1. Introduction

The rapid expansion of modern industry continuously encourages protective coating innovation with functional properties of the materials. As a result, designing protective coatings with good mechanical, tribological, and corrosion-resistant properties is crucial. Because of their higher hardness, better friction coefficient, and good corrosion resistance and transition metal nitrides have become popular as protective coatings to satisfy industry demands. The transition metal nitride refers to a group of compounds created from nitrogen with transition metals – elements identified in Periodic Table groups 3-12 such as titanium, chromium, zirconium, vanadium and tantalum. When these elements combine with nitrogen, it generate nitrides, which are extremely hard and have very high melting temperatures [

1,

2]. Because of this, transition metal nitrides are especially helpful in high-temperature and high-wear environments, such as cutting tools, molds, and engine parts [

3,

4].Transition metal nitride coatings are deposited using a variety of deposition methods. The physical vapor deposition (PVD) approach stands out among various deposition methods due to its layer uniformity, improved morphological properties, and excellent adhesion to the substrate [

5,

6,

7]. HiPIMS, one of the novel PVD methods, generates a dense plasma by ionizing the sputtering target with short-duration, high-power pulses. This results in extremely intense and high-quality plasma generation [

8]. The use of advanced coating materials to address issues in industrial applications is growing in popularity. It has been shown that the design of multilayer structures can significantly enhance the mechanical and tribological properties of coatings [

9].

Recent research on multiple layers deposition of substrate materials exhibited significant enhancement on the hardness, wear resistance, and toughness properties. In one study, the combination of titanium nitride (TiN) with tungsten (W) has demonstrated improved mechanical performance with suitable wear resistance properties for the applications in cutting tools and aerospace components [

10]. Multilayer thin film structures have shown promising result for bioactive coatings. Zhao et al. [

11] incorporated different layers of polymers and bioactive compounds on the metallic substrate for biomedical applications.

The Ta/TaN thin film multilayer coatings on metallic alloy substrates is vital to enhance hardness, adhesion, and friction properties, making them appropriate candidates for tribological applications in diverse engineering and industrial settings. However, the Ta/TaN thin film multilayer coating development on AISI 52100 tool steel substrate using HiPIMS technique is scared in literature. Therefore, the aim of this work is to synthesize Ta/TaN thin film multilayer coatings on 52100 steel substrates using HiPIMS with three different level of N2 gas flow rates. The microstructure, coating thickness, phases, hardness and tribological properties of Ta/TaN multilayer coatings are discussed in this manuscript.

