Submitted:

29 August 2023

Posted:

31 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

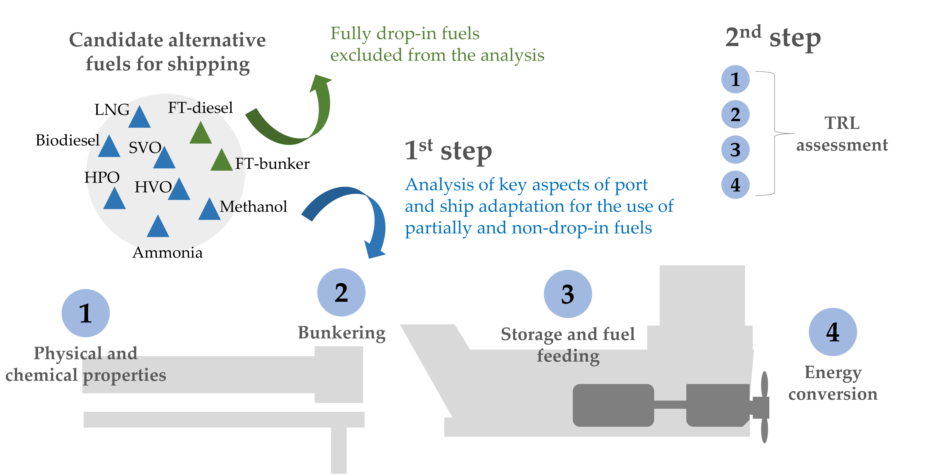

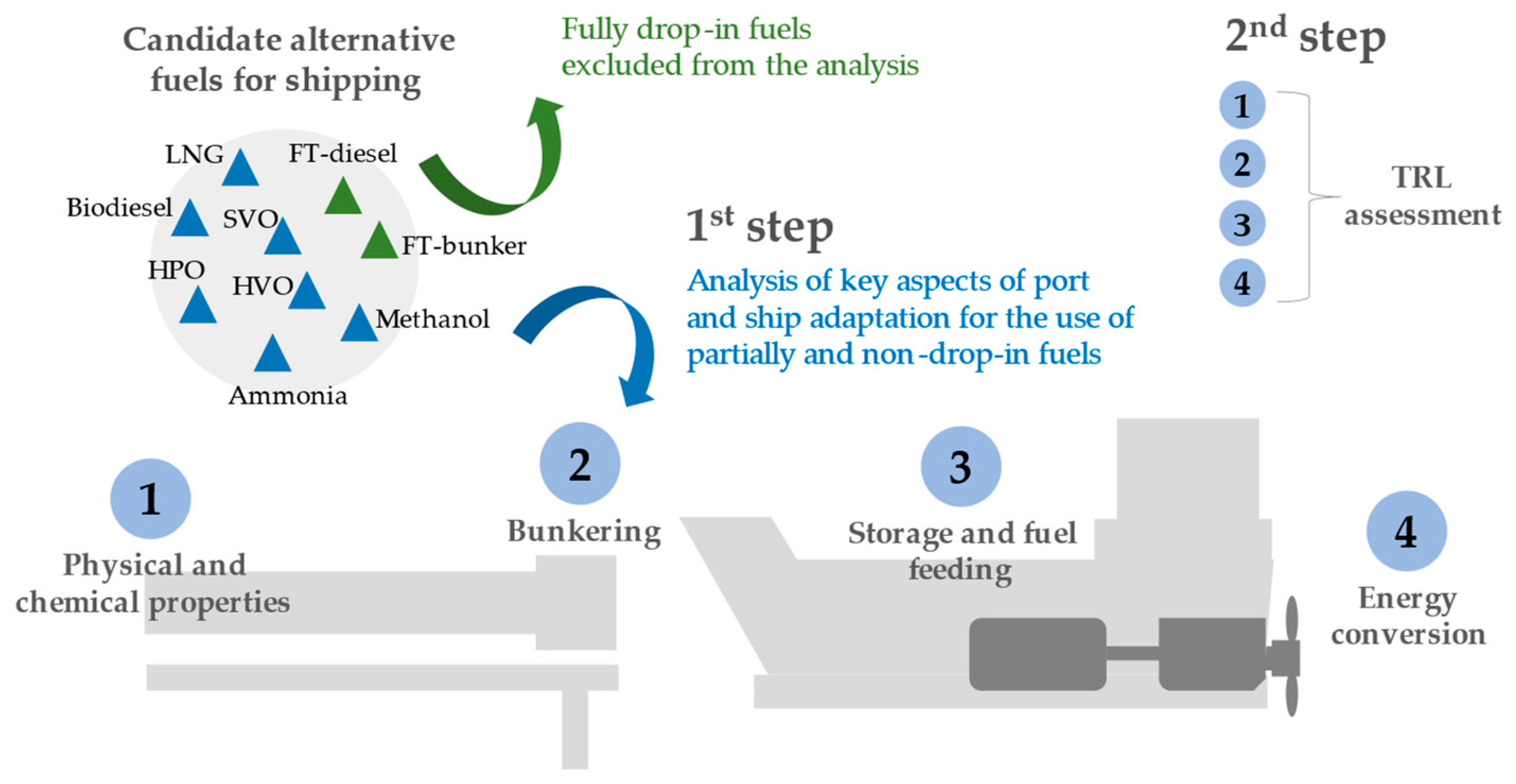

2. Materials and Methods

3. Results

3.1. Physical and Chemical Properties

3.2. Bunkering

3.3. Storage and Fuel Feeding

3.4. Energy Converters

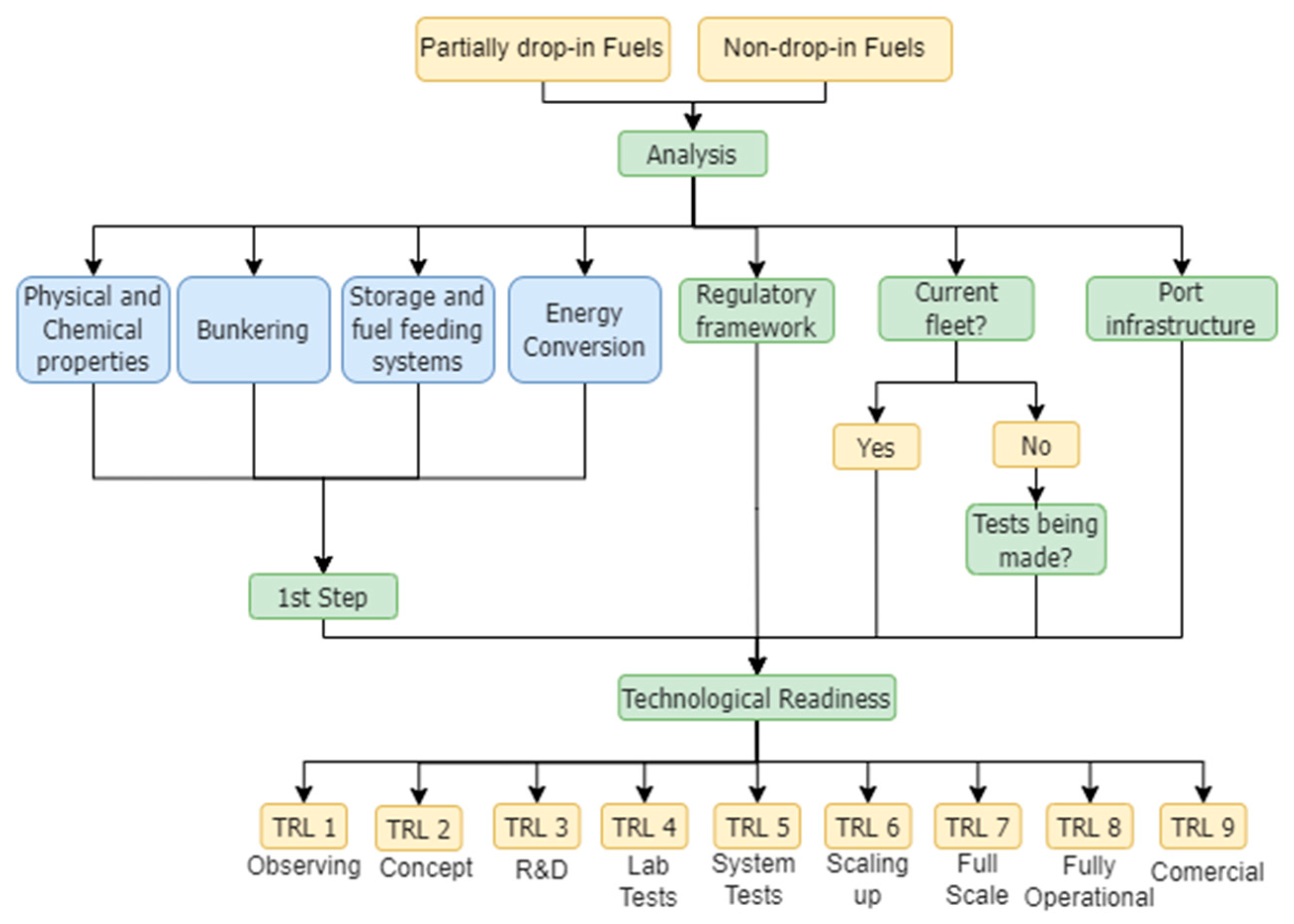

3.5. Technology Readiness

3.6. Summary of results

4. Case Study

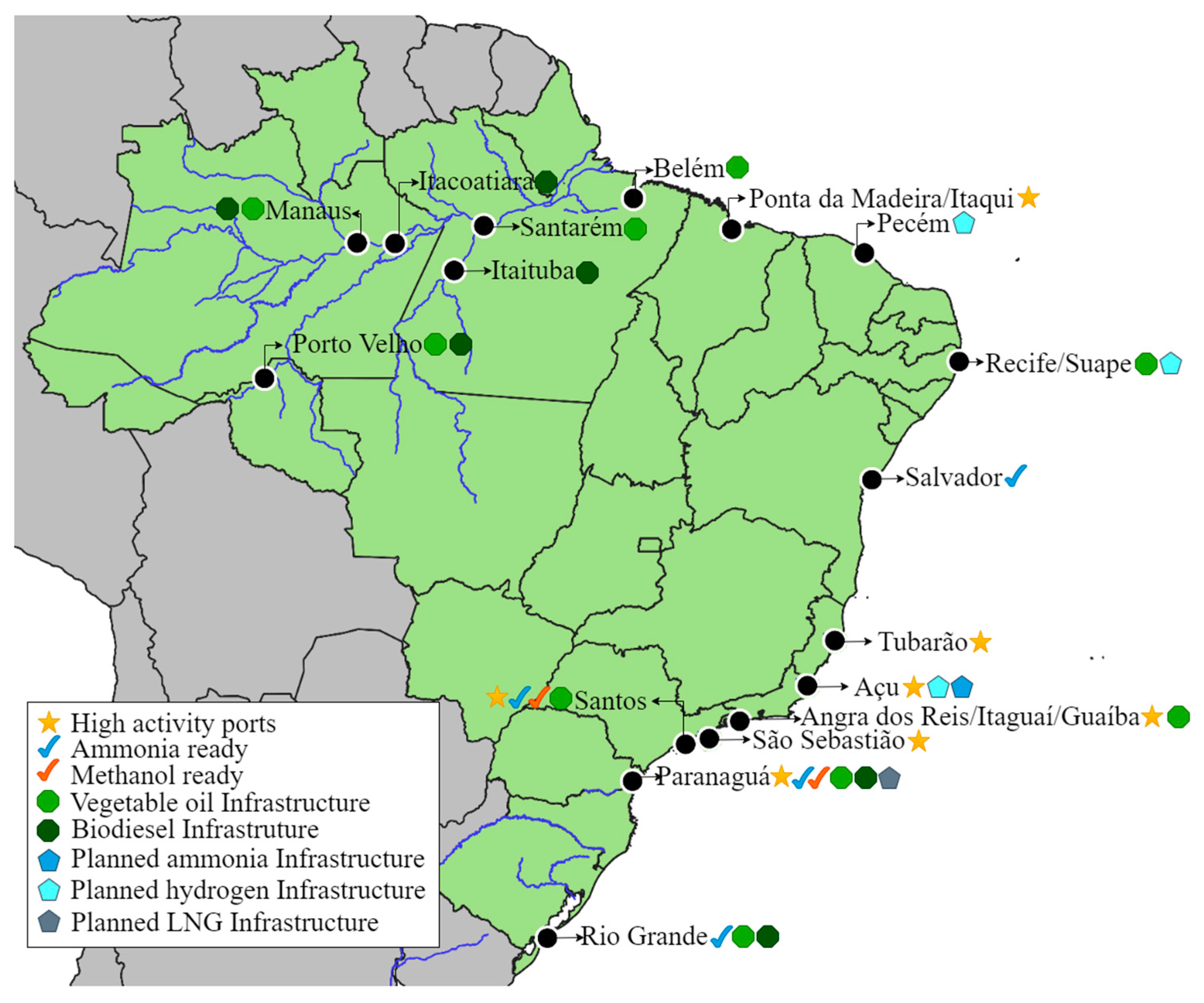

4.1. Main Ports profile and future hubs

4.2. Fleet and cargo profile: challenges and progress in conversion to alternative fuels use

4.3. Thermal Stability of fuels in the main routes

4.4. Fleet profile: loss of cargo space

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Longarela-Ares, Á.; Calvo-Silvosa, A.; Pérez-López, J.B. The Influence of Economic Barriers and Drivers on Energy Efficiency Investments in Maritime Shipping, from the Perspective of the Principal-Agent Problem. Sustain. 2020, 12, 1–42. [Google Scholar] [CrossRef]

- United Nations Chapter 17: Shipping. 2016.

- Faber, J.; Hanayama, S.; Zhang, S.; Pereda, P.; Comer, B.; Hauerhof, E.; Loeff, W.S. van der; Smith, T.; Zhang, Y.; Kosaka, H.; et al. Fourth IMO GHG Study 2020. 2020. [Google Scholar]

- Smith, T.W.P.; Jalkanen, J.P.; Anderson, B.A.; Corbett, J.J.; Faber, J.; Hanayama, S.; O’Keeffe, E.; Parker, S.; Johansson, L.; Aldous, L.; et al. Third IMO Greenhouse Gas Study 2014. 2014. [Google Scholar]

