Submitted:

09 August 2023

Posted:

11 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

| Output | References | Year | Technique | R2 |

|---|---|---|---|---|

| Back-break | [21] | 2008 | ANN | – |

| [22] | 2009 | ANN | 0.9 | |

| [23] | 2010 | FIS | 0.95 | |

| [20] | 2012 | GA-ANN | 0.96 | |

| [24] | 2013 | SVM | 0.92 | |

| [25] | 2013 | ANN | 0.87 | |

| [26] | 2013 | ANN | 0.86 | |

| [27] [28] |

2014 | ANN, ANFIS | ANN = 0.92 | |

| ANFIS=0.96 | ||||

| [29] | 2015 | GP | 0.98 | |

| [29] | 2016 | ANN | 0.77 | |

| [30] | 2016 | ANN-ABC | 0.77 | |

| Fly-rock | [20] | 2011 | ANN-GA | ANN-GA=0.933 |

| [31] | 2012 | GA-ANN | 0.98 | |

| [32] [33] |

2012 | ANN, SVM | ANN = 0.85 | |

| SVM = 0.94 | ||||

| [34] | 2012 | MCs | 0.834 | |

| [35] | 2013 | SVM | 0.95 | |

| [36] | 2014 | ANN-PSO | 0.93 | |

| [37] | 2014 | ANN | 0.98 | |

| [38] [19] |

2014 | ANN, FIS | ANN=0.935 | |

| FIS=0.955 | ||||

| [39] [40] |

2015 | ANN, ANFIS | ANN=0.83 | |

| ANFIS=0.96 | ||||

| [41] | 2016 | ANN | 0.97 | |

| [42] | 2016 | ANN-ACO | 0.99 | |

