Submitted:

11 August 2023

Posted:

14 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

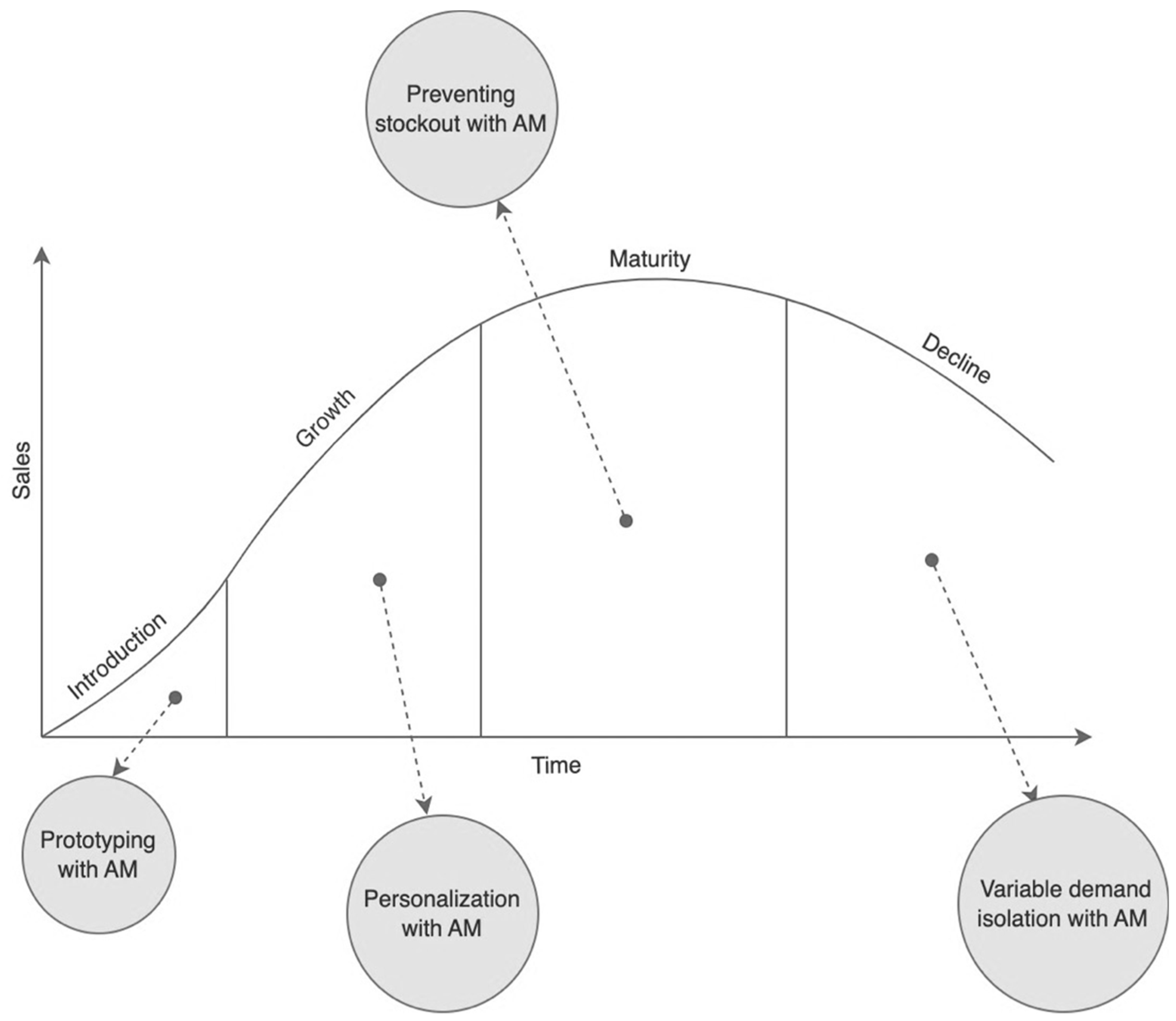

2. Review of Rollout Scenarios

2.1. MAM to Reduce Failure Risk during the Introduction Stage

| Research agenda | Research objectives |

|---|---|

| Assessing the Viability of MAM-Enabled Minimum Viable Products (MVPs) in Aerospace | Conduct case studies and empirical research to investigate successful implementations of MAM in aerospace for prototyping and product launch. Analyze the factors influencing the effectiveness of MVPs produced using MAM in gathering market feedback and facilitating product improvement. |

| Developing a Framework for Balancing Quality and Certification Requirements | Investigate the challenges associated with achieving the necessary quality standards and certification in aerospace when utilizing MAM for MVP development. Propose a framework that ensures MVPs meet regulatory requirements while embracing the inherent iterative nature of MAM-based prototyping. |

| Identifying Barriers to Widespread Adoption of MVPs in Aerospace | Conduct surveys and interviews with industry experts and stakeholders to understand the reasons behind the limited acceptance of MVPs in aerospace. Explore the cultural and organizational factors that hinder the adoption of MVPs and MAM technologies, seeking strategies to overcome resistance. |

| Characterizing Uncertainty Levels in MAM Prototyping | Develop a comprehensive model to assess uncertainty levels in different prototyping areas within aerospace based on market dynamics and technological advancements. Establish guidelines to assist decision-making regarding the most suitable prototyping |

| Evaluating Cost-Benefit Analysis of MAM-Based MVP Launch | Quantify the potential cost savings and time-to-market advantages of introducing MVPs in aerospace through MAM technology. Compare the financial implications of iterative MAM-based prototyping against traditional prototyping methods to showcase its economic viability. |

| Integrating MAM in Existing Aerospace Product Introduction Strategies | Explore how MAM can complement or enhance traditional product introduction strategies in aerospace, taking into account the diverse manufacturing requirements and regulations. Develop practical guidelines for incorporating MAM in existing strategies to ensure seamless integration and optimized results. |

