1. Introduction

In light of the growing environmental consciousness and the increasing demand for wood-based products, there is a pressing need to explore sustainable alternatives that fulfill this demand while minimizing adverse impacts in the environment (Food and Agriculture Organization, 2009; as cited in Adhikari & Ozarska, 201). Existing research has revealed that phellem, the outermost layer of stems and roots in trees and shrubs, has better properties than wood. When most woods are water absorbent and flammable, phellem is impermeable, buoyant, elastic, has a slow burn rate, and repels water during precipitation. Admittedly, the same properties make phellem a potential construction material. This study focuses specifically on coconut palm phellem (COPAP) due to the massive hectarage in the Philippines accounted for coconut palms. Hence, the development of a solution that utilizes COPAP to meet the rising demand for wood-based boards without depleting forest resources.

Therefore, the study generally intends to determine the physico-mechanical properties of coconut palm phellem (COPAP), with the aim to develop a substitute material for drywall panel board. Specifically, the study wants to (1) determine which among the three formulations of COPAP board exhibited the best physico-mechanical properties, (2) compare the physico-mechanical properties of COPAP board with commercially available construction materials namely, particle boards, fiber cement boards, and wafer boards, and finally, (3) identify the possible architectural applications of COPAP board as a new building material.

2. Methods

Materials and Instruments

The phellems used in the study were extracted from the Cocos nucifera tree from Malaybalay, Bukidnon. The machines used for testing were borrowed from the City Engineering Office of Davao City. Testing was held at Qualitest Solutions & Technologies, Inc., B&L Bldg., Beside Ma-a Bridge, Diversion Road, Davao City.

Research Method

This research used experimental methods to be able to introduce the potential of coconut palm phellem as a new building material. COPAP board samples were produced by mixing COPAP, Portland cement, accelerator and portable water, out of which the COPAP and cement are the experimental variables. The three formulations created were: Formulation A which was 40% COPAP and 60% cement; Formulation B which was 25% COPAP and 75% cement; and lastly, Formulation C that was 10% COPAP and 90% cement.

There were three (3) samples assigned per formulation, each of which underwent specific tests that assessed their mechanical properties, namely, Compression Strength Test, Flexural Strength Test, Water Absorption Test, and Fire Resistivity Test. Complementing this quantitative approach, the physical properties of the samples were also observed and recorded in terms of color, texture, porosity, and mass.

