Submitted:

27 July 2023

Posted:

28 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

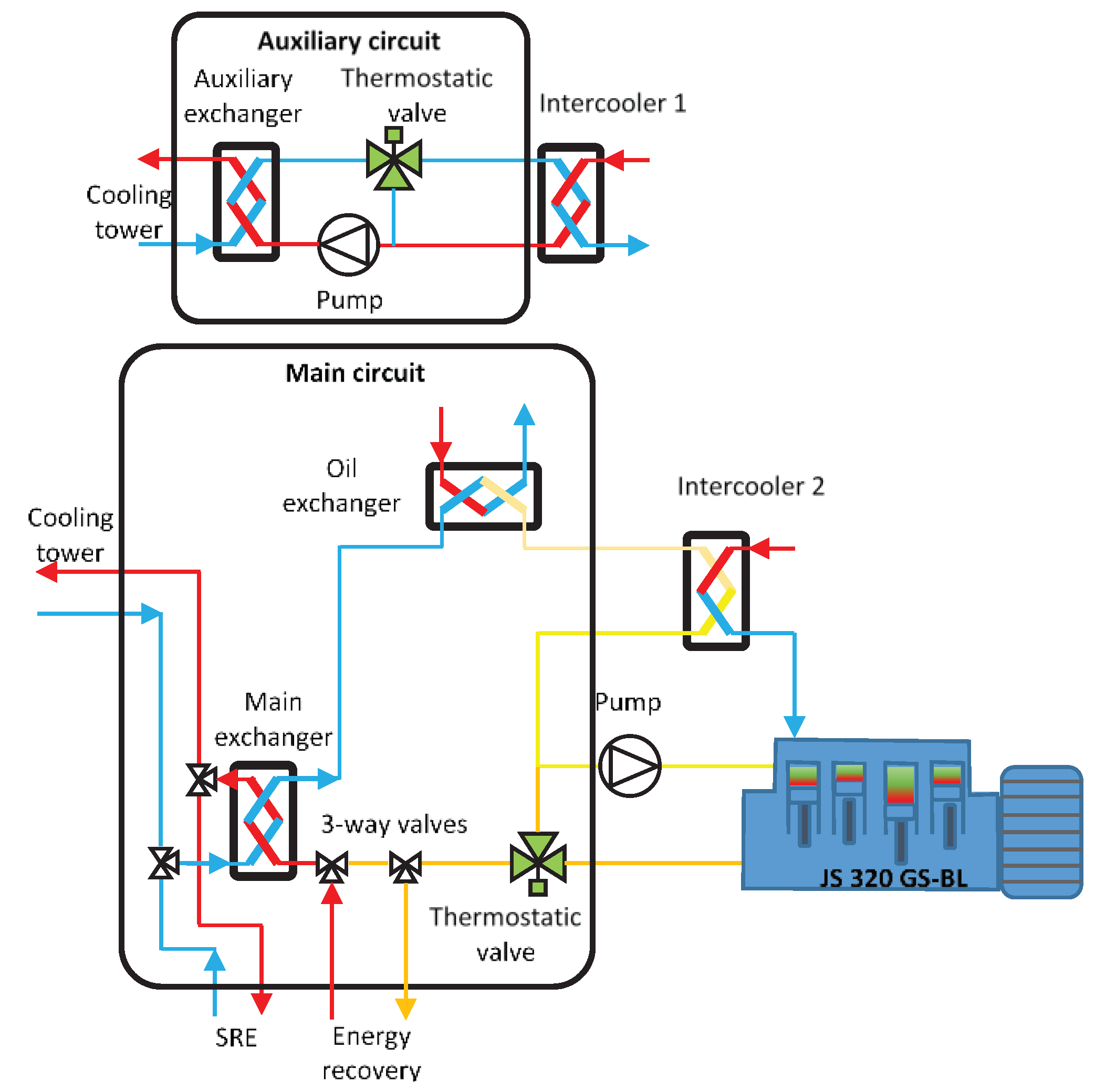

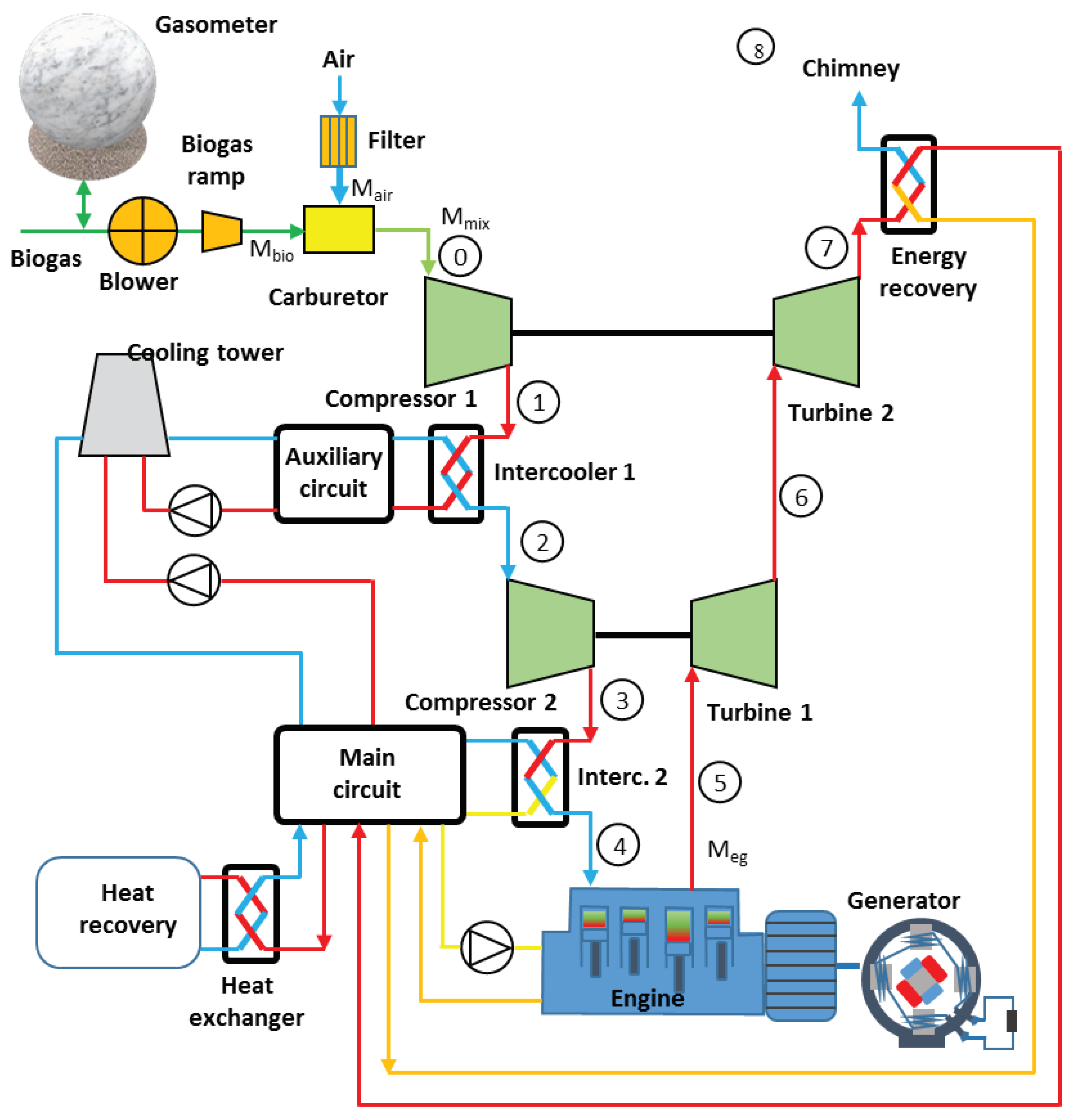

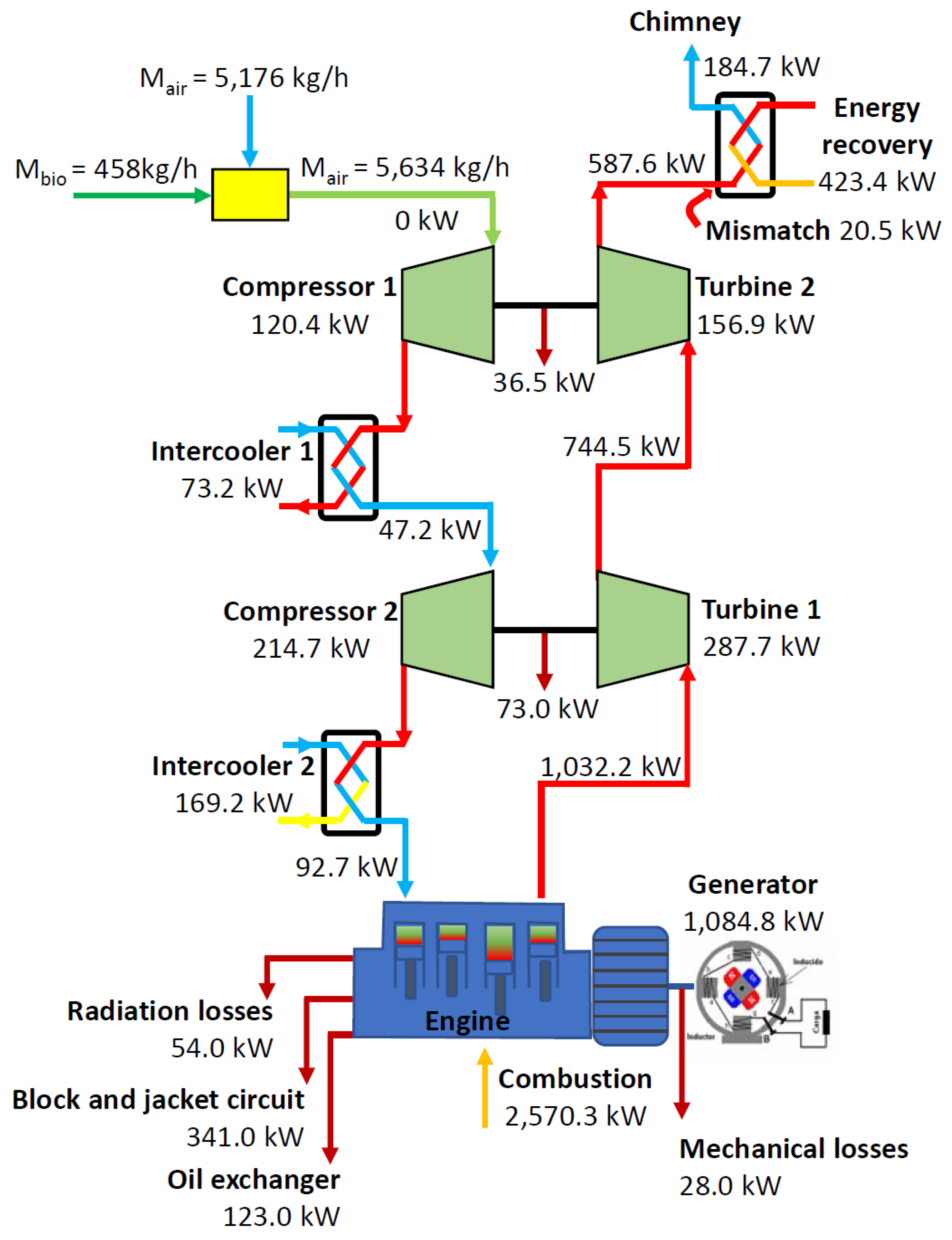

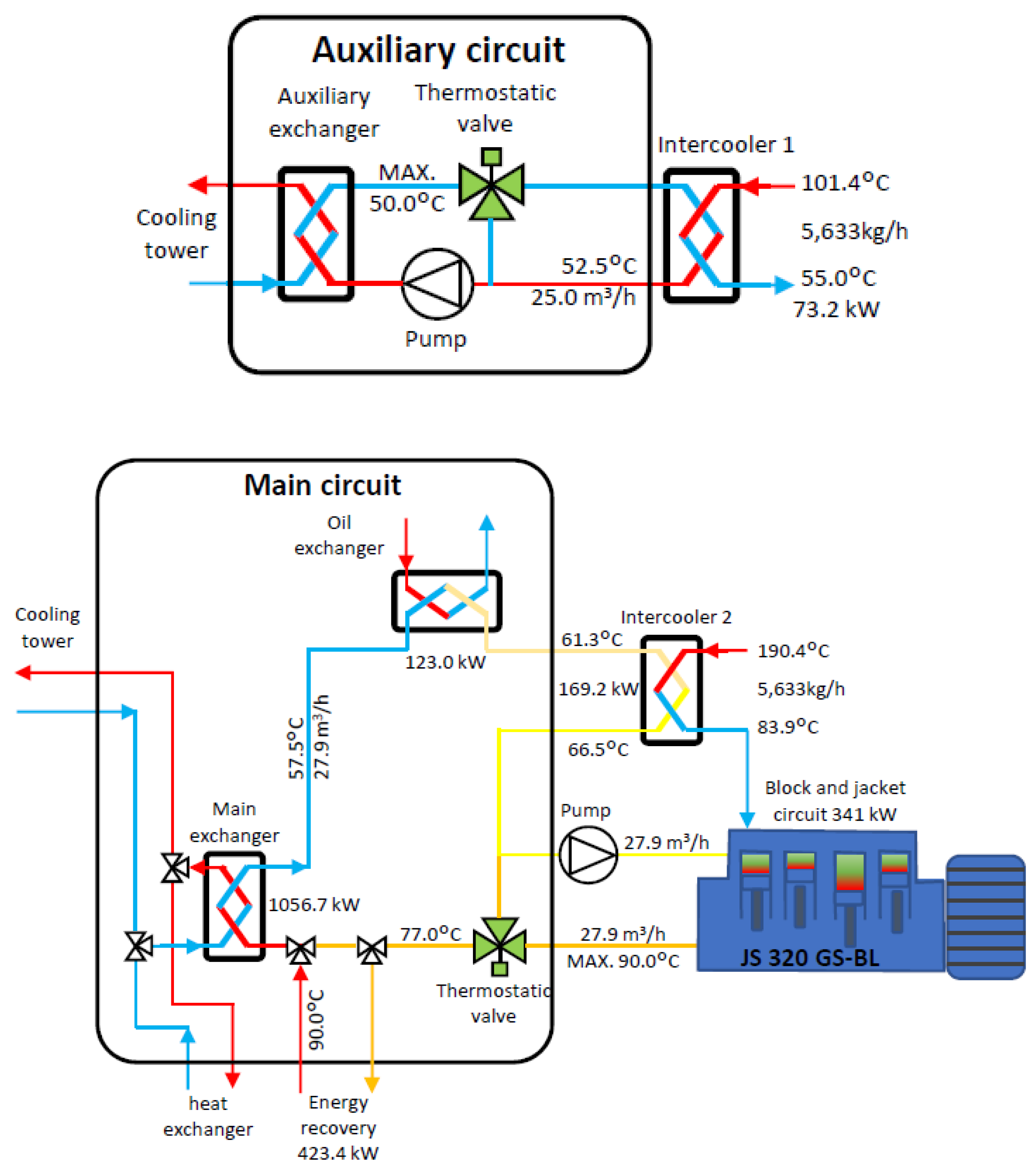