| [2] | 2016 | MCs | 0.855 | |

| [25] | 2018 | ANN-FA | 0.93 | |

| [43] | 2019 | LMR | 0.843 | |

| Rock fragmentation | [44] | 2009 | FIS | 0.96 |

| [29] | 2010 | ANN | 0.98 | |

| [45] | 2011 | ANN | 0.97 | |

| [41] | 2013 | ANN | 0.85 | |

| [21] | 2013 | ANFIS | 0.83 | |

| [22] [23] |

2015 | FIS, LMR | FIS=0.922 | |

| LMR=0.738 | ||||

| [20] | 2016 | ANN-ABC | 0.78 | |

| [24] [25] |

2016 | RES, NLMR | RES=0.866 | |

| NLMR=0.777 | ||||

| [26] | 2018 | ANN-FA | 0.94 |

2. Research Methodology

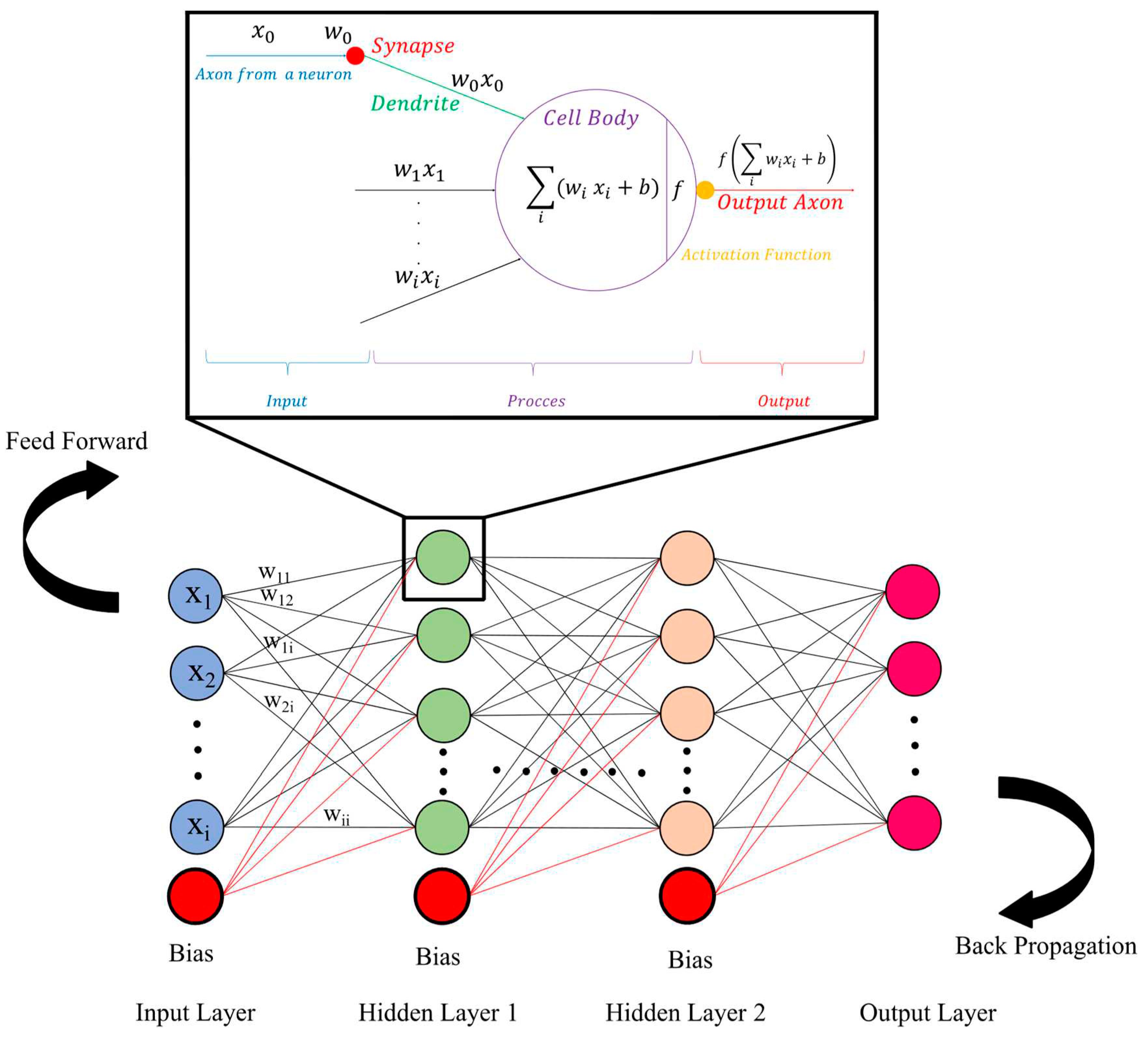

2.1. Multilayer Perception Neural Network (MLPNN)

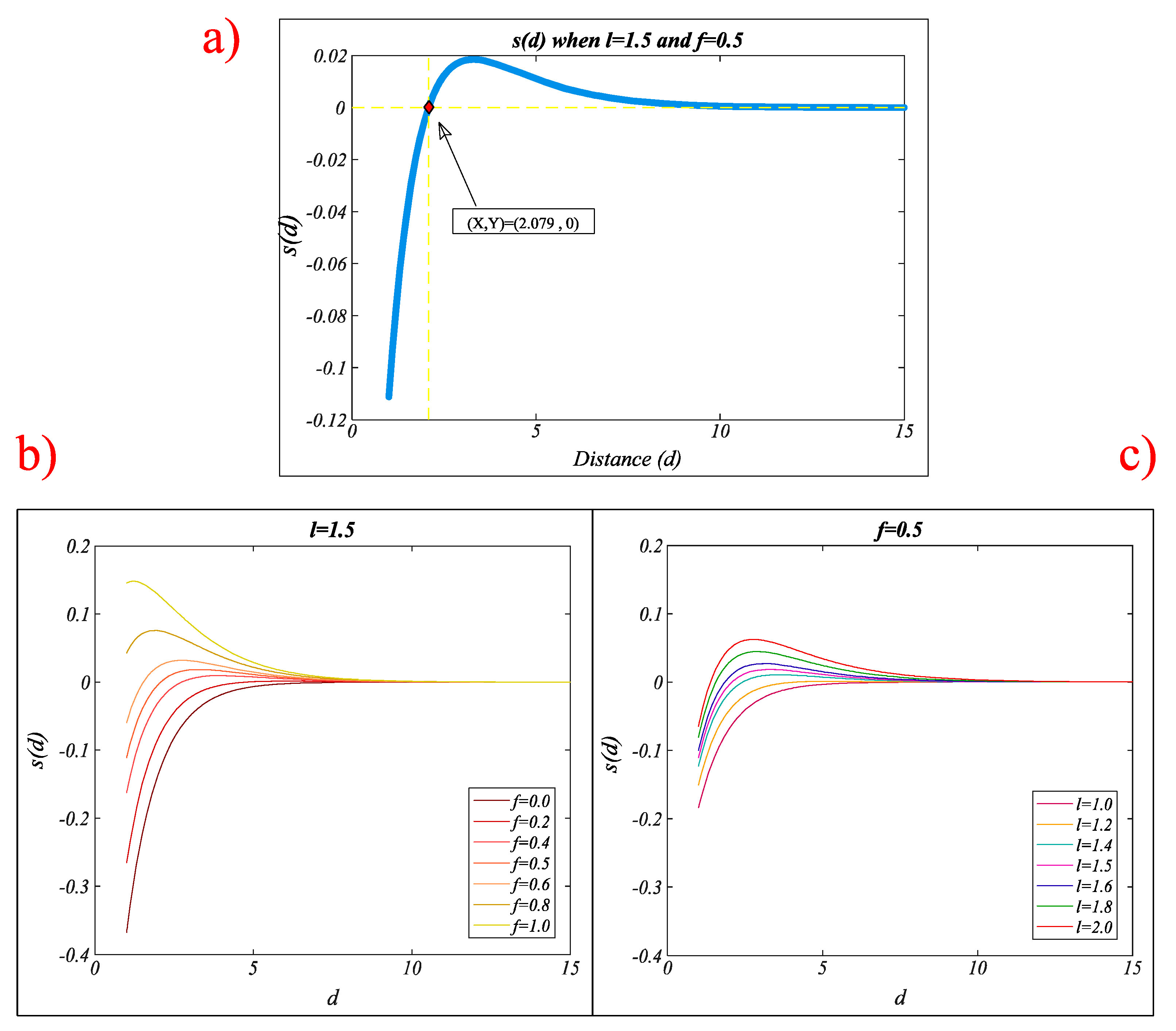

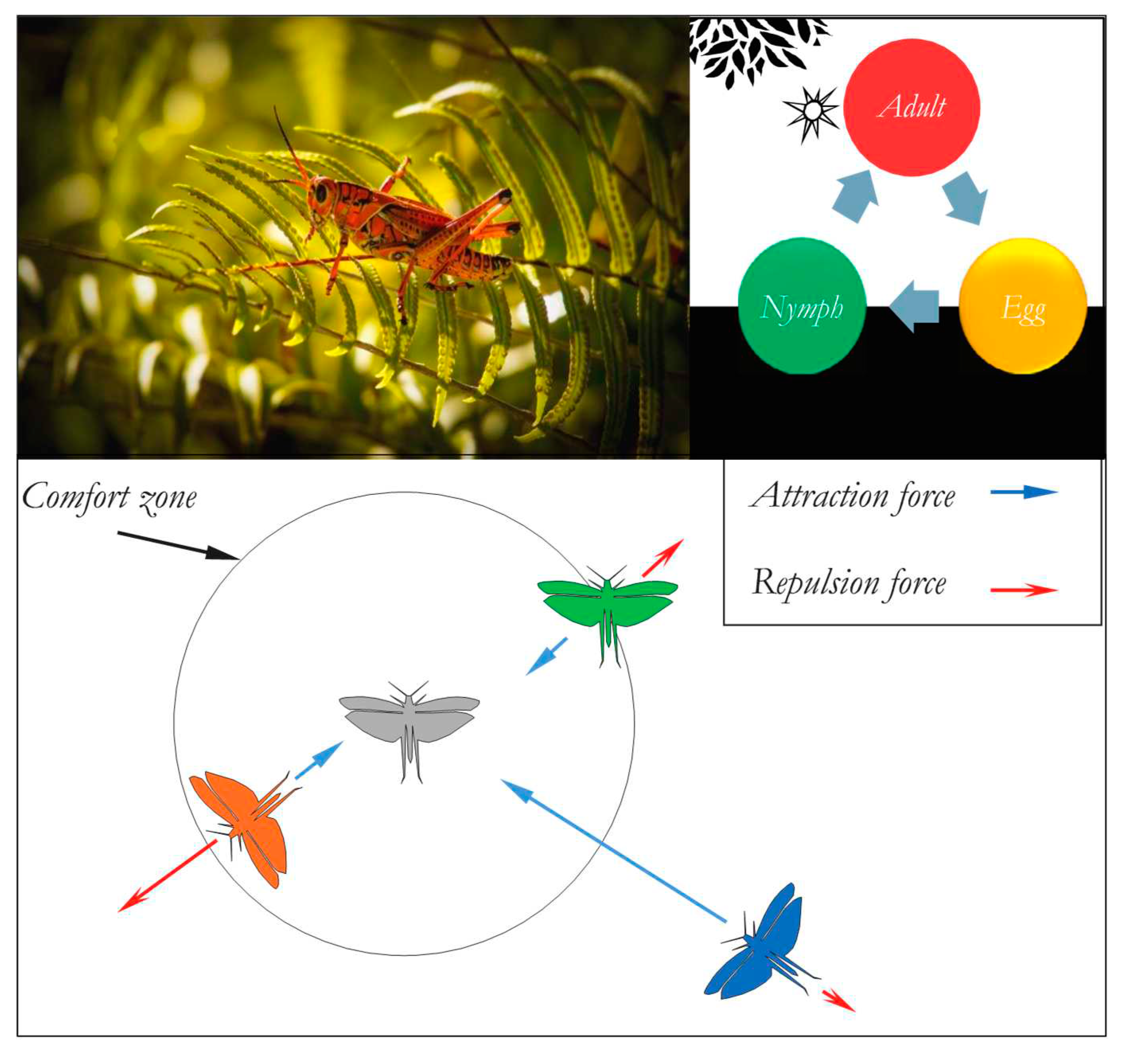

2.2. Grasshopper Optimization Algorithm (GOA)

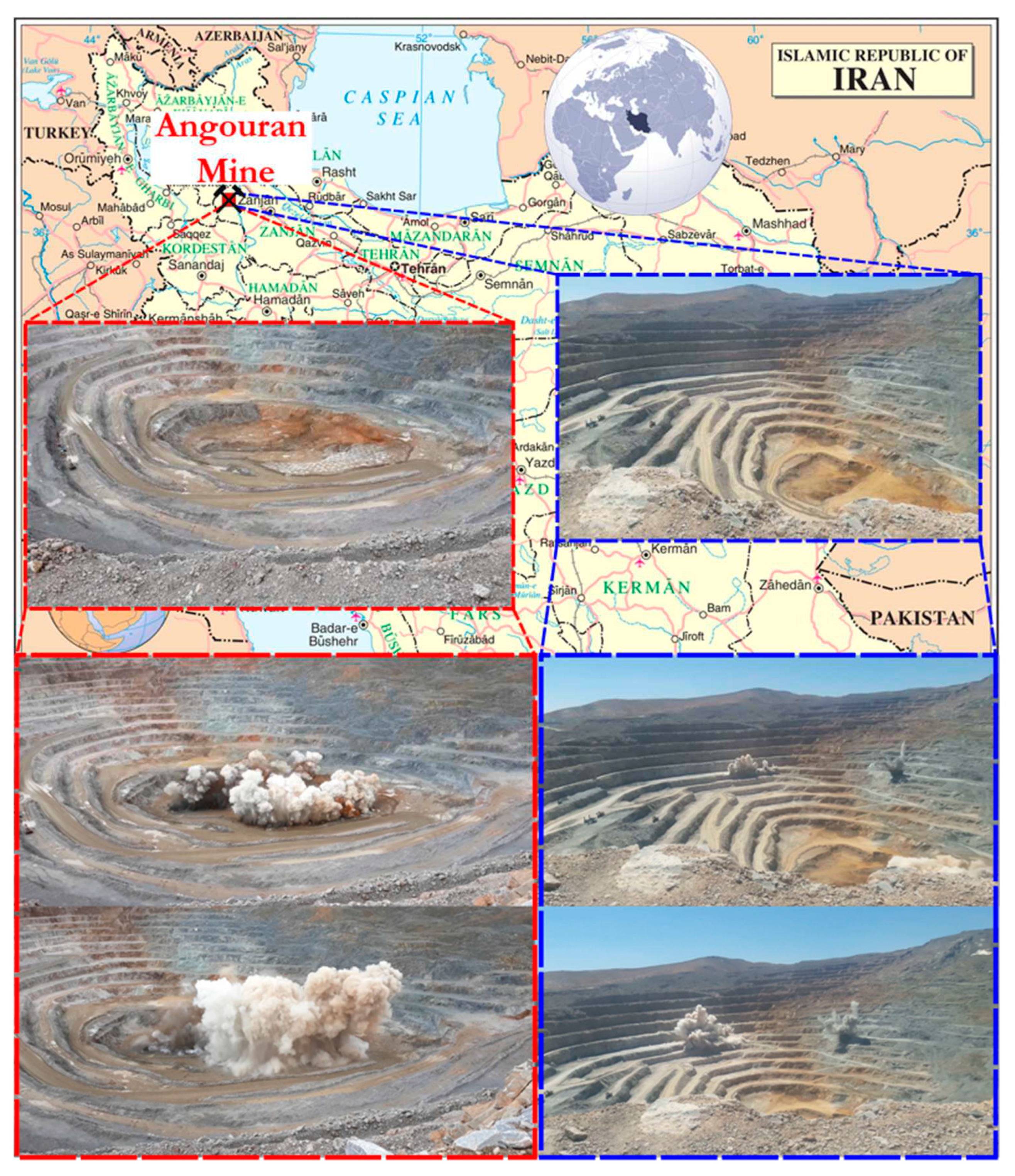

3. Case Study: Anguran Lead-Zinc Mine

| Target | Effective Parameters |

|---|---|

| Back-break | Hole length, Burden, Spacing, Stemming, Charge per delay |

| Fly-rock | Hole length, Burden, Spacing, Stemming, Charge per delay, Hole slope |

4. Results and Discussions

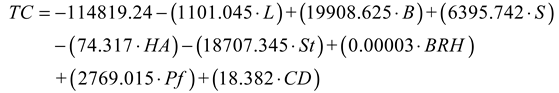

