Submitted:

21 July 2023

Posted:

25 July 2023

You are already at the latest version

Abstract

Keywords:

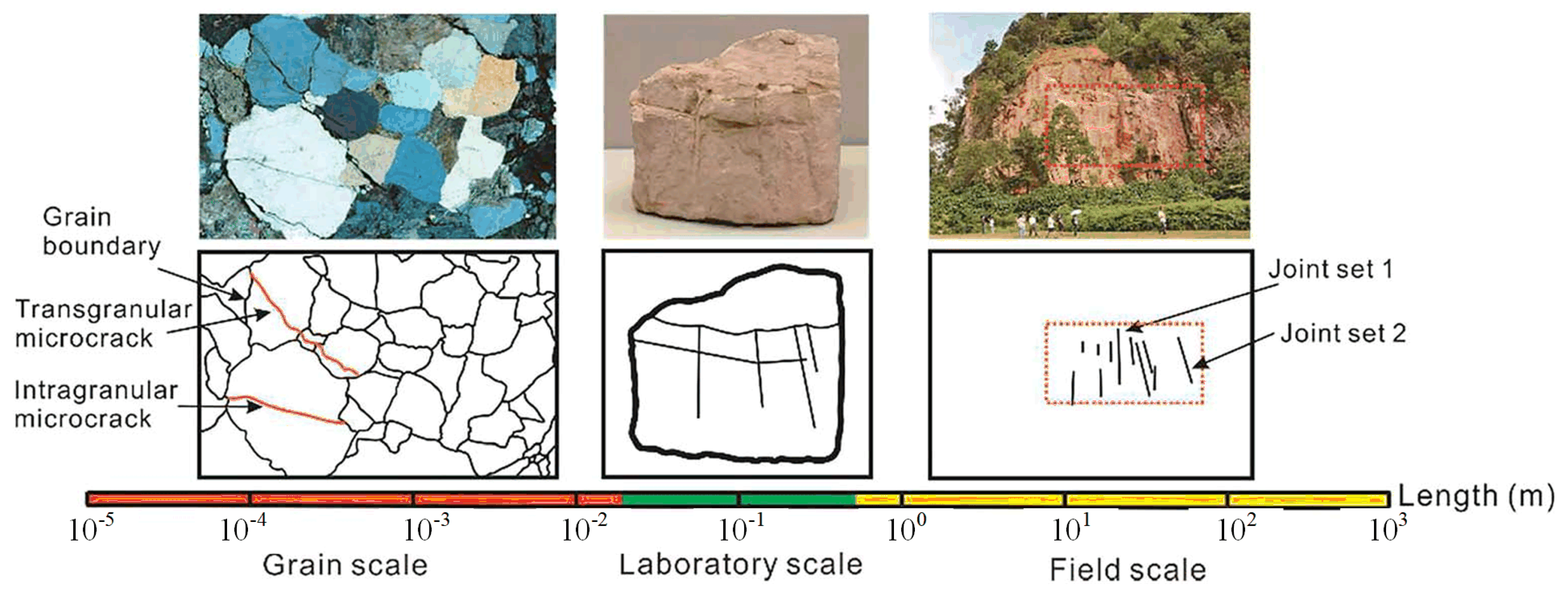

