1. Introduction

Waterborne paints (WBPs) use water as a solvent or dispersion medium and are non-toxic, safe, environmental friendly, etc. [

1,

2,

3]. As awareness of people regarding environmental protection national environmental protection policies increases, WBPs will gradually replace traditional organic paints in furniture, interior decoration, and construction industries. With the continuous development of the WBPs industry, the manufactures of bamboo products have a new direction as the application of WBPs to bamboo furniture will likely become increasingly popular [

4,

5,

6]. “Three parts paint and seven parts painting process” [

7,

8,

9,

10] highlights the significance of the painting process (including the method and amount) to the film properties. Some scholars have studied the finishing process and adhesion mechanism of water-based paint [

11,

12], But in generally speaking,at present, some scholars have done some research on the painting technology of water-based paint, bu they mainly focus on wood painting ,there are few studies on the painting of bamboo waterborne paint.

In this paper,bamboo-laminated lumber for furniture was coated with waterborne acrylic paint. the effects of different painting techniques and quantities on the drying rate, smoothness, hardness, adhesion and wear resistance of the paint film were investigated, finally,the thermal properties of the paint were analysed using thermogravimetry and differential scanning calorimeter to examine the film-forming mechanism,which can provide the theoretical basis for the painting of bamboo ,moreover, these can be used as a reference for waterborne painting of bamboo in furniture production.

2. Materials and Methods

2.1. Materials

Bamboo-laminated lumber, consisting of side-pressured carbonised bamboo sheets, was cut into(100 × 100 × 10) mm3 in size,the number of the samples was about 30. The bamboo-laminated lumber surface remained uncoated, and the moisture content was maintained below 10%.

Waterborne acrylic paints bought from Zhejiang Feida new material Co.,Ltd were divided into primer (D) and topcoat (M). The main performance parameters of the paints are listed in

Table 1.

Additional materials used in this study include gauze strips, absorbent cotton, a high-grade drawing pencil from a Chinese brand, qualitative filter paper and scotch tape.

2.2. Major Equipment

Painting equipments: special wool brush for WPBs, sandpapers (240 #, 320 # and 400 #) and electronic scales.

Analytical equipment: Paint film drying time tester, pencil hardness tester, wear-resisting instrument, super-depth-of-field microscope, thermalgravimetric analyser (TG) and differential scanning calorimeter (DSC).

2.3. Preparation of Paint Films

2.3.1. Different Painting Methods

In this section, a single-factor experimental method was used. Bamboo-laminated lumber was painted using four different techniques (including one-layer primer one-layer topcoat, one-layer primer two-layer topcoat, two-layer primer one-layer topcoat and two-layer primer two-layer topcoat) at room temperature, as shown in

Figure 1. Moreover, amount of paint applied to the primer and topcoat was maintained at (80 ± 5 )g/m

2. Before the primer coating, the bamboo-laminated lumber was placed at room temperature and sanded with 240 # sandpaper until the surface became smooth. Before the topcoat coating, the surface was sanded with 320 # sandpaper until the surface was smooth. After painting, the samples were immediately dried in a temperature and humidity chamber, with conditions set at 50°C, 20% relative humidity and 0 m/s wind speed. Once the paint film was completely dried, bamboo-laminated lumber was left in an indoor environment for a week to acclimate with the drying time and the paint film performance before testing.

2.3.2. Different Amounts of Applied Paint

In this section, the single-factor experimental method based on the result of the different painting methods and the optimal painting techniques was chosen, then four different amounts of paint (60g/m2, 80g/m2, 100 g/m2and 120 g/m2) were applied to primer and topcoat for further examination.

2.4. Testing and Characterisation

The drying rate(including surface drying time and solid drying time)and hardness of the paint film were tested according to GB/T 1728-2020 and GB/T 6739-2006 standards, respectively, while the wear resistance and adhesion of the paint film were tested based on the GB/T 4893.8-2013 standard. Each indicator was tested five times, and the average of the results was calculated. Before the performance tests, the completely dried paint film was allowed to acclimate in a natural environment for one week. Each test was conducted at room temperature. All experiments were repeated five times, and the experimental error was observed to be within 10.0%.

A super-depth-of-field microscope analysed the surface smoothness of the paint films.

The thermal properties of the liquid primer, topcoat and solid films were analysed using TG and DSC. The test temperature ranged from 30°C–600°C, with a heating rate of 10°C/min.

3. Results and Discussion

3.1. Effect of the Painting Method on the Performance of Paint Films

3.1.1. Effect of the Painting Method on the Drying Rate of Paint Films

The drying time of paint film can be divided into surface drying and solid drying. Surface drying time refers tho the paint surface has been dry, but it still contain water or volatile materials,solid drying refers to the moisture and the volatile materials of the paint have been completely dried.

Table 2 shows the paint films’ surface and solid drying time under different painting methods. As shown, the four different painting methods had minimal effect on the film’s drying time; the surface drying times for the primers(first and second ) were 8 and 6 min, respectively, and the solid drying time were 8.5 and 6.5 min, respectively. Alternatively, the surface drying times of topcoats were 6.5 and 6.5 min, which the solid drying time of primers were 7 and 7 min. Notably, the effect of painting techniques on the drying time of the primer is greater than that of the topcoat. This could be because the first primer layer is in direct contact with the bamboo surface, resulting in the primer permeating into the bamboo surface and requiring a longer period for water evaporation. In contrast, when applying the second primer layer, moisture evaporated directly without permeating the surface. Additionally, a chemical reaction between the first primer and the bamboo surface could lead to a longer surface and solid drying time.

3.1.2. Effect of Painting Method on the Mechanical Properties of Paint Films

The mechanical properties of paint films, including hardness, adhesion and wear resistance, for the four different painting methods are shown in

Table 3. The hardness of the films obtained using all these four painting methods was grade B and the adhesion was grade 0, indicating that the painting method has little effect on the hardness and adhesion of the film. In this experiment, the four painting method’s quality loss were 51.24, 71.27, 69.68 and 83.65 mg 100r

−1, respectively. The highest wear resistance was achieved with the one-layer primer one-layer topcoat method, whereas the lowest was observed with the two-layer primer two-layer topcoat method. This may be because the thickness of the film increased with an increase in the paint layers, leading to poor wear resistance. Furthermore, large painting thickness might result in the film's pinhole and hanging, reducing its wear resistance.

