Submitted:

26 July 2023

Posted:

26 July 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

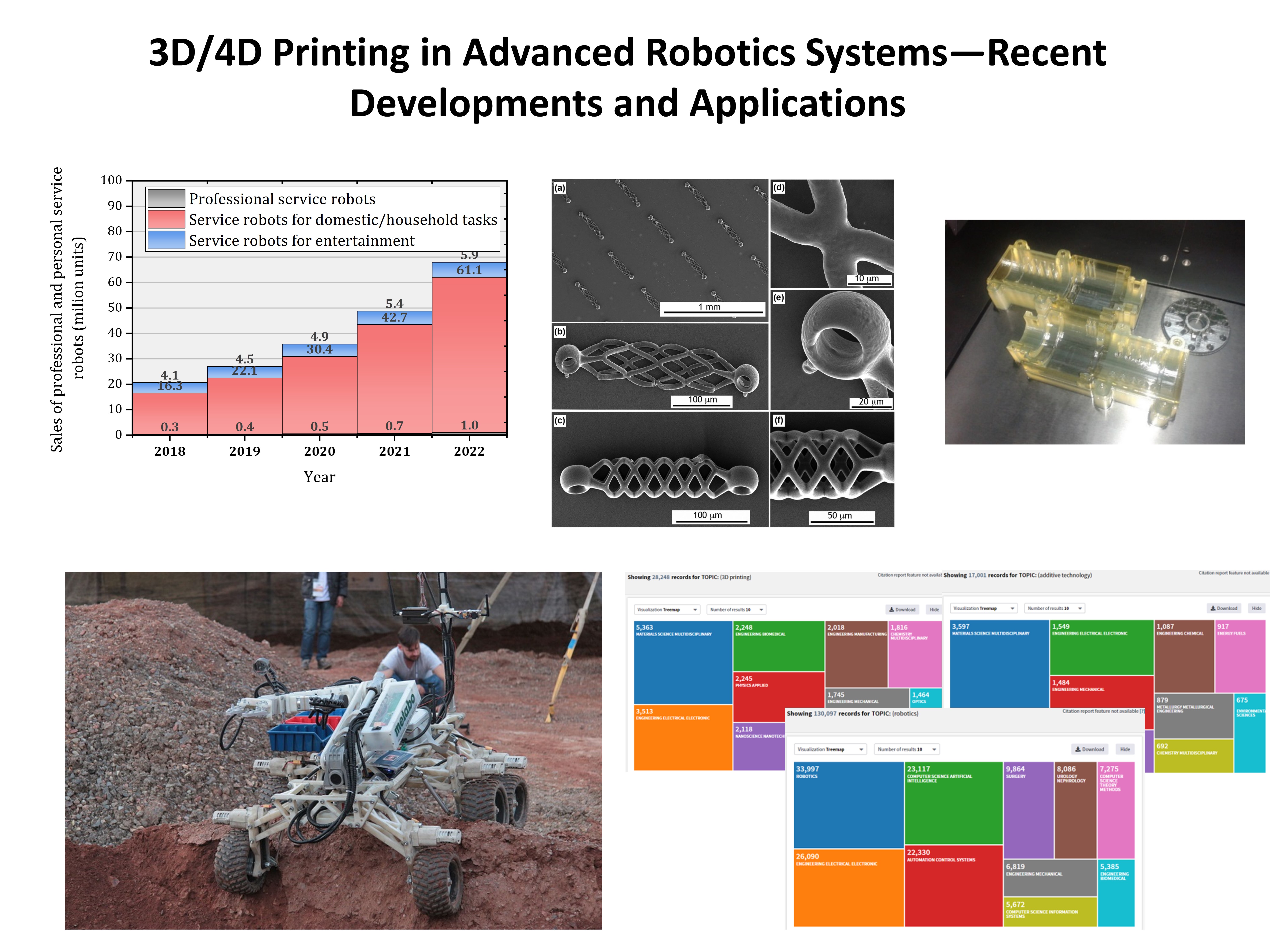

2. Robotics

3. 3D/4D Printing

3.1. Application

3.2. Classification

3.3. Materials

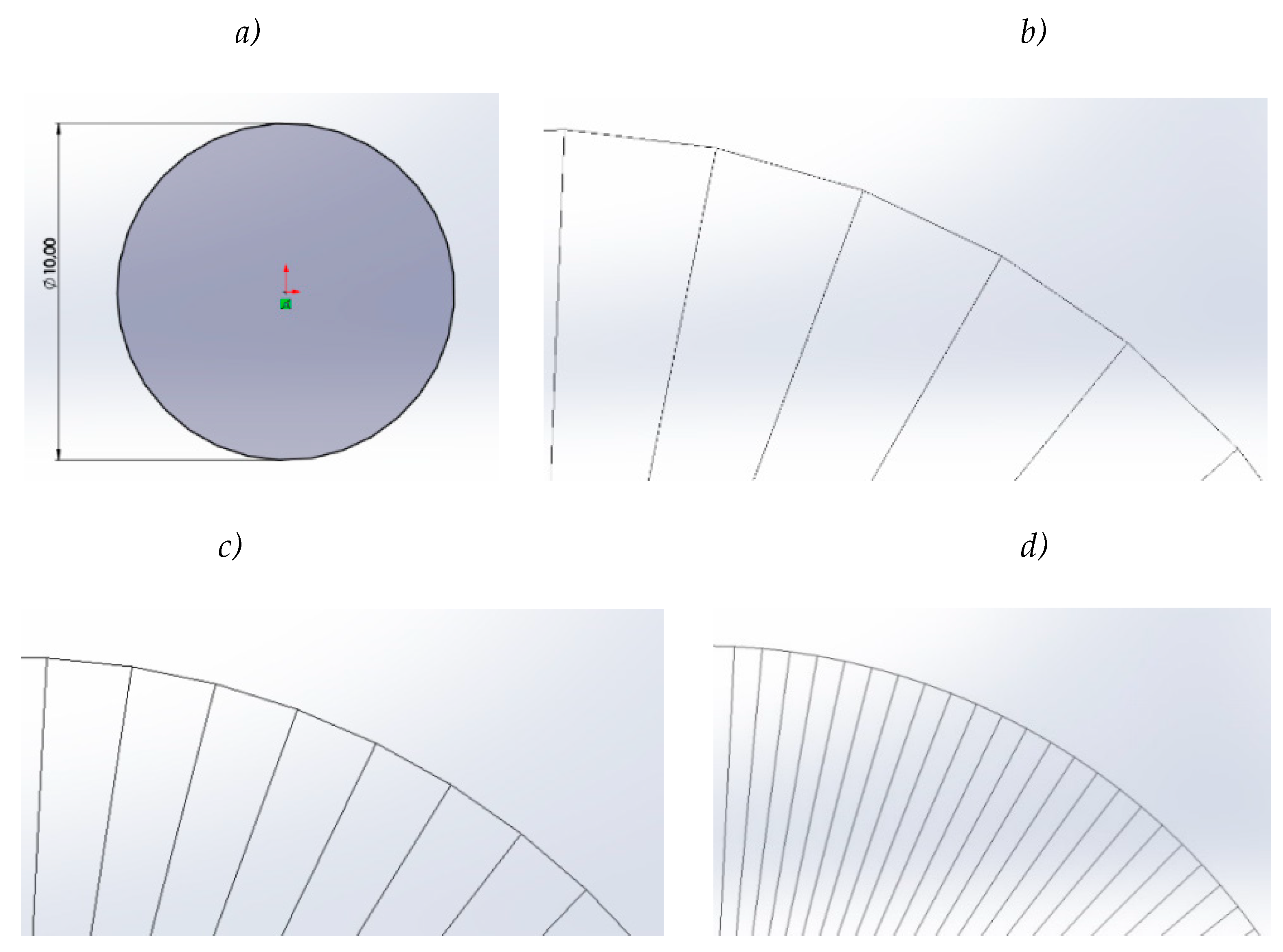

3.4. 3D Models

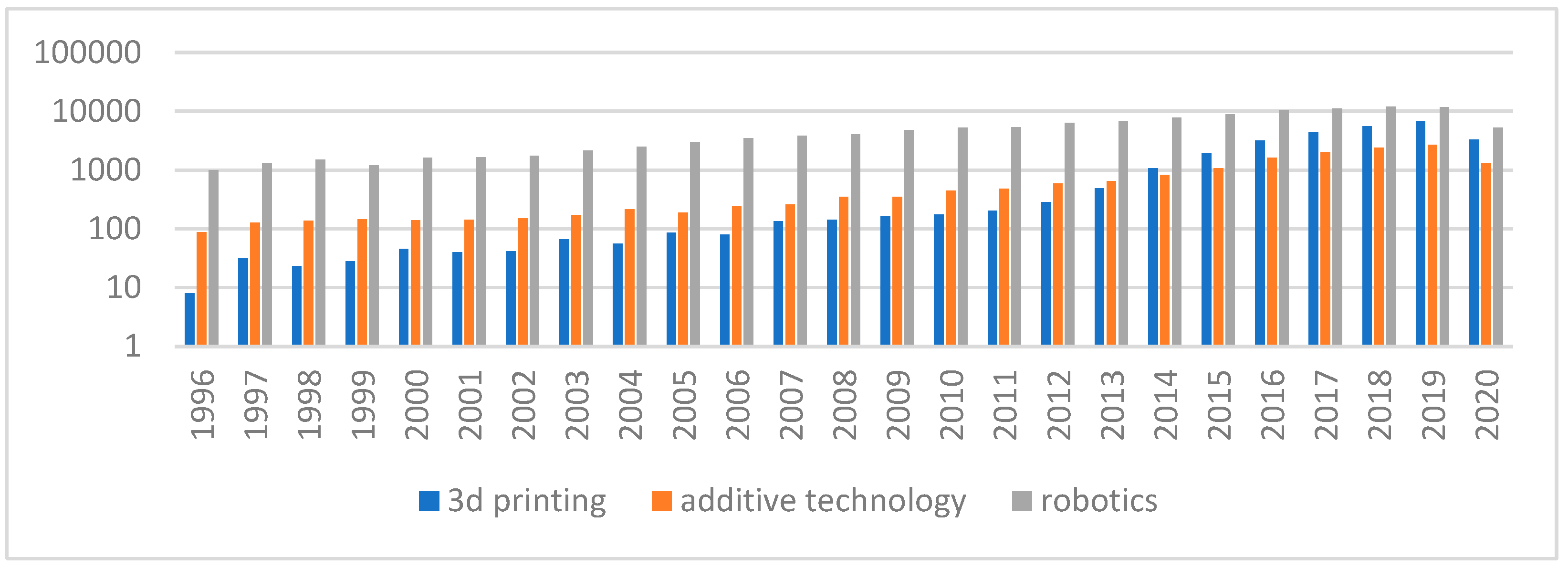

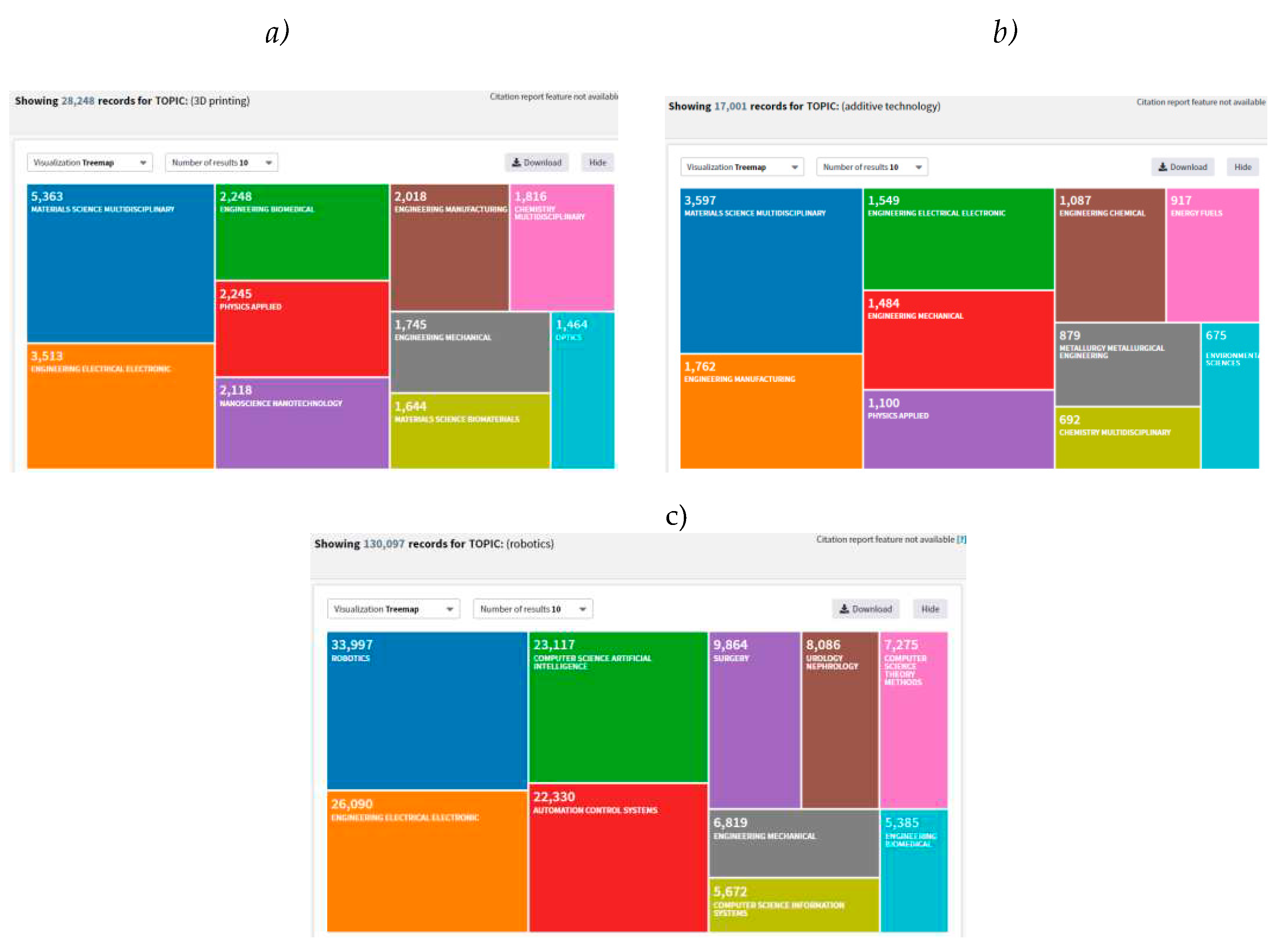

4. State of the Art

5. 3D Printing plastic methods in robotics

5.1. Fused Deposition modeling – FDM/FFF

5.2. Selective Laser Sintering – SLS

5.3. Photocuring Polymer Resin

5.3.1. PolyJet Matrix - PJM

5.3.2. Stereolitography – SLA

5.4. HP Multi Jet Fusion