2.2. MAM to Isolate Personalization in Demand

| Research agenda | Research objectives |

|---|---|

| Parallel Combination of AM and Conventional Manufacturing | Investigate the optimal implementation of a parallel combination of MAM and conventional manufacturing methods for personalized aerospace components. Examine scenarios where MAM is used for customized seat brackets, armrests, and overhead storage compartments, while traditional methods are employed for standardized components like overhead bins, floor panels, and door frames. |

| Series Combination of AM and Conventional Manufacturing | Explore the benefits of a series combination of MAM and conventional manufacturing techniques in aerospace product development. Investigate cases where MAM is utilized for rapid iterations and design testing, leading to final designs transferred to conventional methods for large-scale production, such as casting or precision machining. Examine cases of successful transitions from AM-based prototyping to conventional mass production in the aerospace industry. |

| Complementary Capacity of MAM in Conventional Manufacturing | Investigate how MAM can serve as a complementary capacity to conventional manufacturing methods in aerospace production. Examine scenarios where MAM is utilized alongside traditional techniques to enhance production efficiency and product performance. |

2.3. MAM to Prevent Stockout Events

| Research agenda | Research objectives |

|---|---|

| Assessing the effectiveness of MAM in preventing stockout events in the aerospace | Conduct empirical studies to evaluate how MAM can effectively prevent stockout events in the aerospace industry. Analyze real-world case studies and industry data to quantify the impact of MAM implementation on reducing stockout occurrences and the associated penalties. Compare the performance of MAM-based on-demand production with traditional mass production and inventory management strategies in terms of cost-effectiveness and customer satisfaction. |

| Development of responsive inventory management strategies | Propose inventory management strategies that integrate MAM with traditional manufacturing methods to achieve greater responsiveness to customer demands. Design frameworks to dynamically adjust inventory levels based on demand forecasts and real-time order data. Compare the cost-effectiveness and inventory turnover rates of MAM-based on-demand production with traditional inventory management approaches. |

| Cost-benefit analysis of MAM adoption in aerospace | Evaluate the financial implications of reducing inventory holding costs, avoiding stockout penalties, and meeting customer demand with timely delivery through MAM. Consider the initial investment in MAM technology, operating costs, and long-term financial benefits to determine the overall economic viability and return on investment. |

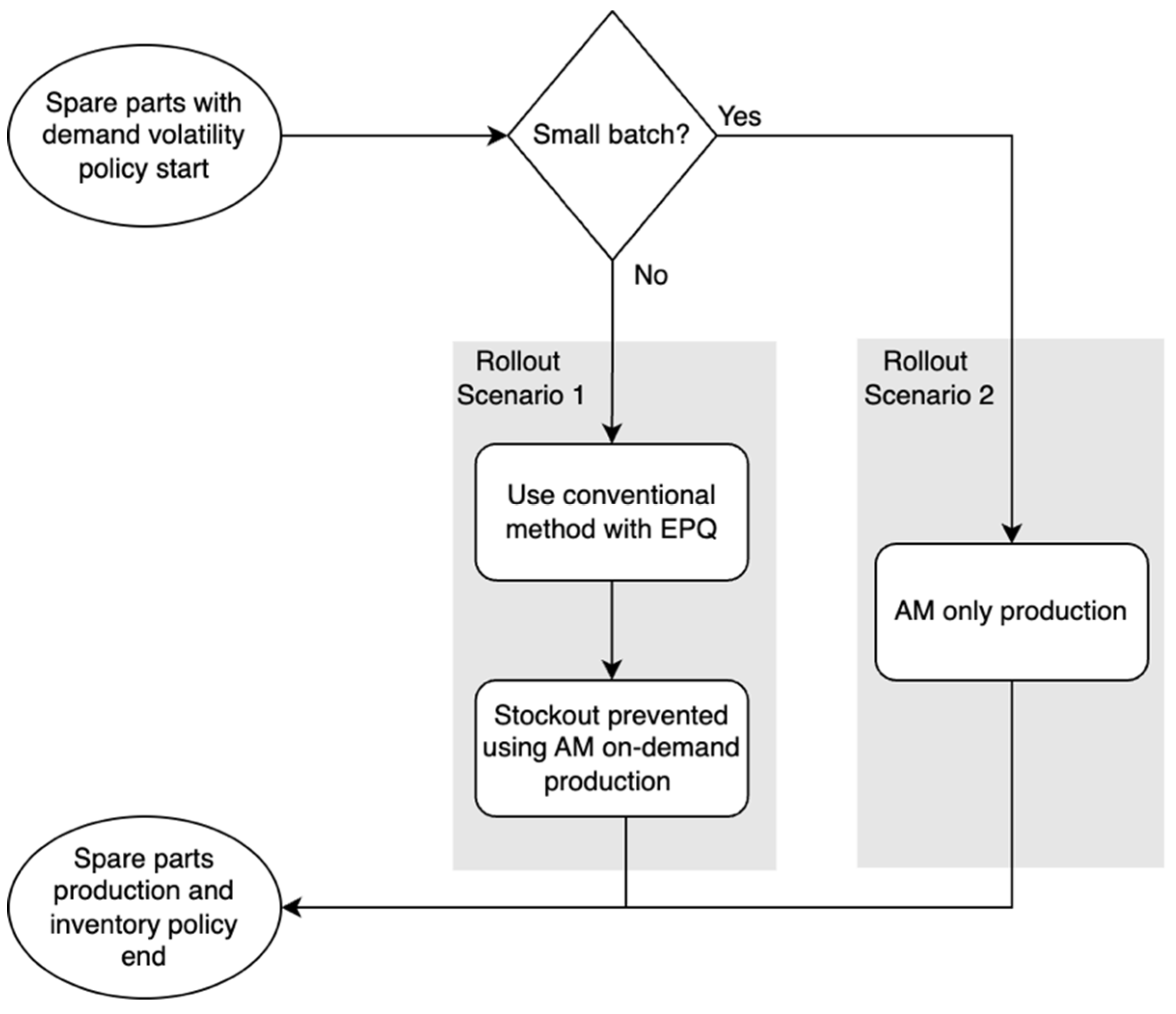

2.4. MAM to Isolate Demand Variability

| Research agenda | Research objectives |

|---|---|

| Assessing the feasibility and cost-benefit of mam for spare parts production | Perform a cost-benefit analysis of implementing MAM for producing spare parts in response to demand variability. Evaluate the economic implications of MAM adoption, considering factors such as inventory holding costs, excess inventory, stockout penalties, and the overall efficiency of the supply chain. |