2.1. Engine description

2.2. Engine performance equations

2.3. Methodology for evaluating decentralized biogas production in mid-size communities

3. Results

3.1. Analysis of engine performance

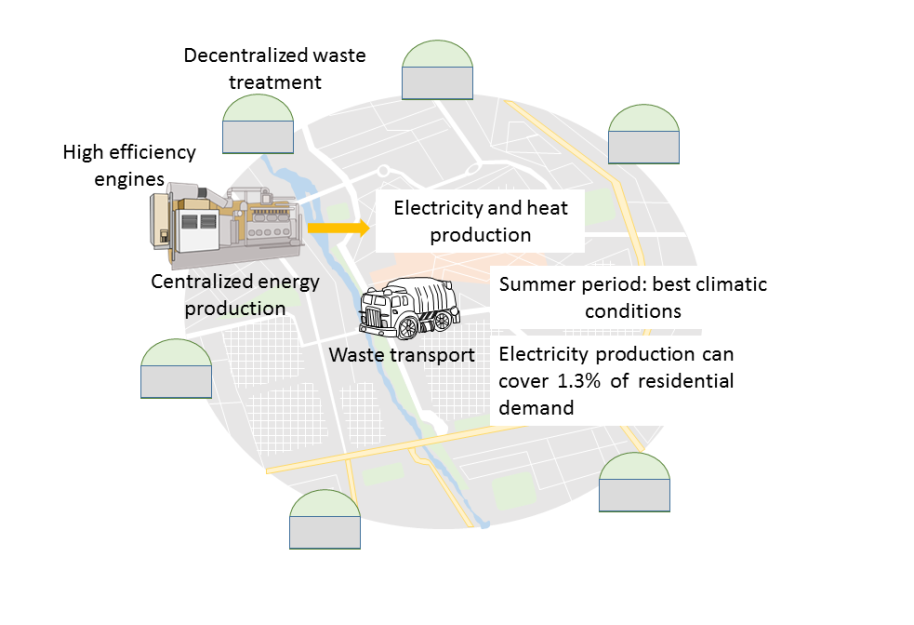

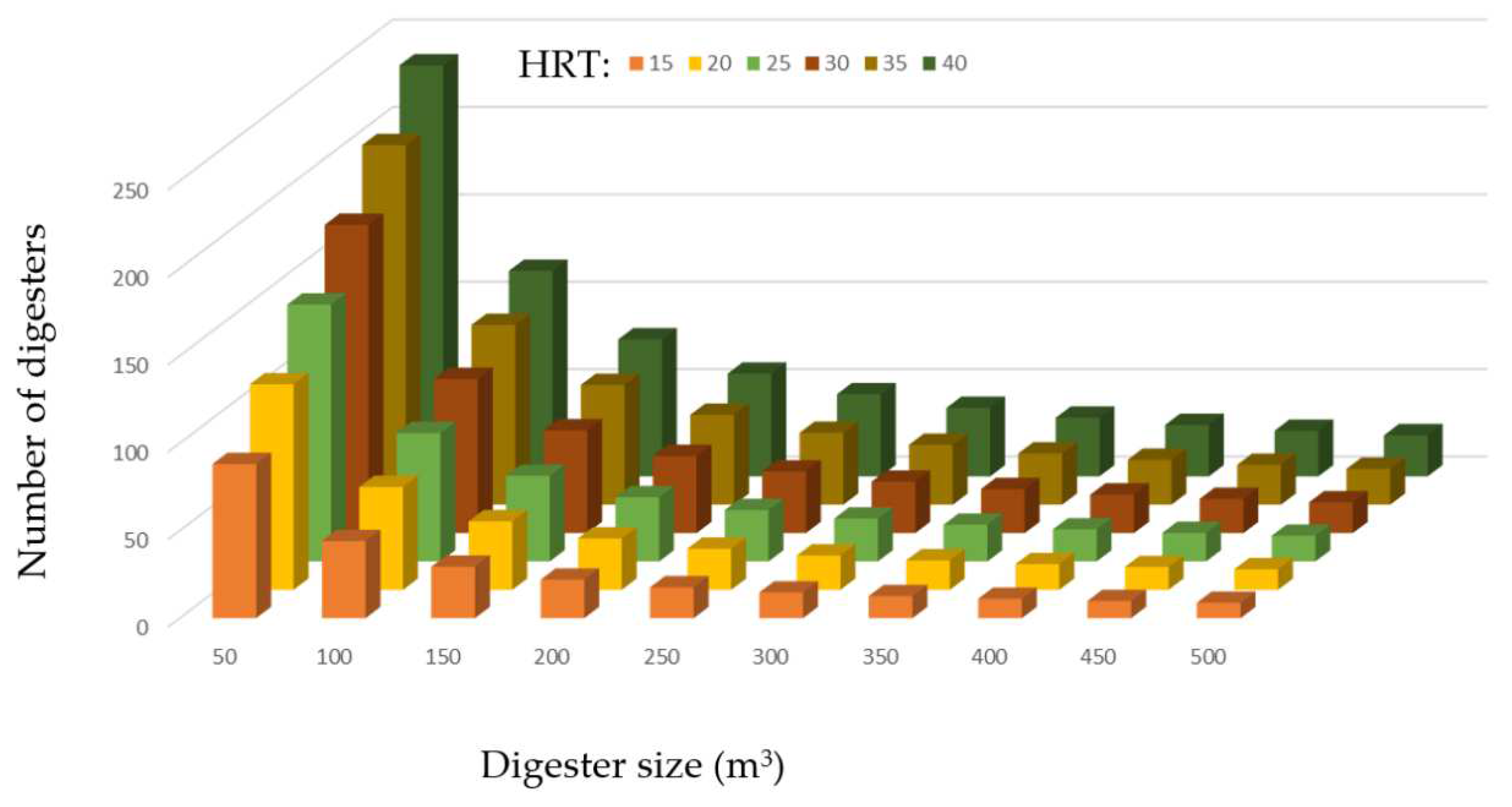