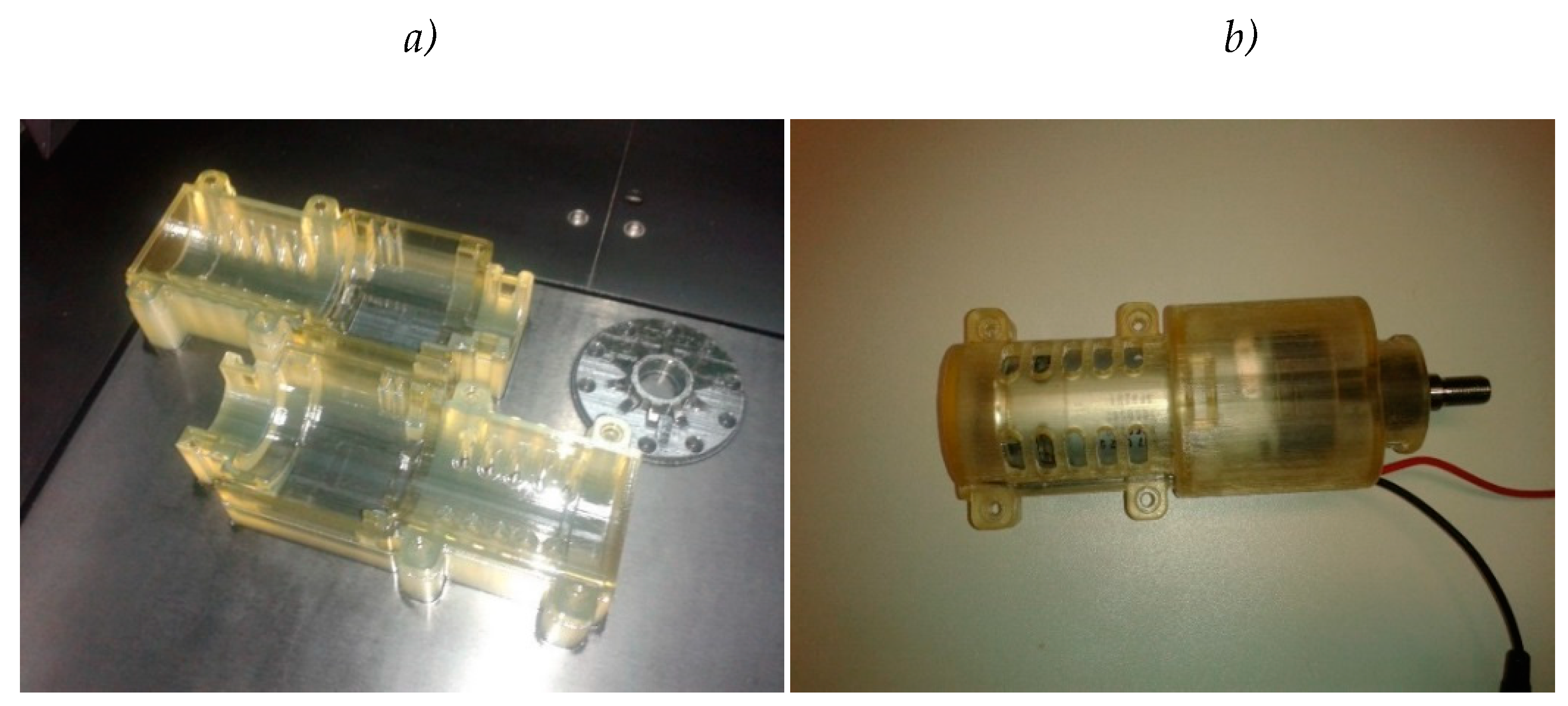

6. Prototypes

7. Final production

8. Conclusions and future work

Author Contributions

References

- Krzysztofik, I.; Takosoglu, J.; Koruba, Z. Selected Methods of Control of the Scanning and Tracking Gyroscope System Mounted on a Combat Vehicle. Annu. Rev. Control 2017, 44, 173–182. https://doi.org/10.1016/j.arcontrol.2016.10.003. [CrossRef]

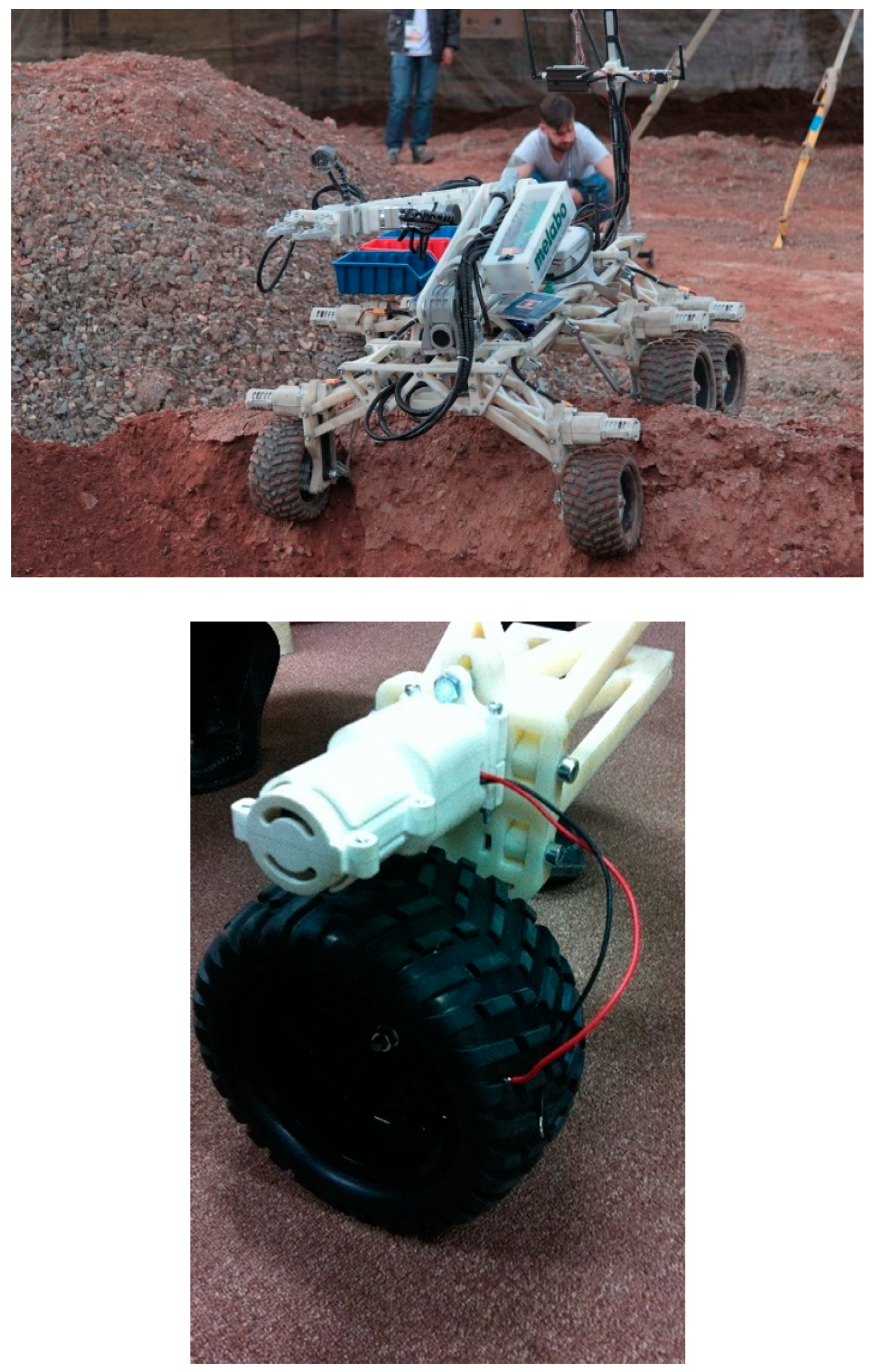

- Tkáčik, M.; Březina, A.; Jadlovská, S. Design of a Prototype for a Modular Mobile Robotic Platform. IFAC-PapersOnLine 2019, 52, 192–197. https://doi.org/10.1016/j.ifacol.2019.12.755. [CrossRef]

