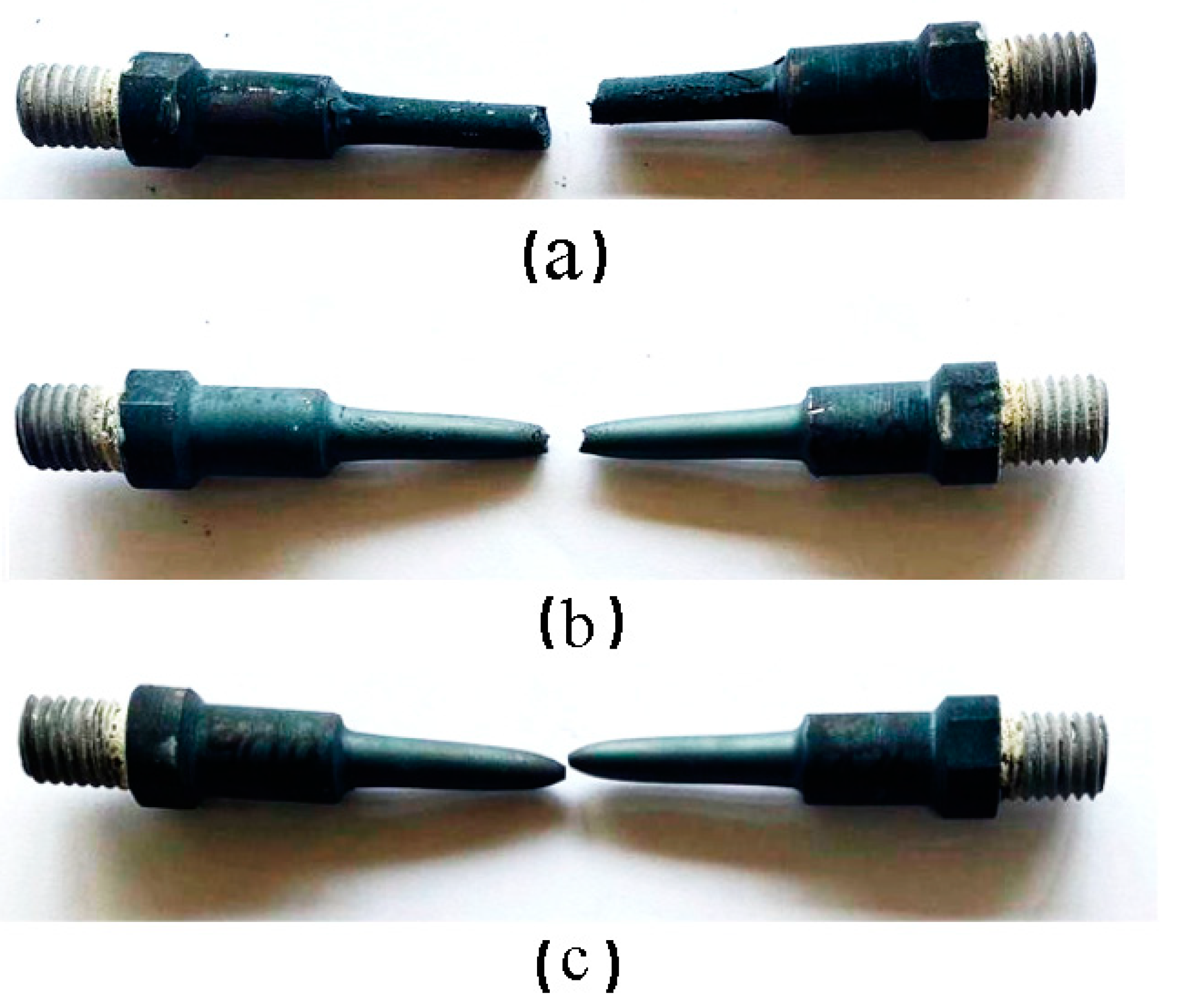

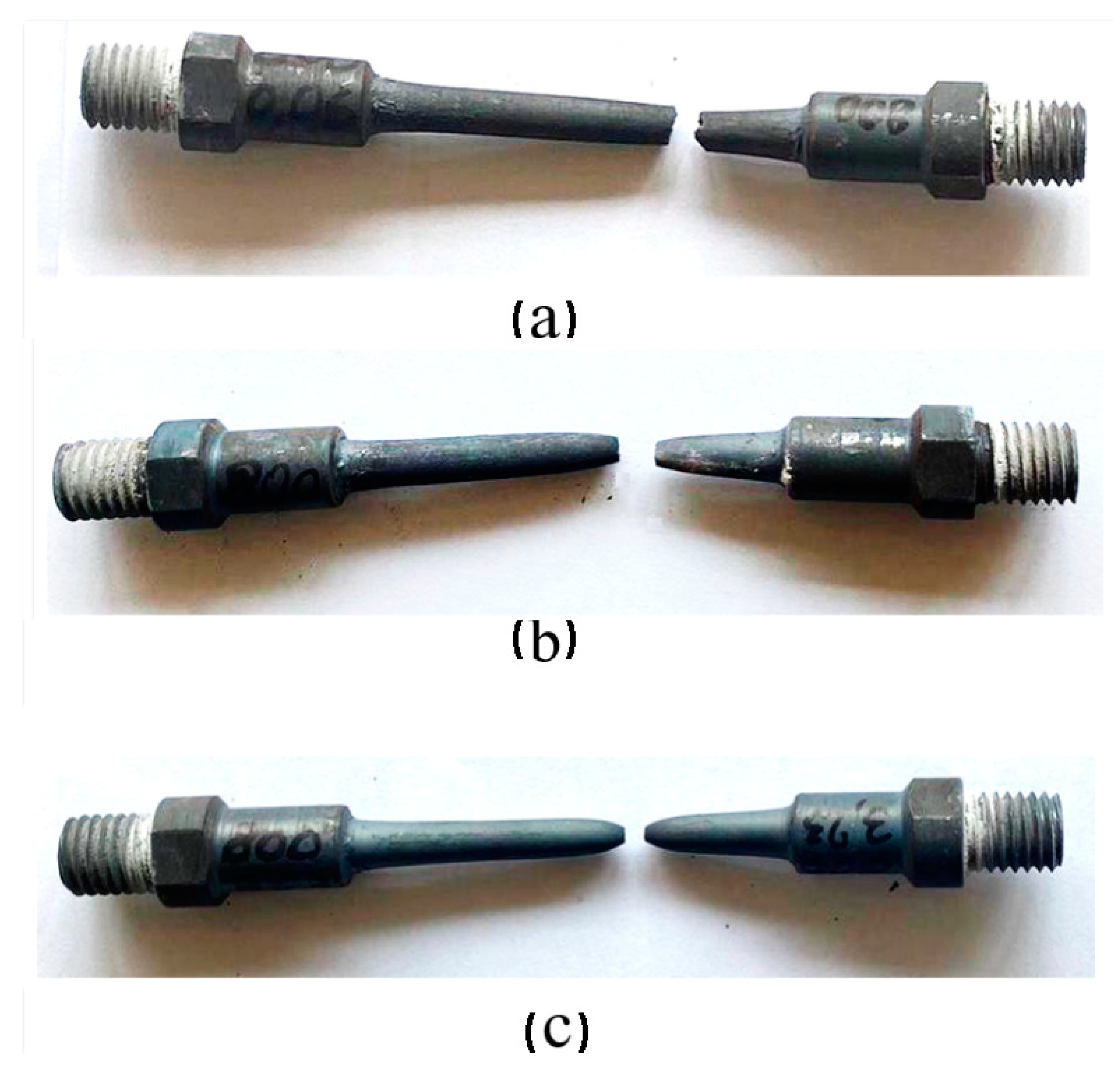

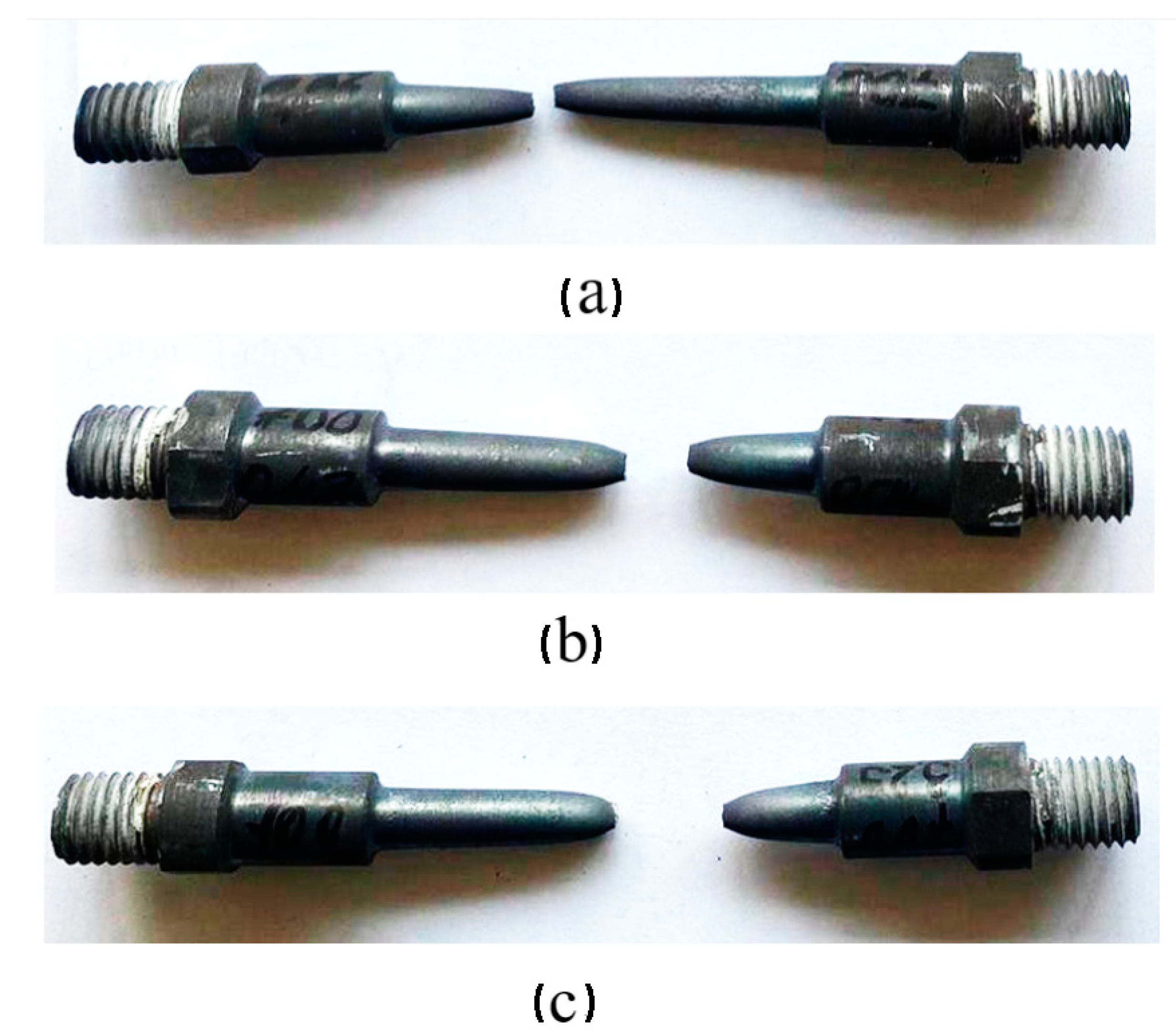

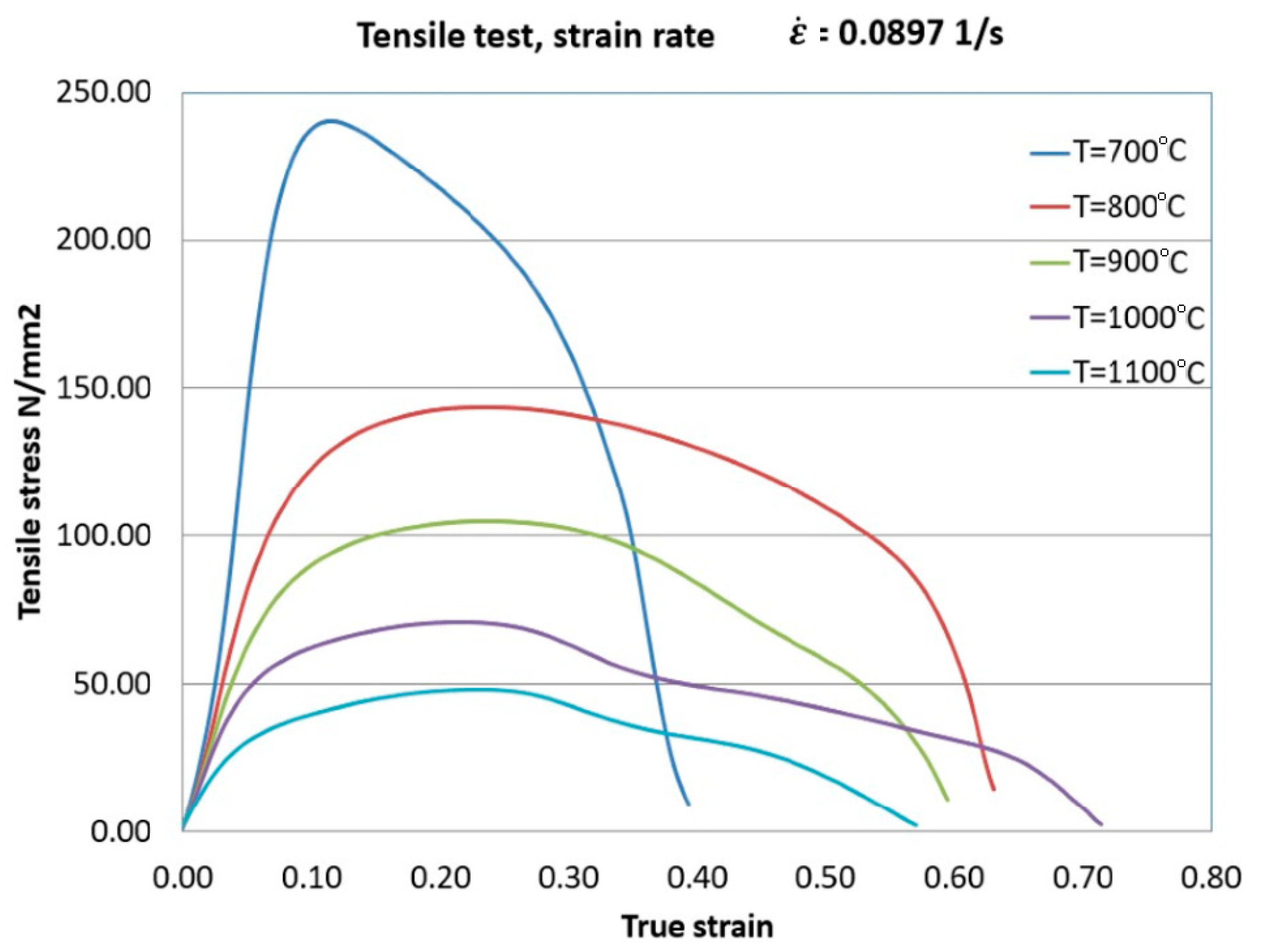

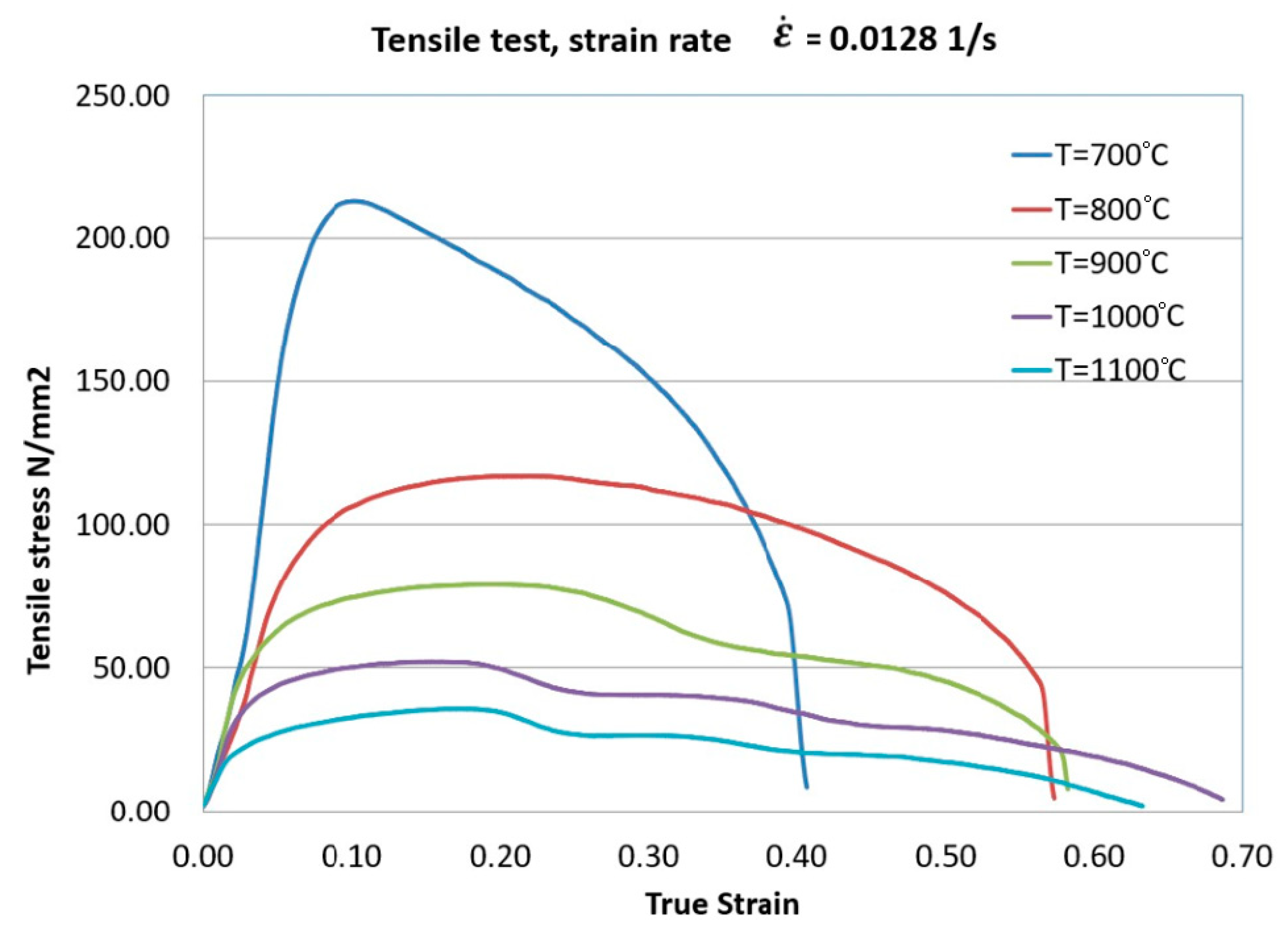

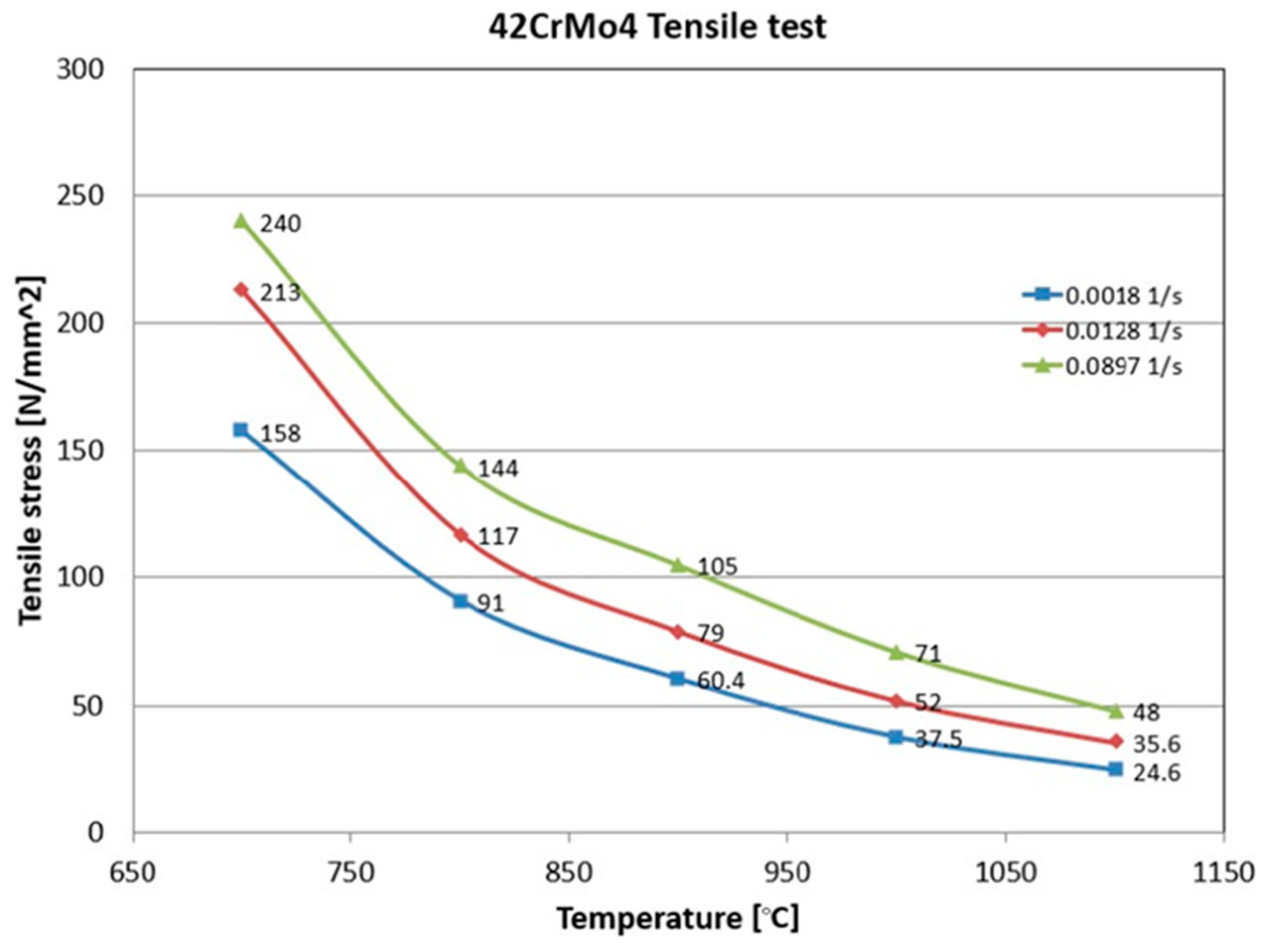