| Supply chain integration and implementation strategies | Develop frameworks and strategies for integrating MAM into the spare parts industry supply chain to effectively manage demand variability. Propose guidelines for optimizing the production process, lead times, and inventory levels through MAM adoption. Address potential challenges and constraints in transitioning from traditional mass production to MAM-based on-demand production. |

| Case studies and industry best practices | Conduct in-depth case studies on successful implementations of MAM for managing demand variability in the aerospace spare parts industry. Analyze best practices and lessons learned from aerospace manufacturers and MRO companies that have effectively leveraged MAM to improve supply chain responsiveness and spare parts availability. |

Conclusion

Funding

Conflicts of Interest

References

- Liao, Y.; Loures, E.R.; Deschamps, F.; Brezinski, G.; Venâncio, A. The impact of the fourth industrial revolution: a cross-country/region comparison. Production 2018, 28. [CrossRef]

- Tavani, D.; Zamparelli, L. Labor-augmenting technical change and the wage share: New microeconomic foundations. Structural Change and Economic Dynamics 2021, 56, 27-34. [CrossRef]

- Adam, G.A.; Zimmer, D. On design for additive manufacturing: evaluating geometrical limitations. Rapid Prototyping Journal 2015, 21, 662-670. [CrossRef]

- Dong, H.; Li, X.; Xu, K.; Zang, Z.; Liu, X.; Zhang, Z.; Xiao, W.; Li, Y. A Review on Solid-State-Based Additive Friction Stir Deposition. Aerospace 2022, 9, 565. [CrossRef]

- Kovacs, S.E.; Miko, T.; Troiani, E.; Markatos, D.; Petho, D.; Gergely, G.; Varga, L.; Gacsi, Z. Additive Manufacturing of 17-4PH Alloy: Tailoring the Printing Orientation for Enhanced Aerospace Application Performance. Aerospace 2023, 10, 619. [CrossRef]

- Wang, Y.-C.; Chen, T.; Lin, Y.-C. 3D Printer Selection for Aircraft Component Manufacturing Using a Nonlinear FGM and Dependency-Considered Fuzzy VIKOR Approach. Aerospace 2023, 10, 591. [CrossRef]

- Thorvald, P.; Fast Berglund, Å.; Romero, D. The cognitive operator 4.0. In Proceedings of the 18th International Conference on Manufacturing Research, ICMR 2021, incorporating the 35th National Conference on Manufacturing Research, 7–10 September 2021, University of Derby, Derby, UK, 2021; pp. 3-8.

- Bergeaud, A.; Cette, G.; Lecat, R. Productivity trends in advanced countries between 1890 and 2012. Review of Income and Wealth 2016, 62, 420-444. [CrossRef]

- Rymarczyk, J. Technologies, opportunities and challenges of the industrial revolution 4.0: theoretical considerations. Entrepreneurial business and economics review 2020, 8, 185-198. [CrossRef]

- Jideani, A.I.; Mutshinyani, A.P.; Maluleke, N.P.; Mafukata, Z.P.; Sithole, M.V.; Lidovho, M.U.; Ramatsetse, E.K.; Matshisevhe, M.M. Impact of industrial revolutions on food machinery-an overview. Journal of Food Research 2020, 9, 42-52. [CrossRef]

- Yeheskel, O.; Globerson, S. The impact of the fourth industrial revolution on organizational control. International Journal of Human Resource Studies 2020, 10, 255267-255267. [CrossRef]

- CHOI, C.; KIM, C.; KIM, C. Towards sustainable environmental policy and management in the fourth industrial revolution: Evidence from big data analytics. The Journal of Asian Finance, Economics and Business 2019, 6, 185-192.

- Nasution, D.A.D.; Muda, I.; Sumekar, A.; Abubakar, E. Analysis of The Economic Behavior of Society E-Commerce as An Impact on The Development of The 4.0 Industrial Revolution and Society 5.0. In Proceedings of the BICED 2020: Proceedings of the 2nd EAI Bukittinggi International Conference on Education, BICED 2020, 14 September, 2020, Bukititinggi, West Sumatera, Indonesia, 2021; p. 217.

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial artificial intelligence in industry 4.0-systematic review, challenges and outlook. IEEE Access 2020, 8, 220121-220139. [CrossRef]

- Gokalp, M.O.; Kayabay, K.; Akyol, M.A.; Eren, P.E.; Koçyiğit, A. Big data for industry 4.0: A conceptual framework. In Proceedings of the 2016 international conference on computational science and computational intelligence (CSCI), 2016; pp. 431-434.

- Georgios, L.; Kerstin, S.; Theofylaktos, A. Internet of things in the context of industry 4.0: An overview. 2019.

- Goel, R.; Gupta, P. Robotics and industry 4.0. A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development 2020, 157-169.

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. International Journal of Production Research 2018, 56, 848-861. [CrossRef]

- Nia, A.R.; Awasthi, A.; Bhuiyan, N. Industry 4.0 and demand forecasting of the energy supply chain: A literature review. Computers & Industrial Engineering 2021, 154, 107128. [CrossRef]

- Peres, R.S.; Rocha, A.D.; Leitao, P.; Barata, J. IDARTS–Towards intelligent data analysis and real-time supervision for industry 4.0. Computers in industry 2018, 101, 138-146. [CrossRef]

- Kazantsev, N.; Pishchulov, G.; Mehandjiev, N.; Sampaio, P.; Zolkiewski, J. Formation of demand-driven collaborations between suppliers in Industry 4.0 production networks. In Proceedings of the 20th International Working Seminar on Production Economics, 2018; pp. 255-266.

