Submitted:

16 August 2023

Posted:

17 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction and review of sources.

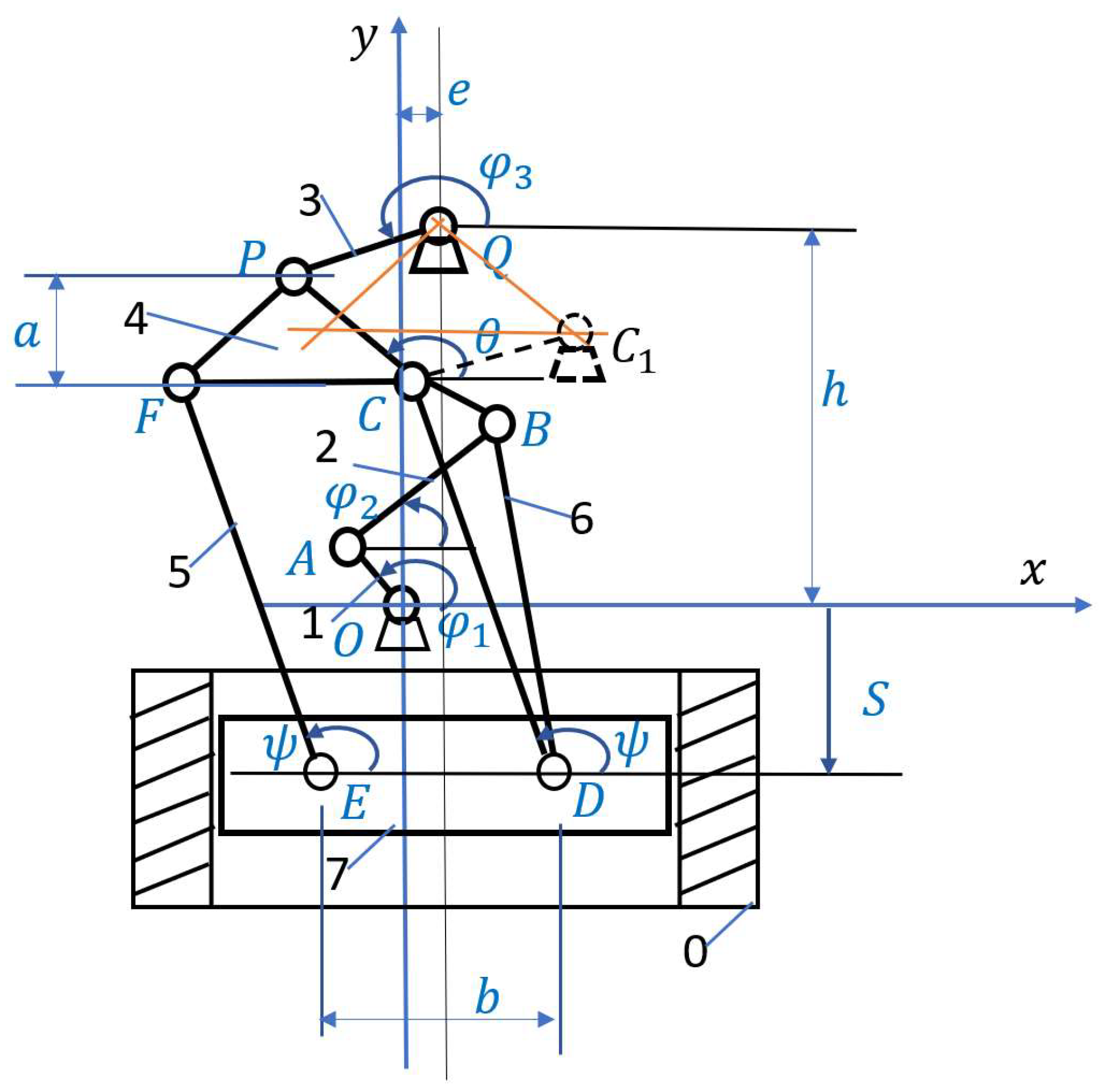

2. Materials and Methods