Procedure

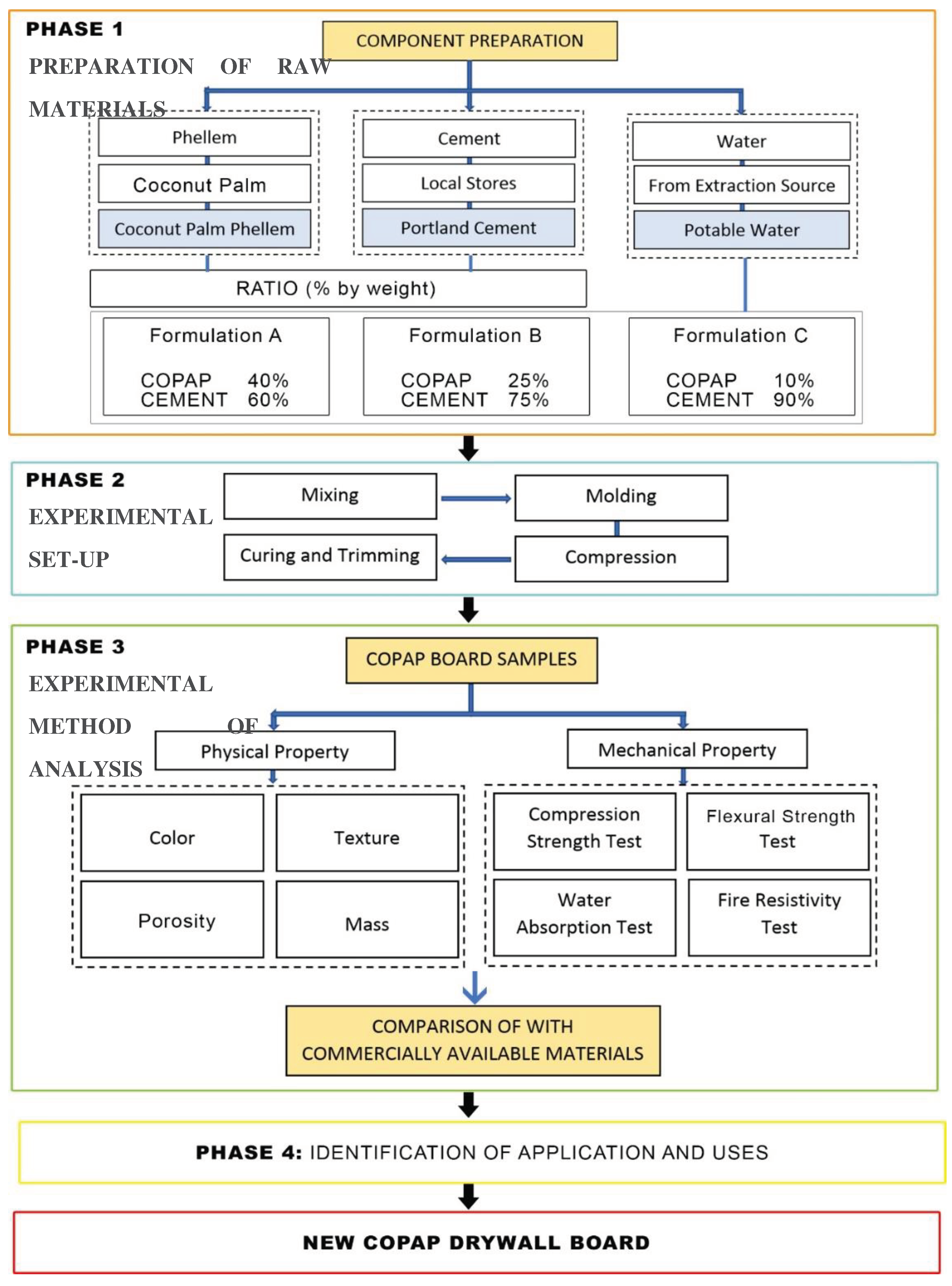

The experimental set-up consisted of four (4) procedural phases. As shown in

Figure 1, Phase 1 of the experiment saw the preparation of Formulations A, B, and C, each having three samples for testing. Whereas the phellems collected were sourced from coconut palms, the Portland cement were retrieved from local hardware stores in Mintal, Davao City and the potable water from the chosen extraction source; an accelerator was also used as a component of the mixtures. The said raw materials were all combined in Phase 2 to produce dry wall board samples according to the prescribed composition per Formulation. Testing and analysis subsequently ensued in Phase 3 which were then compared to their Commercial material counterparts. Lastly, the final phase which was Phase 4, was about the identification of COPAP boards’ application and uses as a new building material.

a. Phase 1: Preparation of Raw Materials

The first phase of the experiment began with the collection of

Cocos nucifera tree barks, which were sun dried for 3 to 5 days (

Figure 2). This was necessary so the phellem can be easily extracted from the barks.

After sun drying the barks, the extraction of phellem was carried out using a wood planer, or by manual pulling with a pair of pliers. Subsequently, the coconut palm phellem (COPAP) were cut into small pieces of approximately 0.25 square cm using a pair of scissors. Afterwards, the phellem underwent another round of sun drying for around 24-48 hours, before using them for Phase 2, to eliminate any remaining moisture content from the cut pieces.

As for the other components of the formulations like cement and accelerator, commercially available options were procured. For the purposes of the study, Ordinary Portland cement is recommended due its wide range of use and applications, while the accelerator, Sikament NN powder was used to facilitate board setting within 24 hours under compression, considering the limited time for experimentation. Finally, the water obtained was sourced from a potable water connection to ensure the absence of unwanted organic matter that may affect the quality of the formulations or the resulting COPAP boards. To help control the quantities of each formulation, as well as the conditions surrounding the process, the following equipment were employed during Phase 1:

Table 1.

Equipment used in the Formulation Process of the COPAP Boards and the operational functions corresponding each equipment.