4.1. Regression-Based Mine-to-Crusher Cost Model

4.2. ANN-Based Model for Predicting the Back-Break and Fly-Rock

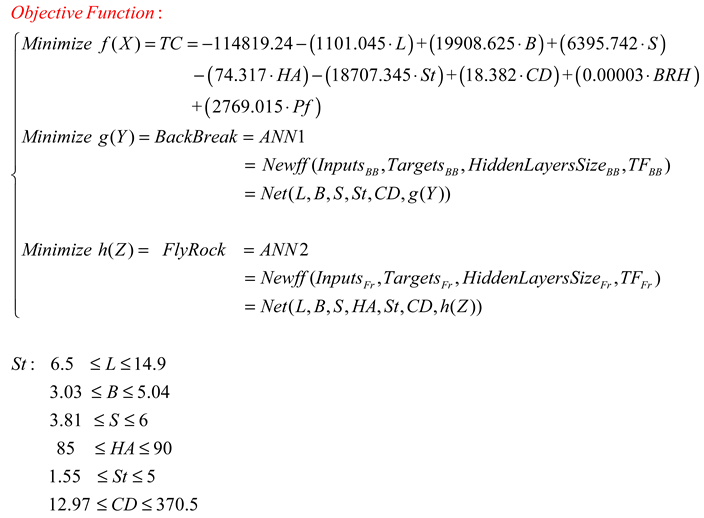

4.3. Optimization of the Blasting Pattern

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lundborg, N.; Persson, A.; Ladegaard-Pedersen, A.; Holmberg, R. Keeping the Lid on Flyrock in Open-Pit Blasting. Eng Min J 1975, 176, 95–100. [Google Scholar]

- Lundborg, N. The Probability of Flyrock; SveDeFo, 1981;

- Gupta, R.N.; Bagchi, A.; Singh, B. Optimising Drilling and Blasting Parameters to Improve Blasting Efficiency. New Delhi CBIP. Rock Mech. India, Status Rep. 1988; 185–206. [Google Scholar]

- Richard, A.B.; Moore, A.J. Golden Pike Cut Back Fly Rock Control and Calibration of a Predictive Model. Terrock Consult. Eng. Report, Kalgoorlie Consol. Gold Mines 2005, 37. [Google Scholar]

- McKenzie, C.K. Flyrock Range and Fragment Size Prediction. In Proceedings of the Proceedings of the 35th annual conference on explosives and blasting technique; International Society of Explosives Engineers, 2009; Vol. 2.