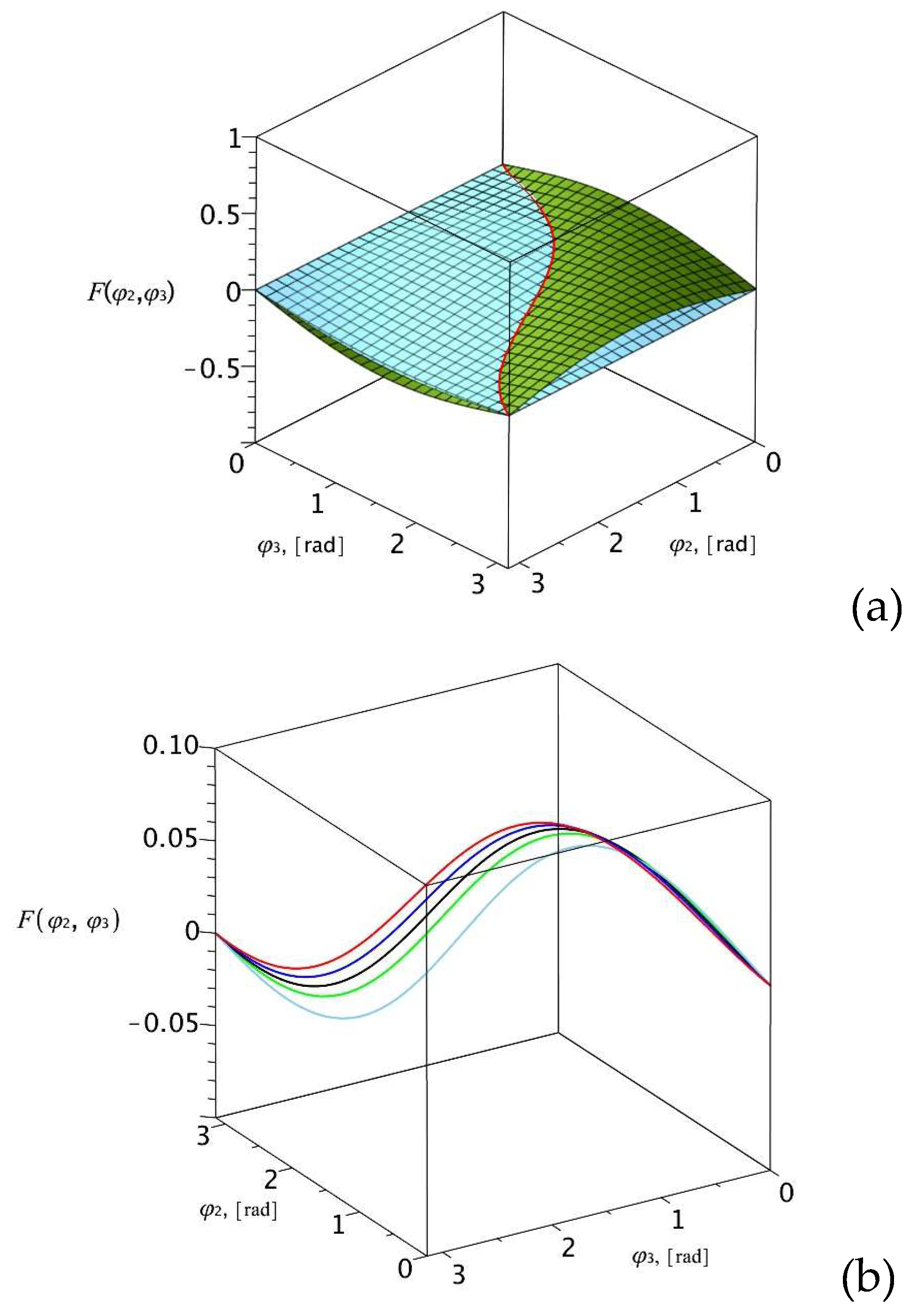

2.1. Kinematic analysis

- [1]

- Constant parameters are set and calculated: ;

- [2]

- ;

- [3]

- [4]

- [5]

- [6]

- [7]