3.1. Hot Tensile Behavior

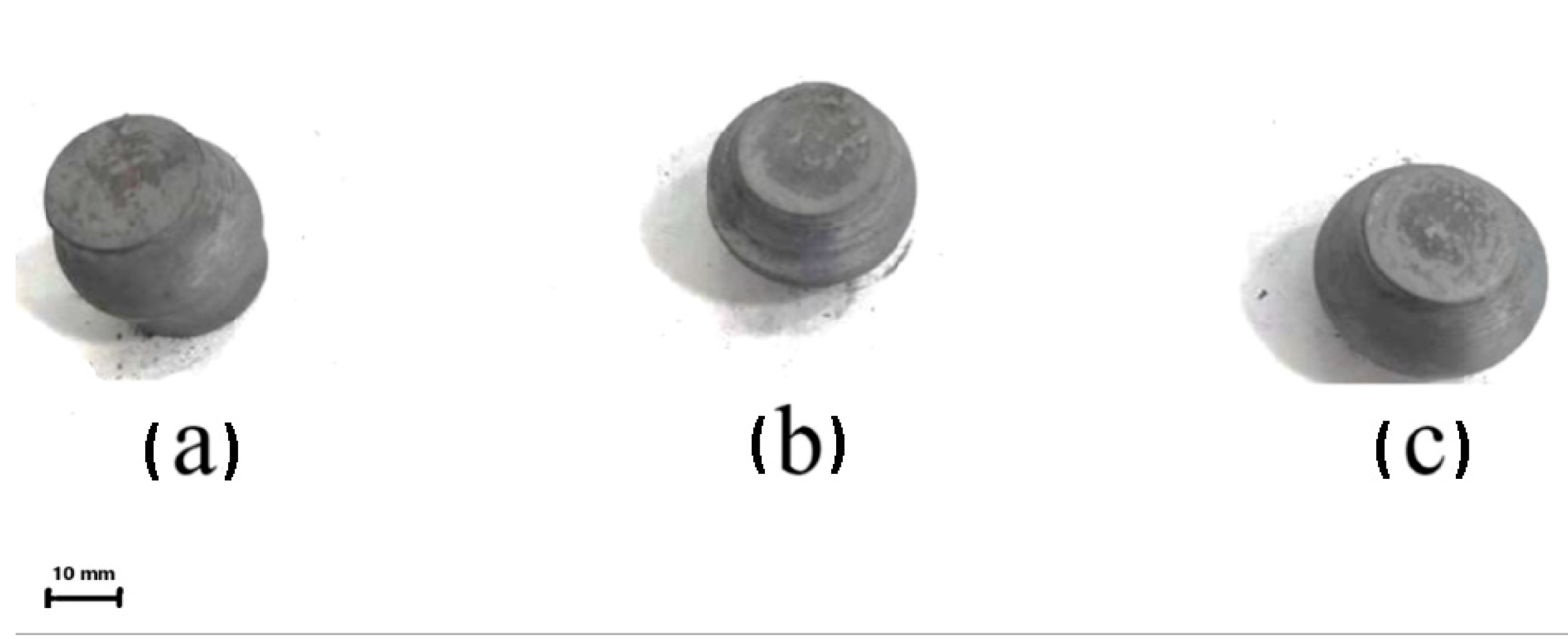

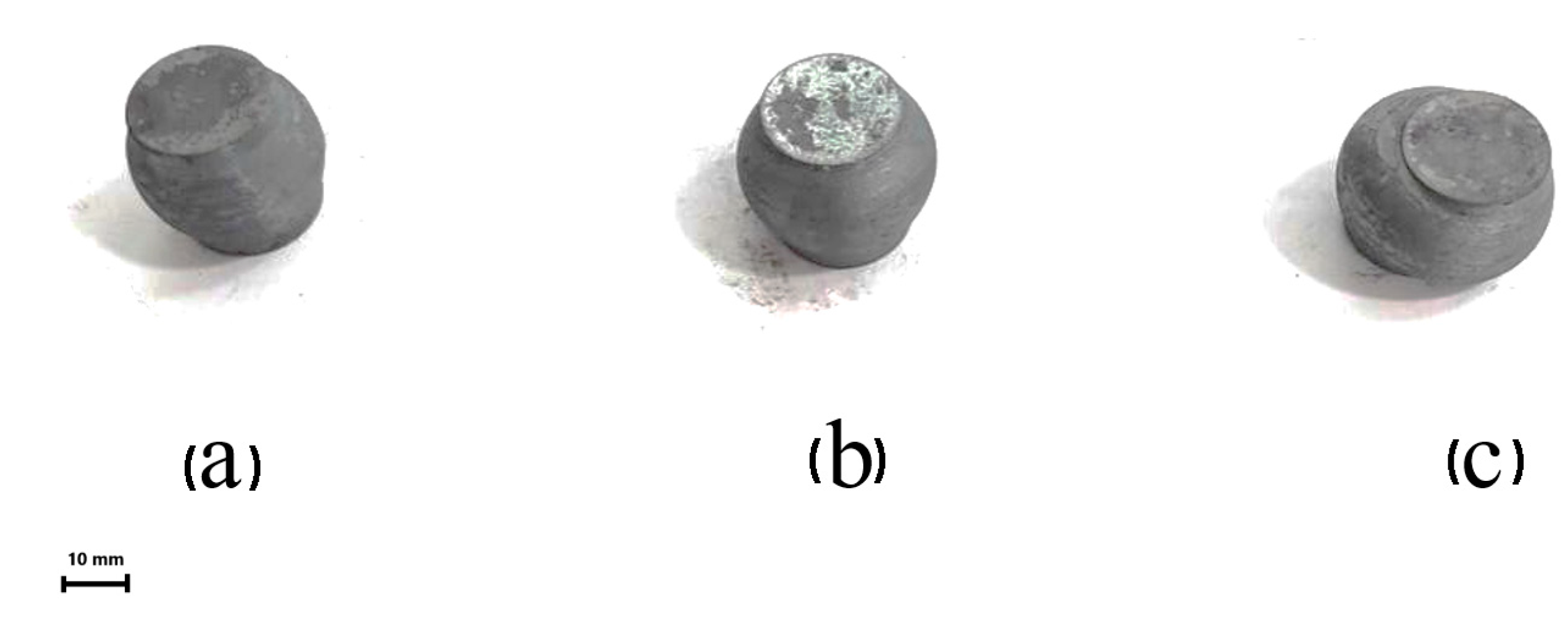

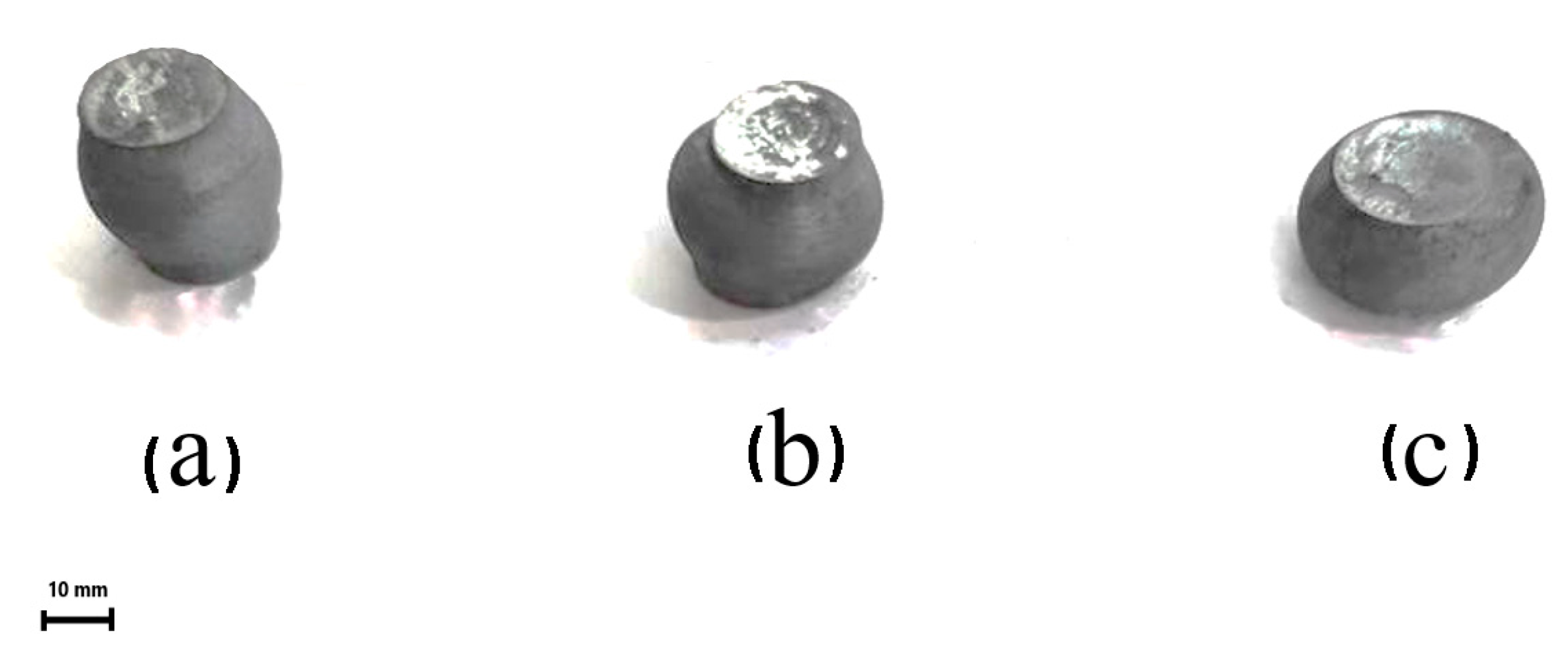

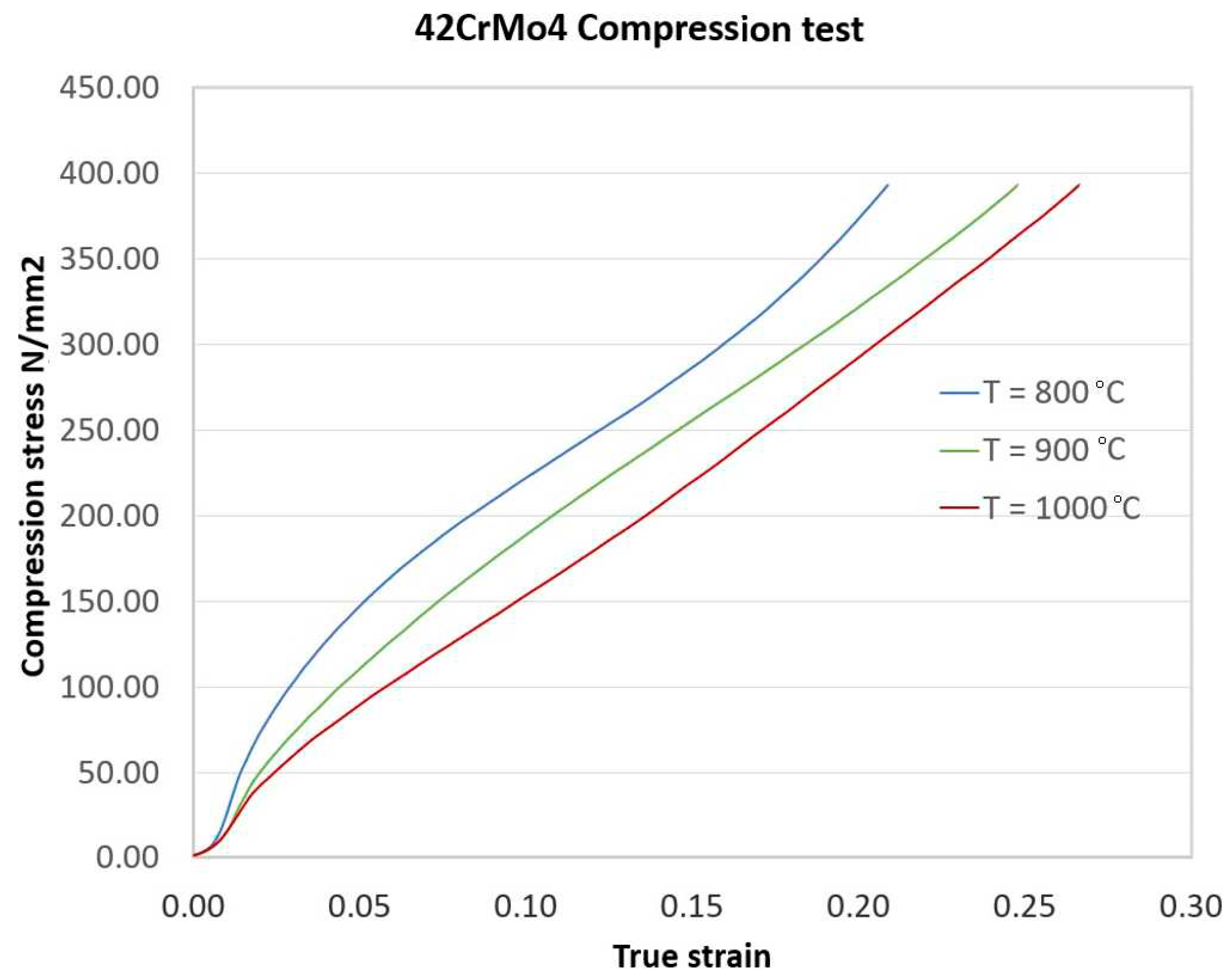

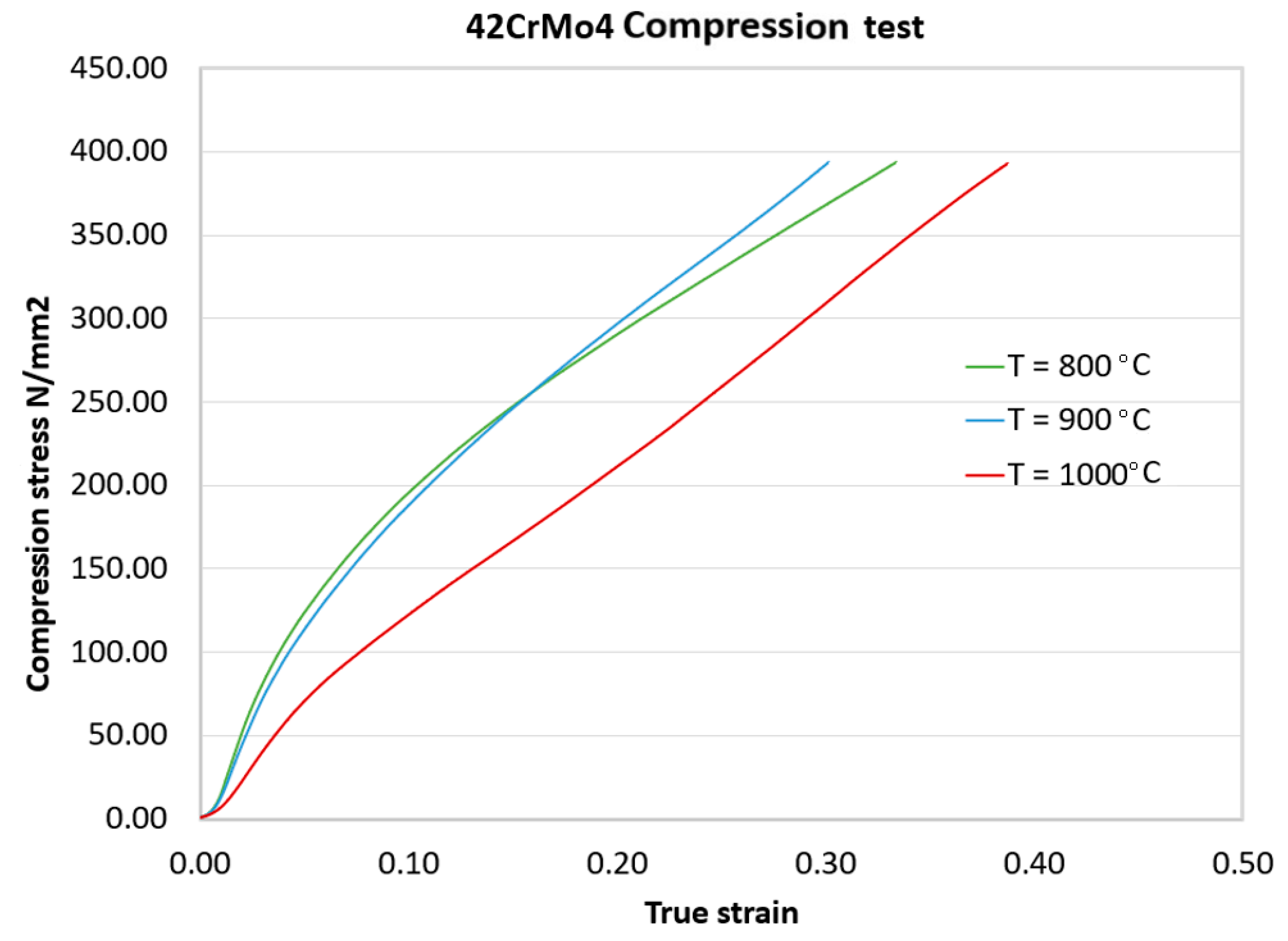

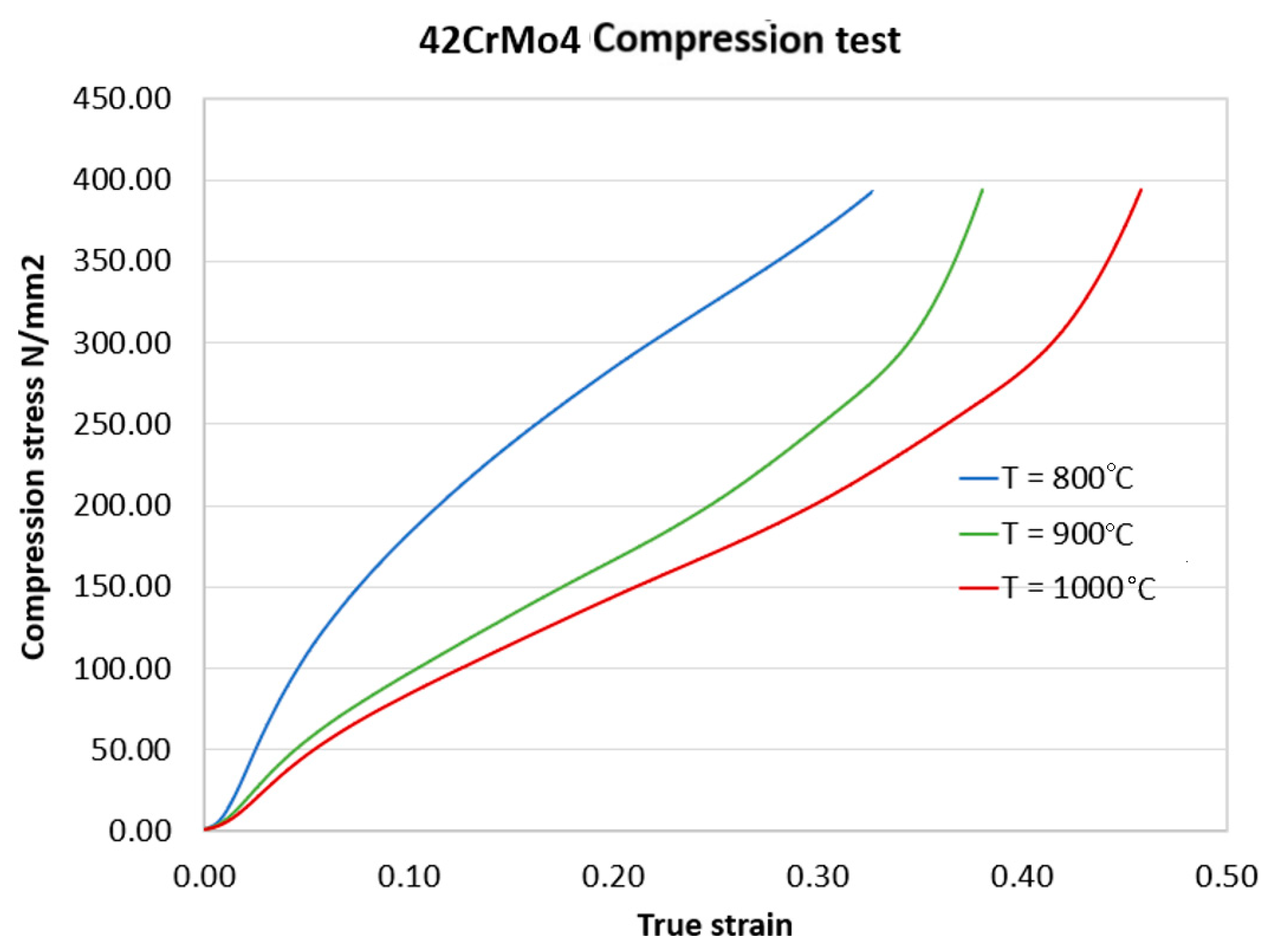