- Monjezi, M.; Bahrami, A.; Yazdian Varjani, A. Simultaneous Prediction of Fragmentation and Flyrock in Blasting Operation Using Artificial Neural Networks. Int. J. Rock Mech. Min. Sci. 2010. [Google Scholar] [CrossRef]

- Rezaei, M.; Monjezi, M.; Yazdian Varjani, A. Development of a Fuzzy Model to Predict Flyrock in Surface Mining. Saf. Sci. 2011. [Google Scholar] [CrossRef]

- Bahrami, A.; Monjezi, M.; Goshtasbi, K.; Ghazvinian, A. Prediction of Rock Fragmentation Due to Blasting Using Artificial Neural Network. Eng. Comput. 2011, 27, 177–181. [Google Scholar] [CrossRef]

- Monjezi, M.; Bahrami, A.; Varjani, A.Y.; Sayadi, A.R. Prediction and Controlling of Flyrock in Blasting Operation Using Artificial Neural Network. Arab. J. Geosci. 2011, 4, 421–425. [Google Scholar] [CrossRef]

- Monjezi, M.; Khoshalan, H.A.; Varjani, A.Y. Prediction of Flyrock and Backbreak in Open Pit Blasting Operation: A Neuro-Genetic Approach. Arab. J. Geosci. 2012, 5, 441–448. [Google Scholar] [CrossRef]

- Amini, H.; Gholami, R.; Monjezi, M.; Torabi, S.R.; Zadhesh, J. Evaluation of Flyrock Phenomenon Due to Blasting Operation by Support Vector Machine. Neural Comput. Appl. 2012. [Google Scholar] [CrossRef]

- Ghasemi, E.; Sari, M.; Ataei, M. Development of an Empirical Model for Predicting the Effects of Controllable Blasting Parameters on Flyrock Distance in Surface Mines. Int. J. Rock Mech. Min. Sci. 2012, 52, 163–170. [Google Scholar] [CrossRef]

- Monjezi, M.; Mehrdanesh, A.; Malek, A.; Khandelwal, M. Evaluation of Effect of Blast Design Parameters on Flyrock Using Artificial Neural Networks. Neural Comput. Appl. 2013. [Google Scholar] [CrossRef]

- Khandelwal, M.; Monjezi, M. Prediction of Backbreak in Open-Pit Blasting Operations Using the Machine Learning Method. Rock Mech. Rock Eng. 2013. [Google Scholar] [CrossRef]

- Mohamad, E.T.; Armaghani, D.J.; Hajihassani, M.; Faizi, K.; Marto, A. A Simulation Approach to Predict Blasting-Induced Flyrock and Size of Thrown Rocks. Electron. J. Geotech. Eng. 2013. [Google Scholar]

- Armaghani, D.J.; Hajihassani, M.; Mohamad, E.T.; Marto, A.; Noorani, S.A. Blasting-Induced Flyrock and Ground Vibration Prediction through an Expert Artificial Neural Network Based on Particle Swarm Optimization. Arab. J. Geosci. 2014, 7, 5383–5396. [Google Scholar] [CrossRef]

- Marto, A.; Hajihassani, M.; Jahed Armaghani, D.; Tonnizam Mohamad, E.; Makhtar, A.M. A Novel Approach for Blast-Induced Flyrock Prediction Based on Imperialist Competitive Algorithm and Artificial Neural Network. Sci. World J. 2014, 2014. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Raina, A.K. Prediction of Blast-Induced Flyrock in Indian Limestone Mines Using Neural Networks. J. Rock Mech. Geotech. Eng. 2014, 6, 447–454. [Google Scholar] [CrossRef]

- Ghasemi, E.; Amini, H.; Ataei, M.; Khalokakaei, R. Application of Artificial Intelligence Techniques for Predicting the Flyrock Distance Caused by Blasting Operation. Arab. J. Geosci. 2014, 7, 193–202. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Gupta, N. Prediction of Blast-Induced Flyrock in Opencast Mines Using ANN and ANFIS. Geotech. Geol. Eng. 2015, 33, 875–891. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mahdiyar, A.; Hasanipanah, M.; Faradonbeh, R.S.; Khandelwal, M.; Amnieh, H.B. Risk Assessment and Prediction of Flyrock Distance by Combined Multiple Regression Analysis and Monte Carlo Simulation of Quarry Blasting. Rock Mech. rock Eng. 2016, 49, 3631–3641. [Google Scholar] [CrossRef]

- Faradonbeh, R.S.; Armaghani, D.J.; Monjezi, M.; Mohamad, E.T. Genetic Programming and Gene Expression Programming for Flyrock Assessment Due to Mine Blasting. Int. J. Rock Mech. Min. Sci. 2016, 88, 254–264. [Google Scholar] [CrossRef]

- Raina, A.K.; Murthy, V.M.S.R. Prediction of Flyrock Distance in Open Pit Blasting Using Surface Response Analysis. Geotech. Geol. Eng. 2016. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Raina, A.K. Simultaneous Prediction of Blast-Induced Flyrock and Fragmentation in Opencast Limestone Mines Using Back Propagation Neural Network. Int. J. Min. Miner. Eng. 2016. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Jahed Armaghani, D.; Bakhshandeh Amnieh, H.; Majid, M.Z.A.; Tahir, M.M.D. Application of PSO to Develop a Powerful Equation for Prediction of Flyrock Due to Blasting. Neural Comput. Appl. 2017. [Google Scholar] [CrossRef]

- Asl, P.F.; Monjezi, M.; Hamidi, J.K.; Armaghani, D.J. Optimization of Flyrock and Rock Fragmentation in the Tajareh Limestone Mine Using Metaheuristics Method of Firefly Algorithm. Eng. Comput. 2018. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Jahed Armaghani, D.; Bakhshandeh Amnieh, H.; Koopialipoor, M.; Arab, H. A Risk-Based Technique to Analyze Flyrock Results Through Rock Engineering System. Geotech. Geol. Eng. 2018, 36, 2247–2260. [Google Scholar] [CrossRef]

- Rad, H.N.; Hasanipanah, M.; Rezaei, M.; Eghlim, A.L. Developing a Least Squares Support Vector Machine for Estimating the Blast-Induced Flyrock. Eng. Comput. 2018, 34, 709–717. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Fallah, A.; Armaghani, D.J.; Azizi, A.; Mohamad, E.T. Three Hybrid Intelligent Models in Estimating Flyrock Distance Resulting from Blasting. Eng. Comput. 2019, 35, 243–256. [Google Scholar] [CrossRef]

- Hudaverdi, T.; Akyildiz, O. A New Classification Approach for Prediction of Flyrock Throw in Surface Mines. Bull. Eng. Geol. Environ. 2019. [Google Scholar] [CrossRef]

- Lu, X.; Hasanipanah, M.; Brindhadevi, K.; Bakhshandeh Amnieh, H.; Khalafi, S. ORELM: A Novel Machine Learning Approach for Prediction of Flyrock in Mine Blasting. Nat. Resour. Res. 2020. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Bakhshandeh Amnieh, H.; Amnieh, H.B. A Fuzzy Rule-Based Approach to Address Uncertainty in Risk Assessment and Prediction of Blast-Induced Flyrock in a Quarry. Nat. Resour. Res. 2020, 29, 1–21. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Koopialipoor, M.; Bahri, M.; Hasanipanah, M.; Tahir, M.M. A SVR-GWO Technique to Minimize Flyrock Distance Resulting from Blasting. Bull. Eng. Geol. Environ. 2020, 79, 4369–4385. [Google Scholar] [CrossRef]