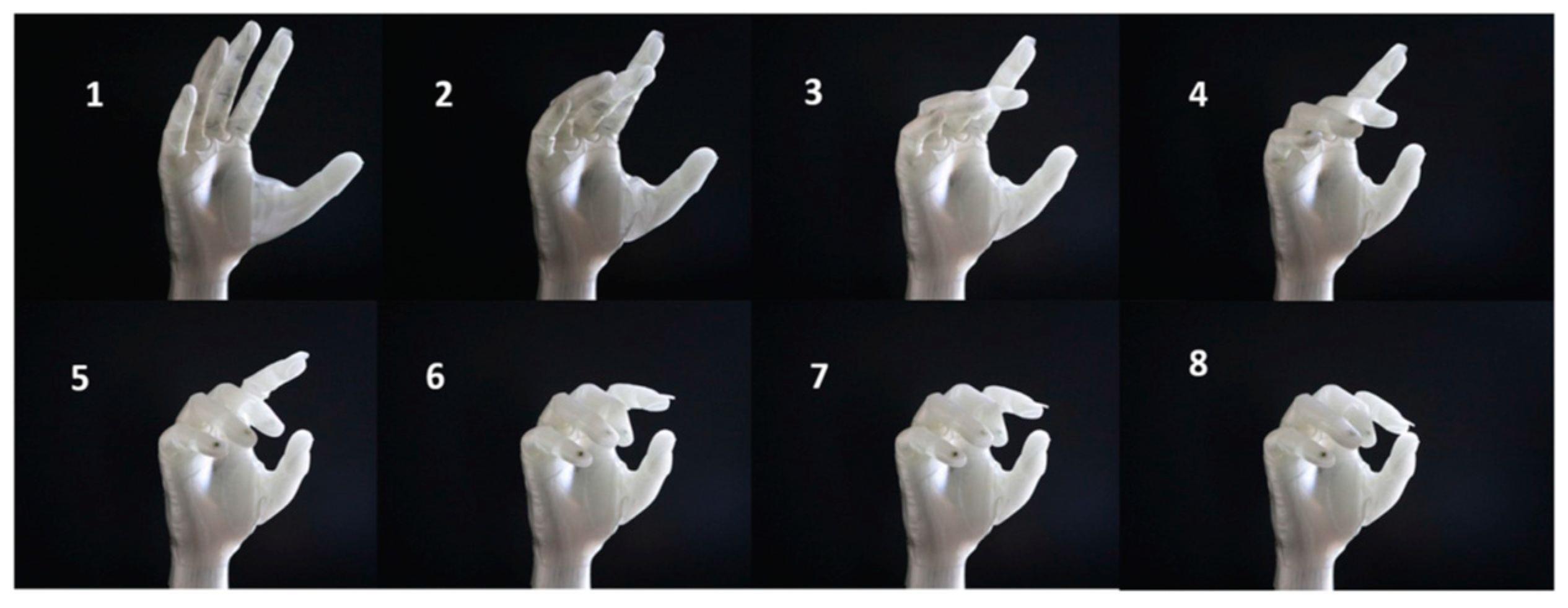

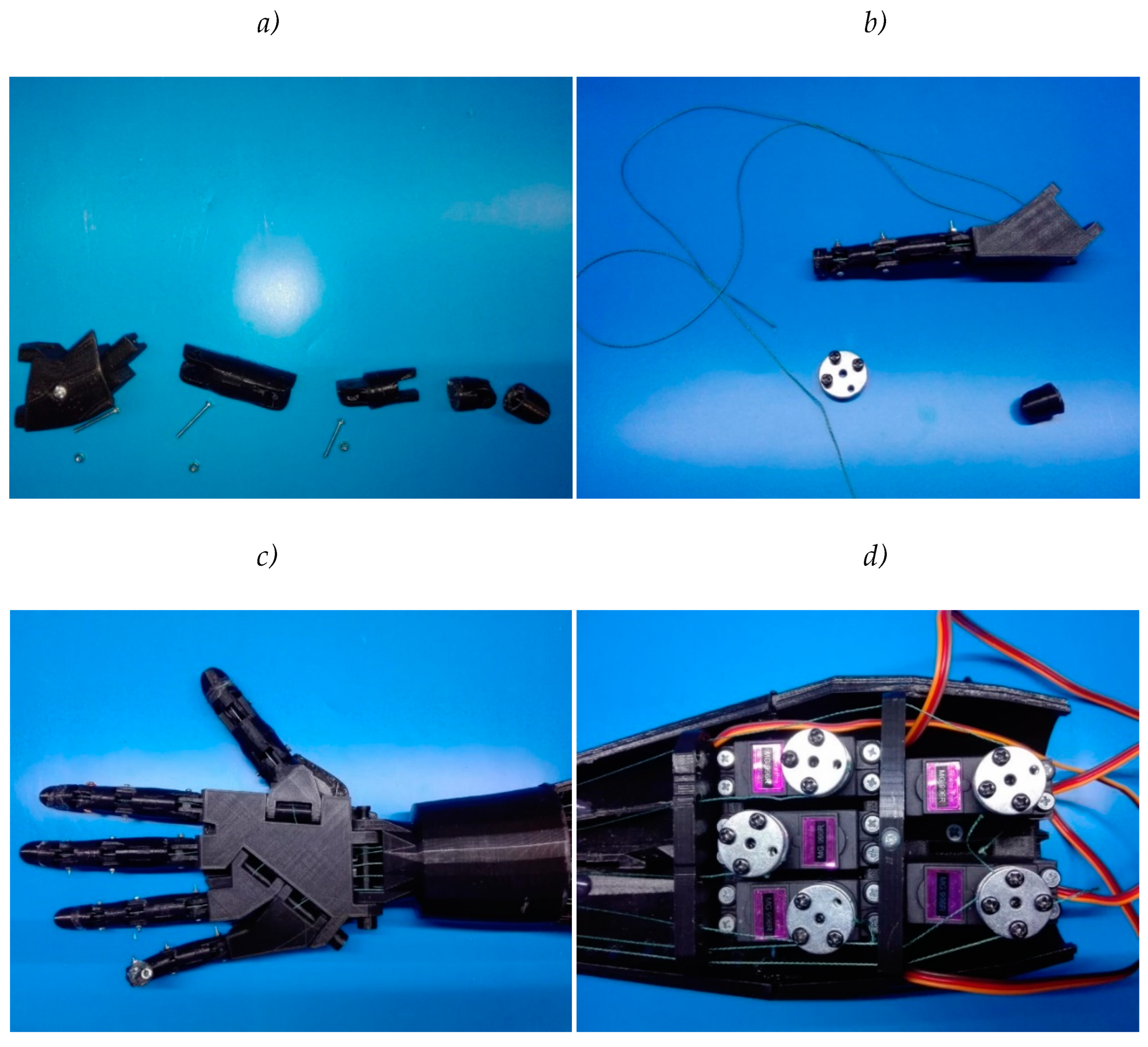

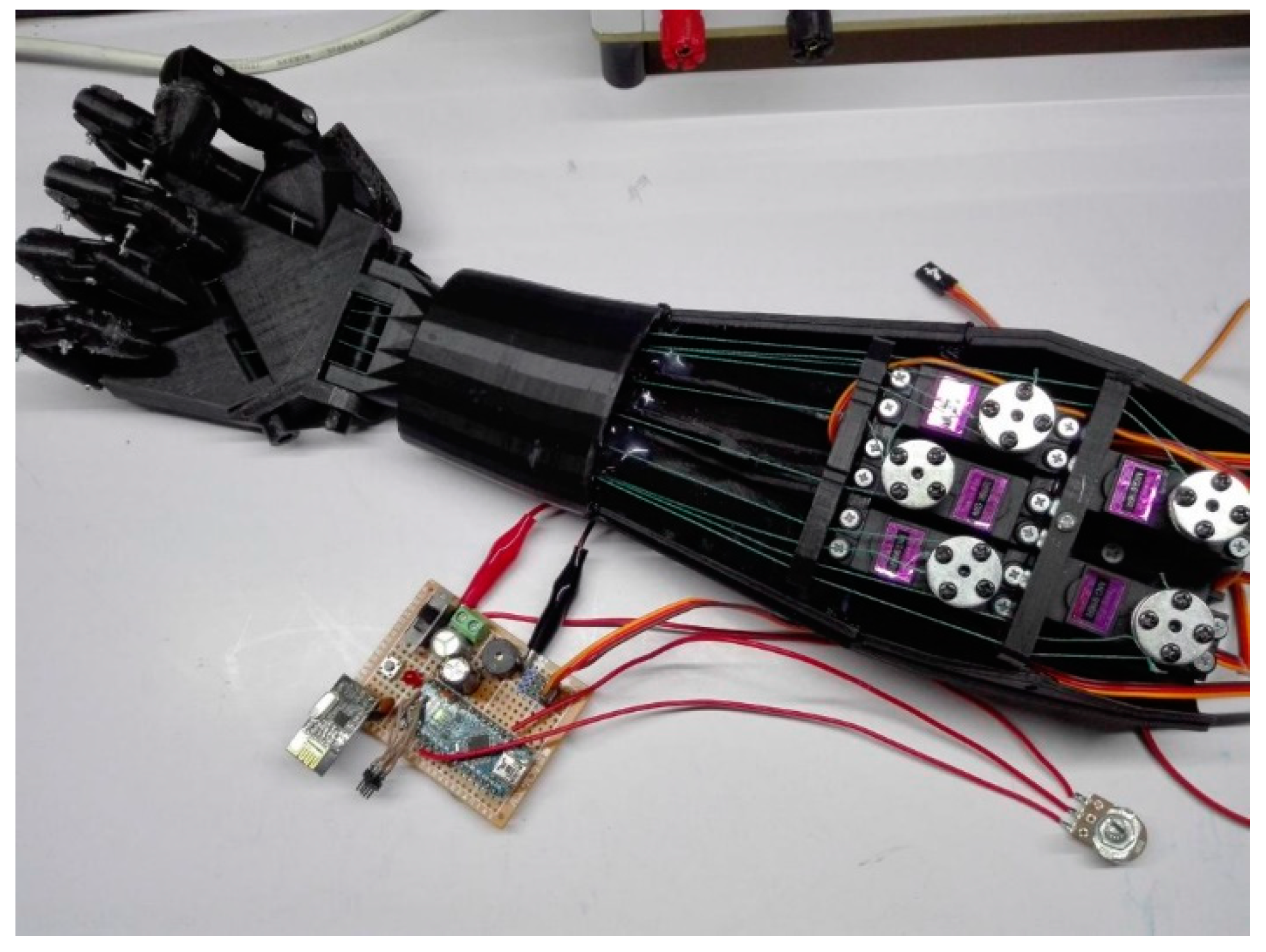

- Li, X.L.; Wu, L.C.; Lan, T.Y. A 3D-Printed Robot Hand with Three Linkage-Driven Underactuated Fingers. Int. J. Autom. Comput. 2018, 15, 593–602. https://doi.org/10.1007/s11633-018-1125-z. [CrossRef]