3.2. Compression Tests Behavior

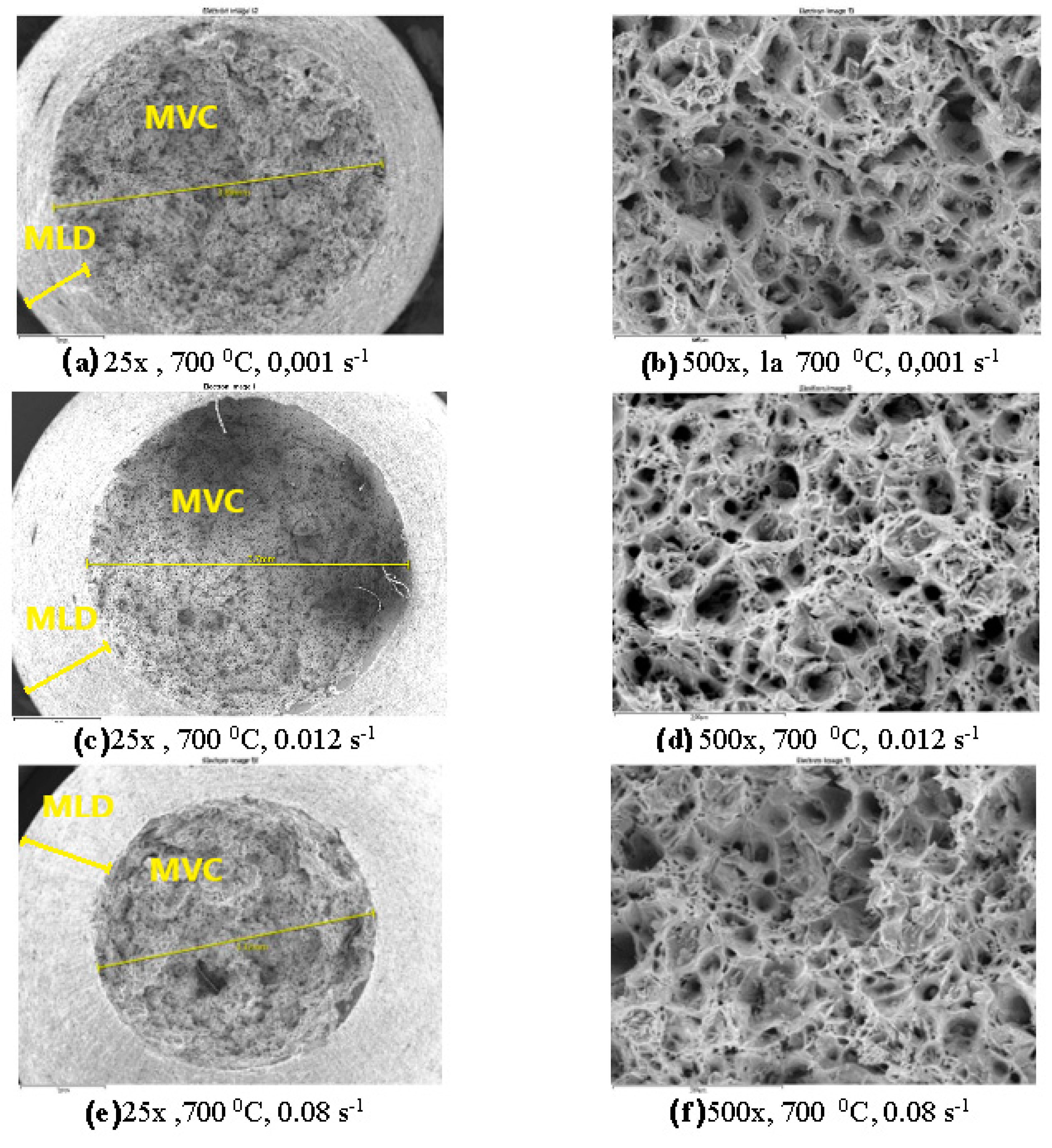

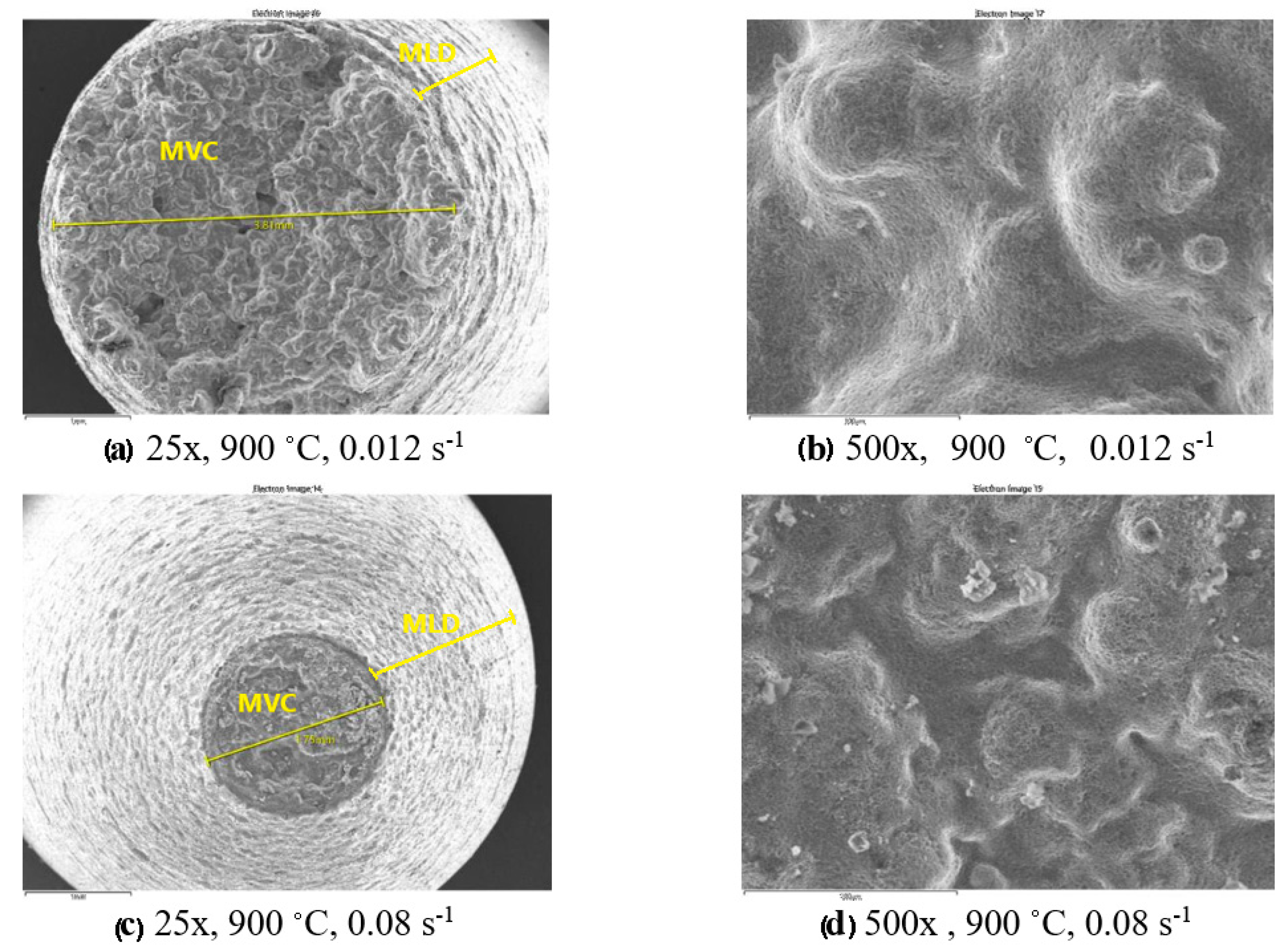

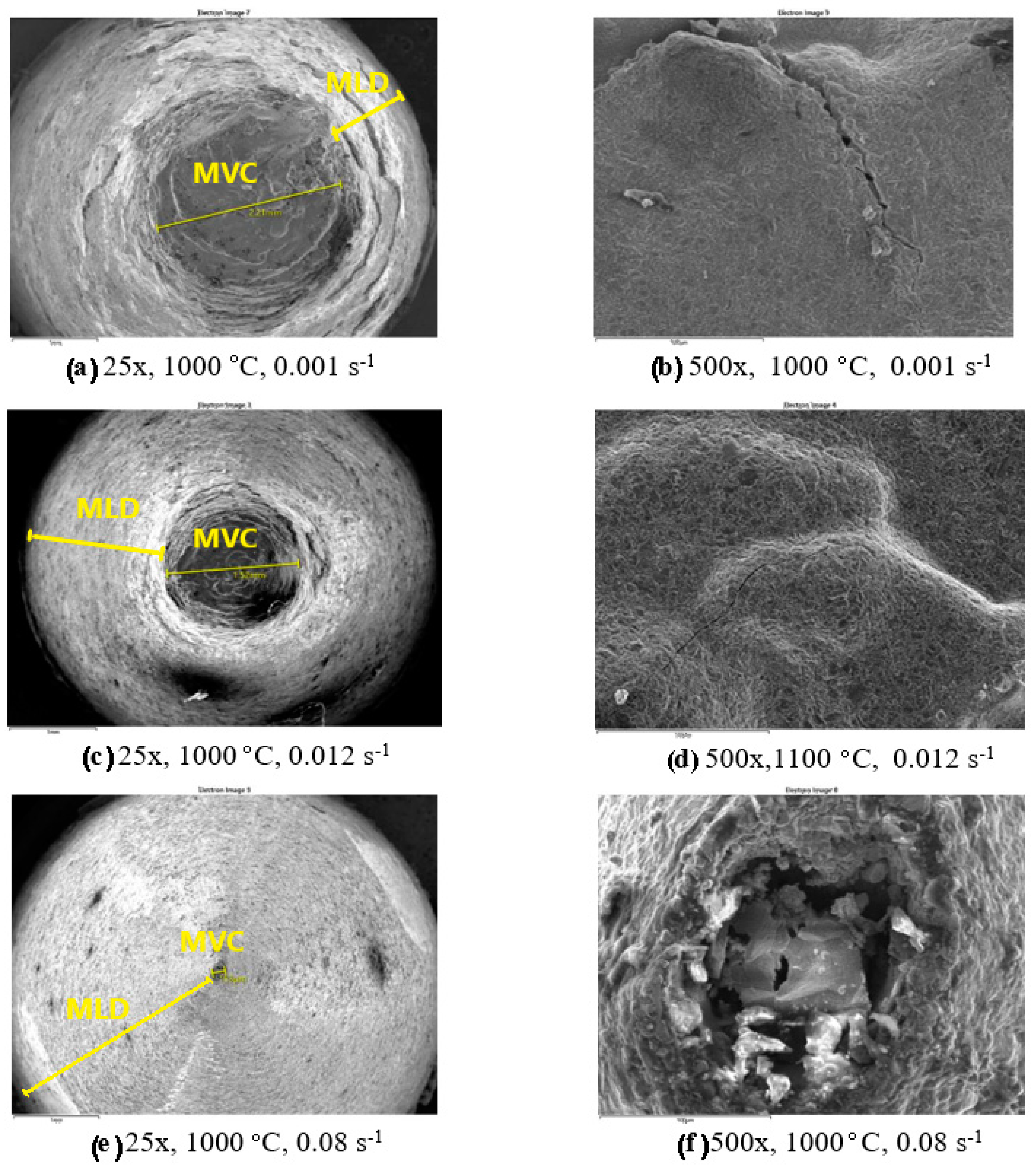

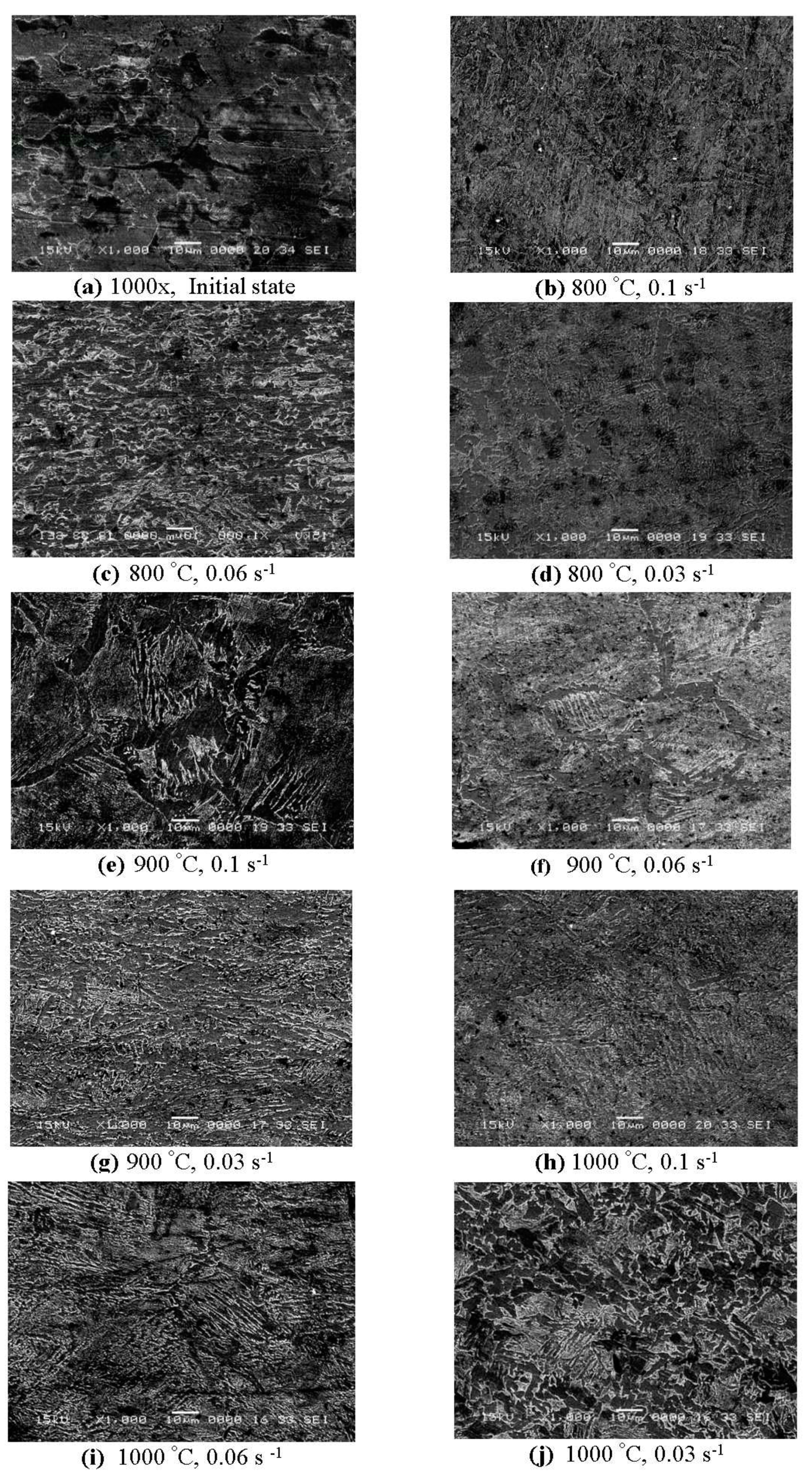

3.3. Structural Analysis

4. Conclusions

- Tensile stress significantly depends on temperature and strain rate. Yield stress increases by increasing strain rate and decreases by increasing temperature.

- The experimental curves show typical characteristics that demonstrate the presence of dynamic recrystallization at high temperatures and low strain rates. At the deformation temperature of 800 °C, 900 °C, 1000 °C, when the balance between hardening and dynamic recovery takes place, the flow curves show a steady phase, in which the flow stress is approximately constant.