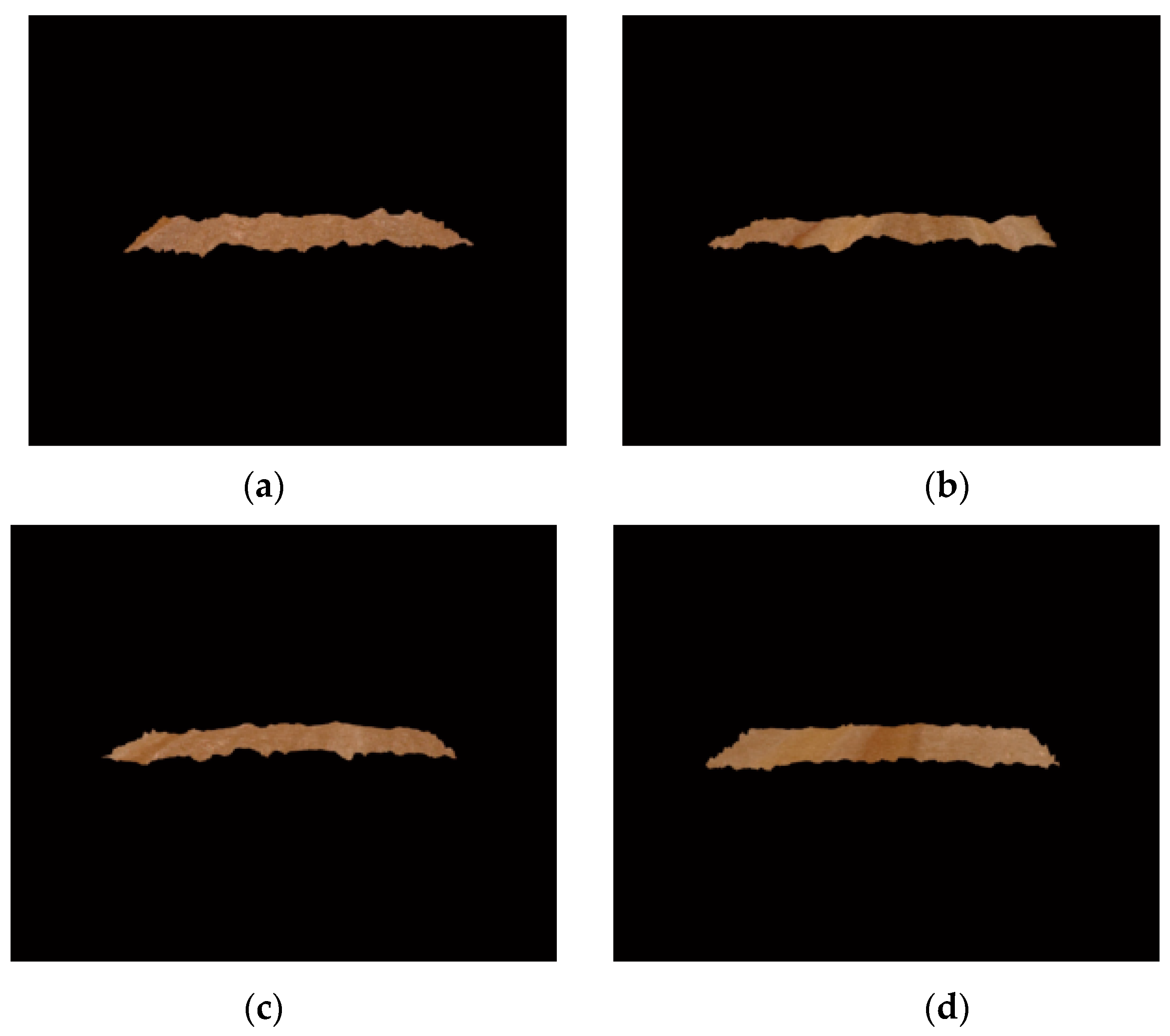

3.1.3. Effect of Painting Method on the Surface Smoothness of Paint Films

The analysis of super-depth-of-field optical microscope is one of the key methods for surface characterization of composite materials. Its advantage lies in the non-destructive optical detection, and the super depth of field, which can observe the micro-area more clearly.The smoothness of the material surface can be directly seen through the super-depth-of-field optical microscope image.

Figure 2 shows a three-dimensional (3D) view of the surface of the paint films painted using the four different painting methods,which measured by the super-depth-of-field optical microscope.

The surface smoothness of the paint film increased with increasing paint layers. Hence, among the different painting techniques, two-layer primer two-layer topcoat had the best film surface smoothness. This is probably because the primer serves to fill gaps on the bamboo surface, while the topcoat fills gaps on the primer layer. As the number of paint layers increases, the remaining pores are filled, resulting in a smoother surface.

3.2. Effect of the Different Paint Amount on the Performance of Paint Films

3.2.1. Effect of Different Paint Amount on the Drying Rate of Paint Films

The results of the mechanical properties of paint films for the four different painting methods show that the film with one-layer primer one-layer topcoat has the best mechanical performance. Consequently, in this section, bamboo-laminated lumber was painted using a one-layer primer one-layer topcoat with different amount of paint, and the surface and solid drying times of the paints are shown in

Table 3.

Table 4 shows that the shortest drying time occurs when the amount of paint applied is 60 g/m

2and that the drying time is longest when the amount of paint applied is 120 g/m

2. The drying times for surface or solid drying were different among the four different painting amounts, showing the following trend: the drying time increases as the amount of paint applied increases. The thickness of the paint increases with the amount of paint, and thus the heat required for water evaporation also increases, which results in a slower drying rate. Additionally, as the amount of paint applied increases, internal molecular motion is relatively difficult, which leads to a slower drying rate. However, a smaller amount of applied paint is not necessarily better as too little paint can weaken the bond between the paint film and the substrate, leading to insufficient adhesion. When the amount of painting reaches a certain degree, the performance of the paint film can meet the requirements.