1. Introduction

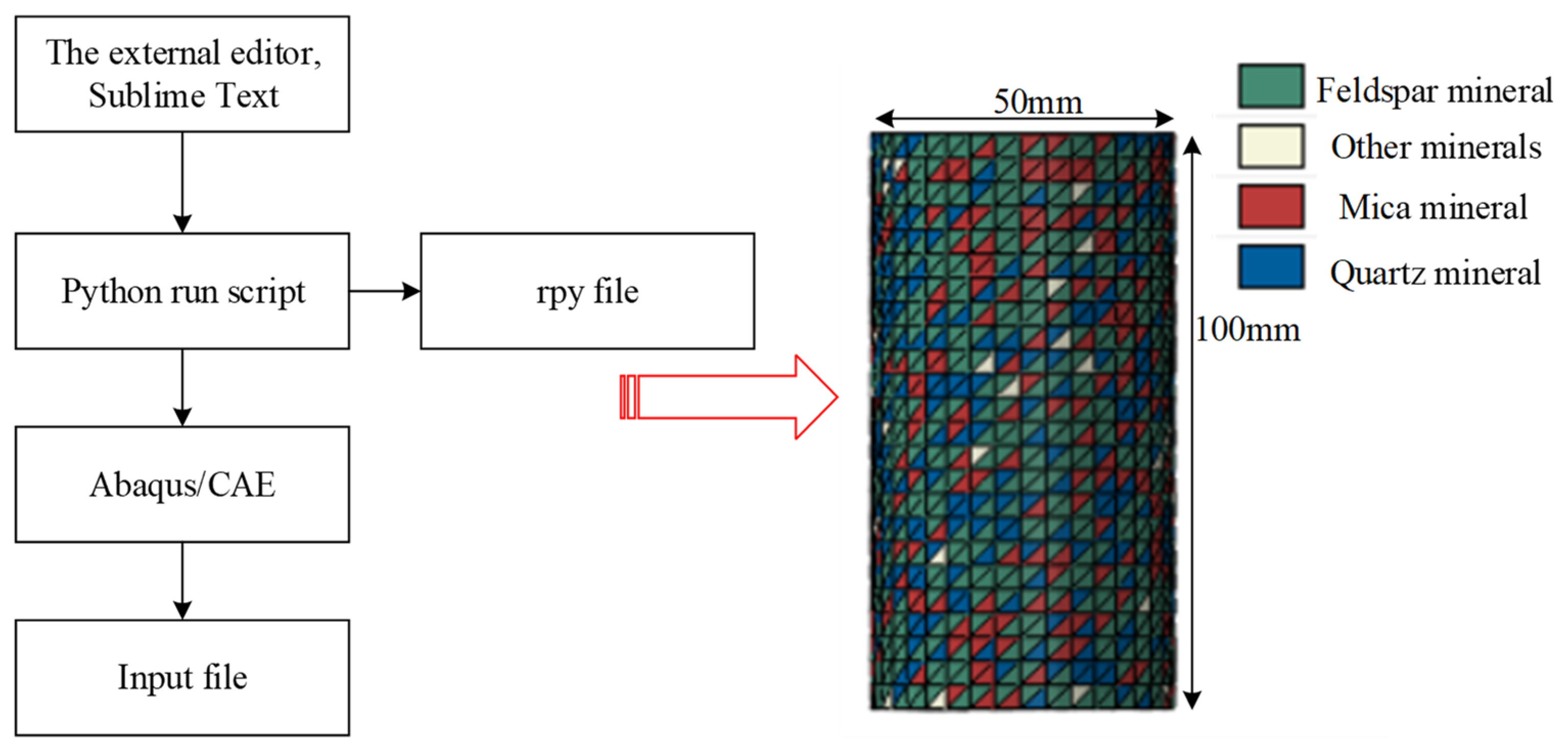

2. Modeling and Validation of Non-Homogeneous Granites