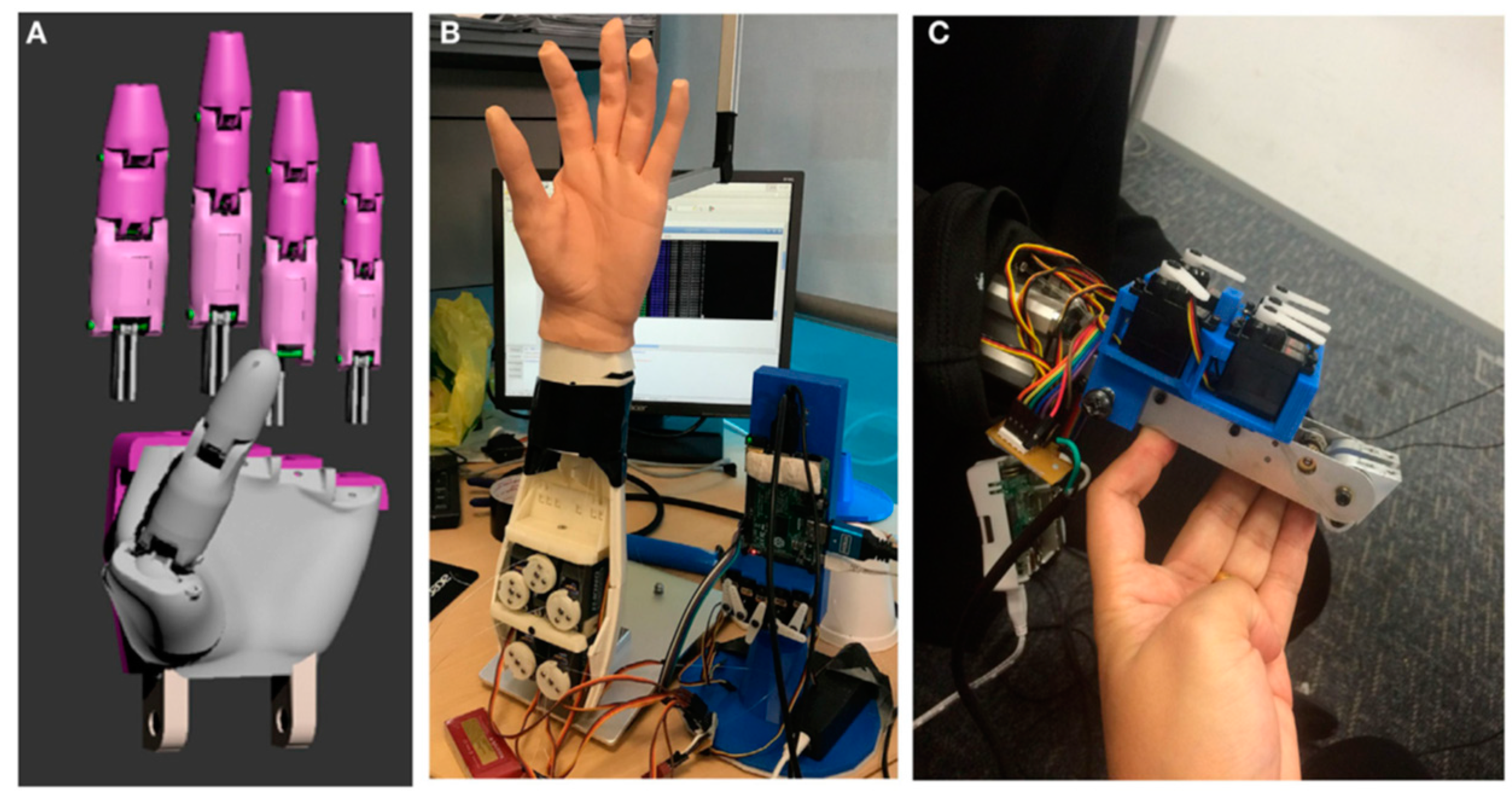

- Bulgarelli, A.; Toscana, G.; Russo, L.O.; Farulla, G.A.; Indaco, M.; Bona, B. A Low-Cost Open Source 3D-Printable Dexterous Anthropomorphic Robotic Hand with a Parallel Spherical Joint Wrist for Sign Languages Reproduction. Int. J. Adv. Robot. Syst. 2016, 13. https://doi.org/10.5772/64113. [CrossRef]

- Tian, L.; Thalmann, N.M.; Thalmann, D.; Zheng, J. The Making of a 3D-Printed, Cable-Driven, Single-Model, Lightweight Humanoid Robotic Hand. Front. Robot. AI 2017, 4, 1–12. https://doi.org/10.3389/frobt.2017.00065. [CrossRef]

- Mohammadi, A.; Lavranos, J.; Zhou, H.; Mutlu, R.; Alici, G.; Tan, Y.; Choong, P.; Oetomo, D. A Practical 3D-Printed Soft Robotic Prosthetic Hand with Multi-Articulating Capabilities. PLoS One 2020, 15, 1–23. https://doi.org/10.1371/journal.pone.0232766. [CrossRef]

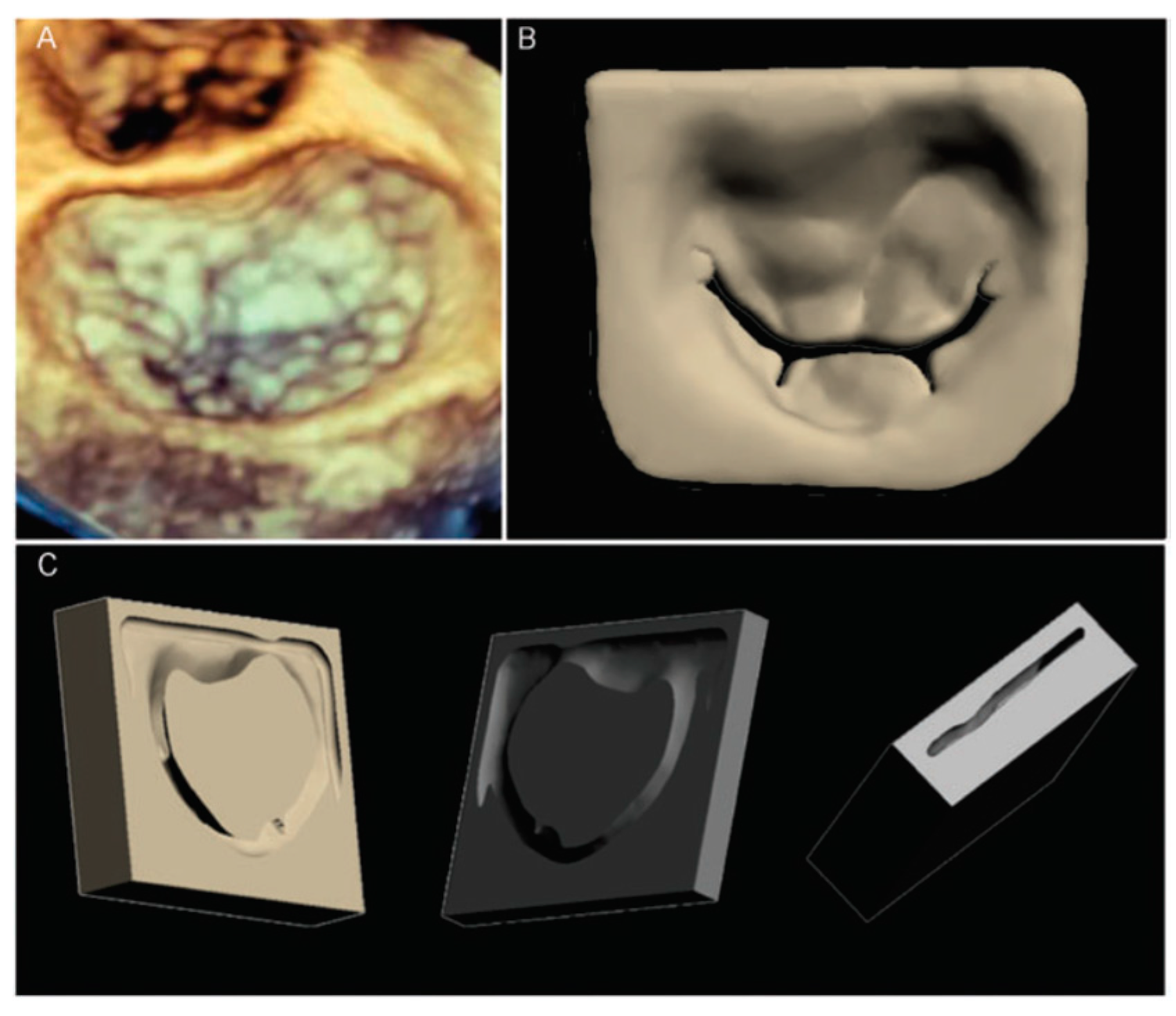

- Premyodhin, N.; Mandair, D.; Ferng, A.S.; Leach, T.S.; Palsma, R.P.; Albanna, M.Z.; Khalpey, Z.I. 3D Printed Mitral Valve Models: Affordable Simulation for Robotic Mitral Valve Repair. Interact. Cardiovasc. Thorac. Surg. 2018, 26, 71–76. https://doi.org/10.1093/icvts/ivx243. [CrossRef]

- Ghazi, A.E.; Teplitz, B.A. Role of 3D Printing in Surgical Education for Robotic Urology Procedures. Transl. Androl. Urol. 2020, 9, 931–941. https://doi.org/10.21037/tau.2020.01.03. [CrossRef]

- Uwechue, R.; Gogalniceanu, P.; Kessaris, N.; Byrne, N.; Chandak, P.; Olsburgh, J.; Ahmed, K.; Mamode, N.; Loukopoulos, I. A Novel 3D-Printed Hybrid Simulation Model for Robotic-Assisted Kidney Transplantation (RAKT). J. Robot. Surg. 2018, 12, 541–544. https://doi.org/10.1007/s11701-018-0780-y. [CrossRef]

- Wei, F.; Xu, M.; Lai, X.; Zhang, J.; Yiengpruksawan, A.; Lu, Y.; Liu, J.; Wang, Z. Three-Dimensional Printed Dry Lab Training Models to Simulate Robotic-Assisted Pancreaticojejunostomy. ANZ J. Surg. 2019, 89, 1631–1635. https://doi.org/10.1111/ans.15544. [CrossRef]

- Lipskas, J.; Deep, K.; Yao, W. Robotic-Assisted 3D Bio-Printing for Repairing Bone and Cartilage Defects through a Minimally Invasive Approach. Sci. Rep. 2019, 9, 1–9. https://doi.org/10.1038/s41598-019-38972-2. [CrossRef]

- Li, M.; Xiong, P.; Yan, F.; Li, S.; Ren, C.; Yin, Z.; Li, A.; Li, H.; Ji, X.; Zheng, Y.; et al. An Overview of Graphene-Based Hydroxyapatite Composites for Orthopedic Applications. Bioact. Mater. 2018, 3, 1–18. https://doi.org/10.1016/j.bioactmat.2018.01.001. [CrossRef]

- Ma, K.; Zhao, T.; Yang, L.; Wang, P.; Jin, J.; Teng, H.; Xia, D.; Zhu, L.; Li, L.; Jiang, Q.; et al. Application of Robotic-Assisted in Situ 3D Printing in Cartilage Regeneration with HAMA Hydrogel: An in Vivo Study. J. Adv. Res. 2020, 23, 123–132. https://doi.org/10.1016/j.jare.2020.01.010. [CrossRef]