2. Materials and Methods

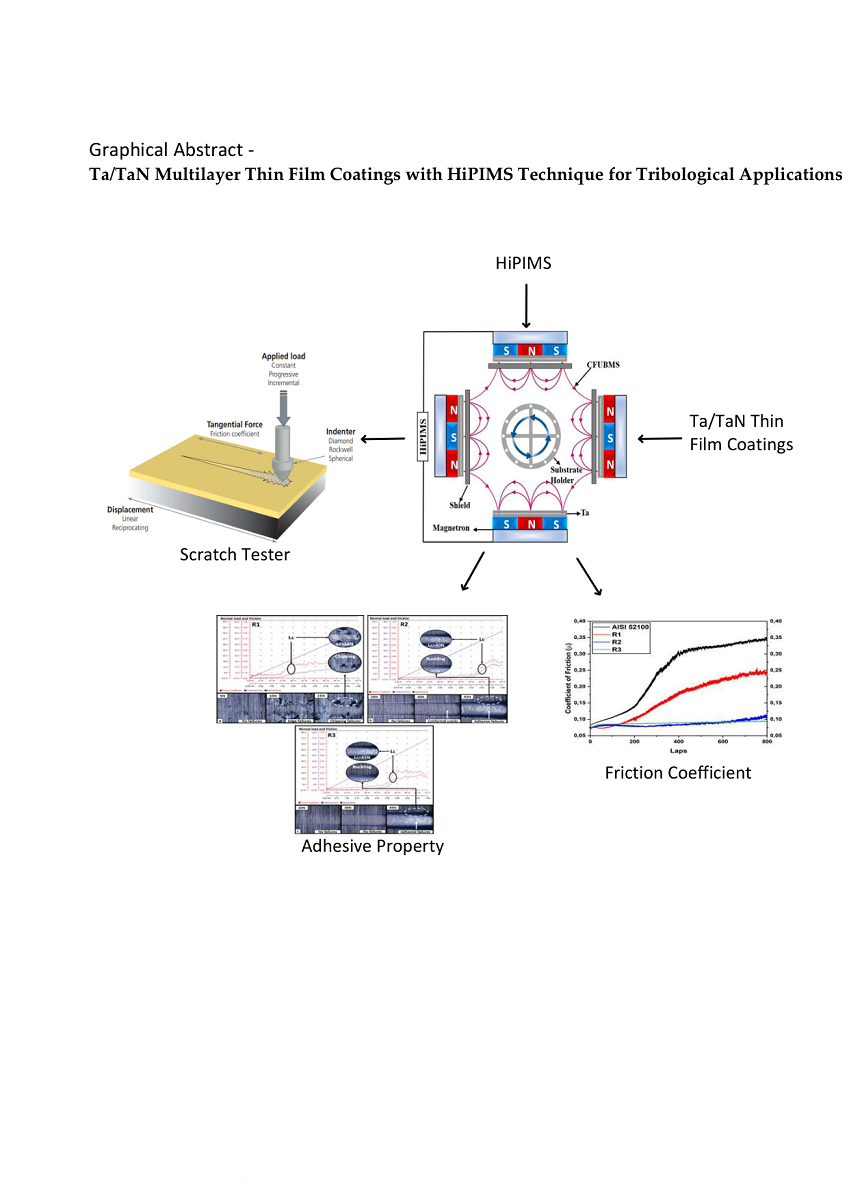

The Ta/TaN thin film multilayer coating was deposited on 52100 tool steel substrates using High Power Impulse Magnetron Sputtering (HiPIMS) with CFUBMS system. Three different N

2 amount of 5, 7, 9 sccm were supplied in this investigation with the sample ID of R1, R2, R3. The detail deposition parameters can be found elsewhere [