2.1. Modeling of Non-Homogeneous Granites

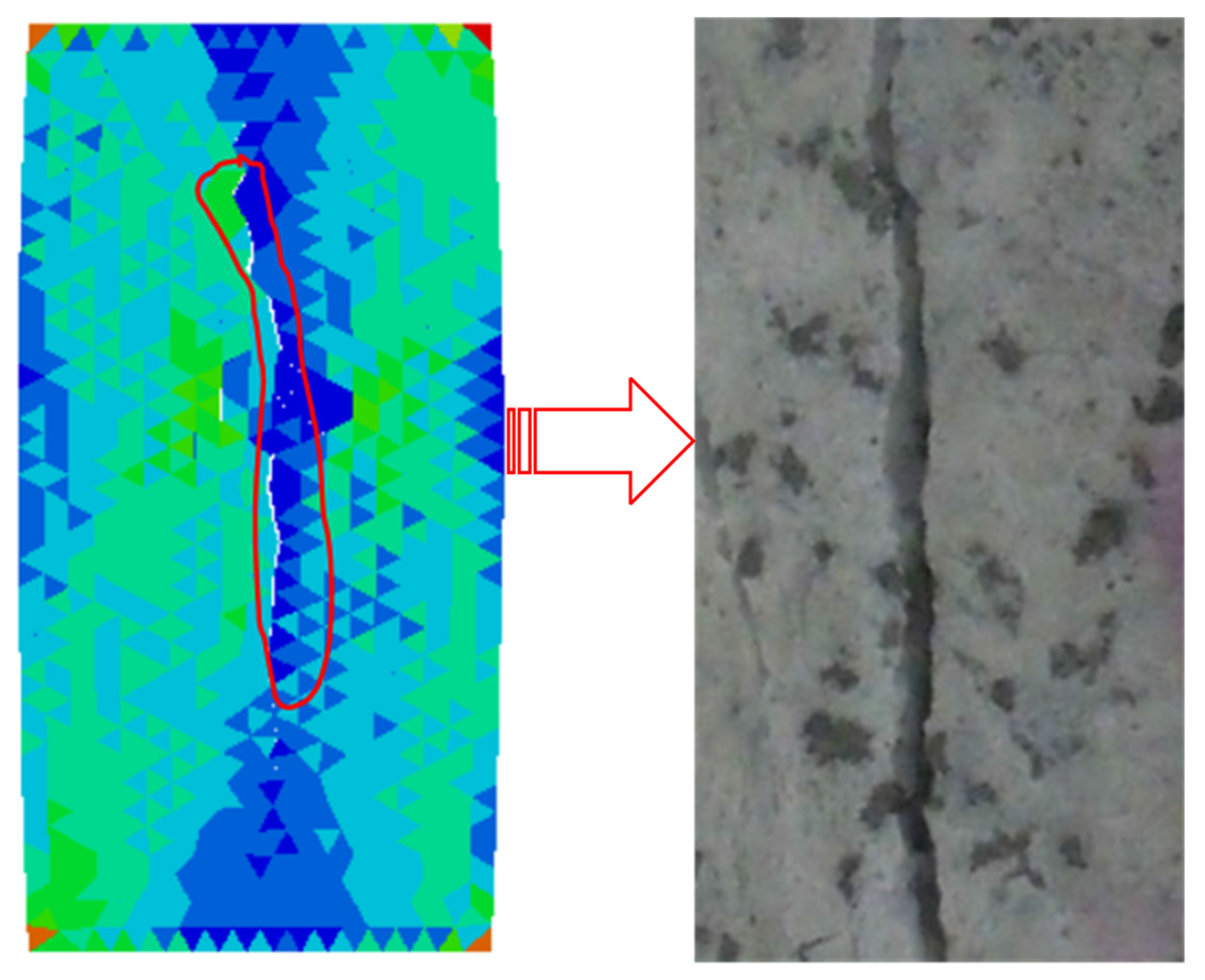

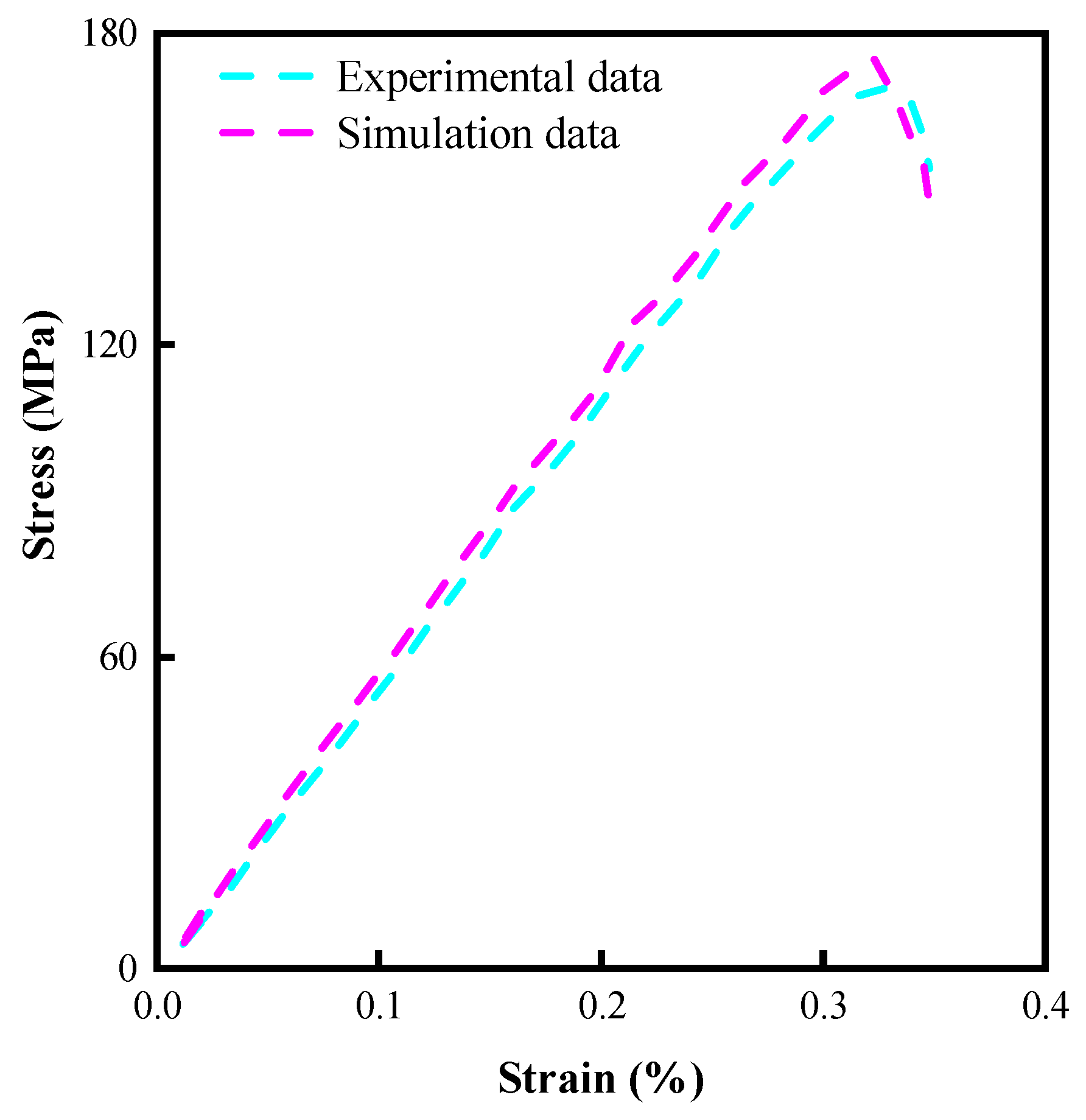