Table 1.

Equipment used in the Formulation Process of the COPAP Boards and the operational functions corresponding each equipment.

| Equipment Used |

Purpose |

| Digital Weighing Scale |

Used for measuring the weight of each sample |

| Measuring Cup |

Used to accurately measure the ratio compositions of each sample |

| Mixing Plate and Hand Trowel |

The raw materials were mixed in this plate. A hand trowel was used for mixing. |

| Plastic Sheets |

To ensure the mixture will not stick to its molds, these plastic sheets were placed on the molds before the mixture was poured into it. |

| Petroleum Jelly |

To ensure the mixture will not stick to the plastic sheets, the sheets were coated with petroleum jelly before the mixture was poured into it. |

| Weights |

To compress the mixture |

| Moulds |

To determine the shape or form of the formulations as they harden into boards |

During the preparation of Formulations A, B, and C, the amount of water added to each sample varied between 1% – 5% by weight of the water in the mix, while the amount of accelerator added to each sample was assumed to be 2% of the amount of water. These amounts were based on the following formula, which were derived to determine how much water and accelerator are supposed to be added per sample, depending on the formulation they will be tested for.

Equation 1 shows the calculation of the water absorption percentage and

Equation 2 shows the calculation of the accelerator percentage.

b. Phase 2: Experimental Setup

Following the sun-drying the coconut palm phellem (COPAP), the experiment advanced to the second phase. In this phase, the COPAP pieces obtained from Phase 1 were combined with Portland cement and water on a mixing plate using a small hand trowel. Accurate measurements of the proportions were ensured by employing a measuring cup, adhering to the following ratios for formulating the mixtures:

Table 2.

Ratio of Sample Composition.

Table 2.

Ratio of Sample Composition.

| Formulation Type |

Ratio of Material Composition |

Number of Samples |

| COPAP |

Cement |

| A |

40% |

60% |

3 |

| B |

25% |

75% |

3 |

| C |

10% |

90% |

3 |

Afterwards, the mixtures were poured in moulds made of plywood, with wooden studs for framing, and held together by wooden screws. Using the same hand trowel, the mixtures were spread evenly to cover even the corners inside the mold, and were covered with a transparent plastic sheet. For testing purposes, all samples per formulation followed the same dimensions which was 12” x 12” x 1”.

Figure 1.

(left) Spreading the mixture in a wooden mould; (middle) Placing a weight on top of the samples and leaving it there for 24 hours; (right) Cured COPAP samples ready for testing.

Figure 1.

(left) Spreading the mixture in a wooden mould; (middle) Placing a weight on top of the samples and leaving it there for 24 hours; (right) Cured COPAP samples ready for testing.

Subsequently, the samples were pressed for 24 hours using 40 kg/ft3 weights having a flat surface. The samples were then cured for three (3) days, after which the hardened board samples were removed from their respective moulds. In preparation for Phase 3, the surfaces of these boards were removed of any bumps and protrusions using a cutter, so the surface is flat and even.

c. Phase 3: Analysis of COPAP Board Samples

In line with the main objective of this study, the COPAP board samples were evaluated in terms of their physico-mechanical properties. The assessment encompassed both physical and mechanical aspects. In terms of physical properties, an analysis was conducted through a combination of visual observations, photo-documentations, and measurements; The boards’ color and texture were identified descriptively based on what was visually observed, while their mass was measured using a weighing scale. The volume and actual dimensions of the boards were determined using a ruler, and their density was calculated by dividing the mass by its area.

Meanwhile, the mechanical properties of the COPAP Board samples were evaluated in accordance with the prescribed guidelines outlines by ASTM D1037 (Standard specifications for evaluating properties of wood-base fiber and particle panel materials) for the compressive strength and absorption test; and ASTM E84-15a (Standard Test Method for Surface Burning Characteristics of Building Materials) for the fire resistivity and behavior of the material.