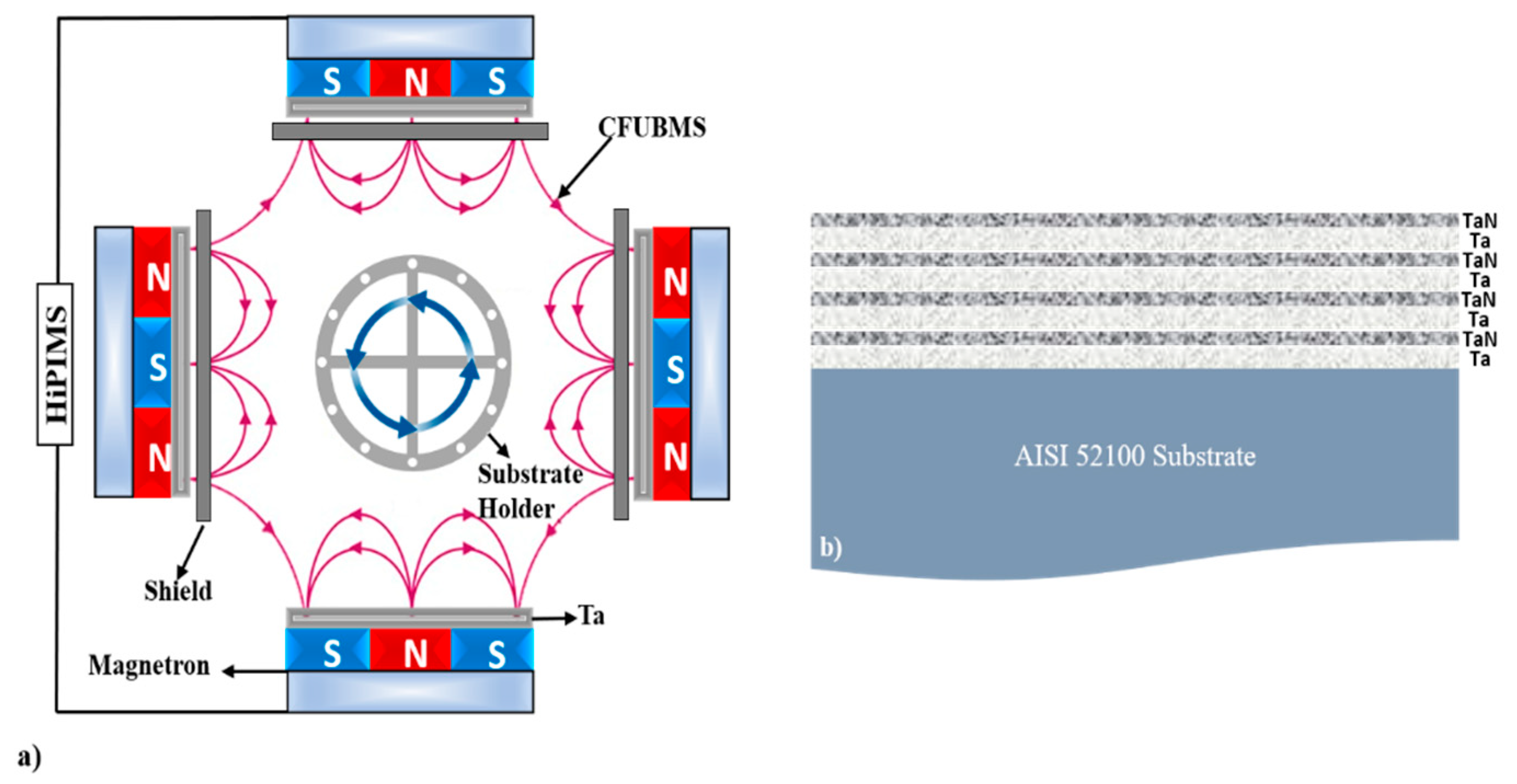

12] The HiPIMS technique used for the synthesis of the Ta/TaN coatings and the architecture Ta/TaN multilayer thin film coating are shown in

Figure 1.

In this study, the method employed for substrate preparation and the synthesis of the desired architecture is presented in a systematic manner. Prior to deposition, the substrate underwent a meticulous polishing process utilizing SiC abrasive papers of varying coarseness, including 240, 400, 600, 800, and 1200 grits. This step aimed to achieve an optimal surface condition for subsequent coating procedures. Next, a thorough cleaning procedure was carried out on the polished substrate using both acetone and ethyl alcohol in an ultrasonic bath. This meticulous cleaning process ensured the removal of any contaminants or residues that could potentially interfere with the coating's adhesion and performance. Subsequently, the substrates were gently dried using an air blower to avoid any adverse effects on the prepared surface.

The main step consists of the etching of substrate material in a 5% nital solution for subsequent thin film coating on the surface.

Figure 1a shows the HiPIMS technique utilized during the coating process to ensure controlled and precise deposition. For ion cleaning, a -800 V was applied to the substrates for 30-minute for a better cleaning and adhesion property during the coating process.

Tantalum (Ta) was selected as the target material, and a voltage of 600 V was set for the HiPIMS process. First, Ta thin layer was deposited for 5 minutes followed by the deposition of tantalum nitride (TaN) layer for 15 minutes in presence of supplied nitrogen gas in the chamber. This process was repeated four times to deposit the desired multilayer coatings of Ta/TaN as shown in

Figure 1b.

The Rigaku DMax-2200 X-ray diffraction (XRD) system was used for phase identification with a wavelength of 1.5405 and a diffraction angle of 20-80°. Hardness property was evaluated using the Buehler Micromet 2001 micro-hardness tester with a Knoop indenter and a 10gf load applied for 15 seconds. The CSM Instruments scratch tester, equipped with a Rockwell C diamond indenter with a 200-tip radius, was used to examine the adhesion property (critical load value) of coating with a progressive loading rate of 100 N/min.

The coefficients of friction of the Ta/TaN coatings were assessed under specific conditions, including a 1 N load, 10 cm/s velocity, and a 6.25 mm diameter Al2O3 counterpart, using the CSM tribotester system. These parameters allowed for a comprehensive understanding of the coatings' frictional properties and their potential applications in the tribological field.