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Enabling flexible manufacturing system (FMS) through the applications of industry 4.0 technologies. Internet of Things and Cyber-Physical Systems 2022, 2, 49-62. [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Materials & Design 2021, 209, 110008. [CrossRef]

- Bian, Z.; Wang, X.; Zhang, Z.; Song, C.; Gao, T.; Hu, W.; Sun, L.; Chen, X. An ML-Based Approach for HCF Life Prediction of Additively Manufactured AlSi10Mg Considering the Effects of Powder Size and Fatigue Damage. Aerospace 2023, 10, 586. [CrossRef]

- Miko, T.; Petho, D.; Gergely, G.; Markatos, D.; Gacsi, Z. A Novel Process to Produce Ti Parts from Powder Metallurgy with Advanced Properties for Aeronautical Applications. Aerospace 2023, 10, 332. [CrossRef]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid prototyping journal 2022, 28, 87-100. [CrossRef]

- Bandyopadhyay, A.; Bose, S. Additive manufacturing; CRC press: 2019.

- Ben-Ner, A.; Siemsen, E. Decentralization and localization of production: The organizational and economic consequences of additive manufacturing (3D printing). California Management Review 2017, 59, 5-23.

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: rapid prototyping comes of age. Rapid prototyping journal 2012, 18, 255-258. [CrossRef]

- Touri, M.; Kabirian, F.; Saadati, M.; Ramakrishna, S.; Mozafari, M. Additive manufacturing of biomaterials− the evolution of rapid prototyping. Advanced Engineering Materials 2019, 21, 1800511. [CrossRef]

- Kang, Y.G.; Lee, K.M.; Choi, G. Rapid Prototyping of Three-Phase AC Machine Drive System with Subtractive and Additive Manufacturing. Energies 2023, 16, 2266. [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Boumpakis, A.; Kontodina, T.; Tsongas, K.; Tzetzis, D.; Kostavelis, I.; Givissis, P.; Tzovaras, D. Development of biodegradable customized tibial scaffold with advanced architected materials utilizing additive manufacturing. Journal of the Mechanical Behavior of Biomedical Materials 2023, 141, 105796. [CrossRef]

- Bai, L.; Gong, C.; Chen, X.; Sun, Y.; Zhang, J.; Cai, L.; Zhu, S.; Xie, S.Q. Additive manufacturing of customized metallic orthopedic implants: Materials, structures, and surface modifications. Metals 2019, 9, 1004. [CrossRef]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. Journal of Manufacturing Systems 2019, 53, 124-149. [CrossRef]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. The impact of metal additive manufacturing on the aerospace industry. Metals 2019, 9, 1286. [CrossRef]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Mortágua, J.P. Selective laser melting (SLM) and topology optimization for lighter aerospace componentes. Procedia Structural Integrity 2016, 1, 289-296. [CrossRef]

- Van Sice, C.; Faludi, J. Comparing environmental impacts of metal additive manufacturing to conventional manufacturing. Proceedings of the Design Society 2021, 1, 671-680. [CrossRef]

- Alogla, A.; Baumers, M.; Tuck, C. Analysis of the effects of operator experience and learning in laser sintering. International Journal of Mechatronics and Manufacturing Systems 2021, 14, 87-110.

- Kannan, G.B.; Rajendran, D.K. A review on status of research in metal additive manufacturing. Advances in 3D printing & additive manufacturing technologies 2017, 95-100.

- Emmelmann, C.; Kranz, J.; Herzog, D.; Wycisk, E. Laser additive manufacturing of metals. In Laser Technology in Biomimetics: Basics and Applications; Springer: 2014; pp. 143-162.

- Alogla, A.A.; Baumers, M.; Tuck, C.; Elmadih, W. The impact of additive manufacturing on the flexibility of a manufacturing supply chain. Applied Sciences 2021, 11, 3707. [CrossRef]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. International journal of production economics 2014, 149, 194-201. [CrossRef]