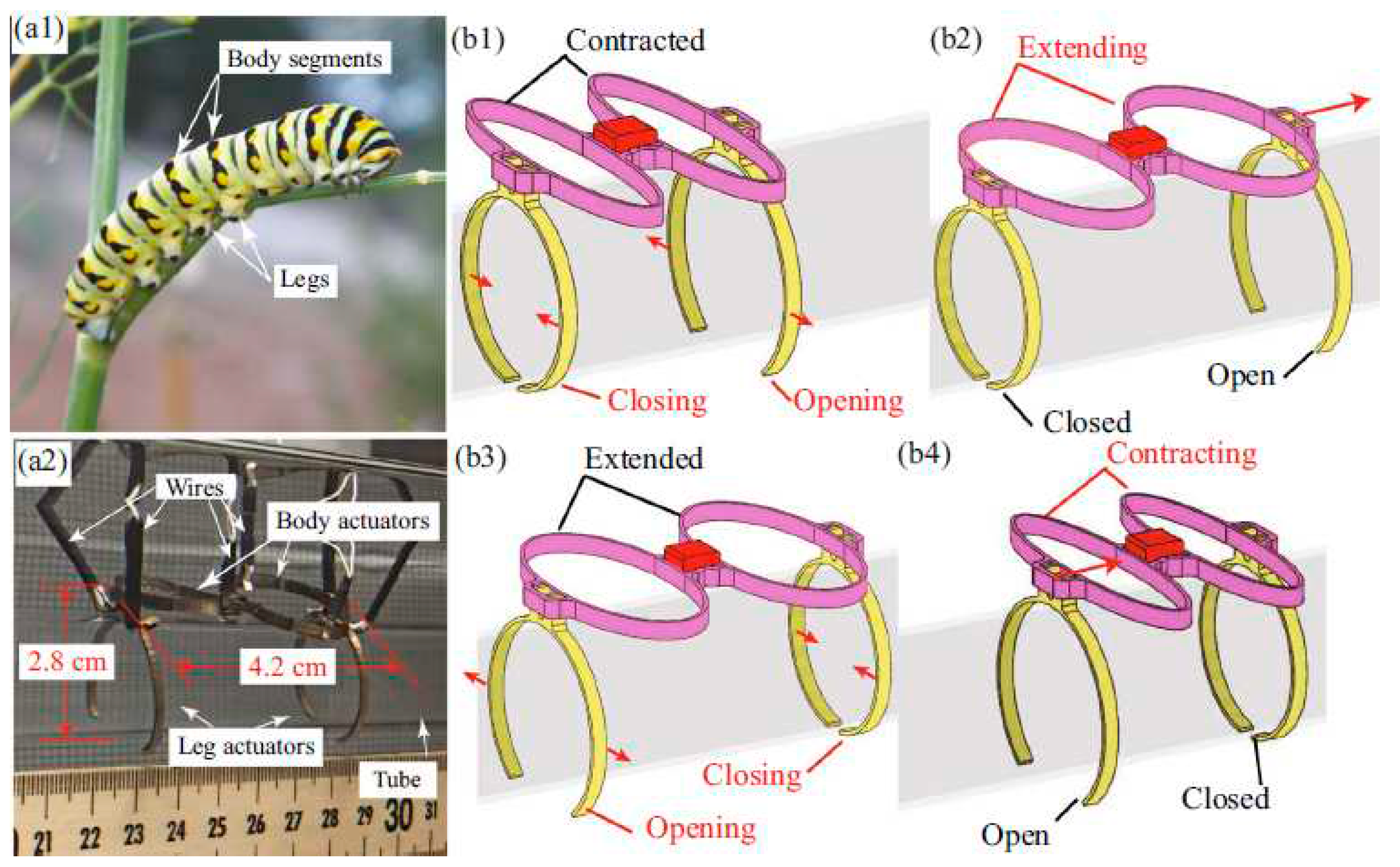

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D Printing of Robotic Soft Actuators with Programmable Bioinspired Architectures. Nat. Commun. 2018, 9. https://doi.org/10.1038/s41467-018-03216-w. [CrossRef]

- Wang, J.; Xiao, X.; Huang, Z.; Melzer, A. 3D-Printing Based Transducer Holder for Robotic Assisted Ultrasound Guided HIFU. Procedia Manuf. 2019, 30, 3–10. https://doi.org/10.1016/j.promfg.2019.02.002. [CrossRef]

- Vogt, D.M.; Becker, K.P.; Phillips, B.T.; Graule, M.A.; Rotjan, R.D.; Shank, T.M.; Cordes, E.E.; Wood, R.J.; Gruber, D.F. Shipboard Design and Fabrication of Custom 3D-Printed Soft Robotic Manipulators for the Investigation of Delicate Deep-Sea Organisms. PLoS One 2018, 13, 1–16. https://doi.org/10.1371/journal.pone.0200386. [CrossRef]

- Shih, B.; Christianson, C.; Gillespie, K.; Lee, S.; Mayeda, J.; Huo, Z.; Tolley, M.T. Design Considerations for 3D Printed, Soft, Multimaterial Resistive Sensors for Soft Robotics. Front. Robot. AI 2019, 6, 1–12. https://doi.org/10.3389/frobt.2019.00030. [CrossRef]

- Ota, H.; Emaminejad, S.; Gao, Y.; Zhao, A.; Wu, E.; Challa, S.; Chen, K.; Fahad, H.M.; Jha, A.K.; Kiriya, D.; et al. Application of 3D Printing for Smart Objects with Embedded Electronic Sensors and Systems. Adv. Mater. Technol. 2016. https://doi.org/10.1002/admt.201600013. [CrossRef]

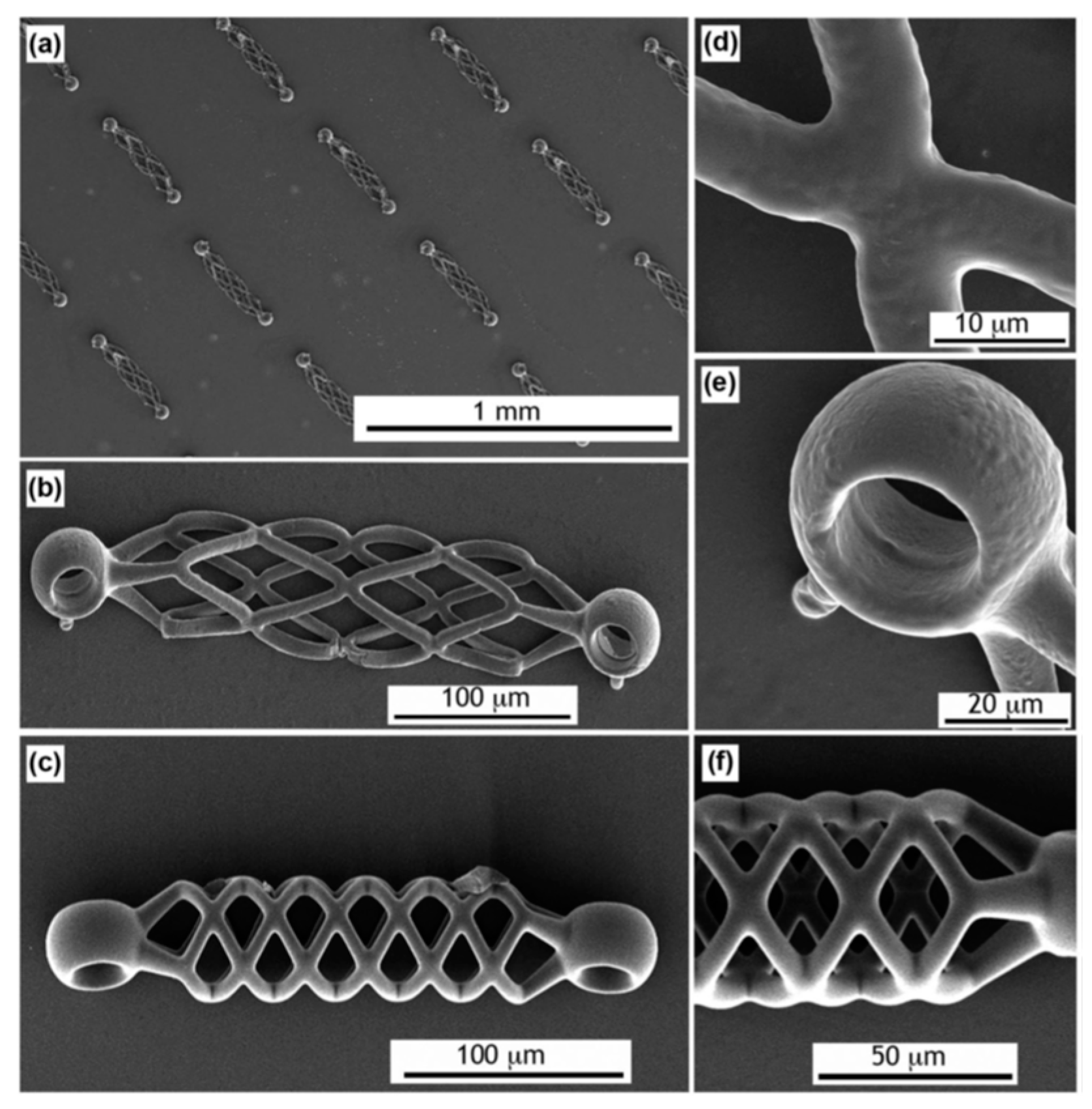

- de Marco, C.; Alcântara, C.C.J.; Kim, S.; Briatico, F.; Kadioglu, A.; de Bernardis, G.; Chen, X.; Marano, C.; Nelson, B.J.; Pané, S. Indirect 3D and 4D Printing of Soft Robotic Microstructures. Adv. Mater. Technol. 2019, 4, 1–7. https://doi.org/10.1002/admt.201900332. [CrossRef]

- Subrin, K.; Bressac, T.; Garnier, S.; Ambiehl, A.; Paquet, E.; Furet, B. Improvement of the Mobile Robot Location Dedicated for Habitable House Construction by 3D Printing. IFAC-PapersOnLine 2018, 51, 716–721. https://doi.org/10.1016/j.ifacol.2018.08.403. [CrossRef]

- Jones, A.; Straub, J. Concepts for 3D Printing-Based Self-Replicating Robot Command and Coordination Techniques. Machines 2017. https://doi.org/10.3390/machines5020012. [CrossRef]

- Sanfilippo, F.; Helgerud, E.; Stadheim, P.A.; Aronsen, S.L. Serpens: A Highly Compliant Low-Cost ROS-Based Snake Robot with Series Elastic Actuators, Stereoscopic Vision and a Screw-Less Assembly Mechanism. Appl. Sci. 2019. https://doi.org/10.3390/app9030396. [CrossRef]

- Rubies, E.; Palacín, J. Design and FDM/FFF Implementation of a Compact Omnidirectional Wheel for a Mobile Robot and Assessment of ABS and PLA Printing Materials. Robotics 2020. https://doi.org/10.3390/ROBOTICS9020043. [CrossRef]

- Castelli, K.; Giberti, H. Additive Manufacturing as an Essential Element in the Teaching of Robotics. Robotics 2019. https://doi.org/10.3390/robotics8030073. [CrossRef]

- Tawk, C.; Alici, G. Finite Element Modeling in the Design Process of 3D Printed Pneumatic Soft Actuators and Sensors. Robotics 2020, 9, 52. https://doi.org/10.3390/robotics9030052. [CrossRef]

- Stano, G.; Arleo, L.; Percoco, G. Additive Manufacturing for Soft Robotics: Design and Fabrication of Airtight, Monolithic Bending PneuNets with Embedded Air Connectors. Micromachines 2020. https://doi.org/10.3390/MI11050485. [CrossRef]

- Fry, N.R.; Richardson, R.C.; Boyle, J.H. Robotic Additive Manufacturing System for Dynamic Build Orientations. Rapid Prototyp. J. 2020, 26, 659–667. https://doi.org/10.1108/RPJ-09-2019-0243. [CrossRef]

- Carrico, J.D.; Hermans, T.; Kim, K.J.; Leang, K.K. 3D-Printing and Machine Learning Control of Soft Ionic Polymer-Metal Composite Actuators. Sci. Rep. 2019. https://doi.org/10.1038/s41598-019-53570-y. [CrossRef]

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of Additive Manufacturing: Overview of 4D and 3D Printed Smart and Advanced Materials and Their Applications. Chem. Eng. J. 2021. [CrossRef]

- Hann, S.Y.; Cui, H.; Nowicki, M.; Zhang, L.G. 4D Printing Soft Robotics for Biomedical Applications. Addit. Manuf. 2020. https://doi.org/10.1016/j.addma.2020.101567. [CrossRef]

- Bajpai, A.; Baigent, A.; Raghav, S.; Brádaigh, C.; Koutsos, V.; Radacsi, N. 4D Printing: Materials, Technologies, and Future Applications in the Biomedical Field. Sustain. 2020. [CrossRef]

- Lee, A.Y.; Zhou, A.; An, J.; Chua, C.K.; Zhang, Y. Contactless Reversible 4D-Printing for 3D-to-3D Shape Morphing. Virtual Phys. Prototyp. 2020. https://doi.org/10.1080/17452759.2020.1822189. [CrossRef]