3. Results and Discussion

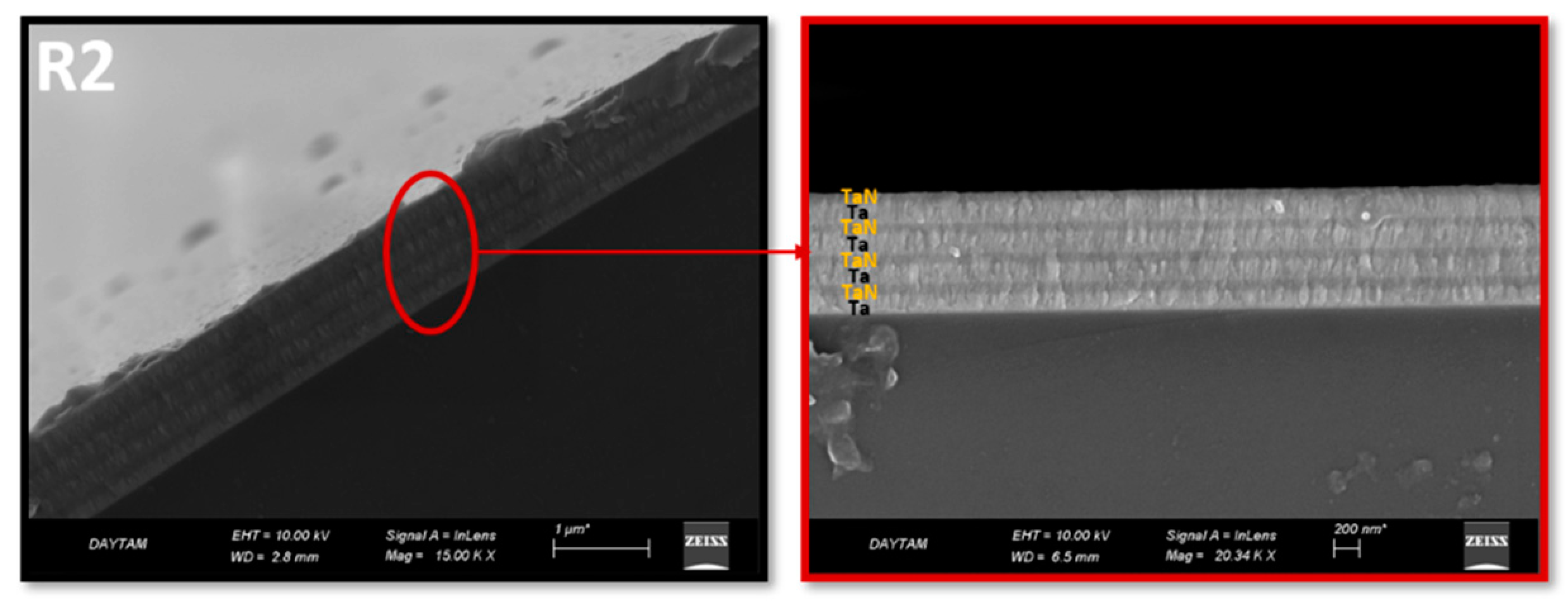

The microstructural characteristics, elemental analysis, film thickness and film hardness of Ta/TaN multilayer thin film coatings, meticulously deposited on tool steel substrate using HiPIMS technique are presented and discussed in this section. The SEM was employed to investigate the microstructural features of the coatings, as shown in

Figure 2, along with an accompanying table (

Table 1) displaying the film thickness, film hardness and elemental composition of the deposited films.

Upon examination of the SEM cross-sectional images presented in

Figure 2, it was evident that the Ta/TaN multilayer thin film coatings exhibited a distinctive columnar microstructure, characteristic of coatings synthesized via the HiPIMS technique. According to Thorton's structural region model [

13], the obtained microstructure belongs to within 'Zone 1', indicating a favorable microstructural arrangement for the intended hardness development.

The analysis of

Table 1 revealed valuable insights into the impact of nitrogen (N

2) concentration on the coating property. The highest film thickness of 1044 nm was achieved in sample R1, characterized by the lowest nitrogen content. However, as the N

2 concentration increased, a nitride phase (TaN) formed on the substrate surfaces within the reactive gas chamber [

8]. Consequently, the deposition rate decreased, leading to a proportional reduction in film thickness for samples R2 and R3 (see

Table 1). The elemental analysis data, obtained through EDS, was found to be in general agreement with the applied process parameters, showcasing a consistent increase in nitrogen content of 5.83%, 13.7%, and 18.13%, respectively, as the N

2 gas flow rate increased. The hardness value of the Ta/TaN multilayer thin film coatings deposited on 52100 steel substrate surface using the HiPIMS system with varying N

2 concentrations (5, 7, and 9 sccm), were measured to be 28 GPa, 24 GPa, and 19 GPa for R1, R2, and R3 samples, respectively (

Table 1). In generally, all coating surfaces exhibited significantly higher hardness compared to the uncoated 52100 substrate (~5.4 GPa). Particularly, the film deposited at 5 sccm N

2 (N

2/Ar: 5/20) achieved the highest hardness (~28 GPa).