- Nepomuceno de Oliveira, M.A.; Szklo, A.; Castelo Branco, D.A. Implementation of Maritime Transport Mitigation Measures According to Their Marginal Abatement Costs and Their Mitigation Potentials. Energy Policy 2022, 160, 112699. [Google Scholar] [CrossRef]

- Lagouvardou, S.; Psaraftis, H.N.; Zis, T. A Literature Survey on Market-Based Measures for the Decarbonization of Shipping. Sustain. 2020, 12. [Google Scholar] [CrossRef]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-Art Technologies, Measures, and Potential for Reducing GHG Emissions from Shipping – A Review. Transp. Res. Part D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Maritime Knowledge Centre Final Report - Framework CO2 Reduction in Shipping. 2017.

- Serra, P.; Fancello, G. Towards the IMO’s GHG Goals: A Critical Overview of the Perspectives and Challenges of the Main Options for Decarbonizing International Shipping. Sustain. 2020, 12. [Google Scholar] [CrossRef]

- IMO 2023 IMO Strategy on Reduction of GHG Emissions from Ships. 2023.

- IMO Adoption of the Initial IMO Strategy on Reduction of GHG Emissions from Ships and Existing IMO Activity Related to Reducing GHG Emissions in the Shipping Sector. 2018.

- DNV GL Maritime Forecast To 2050. Energy Transit. Outlook 2019 2019, 118.

- IPCC Climate Change 2014 - Synthesys Report. 2015.

- Bengtsson, S.; Andersson, K.; Fridell, E. A Comparative Life Cycle Assessment of Marine Fuels: Liquefied Natural Gas and Three Other Fossil Fuels. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 97–110. [Google Scholar] [CrossRef]