- Murlidhar, B.R.; Nguyen, H.; Rostami, J.; Bui, X.N.; Armaghani, D.J.; Ragam, P.; Mohamad, E.T. Prediction of Flyrock Distance Induced by Mine Blasting Using a Novel Harris Hawks Optimization-Based Multi-Layer Perceptron Neural Network. J. Rock Mech. Geotech. Eng. 2021. [Google Scholar] [CrossRef]

- Hosseini, S.; Poormirzaee, R.; Hajihassani, M.; Kalatehjari, R. An ANN-Fuzzy Cognitive Map-Based Z-Number Theory to Predict Flyrock Induced by Blasting in Open-Pit Mines. Rock Mech. Rock Eng. 2022, 1–18. [Google Scholar] [CrossRef]

- Hosseini, S.; Mousavi, A.; Monjezi, M.; Khandelwal, M. Mine-to-Crusher Policy: Planning of Mine Blasting Patterns for Environmentally Friendly and Optimum Fragmentation Using Monte Carlo Simulation-Based Multi-Objective Grey Wolf Optimization Approach. Resour. Policy 2022, 79, 103087. [Google Scholar] [CrossRef]

- Lawal, A.I.; Ojo, O.J.; Kim, M.; Kwon, S. Determination of Blast-Induced Flyrock Using a Drone Technology: A Bibliometric Overview with Practical Soft Computing Implementation. Arab. J. Geosci. 2022, 15, 1–18. [Google Scholar] [CrossRef]

- Ye, J.; He, X. A Novel Hybrid of ANFIS-Based Models Using Optimisation Approaches to Predict Mine Blast-Induced Flyrock. Int. J. Environ. Sci. Technol. 2023, 20, 3673–3686. [Google Scholar] [CrossRef]

- Barkhordari, M.S.; Armaghani, D.J.; Fakharian, P. Ensemble Machine Learning Models for Prediction of Flyrock Due to Quarry Blasting. Int. J. Environ. Sci. Technol. 2022, 19, 8661–8676. [Google Scholar] [CrossRef]

- Bhatawdekar, R.M.; Kumar, R.; Sabri Sabri, M.M.; Roy, B.; Mohamad, E.T.; Kumar, D.; Kwon, S. Estimating Flyrock Distance Induced Due to Mine Blasting by Extreme Learning Machine Coupled with an Equilibrium Optimizer. Sustainability 2023, 15, 3265. [Google Scholar] [CrossRef]

- Yari, M.; Armaghani, D.J.; Maraveas, C.; Ejlali, A.N.; Mohamad, E.T.; Asteris, P.G. Several Tree-Based Solutions for Predicting Flyrock Distance Due to Mine Blasting. Appl. Sci. 2023, 13, 1345. [Google Scholar] [CrossRef]

- Chou, J.-S.; Truong, D.-N. A Novel Metaheuristic Optimizer Inspired by Behavior of Jellyfish in Ocean. Appl. Math. Comput. 2021, 389, 125535. [Google Scholar] [CrossRef]

| Parameters | Notation | Unit | Minimum | Maximum | Mean | Std. Deviation | |

|---|---|---|---|---|---|---|---|

| Inputs | Number of holes | n | - | 10.00 | 180.00 | 73.96 | 35.79 |

| Hole length | L | m | 6.50 | 12.50 | 10.65 | 0.87 | |

| Burden | B | m | 3.80 | 4.20 | 4.13 | 0.11 | |

| Spacing | S | m | 4.80 | 5.00 | 4.95 | 0.08 | |

| Hole slope | HA | degree | 80.00 | 90.00 | 85.19 | 3.20 | |

| Stemming | St | m | 2.00 | 4.90 | 3.44 | 0.63 | |

| Blasted rock per hole | BRH | ton | 41.87 | 788.42 | 392.37 | 163.65 | |

| Powder factor | Pf | Kg/m3 | 0.11 | 0.56 | 0.33 | 0.09 | |

| Charge per delay | CD | Kg | 55.36 | 274.61 | 165.42 | 41.25 | |

| Back-break | BB | m | 2.5 | 9.5 | 5.84 | 0.86 | |

| Fly-rock | Fr | m | 59 | 329 | 114.5 | 17.71 | |

| Operations Cost | Notation | Min | Max | Ave | Std |

|---|---|---|---|---|---|

| Drilling | DC | 181.89 | 6062.41 | 1991.90 | 963.65 |

| Blasting | BC | 95.36 | 10913.46 | 2419.22 | 1360.03 |

| Loading | LC | 932.55 | 31703.24 | 10201.58 | 4950.74 |

| Hauling | HC | 2613.54 | 88850.47 | 28590.62 | 13874.78 |

| Crushing | CC | 0.09 | 176496 | 31308.46 | 37822.67 |

| Secondary Blasting | SBC | 0 | 63.97 | 24.97 | 6.69 |

| Hydraulic Hammer | HHC | 0 | 219.05 | 84.24 | 31.28 |

| Bulldozing and Grading | BC | 22.87 | 2087.57 | 105.48 | 103.44 |

| Loader | LC | 58.75 | 1031.13 | 222.24 | 90.60 |

| Secondary Crushing | SCC | 0 | 44123.99 | 8543.94 | 9614.75 |

| Additional Loading | ALC | 0 | 466.76 | 28.51 | 28.30 |

| Additional Hauling | AHC | 0 | 223.81 | 66.87 | 32.78 |

| Compensation | CC | 0 | 6774.27 | 346.62 | 415.46 |

| Total | TC | 5887.58 | 351784.60 | 83934.65 | 53208.73 |

| ANOVA | ||||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | df | Mean Square | F | Sig. | ||||

| Regression | 2.14×1013 | 9 | 2.38×1012 | 129555.928 | 0.000 | |||

| Residual | 9.13×1011 | 49787 | 1.84×107 | |||||

| Total | 2.23×1013 | 49796 | ||||||

| Coefficients | ||||||||

| Unstandardized Coefficients | Standardized Coefficients | t | Sig. | Collinearity Statistics | ||||

| B | Std. Error | Beta | Tolerance | VIF | ||||

| (Constant) | -114819.236 | 2005.136 | - | -57.263 | 0.000 | - | - | |

| L | -1101.045 | 35.276 | -0.038 | -31.212 | 0.000 | 0.558 | 1.793 | |

| B | 19908.625 | 258.902 | 0.093 | 76.896 | 0.000 | 0.562 | 1.779 | |

| S | 6395.742 | 332.387 | 0.017 | 19.242 | 0.000 | 0.995 | 1.005 | |

| HA | -74.317 | 7.946 | -0.010 | -9.352 | 0.000 | 0.697 | 1.435 | |

| St | -18707.345 | 44.512 | -0.591 | -420.277 | 0.000 | 0.416 | 2.406 | |

| BRH | 0.00003 | 0.146 | 0.000 | -0.002 | 0.998 | 0.613 | 1.630 | |

| Pf | 2769.01 | 278.989 | 0.011 | 9.925 | 0.000 | 0.646 | 1.547 | |

| CD | 18.38 | 0.513 | 0.036 | 35.826 | 0.000 | 0.830 | 1.205 | |

| Model | Training Algorithm | Structure | Transfer Function | Train | Test | Validation | Train Rating | Test Rating | Validation Rating | Total Rank | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | |||||