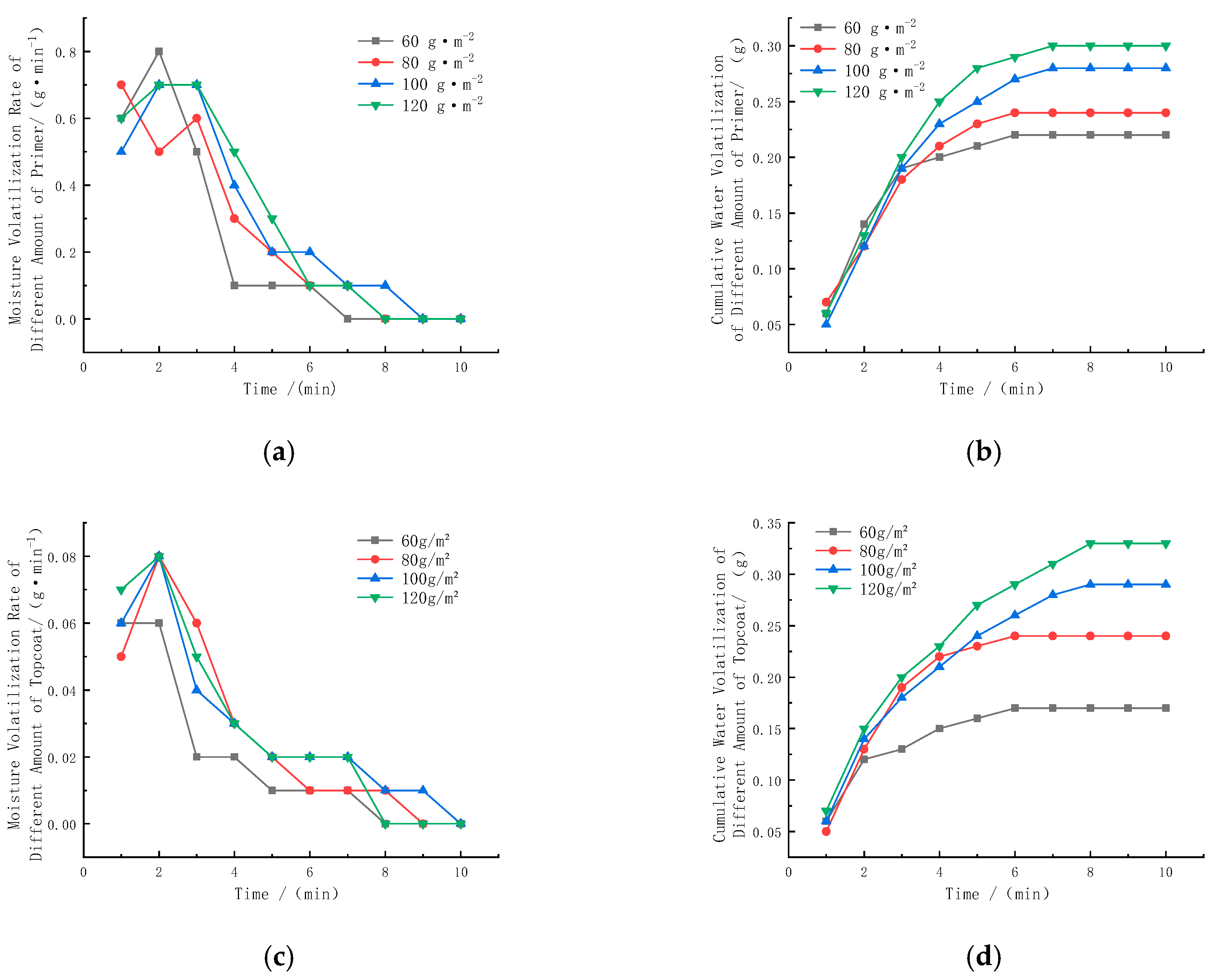

Figure 3 shows the moisture curves of the primer and topcoat painting tinplate at different paint amounts. As seen in

Figure 2, the moisture volatilisation rate, which represents the drying rate of the paint film, increases first and then decreases rapidly and then tends to zero; at approximately 2 min, the water volatilisation rate reaches its highest value; furthermore, the drying rate decreases gradually with an increase in the amount of paint. The moisture volatilisation reaches the saturation point fastest, so that the drying time of the film is the shortest. The results in

Figure 3 are consistent with those in

Table 3. The smaller the amount, the thinner will be the painting, and faster will be the surface water evaporation rate in comparison to the paint film’s curing speed. When the paint thickness increases, the curing layer on the film’s surface affects water evaporation. The drying speed of the paint film is affected by the coordination of moisture volatilisation and curing speed of the paint film; a high number of film-forming substances in the paint reduces the rate of water leaving the film's surface, which results in a decrease in the drying rate.

3.2.2. Effect of Amount of Paint on the Mechanical Properties of Paint Films

Table 5 shows the hardness, adhesion and wear resistance of paint films for four different painting amounts. It can be observed that when the amount of paint applied is 60 g/m

2, the paint film’s hardness is lowest, with a grade of 2B, indicating that the amount of paint affect the hardness of the film. As the paint amount increases, the hardness of the film will be improves. However, once the hardness reaches a certain level, the amount of applied paint no longer affects the film’s hardness. Here, the paint film's hardness was B grade for the other three painting amounts. The adhesion of the paint films was grade 0. During painting, a large one-time paint amount can lead to film uniformity issues, and painting becomes difficult due to paint hanging as a result of a large amount. The highest wear resistance for the paint film was observed when the amount of paint applied was 80 g/m

2, whereas the lowest wear resistance was found at 120 g/m

2. The reason could be that when using a large amount of paint, part of the paint cannot penetrate the substrate and accumulate on its surface, making it more susceptible to wear. However, if the amount of paint is too small, it cannot form enough paint nails between the paint and bamboo, reducing the effect of the force and making it easy to wear. Therefore, 80 g/m

2 paint is appropriate for wear resistance.