- IMO MEPC.1/Circ.795/Rev.6: Unified Interpretations to MARPOL Annex VI. 2022.

- Mærsk Mc-Kinney Møller Center Using Bio-Diesel Onboard Vessels: An Overview of Fuel Handling and Emission Management Considerations. 2023.

- ABS Biofuels as Marine Fuel. 2021.

- Florentinus, A.; Hamelinck, C.; Bos, A. van den; Winkel, R.; Maarten, C. Potential of Biofuels for Shipping, 2012.

- IEA Biofuels for the Marine Shipping Sector. 2017.

- Winnes, H.; Fridell, E.; Hansson, J. Biofuels for Low Carbon Shipping. 2019.

- Laursen, R.; Barcarolo, D.; Patel, H.; Dowling, M.; Penfold, M.; Faber, J.; Király, J.; van der Ven, R.; Pang, E.; van Grinsven, A. Update on Potential of Biofuels in Shipping; Lisbon. 2022. [Google Scholar]

- ABS Ammonia As Marine Fuel. NH3 Fuel Conf. 2020.

- ABS Hydrogen as Marine Fuel. Sustain. Whitepaper 2021.

- Ash, N.; Scarbrough, T. Sailing on Solar. Could Green Ammonia Decarbonise International Shipping? 2019. [Google Scholar]

- Earl, T.; Ambel, C.C.; Hemmings, B.; Gilliam, L.; Abbasov, F.; Officer, S. Roadmap to Decarbonising European Shipping. Transp. Environ. 2018, 22. [Google Scholar]

- Hansson, J.; Brynolf, S.; Fridell, E.; Lehtveer, M. The Potential Role of Ammonia as Marine Fuel-Based on Energy Systems Modeling and Multi-Criteria Decision Analysis. Sustain. 2020, 12, 10–14. [Google Scholar] [CrossRef]

- ABS LNG as Marine Fuel. 2021.

- Boulougouris, E.K.; Chrysinas, L.E. LNG Fueled Vessels Design Training. 2015.