| ANN 1 | LM | 6-3-1 | T-T-T | 0.907 | 2.560 | 0.822 | 3.405 | 0.855 | 2.377 | 8 | 5 | 3 | 23 | 14 | 23 | 76 |

| ANN 2 | LM | 6-5-1 | T-T-T | 0.847 | 1.908 | 0.964 | 1.774 | 0.935 | 2.061 | 3 | 19 | 24 | 24 | 17 | 13 | 100 |

| ANN 3 | OSS | 6-3-1 | T-T-T | 0.841 | 3.415 | 0.751 | 5.086 | 0.833 | 2.218 | 11 | 8 | 1 | 16 | 27 | 2 | 65 |

| ANN 4 | OSS | 6-5-5-1 | T-T-T | 0.800 | 0.092 | 0.880 | 8.648 | 0.841 | 4.281 | 22 | 14 | 26 | 2 | 24 | 10 | 98 |

| ANN 5 | OSS | 6-7-5-1 | T-T-T | 0.900 | 0.106 | 0.899 | 0.256 | 0.899 | 0.269 | 6 | 17 | 13 | 13 | 6 | 6 | 61 |

| ANN 6 | SCG | 6-3-1 | T-T-T | 0.924 | 2.317 | 0.552 | 5.100 | 0.749 | 3.896 | 12 | 29 | 14 | 29 | 13 | 29 | 126 |

| ANN 7 | SCG | 6-7-5-1 | T-T-T | 0.848 | 3.153 | 0.578 | 5.624 | 0.693 | 4.174 | 23 | 11 | 4 | 27 | 29 | 16 | 110 |

| ANN 8 | GDX | 6-3-1 | T-T-T | 0.910 | 1.136 | 0.937 | 2.370 | 0.778 | 3.735 | 25 | 25 | 15 | 11 | 7 | 11 | 94 |

| ANN 9 | GDX | 6-5-1 | T-T-T | 0.554 | 5.846 | 0.584 | 4.401 | 0.639 | 5.157 | 28 | 23 | 11 | 20 | 22 | 3 | 107 |

| ANN 10 | LM | 6-6-1 | T-T-T | 0.852 | 3.100 | 0.791 | 3.645 | 0.813 | 4.038 | 14 | 21 | 12 | 25 | 2 | 26 | 100 |

| ANN 11 | LM | 6-10-1 | T-T-T | 0.937 | 2.074 | 0.931 | 2.597 | 0.923 | 1.761 | 24 | 9 | 28 | 4 | 11 | 20 | 96 |

| ANN 12 | LM | 6-5-5-1 | T-T-P-T | 0.947 | 1.920 | 0.777 | 4.265 | 0.866 | 2.922 | 7 | 6 | 8 | 15 | 20 | 15 | 71 |

| ANN 13 | LM | 6-5-6-1 | T-T-P-T | 0.947 | 1.884 | 0.905 | 2.945 | 0.528 | 5.167 | 2 | 12 | 2 | 17 | 16 | 17 | 66 |

| ANN 14 | LM | 6-5-7-1 | T-P-T-T | 0.848 | 3.075 | 0.738 | 4.907 | 0.705 | 5.213 | 29 | 16 | 25 | 22 | 23 | 27 | 142 |

| ANN 15 | LM | 6-5-8-1 | T-T-T-P | 0.839 | 3.577 | 0.745 | 4.008 | 0.734 | 3.452 | 9 | 20 | 18 | 14 | 12 | 14 | 87 |

| ANN 16 | LM | 6-6-8-1 | T-T-T-P | 0.892 | 0.021 | 0.810 | 3.463 | 0.914 | 3.063 | 17 | 27 | 10 | 21 | 28 | 9 | 112 |

| ANN 17 | LM | 6-6-10-1 | T-T-T-P | 0.946 | 0.035 | 0.563 | 5.899 | 0.565 | 7.028 | 16 | 4 | 16 | 9 | 19 | 24 | 88 |

| ANN 18 | LM | 6-6-11-1 | T-T-T-T | 0.999 | 0.049 | 0.994 | 0.477 | 0.998 | 0.666 | 1 | 3 | 22 | 12 | 30 | 22 | 90 |

| ANN 19 | LM | 6-5-7-1 | T-T-T-T | 0.864 | 3.216 | 0.578 | 4.178 | 0.777 | 4.095 | 15 | 2 | 9 | 18 | 5 | 25 | 74 |

| ANN 20 | LM | 6-5-7-1 | T-T-T-T | 0.856 | 3.231 | 0.577 | 4.527 | 0.769 | 4.472 | 30 | 30 | 29 | 30 | 25 | 30 | 174 |

| ANN 21 | LM | 6-6-10-1 | T-T-T-T | 0.826 | 3.205 | 0.669 | 4.764 | 0.854 | 4.205 | 21 | 26 | 21 | 10 | 9 | 4 | 91 |

| ANN 22 | LM | 6-6-12-1 | T-T-T-T | 0.863 | 3.192 | 0.520 | 4.273 | 0.824 | 3.884 | 5 | 1 | 30 | 19 | 15 | 5 | 75 |

| ANN 23 | LM | 6-8-5-1 | T-T-P-T | 0.910 | 0.099 | 0.903 | 0.643 | 0.906 | 0.536 | 27 | 28 | 7 | 1 | 8 | 1 | 72 |

| ANN 24 | LM | 6-8-9-1 | T-T-T-T | 0.908 | 0.364 | 0.814 | 2.427 | 0.920 | 3.121 | 10 | 10 | 17 | 3 | 4 | 21 | 65 |

| ANN 25 | LM | 6-8-10-1 | T-L-T-T | 0.855 | 3.271 | 0.638 | 4.582 | 0.766 | 3.461 | 18 | 15 | 6 | 5 | 10 | 7 | 61 |

| ANN 26 | LM | 6-9-11-1 | T-T-T-T | 0.846 | 3.471 | 0.673 | 4.343 | 0.788 | 3.122 | 26 | 22 | 19 | 28 | 21 | 28 | 144 |

| ANN 27 | LM | 6-10-5-1 | T-T-T-L | 0.832 | 3.434 | 0.828 | 3.184 | 0.787 | 3.726 | 20 | 7 | 27 | 7 | 26 | 12 | 99 |

| ANN 28 | LM | 6-10-7-1 | T-T-T-T | 0.829 | 3.533 | 0.803 | 4.420 | 0.687 | 3.204 | 4 | 24 | 20 | 6 | 18 | 19 | 91 |

| ANN 29 | LM | 6-12-8-1 | T-L-T-T | 0.838 | 3.443 | 0.690 | 4.079 | 0.743 | 4.419 | 19 | 13 | 23 | 26 | 3 | 8 | 92 |

| ANN 30 | LM | 6-12-9-1 | T-T-T-T | 0.842 | 3.056 | 0.677 | 5.314 | 0.529 | 6.791 | 13 | 18 | 5 | 8 | 1 | 18 | 63 |

| Model | Training Algorithm | Structure | Transfer Function | Train | Test | Validation | Train Rating | Test Rating | Validation Rating | Total Rank | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | R2 | RMSE | |||||