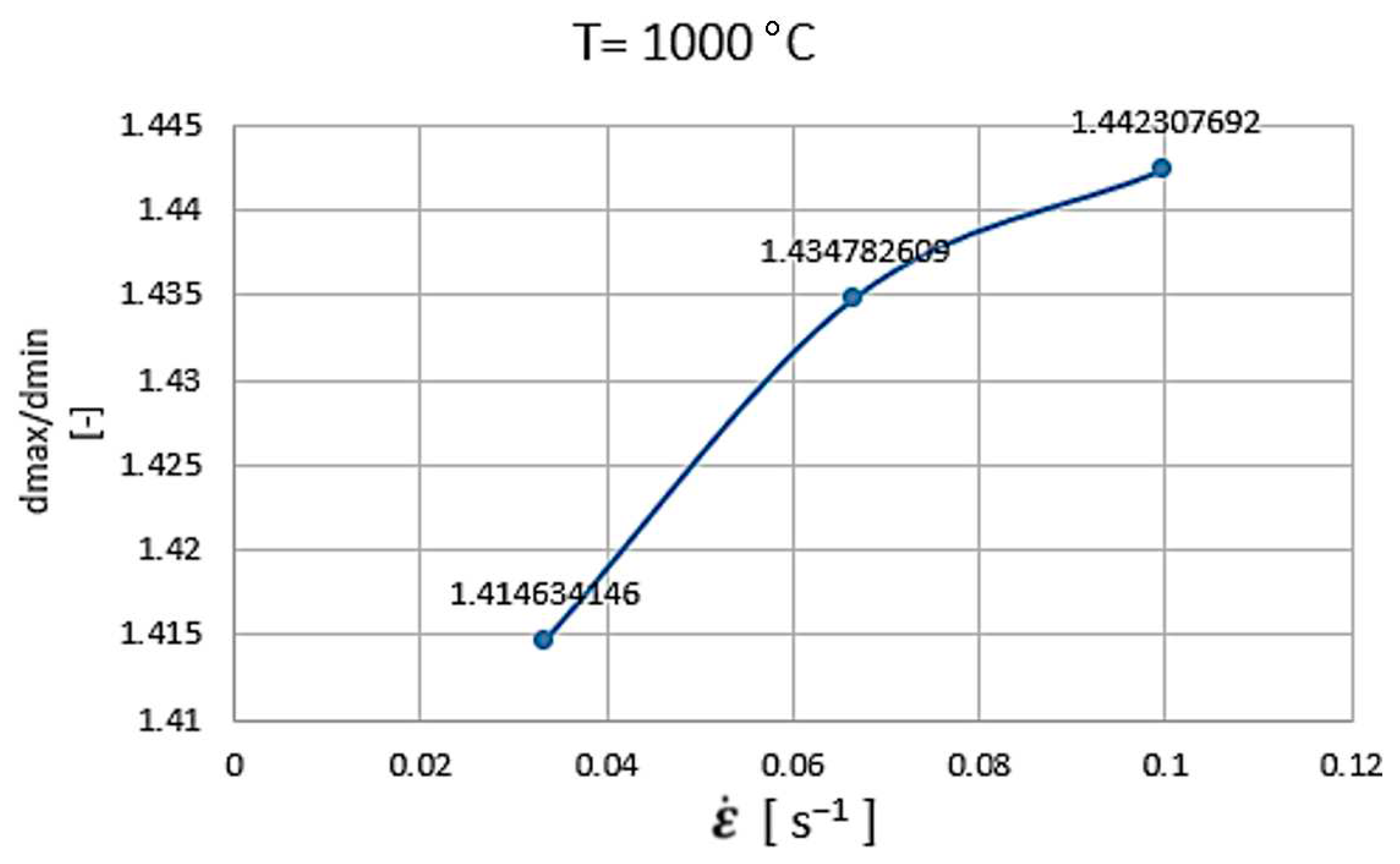

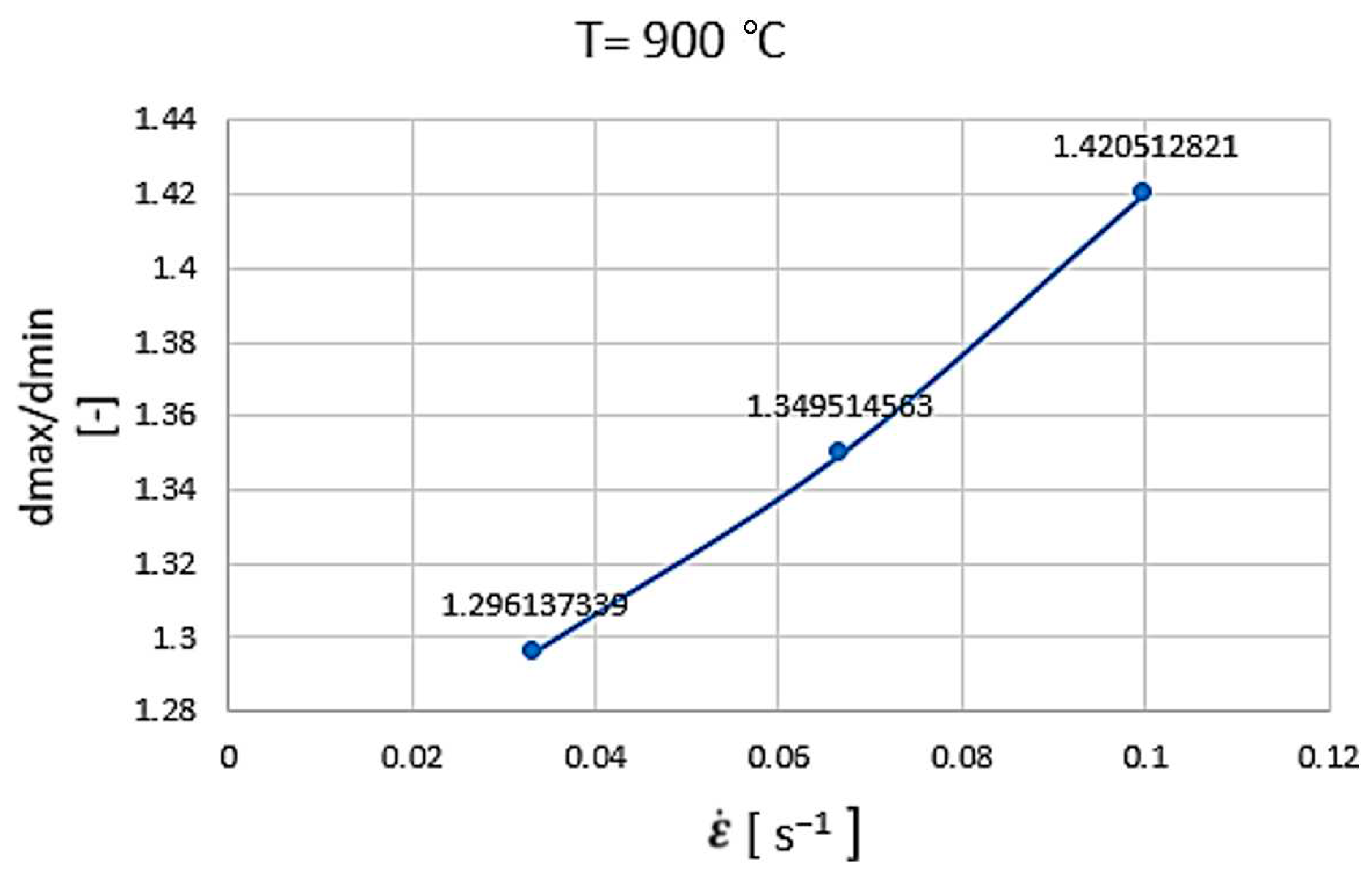

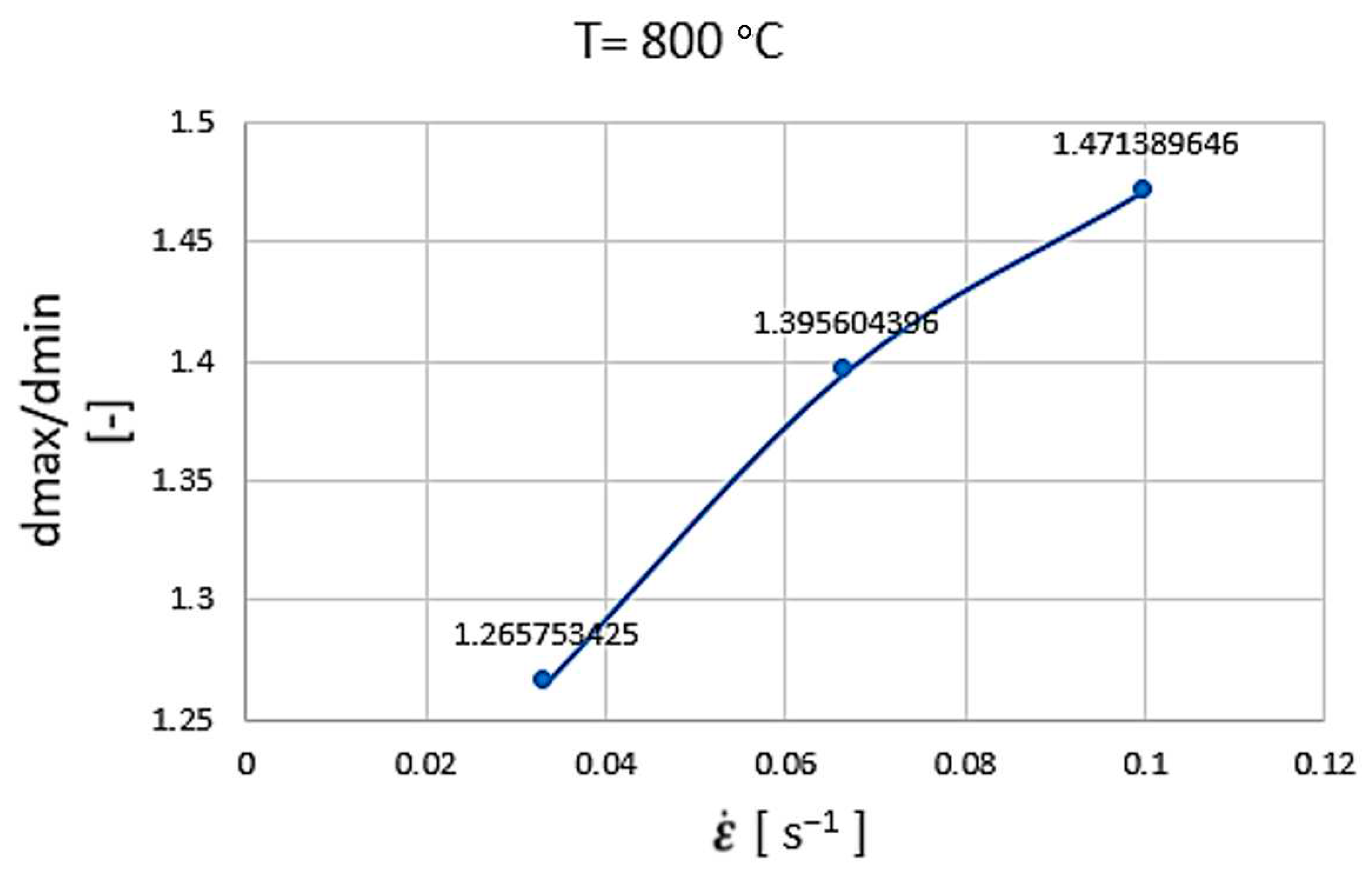

- In case of compression tests is observed that once the strain rate increases, the true strain is slightly increasing, depending on temperature. The greatest non-uniformity of the deformations is observed in the case of the temperature of 1000 °C. By increasing the deformation speed, the non-uniformity of the deformations increases.

- Scanning electron microscopy investigations demonstrate the influence of temperature and strain rate on the formability and structural change of the material.

- For all the presented deformation conditions. the presence of the fracture through the ductile fracture mechanism was produced by the localized of necking and the coalescence of microvoids.

- By increasing the deformation temperature and reducing the strain rate. the fracture behavior of 42CrMo4 steel can be improved.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| l0. d0 | the initial dimensions (length and diameter) of the sample [mm]; |

| l1. d1 | the final dimensions of the sample [mm]; |

| dr | diameter of the sample in the fracture area [mm]; |

| longitudinal and transversal strains [%]; | |

| V | the deformation speed [mm/s]; |

| the strain rate [s−1]; | |

| T | the deformation temperature [°C]; |

| h0, h1 | initial and final height of the sample [mm]; |

| dmin, dmax | minimum and maximum diameter of the deformed sample [mm]. |

References

- Karadeniz, E. Influence of different initial microstructure on the process of spheroidization in cold forging. Materials Design 2008, 29, 251–256. [Google Scholar] [CrossRef]

- Chaouch, D., Guessasma S., Sadok A. Finite Element simulation coupled to optimisation stochastic process to assess the effect of heat treatment on the mechanical properties of 42CrMo4 steel. Materials and Design 2012, 34, 679–684. [CrossRef]

- Arivazhagan, N., Singh S., Prakash S., Reddy GM. An assessment of hardness, impact strength, and hot corrosion behaviour of friction-welded dissimilar weldments between AISI 4140 and AISI 304. Int J Adv Manuf Technol 2008, 39, 679–689. [CrossRef]

- Demir, T., Ubeyli M., Yildrim RO. Investigation on the ballistic impact behaviour of various alloys against 7.62 mm armour piercing projectile. Materials Design 2008, 29, 2009–2016. [CrossRef]

- Rodriguez, E., Flores M., Perez A., Mercado-Solis RD., González R., Rodríguez J., González López JR., Rodriguez J., Valtierra S. Erosive wear by silica sand on AISI H13 and 4140 steels. Wear 2009, 267, 2109–15. [CrossRef]