- Ge, J.; Wang, X. Techno-Economic Study of LNG Diesel Power (Dual Fuel) Ship. WMU J. Marit. Aff. 2017, 16, 233–245. [Google Scholar] [CrossRef]

- Ellis, J.; Tanneberger, K. Study on the Use of Ethyl and Methyl Alcohol as Alternative Fuels in Shipping, 2015.

- ABS Methanol as Marine Fuel. 2021; 1.

- MAN Diesel & Turbo Using Methanol Fuel in the MAN B&W ME-LGI Series. 2014, 1–16.

- Rachow, M.; Loest, S.; Bramastha, A.D. Analysis of the Requirement for the Ships Using Methanol as Fuel. Int. J. Mar. Eng. Innov. Res. 2018, 3. [Google Scholar] [CrossRef]

- Deniz, C.; Zincir, B. Environmental and Economical Assessment of Alternative Marine Fuels. J. Clean. Prod. 2016, 113, 438–449. [Google Scholar] [CrossRef]

- ANTAQ Anuário ANTAQ. Available online: http://web.antaq.gov.br/ANUARIO/ (accessed on 24 June 2021).

- Ministério da Indústria, C.E. e S. Exportação e Importação Geral Available online:. Available online: http://comexstat.mdic.gov.br/pt/geral (accessed on 10 May 2023).

- Tagomori, I.S.; Rochedo, P.R.R.; Szklo, A. Techno-Economic and Georeferenced Analysis of Forestry Residues-Based Fischer-Tropsch Diesel with Carbon Capture in Brazil. Biomass and Bioenergy 2019, 123, 134–148. [Google Scholar] [CrossRef]

- Carvalho, F.; Portugal-pereira, J.; Junginger, M.; Szklo, A. Biofuels for Maritime Transportation: A Spatial, Techno-economic, and Logistic Analysis in Brazil, Europe, South Africa, and the Usa. Energies 2021, 14. [Google Scholar] [CrossRef]

- Carvalho, F.; Müller-Casseres, E.; Poggio, M.; Nogueira, T.; Fonte, C.; Wei, H.K.; Portugal-Pereira, J.; Rochedo, P.R.R.; Szklo, A.; Schaeffer, R. Prospects for Carbon-Neutral Maritime Fuels Production in Brazil. J. Clean. Prod. 2021, 326. [Google Scholar] [CrossRef]

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the Transport Sector: A Review of Production Costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- He, Z.; Cui, M.; Qian, Q.; Zhang, J.; Liu, H.; Han, B. Synthesis of Liquid Fuel via Direct Hydrogenation of CO2. Proc. Natl. Acad. Sci. U. S. A. 2019, 116, 12654–12659. [Google Scholar] [CrossRef]

- Carvalho, F.; Müller-Casseres, E.; Portugal-Pereira, J.; Junginger, M.; Szklo, A. Lignocellulosic Biofuels Use in the International Shipping: The Case of Soybean Trade from Brazil and the U.S. to China. Clean. Prod. Lett. 2023, 4, 100028. [Google Scholar] [CrossRef]

- DNV GL Comparison of Alternative Marine Fuels. 2019.

- Müller-Casseres, E.; Carvalho, F.; Nogueira, T.; Fonte, C.; Império, M.; Poggio, M.; Wei, H.K.; Portugal-Pereira, J.; Rochedo, P.R.R.; Szklo, A.; et al. Production of Alternative Marine Fuels in Brazil: An Integrated Assessment Perspective. Energy 2021, 219. [Google Scholar] [CrossRef]

- US Department of Energy Technology Readiness Assessment Guide. SpringerReference 2011, 73.

- Mestemaker, I.B.T.W.; Van Biert, L.; Visser, I.K. The Maritime Energy Transition from a Shipbuilder’s Perspective. 2020. [CrossRef]

- Gray, N.; McDonagh, S.; O’Shea, R.; Smyth, B.; Murphy, J.D. Decarbonising Ships, Planes and Trucks: An Analysis of Suitable Low-Carbon Fuels for the Maritime, Aviation and Haulage Sectors. Adv. Appl. Energy 2021, 1, 100008. [Google Scholar] [CrossRef]

- Russo, D.; Dassisti, M.; Lawlor, V.; Olabi, A.G. State of the Art of Biofuels from Pure Plant Oil. Renew. Sustain. Energy Rev. 2012, 16, 4056–4070. [Google Scholar] [CrossRef]

- Jiménez Espadafor, F.; Torres García, M.; Becerra Villanueva, J.; Moreno Gutiérrez, J. The Viability of Pure Vegetable Oil as an Alternative Fuel for Large Ships. Transp. Res. Part D Transp. Environ. 2009, 14, 461–469. [Google Scholar] [CrossRef]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Biofuel as an Alternative Shipping Fuel: Technological, Environmental and Economic Assessment. Sustain. Energy Fuels 2019, 3, 899–909. [Google Scholar] [CrossRef]

- British Standard ISO / FDIS 8217 Petroleum Products - Fuels (Class F) - Specifications of Marine Fuels; 2012; p. 42;

- Taylor, D.A. Introduction to Marine Engineering; Elsevier, Ed.; Second Edi.; Wiltshire. 1996.