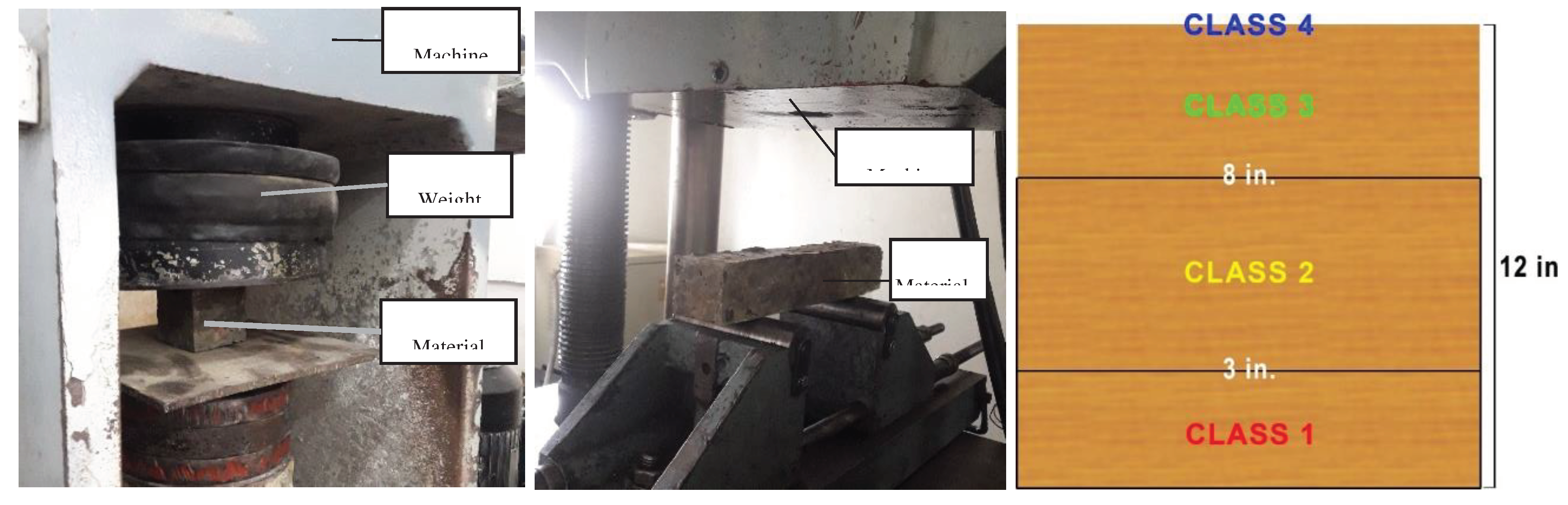

Figure 4.

(left) 2” x 2” COPAP board specimen loaded on a self-aligning loading block ready for a compressive strength test; (middle) 2”x 2” x 12” COPAP board specimen on a loading block for a flexural strength test; (right) Flame Spread Classification Guide showing the lengths that determine the flame spread rating of a material.

Figure 4.

(left) 2” x 2” COPAP board specimen loaded on a self-aligning loading block ready for a compressive strength test; (middle) 2”x 2” x 12” COPAP board specimen on a loading block for a flexural strength test; (right) Flame Spread Classification Guide showing the lengths that determine the flame spread rating of a material.

For the Absorption Test, the water absorbed was determined via the differences between the samples’ dry weight and wet weight (in grams). Time for all samples in all three trials was controlled. The Water Absorption Rate was then calculated by dividing the weight of the Water Absorbed, by the Wet Weight of the material, and the resulting value was multiplied by 100 to express the water absorption rate in percentage.

As the final part of this phase, the results of the experimental setups consisting of the COPAP board samples were compared with one another, and with a control setup comprising of conventional drywall boards available in the market.

d. Phase 4: Identification of Application and Uses

Phase 4 comes at the latter part of the study—when the results have already been interpreted, and the physico-mechanical properties evaluated.

Data Analysis

Overall, the standard tests used in the study were Compressive Strength Test, Tensile or Flexural Strength Test, Water Absorption Test, and Fire Resistance Test. To prove any significance exists between the volume of the COPAP board samples with the physico-mechanical properties, Pearson’s Correlation Coefficient was employed to measure the strength of the correlations. The measure for this type of correlation can range from -1 to +1, and a value of zero (0) would indicate that there is no significant relationship existing within the variables. Correlation coefficient values less than +0.8 at the same time greater than -0.8 are not considered significant.