- Cristea, AF., Ninacs R., Haragâş S., Studies regarding the kinematic and functioning of unconventional worm Gear. Acta Technica Napocensis Series-Applied Mathematics Mechanics and Engineering 2022, 65, 437–442.

- Sas-Boca, IM. Frunza, D., Popa, F., Ilutiu-Varvara, DA., Tintelecan, MC. Influence of Temperature and Strain Rate on Microstructure and Fracture Mechanism of Mild Steel. Procedia Manufacturing 2020, 46, 891–898. [CrossRef]

- Ilhan, E., Findik F., Aslanlar S. An investigation of the factors affecting the design of drum dryers. Mater Des 2003, 24, 503–507. [CrossRef]

- Nouari, M., Molinari A. Experimental verification of a diffusion tool wear model using a 42CrMo4 steel with an uncoated cemented tungsten carbide at various cutting speeds. Wear 2005, 259, 1151–1159. [CrossRef]

- Starke, P., Walther F., Eifler D. New fatigue life calculation method for quenched and tempered steel SAE 4140. Mater Sci Eng A 2009, 523, 246–52. [CrossRef]

- Lin, YC., Chen MS., Zhong J. Microstructural evolution in 42CrMo steel during compression at elevated temperatures. Mater Lett 2008, 62, 2136–2139. [CrossRef]

- Arun S., Thakare AS., Butee SP., Kamble KR. Improvement in Mechanical Properties of 42CrMo4 Steel Through Novel Thermomechanical Processing Treatment. Metallography, Microstructure, and Analysis 2020, 9, 759–773. [CrossRef]

- Miokovic, T., Schulze V., Vohringer O., Lohe D. Prediction of phase transformations during laser surface hardening of AISI 4140 including the effects of inhomogeneous austenite formation. Mater Sci Eng A 2006, 435–436, 547–555. [CrossRef]

- Nikitin, I., Besel M. Correlation between residual stress and plastic strain amplitude during low cycle fatigue of mechanicallysurface treated austenitic stainless steel AISI 304 and ferritic–pearlitic steel SAE 1045. Mater Sci Eng A 2008, 491, 297–303. [CrossRef]

- Pop, M., Frunza D., Popa F., Neag A. Aspects Regarding the Hot Fracture Behavior of 42CrMo4 Alloy. Roumanian Journal of Phisycs 2017, 62, 1–13.

- Pop M., Neag A., Frunza D., Popa F., Thermomechanical study on 42CrMo4 steel formability. Acta Technica Napocensis, Applied Mathematics, Mechanics 2019, 62, 287–294.

- Lin, YC., Chen MS., Zhong J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput Mater Sci 2008, 42, 470–477. [CrossRef]

- Lin, YC., Chen MS., Zhong J. Prediction of 42CrMo steel flow stress at high temperature and strain rate. Mech Res Commun 2008, 35, 142–150. [CrossRef]

- Totik, Y., Sadeler R., Kaymaz I. Hot workability of AISI 4140 steel with hot torsion test. J Mech Behav Mater 2002, 13, 65–72.