- Tiwari, A. Converting a Diesel Engine to Dual-Fuel Engine Using Natural Gas. Int. J. Energy Sci. Eng. 2015, 1, 163–169. [Google Scholar] [CrossRef]

- Bhavani, K.; Murugesan, S. Diesel to Dual Fuel Conversion Process Development. Int. J. Eng. Technol. 2018, 7, 306–310. [Google Scholar] [CrossRef]

- De-Troya, J.J.; Álvarez, C.; Fernández-Garrido, C.; Carral, L. Analysing the Possibilities of Using Fuel Cells in Ships. Int. J. Hydrogen Energy 2016, 41, 2853–2866. [Google Scholar] [CrossRef]

- Burel, F.; Taccani, R.; Zuliani, N. Improving Sustainability of Maritime Transport through Utilization of Liquefied Natural Gas (LNG) for Propulsion. Energy 2013, 57, 412–420. [Google Scholar] [CrossRef]

- Ushakov, S.; Lefebvre, N. Assessment of Hydrotreated Vegetable Oil (HVO) Applicability as an Alternative Marine Fuel Based on Its Performance and Emissions Characteristics. SAE Int. J. Fuels Lubr. 2019, 12, 4–12. [Google Scholar] [CrossRef]

- Mendes, F.L.; da Silva, V.T.; Pacheco, M.E.; Toniolo, F.S.; Henriques, C.A. Bio-Oil Hydrotreating Using Nickel Phosphides Supported on Carbon-Covered Alumina. Fuel 2019, 241, 686–694. [Google Scholar] [CrossRef]

- Ammar, N.R. An Environmental and Economic Analysis of Methanol Fuel for a Cellular Container Ship. Transp. Res. Part D Transp. Environ. 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Kim, K.; Roh, G.; Kim, W.; Chun, K. A Preliminary Study on an Alternative Ship Propulsion System Fueled by Ammonia: Environmental and Economic Assessments. J. Mar. Sci. Eng. 2020, 8. [Google Scholar] [CrossRef]

- Veses, A.; Martínez, J.D.; Callén, M.S.; Murillo, R.; García, T. Application of Upgraded Drop-in Fuel Obtained from Biomass Pyrolysis in a Spark Ignition Engine. Energies 2020, 13, 1–15. [Google Scholar] [CrossRef]

- PETROBRAS Combustíveis Marítimos. 2021.

- Kass, M.; Abdullah, Z.; Biddy, M.; Drennan, C.; Hawkins, T.; Jones, S.; Holladay, J.; Longman, D.; Newes, E.; Theiss, T.; et al. Understanding the Opportunities of Biofuels for Marine Shipping. 2018. [Google Scholar]

- Bart, J.C.J.; Palmeri, N.; Cavallaro, S. Vegetable Oil Formulations for Utilisation as Biofuels. Biodiesel Sci. Technol. 2010, 114–129. [Google Scholar] [CrossRef]

- Nguyen, T.A. Sustainability Assessment of Inedible Vegetable Oil-Based Biodiesel for Cruise Ship Operation in Ha Long Bay, Vietnam, 2017.

- Blin, J.; Brunschwig, C.; Chapuis, A.; Changotade, O.; Sidibe, S.S.; Noumi, E.S.; Girard, P. Characteristics of Vegetable Oils for Use as Fuel in Stationary Diesel Engines - Towards Specifications for a Standard in West Africa. Renew. Sustain. Energy Rev. 2013, 22, 580–597. [Google Scholar] [CrossRef]

- Dan-Bunkering CCAI Calculator. Available online: https://dan-bunkering.com/Pages/Solutions/Tools-and-specs/Tool-ccai.aspx (accessed on 15 June 2020).

- Whitehouse, S.; Poulsen, J. Life Cycle GHG Emission Study on the Use of LNG as Marine Fuel. Report 2019, 158. [Google Scholar]

- Boulougouris, E.K.; Chrysinas, L.E. LNG Fueled Vessels Design Training; Glasgow. 2015. [Google Scholar]

- Torres-García, M.; García-Martín, J.F.; Jiménez-Espadafor Aguilar, F.J.; Barbin, D.F.; Álvarez-Mateos, P. Vegetable Oils as Renewable Fuels for Power Plants Based on Low and Medium Speed Diesel Engines. J. Energy Inst. 2019. [Google Scholar] [CrossRef]

- Lin, C.Y. Strategies for Promoting Biodiesel Use in Marine Vessels. Mar. Policy 2013, 40, 84–90. [Google Scholar] [CrossRef]

- Engman, M.A.; Hartikka, T.; Honkanen, M.; Kiiski, U.; Kuronen, M.; Mik-, S.; Oyj, N.O. Hydrotreated Vegetable Oil (HVO) - Premium Renewable Biofuel for Diesel Engines; Espoo. 2014. [Google Scholar]

- Chong, K.J.; Bridgwater, A. V. Fast Pyrolysis Oil Fuel Blend for Marine Vessels. Environ. Prog. Sustain. Energy 2014, 36, 677–684. [Google Scholar] [CrossRef]

- Veses, A.; López, J.M.; García, T.; Callén, M.S. Prediction of Elemental Composition, Water Content and Heating Value of Upgraded Biofuel from the Catalytic Cracking of Pyrolysis Bio-Oil Vapors by Infrared Spectroscopy and Partial Least Square Regression Models. J. Anal. Appl. Pyrolysis 2018, 132, 102–110. [Google Scholar] [CrossRef]

- Mohd Noor, C.W.; Noor, M.M.; Mamat, R. Biodiesel as Alternative Fuel for Marine Diesel Engine Applications: A Review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Paulauskiene, T.; Bucas, M.; Laukinaite, A. Alternative Fuels for Marine Applications: Biomethanol-Biodiesel-Diesel Blends. Fuel 2019, 248, 161–167. [Google Scholar] [CrossRef]

- Huang, Y. Conversion of a Pilot Boat to Operation on Methanol, CHALMERS UNIVERSITY OF TECHNOLOGY, 2015.

- Hansson, J.; Fridell, E.; Brynolf, S. On the Potential of Ammonia as Fuel for Shipping – A Synthesis of Knowledge. 2019.

- Lewis, J. Fuels Without Carbon: Prospects and the Pathway Forward for Zero-Carbon Hydrogen and Ammonia Fuel. 2018.

- Sheriff, A.M.; Tall, A. Assessment of Ammonia Ignition as a Maritime Fuel, Using Engine Experiments and Chemical Kinetic Simulations, World Maritime University, 2019.

- ABS Low Carbon Shipping. 2019.

- Svanberg, M.; Ellis, J.; Lundgren, J.; Landälv, I. Renewable Methanol as a Fuel for the Shipping Industry. Renew. Sustain. Energy Rev. 2018, 94, 1217–1228. [Google Scholar] [CrossRef]

- IMO Studies on the Feasability and Use of LNG as a Fuel for Shipping. 2016.

- American Bureau of Shipping LNG Bunkering : Technical and Operational Advisory; 2014; Vol. Vol. 01.