To understand the market potential of the COPAP boards as a substitute for dry wall material, the direct cost of the samples was also presented. A tabulation of materials with their corresponding unit prices was made to determine the total direct cost of the experiment.

3. Results

Physical Properties

Table 3 shows that all COPAP board samples were gray in color. Only Formulation C generated samples with a smooth finish; the same also has the heaviest samples relative to the average weights of Formulations A and B.

Mechanical Properties

For all standard tests conducted, every formulation had three (3) samples tested for 3 trials each. The average values of these trials were then calculated and used as variables for analysis.

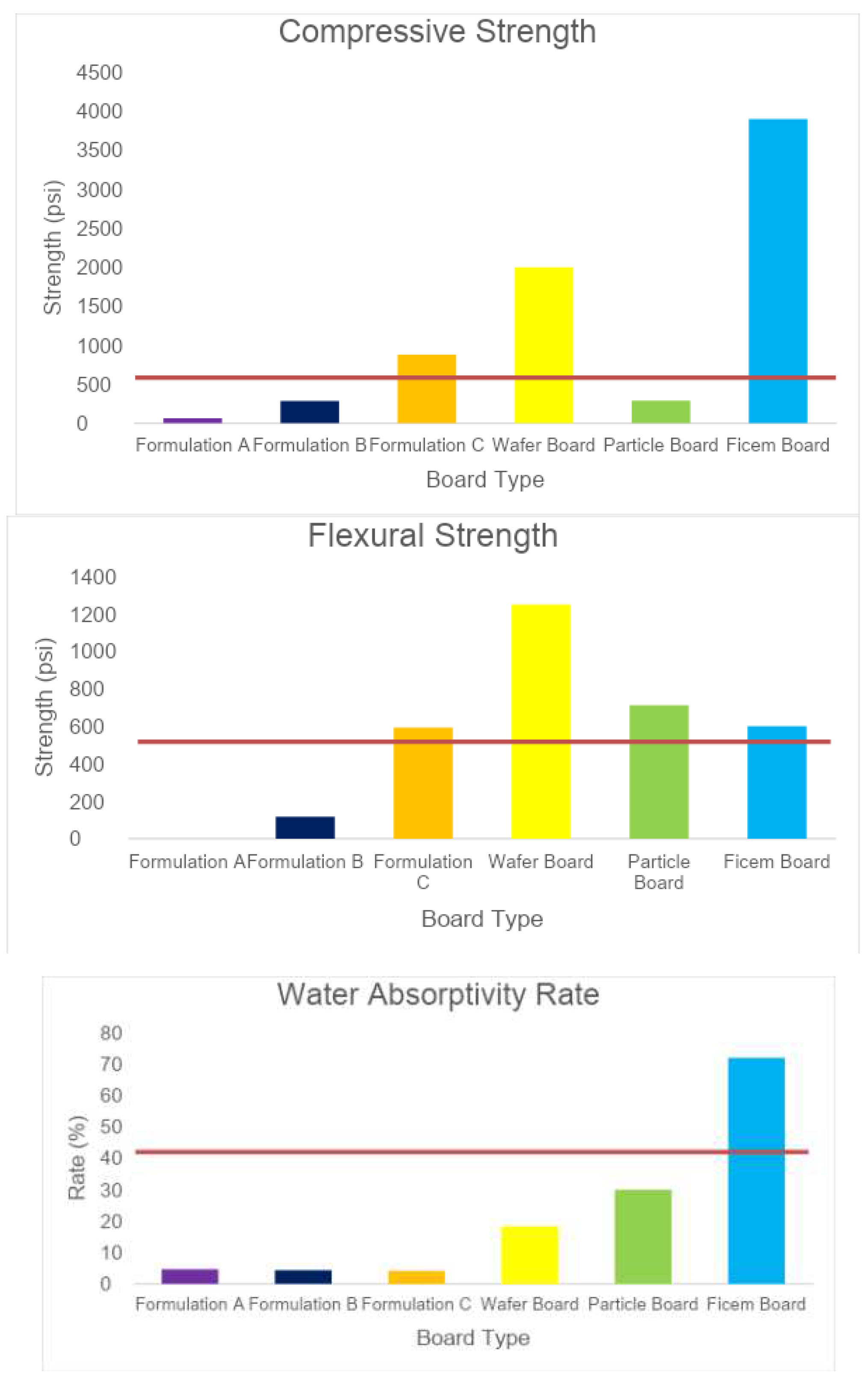

a. Compressive Strength and Flexural Strength

According to the results of the compressive strength test and flexural strength test (

