Submitted:

25 July 2023

Posted:

27 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

2.1. Materials

2.2. Methods

2.2.1. Preparation of the Biocomposite

2.2.2. Composite Fabrication

2.2.3. Taguchi Design

2.3. Determination of the Flexural Strength

3. Results

3.1. Flexural Strength of the Biocomposite

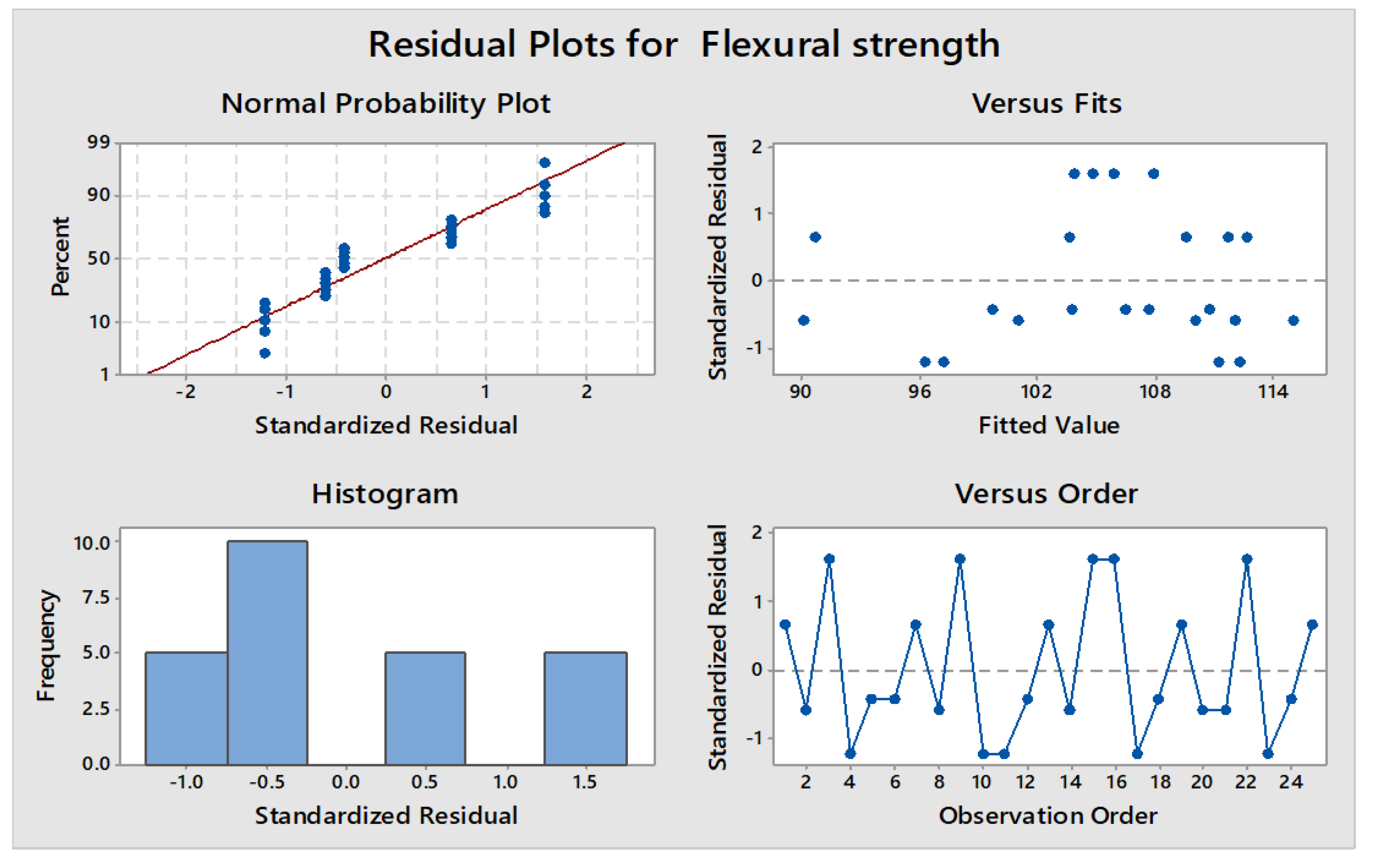

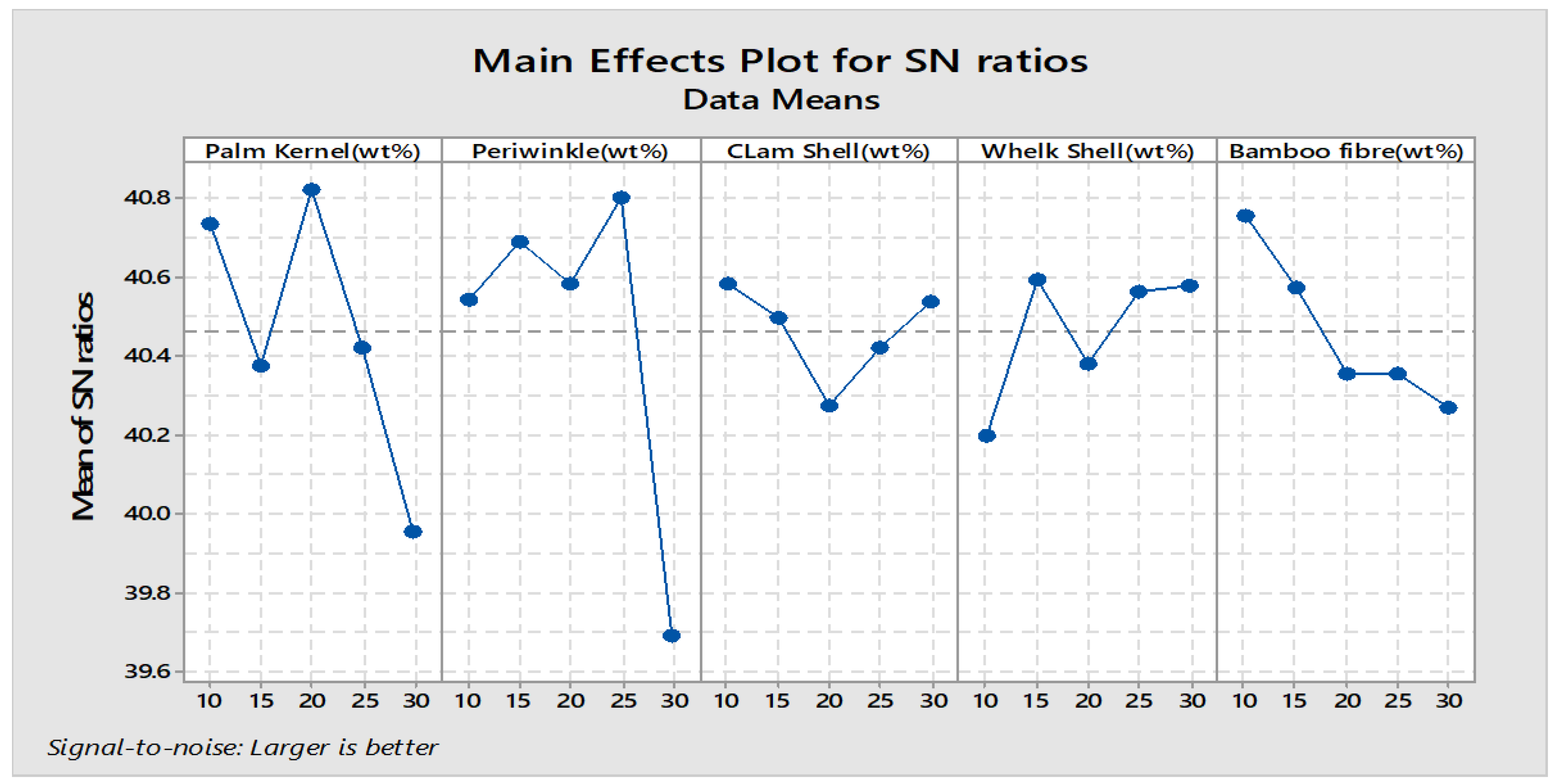

3.2. ANOVA of the Flexural Strength