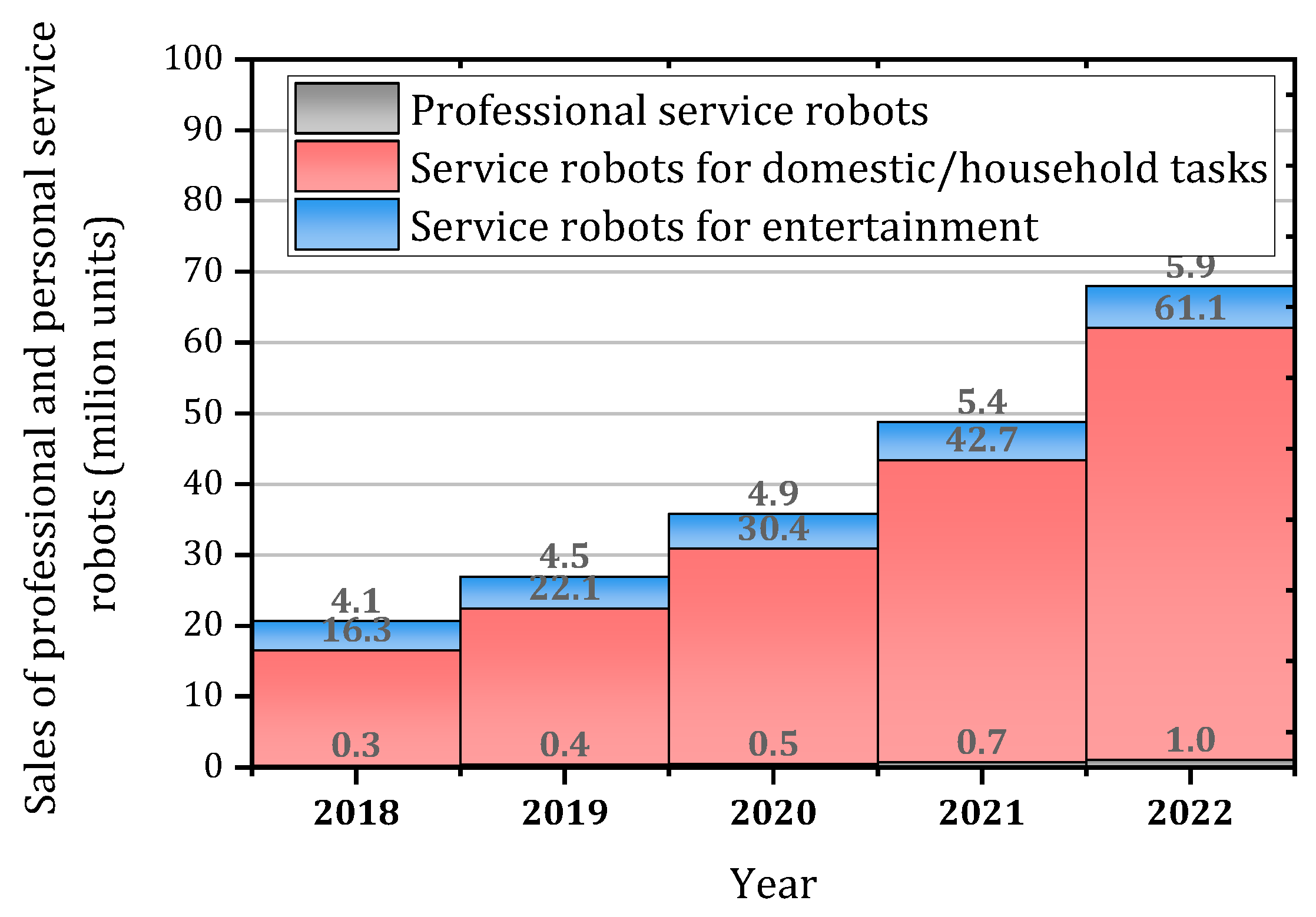

- Blachowicz, T.; Ehrmann, A. 3D Printed MEMS Technology-Recent Developments and Applications. Micromachines 2020. https://doi.org/10.3390/MI11040434. [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dmensonal Objects By Stereo Thography. Patent 1984, 16.

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. United States Pat. 1992.

- Deckard, C.R.; Rock, R.; Joseph, J. Method for Selective Laser Sintering With Layerwise Cross-Scanning. 1992, 12.

- Feygin, M.; Pak, S.S. Laminated Object Manufacturing Apparatus and Method. 1999, 52.

- Data, R.U.S.A. ( 12 ) United States Patent at Adhesive and at Additive Successively Layer Composite Powder Apply Slice Pattern of Binder on Each Layer of Powder to Form Object. 2016, 2.

- James, W.; Tentoni, P.E.B. United States Patent ( 19 ). 1996.

- Kozior, T. The Influence of Selected Selective Laser Sintering Technology Process Parameters on Stress Relaxation, Mass of Models, and Their Surface Texture Quality. 3D Print. Addit. Manuf. 2020, 7. https://doi.org/10.1089/3dp.2019.0036. [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the Surface Texture and Mechanical Properties of FDM Printed Samples after Thermal and Chemical Treatment. Stroj. Vestnik/Journal Mech. Eng. 2020, 66. https://doi.org/10.5545/sv-jme.2019.6322. [CrossRef]

- Kozior, T.; Kundera, C. Surface Texture of Models Manufactured by FDM Technology. In Proceedings of the AIP Conference Proceedings; 2018; Vol. 2017. [CrossRef]

- Skrzyniarz, M.; Nowakowski, L.; Blasiak, S. Geometry, Structure and Surface Quality of a Maraging Steel Milling Cutter Printed by Direct Metal Laser Melting. Materials (Basel). 2022, 15. https://doi.org/10.3390/ma15030773. [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Wortmann, M.; Lilia, S.; Ehrmann, A. Electrospinning on 3D Printed Polymers for Mechanically Stabilized Filter Composites. Polymers (Basel). 2019, 11. https://doi.org/10.3390/polym11122034. [CrossRef]

- Kozior, T.; Trabelsi, M.; Mamun, A.; Sabantina, L.; Ehrmann, A. Stabilization of Electrospun Nanofiber Mats Used for Filters by 3D Printing. Polymers (Basel). 2019, 11. https://doi.org/10.3390/polym11101618. [CrossRef]

- Kozior, T.; Blachowicz, T.; Ehrmann, A. Adhesion of Three-Dimensional Printing on Textile Fabrics: Inspiration from and for Other Research Areas. J. Eng. Fiber. Fabr. 2020, 15. https://doi.org/10.1177/1558925020910875. [CrossRef]

- Zolfagharian, A.; Mahmud, M.A.P.; Gharaie, S.; Bodaghi, M.; Kouzani, A.Z.; Kaynak, A. 3D/4D-Printed Bending-Type Soft Pneumatic Actuators: Fabrication, Modelling, and Control. Virtual Phys. Prototyp. 2020. [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Self-Expanding/Shrinking Structures by 4D Printing. Smart Mater. Struct. 2016. https://doi.org/10.1088/0964-1726/25/10/105034. [CrossRef]

- Zolfagharian, A.; Denk, M.; Bodaghi, M.; Kouzani, A.Z.; Kaynak, A. Topology-Optimized 4D Printing of a Soft Actuator. Acta Mech. Solida Sin. 2020. https://doi.org/10.1007/s10338-019-00137-z. [CrossRef]

- Blasiak, S.; Laski, P.A.; Takosoglu, J.E. Rapid Prototyping of Pneumatic Directional Control Valves. Polymers (Basel). 2021, 13. https://doi.org/10.3390/polym13091458. [CrossRef]

- Blasiak, S.; Takosoglu, J.E.; Laski, P.A. Optimizing The Flow Rate In A Pneumatic Directional Control Valve. In Proceedings of the Proceedings of 20th International Conference on Engineering Mechanics 2014; Fuis, V., Ed.; Brno Univ. Technol., Inst. Solid Mechan. Mechatron. & Biomechan., 2014; pp. 96–99.

- Tamay, D.G.; Usal, T.D.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D Printing of Polymers for Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2019. [CrossRef]

- Tibbits, S. The Emergence of 4D Printing.

- Tibbits, S. 4D Printing: Multi-Material Shape Change. Archit. Des. 2014. https://doi.org/10.1002/ad.1710. [CrossRef]

- McCracken, J.M.; Nuzzo, R.G. 4D Printing for Spatially and Temporally Dynamic Bioscaffolds. In Proceedings of the Abstracts of Papers, 249th ACS National Meeting & Exposition, Denver, CO, United States, March 22-26, 2015; 2015.

- De Marco, C.; Pané, S.; Nelson, B.J. 4D Printing and Robotics. Sci. Robot. 2018. [CrossRef]

- López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. 4D Printed Actuators with Soft-Robotic Functions. Macromol. Rapid Commun. 2018, 39, 3–9. https://doi.org/10.1002/marc.201700710. [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Bodaghi, M.; Kouzani, A.Z.; Gharaie, S.; Nahavandi, S. Control-Based 4D Printing: Adaptive 4D-Printed Systems. Appl. Sci. 2020. [CrossRef]

- Carrico, J.D.; Leang, K.K. Fused Filament 3D Printing of Ionic Polymer-Metal Composites for Soft Robotics. In Proceedings of the Electroactive Polymer Actuators and Devices (EAPAD) 2017; 2017.

- Singh, D.; Tawk, C.; Mutlu, R.; Sariyildiz, E.; Alici, G. A 3D Printed Soft Robotic Monolithic Unit for Haptic Feedback Devices. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM; 2019.

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-Printing: A Review on Current Smart Materials, Technologies, and Applications. Int. J. Smart Nano Mater. 2019. https://doi.org/10.1080/19475411.2019.1591541. [CrossRef]

- Ahmed, K.; Shiblee, M.N.I.; Khosla, A.; Nagahara, L.; Thundat, T.; Furukawa, H. Review—Recent Progresses in 4D Printing of Gel Materials. J. Electrochem. Soc. 2020. https://doi.org/10.1149/1945-7111/ab6e60. [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R.; et al. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2019. https://doi.org/10.1002/adfm.201806412. [CrossRef]

- Zarek, M.; Mansour, N.; Shapira, S.; Cohn, D. 4D Printing of Shape Memory-Based Personalized Endoluminal Medical Devices. Macromol. Rapid Commun. 2017. https://doi.org/10.1002/marc.201600628. [CrossRef]