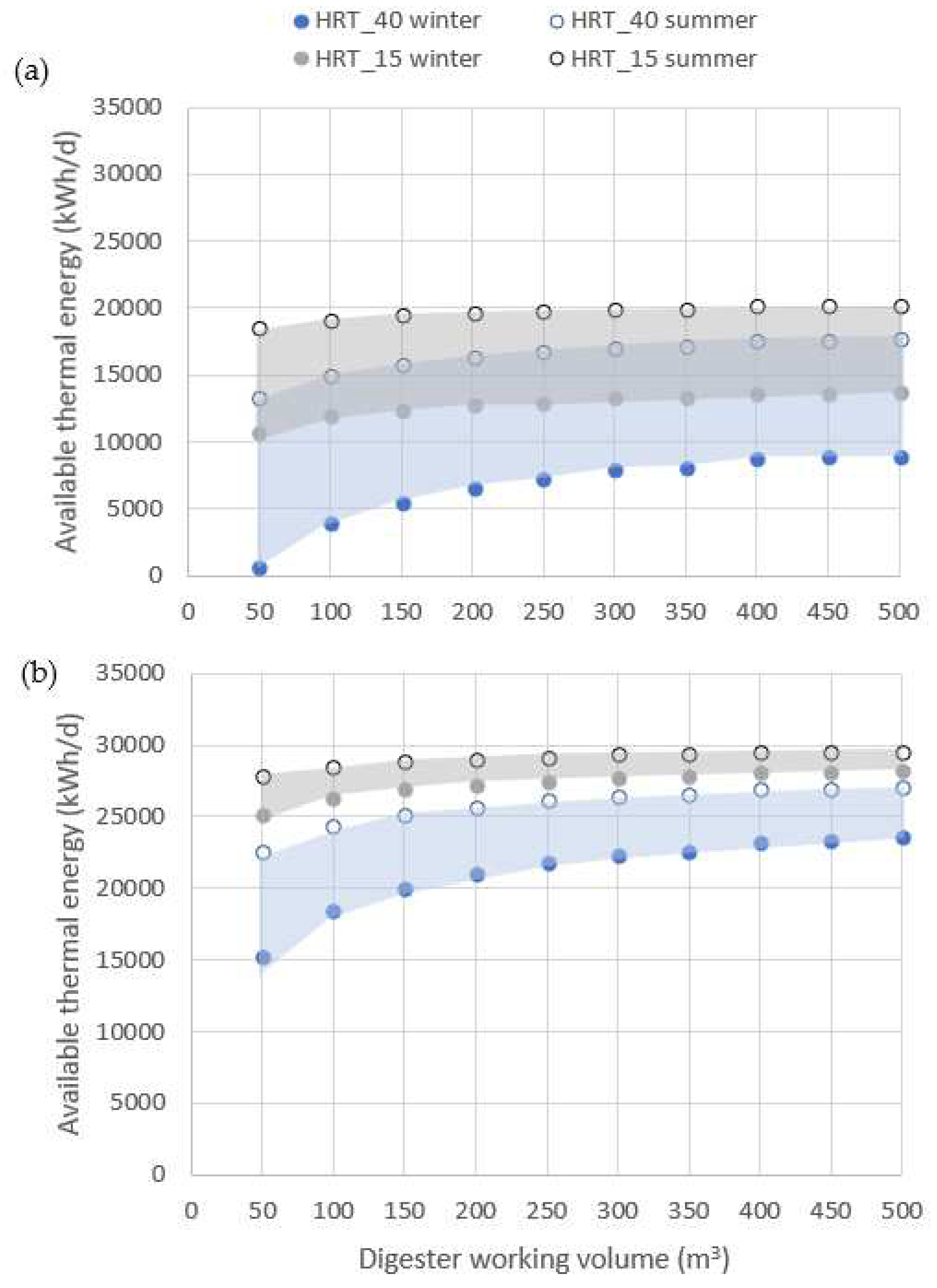

3.2. Technical feasibility of decentralized configuration

3.3. A practical solution is necessary to digestate final disposal

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Gadaleta, G.; De Gisi, S.; Notarnicola, M. Feasibility Analysis on the Adoption of Decentralized Anaerobic Co-Digestion for the Treatment of Municipal Organic Waste with Energy Recovery in Urban Districts of Metropolitan Areas. Int. J. Environ. Res. Public Health 2021, 18(4), 1820. [Google Scholar] [CrossRef] [PubMed]