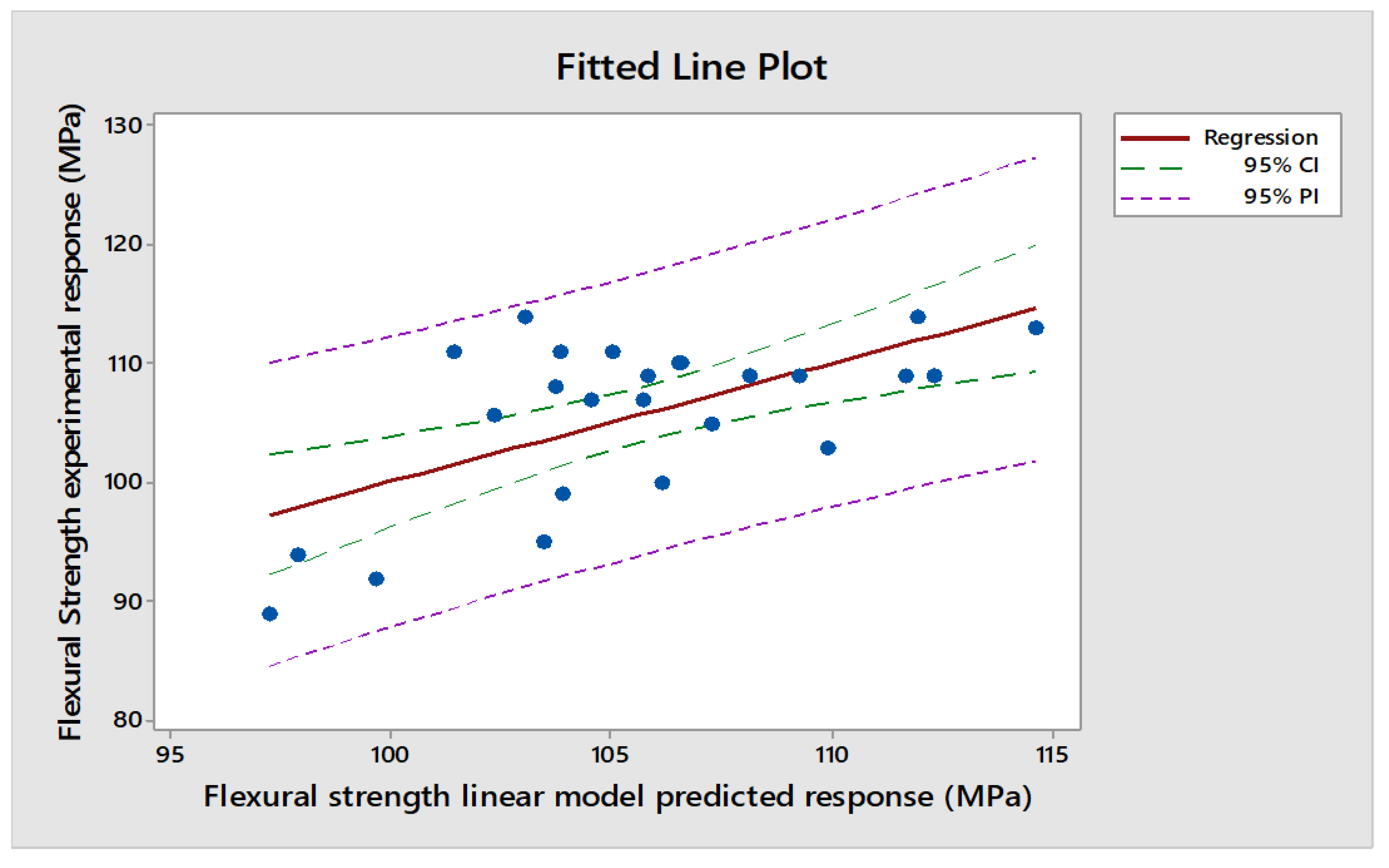

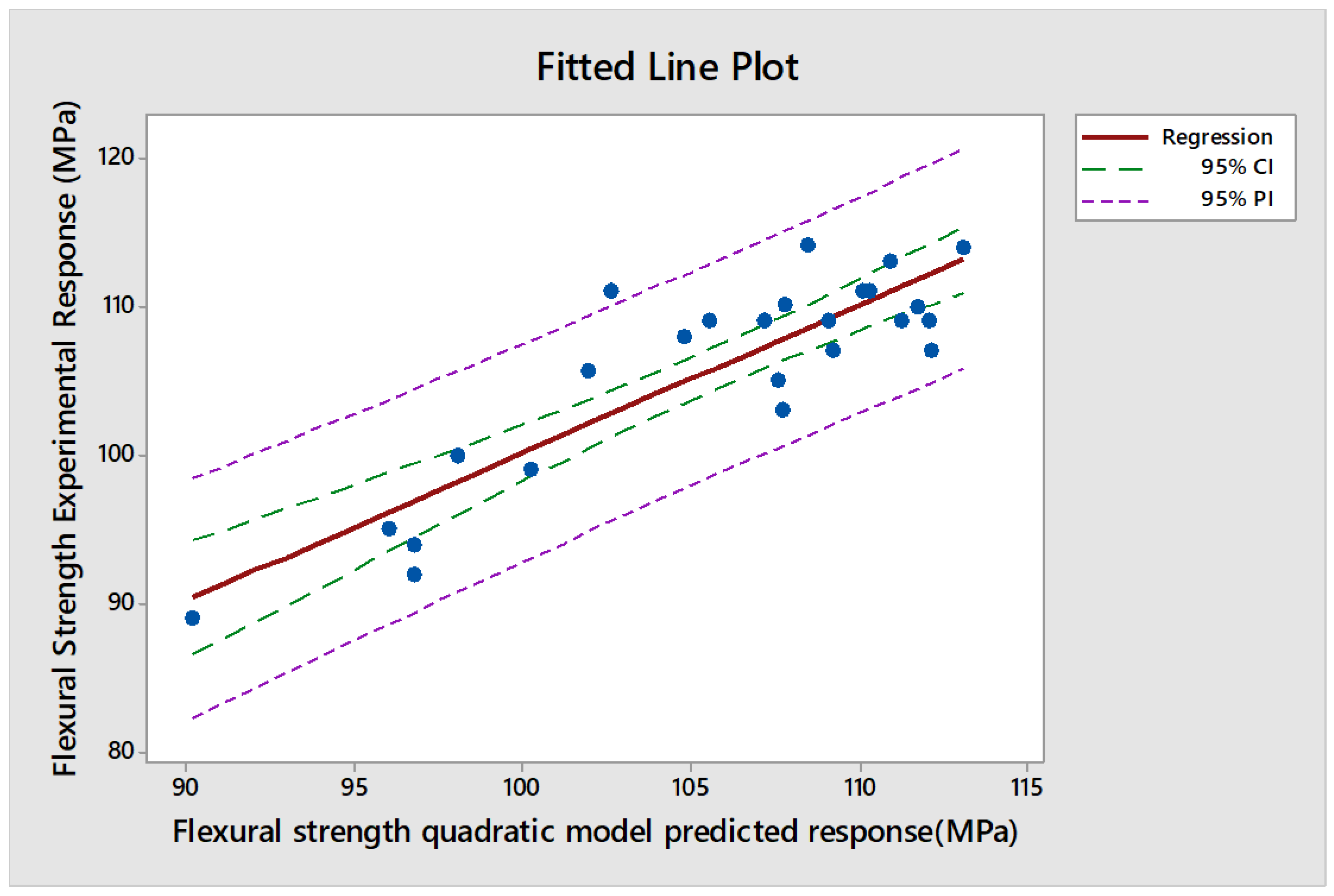

3.3. Regression Analysis of the Flexural Strength Response

3.4. Confirmation Experiment for Flexural Strength

4. Conclusions

References

- Achukwu, E.O.; Barnabas, A.M.; Mamman, A.; Uzochukwu, M.I. Fabrication of Palm Kernel Shell Epoxy Composites and Study of Their Mechanical Properties. Nigerian Journal of Materials Science and Engineering 2020, 6, 32. [Google Scholar]