- Florentinus, A.; Hamelinck, C.; Bos, A. van den; Winkel, R.; Maarten, C. Potential of Biofuels for Shipping. 2012, 31, 1–114.

- FAO Code of Practice for the Storage and Transport of Edible Fats and Oils in Bulk. 2015.

- Neste Neste Renewable Diesel Handbook; Espoo. 2020.

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Fuel Oil Quality and Combustion of Fast Pyrolysis Bio-Oils. VTT Publ. 2013, 79. [Google Scholar] [CrossRef]

- IMO MSC.1-Circ.1621: Interim Guidelines for the Safety of Ships Using Methyl/Ethyl Alcohol as Fuel; 2020; Vol. 44;

- Duong, P.A.; Ryu, B.R.; Song, M.K.; Nguyen, H. Van; Nam, D.; Kang, H. Safety Assessment of the Ammonia Bunkering Process in the Maritime Sector: A Review. Energies 2023, 16. [Google Scholar] [CrossRef]

- Mokhatab, S.; Mak, J.Y.; Valappil, J. V.; Wood, D.A. Handbook of Liquefied Natural Gas; 2013; ISBN 9780124046450.

- Mærsk Mc-Kinney Møller Center Preparing Container Vessels for Conversion to Green Fuels. 2022.

- Mathew, B.C.; Thangaraja, J. Material Compatibility of Fatty Acid Methyl Esters on Fuel Supply System of CI Engines. Mater. Today Proc. 2018, 5, 11678–11685. [Google Scholar] [CrossRef]

- American Bureau of Shipping Propulsion and Auxiliary Systems for Gas Fuelled Ships; 2011; Vol. 2011;

- DNV GL Part 6 Additional Class Notations Chapter 2 Propulsion, Power Generation and Auxiliary Systems. Rules Classif. Ships 2020.

- Man Energy Solutions Engineering the Future Future in the: Two-Stroke Green-Ammonia Engine. 2019.

- Alfa Laval; Hafnia; Haldor Topsoe; Vestas; Siemens Gamesa Ammonfuel-an Industrial View of Ammonia as a Marine Fuel. 2020.

- Dincer, I.; Siddiqui, O. Ammonia Fuel Cells; Elsevier: Amsterdam, 2020; Vol. 1, ISBN 978-0-12-822825-8. [Google Scholar]

- Erdemir, D.; Dincer, I. A Perspective on the Use of Ammonia as a Clean Fuel: Challenges and Solutions. Int. J. Energy Res. 2021, 45, 4827–4834. [Google Scholar] [CrossRef]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.D.K.A.; Okafor, E.C. Science and Technology of Ammonia Combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- Wolfram, P.; Kyle, P.; Zhang, X.; Gkantonas, S.; Smith, S. Using Ammonia as a Shipping Fuel Could Disturb the Nitrogen Cycle. Nat. Energy 2022, 7, 1112–1114. [Google Scholar] [CrossRef]

- El-Gohary, M.M. The Future of Natural Gas as a Fuel in Marine Gas Turbine for LNG Carriers. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2012, 226, 371–377. [Google Scholar] [CrossRef]

- DNV GL Alternative Fuels Insight Available online: https://afi.dnvgl.com/.

- World Fuel Services ISO 8217:2017 Tables 1 & 2 Fuel Standard for Marine Distillate Fuels and for Marine Residual Fuels. 2019, 0–1.

- Mohd Noor, C.W.; Noor, M.M.; Mamat, R. Biodiesel as Alternative Fuel for Marine Diesel Engine Applications: A Review. Renew. Sustain. Energy Rev. 2018, 94, 127–142. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. Exhaust Emissions and Engine Performance Analysis of a Marine Diesel Engine Fuelledwith Parinari Polyandra Biodiesel–Diesel Blends. Energy Reports 2020, 6, 2999–3007. [Google Scholar] [CrossRef]

- Van Uy, D.; The Nam, T. Fuel Continuous Mixer - an Approach Solution to Use Straight Vegetable Oil for Marine Diesel Engines. TransNav, Int. J. Mar. Navig. Saf. Sea Transp. 2018, 12, 151–157. [Google Scholar] [CrossRef]

- No, S.Y. Application of Straight Vegetable Oil from Triglyceride Based Biomass to IC Engines – A Review. Renew. Sustain. Energy Rev. 2017, 69, 80–97. [Google Scholar] [CrossRef]

- No, S.Y. Application of Hydrotreated Vegetable Oil from Triglyceride Based Biomass to CI Engines - A Review. Fuel 2014, 115, 88–96. [Google Scholar] [CrossRef]

- BNDES Portos. Available online: https://hubdeprojetos.bndes.gov.br/pt/setores/Portos#1 (accessed on 22 June 2021).

- MME Programa Combustível Do Futuro. Available online: https://www.gov.br/mme/pt-br/programa-combustivel-do-futuro (accessed on 5 July 2023).

- Rede Brasil Pacto Global Da ONU No Brasil Lança GT de Negócios Oceânicos Para Impulsionar a Descarbonização de Portos e Transportes Marítimos. Available online: https://www.pactoglobal.org.br/noticia/676/pacto-global-da-onu-no-brasil-lanca-gt-de-negocios-oceanicos-para-impulsionar-a-descarbonizacao-de-portos-e-transportes-maritimos (accessed on 30 July 2023).

- Reis, R.G. Nimofast Signed a Partnership with Kanfer Shipping to Sell and Deliver LNG via Small-Scale LNG. Available online: https://www.nimofast.com/post/nimofast-signed-a-partnership-with-kanfer-shipping-to-sell-and-deliver-lng-via-small-scale-lng (accessed on 10 January 2023).

- Portos do Paraná Relatório de 2021: Sustentabilidade. 2021.

- Pecém Hub de Hidrogênio Verde No Complexo de Pecém. Available online: https://www.complexodopecem.com.br/hubh2v/), (accessed on 20 August 2023).