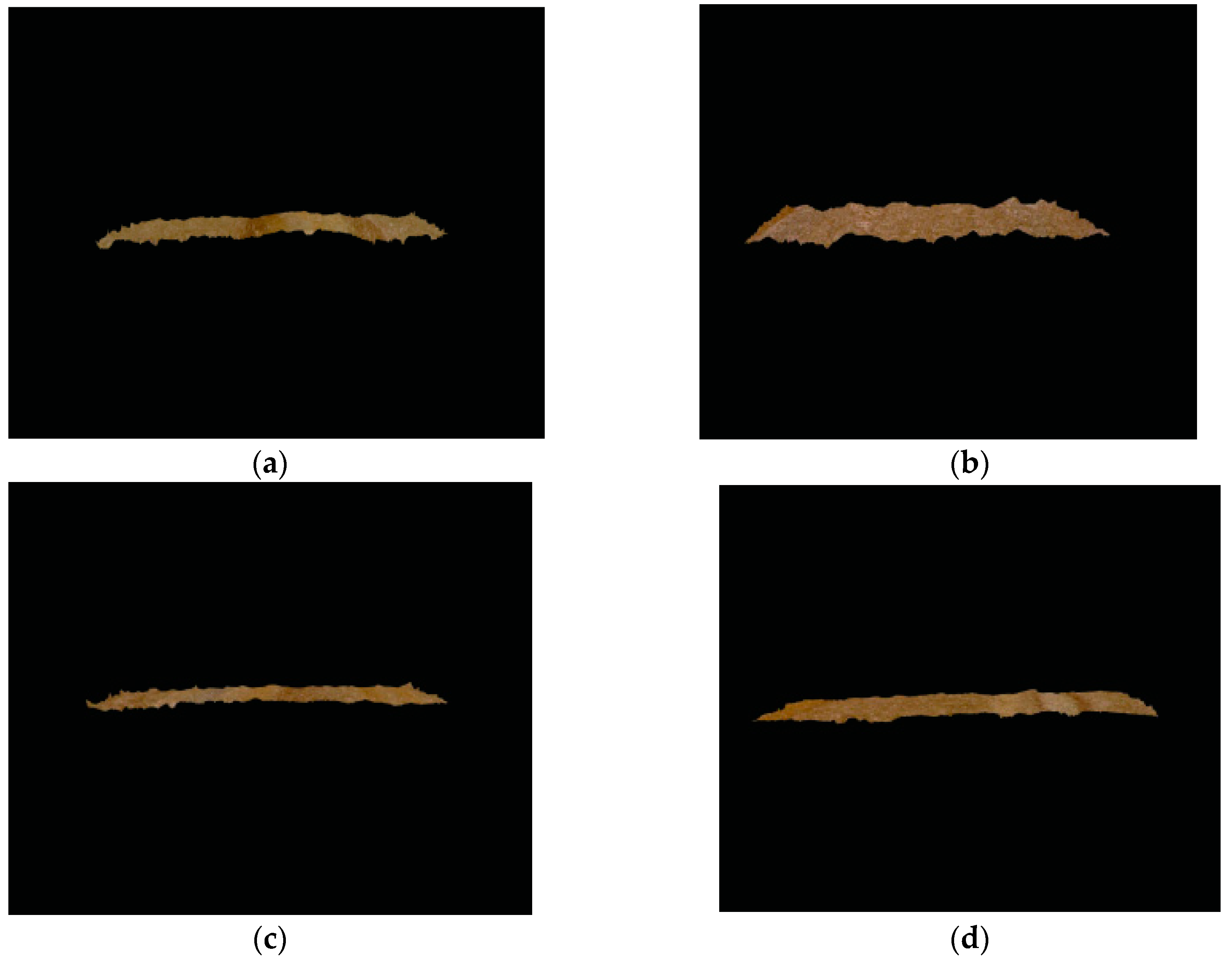

3.2.3. Effect of Amount of Applied Paint on the Surface Smoothness of Paint Films

Figure 4 shows the 3D view of the paint film surfaces when applying four different paint amounts. As can be seen from the figure, the flatness of the paint film surface gradually increases with an increase in the amount of applied paint. This may be because, when the paint amount is small, the paint cannot completely cover the pores existing on the surface. Therefore, an increase in the coating amount can effectively fill the pores; hence, the surface smoothness of the film is highest when the paint amount was 120 g/m

2.

3.3. Thermal Properties Analyses of the Paints and Paint Films

3.3.1. Analyses of TG and DTG

TG analysis is a method of measuring the relationship between the mass of a substance and temperature or time at a programmed temperature. By analyzing the TG curves, we can know the thermal stability, thermal decomposition of the material and its possible intermediate products.

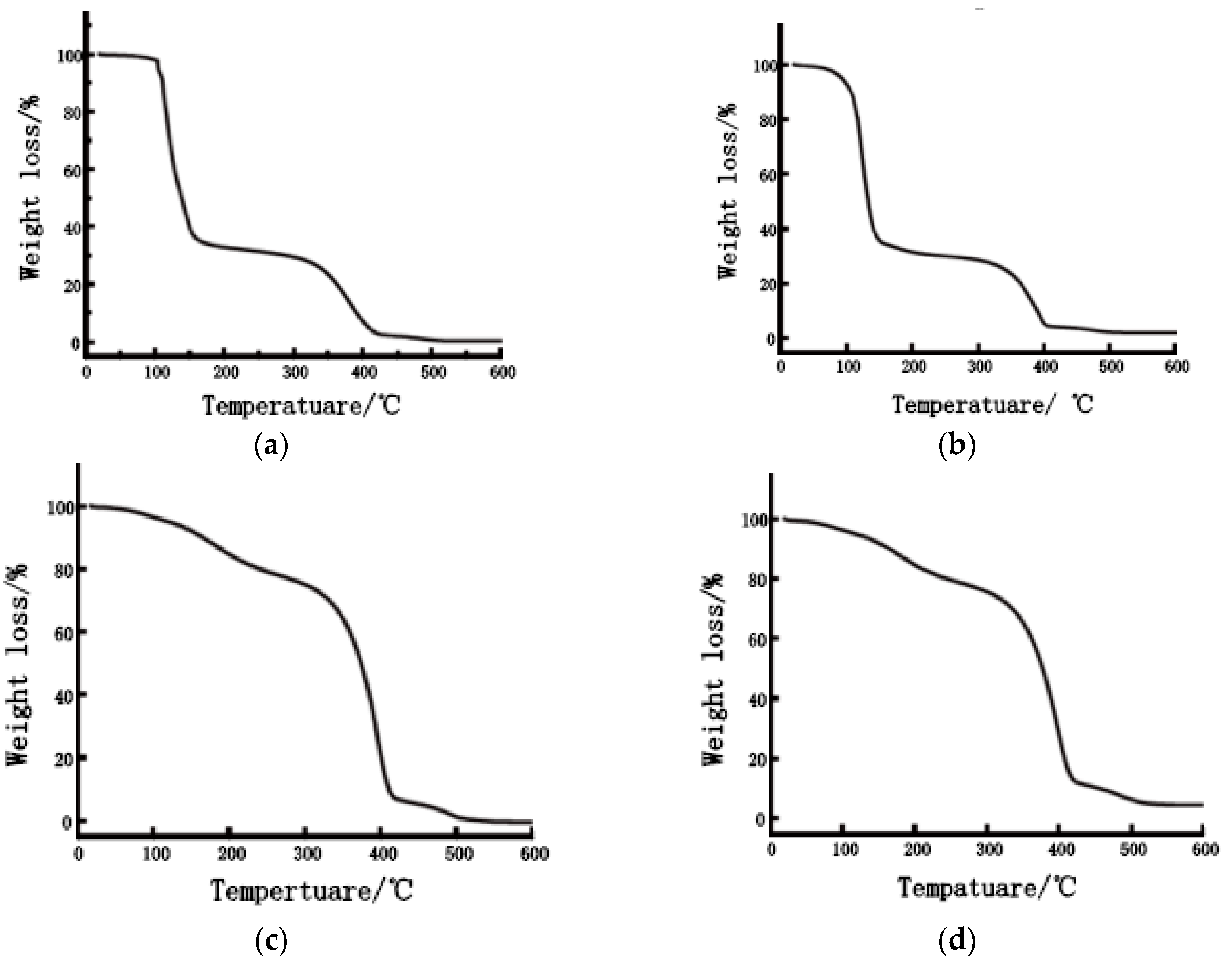

Figure 5 shows the TG curves of the paints and films. The thermal decomposition processes of primer and topcoat are the same (

Figure 5), which can be divided into two steps. First, thermal decomposition occurred when the temperature reaches 100℃, mainly due to water evaporation. Furthermore, the quality of the paints decreases rapidly, and at around 140℃, the water has completely evaporated, transforming the liquid paints into solids; then the teds to be stabilised. Second, thermal decomposition occurred when the temperature reaches 360℃, which corresponds to the thermal decomposition of polymers (organic components) in the solid paints; the quality of the paints decreases rapidly again, and thermal decomposition of the polymers was completed at approximately 400°C. The rate of paint weightlessness was 98%. Like liquid paints, the thermal decomposition process of primer and topcoat films can be divided into two steps. First is the evaporation of residual water and other additives in films; then, the rate of film weightlessness was not more than 25%. Second is the thermal decomposition of polymers in the films when the temperature reaches 340°C. In these steps, the quality of the paints decreases rapidly, and the rate of weight loss is consistent with that of liquid paints, which is finally at 98%.