| ANN 1 | LM | 6-3-1 | T-T-T | 0.783 | 3.955 | 0.730 | 1.571 | 0.865 | 2.472 | 8 | 5 | 3 | 23 | 14 | 23 | 76 |

| ANN 2 | LM | 6-5-1 | T-T-T | 0.723 | 2.000 | 0.920 | 1.496 | 0.881 | 3.496 | 3 | 19 | 24 | 24 | 17 | 13 | 100 |

| ANN 3 | OSS | 6-3-1 | T-T-T | 0.791 | 3.565 | 0.709 | 2.706 | 0.996 | 4.755 | 11 | 8 | 1 | 16 | 27 | 2 | 65 |

| ANN 4 | OSS | 6-5-5-1 | T-T-T | 0.903 | 2.623 | 0.926 | 4.685 | 0.971 | 3.833 | 22 | 14 | 26 | 2 | 24 | 10 | 98 |

| ANN 5 | OSS | 6-7-5-1 | T-T-T | 0.759 | 2.350 | 0.850 | 2.996 | 0.785 | 4.462 | 6 | 17 | 13 | 13 | 6 | 6 | 61 |

| ANN 6 | SCG | 6-3-1 | T-T-T | 0.816 | 0.729 | 0.858 | 0.925 | 0.841 | 0.763 | 12 | 29 | 14 | 29 | 13 | 29 | 126 |

| ANN 7 | SCG | 6-7-5-1 | T-T-T | 0.918 | 3.387 | 0.741 | 1.330 | 0.999 | 3.019 | 23 | 11 | 4 | 27 | 29 | 16 | 110 |

| ANN 8 | GDX | 6-3-1 | T-T-T | 0.923 | 1.253 | 0.859 | 3.222 | 0.796 | 3.785 | 25 | 25 | 15 | 11 | 7 | 11 | 94 |

| ANN 9 | GDX | 6-5-1 | T-T-T | 0.960 | 1.562 | 0.835 | 2.214 | 0.937 | 4.668 | 28 | 23 | 11 | 20 | 22 | 3 | 107 |

| ANN 10 | LM | 6-6-1 | T-T-T | 0.837 | 1.645 | 0.836 | 1.391 | 0.762 | 1.249 | 14 | 21 | 12 | 25 | 2 | 26 | 100 |

| ANN 11 | LM | 6-10-1 | T-T-T | 0.922 | 3.514 | 0.968 | 4.446 | 0.820 | 2.615 | 24 | 9 | 28 | 4 | 11 | 20 | 96 |

| ANN 12 | LM | 6-5-5-1 | T-T-P-T | 0.771 | 3.903 | 0.805 | 2.911 | 0.929 | 3.197 | 7 | 6 | 8 | 15 | 20 | 15 | 71 |

| ANN 13 | LM | 6-5-6-1 | T-T-P-T | 0.715 | 3.081 | 0.723 | 2.423 | 0.880 | 2.881 | 2 | 12 | 2 | 17 | 16 | 17 | 66 |

| ANN 14 | LM | 6-5-7-1 | T-P-T-T | 0.962 | 2.561 | 0.923 | 2.044 | 0.938 | 1.236 | 29 | 16 | 25 | 22 | 23 | 27 | 142 |

| ANN 15 | LM | 6-5-8-1 | T-T-T-P | 0.787 | 1.980 | 0.867 | 2.975 | 0.831 | 3.274 | 9 | 20 | 18 | 14 | 12 | 14 | 87 |

| ANN 16 | LM | 6-6-8-1 | T-T-T-P | 0.845 | 1.174 | 0.814 | 2.115 | 0.998 | 4.253 | 17 | 27 | 10 | 21 | 28 | 9 | 112 |

| ANN 17 | LM | 6-6-10-1 | T-T-T-P | 0.841 | 4.279 | 0.862 | 3.355 | 0.909 | 1.889 | 16 | 4 | 16 | 9 | 19 | 24 | 88 |

| ANN 18 | LM | 6-6-11-1 | T-T-T-T | 0.705 | 4.304 | 0.913 | 3.124 | 1.000 | 2.584 | 1 | 3 | 22 | 12 | 30 | 22 | 90 |

| ANN 19 | LM | 6-5-7-1 | T-T-T-T | 0.840 | 4.486 | 0.813 | 2.371 | 0.782 | 1.396 | 15 | 2 | 9 | 18 | 5 | 25 | 74 |

| ANN 20 | LM | 6-5-7-1 | T-T-T-T | 0.987 | 0.231 | 0.979 | 0.527 | 0.973 | 0.472 | 30 | 30 | 29 | 30 | 25 | 30 | 174 |

| ANN 21 | LM | 6-6-10-1 | T-T-T-T | 0.897 | 1.199 | 0.889 | 3.243 | 0.811 | 4.639 | 21 | 26 | 21 | 10 | 9 | 4 | 91 |

| ANN 22 | LM | 6-6-12-1 | T-T-T-T | 0.752 | 4.670 | 0.989 | 2.326 | 0.872 | 4.567 | 5 | 1 | 30 | 19 | 15 | 5 | 75 |