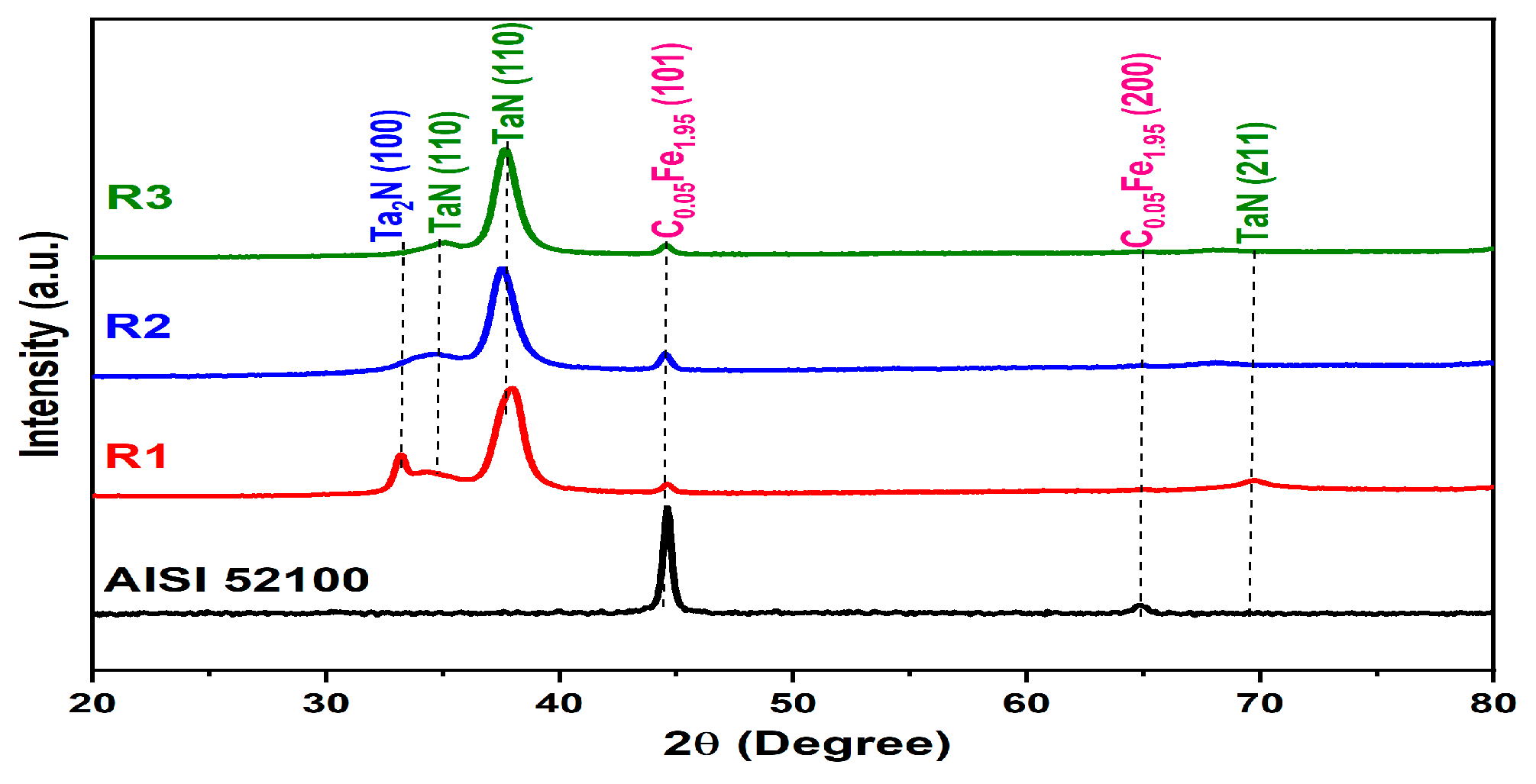

Figure 3 presents the XRD reflection peak results of the multilayer Ta/TaN coatings, with the application of varying N

2 concentrations using HiPIMS, on AISI 52100 steel. In the XRD data of the AISI 52100 substrate, prominent peaks corresponding to C0.05Fe1.95 (101) [JCPDS Card: 044-1290] at 44.183° and C0.05Fe1.95 (200) [JCPDS Card: 044-1290] at 65.222° were clearly observed. Subsequent analysis of the peak reflections in samples R1, R2, and R3 revealed distinct patterns of TaN and Ta

2N phases with varying structures.

In sample R1, where a N

2 flow rate of 5 sccm was employed, peak reflections were identified as Ta

2N (100) in a hexagonal structure at 33.969° [JCPDS Card: 029-1321], TaN (110) in a hexagonal structure at 34.528° [JCPDS Card: 074-0226], TaN (110) in a cubic structure at 37.735° [JCPDS Card: 025-1278], and TaN (211) in a cubic structure at 68.142° [JCPDS Card: 029-1321]. In sample R2, where a N

2 flow rate of 7 sccm was utilized, peak reflections were predominantly identified as TaN (110) in a hexagonal structure at 34.528° [JCPDS Card: 074-0226], TaN (110) in a cubic structure at 37.735° [JCPDS Card: 025-1278], and TaN (211) in a cubic structure at 68.142° [JCPDS Card: 029-1321]. Finally, in sample R3, employing a N