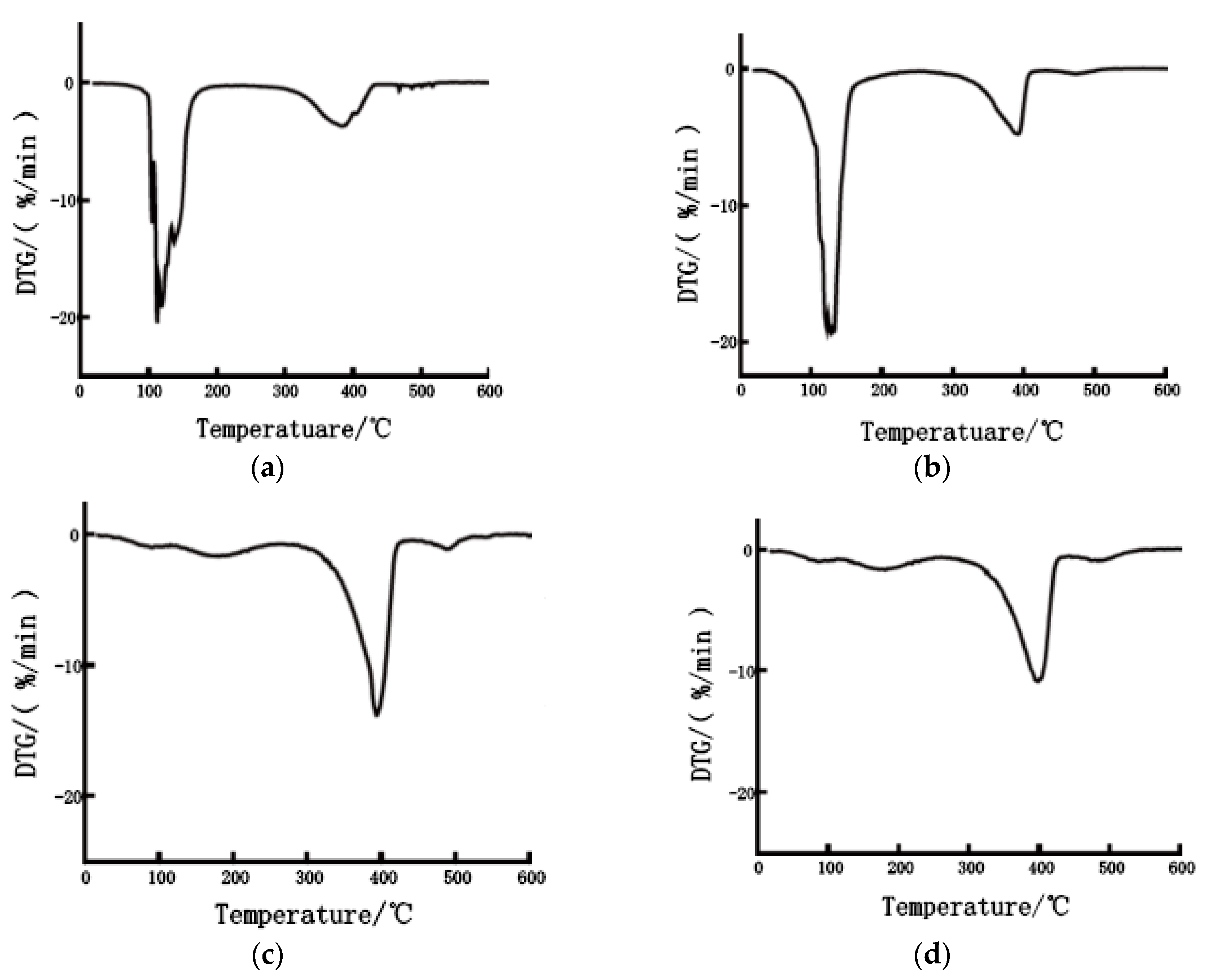

DTG, which also can be called is a technique for recording the first derivative of a TG curve to temperature or time. In the DTG curve, the rate of mass change is taken as the vertical coordinate, and the temperature or time is taken as the horizontal coordinate.

Figure 6 shows the DTG curves of the paints and films. DTG indicates the weight loss rate. As seen in

Figure 6, the first peak of the DTG curves for the primer occurred at approximately 110℃, whereas it appeared at about 125℃ for the topcoat. Similarly, in the DTG curves of the films, the temperature of the peak of the primer film was 400°C, which is lower than that of the topcoat film. Simultaneously, the thermal loss rate of the primer was higher than that of the topcoat, and all of these results show that the thermal stability of the topcoat was better.