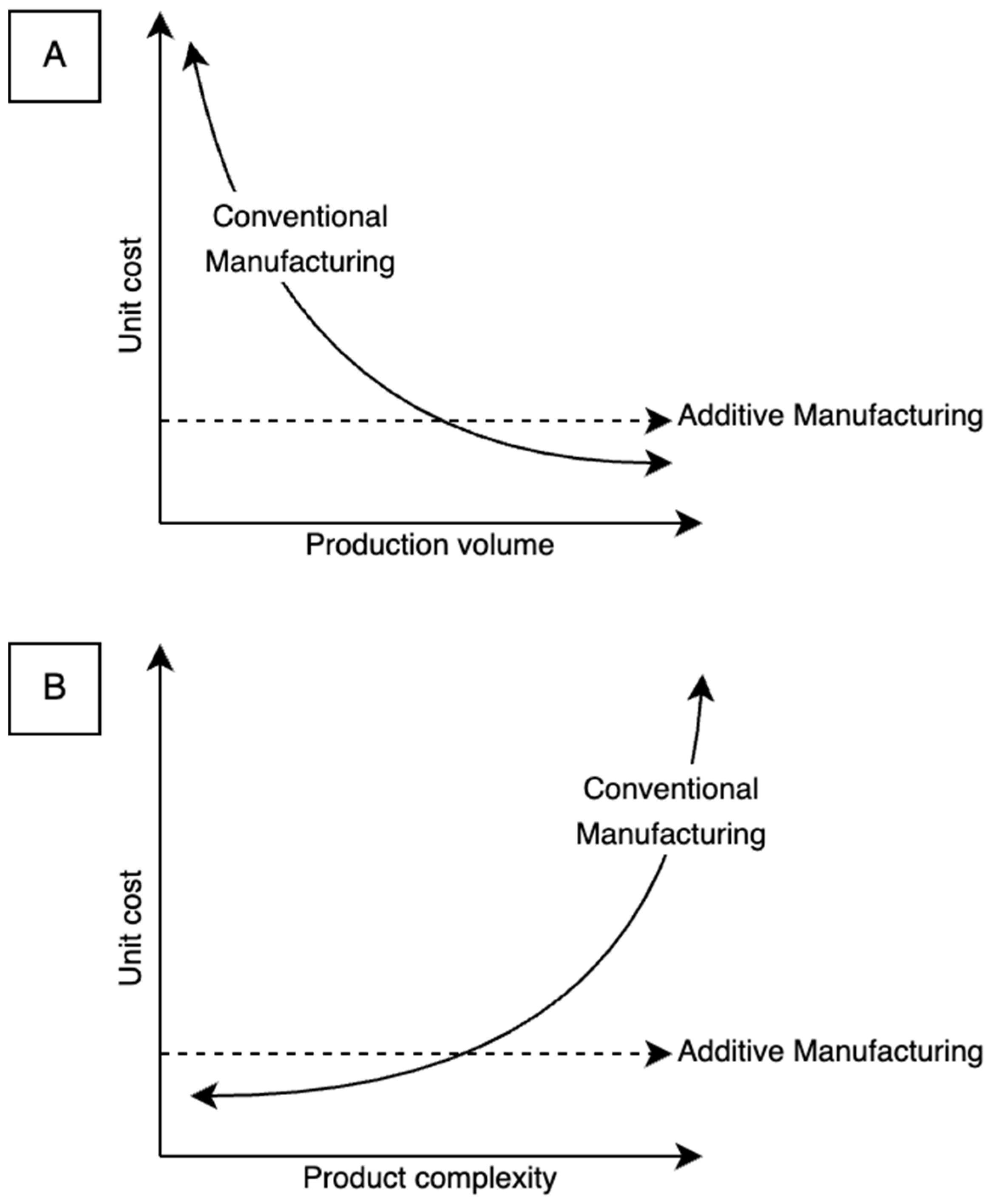

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: machine productivity, economies of scale and technology-push. Technological forecasting and social change 2016, 102, 193-201. [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manufacturing 2019, 30, 11-18. [CrossRef]

- Fera, M.; Macchiaroli, R.; Fruggiero, F.; Lambiase, A. A new perspective for production process analysis using additive manufacturing—complexity vs production volume. The International Journal of Advanced Manufacturing Technology 2018, 95, 673-685. [CrossRef]

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Madera, I.; Mouriaux, F. Designing for additive manufacturing: lightweighting through topology optimization enables lunar spacecraft. Journal of Mechanical Design 2017, 139, 100905. [CrossRef]

- Yang, S.; Tang, Y.; Zhao, Y.F. A new part consolidation method to embrace the design freedom of additive manufacturing. Journal of Manufacturing Processes 2015, 20, 444-449. [CrossRef]

- Schmelzle, J.; Kline, E.V.; Dickman, C.J.; Reutzel, E.W.; Jones, G.; Simpson, T.W. (Re) Designing for part consolidation: Understanding the challenges of metal additive manufacturing. Journal of Mechanical Design 2015, 137, 111404. [CrossRef]

- Cao, H.; Folan, P. Product life cycle: the evolution of a paradigm and literature review from 1950–2009. Production Planning & Control 2012, 23, 641-662. [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J.; Tuomi, J. Risk reduction in new product launch: A hybrid approach combining direct digital and tool-based manufacturing. Computers in Industry 2015, 74, 29-42.

- Sasson, A.; Johnson, J.C. The 3D printing order: variability, supercenters and supply chain reconfigurations. International Journal of Physical Distribution & Logistics Management 2016, 46, 82-94.

- Chiu, M.-C.; Lin, Y.-H. Simulation based method considering design for additive manufacturing and supply chain: An empirical study of lamp industry. Industrial Management & Data Systems 2016, 116, 322-348.

- Alogla, A. The impact of adopting Additive Manufacturing on responsive supply chain performance. University of Nottingham, 2021.

- Gibbons, D.W.; Serfontein, J.-P.L.; Van der Merwe, A.F. Mapping the path to certification of metal laser powder bed fusion for aerospace applications. Rapid Prototyping Journal 2021, 27, 355-361. [CrossRef]

- Hilal, H.; Lancaster, R.; Jeffs, S.; Boswell, J.; Stapleton, D.; Baxter, G. The influence of process parameters and build orientation on the creep behaviour of a laser powder bed fused Ni-based superalloy for aerospace applications. Materials 2019, 12, 1390. [CrossRef]

- Pirozzi, C.; Franchitti, S.; Borrelli, R.; Chiariello, A.; Di Palma, L. The effect of post-processing on the mechanical behavior of Ti6Al4V manufactured by electron beam powder bed fusion for general aviation primary structural applications. Aerospace 2020, 7, 75. [CrossRef]

- Liu, Z.; He, B.; Lyu, T.; Zou, Y. A review on additive manufacturing of titanium alloys for aerospace applications: Directed energy deposition and beyond Ti-6Al-4V. Jom 2021, 73, 1804-1818. [CrossRef]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering 2015, 229, 2132-2147. [CrossRef]

- Patel, R.; Dhimmar, V.; Kagzi, S.; Patel, M. Investigation of Fused Deposition Modelling Process Parameters in 3D Printing for Composite Material (Poly Lactic Acid and Banana Fibre). International Journal of Automotive and Mechanical Engineering 2022, 19, 10028–10038-10028–10038. [CrossRef]

- Pant, M.; Pidge, P.; Nagdeve, L.; Kumar, H. A Review of Additive Manufacturing in Aerospace Application. Journal of Composite & Advanced Materials/Revue des Composites et des Matériaux Avancés 2021, 31.

- Cooper, R.G. Perspective: The stage-gate® idea-to-launch process—update, what's new, and nexgen systems. Journal of product innovation management 2008, 25, 213-232.