Table 4), Formulation C with 10% COPAP and 90% Portland cement generated the highest average compressive and flexural strength of 880.6 psi and 592.6 psi respectively.

Table 4.

Compressive and Flexural strengths of the COPAP board samples.

Table 4.

Compressive and Flexural strengths of the COPAP board samples.

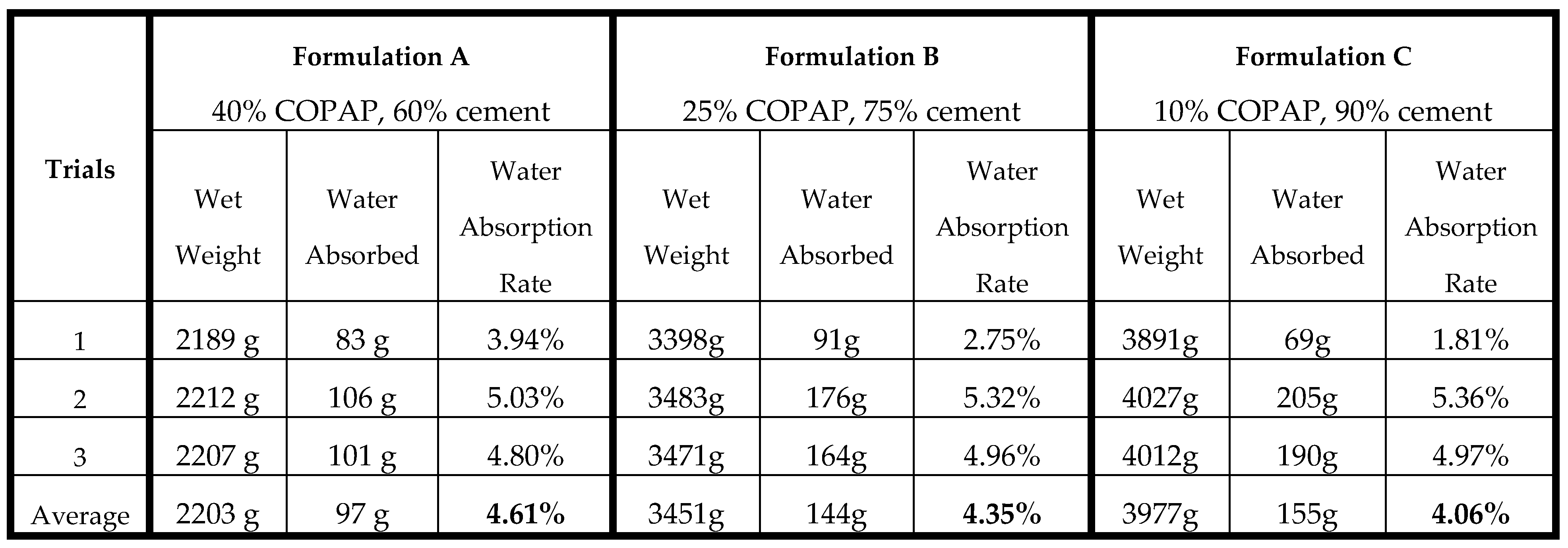

b. Water Absorption Capability

The Absorption Test showed that Formulation A, with 40% COPAP and 60% cement, absorbed the most water at a rate of 4.61% while Formulation C, with 10% COPAP and 90% cement, absorbed the least at a rate of 4.06%.

Table 5.

Water Absorption Rate of the COPAP Board Samples.

Table 5.