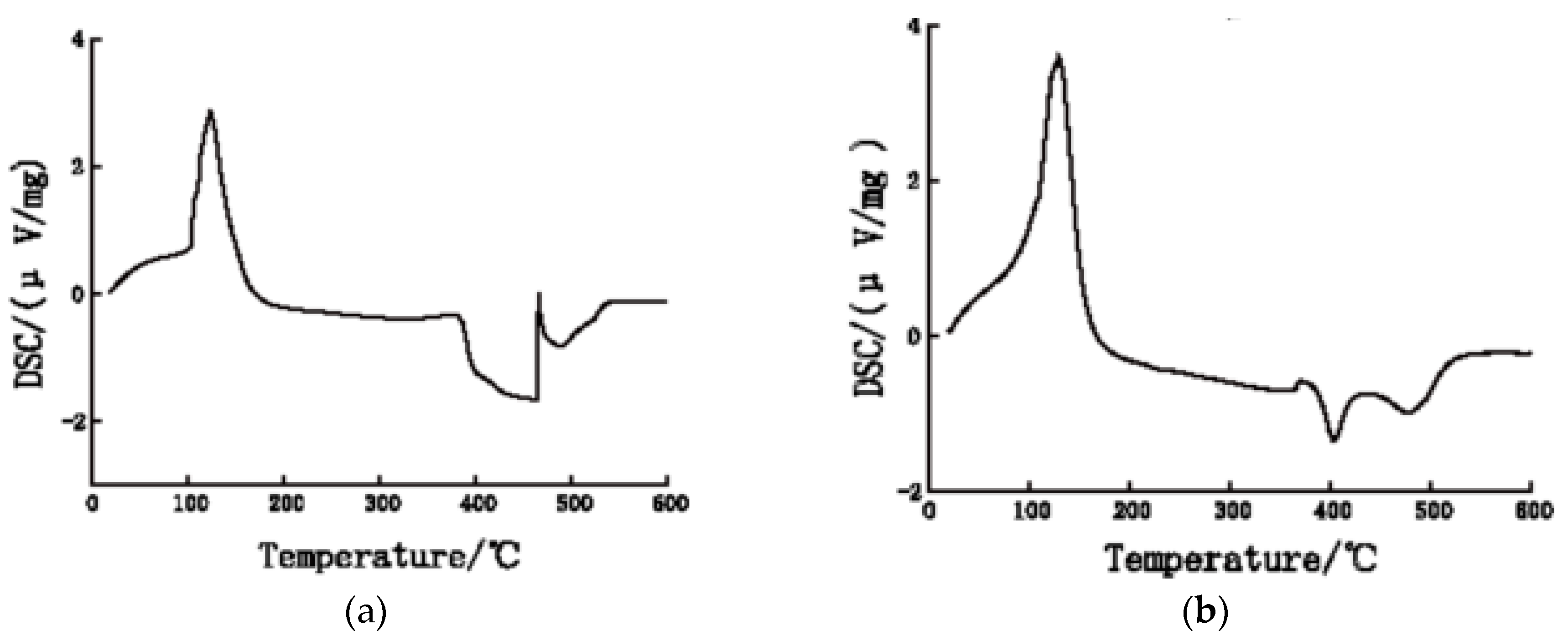

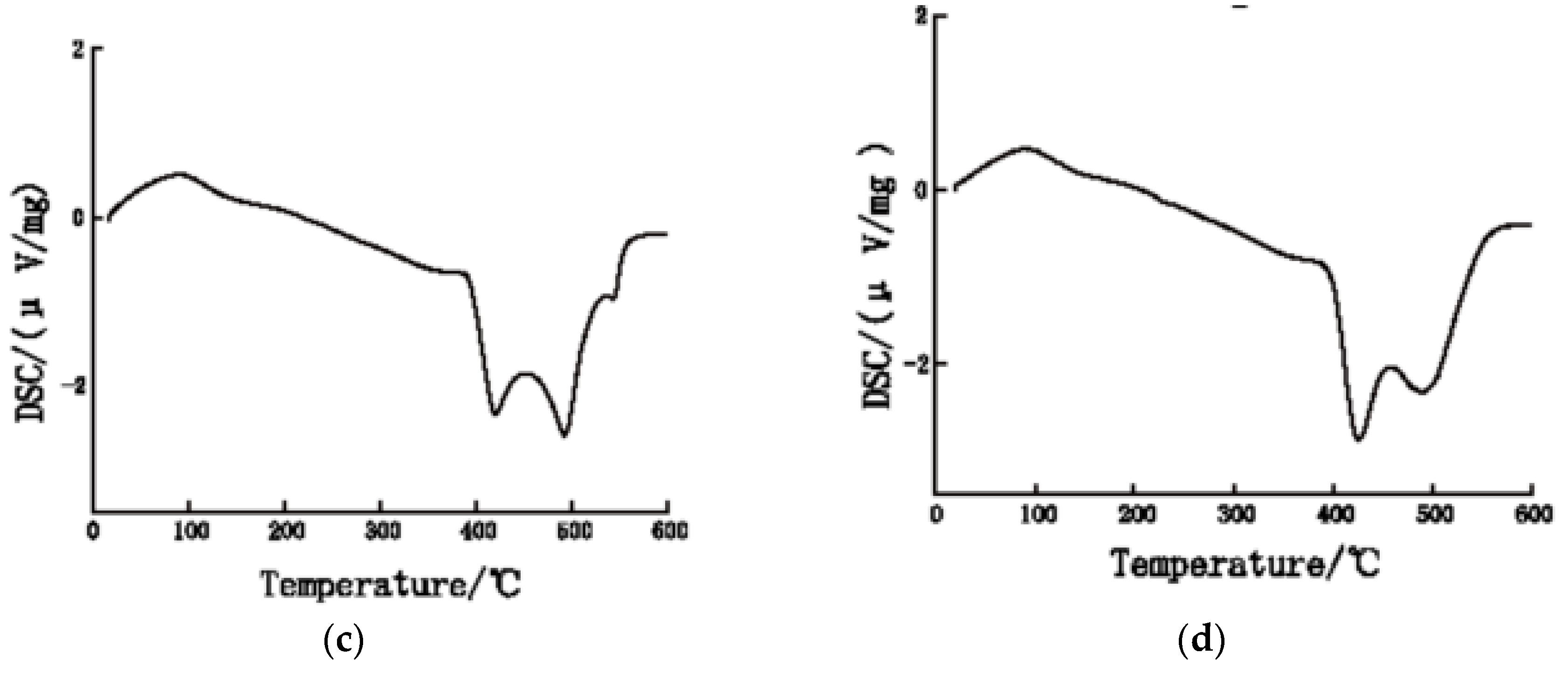

3.3.2. Analysis of DSC

Figure 7 shows the DSC curves of the paints and films. DSC curves are consistent with the results of TG; the DSC curves of primer and topcoat, first, it is mainly the thermal decomposition of water and additives at 100°C–200°C. Second, it is mainly the thermal decomposition of polymers (organic components) in the paints at 350–550℃. In the DSC curves of films, there is no peak between 100°C–200°C as there is no water decomposition; besides, there are two peaks between 400°C–500°C, at about 410°C and 450°C ℃, respectively.