- Nenciu, F.; Stanciulescu, I.; Vlad, H.; Gabur, A.; Turcu, O.L.; Apostol, T.; Vladut, V.N.; Cocarta, D.M.; Stan, C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability 2022, 14(5), 2835. [Google Scholar] [CrossRef]

- González, R.; Hernández, J.E.; Gómez, X.; Smith, R.; González Arias, J.; Martínez, E.J.; Blanco, D. Performance evaluation of a small-scale digester for achieving decentralised management of waste. Waste Manag. 2020, 118, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Decentralized Biogas Technology of Anaerobic Digestion and Farm Ecosystem: Opportunities and Challenges. Front. Energy Res. 2014, 2. [Google Scholar] [CrossRef]

- Voegeli, Y.; Zurbrügg, C. Decentralised anaerobic digestion of kitchen and market waste in developing countries- ‘state of the art’ in south India. Proceedings of Second International Symposium on Energy from Biomass and Waste Venice, Italy, 17–20 November 2008. [Google Scholar]

- Raha, D.; Mahanta, P.; Clarke, M.L. The implementation of decentralised biogas plants in Assam, NE India: The impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 2014, 68, 80–91. [Google Scholar] [CrossRef]

- Luo, T.; Khoshnevisan, B.; Huang, R.; Chen, Q.; Mei, Z.; Pan, J.; Liu, H. Analysis of revolution in decentralized biogas facilities caused by transition in Chinese rural areas. Renew. Sustain. Energy Rev. 2020, 133, 110133. [Google Scholar] [CrossRef]

- Samer, M.; Abdelaziz, S.; Refai, M.; Abdelsalam, E. Techno-economic assessment of dry fermentation in household biogas units through co-digestion of manure and agricultural crop residues in Egypt. Renew. Energy. 2020, 149, 226–234. [Google Scholar] [CrossRef]

- Bruun, S.; Jensen, L.S.; Khanh Vu, V.T.; Sommer, S. Small-scale household biogas digesters: An option for global warming mitigation or a potential climate bomb? Renew. Sustain. Energy Rev. 2014, 33, 736–741. [Google Scholar] [CrossRef]

- Luo, T.; Zhu, N.; Shen, F.; Long, E.; Long, Y.; Chen, X.; Mei, Z. A Case Study Assessment of the Suitability of Small-Scale Biogas Plants to the Dispersed Agricultural Structure of China. Waste Biomass Valorization 2016, 7, 1131–1139. [Google Scholar] [CrossRef]

- Mench, J.A. Farm animal welfare in the U.S.A.: Farming practices, research, education, regulation, and assurance programs. Appl. Anim. Behav. Sci. 2008, 113, 298–312. [Google Scholar] [CrossRef]

- Hötzel, M.J. Improving farm animal welfare: is evolution or revolution needed in production systems? In Dilemmas in animal welfare; Wallingford UK CABI, 2023; pp. 67–84. [Google Scholar] [CrossRef]

- Wilkinson, K.G. A comparison of the drivers influencing adoption of on-farm anaerobic digestion in Germany and Australia. Biomass Bioenerg. 2011, 35, 1613–1622. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Power, N.; Lyons, G.A.; Bartlett, J. An Investigation of the Potential Adoption of Anaerobic Digestion for Energy Production in Irish Farms. Environments 2021, 8(2), 8. [Google Scholar] [CrossRef]

- Velásquez Piñas, J.A.; Venturini, O.J.; Silva Lora, E.E.; del Olmo, O.A.; Calle Roalcaba, O.D. An economic holistic feasibility assessment of centralized and decentralized biogas plants with mono-digestion and co-digestion systems. Renew. Energy 2019, 139, 40–51. [Google Scholar] [CrossRef]

- González, R.; Blanco, D.; Cascallana, J.G.; Carrillo-Peña, D.; Gómez, X. Anaerobic Co-Digestion of Sheep Manure and Waste from a Potato Processing Factory: Techno-Economic Analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- Imeni, S.M.; Puy, N.; Ovejero, J.; Busquets, A.M.; Bartroli, J.; Pelaz, L.; Ponsá, S.; Colón, J. Techno-Economic Assessment of Anaerobic Co-digestion of Cattle Manure and Wheat Straw (Raw and Pre-treated) at Small to Medium Dairy Cattle Farms. Waste Biomass Valorization 2020, 11, 4035–4051. [Google Scholar] [CrossRef]

- Fuldauer, L.I.; Parker, B.M.; Yaman, R.; Borrion, A. Managing anaerobic digestate from food waste in the urban environment: Evaluating the feasibility from an interdisciplinary perspective. J. Clean. Prod. 2018, 185, 929–940. [Google Scholar] [CrossRef]

- Babbitt, C.W. The role of clean technology research in creating sustainable urban food waste solutions. Clean Technol. Environ. Policy 2020, 22, 1–4. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, D.; Chen, J.; He, Y.; Dai, Y.; Loh, K.-C.; Tong, Y.W. Assessment and optimization of a decentralized food-waste-to-energy system with anaerobic digestion and CHP for energy utilization. Energy Convers. Manag. 2021, 228, 113654. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; González, R.; Gómez, X. Is Decentralized Anaerobic Digestion a Solution? Analyzing Biogas Production and Residential Energy Demand. Eng 2022, 3, 662–676. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Heaven, S.; Banks, C. Energy potential from the anaerobic digestion of food waste in municipal solid waste stream of urban areas in Vietnam. Int. J. Energy Environ. Eng. 2014, 5, 365–374. [Google Scholar] [CrossRef]