- Lin, YC., Chen MS., Zhong J. Effect of temperature and strain rate on the compressive deformation behavior of 42CrMo steel. J Mater Process Technol 2008, 205, 308–315. [CrossRef]

- Lin, YC., Zhang J., Zhong J. Application of neural networks to predict the elevated temperature flow behavior of a low alloy steel. Comput Mater Sci. 2008, 43, 752–758. [CrossRef]

- Quan, GZ., Zhao L., Chen T., Wang Y., Mao YP., Lv WQ., Zhou J. Identification for the optimal working parameters of as-extruded 42CrMo high-strength steel from a large range of strain, strain rate and temperature. Mater Sci Eng A 2012, 538, 364–73. [CrossRef]

- Quan, GZ., Wang Y., Liu YY., Zhou J. Effect of Temperatures and Strain Rates on the Average Size of Grains Refined by Dynamic Recrystallization for as-extruded 42CrMo Steel. Mater. Res 2013, 16, 1092–1105. [CrossRef]

- Huang, YC., Lin YC., Deng J., Liu G., Chen MS. Hot tensile deformation behaviors and constitutive model of 42CrMo steel. Materials and Design 2014, 53, 349–356. [CrossRef]

- Quan, GZ., Li GS., Chen T., Wang YX., Zhang YW., Zhou J. Dynamic recrystallization kinetics of 42CrMo steel during compression at different temperatures and strain rates. Mater Sci Eng A 2011, 528, 4643–51. [CrossRef]

- Chen, MS., Lin YC., Ma XS. The kinetics of dynamic recrystallization of 42CrMo steel. Mater Sci Eng A 2012, 556, 260–6. [CrossRef]

- Yang, D., Chen W., Zhou R., Wang S., Ma Y., Zan X., Peng L. Microstructure evolution of dynamic recrystallizatin of 42CrMo steel during multi-stage forging by FEM. App Mech Mater 2012, 217–219, 415–418. [CrossRef]

- Lin YC., Chen MS., Zhong J. Study of Static Recrystallization Kinetics in a Low Alloy Steel. Comput. Mater. Sci. 2008, 44, 316–321. [CrossRef]

- Lin, YC., Chen MS., Zhong J. Study of Metadynamic Recrystallization Behaviors in a Low Alloy Steel. J. Mater. Process. Technol. 2009, 209, 2477–2482. [CrossRef]

- Lin, YC., Liu YX., Liu G., Chen MS., Huang YC., Prediction of Ductile Fracture Behaviors for 42CrMo Steel at Elevated Temperatures. JMEPEG 2015, 24, 221–228. [CrossRef]

- Li, YY., Zhao SD., Fan SQ., Zhong B. Plastic Properties and Constitutive Equations of 42CrMo Steel During Warm Forming Process. Mater. Sci. Technol 2014, 30, 645–652. [CrossRef]

- Huang YC., Lin YC., Deng J., Liu G., Chen MS. Hot tensile deformation behaviors and constitutive model of 42CrMo steel. Materials & Design 2014, 53, 349–356. [CrossRef]

- Lin YC., Chen XM. A crtitical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 2011, 32, 1733–1759. [CrossRef]

- Zhu Z., Lu Y., Xie Q., Li D., Gao N. Mechanical properties and dynamic constitutive model of 42CrMo steel. Materials and Design 2017, 119, 171–179. [CrossRef]

- Kim, SI., Lee Y., Byon SM. Study on constitutive relation of AISI4140 steel subject to large strain at elevated temperatures, J. Mater. Process. Technol. 2003, 140, 84–89. [CrossRef]

- Sheng ZQ., Shivpuri R. Modeling flow stress of magnesium alloys at elevated temperature. Mater. Sci. Eng. A 2006, 419, 202–208. [CrossRef]

- Lu Y., Zhu Z., Li D., Xie Q. Constitutive model of 42CrMo steel under a wide range of strain rates based on crystal plasticity theory. Materials Science & Engineering A 2017, 679, 215–222. [CrossRef]

- Kimm JS.,. Bergmann JA, Woste F., Pohl F., Wiederkehr P., Theisen W. Deformation behavior of 42CrMo4 over a wide range of temperatures and strain rates in Split-Hopkinson pressure bar tests. Materials Science & Engineering A 2021, 826. [CrossRef]

- Nurnberger F., Grydin O., Yu Z., Schaper M. Microstructural behavior of tempering Steels during precision forging and quenching from hot-forming temperatures. Metall. Min. Ind. 2011, 3, 79–86.

- Nurnberger, F., Grydin O., Schaper M, Bach FW., Koczurklewicz B., Milenin A. Microstructure transformations in tempering steels during continuous cooling from hot forging temperatures. Steel Res. Int. 2010, 81, 224–233. [CrossRef]

- Momeni, A., Dehghani K. Prediction of dynamic recrystallization kinetics and grain size for 410 martensitic stainless steel during hot deformation. Met Mater Int 2010, 16, 843–9. [CrossRef]

- Mirzaee, M., Keshmiri H., Ebrahimi GR., Momeni A. Dynamic recrystallization and precipitation in low carbon low alloy steel 26NiCrMoV 14–5. Mater Sci Eng A 2012, 551, 25–31. [CrossRef]

- Arniella V., Zafra A., Álvarez G., Belzunce J., Rodríguez C. Comparative study of embrittlement of quenched and tempered steels in hydrogen environments. International Journal of Hydrogen Energy 2022, 47, 17056–17068. [CrossRef]

- Andreatta, F., Zanocco M., Virgilio S., Machetta P., Silvonen A., Lanzutti A., Fedrizzi L., Localized attack at inclusions in 42CrMo4 QT steel. Electrochimica Acta 2023, 462. [CrossRef]

- Peral, LB., Díaz A., Arniella V., Belzunce J., Alegre JM., Cuesta II., Influence of hydrogen on the hydraulic fracture behavior of a 42CrMo4 steel welds: Effect of the prior austenite grain size. Engineering Fracture Mechanics 2023, 289. [CrossRef]

- Polášek, M., Krbaťa M., Eckert M., Mikuš P., Cíger R., Contact Fatigue Resistance of Gun Barrel Steels. Procedia Structural Integrity 2023, 43, 306–311. [CrossRef]

- Dieter G., Kuhn H., Semiatin S. Handbook of workability and process design, ASM International 2003, Materials Park. OH. 17-19, pp. 81.

- Edward, GH. and Ashby MF. Intergranular Fracture During Powder-Law Creep. Acta Metall. 1979, 27, 1505–1518. [Google Scholar] [CrossRef]

- Chokshi, AH. The Development of Cavity Growth Maps for Superplastic Materials. J. Mater. Sci. 1986, 21, 2073–2082. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|

| 0.38 – 0.45 | Max 0.4 | 0.6 – 0.9 | Max 0.025 | Max 0.035 | 0.9 – 1.2 | 0.15 – 0.3 |

| Crt No. | Material | l0 [mm] |

d0 [mm] |

l1 [mm] |

d1 [mm] |

dr [mm] |

εl [%] |

[%] |

V [m/s] |

[s−1] |

T [°C] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 42CrMo4 | 36 | 8 | 59.6 | 5.1 | 6.3 | 65.56 | 36.3 | 0.066 | 0.001833 | 1000 |

| 2 | 42CrMo4 | 36 | 8 | 57.0 | 5.0 | 6.5 | 58.33 | 37.5 | 0.066 | 0.001833 | 950 |

| 3 | 42CrMo4 | 36 | 8 | 56.7 | 4.3 | 6.5 | 57.50 | 46.3 | 0.066 | 0.001833 | 900 |

| 4 | 42CrMo4 | 36 | 8 | 56.3 | 3.9 | 6.3 | 56.39 | 51.3 | 0.066 | 0.001833 | 850 |

| 5 | 42CrMo4 | 36 | 8 | 56.0 | 2.9 | 6.8 | 55.56 | 63.8 | 0.066 | 0.001833 | 800 |

| 6 | 42CrMo4 | 36 | 8 | 49.9 | 3.4 | 5.5 | 38.61 | 57.5 | 0.066 | 0.001833 | 750 |

| 7 | 42CrMo4 | 36 | 8 | 42.2 | 2.3 | 7.5 | 17.22 | 71.3 | 0.066 | 0.001833 | 700 |

| 8 | 42CrMo4 | 36 | 8 | 61.2 | 3.9 | 6.7 | 70.00 | 51.3 | 0.462 | 0.012833 | 1000 |

| 9 | 42CrMo4 | 36 | 8 | 53.7 | 3.0 | 6.1 | 49.17 | 62.5 | 0.462 | 0.012833 | 900 |

| 10 | 42CrMo4 | 36 | 8 | 50.0 | 2.8 | 5.8 | 38.89 | 65.0 | 0.462 | 0.012833 | 800 |

| 11 | 42CrMo4 | 36 | 8 | 48.0 | 2.6 | 5.6 | 33.33 | 67.5 | 0.462 | 0.012833 | 700 |

| 12 | 42CrMo4 | 36 | 8 | 63.5 | 5.5 | 6.4 | 76.39 | 31.3 | 3.230 | 0.089722 | 1000 |

| 13 | 42CrMo4 | 36 | 8 | 63.1 | 3.0 | 6.0 | 75.28 | 62.5 | 3.230 | 0.089722 | 900 |

| 14 | 42CrMo4 | 36 | 8 | 59.7 | 2.6 | 6.1 | 65.83 | 67.5 | 3.230 | 0.089722 | 800 |

| 15 | 42CrMo4 | 36 | 8 | 43.5 | 2.2 | 7.5 | 20.83 | 72.5 | 3.230 | 0.089722 | 700 |

| Crt. No. | Material | T [°C] |

d0 [mm] |

h0[mm] | V [m/s] |

dmin [mm] |

dmax [mm] |

h1 [mm] |

εh [%] |

εd [%] |

[−] |

[s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 800 | 18 | 30 | 0.003 | 18.35 | 27 | 17.1 | 43 | 5 | 1.47139 | 0.1 |

| 2. | 42CrMo4 | 800 | 18 | 30 | 0.002 | 18.2 | 25.4 | 19.2 | 36 | 41 | 1.395604 | 0.066 |

| 3. | 42CrMo4 | 800 | 18 | 30 | 0.001 | 18.25 | 23.1 | 23.2 | 22 | 28 | 1.265753 | 0.033 |

| Crt. No. | Material | T [°C] |

d0 [mm] |

h0 [mm] |

V [m/s] |

dmin [mm] |

dmax [mm] |

h1 [mm] |

εh [%] |

εd [%] |

[–] |

[s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 900 | 18 | 30 | 0.003 | 19.5 | 27.7 | 15.7 | 47 | 53 | 1.420 | 0.1 |

| 2. | 42CrMo4 | 900 | 18 | 30 | 0.002 | 20.6 | 27.8 | 18.1 | 39 | 54 | 1.349 | 0.066 |

| 3. | 42CrMo4 | 900 | 18 | 30 | 0.001 | 23.3 | 30.2 | 21.9 | 27 | 67 | 1.296 | 0.033 |

| Crt. No. | Material | T [°C] |

d0 [mm] |

h0 [mm] |

V [m/s] |

dmin [mm] |

dmax [mm] |

h1 [mm] |

εh [%] |

εd [%] |

[–] |

[s−1] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | 42CrMo4 | 1000 | 18 | 30 | 0.003 | 20.8 | 30 | 13.1 | 56 | 66 | 1.43269 | 0.1 |

| 2. | 42CrMo4 | 1000 | 18 | 30 | 0.002 | 18.4 | 26.4 | 18.3 | 39 | 46 | 1.43478 | 0.066 |

| 3. | 42CrMo4 | 1000 | 18 | 30 | 0.001 | 18.45 | 26.1 | 21.1 | 29 | 45 | 1.41463 | 0.033 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).