Water Absorption Rate of the COPAP Board Samples.

c. Fire Resistivity and Behavior

Formulations B and C were found to be non-combustible. Formulation A ignited at an average time of 16 seconds after ignition. After the time limit of 1.5 min, the flame continued to burn by 1 second only after which it self-extinguished. The area consumed by the flame, spread up to ½ in.

Table 6.

Fire Performance of Formulation A COPAP Board Samples.

Table 6.

Fire Performance of Formulation A COPAP Board Samples.

Table 7.

Behavior of Formulations B and C after the Fire Test.

4. Discussion

Among the formulations, Formulation C performed the best, as it passed all the physico-mechanical property testing as summarized in

Table 8. In contrast, Formulations A and B did not meet the requirements in compressive and flexural testing. However, all formulations successfully passed the water absorption test. And in terms of fire performance, B and C were found to be non-combustible, and only Formulation A was flammable.

Correlational Analysis

Table 9 suggests that the volume of COPAP in the mixture highly correlates to the mechanical properties of the resulting board samples. The study examined linear relationships between the variables using Pearson’s Correlation Coefficient, and discovered, first, a strong negative correlation (-0.9670) between the volume of coconut palm phellem and the compressive strength of the product, indicating that as COPAP volume decreases, the compressive strength increases.

Similarly, there is also a strong negative correlation (-0.94387) between the volume of coconut palm phellem and the flexural strength of the product, indicating that as COPAP volume decreases, the flexural strength increases.

In terms of fire performance, there is also a strong negative correlation (-0.86603), which suggests that as the COPAP volume decreases, the fire resistivity of the material increases.

In contrast, the Pearson’s Correlation Coefficient Analysis demonstrates a strong positive correlation (0.999505) between the COPAP volume and water absorptivity rate, that is, as the coco palm phellem volume increases, the rate of absorptivity also increases.

It is noteworthy that while the volume of coconut palm phellem is the variable being tested, the mechanical properties of the samples are also heavily influenced by the percentage of cement and water in the formulations, as changing the compositions of the coconut palm phellem in the mixtures also alters the amount of cement and water in proportional quantities.

5. Conclusion

In summary, the project aimed to develop a drywall panel board made from coconut palm phellem (COPAP) and determine its physico-mechanical properties as an alternative wood-based board. Specifically, the study wanted to determine which among the three formulations of COPAP board exhibited the best physico-mechanical properties, compare the physico-mechanical properties of COPAP board with commercially available construction materials namely, particle boards, fiber cement boards, and wafer boards, and finally, identify the possible architectural applications of COPAP board as a new building material.

In the study, there were three different formulations tested, from which Formulation C (10% COPAP, 90% cement, and 50% water) exhibited the best physico-mechanical properties in terms of compressive and flexural strength, fire resistivity, and water absorption. It fared better than the particle board in terms of compressive strength, better than wafer and particle board in fire resistivity, performed best in the water absorption test, and was almost equivalent in flexural strength to fiber cement board. With these findings, the study concludes that COPAP boards can be a viable construction material as non-load bearing dry walls though it is not recommended for flooring and ceiling applications since its flexural strength is just above the minimum requirement. Nonetheless, the study concludes that COPAP board can be used for projects that entail a high number of interior partitions, such as offices, BPO firms and commercial stalls in shopping malls, etc.

Future investigations may explore and assess other properties of COPAP boards like thermal and sound insulation, resistance to rot and other properties that may prove its competetive advantage over commercially available dry wall products.

References

- Ani, P.A., and Castillo, M. The Philippine Coconut Industry: Status, Policies, and Strategic Directions for Development (2019). Retrieved from http://ap.fftc.agnet.org/files/ap_policy/969/969_1.pdf.

- ASTM International. D 1037 Standard Test Methods for Evaluating Properties of Wood-Base Panel Materials. Retrieved from http://www.smartjd.org/pdf/187/11183596.pdf.

- BamCore LLC (2018). Fire safety in the building codes focuses on two product characteristics. Retrieved from http://bamcore.com/bamcore-attributes/safer/bamcore-fire-performance/.