- Miller, K.E.; Herman, T.; Philipinanto, D.A.; Davis, S.C. Anaerobic Digestion of Food Waste, Brewery Waste, and Agricultural Residues in an Off-Grid Continuous Reactor. Sustainability 2021, 13, 6509. [Google Scholar] [CrossRef]

- Win, S.S.; Hegde, S.; Chen, R.B.; Trabold, T.A. Feasibility Assessment of Low-Volume Anaerobic Digestion Systems for Institutional Food Waste Producers. Energy Sustainability. American Society of Mechanical Engineers 2017, 57595, V001T02A003. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Carrillo-Peña, D.; Morán, A.; Smith, R.; Gómez, X. Energy Balance of Turbocharged Engines Operating in a WWTP with Thermal Hydrolysis. Co-Digestion Provides the Full Plant Energy Demand. Appl. Sciences 2021, 11, 11103. [Google Scholar] [CrossRef]

- Jenbacher. Available online: Jenbacher type 3 gas engine, https://www.clarke-energy.com/gas-engines/type-3-gas-engines/. (accessed on 10th January 2023).

- Jenbacher. Technical Description Genset JGS 320 GS B L. AB Energy 320-18. Available online: https://www.energy-motors.com/sites/default/files/ge_jenbacher_j320.pdf. (accessed on 10th January 2023).

- Honeywell: Garret Performance Engine Parts Catalogue, Volume 6. Available online: https://images.carid.com/garrett/items/pdf/garrett-product-catalog.pdf. (accessed on 15th January 2023).

- The engineering toolbox. Available online: https://www.engineeringtoolbox.com/individual-universal-gas-constant-d_588.html. (accessed on 15th January 2023).

- Urieli, I. Specific heat capacities of air. Available online: https://www.ohio.edu/mechanical/thermo/property_tables/air/air_Cp_Cv.html. (accessed on 15th January 2023).

- Abu-Nada, E.; Al-Hinti, I.; Al-Sarkhi, A.; Akash, B. Thermodynamic modeling of spark-ignition engine: Effect of temperature dependent specific heats. Int. Commun. Heat Mass Transf. 2006, 33, 1264–1272. [Google Scholar] [CrossRef]

- UNEP: Annual per capita household food waste of selected countries worldwide as of 2020. Available online: https://www.statista.com/statistics/933059/per-capita-food-waste-of-selected-countries/. (accessed on 10th February 2023).

- Manu, M.K.; Kumar, R.; Garg, A. Physical and chemical characterization of yard waste. Int. J. Appl. Eng. Res. 2013, 8, 1891–1896. [Google Scholar]

- Redondas, V.; Moran, A.; Martínez, J.E.; Fierro, J.; Gomez, X. Effect of methanogenic effluent recycling on continuous H2 production from food waste. Environ. Prog. Sustain. Energy 2015, 34, 227–233. [Google Scholar] [CrossRef]

- Odejobi, O.J.; Ajala, O.O.; Osuolale, F.N. Anaerobic co-digestion of kitchen waste and animal manure: a review of operating parameters, inhibiting factors, and pretreatment with their impact on process performance. Biomass Convers. Biorefinery 2023, 13, 5515–5531. [Google Scholar] [CrossRef]

- Helenas Perin, J.K.; Biesdorf Borth, P.L.; Torrecilhas, A.R.; Santana da Cunha, L.; Kuroda, E.K.; Fernandes, F. Optimization of methane production parameters during anaerobic co-digestion of food waste and garden waste. J. Clean. Prod. 2020, 272, 123130. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Tartakovsky, B.; Martínez-Núñez, M.F.; Morán, A. A comparison of analytical techniques for evaluating food waste degradation by anaerobic digestion. Bioprocess Biosyst. Eng. 2010, 33, 427–438. [Google Scholar] [CrossRef]

- González, R.; Rosas, J.G.; Blanco, D.; Smith, R.; Martínez, E.J.; Pastor-Bueis, R.; Gómez, X. Anaerobic digestion of fourth range fruit and vegetable products: comparison of three different scenarios for its valorisation by life cycle assessment and life cycle costing. Environ. Monit. Assess. 2020, 192, 551. [Google Scholar] [CrossRef]

- Panigrahi, S.; Sharma, H.B.; Dubey, B.K. Overcoming yard waste recalcitrance through four different liquid hot water pretreatment techniques – Structural evolution, biogas production and energy balance. Biomass Bioenerg. 2019, 127, 105268. [Google Scholar] [CrossRef]

- Favoino, E.; Giavini, M. Bio-waste generation in the EU: Current capture levels and future potential. Available online: https://zerowasteeurope.eu/wp-content/uploads/2020/07/2020_07_06_bic_zwe_report_bio_waste.pdf. (accessed on 10th February 2023).

- Expansion: España - Consumo de electricidad. Available online: https://datosmacro.expansion.com/energia-y-medio-ambiente/electricidad-consumo/espana. (accessed on 10th February 2023).

- IDAE: Consumo por usos del sector residencial. Available online: https://informesweb.idae.es/consumo-usos-residencial/informe.php. (accessed on 10th February 2023).

- INE: Promedio de personas en los hogares de España en 2020, según comunidad autónoma [Gráfica]. Available online: https://es.statista.com/estadisticas/1013728/promedio-de-personas-en-los-hogares-en-espana-segun-comunidad-autonoma/#:~:text=Tamaño medio del hogar según CC.&text=En el conjunto de España,2%2C5 personas por hogar. (accessed on 10th February 2023).

- Otero, M.; Sánchez, M.E.; Gómez, X. Co-firing of coal and manure biomass: A TG–MS approach. Bioresour. Technol. 2011, 102, 8304–8309. [Google Scholar] [CrossRef] [PubMed]

- Freda, C.; Nanna, F.; Villone, A.; Barisano, D.; Brandani, S.; Cornacchia, G. Air gasification of digestate and its co-gasification with residual biomass in a pilot scale rotary kiln. Int. J. Energy Environ. Eng. 2019, 10, 335–346. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- González, R.; Peña, D.C.; Gómez, X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Appl. Sci. 2022, 12, 8884. [Google Scholar] [CrossRef]

- Tian, H.; Wang, X.; Lim, E.Y.; Lee, J.T.E.; Ee, A.W.L.; Zhang, J.; Tong, Y.W. Life cycle assessment of food waste to energy and resources: Centralized and decentralized anaerobic digestion with different downstream biogas utilization. Renew. Sustain. Energy Rev. 2021, 150, 111489. [Google Scholar] [CrossRef]

- González, R.; García-Cascallana, J.; Gómez, X. Energetic valorization of biogas. A comparison between centralized and decentralized approach. Renew. Energy 2023, 119013. [Google Scholar] [CrossRef]

- Heiman, M. From ‘Not in My Backyard! ’ to ‘Not in Anybody’s Backyard!’ J. Am. Plan. Assoc. 1990, 56, 359–362. [Google Scholar] [CrossRef]

- Diario de León: Las ciudades de Castilla y León disponen de 22,54 metros cuadrados de zona verde por habitante. Available online: https://ileon.eldiario.es/actualidad/ciudades-castilla-leon-disponen-metros-cuadrados-zona-verde-habitante_1_9449713.html#:~:text=León ciudad cuenta con el,superficie urbana catalogada como verde. (accessed on 10th May 2023).