- He, P.; Pei, Y.; Lin, C.; Ye, D. Ambidextrous marketing capabilities, exploratory and exploitative market-based innovation, and innovation performance: an empirical study on China’s manufacturing sector. Sustainability 2021, 13, 1146. [CrossRef]

- Jesemann, I.; Beichter, T.; Herburger, K.; Constantinescu, C.; Rüger, M. Migration of the Lean-Startup approach from High-Tech startups towards product design in large manufacturing companies. Procedia CIRP 2020, 91, 594-599. [CrossRef]

- Bortolini, R.F.; Nogueira Cortimiglia, M.; Danilevicz, A.d.M.F.; Ghezzi, A. Lean Startup: a comprehensive historical review. Management Decision 2021, 59, 1765-1783. [CrossRef]

- Cooper, R.G.; Sommer, A.F. Agile–Stage-Gate for Manufacturers: Changing the Way New Products Are Developed Integrating Agile project management methods into a Stage-Gate system offers both opportunities and challenges. Research-Technology Management 2018, 61, 17-26.

- Cooper, R.G.; Sommer, A.F. The agile–stage-gate hybrid model: a promising new approach and a new research opportunity. Journal of Product Innovation Management 2016, 33, 513-526. [CrossRef]

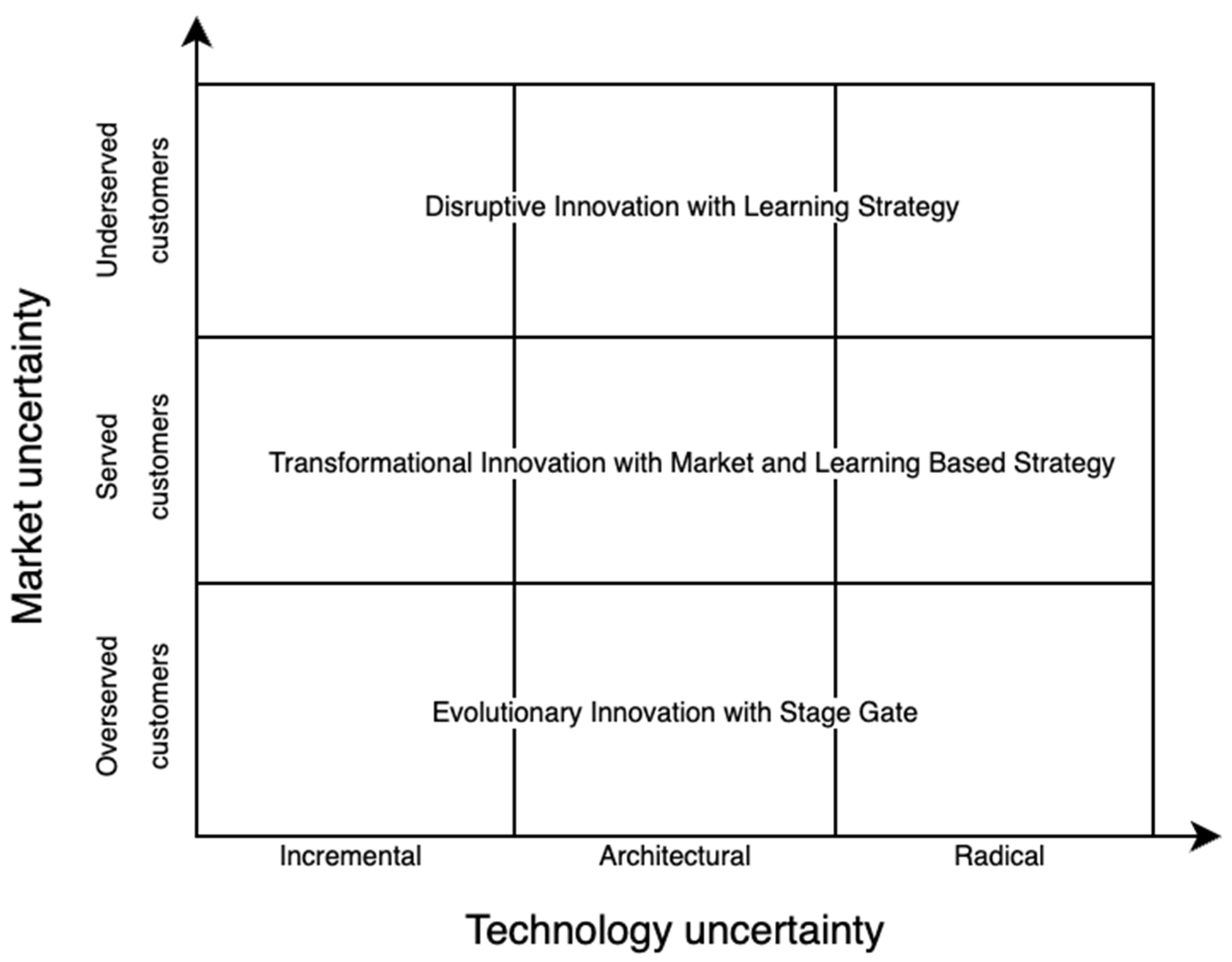

- Koen, P.A.; Bertels, H.M.; Elsum, I.R. The three faces of business model innovation: Challenges for established firms. Research-Technology Management 2011, 54, 52-59.

- Christensen, C.; Raynor, M. The innovator's solution: Creating and sustaining successful growth; Harvard Business Review Press: 2013.

- Christensen, C.M. The innovator's dilemma: when new technologies cause great firms to fail; Harvard Business Review Press: 2013.