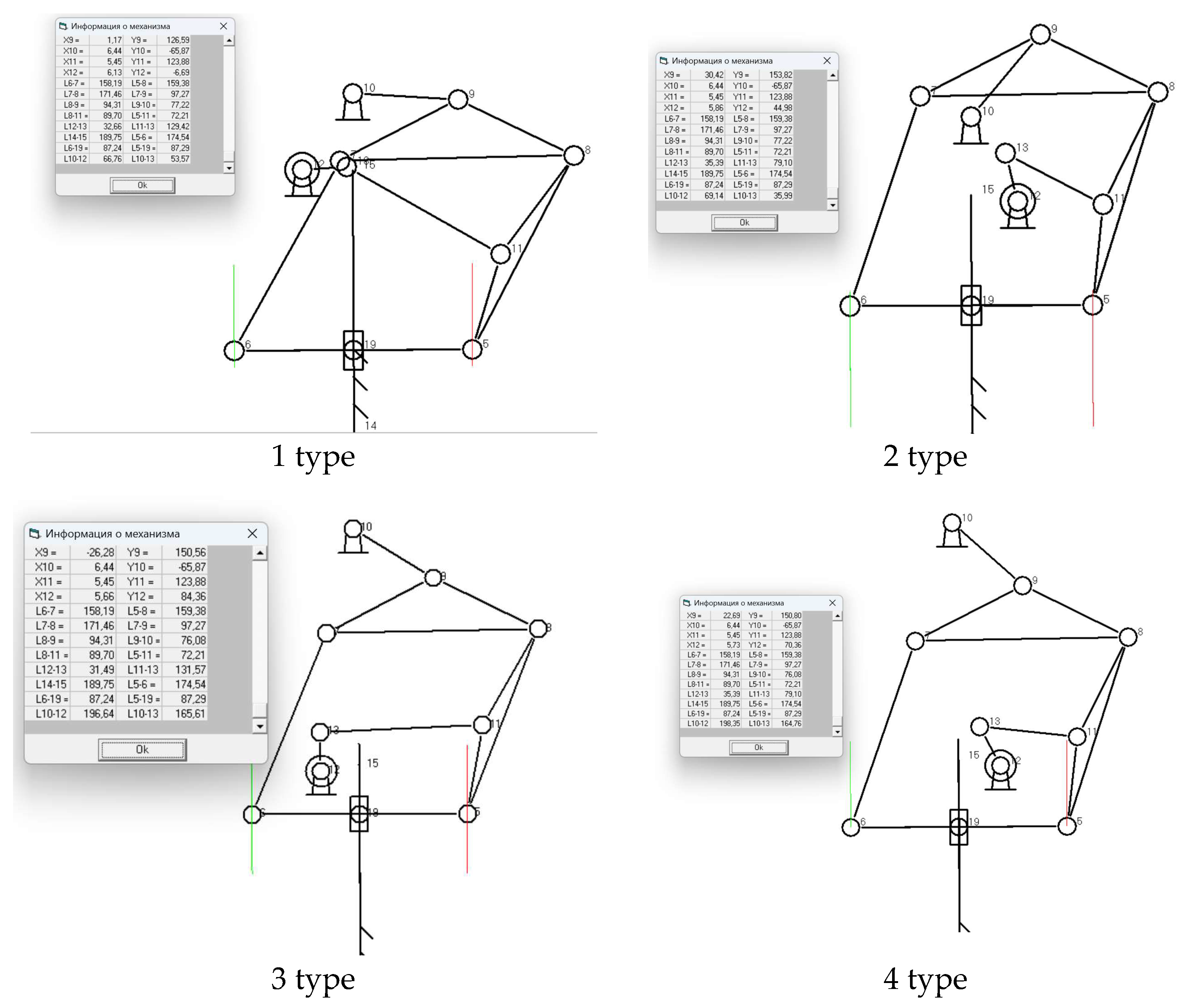

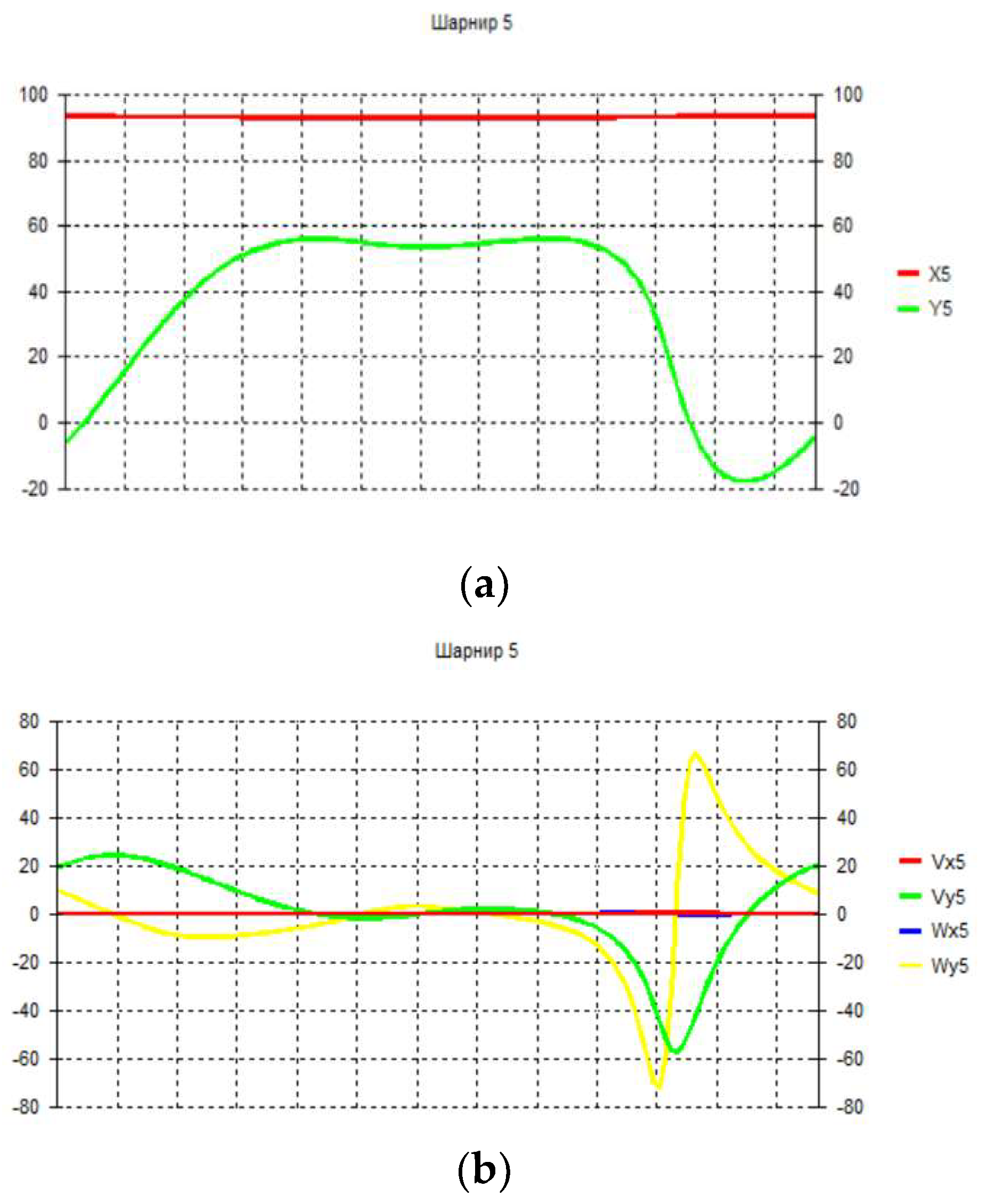

3. Numerical experiment and discussion of results.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Evgrafov, M.; Semyonov, Yu.; Sloushch, A. Theory of mechanisms and machines: study guide. - M.: Publishing Center "Academy", 2006.- 560 p.

- Bocharov, Yu. Forging and stamping equipment. - М.: Publishing Center "Academy", 2008. – 480 p.