- Akindapo, J.O.; Agov, E.T.; Garba, D.K.; Ogabi, R.O. Comparative Assessment of Mechanical Properties of Groundnut Shell and Rice Husk Reinforced Epoxy Composites. American Journal of Mechanical Engineering 2017, 5, 76–86. [Google Scholar]

- Alias NS Ismail HWahab, M.K.; Ragunathan SArdhyananta, H.; Ting, S.S. Development of new material based on polyvinyl alcohol//palm kernel shell powder biocomposites. Advances in Environmental Studies 2018, 2, 98–107. [Google Scholar]

- Estaji, S.; Paydayesh, A.; Mousavi, S.R.; Khonakdar, H.A.; Abiyati, M.M. Polycarbonate/poly (methyl methacrylate)/silica aerogel blend composites for advanced transparent thermal insulations: mechanical, thermal, and optical studies. Polym Compos 2021, 42, 5323. [Google Scholar] [CrossRef]

- Ghanbari, A.; Sadat Jalili, N.; Haddadi, S.A.; Arjmand, M.; Nofar, M. Mechanical properties of extruded glass fiber reinforced thermoplastic polyolefin composites. Polym Compos 2020, 41, 3748. [Google Scholar] [CrossRef]

- Ikumapayi, O.M.; Akinlabi, E.T. Composition, Characteristics and Socioeconomic benefits of palm kernel shell exploitation – An overview. Journal of Environmental Science and Technology 2018, 1, 220–232. [Google Scholar] [CrossRef]

- Mousavi, S.R.; Faraj Nejad, S.; Jafari, M.; Paydayesh, A. Polypropylene/ethylene propylene diene monomer/cellulose nanocrystal ternary blend nanocomposites: effects of different parameters on mechanical, rheological, and thermal properties. Polym Compos 2021, 42, 4187. [Google Scholar] [CrossRef]

- Ngo, T.D. Natural fibers for sustainable bio-composites. In Natural and Artificial FiberReinforced Composites as Renewable Sources; Gunay, E., Ed.; IntechOpen: Croatia, 2018. [Google Scholar]

- Oromiehie, E.; Gangadhara, P.; Compston, P.; Rajan, G. Automated fiber placement based composite structures: Review on the defects, impacts and inspections techniques. Composite Structures. 2019, 110987, 224. [Google Scholar] [CrossRef]

- Razavi, M.; Sadeghi, N.; Jafari, S.H.; Khonakdar, H.A.; Wagenknecht, U.; Leuteritz, A. Thermo-rheological probe of microstructural evolution and degradation pathway in the flame-retarded PP/EVA/NOR/clay nanocomposites. Rheologica Acta 2022, 61, 25. [Google Scholar] [CrossRef]

- Safi, B.; Saidi, M.; Daoui, A.; Bellal, A.; Mechekak, A.; Toumi, K. The use of seashells as a fine aggregate (by sand substition) in selfcompacting mortar (SCM). Construction Building Materials 2015, 78, 430–438. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of natural fibers and its composites: An overview. Natural Resources. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Shi, J.; Yao, R.; Kong, Z.; Ni, F.; Zheng, J. Strength analysis on hybrid welding interface of polymer and short carbon fiber reinforced composite. Journal of Mater Sci 2021, 1. [Google Scholar] [CrossRef]