3.3.3. Analysis of the Film-Forming Mechanism

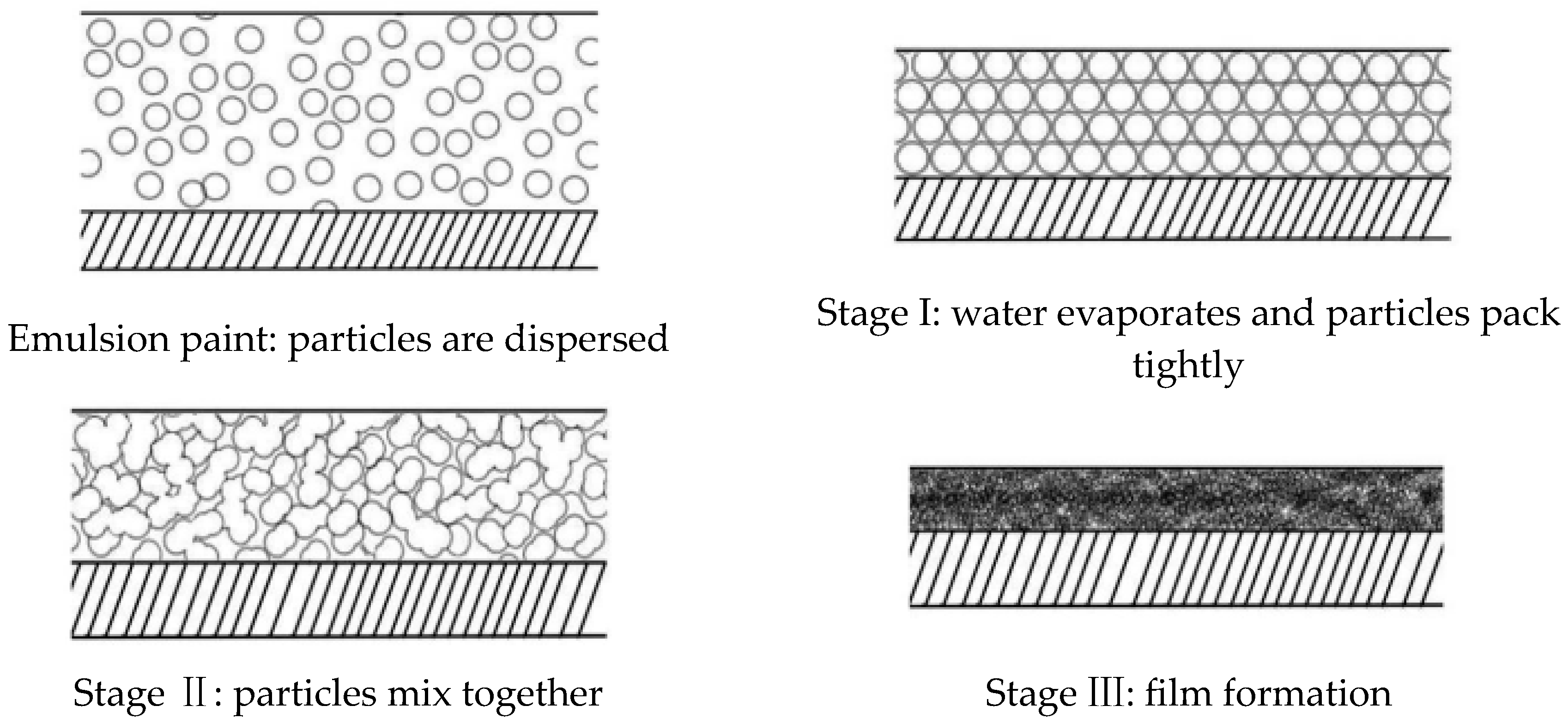

In the thermal analysis results of paints, regardless of primer or topcoat, the first step is the decomposition of water and additives. Hence, the film forming of paint on the bamboo-laminated lumber can be divided into the following stages, as seen in

Figure 8. First, particles are dispersed in the emulsion paint, then in stage I, water evaporates, and particles pack tightly. In stage Ⅱ, particle mix together, and finally in state Ⅲ , the mixed particles form the film.

We know that waterborne acrylic paint is one of the water-soluble paint, so the particles of the paint are dispersed uniformly(emulsion paint). The water in the pants evaporates when painting on the bamboo-laminated lumber(stage I).With the further evaporation of water, the average contact number and contact area of latex particles increase, and the irreversible interaction between particles from disordered state at contact interface deforms, and the density of arrangement increases, the local and the whole reaches the most compact accumulation state., at this stage the force further causes the latex particles to fuse and deform(stage Ⅱ).Then, the force or surface tension produced by the shrinking surface plays a leading role, and the molecular chains at the polymer interface diffuse, infiltrate and entangle each other, and the boundary of the particles is fully fused, macroscopically, it can form continuous paint film with certain mechanical properties(stage Ⅲ).

4. Conclusions

In this study, we coated bamboo-laminated lumber for furniture with waterborne acrylic paints and investigated the effects of different painting methods and amounts on the drying rate, smoothness, hardness, adhesion and wear resistance of the paint film. These results can be used as a reference for waterborne bamboo painting in furniture production. The following conclusions were drawn from our analysis.

(1) The painting technique did not considerably affect the drying time, flatness, hardness and adhesion of the paint film; however, it had a certain influence on wear resistance. In this paper, the flatness of the films was relatively similar when using different painting techniques. The drying times of the surface and solid of the primer were 8 and 8.5 min, respectively, whereas those of the topcoat were 6.5 and 7 min, respectively.. The hardness and adhesion of the paint films were grade B and grade 0, respectively. The paint film exhibited the best wear resistance (51.24 mg·100 r-1) when painted with one-layer primer one-layer topcoat.

(2) The amount of applied paint remarkably influenced the drying time and flatness of the paint film. As the amount increased, the surface/solid drying time of the paints also increased, and the flatness of the paint film increased first and then decreased. When the amount of applied paint was 80 g/m2, the film’s adhesion, hardness and wear resistance were the best at grade 0, grade B and 51.24 mg 100 r−1, respectively.

(3) The thermal analysis results of the primer and topcoat showed that water decomposed at 100°C, while the thermal decomposition of organic components occurred at 350°C. The weight loss of the primer and topcoat was the same, but the thermal loss rate of primers was higher than that of topcoats. This indicates that the thermal stability of topcoat was better.

Author Contributions

The manuscript was written with the contributions of all authors. Conceptualization, Hongyan Wang, Shaofei Yuan, and Qin Li; methodology, Hongyan Wang and Qin Li; formal analysis, Hongyan Wang, and Jian Zhang; writing—original draft preparation, Jie Che; writing—review and editing, Hongyan Wang.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgements

The authors gratefully thank the financial support from Forestry Science and Technology Extension Demonstration Project of Central Finance (Grant No.〔2021〕TS 03) and the project of Science and Technology of Zhejiang government (2021F1065-3).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yao, H.R.; Li, L.J.; Li, W.S.; Qi, D.; Fu, W.L.; Wang, N. Application of nanomaterials in waterborne coatings: a review. Resources Chemicals and Materials 2022, 1, 184–200. [CrossRef]

- Si, Z.; Zhang, M.; Su, X.; Yan, L.W.; Cao, L.F.; Wang, W.; Liu, Y.G. Research status and development trend of environmental friendly waterborne coatings. Coating and Protection 2021, 42, 24–29, 46.

- García-Pacios, V.; Costa, V.; Colera, M.; Martín-Martínez, J.M.. Waterborne polyurethane dispersions obtained with polycarbonate of hexanediol intended for use as coatings. Prog. Org. Coat. 2011, 71, 136–146. [CrossRef]

- Wu, Y.; Zhang, H.; Yang, L.; Wang, S.; Meng, Y. Understanding the effect of extractives on the mechanical properties of the waterborne coating on wood surface by nanoindentation 3D mapping. J. Mater. Sci. 2021, 56, 1401–1412. [CrossRef]

- Wu, Y.; Sun, Y.; Yang, F.; Zhang, H.; Wang, Y. The implication of benzene–ethanol extractive on mechanical properties of waterborne coating and wood cell wall by nanoindentation. Coatings 2019, 9, 449. [CrossRef]

- Yi, Y.F. Synthesis, characterization and properties of waterborne polyurethane acrylic hybrid emulsions. Taiyuan University of Technology, 2017.