- Waller, D.; Polizzi, A.; Iten, J. Feasibility study of additively manufactured Al-6061 RAM2 parts for aerospace applications. In Proceedings of the AIAA Scitech 2019 Forum, 2019; p. 0409. [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. International Journal of Lightweight Materials and Manufacture 2021, 4, 246-261. [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Progress in materials science 2019, 106, 100578. [CrossRef]

- Muhammad, M.; Nezhadfar, P.; Thompson, S.; Saharan, A.; Phan, N.; Shamsaei, N. A comparative investigation on the microstructure and mechanical properties of additively manufactured aluminum alloys. International Journal of Fatigue 2021, 146, 106165. [CrossRef]

- Pollock, T.; Clarke, A.; Babu, S. Design and tailoring of alloys for additive manufacturing. Metallurgical and Materials Transactions A 2020, 51, 6000-6019. [CrossRef]

- Katsarelis, C.; Chen, P.; Gradl, P.; Protz, C.; Jones, Z.; Ellis, D.; Evans, L. Additive manufacturing of NASA HR-1 material for liquid rocket engine component applications; 2019.

- Hassen, A.A.; Lindahl, J.; Chen, X.; Post, B.; Love, L.; Kunc, V. Additive manufacturing of composite tooling using high temperature thermoplastic materials. In Proceedings of the SAMPE Conference Proceedings, Long Beach, CA, 2016; pp. 2648-2658.

- Kunc, V.; Lindahl, J.; Dinwiddie, R.; Post, B.; Love, L.; Matlack, M.; Fahey, R.; Hassen, A.A. Investigation of in-autoclave additive manufacturing composite tooling. In Proceedings of the CAMX Conference, Anaheim, CA, 2016.

- Post, B.; Lind, R.; Lloyd, P.; Kunc, V.; Linhal, J.; Love, L. The economics of big area additive manufacturing. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, 2016.

- Billah, K.M.M.; Heineman, J.; Mhatre, P.; Roschli, A.; Post, B.; Kumar, V.; Kim, S.; Haye, G.; Jackson, J.; Skelton, Z. Large-scale additive manufacturing of self-heating molds. Additive Manufacturing 2021, 47, 102282. [CrossRef]

- Hassen, A.A.; Noakes, M.; Nandwana, P.; Kim, S.; Kunc, V.; Vaidya, U.; Love, L.; Nycz, A. Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing. Additive Manufacturing 2020, 32, 101093. [CrossRef]

- Yasa, E.; Poyraz, O.; Cizioglu, N.; Pilatin, S. Repair and manufacturing of high performance tools by additive manufacturing. Notes 2015, 148, 107.

- Gobetz, Z.; Rowen, A.; Heilferty, S.; Dickman, C.; Martukanitz, R. Utilization of Additive Manufacturing for Aerospace Heat Exchangers. Office of Naval Research: Arlington, VA, USA 2016, 55.

- Saltzman, D.; Bichnevicius, M.; Lynch, S.; Simpson, T.W.; Reutzel, E.W.; Dickman, C.; Martukanitz, R. Design and evaluation of an additively manufactured aircraft heat exchanger. Applied Thermal Engineering 2018, 138, 254-263. [CrossRef]

- Gradl, P.R.; Protz, C.S.; Wammen, T. Additive manufacturing and hot-fire testing of liquid rocket channel wall nozzles using blown powder directed energy deposition inconel 625 and JBK-75 Alloys. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, 2019; p. 4362. [CrossRef]

- Gradl, P.R. Principles of Directed Energy Deposition for Aerospace Applications. In Proceedings of the Drive AM Industry Connect, 2021.

- Kumar, L.J.; Krishnadas Nair, C. Current trends of additive manufacturing in the aerospace industry. Advances in 3D printing & additive manufacturing technologies 2017, 39-54. [CrossRef]

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Vernon, R.; Madera, I.J.; Yancey, R.; Mouriaux, F. Additive manufacturing of lightweight, optimized, metallic components suitable for space flight. Journal of Spacecraft and Rockets 2017, 54, 1050-1059. [CrossRef]

- Tomlin, M.; Meyer, J. Topology optimization of an additive layer manufactured (ALM) aerospace part. In Proceedings of the Proceeding of the 7th Altair CAE technology conference, 2011; pp. 1-9.

- Chougrani, L.; Pernot, J.-P.; Véron, P.; Abed, S. Parts internal structure definition using non-uniform patterned lattice optimization for mass reduction in additive manufacturing. Engineering with Computers 2019, 35, 277-289. [CrossRef]

- Allison, T.C.; Rimpel, A.M.; Moore, J.J.; Wilkes, J.C.; Pelton, R.; Wygant, K. Manufacturing and testing experience with direct metal laser sintering for closed centrifugal compressor impellers. In Proceedings of the Proceedings of the 43rd Turbomachinery Symposium, 2014.

- Snyder, J.C.; Thole, K.A. Effect of additive manufacturing process parameters on turbine cooling. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, 2019; p. V05BT21A002. [CrossRef]

- Kerstens, F.; Cervone, A.; Gradl, P. End to end process evaluation for additively manufactured liquid rocket engine thrust chambers. Acta Astronautica 2021, 182, 454-465. [CrossRef]

- Meng, L.; Zhang, W.; Quan, D.; Shi, G.; Tang, L.; Hou, Y.; Breitkopf, P.; Zhu, J.; Gao, T. From topology optimization design to additive manufacturing: Today’s success and tomorrow’s roadmap. Archives of Computational Methods in Engineering 2020, 27, 805-830. [CrossRef]

- Zhu, J.-H.; Li, Y.; Zhang, W.-H.; Hou, J. Shape preserving design with structural topology optimization. Structural and Multidisciplinary Optimization 2016, 53, 893-906. [CrossRef]

- Nagy, D.; Zhao, D.; Benjamin, D. Nature-based hybrid computational geometry system for optimizing component structure. In Proceedings of the Humanizing Digital Reality: Design Modelling Symposium Paris 2017, 2018; pp. 167-176.

- Jia, D.; Li, F.; Zhang, Y. 3D-printing process design of lattice compressor impeller based on residual stress and deformation. Scientific Reports 2020, 10, 600. [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. Additive manufacturing for the aerospace industry 2019, 7-31.