2 flow rate of 9 sccm, peak reflections were characterized as TaN (110) with hexagonal structure at 34.528° [JCPDS Card: 074-0226], TaN (110) with cubic structure at 37.735° [JCPDS Card: 025-1278], and TaN (211) with cubic structure at 68.142° [JCPDS Card: 029-1321]. The XRD diffraction analysis of R1 films revealed a prominent growth of Ta

2N (100) in a close-packed hexagonal structure. It has been previously reported that this preferred orientation in TaN films has a positive influence on hardness as shown in

Table 1. However, when the nitride ratio in the film exceeds 5%, the preferred orientation shifts from hexagonal-Ta

2N structure to cubic-TaN structure, subsequently leading to a decrease in hardness [

14].

Furthermore, the presence of Ta2N (100) in the hexagonal structure significantly influenced the hardness values, particularly in the R1 coating, where the highest hardness value of 28 GPa was achieved. This suggests that the microstructural arrangement of the coatings played a vital role in influencing their hardness property. In summary, the findings of the microstructural analysis, elemental composition, and XRD reflection peak patterns have provided valuable insights into the influence of nitrogen concentration on the Ta/TaN multilayer thin film coatings.

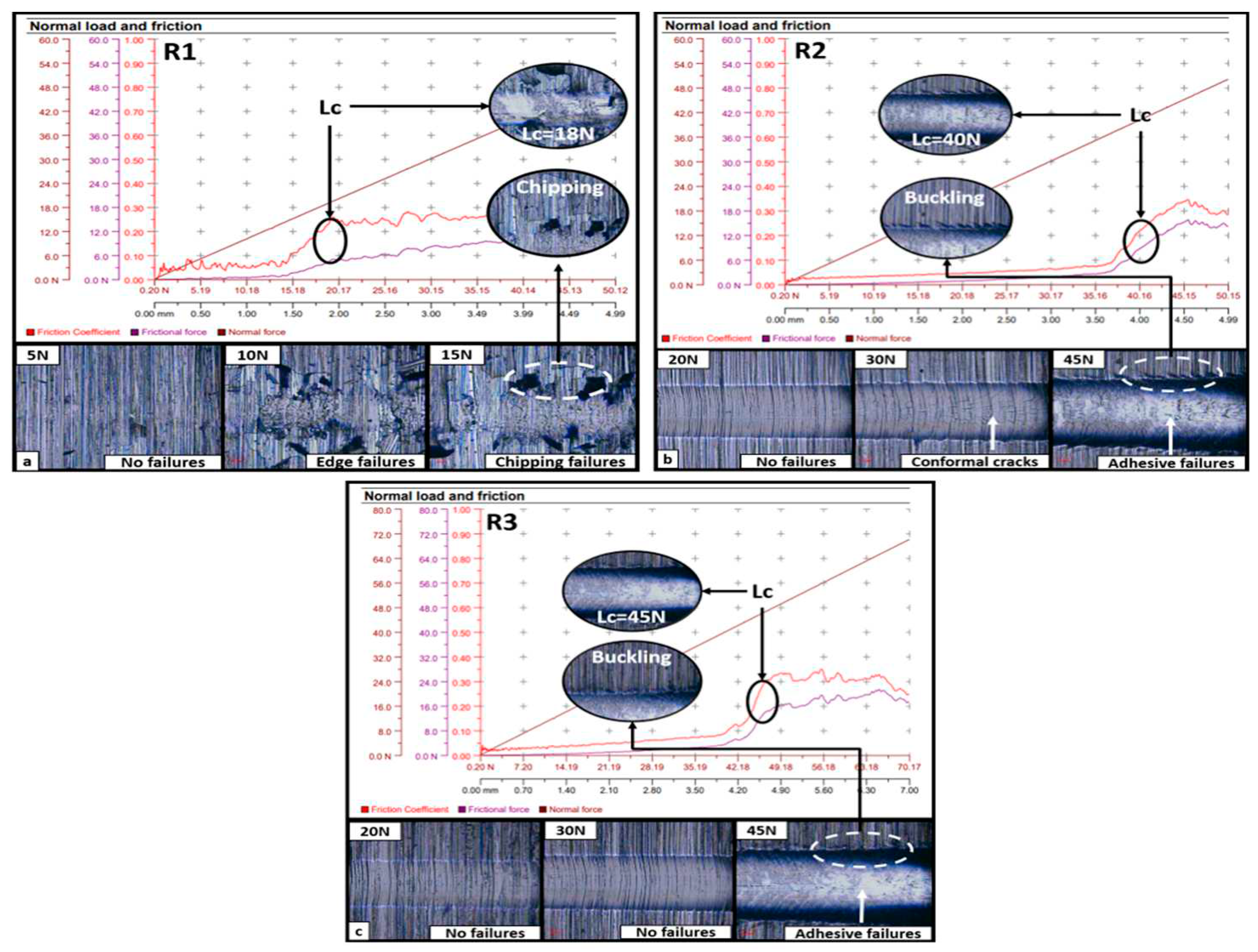

The adhesion properties of the Ta/TaN multilayer thin film coatings were evaluated using the CSM Instruments scratch tester as shown in

Figure 4, and the critical load value was obtained. Remarkably, the highest critical load value of 45 N was observed in R3 sample, which exhibited the lowest hardness value. Conversely, the highest hardness value was found in R1 sample deposited at 5 sccm nitrogen, while the lowest critical load value was recorded in the same sample. Beyond the 10 N load value, compressive stress initiated chipping/flaking in the coating (as shown in

Figure 4), resulting in the rupture of particles on the film's edges or surface. This phenomenon led to irregular and rough areas on the film surface, affecting its overall performance and durability [

15].

After the 18 N load value, the occurrence of adhesive failures increased, causing the coating to separate from the substrate. In contrast, R2 and R3 samples showed no flaking/chipping until reaching their respective critical load values (

Figure 4). Instead, conformal cracks started to appear in these coatings after the 30 N load value. Such cracks arise due to stress interactions between the film and the substrate, manifesting as irregular cracks parallel to the substrate. These conformal cracks diminish the film's flexibility and influence its mechanical properties [

16]. Notably, at 40 N values, buckling edge failures were observed in R2 and R3 samples, as depicted in

Figure 4. While this type of failure was more pronounced in the R2 coating, it was less evident in the R3 coating. Buckling failure typically arises from compressive stresses in front of the moving tip and can have a negative impact on the coating characteristics.