- Smith, T.; Krantz, R.; Mouftier, L.; Christiansen, E.S. Insight Briefing Series: Hydrogen as a Cargo. 2021. [Google Scholar]

- Porto do Açu Relatório de Sustentabilidade 2021. 2021.

- Engie Porto de Suape Quer Construir Planta de Hidrogênio Verde Estimada Em US$ 3,5 Bi. Available online: https://www.alemdaenergia.engie.com.br/porto-de-suape-quer-construir-planta-de-hidrogenio-verde-estimada-em-us-35-bi/ (accessed on 20 August 2023).

- Carlton, J. Ship Types, Duties, and General Characteristics. Encycl. Marit. Offshore Eng. 2018, 1–20. [Google Scholar] [CrossRef]

- UDOP Bunker One Testará Biodiesel Em Embarcações No Brasil Em 2022. Available online: https://www.udop.com.br/noticia/2021/12/21/bunker-one-testara-biodiesel-em-embarcacoes-no-brasil-em-2022.html (accessed on 10 March 2023).

- Petrobras Navio Da Transpetro Recebe Primeiro Abastecimento de Bunker Com Conteúdo Renovável. Available online: https://transpetro.com.br/transpetro-institucional/noticias/navio-da-transpetro-recebe-primeiro-abastecimento-de-bunker-com-conteudo-renovavel.htm (accessed on 11 March 2022).

- epbr Petrobras Testa Combustível Marítimo Com 24% de Biodiesel. Available online: https://epbr.com.br/petrobras-testa-combustivel-maritimo-com-24-de-biodiesel/ (accessed on 15 July 2023).

- Petrobras Vamos Ampliar Capacidade de Produção de Diesel Com Conteúdo Renovável Ainda Em 2023. Available online: https://petrobras.com.br/fatos-e-dados/vamos-ampliar-capacidade-de-producao-de-diesel-com-conteudo-renovavel-ainda-em-2023.htm (accessed on 20 July 2023).

- Norwegian Government The Government’s Action Plan for Green Shipping. 2019.

- NASA NASA Data Access Viewer. Available online: https://power.larc.nasa.gov/data-access-viewer/ (accessed on 8 August 2023).

- Goulielmos, A.M. The “Kondratieff Cycles” in Shipping Economy since 1741 and till 2016. Mod. Econ. 2017, 08, 308–332. [Google Scholar] [CrossRef]

- VALE Terminal Marítimo Ponta Da Madeira Completa 35 Anos Com Novo Patamar de Embarque. Available online: https://www.vale.com/pt/w/terminal-marítimo-ponta-da-madeira-completa-35-anos-com-novo-patamar-de-embarque (accessed on 5 August 2023).

- Bilgili, L. A Systematic Review on the Acceptance of Alternative Marine Fuels. Renew. Sustain. Energy Rev. 2023, 182, 113367. [Google Scholar] [CrossRef]

- Lindstad, E.; Polić, D.; Rialland, A.; Sandaas, I.; Stokke, T. Decarbonizing Bulk Shipping Combining Ship Design and Alternative Power. Ocean Eng. 2022, 266. [Google Scholar] [CrossRef]

- Law, L.C.; Mastorakos, E.; Evans, S. Estimates of the Decarbonization Potential of Alternative Fuels for Shipping as a Function of Vessel Type, Cargo, and Voyage. 2022.

- Intergovernmental Panel on Climate Change Global Warming of 1.5°C; 2018; ISBN 9781009157940.

| Partially drop-in1 | Non-drop-in1 |

|---|---|

| Biodiesel | Ammonia |

| Hydrotreated Pyrolysis Oil (HPO) | Liquefied Natural Gas (LNG) |

| Hydrotreated Vegetable Oil (HVO) | Methanol |

| Straight Vegetable Oil (SVO) |

| Segment | Analysed aspects |

|---|---|

| Physical and chemical properties | Heating value Volumetric density Energy density Kinematic viscosity Acidity Flash point CCAI Other properties |

| Bunkering | Pressurization Liquefaction Tank shape Inertisation Ventilation Maintenance |

| Storage and fuel feeding | Pressurization Liquefaction Tank location Tank volume Inertisation Ventilation reinforcement Maintenance Need for double-wall Materials Drainage Preheating Filtering |

| Energy conversion | Converter type Need for pilot fuel Engine adjustments |

| Fuel Property | Heating Value | Volumetric density | Energy density | Viscosity at 40° C | Acidity | Flash Point | Aromaticity Index (CCAI) |

|---|---|---|---|---|---|---|---|

| Unit | MJ/kg | kg/m³ | MJ/m³ | mm/s² | Mg KOH/g | °C | - |

| HFO | 40.0a | 991a | 39,640 | 380i | 2.5i | >60i | 856.5p |

| MGO | 42.0a | 890a | 37,380 | 3.5i | 0.5i | >60i | 808.1p |

| LNG | 50.0b | 415b | 20,750 | - | - | -188b | - |

| Biodiesel | 37.1c | 885c | 32,833.5 | 4-6j | 0.052-0.295m | >93c | 822.6p |

| SVO | 37-39.62a | 900-930a | 33,300-36,847 | 14-40k | 0.02-20n | >400k | 836.6-878.7p |

| HVO | 44.1d | 780d | 34,398 | 3d | - | 99d | 738.4p |

| HPO | 28.9e | 1150h | 33,235 | 9h | 21.3-76.1h | 53-101h | 1076p |

| Ammonia | 18.6g | 758g | 14,101 | - | - | 132o | - |

| Methanol | 20.1f | 798f | 16,040 | 0.58l | - | 12f | 837.6p |

| Criteria | LNG | Biodiesel | SVO | HVO | HPO | Methanol | Ammonia |

|---|---|---|---|---|---|---|---|

| Energy density HFO/fuel | 1.91 | 1.21 | 1.19-1.08 | 1.15 | 1.19 | 2.47 | 2.81 |

| Bunkering readiness | Already worldwide stablished | Adaptation to biodiesel properties, narrow shaped tanks, constant cleaning | Procedures are similar from HFO bunkering | Procedures are similar from MDO bunkering | Urge of development all bunkering process | Under establishment, ventilation reinforcement | Ammonia bunkering is already done to chemical industry |