- Xue, L.; Li, Y.; Chen, J.; Wang, S. Laser Consolidation: A Novel Additive Manufacturing Process for Making Net-Shape Functional Metallic Components for Gas Turbine Applications. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, 2015; p. V006T021A016. [CrossRef]

- Du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and functional: a review of biomimetic design in additive manufacturing. Additive Manufacturing 2019, 27, 408-427. [CrossRef]

- Schuh, G.; Doelle, C.; Schloesser, S. Agile Prototyping for technical systems–Towards an adaption of the Minimum Viable Product principle. DS 91: Proceedings of NordDesign 2018, Linköping, Sweden, 14th-17th August 2018 2018.

- Tripathi, N.; Oivo, M.; Liukkunen, K.; Markkula, J. Startup ecosystem effect on minimum viable product development in software startups. Information and Software Technology 2019, 114, 77-91. [CrossRef]

- Gonçalves, C.D.; Trabasso, L.G.; Loureiro, G. Integrated CE tools for postponed aerospace product and process decisions. In Proceedings of the Proceedings of the 2006 conference on Leading the Web in Concurrent Engineering: Next Generation Concurrent Engineering, 2006; pp. 477-487.

- Gonçalves, C.D.; Loureiro, G.; Trabasso, L.G. Product customisation through postponement and CE tools integration in an aerospace company. International Journal of Mass Customisation 2011, 4, 1-21. [CrossRef]

- Hur, J.; Lee, K.; Kim, J. Hybrid rapid prototyping system using machining and deposition. Computer-Aided Design 2002, 34, 741-754. [CrossRef]

- Akula, S.; Karunakaran, K. Hybrid adaptive layer manufacturing: An Intelligent art of direct metal rapid tooling process. Robotics and Computer-Integrated Manufacturing 2006, 22, 113-123. [CrossRef]

- Song, Y.-A.; Park, S. Experimental investigations into rapid prototyping of composites by novel hybrid deposition process. Journal of Materials Processing Technology 2006, 171, 35-40. [CrossRef]

- Xiong, X.; Zhang, H.; Wang, G. Metal direct prototyping by using hybrid plasma deposition and milling. Journal of Materials Processing Technology 2009, 209, 124-130. [CrossRef]

- Kerbrat, O.; Mognol, P.; Hascoët, J.-Y. A new DFM approach to combine machining and additive manufacturing. Computers in Industry 2011, 62, 684-692. [CrossRef]

- Froes, F. Combining additive manufacturing with conventional casting and reduced density materials to greatly reduce the weight of airplane components such as passenger seat frames. In Additive manufacturing for the aerospace industry; Elsevier: 2019; pp. 419-425. [CrossRef]

- Lee, J.Y.; Johnson, G. Contracting for vendor-managed inventory with a time-dependent stockout penalty. International Transactions in Operational Research 2020, 27, 1573-1599.

- Alogla, A.A.; Baumers, M.; Tuck, C.J. Characterizing the Cost of Additive Manufacturing: The Impact of Demand Volatility and the Absence of Inventory. Available at SSRN 4258585.

- Dadzie, K.Q.; Winston, E. Consumer response to stock-out in the online supply chain. International Journal of Physical Distribution & Logistics Management 2007, 37, 19-42.

- Sarkar, B.; Sana, S.S.; Chaudhuri, K. Optimal reliability, production lotsize and safety stock: An economic manufacturing quantity model. International Journal of Management Science and Engineering Management 2010, 5, 192-202. [CrossRef]

- Grondys, K. Issues of Safety Stock Management of Spare Parts in Industrial Companies. International Journal of Arts & Sciences 2015, 8, 553.

- Anderson, E.T.; Fitzsimons, G.J.; Simester, D. Measuring and mitigating the costs of stockouts. Management science 2006, 52, 1751-1763. [CrossRef]

- Pastore, E.; Alfieri, A.; Zotteri, G. An empirical investigation on the antecedents of the bullwhip effect: Evidence from the spare parts industry. International Journal of Production Economics 2019, 209, 121-133. [CrossRef]

- Babai, M.Z.; Chen, H.; Syntetos, A.A.; Lengu, D. A compound-Poisson Bayesian approach for spare parts inventory forecasting. International Journal of Production Economics 2021, 232, 107954. [CrossRef]

- Digiesi, S.; Mossa, G.; Rubino, S. A sustainable EOQ model for repairable spare parts under uncertain demand. IMA Journal of Management Mathematics 2015, 26, 185-203. [CrossRef]

- Alogla, A.A.; Alruqi, M. Aircraft assembly snags: human errors or lack of production design? Aerospace 2021, 8, 391.

- Crute, V.; Ward, Y.; Brown, S.; Graves, A. Implementing Lean in aerospace—challenging the assumptions and understanding the challenges. Technovation 2003, 23, 917-928. [CrossRef]

- Alogla, A.; Baumers, M.; Tuck, C. The impact of adopting additive manufacturing on the performance of a responsive supply chain. In Proceedings of the Proceedings of the 24th International Symposium on Logistics (ISL 2019): Supply Chain Networks vs Platforms: Innovations, Challenges and Opportunities, Wurzburg, Germany, 2019; pp. 14-17.

- Coykendall, J.; Cotteleer, M.; Holdowsky, J.; Mahto, M. 3D opportunity in aerospace and defense: Additive manufacturing takes flight. A Deloitte series on additive manufacturing 2014, 1.

- Froes, F.H.; Boyer, R. Additive manufacturing for the aerospace industry; Elsevier: 2019.

- Alogla, A.A.; Alzahrani, A.; Alghamdi, A. The Role of Additive Manufacturing in Reducing Demand Volatility in Aerospace: A Conceptual Framework. Aerospace 2023, 10, 381. [CrossRef]

| Studies | Market uncertainty level | Technology uncertainty level | Type of innovation |

|---|---|---|---|

|

Low | Low | Incremental |

|

Low | Medium | Architectural |

|

Low | High | Radical |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).