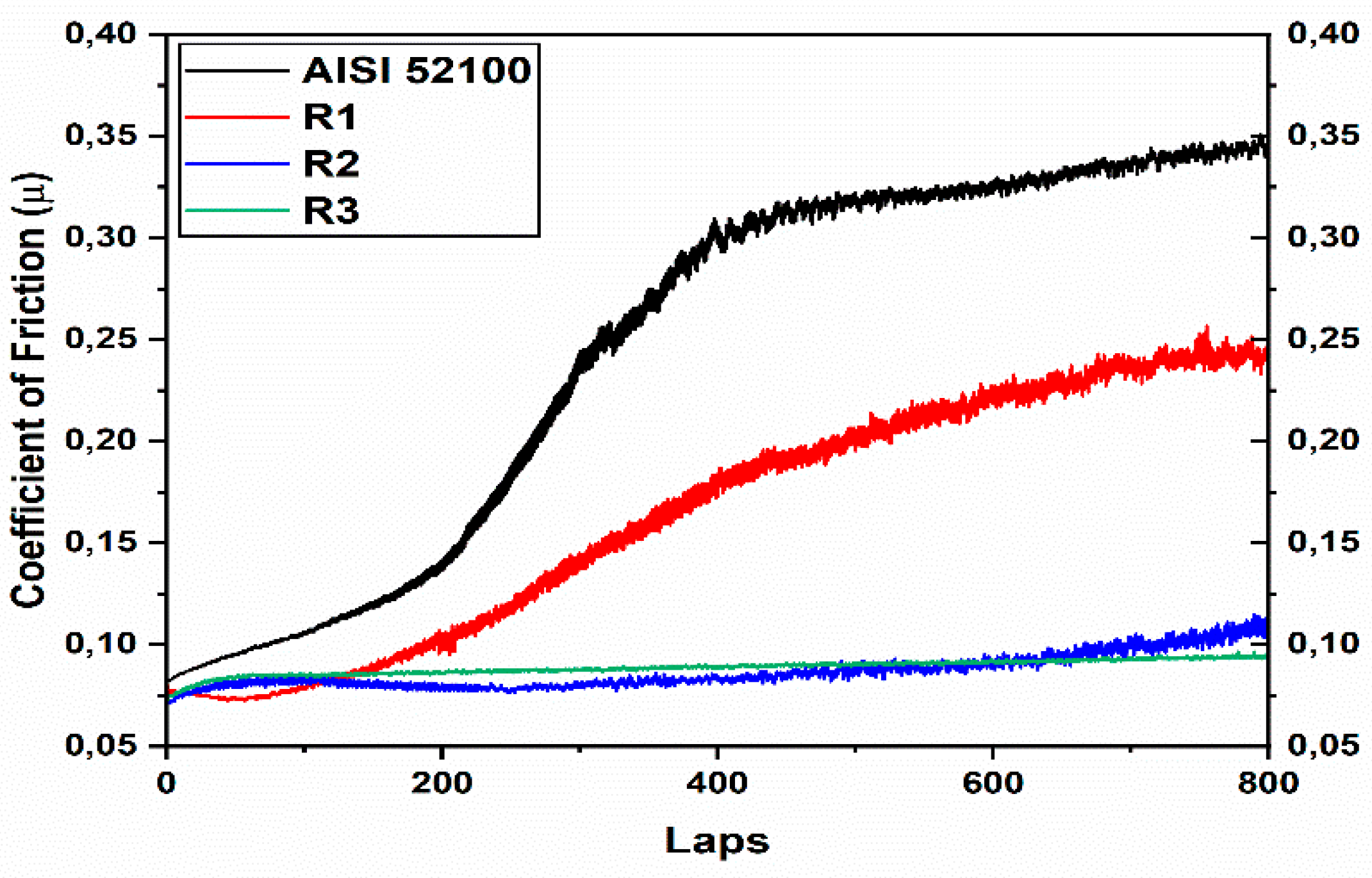

The friction coefficient tests of the Ta/TaN multilayer thin film coating and the AISI 52100 substrate were performed using a pin-on-disc tribometer as shown in in

Figure 5. The average friction coefficient of AISI 52100 substrate was 0.36, while for the R1, R2, and R3 samples, the average friction coefficient values were 0.27, 0.13, and 0.094, respectively. Baes on the findings, it can be said that the tribological properties of the Ta/TaN multilayer thin film coatings exhibited a significant improvement compared to the uncoated substrate.

Upon examining the friction property, as depicted in

Figure 5a, it is observed that the friction coefficient in R1 remains consistent. However, visual inspection of the wear scar surface of the R1 sample revealed densely formed wear particles at the contact point. These wear particles induced abrasive wear, consequently contributing to an increase in the coefficient of friction [

17]. Additionally, the fact that the R1 sample possesses higher hardness but weaker adhesion compared to other two samples plays a role in negatively influencing the friction and wear properties at the contact point.

In contrast, R2 and R3 samples exhibited stable friction coefficient curves with a scarcity of wear particles (visual inspection) at the contact point. The lowest friction coefficient was recorded in the R3 sample, which also demonstrated the highest adhesion value. These friction coefficient values observed in R2 and R3 coatings are highly promising when benchmarked against substrate material. However, the current analysis of the friction coefficient sheds valuable light on the superior tribological performance of the Ta/TaN multilayer thin film coatings in comparison to the substrate. These findings underscore the potential of this coating for tribological applications, where enhanced friction and wear resistance are sought after.