- Yao, X.; Raine, T.P.; Liu, M.; Zakaria, M.; Kinloch, I.A.; Bissett, M.A. Effect of graphene nanoplatelets on the mechanical and gas barrier properties of woven carbon fiber/epoxy composites. J Mate Sci 2021, 1. [Google Scholar] [CrossRef]

| S/N | Factors | Level (wt%) | ||||

|---|---|---|---|---|---|---|

| 1 | Palm Kernel Shell | 10 | 15 | 20 | 25 | 30 |

| 2 | Periwinkle Shell | 10 | 15 | 20 | 25 | 30 |

| 3 | Clam Shell | 10 | 15 | 20 | 25 | 30 |

| 4 | Whelk Shell | 10 | 15 | 20 | 25 | 30 |

| 5 | Bamboo Fiber | 10 | 15 | 20 | 25 | 30 |

| S/N | Palm Kernel Shell | Periwinkle Shell | Clam Shell | Whelk Shell | Bamboo Fiber | Flexural Strength (MPa) | S/N Ratio for Flexural Strength |

|---|---|---|---|---|---|---|---|

| 1 | 10 | 10 | 10 | 10 | 10 | 112.99 | 41.0608 |

| 2 | 10 | 15 | 15 | 15 | 15 | 113.98 | 41.1366 |

| 3 | 10 | 20 | 20 | 20 | 20 | 108.96 | 40.7453 |

| 4 | 10 | 25 | 25 | 25 | 25 | 110.07 | 40.8334 |

| 5 | 10 | 30 | 30 | 30 | 30 | 98.94 | 39.9074 |

| 6 | 15 | 10 | 15 | 20 | 25 | 102.94 | 40.2517 |

| 7 | 15 | 15 | 20 | 25 | 30 | 104.95 | 40.4196 |

| 8 | 15 | 20 | 25 | 30 | 10 | 108.99 | 40.7477 |

| 9 | 15 | 25 | 30 | 10 | 15 | 110.98 | 40.9049 |

| 10 | 15 | 30 | 10 | 15 | 20 | 94.91 | 39.5462 |

| 11 | 20 | 10 | 20 | 30 | 15 | 108.99 | 40.7477 |

| 12 | 20 | 15 | 25 | 10 | 20 | 106.96 | 40.5844 |

| 13 | 20 | 20 | 30 | 15 | 25 | 113.99 | 41.1373 |

| 14 | 20 | 25 | 10 | 20 | 30 | 110.94 | 40.9018 |

| 15 | 20 | 30 | 15 | 25 | 10 | 108.97 | 40.7461 |

| 16 | 25 | 10 | 25 | 15 | 30 | 107.96 | 40.6653 |

| 17 | 25 | 15 | 30 | 20 | 10 | 108.92 | 40.7422 |

| 18 | 25 | 20 | 10 | 25 | 15 | 109.97 | 40.8255 |

| 19 | 25 | 25 | 15 | 30 | 20 | 110.92 | 40.9002 |

| 20 | 25 | 30 | 20 | 10 | 25 | 88.89 | 38.9771 |

| 21 | 30 | 10 | 30 | 25 | 20 | 99.93 | 39.9939 |

| 22 | 30 | 15 | 10 | 30 | 25 | 106.96 | 40.5844 |

| 23 | 30 | 20 | 15 | 10 | 30 | 93.92 | 39.4552 |

| 24 | 30 | 25 | 20 | 15 | 10 | 105.66 | 40.4782 |

| 25 | 30 | 30 | 25 | 20 | 15 | 91.92 | 39.2682 |

| Unreinforced with shell/fiber | - | - | - | - | - | 72.33 | - |

| Confirmation test. |

| Level | Palm Kernel Shell | Periwinkle Shell | Clam Shell | Whelk Shell | Bamboo Fiber |

|---|---|---|---|---|---|

| 1 | 40.74 | 40.54 | 40.58 | 40.20 | 40.76 |

| 2 | 40.37 | 40.69 | 40.50 | 40.59 | 40.58 |

| 3 | 40.82 | 40.58 | 40.27 | 40.38 | 40.35 |

| 4 | 40.42 | 40.80 | 40.42 | 40.56 | 40.36 |

| 5 | 39.96 | 39.69 | 40.54 | 40.58 | 40.27 |

| Delta | 0.87 | 1.11 | 0.31 | 0.40 | 0.49 |

| Rank | 2 | 1 | 5 | 4 | 3 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|---|---|