- Matthews, S.; Tanninen, P.; Toghyani, A.; Eskelinen, H.; Ovaska, S.-S.; Leminen, V.; Varis, J. Novel method for Selection of Drive Motor in Paperboard Forming Press Utilizing Multi-Dynamics Model based on Material Thickness//27th International Conference on Flexible Automation and Intelligent Manufacturing, FAIM2017, 27-, Sami Matthews et al. /Procedia Manufacturing 11 (2017) 2091 – 2098, Modena, Italy. 30 June.

- Chen, Y.; Sun, Y.; Yang, D. Investigations on the dynamic characteristics of a planar slider-crank mechanism for a high-speed press system that considers joint clearance// Journal of Mechanical Science and Technology 31 (1) (2017) 75~85.

- Telegin, I.; Shumilova, T. Comparing the efficiency of flowsheets for hot die forging on crank presses// MATEC Web of Conferences 224, 01092 (2018). ICMTMTE 2018.

- Tuleshov, A.; Drakunov, Yu. and etc. Crank Lever Presses Based on the Stephenson Mechanism II: Monograph, ISBN978-601-332-973-4, Almaty, 2020.-240 p.

- Moldabekov, M.; Tuleshov, A.; Ualiev, G. Mathematical modeling of the dynamics of mechanisms and machines. - Almaty: Kazak University, 1998. - 204 p.

- Shihao, Liu.; Mao, Lin. 9: Design and test of the crank slider mechanism feeding type rubber rotary cutting machine// Springer Nature Switzerland AG 2020 2, 2020. [CrossRef]

- Ouyang, P.; Li, Q.; Zhang, W. Design, modelling and control of a hybrid machine system, Mechatronics 14 (2004) 1197–1217.

- Yuan, Z.; Gilmartin, M.; Douglas, S. Design of hybrid machines for nonuniform motion production, Proc. Inst. Mech. Eng. C 219 (2005) 491–499.

- Kutuk, M.; Dulger, L. A hybrid press system: Motion design and inverse kinematics issues/Engineering Science and Technology an International Journal, 2016. P.846-856.

- Tuleshov, A.; Jamalov, N.; Jomartov, A. and etc. Patent of the Republic of Kazakhstan for invention No. 33874. Crank-slide mechanism of the press. applicant. and patent holder JIME named after Dzholdasbekov, U. - No. 2018/0225.1 dated 04/10/2018; publ. 09/06/2019, bul.

- Jamalov, N.; Tuleshov, A.; Jomartov, A.; Seidakhmet, A.; Kamal, A. Eurasian patent for invention No. 038760. Crank-knee press mechanism. Applicant and patent holder of the Dzholdasbekov U. JIME dated 10/15/2021 (Derwent Innovations Index).

- Tuleshov, A.; Halicioglu, R.; Shadymanova, A. and Kuatova, M. Kinematic synthesis method and eccentricity effects of a Stephenson mechanism, Mech. Sci., 12, 1-8, 2021.

- Connor, A.; Douglas, S. and Gilmartin, M. The synthesis of hybrid five-bar path generating mechanisms using genetic algorithms, 1st International Conference on Genetic Algorithms in Engineering Systems: Innovations and Applications, 313–318, Galesia, 1995.

- Dülger, L.; Kireçci, A. and Topalbekiroglu, M. Modeling and simulation of a hybrid actuator, Mech. Mach. Theory, 38, 395– 407, 2003.

- Yu, H. 3. [CrossRef]

- Li, H. and Zhang, Y. Seven bar mechanical press with hybrid driven mechanism for deep drawing; part 1: kinematics analysis and optimum design, part 2: dynamic modeling and simulation, J. Mech. Sci. Technol., 11, 2153–2160, 2161–2167, 2010. [Google Scholar]

- Li, H. and Tso, P. L.: Experimental study on a hybrid driven press using iterative learning control, International Journal of Machine Tools and Manufacture, 48, 209–219, 2008.

- Tso, P. L. : Optimal Design of a Hybrid-Driven Servo Press and Experimental Verification, J. Mech. 0345; 03. [Google Scholar] [CrossRef]

- Yan, H. S. and Chen, W. R. "A variable input speed approach for improving the output motion characteristics of Watt-type presses," International Journal of Machine Tools and Manufacture, vol. 40(5), pp. 675-690, 2000.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).