4. Conclusion

In conclusion, the present study successfully synthesized and characterized the multilayer thin film Ta/TaN Coatings using HiPIMS system under three different N2 gas flow rates. It was observed that the film thickness decreased as the N2 concentration increased, resulting in a decrease in the deposition rate. Remarkably, the highest coating hardness was achieved in R1, where a N2 flow rate of 5 sccm was applied. This enhancement in hardness was attributed to the preferred orientation of Ta2N (100) within the hexagonal structure of R1.

The adhesion property of the Ta/TaN multilayer thin film coating demonstrated that R3 exhibited the highest value of 45 N critical load, while R1 presented the lowest adhesion value of 18 N critical load. Notably, edge failure was not observed in R2 or R3 samples up to 40 N critical load value, indicating the robustness of this coating under progressive load.

The coefficient of friction values for the Ta/TaN multilayer thin film thin films were measured as 0.27, 0.13, and 0.094 for R1, R2, and R3, respectively. A noteworthy observation is that the tribological properties of the Ta/TaN multilayer thin film coated steel exhibited a substantial improvement compared to the uncoated substrate (µ=0.36). Specifically, the lowest coefficient of friction was observed in R3, where the highest adhesion value was attained. These friction coefficient values obtained in R2 and R3 samples demonstrate great promise when benchmarked against substrate material.

The comprehensive investigation of the Ta/TaN multilayer thin film coatings has provided valuable insights into their micro-structural, phase and hardness behavior, paving the way for their potential applications in tribological field requiring enhanced hardness, adhesion, and friction properties.