| Palm Kernel(wt%) | 4 | 333.78 | 28.13% | 333.78 | 83.45 | 3.62 | 0.120 |

| Periwinkle(wt%) | 4 | 532.90 | 44.90% | 532.90 | 133.23 | 5.79 | 0.045 |

| CLam Shell(wt%) | 4 | 40.97 | 3.45% | 40.97 | 10.24 | 0.44 | 0.774 |

| Whelk Shell(wt%) | 4 | 74.77 | 6.30% | 74.77 | 18.69 | 0.81 | 0.578 |

| Bamboo fiber(wt%) | 4 | 112.27 | 9.46% | 112.27 | 28.07 | 1.22 | 0.426 |

| Error | 4 | 92.10 | 7.76% | 92.10 | 23.03 | ||

| Total | 24 | 1186.79 | 100.00% | ||||

| S | 4.79849 | ||||||

| R-sq | 92.24% |

| S/N | Palm Kernel Shell | Periwinkle Shell | Clam Shell | Whelk Shell | Bamboo Fiber | Actual Flexural Strength (MPa) | Predicted linear Flexural Strength (MPa) | Predicted quadratic Flexural Strength (MPa |

|---|---|---|---|---|---|---|---|---|

| 1 | 10 | 10 | 10 | 10 | 10 | 112.99 | 114.61 | 110.90 |

| 2 | 10 | 15 | 15 | 15 | 15 | 113.98 | 111.94 | 113.10 |

| 3 | 10 | 20 | 20 | 20 | 20 | 108.96 | 109.27 | 112.06 |

| 4 | 10 | 25 | 25 | 25 | 25 | 110.07 | 106.60 | 107.79 |

| 5 | 10 | 30 | 30 | 30 | 30 | 98.94 | 103.93 | 100.28 |

| 6 | 15 | 10 | 15 | 20 | 25 | 102.94 | 109.95 | 107.74 |

| 7 | 15 | 15 | 20 | 25 | 30 | 104.95 | 107.28 | 107.57 |

| 8 | 15 | 20 | 25 | 30 | 10 | 108.99 | 111.68 | 111.24 |

| 9 | 15 | 25 | 30 | 10 | 15 | 110.98 | 105.06 | 110.32 |

| 10 | 15 | 30 | 10 | 15 | 20 | 94.91 | 103.47 | 96.04 |

| 11 | 20 | 10 | 20 | 30 | 15 | 108.99 | 112.36 | 105.58 |

| 12 | 20 | 15 | 25 | 10 | 20 | 106.96 | 105.74 | 112.11 |

| 13 | 20 | 20 | 30 | 15 | 25 | 113.99 | 103.07 | 108.46 |

| 14 | 20 | 25 | 10 | 20 | 30 | 110.94 | 101.47 | 102.64 |

| 15 | 20 | 30 | 15 | 25 | 10 | 108.97 | 105.88 | 107.20 |

| 16 | 25 | 10 | 25 | 15 | 30 | 107.96 | 103.74 | 104.81 |

| 17 | 25 | 15 | 30 | 20 | 10 | 108.92 | 108.15 | 109.09 |

| 18 | 25 | 20 | 10 | 25 | 15 | 109.97 | 106.55 | 111.75 |

| 19 | 25 | 25 | 15 | 30 | 20 | 110.92 | 103.88 | 110.09 |

| 20 | 25 | 30 | 20 | 10 | 25 | 88.89 | 97.26 | 90.25 |

| 21 | 30 | 10 | 30 | 25 | 20 | 99.93 | 106.15 | 98.08 |

| 22 | 30 | 15 | 10 | 30 | 25 | 106.96 | 104.56 | 109.20 |

| 23 | 30 | 20 | 15 | 10 | 30 | 93.92 | 97.94 | 96.81 |

| 24 | 30 | 25 | 20 | 15 | 10 | 105.66 | 102.34 | 101.98 |

| 25 | 30 | 30 | 25 | 20 | 15 | 91.92 | 99.67 | 96.84 |

| Unreinforced with shell/fiber | - | - | - | - | - | 72.33 | ||

| Confirmation test. | 20 | 25 | 10 | 15 | 10 | 114.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).