- Peelle, E.; Ellis, R. Beyond the not-in-my-backyard impasse. Forum Appl. Res. Publ. Pol.; (United States) 1987, 2.

- Xu, M.; Lin, B. Exploring the “not in my backyard” effect in the construction of waste incineration power plants - based on a survey in metropolises of China. Environ. Impact Assess. Rev. 2020, 82, 106377. [Google Scholar] [CrossRef]

- Nie, Y.; Zhao, J.; Zhang, Y.; Zhou, J. Risk Evaluation of “Not-In-My-Back-Yard” Conflict Potential in Facilities Group: A Case Study of Chemical Park in Xuwei New District, China. Sustainability 2020, 12, 2723. [Google Scholar] [CrossRef]

- He, L.; Yang, Q.; Liu, X.; Fu, L.; Wang, J. Exploring Factors Influencing Scenarios Evolution of Waste NIMBY Crisis: Analysis of Typical Cases in China. Int. J. Environ. Res. Public Health 2021, 18, 2006. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Ru, P.; Su, J.; Anadon, L.D. Not in my backyard, but not far away from me: Local acceptance of wind power in China. Energy 2015, 82, 722–733. [Google Scholar] [CrossRef]

- Štilić, A.; Puška, A. Integrating Multi-Criteria Decision-Making Methods with Sustainable Engineering: A Comprehensive Review of Current Practices. Eng 2023, 4, 1536–1549. [Google Scholar] [CrossRef]

- Herrmann, C.; Heiermann, M.; Idler, C.; Prochnow, A. Particle Size Reduction during Harvesting of Crop Feedstock for Biogas Production I: Effects on Ensiling Process and Methane Yields. BioEnergy Res. 2012, 5, 926–936. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Barrios, X.G.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Zheng, M.; Li, X.; Li, L.; Yang, X.; He, Y. Enhancing anaerobic biogasification of corn stover through wet state NaOH pretreatment. Bioresour. Technol. 2009, 100, 5140–5145. [Google Scholar] [CrossRef]

- Kim, D.; Kim, J.; Lee, C. Effect of Mild-Temperature Thermo-Alkaline Pretreatment on the Solubilization and Anaerobic Digestion of Spent Coffee Grounds. Energies 2018, 11, 865. [Google Scholar] [CrossRef]

- Amin, F.R.; Khalid, H.; Zhang, H.; Rahman, S. u.; Zhang, R.; Liu, G.; Chen, C. Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Express 2017, 7, 72. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.-C.; Zhang, J. Food waste enhanced anaerobic digestion of biologically pretreated yard waste: Analysis of cellulose crystallinity and microbial communities. Waste Manag. 2018, 79, 109–119. [Google Scholar] [CrossRef]

- Morello, R.; Di Capua, F.; Pontoni, L.; Papirio, S.; Spasiano, D.; Fratino, U.; Pirozzi, F.; Esposito, G. Microaerobic Digestion of Low-Biodegradable Sewage Sludge: Effect of Air Dosing in Batch Reactors. Sustainability 2021, 13, 9869. [Google Scholar] [CrossRef]

- Montalvo, S.; Huiliñir, C.; Ojeda, F.; Castillo, A.; Lillo, L.; Guerrero, L. Microaerobic pretreatment of sewage sludge: Effect of air flow rate, pretreatment time and temperature on the aerobic process and methane generation. Int. Biodeterior. Biodegradation 2016, 110, 1–7. [Google Scholar] [CrossRef]

- León Gómez, J.C.; De León Aldaco, S.E.; Aguayo Alquicira, J. A Review of Hybrid Renewable Energy Systems: Architectures, Battery Systems, and Optimization Techniques. Eng 2023, 4, 1446–1467. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; Cascallana, J.G.; González, R.; Gómez, X. High-Solid Anaerobic Digestion: Reviewing Strategies for Increasing Reactor Performance. Environments 2021, 8, 80. [Google Scholar] [CrossRef]

- Abbassi-Guendouz, A.; Brockmann, D.; Trably, E.; Dumas, C.; Delgenès, J.-P.; Steyer, J.-P.; Escudié, R. Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour. Technol. 2012, 111, 55–61. [Google Scholar] [CrossRef]

- Pastor-Poquet, V.; Papirio, S.; Trably, E.; Rintala, J.; Escudié, R.; Esposito, G. High-solids anaerobic digestion requires a trade-off between total solids, inoculum-to-substrate ratio and ammonia inhibition. Int. J. Environ. Sci. Technol. 2019, 16, 7011–7024. [Google Scholar] [CrossRef]

- Jansson, A.T.; Patinvoh, R.J.; Sárvári Horváth, Ii.; Taherzadeh, M.J. Dry Anaerobic Digestion of Food and Paper Industry Wastes at Different Solid Contents. Fermentation 2019, 5, 40. [Google Scholar] [CrossRef]

- González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand. Appl. Sci. 2021, 11, 11660. [Google Scholar] [CrossRef]

- Casini, D.; Barsali, T.; Rizzo, A.M.; Chiaramonti, D. Production and characterization of co-composted biochar and digestate from biomass anaerobic digestion. Biomass Convers. Biorefinery 2021, 11, 2271–2279. [Google Scholar] [CrossRef]

- Gómez, X.; Diaz, M.C.; Cooper, M.; Blanco, D.; Morán, A.; Snape, C.E. Study of biological stabilization processes of cattle and poultry manure by thermogravimetric analysis and 13C NMR. Chemosphere 2007, 68, 1889–1897. [Google Scholar] [CrossRef]