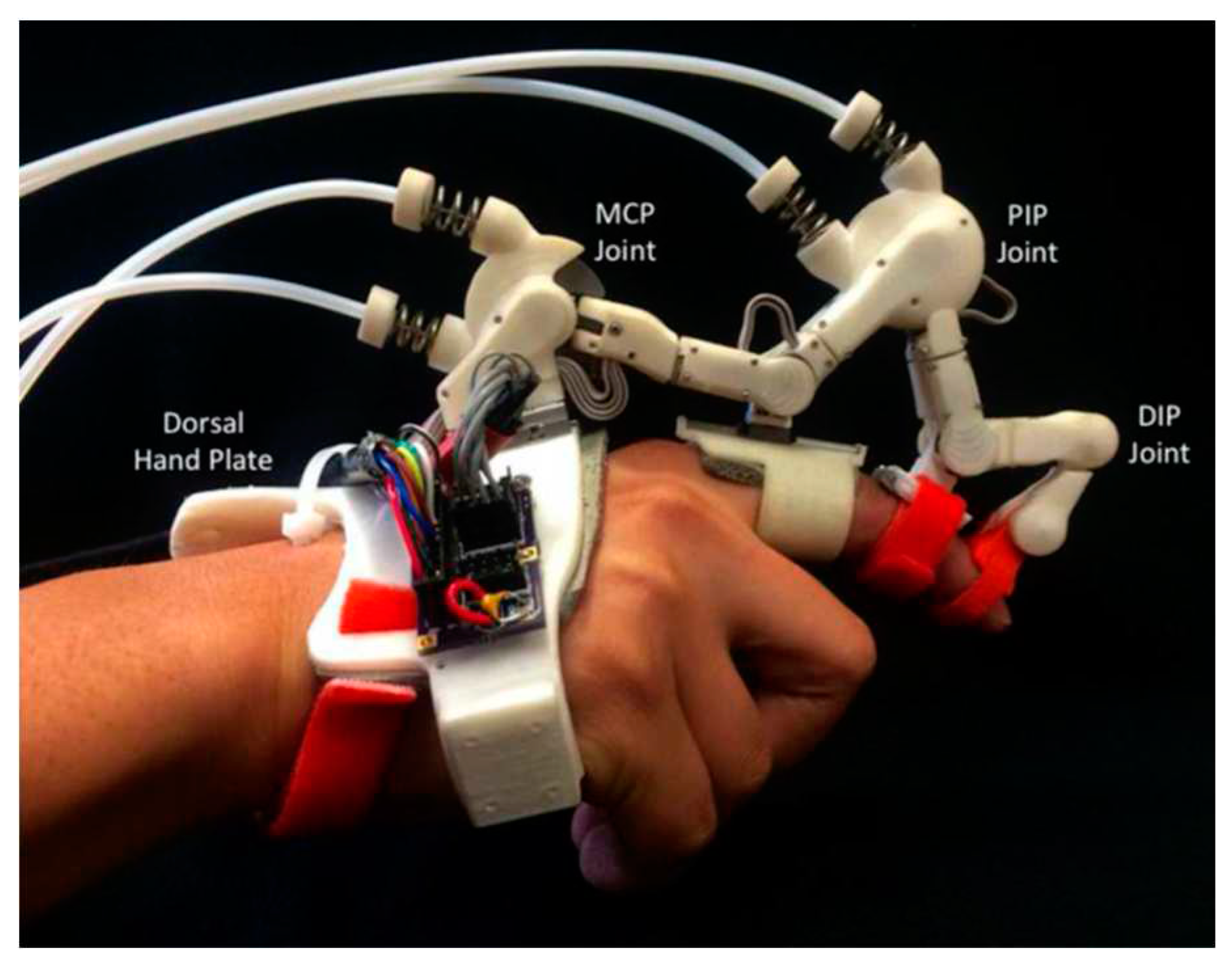

- Păcurar, A.; Rău, M.; Păcurar, R.; Guţiu, E.; Bacali, L.; Cosma, C. Research Regarding the Design and Manufacturing of Hand Orthosis by Using Fused Deposition Modeling Technology. MATEC Web Conf. 2019, 299, 01008. https://doi.org/10.1051/matecconf/201929901008. [CrossRef]

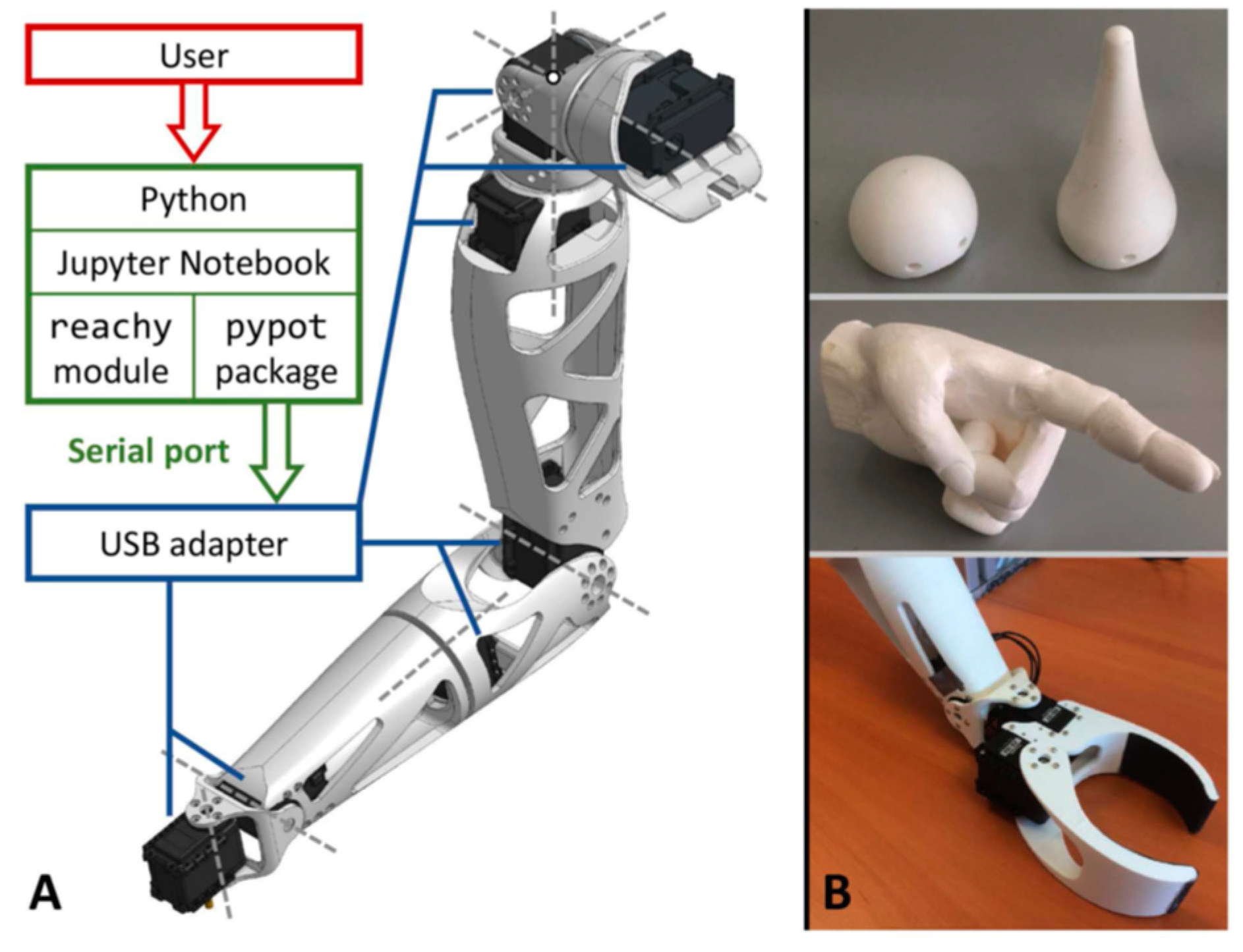

- Gutiérrez, S.C.; Zotovic, R.; Navarro, M.D.; Meseguer, M.D. Design and Manufacturing of a Prototype of a Lightweight Robot Arm. Procedia Manuf. 2017, 13, 283–290. https://doi.org/10.1016/j.promfg.2017.09.072. [CrossRef]

- Zmarzły, P.; Kozior, T.; Gogolewski, D. Dimensional and Shape Accuracy of Foundry Patterns Fabricated through Photo-Curing. Teh. Vjesn. 2019, 26. https://doi.org/10.17559/TV-20181109115954. [CrossRef]

- Hamidi, A.; Tadesse, Y. 3D Printing of Very Soft Elastomer and Sacrificial Carbohydrate Glass/Elastomer Structures for Robotic Applications. Mater. Des. 2020, 187, 108324. https://doi.org/10.1016/j.matdes.2019.108324. [CrossRef]

- Siradjuddin, I.; Wicaksono, R.P.; Murdani, A.; Dewatama, D.; Ronilaya, F.; Rohadi, E.; Asmara, R.A. A Low Cost 3D-Printed Robot Joint Torque Sensor. In Proceedings of the MATEC Web of Conferences; 2018; Vol. 197. [CrossRef]

- Jing, D.O.U.; Devine, D.M.; Lyons, J. 3D Printed End of Arm Tooling (EOAT) for Robotic Automation. Robotics 2018. https://doi.org/10.3390/robotics7030049. [CrossRef]

- EOS GmbH Available online: https://www.eos.info/en/additive-manufacturing/3d-printing-plastic.

- Kundera, C.; Kozior, T. Research of the Elastic Properties of Bellows Made in SLS Technology. In Proceedings of the Advanced Materials Research; 2014; Vol. 874. [CrossRef]

- Takosoglu, J. Angular Position Control System of Pneumatic Artificial Muscles. Open Eng. 10, 681–687. https://doi.org/10.1515/eng-2020-0077. [CrossRef]

- Won, J.; DeLaurentis, K.; Mavroidis, C. Rapid Prototyping of Robotic Systems. In Proceedings of the Proceedings 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation. Symposia Proceedings (Cat. No.00CH37065); 2000; Vol. 4, pp. 3077–3082 vol.4.

- Yap, Y.L.; Sing, S.L.; Yeong, W.Y. A Review of 3D Printing Processes and Materials for Soft Robotics. Rapid Prototyp. J. 2020. [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Kouzani, A. Closed-Loop 4D-Printed Soft Robots. Mater. Des. 2020, 188. [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29. https://doi.org/10.1002/adma.201703817. [CrossRef]

- Yonghua, C.; Chen, Z. Joint Analysis in Rapid Fabrication of Non-assembly Mechanisms. Rapid Prototyp. J. 2011, 17, 408–417. https://doi.org/10.1108/13552541111184134. [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.H.; Lee, J.W.; Choi, K.H. 3D Printing for Soft Robotics–a Review. Sci. Technol. Adv. Mater. 2018, 19. [CrossRef]

- Chan, V.; Jeong, J.H.; Bajaj, P.; Collens, M.; Saif, T.; Kong, H.; Bashir, R. Multi-Material Bio-Fabrication of Hydrogel Cantilevers and Actuators with Stereolithography. Lab Chip 2012, 12, 88–98. https://doi.org/10.1039/c1lc20688e. [CrossRef]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Moghadam, A.A.A.; Gibson, I.; Kaynak, A. Evolution of 3D Printed Soft Actuators. Sensors Actuators, A Phys. 2016, 250. [CrossRef]

- Wang, H.C.; El Wahed, A.K. Development of a Novel Latching-Type Electromagnetic Actuator for Applications in Minimally Invasive Surgery. Actuators 2020, 9. https://doi.org/10.3390/ACT9020041. [CrossRef]

- Laski, P.A. The Design of a Proportional Slit Valve with a Piezoelectric Actuator. In Proceedings of the ENGINEERING MECHANICS 2016; Zolotarev, I and Radolf, V., Ed.; ACAD SCI CZECH REPUBLIC, INST THERMOMECHANICS: DOLEJSKOVA 5, PRAGUE 8, 182 00, CZECH REPUBLIC, 2016; pp. 350–353.

- Laski, P.A. Fractional-Order Feedback Control of a Pneumatic Servo-Drive. Bull. POLISH Acad. Sci. Sci. 2019, 67, 53–59. https://doi.org/10.24425/bpas.2018.126120. [CrossRef]