| Material Compatibility | Aluminium and stainless steel | Stainless steel or zinc reinforcement | Stainless or mild steel if coated with zinc silicate | No changes are needed | Stainless steel | Stainless or austenitic manganese steel | Stainless steel |

| Storage tanks | Double walled, cryogenic storage (-162°), 10 bar pressure, inert | Isolated from machinery | Isolated from machinery, coated with vegetable oil inert material | Constant Maintenance to avoid water contamination | Isolated from machinery, coated with biomass oil inert material | Double walled, detection system to leakages | Double walled, isolated from machinery, pressure of 8.6 bar |

| Engine Feed | Double walled, Ventilation reinforcement, 10 bar feed pressure | Filtering, constant maintenance | Pre-heating (67 to 78°C), filtering, constant maintenance | No changes are needed | Pre-heating, piping designed to do not block solid particles, filtering | Double walled, ventilation reinforcement, pressure of 10 bar | Double walled, ventilation reinforcement |

| Engine Option | Dual fuel | Diesel Engine | Diesel Engine | Diesel Engine | Diesel Engine | Dual fuel | Fuel Cell |

| Safety | Flammable | Low temperature use restricted due to low pour point, low toxic | Low toxicity | Low toxicity | Low toxicity | Highly toxic and flammable | Highly toxic and flammable |

| TRL | 9 | 7 | 5 | 5 | 2 | 8 | 5 |

| Port | Cargo Movement (106 metric-ton) | Main Products | Main Destinations |

|---|---|---|---|

| Açu | 39.0 | Oil and derivatives, containers, cooper, Iron and Steel | Suape, Madre de Deus, Santos, Rio de Janeiro, Vitória |

| Angra dos Reis | 29.3 | Iron and Steel, Oil and derivatives | Alexandria (Egipt), Mersin (Turkey), Kabil (Indonesia), Qingdao (China), Aratu |

| Belém | 2.6 | Containers, Oil and derivatives, Corn, General Cargo | Manaus, Barcarena, Fortaleza, Madre de Deus, Santarém |

| Guaíba | 26.3 | Iron Ore, Wood, Cellulose Pulp | Rio de Janeiro, Rio Grande, Port Talbot (Wales), Ijmuiden and Rotterdam (Netherlands) |

| Itacoatiara | 7.0 | Soy, Soy Oil, Ethanol, Fossil Fuels, Oil and derivatives | Fortaleza, Manaus, Itaqui |

| Itaguaí | 46.9 | Containers | Santos, Imbituba, Suape, Callao (Peru), Rotterdam (Netherlands) |

| Itaituba | 6.1 | Oil and derivatives, Corn, Soy | Belém, Manaus, Porto Velho, Santarém, Santana |

| Itaqui | 20.3 | Oil and derivatives, Containers, Ethanol, Chemical products | Belém, Aratu, Fortaleza, Santos, Suape |

| Manaus | 6.0 | Oil and derivatives, Containers, General Cargo | Belém, Fortaleza, Santos, Suape, Itacoatiara |

| Paranaguá | 32.6 | Containers, Oil and derivatives, Chemical Products, Wheat | Belém, Fortaleza, Santos, Suape, Itaguaí |

| Pecém | 10.4 | Containers, Iron and Steel, Oil and derivatives, Manganese | Los Angeles (USA), Manaus, Cubatão, Brownsville (USA), Santos |

| Ponta da Madeira | 186.6 | Iron Ore | Qingdao (China), Labuan (Malaysia), Kwangyang (Korea), Sohrar (Oman), Pecém |

| Porto Velho | 14.2 | Soy, Corn, Containers, General Cargo | Santarém, Itacoatiara, Belém, Long Beach (USA), Montoir De Bretagne (France) |

| Recife | 0.3 | Sugar, Salt, Oil and derivatives, Fossil fuels | Dubai (UAE), Fernando de Noronha, Baltimore (USA), Barra Do Riacho, Douala (Cameroon) |

| Rio Grande | 20.0 | Soy, Containers, Wood, Fertilizers | Tanger (Morocco), Pecém, Antwerpen (Belgiun), Porto Alegre, Dafeng (China) |

| São Sebastião | 12.6 | Oil and derivatives, Sugar | Singapore, Qingdao (China), Manaus, Itaqui, Itacoatiara |

| Salvador | 4.5 | Oil and derivatives, Cellulose Pulp, Containers | Vila do Conde, Belém, São Sebastião, Changshu (China), Santos |

| Santarém | 6.5 | Oil and derivatives, Soy, Corn, Fertilizers | Itaituba, Algete and Barcelona (Spain), Belém, Rotterdam (Netherlands) |

| Santos | 99.1 | Soy, Oil and derivatives, Soy Oil, Containers | Anshan, Koh Sichang (China), Bandar Khomeini (Iran), Singapore, São Sebastião |

| Suape | 11.8 | Oil and derivatives, Containers, Sugar, Ethanol | Singapore, Manaus, Fortaleza, Itaqui, Santos |

| Tubarão | 62.7 | Iron Ore, Soy | Tangshan, Qingdao and Rizhao (China), Labuan (Malaysia), Rio de Janeiro |

| Ship Type | Products transported | Average age (2023) | Average DWT | Fleet size |

|---|---|---|---|---|

| Tanker | Crude oil and derivatives | 10 | 89,054 | 54 |

| Bulk | Dry Bulk | 15 | 57,007 | 21 |

| Container | Container | 13 | 45,009 | 33 |

| Chemical Tanker | Chemical products | 18 | 26,234 | 8 |

| Pipe Laying Support Vessel (PLSV) | Offshore Pipes | 9 | 10,661 | 8 |

| Subsea Equipment Support Vessel | Subsea Equipment | 15 | 7,570 | 2 |

| LPG Tanker | Liquefied petroleum gas | 11 | 5,481 | 8 |

| Liquefied Gas Tanker | Liquefied gases | 13 | 5,455 | 11 |

| 1 | Net zero emissions are achieved when human caused GHG emissions are balanced globally by human induced removals of CO2 on a global scale during a defined period [131]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).