- Núñez, F.; Pérez, M.; Leon-Fernández, L.F.; García-Morales, J.L.; Fernández-Morales, F.J. Effect of the mixing ratio on the composting of OFMSW digestate: assessment of compost quality. J. Mater. Cycles Waste Manag. 2022, 24, 1818–1831. [Google Scholar] [CrossRef]

- Alzate, S.; Restrepo-Cuestas, B.; Jaramillo-Duque, Á. Municipal Solid Waste as a Source of Electric Power Generation in Colombia: A Techno-Economic Evaluation under Different Scenarios. Resources 2019, 8, 51. [Google Scholar] [CrossRef]

- Nubi, O.; Morse, S.; Murphy, R.J. Prospective Life Cycle Costing of Electricity Generation from Municipal Solid Waste in Nigeria. Sustainability 2022, 14, 13293. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-Economic and Environmental Assessment of Power Supply Chain by Using Waste Biomass Gasification in Iceland. Biophys. Econ. Sustain. 2020, 5, 7. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.-J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef] [PubMed]

- Cesaro, A. The valorization of the anaerobic digestate from the organic fractions of municipal solid waste: Challenges and perspectives. J. Environ. Manage. 2021, 280, 111742. [Google Scholar] [CrossRef] [PubMed]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J.; Dudek, M.; Świca, I.; Rudnicka, A. The Cultivation of Lipid-Rich Microalgae Biomass as Anaerobic Digestate Valorization Technology—A Pilot-Scale Study. Processes 2020, 8, 517. [Google Scholar] [CrossRef]

- Ermis, H.; Güven-Gülhan, Ü.; Çakır, T.; Altınbaş, M. Microalgae growth and diversity in anaerobic digestate compared to synthetic media. Biofuel Res. J. 2022, 9, 1551–1556. [Google Scholar] [CrossRef]

- Pastor-Bueis, R.; Mulas, R.; Gómez, X.; González-Andrés, F. Innovative liquid formulation of digestates for producing a biofertilizer based on Bacillus siamensis: Field testing on sweet pepper. J. Plant Nutr. Soil Sci. 2017, 180, 748–758. [Google Scholar] [CrossRef]

| Parameters of Engine type J 320 GS-D121 | Value |

|---|---|

| Engine strokes (strokes/cycle) | 4 |

| Total displacement (cm3) | 48,670 |

| Number of cylinders (units) | 20 in V |

| Number of cylinder lines (units) | 2 |

| Angle of the cylinders (°) | 70 |

| B, bore (mm) | 135 |

| S, stroke (mm) | 170 |

| S/B, stroke/bore ratio | 1.26 |

| rC, engine compression ratio (dimensionless) | 11.8 |

| n, engine rotation speed (rpm) | 1,500 |

| Average piston speed (m/s) | 8.5 |

| Piston displacement (L) | 2.43 |

| Piston area (cm2) | 143 |

| Combustion chamber volume (cm3) | 225 |

| Combustion chamber/displacement ratio(%) | 6.8 |

| Performance parameters of engine type J 320 GS-D121 | Degree of loading (%) | ||

|---|---|---|---|

| 100 | 75 | 50 | |

| Minimum LHV1 of biogas (kWh/m3) | 5 | ||

| 2CH4 number/Minimum CH4 number | 135/100 | ||

| Peng, engine mechanical power (kW) | 1,095 | 821 | 548 |

| Electrical power (cos φ = 1) (kW) | 1,067 | 798 | 529 |

| MEP, mean effective pressure (kPa) | 1,800 | 1,350 | 901 |

| Radiation power losses (kW) | 54 | ||

| Mechanical power losses (kW) | 28 | 23 | 19 |

| Power loss of exhaust gases (100 °C) (kW) | 685 | ||

| Power loss of exhaust gases (180 °C) (kW) | 550 | ||

| Power loss of exhaust gases (0 °C) (kW) | 740 | ||

| Exhaust gas temperature (°C) | 490 | ||

| Mair, air mass flow inlet (kg/h) | 5,176 | ||

| Meg, Exhaust gas mass flow (wet) (kg/h) | 5,634 | ||

| Mbio, biogas mass flow (kg/h) | 458 | ||

| ηmec, Mechanical efficiency (%) | 41.2 | 40.1 | 38.2 |

| Electrical efficiency (cos φ = 1) (%) | 40.2 | 39 | 36.8 |

| ηe, engine thermal efficiency (%) | 41.3 | ||

| Energy efficiency (%) | 82.5 | ||

| BC, biogas consumption (kW) | 2,655 | 2,046 | 1,436 |

| Min-Max biogas pressure range at the biogas inlet train (mbar) | 80-200 | ||

| Main circuit thermal power (kW) | 645 | 519 | 394 |

| Block and jacket circuit power (kW) | 341 | 336 | 296 |

| PINT-2, intercooler 2 power (kW) | 181 | 78 | 5 |

| Oil exchanger power (kW) | 123 | 105 | 93 |

| Auxiliary circuit thermal power (kW) | 77 | 58 | 38 |

| PINT-1, intercooler 1 power (kW) | 77 | 58 | 38 |

| F, ratio fuel/air (%) | 8.8 | ||

| Max. admissible exhaust back pressure after engine (kPa) | 6 | ||

| Max. admissible pressure drop in front of intake-air filter (kPa) | 1 | ||

| Turbocharger parameters | Value | References |

|---|---|---|

| Maximum temperature of the mixture at second intercooler (°C) | 83.9 | [26] |

| Maximum temperature of mixture at first intercooler (°C) | 55 | [26] |

| ηmec1, ηmec2, Mechanical efficiency of turbocharger transmission | 97 | [28] |

| R, universal constant of ideal gas (J/kg K) | 287.05 | [29] |

| γ, adiabatic coefficient of air, mixture and gases (dimensionless) | 1.4 | [30] |

| Parameter | Food waste | Reference | Garden waste | References |

|---|---|---|---|---|

| Production (kg/year per capita) | 77 | [32] | 1101 | |

| TS content (g/kg) | 150 | 610 | [33] | |

| %VS | 90 | [34,35] | 77.52 | [33,36] |

| SMP (mL CH4/g VS) | 340 | [37,38] | 257 | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).