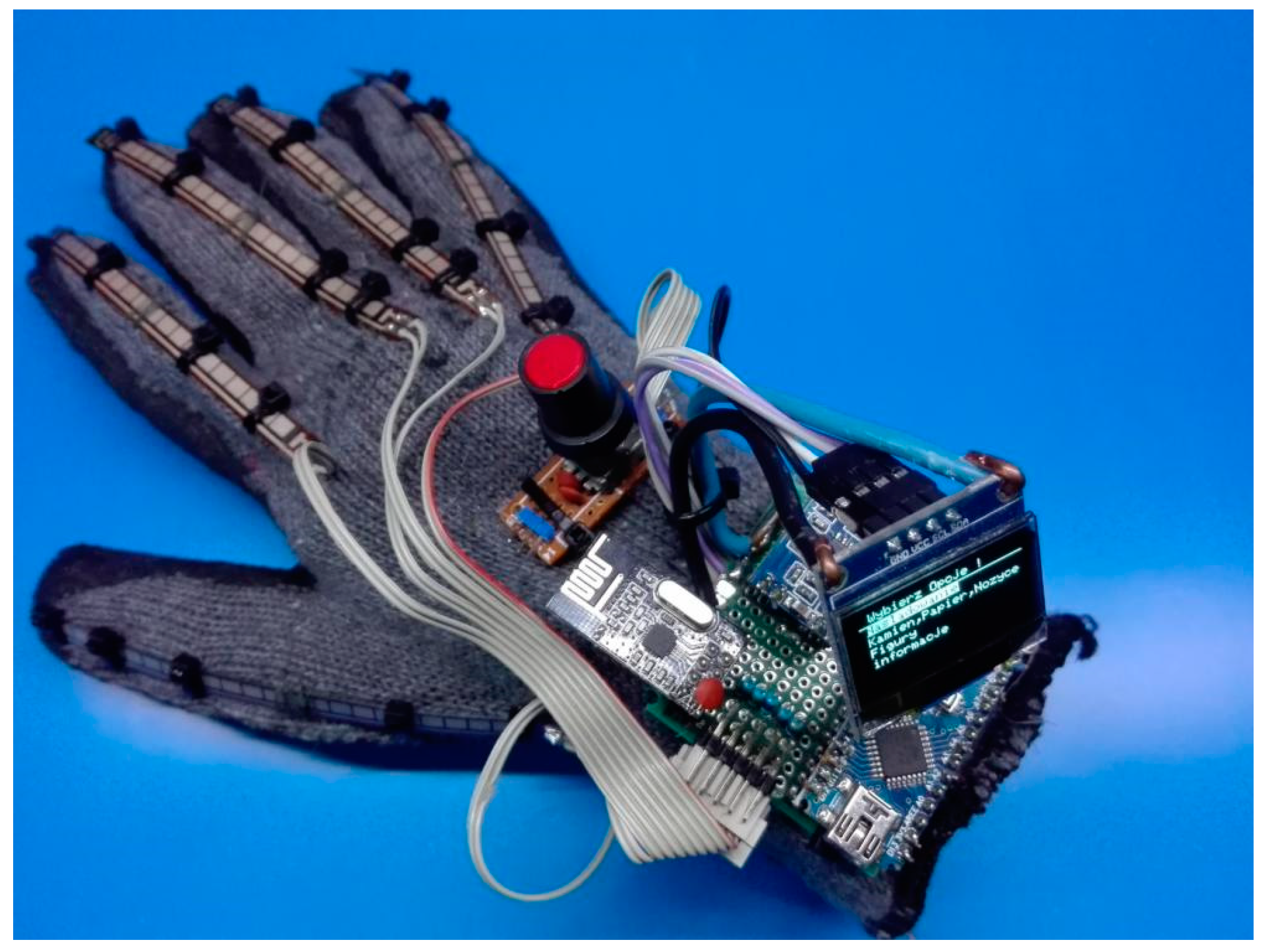

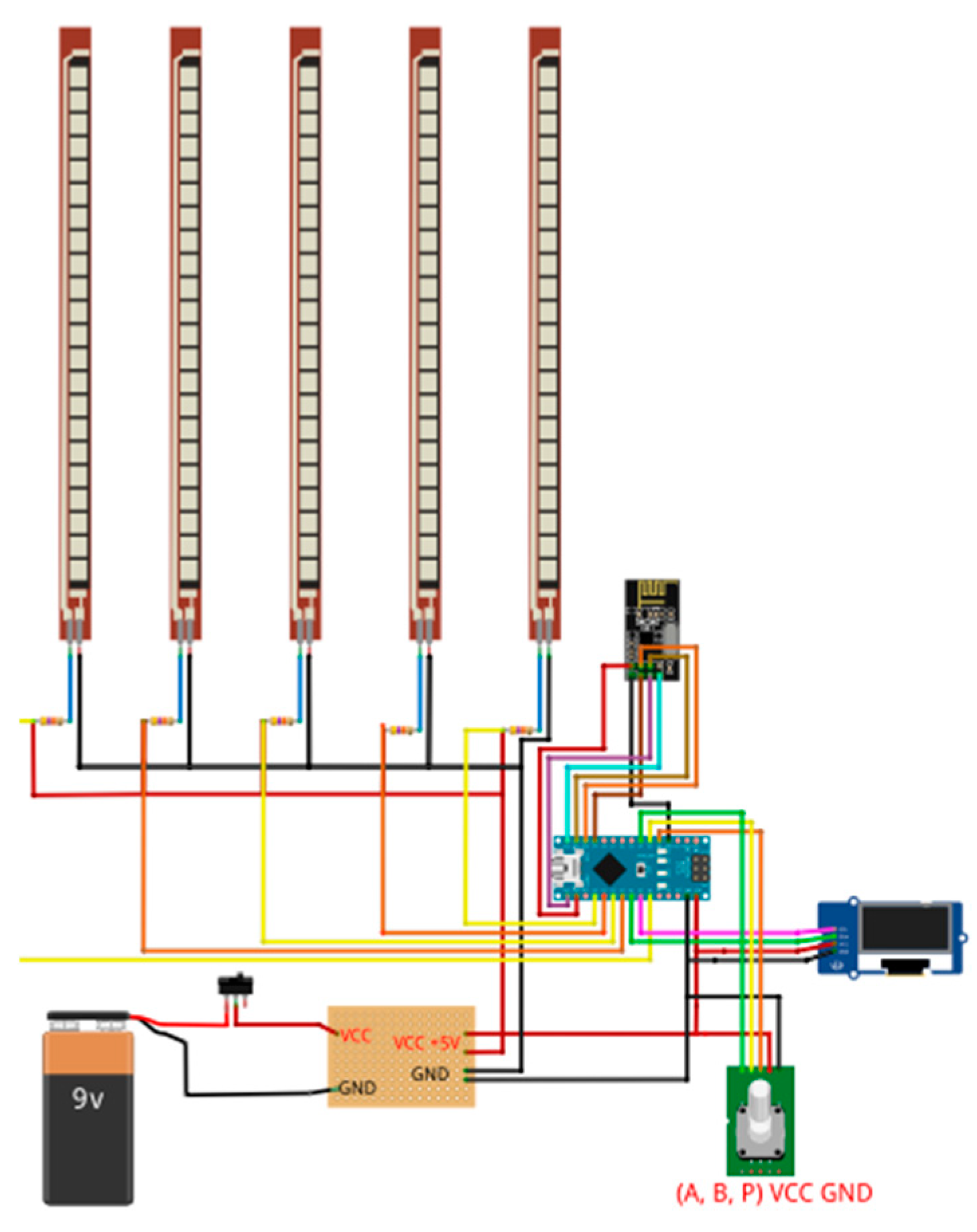

- Majsterkowo Available online: https://majsterkowo.pl/reka-wydrukowana-w-3d-sterowana-bzprzewodowo/ available on 02.10.2020.

- Inmoov Available online: http://inmoov.fr/ available on 02.10.2020.

- Gaspar, T.; Denisa, M.; Radanovic, P.; Ridge, B.; Savarimuthu, T.R.; Kramberger, A.; Priggemeyer, M.; Rossmann, J.; Woergoetter, F.; Ivanovska, T.; et al. Smart Hardware Integration with Advanced Robot Programming Technologies for Efficient Reconfiguration of Robot Workcells. Robot. Comput. Integr. Manuf. 2020, 66. https://doi.org/10.1016/j.rcim.2020.101979. [CrossRef]

- Madden, K.E.; Deshpande, A.D. On Integration of Additive Manufacturing During the Design and Development of a Rehabilitation Robot: A Case Study. J. Mech. Des. 2015, 137. https://doi.org/10.1115/1.4031123. [CrossRef]

- Byrne, O.; Coulter, F.; Glynn, M.; Jones, J.F.X.; Annaidh, A.N.; O’Cearbhaill, E.D.; Holland, D.P. Additive Manufacture of Composite Soft Pneumatic Actuators. SOFT Robot. 2018, 5, 726–736. https://doi.org/10.1089/soro.2018.0030. [CrossRef]

- Hainsworth, T.; Smith, L.; Alexander, S.; MacCurdy, R. A Fabrication Free, 3D Printed, Multi-Material, Self-Sensing Soft Actuator. IEEE Robot. Autom. Lett. 2020, 5, 4118–4125. https://doi.org/10.1109/LRA.2020.2986760. [CrossRef]

- Ashuri, T.; Armani, A.; Jalilzadeh Hamidi, R.; Reasnor, T.; Ahmadi, S.; Iqbal, K. Biomedical Soft Robots: Current Status and Perspective. Biomed. Eng. Lett.. https://doi.org/10.1007/s13534-020-00157-6. [CrossRef]

- Bochnia, J.; Blasiak, S. Stress Relaxation and Creep of a Polymer-Aluminum Composite Produced through Selective Laser Sintering. Polymers (Basel). 2020, 12. https://doi.org/10.3390/polym12040830. [CrossRef]

- Bochnia, J.; Blasiak, S. The Creep of Material Obtained Using SLS Technology. MM Sci. J. 2020, 2020, 3774–3778. https://doi.org/10.17973/MMSJ.2020_03_2019022. [CrossRef]

- Bochnia, J.; Blasiak, S. Fractional Relaxation Model of Materials Obtained with Selective Laser Sintering Technology. Rapid Prototyp. J. 2019, 25, 76–86. https://doi.org/10.1108/RPJ-11-2017-0236. [CrossRef]

- Gorn, M.; Cerwenka, G.; Gralow, M.; Emmelmann, C. Industrial 3D Printing for Modern Machine and Handling Systems Potential and Solutions. J. Laser Appl. 2019, 31. https://doi.org/10.2351/1.5096098. [CrossRef]

- Velez, M.; Toala, E.; Cristobal Zagal, J. Koala 3D: A Continuous Climbing 3D Printer. Robot. Comput. Integr. Manuf. 2020, 64. https://doi.org/10.1016/j.rcim.2020.101950. [CrossRef]

- Maciejewski, I. Research into the Effectiveness of Operation of the Seat Suspension System Used to Protect Industrial and Construction Machinery Operators from Vibrations. Arch. Automot. Eng. – Arch. Motoryz. 2013, 62, 17–31.

- Kozior, T.; Bochnia, J. The Influence of Printing Orientation on Surface Texture Parameters in Powder Bed Fusion Technology with 316L Steel. Micromachines 2020. https://doi.org/10.3390/MI11070639. [CrossRef]

- Kozior, T.; Bochnia, J.; Zmarzły, P.; Gogolewski, D.; Mathia, T.G. Waviness of Freeform Surface Characterizations from Austenitic Stainless Steel (316L) Manufactured by 3D Printing-Selective Laser Melting (SLM) Technology. Materials (Basel). 2020. https://doi.org/10.3390/ma13194372. [CrossRef]

| Technology | Min. Feature Size (μm) |

Material |

|---|---|---|

| Fused deposition modeling (FDM)Fused filament fabrication (FFF) | <400 | Div. Polymers (e.g. ABS, PLA), composites based on polymers, with carbon fiber or metal powders |

| Selective laser sintering (SLS) | 200 | Diverse polymers (e.g. Polyamide with carbon fiber) |

| Robot dispensing | 200 | Hydrogels |

| Stereolithography (SLA) | 30-70 | Photosensitive polymers |

| 3D inkjet printing | 28 | Photoresist |

| Resonant direct laser writing | 1-4 | IP-Dip photoresist |

| Multiphoton absorption polymerization | 1 | SU8 photoresist |

| Two-photon polymerization | 0.28-1.5 | Photoresist |

| Direct laser writing | 0.085-1.5 | Photoresist |

| Technology | Possible Applications |

|---|---|

| Fused deposition modeling (FDM) Fused filament fabrication (FFF) |

Mechanical components of robots, Dielectric-conductive systems, switches |

| Stereolithography | Microfluidic devices, conductive parts, molds, cantilevers, magnetic actuators |

| 3D inkjet printing | Microfluidic devices, Venturi microflowmeter, conductive structures, strain gauge sensors |

| Binder jet printing | Microfluidic devices, in-line injection of volatile organic compounds |

| Two-photon polymerization | Microfluidic devices, electrothermal microactuator |

| Micro-stereolithography | In situ tensile tests of micro- or nanowires, electrothermal microactuator |

| Multiphoton absorption polymerization | Microfluidic devices, photonic crystals, nanophotonic devices |

| Selective laser sintering | Mechanical elements of robots, springs, thin-walled elements, e.g. bellows |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).