| ANN 23 | LM | 6-8-5-1 | T-T-P-T | 0.951 | 1.055 | 0.801 | 4.903 | 0.809 | 4.942 | 27 | 28 | 7 | 1 | 8 | 1 | 72 |

| ANN 24 | LM | 6-8-9-1 | T-T-T-T | 0.789 | 3.463 | 0.864 | 4.607 | 0.768 | 2.592 | 10 | 10 | 17 | 3 | 4 | 21 | 65 |

| ANN 25 | LM | 6-8-10-1 | T-L-T-T | 0.854 | 2.619 | 0.782 | 4.319 | 0.813 | 4.279 | 18 | 15 | 6 | 5 | 10 | 7 | 61 |

| ANN 26 | LM | 6-9-11-1 | T-T-T-T | 0.945 | 1.582 | 0.869 | 1.268 | 0.930 | 1.107 | 26 | 22 | 19 | 28 | 21 | 28 | 144 |

| ANN 27 | LM | 6-10-5-1 | T-T-T-L | 0.893 | 3.683 | 0.946 | 4.106 | 0.978 | 3.696 | 20 | 7 | 27 | 7 | 26 | 12 | 99 |

| ANN 28 | LM | 6-10-7-1 | T-T-T-T | 0.749 | 1.369 | 0.888 | 4.282 | 0.888 | 2.629 | 4 | 24 | 20 | 6 | 18 | 19 | 91 |

| ANN 29 | LM | 6-12-8-1 | T-L-T-T | 0.866 | 2.713 | 0.918 | 1.354 | 0.767 | 4.257 | 19 | 13 | 23 | 26 | 3 | 8 | 92 |

| ANN 30 | LM | 6-12-9-1 | T-T-T-T | 0.829 | 2.220 | 0.770 | 3.378 | 0.757 | 2.748 | 13 | 18 | 5 | 8 | 1 | 18 | 63 |

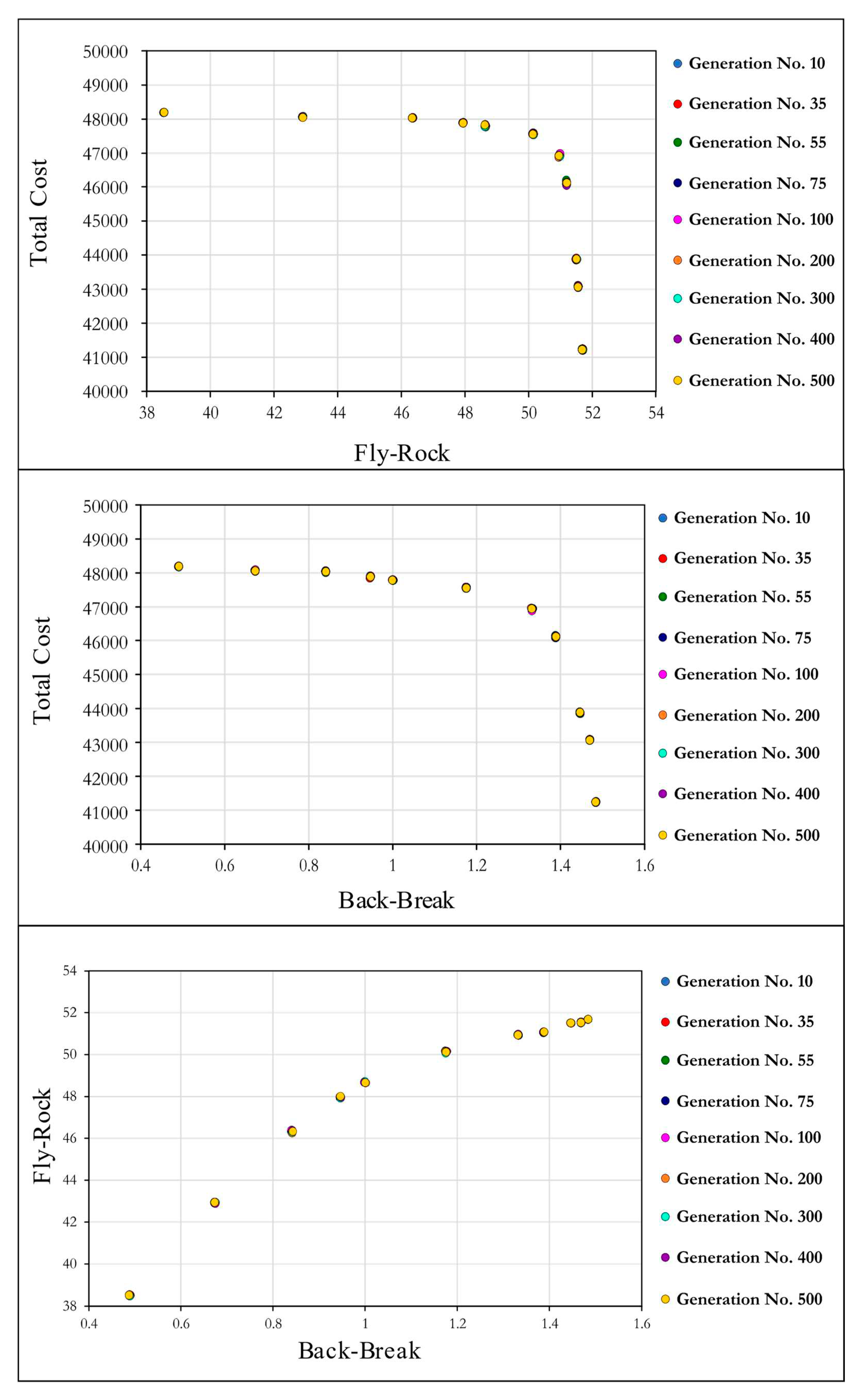

| Pareto Solution | Costs ($ per Blast) | Fly-Rock (m) | Back-Break (m) | Costs Increase (%) | Fly-Rock Reduction (%) | Back-Break Reduction (%) |

|---|---|---|---|---|---|---|

| 1 | 41157.28 | 51.69 | 1.48 | 0 | 0 | 0 |

| 2 | 43348.23 | 51.56 | 1.47 | 5.32 | 1.01 | 0.27 |

| 3 | 44306.00 | 51.51 | 1.45 | 7.65 | 2.57 | 0.36 |

| 4 | 46965.96 | 51.2 | 1.39 | 14.11 | 6.52 | 0.96 |

| 5 | 47937.19 | 50.96 | 1.33 | 16.47 | 10.28 | 1.42 |

| 6 | 48685.52 | 50.15 | 1.17 | 18.29 | 20.83 | 3.00 |

| 7 | 48964.96 | 48.65 | 1.00 | 18.97 | 32.61 | 5.89 |

| 8 | 49060.83 | 47.96 | 0.95 | 19.20 | 36.23 | 7.23 |

| 9 | 49246.71 | 46.35 | 0.84 | 19.65 | 43.33 | 10.34 |

| 10 | 49286.71 | 42.91 | 0.67 | 19.75 | 54.65 | 16.99 |

| 11 | 49442.78 | 38.53 | 0.49 | 20.13 | 66.95 | 25.47 |

| Blasting Pattern | L | B | S | HA | St | BRH | Pf | CD |

|---|---|---|---|---|---|---|---|---|

| 1 | 11.30 | 3.13 | 3.81 | 85.5 | 1.27 | 336.89 | 0.040 | 121.28 |

| 2 | 12.20 | 3.14 | 3.75 | 85.0 | 1.73 | 359.14 | 0.044 | 50.45 |

| 3 | 11.88 | 3.11 | 3.81 | 85.2 | 2.17 | 351.92 | 0.043 | 135.14 |

| 4 | 10.23 | 3.13 | 3.77 | 85.2 | 3.50 | 301.79 | 0.037 | 122.35 |

| 5 | 11.21 | 3.23 | 3.95 | 85.6 | 1.39 | 357.56 | 0.037 | 125.36 |

| 6 | 12.25 | 3.13 | 3.76 | 85.3 | 2.90 | 360.42 | 0.044 | 71.24 |

| 7 | 11.95 | 3.10 | 3.81 | 85.7 | 1.50 | 352.85 | 0.043 | 178.87 |

| 8 | 10.80 | 3.23 | 3.80 | 85.9 | 2.15 | 331.4 | 0.037 | 220.29 |

| 9 | 10.30 | 3.14 | 3.92 | 90.0 | 1.67 | 316.95 | 0.036 | 99.58 |

| 10 | 11.40 | 3.42 | 4.20 | 85.3 | 2.87 | 409.37 | 0.034 | 202.75 |

| 11 | 11.60 | 3.46 | 4.15 | 85.2 | 1.55 | 416.41 | 0.034 | 25.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).