- Bhirud, A., Jagtap, P.C, and Nandkumar I.N. (2015). Analysis of Critical Success Factors in Application of “DRYWALL” Technique in Construction Industry. Retrieved From https://pdfs.semanticscholar.org/673c/50f49e607193b37de64645b5 ce4fd58f713f.pdf?_ga=2.24614143.439020342.1568334627-1211722586.1567826209.

- Boesel, L.F., Silva, S.P., et al. (2005). Cork: Properties, Capabilities, and Applications. Retrieve from http://repositorium.sdum.uminho.pt/bitstream/1822/4005/1/0105.pdf.

- Composites UK (2017). Fire Performance. Retrieved from https://compositesuk.co.uk/system/files/documents/2%20Technical%20Sheet%20-%20Fire%20Performance.pdf.

- Department of Environment and National Resources. 2017 Philippine Forestry Statistics. Retrieved from https://drive.google.com/file/d/1iOm6bwe7RN4B4D- cf3wbufySwYHRKgba/view.

- FAO (2009) Global demand for wood products. Retrieved from http://www.fao.org/3/i0350e/i0350e02a.pdf. Fern, K. (2014). Tropical Plants Database. Retrieved from http://tropical.theferns.info/viewtropical.php?id=Acacia+confusa.

- Gypsum Association. GA-214-10E: Recommended Levels of Finish Drywall Board. Retrieved from https://www.usg.com/content/dam/USG_Marketing_Communications /canada/product_promotional_materials/finished_assets/cgc- construction-handbook-ch05-finishing-drywall-systems-can-en.pdf.

- Gypsum Association (2019). Drywall Board Typical Mechanical and Physical Properties. Retrieved from https://www.americangypsum.com/sites/default/files/documents/GA- 235%20Gypsum%20Board%20Typical%20Mechanical%20and%20 Physical%20Properties.pdf.

- ICC ES Evaluation Service Report, ESR-1785 & 2012 edition of the AF&PA American Wood Council’s, Allowable Stress Design (ASD)/LRFD Manual for Engineered Wood Construction. Retrieve from https://www.awc.org/pdf/codes-standards/publications/archives/lrfd/ AWC-LRFD2012-Manual-1211.pdf.

- Hiziroglu, S. Oriented Strand Board as a Building Material. Retrieved from http://pods.dasnr.okstate.edu/docushare/dsweb/Get/Document-3164/FAPC-145web.pdf.

- Jabber, M.A., Shawia, N.B., and Mamouri, A.F. (2014). Mechanical and physical properties of natural fiber cement board for building partitions. Retrieved from http://netjournals.org/pdf/PSRI/2014/3/14-021.pdf.

- Johansson, E. (1994) Wood wool boards. Retrieved from http://www.hdm.lth.se/fileadmin/hdm/BI_Volume_06__3_1994_Woo dwool_Slabs__-_Manufacture__Properties_and_Use.pdf.

- Knobloch, M. Manufacture of Shaped Articles By Compression Molding A Fibrous Material With Simultaneous Adhesive Bonding And The Shaped Articles. Retrieved from https://patentimages.storage.googleapis.com/70/f2/fe/6bd32219d707d0/US5401567.pdf.

- Lewis, R. (2020) Drywall Board Market 2019: Global Industry Analysis, Share, Size, Price Trends, Demand and Business Opportunities 2024. Retrieved from https://menafn.com/1099276204/Gypsum-Board- Market-2019-Global-Industry-Analysis-Share-Size-Price-Trends- Demand-and-Business-Opportunities-2024.

- Mikkelson P.S. Collected rainfall as a water source in Danish households – what is the potential and what are the costs? Retrieved from https://www.sciencedirect.com/science/article/abs/pii/S0273122399000864. World Health Organization (2019) Water shortage in the Philippines threatens sustainable development and health. Retrieved from https://www.who.int/philippines/news/feature-stories/detail/water-shortage-in-the-philippines-threatens-sustainable-development-and-health.

- World Wildlife Fund (2020) Water Scarcity. Retrieved from https://www.worldwildlife.org/threats/water-scarcity.

- Venkatarama Reddy, B.V. (2004) Sustainable building technologies. Retrieved from http://eprints.iisc.ac.in/2385/1/sustainable.pdf.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).