- Yang, F.; Wu, Y.; Zhang, S.; Zhang, H.; Zhao,, S.; Zhang, J.; Fei, B. Mechanical and thermal properties of waterborne polyurethane coating modified through one-step cellulose nanocrystals/graphene materials sols method. Coatings 2019, 10, 40–50. [CrossRef]

- Mya, B.; Asfa, B.; Maa, D.; Lkka, C.; Kh, E.; Baa, B. Response surface optimization of syngas production from greenhouse gases via DRM over high performance Ni–W catalyst. Int. J. Hydrog.Energy 2022, 47, 31058–31071. [CrossRef]

- Zhou, H.; Wang, H.; Zhu, X.B.; Zhang, Y.; Qian, Y.L.; Zhang, P.Y.; Cai, Y. Synthesis and characterization of acrylate/waterborne polyurethane three layers shell-core hybrid latexes. Chemical Research 2016, 27, 369–373. [CrossRef]

- Wang, S.C.; Li, W.P.; Han, D.X.; Liu, H.C.; Zhu, L.Q. Preparation and application of a waterborne acrylic copolymer-siloxane composite: improvement on the corrosion resistance of zinc-coated NdFeB magnets. RSC Adv. 2015, 5, 81759–81767. [CrossRef]

- Lin, X.Y; Zhang, Q.H; Huang Y.H; Huang Q.F; Yang, X. Painting technology and adhesion mechanism of waterborne paint based on bamboo laminated lumber. Journal of Beijing Forestry University 2022, 44, 158-164.

- Chen, H; Zhang Y; Yang X; Ji, H; Zhong, T.H; Wang, G.A comparative study of the microstructure and water permeability between flattened bamboo and bamboo culm. Journal of Wood Science 2019, 65, 64-77. [CrossRef]

Figure 1.

Painting process.

Figure 1.

Painting process.

Figure 2.

Surface smoothness of films in four painting methods was analysed using super-depth-of-field microscope ((a): one-layer primer one-layer topcoat, (b): one-layer primer two-layer topcoat, (c): Two-layer primer one-layer topcoat, (d): Two-layer primer two-layer topcoat).

Figure 2.

Surface smoothness of films in four painting methods was analysed using super-depth-of-field microscope ((a): one-layer primer one-layer topcoat, (b): one-layer primer two-layer topcoat, (c): Two-layer primer one-layer topcoat, (d): Two-layer primer two-layer topcoat).

Figure 3.

Moisture curves of primer and topcoat painting tinplate in different paint amounts ((a): the water volatilisation of primer, (b): the cummlative water volatilisation of primer, (c): the water volatilisation of topcoat, (d): the cummlative water volatilisation of topcoat).

Figure 3.

Moisture curves of primer and topcoat painting tinplate in different paint amounts ((a): the water volatilisation of primer, (b): the cummlative water volatilisation of primer, (c): the water volatilisation of topcoat, (d): the cummlative water volatilisation of topcoat).

Figure 4.

Super-depth-of-field microscope analysed the surface smoothness of the films in the four painting methods ((a–d) are the amount of applied paint 60 g/m2,80 g/m2 ,100 g/m2 and 120 g/m2).

Figure 4.

Super-depth-of-field microscope analysed the surface smoothness of the films in the four painting methods ((a–d) are the amount of applied paint 60 g/m2,80 g/m2 ,100 g/m2 and 120 g/m2).

Figure 5.

TG curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 5.

TG curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 6.

DTG curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 6.

DTG curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 7.

DSC curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 7.

DSC curves of paints and films ((a): the primer, (b): the topcoat, (c): the primer film, (d): the topcoat film).

Figure 8.

Diagram of film formation.

Figure 8.

Diagram of film formation.

Table 1.

Main performance parameters of waterborne acrylic paints.

Table 1.

Main performance parameters of waterborne acrylic paints.

| Paints |

pH value |

Clour |

Particle size/nm |

Polymer dispersity index |

Solid content/% |

| Primer (D) |

7 |

Light yellow |

221.8 |

1.000 |

29 |

| Topcoat (M) |

7 |

Milky white |

925.2 |

1.000 |

38 |

Table 2.

Surface and solid drying time of the paint films with different painting methods.

Table 2.

Surface and solid drying time of the paint films with different painting methods.

| Painting Methods |

First Primer |

Second Primer |

First Topcoat |

Second Topcoat |

| Surface Drying Time (min) |

Solid Drying Time (min) |

Surface Drying Time (min) |

Solid Drying Time (min) |

Surface Drying Time (min) |

Solid Drying Time (min) |

Surface Drying Time (min) |

Solid Drying Time (min) |

| one-layer primer one-layer topcoat |

8 (0.5) |

8.5 (0.41) |

/ |

/ |

6.5 (0.5) |

7 (0.38) |

/ |

/ |

| one-layer primer two-layer topcoat |

8 (0.5) |

8.5 (0.41) |

/ |

/ |

6.5 (0.5) |

7 (0.38) |

6.5 (0.58) |

7 (0.51) |

| two-layer primer one-layer topcoat |

8 (0.5) |

8.5 (0.41) |

6 (0.36) |

6.5 (0.53) |

6.5 (0.43) |

7 (0.46) |

/ |

/ |

| two-layer primer two-layer topcoat |

8 (0.5) |

8.5 (0.41) |

6 (0.36) |

6.5 (0.53) |

6.5 (0.43) |

7 (0.46) |

6.5 (0.41) |

7 (0.42) |

Table 3.

Mechanical properties of paint films in different painting methods.

Table 3.

Mechanical properties of paint films in different painting methods.

| Painting methods |

Hardness

(grade) |

Adhesion

(grade) |

Loss of film quality

(mg·100r−1) |

| one-layer primer one-layer topcoat |

B |

0 |

51.24 (2.06) |

| one-layer primer two-layer topcoat |

B |

0 |

71.27 (8.29) |

| two-layer primer one-layer topcoat |

B |

0 |

69.68 (10.46) |

| two-layer primer two-layer topcoat |

B |

0 |

83.65 (9.06) |

Table 4.

Surface and solid drying times of the paint films after applying different amounts of paint.

Table 4.

Surface and solid drying times of the paint films after applying different amounts of paint.

| Amount of paint (g/m2) |

Primer |

Topcoat |

| Surface Drying time (min) |

Solid Drying Time (min) |

Surface Drying time (min) |

Solid Drying Time (min) |

| 60 |

7 (0.39) |

7.5 (0.43) |

6 (0.31) |

7 (0.34) |

| 80 |

8 (0.5) |

8.5 (0.41) |

6.5 (0.5) |

7.5 (0.38) |

| 100 |

9 (0.64) |

10 (0.58) |

8 (0.52) |

9 (0.36) |

| 120 |

10 (0.34) |

10.5 (0.29) |

9 (0.63) |

9.5 (0.56) |

Table 5.

Mechanical properties of the paint films when different amount of paint is applied.

Table 5.

Mechanical properties of the paint films when different amount of paint is applied.

Painting amount

(g/m2) |

Hardness

(grade) |

Adhesion

(grade) |

Loss of film quality

(mg·100r−1) |

| 60 |

2B |

0 |

75.41 (6.77) |

| 80 |

B |

0 |

51.24 (2.06) |

| 100 |

B |

0 |

83.16 (6.71) |

| 120 |

B |

0 |

89.65 (3.68) |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).