2.2. Granite Model Validation

3. Construction of the Model

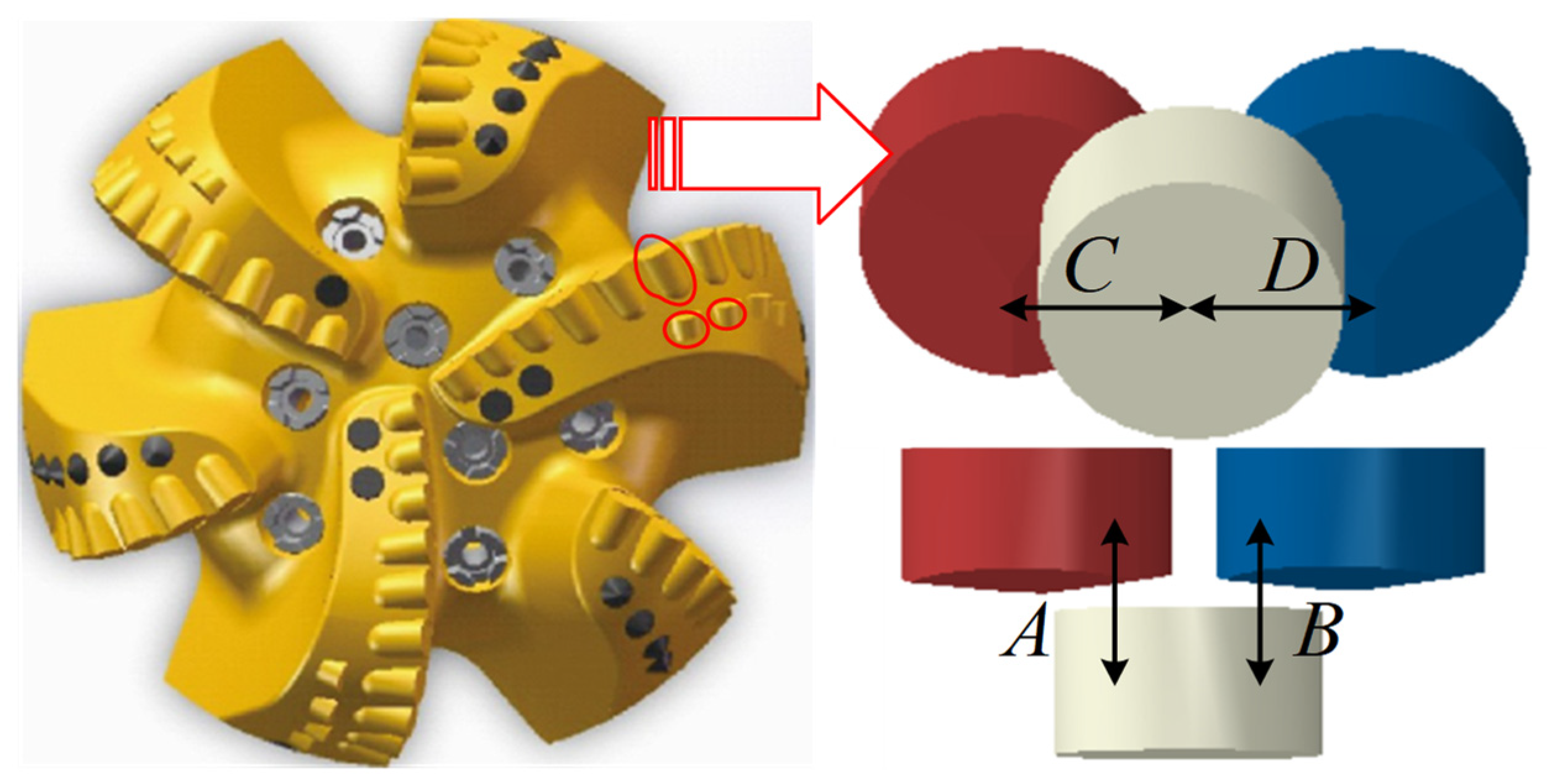

3.1. Simplification and Creation of 3D Models

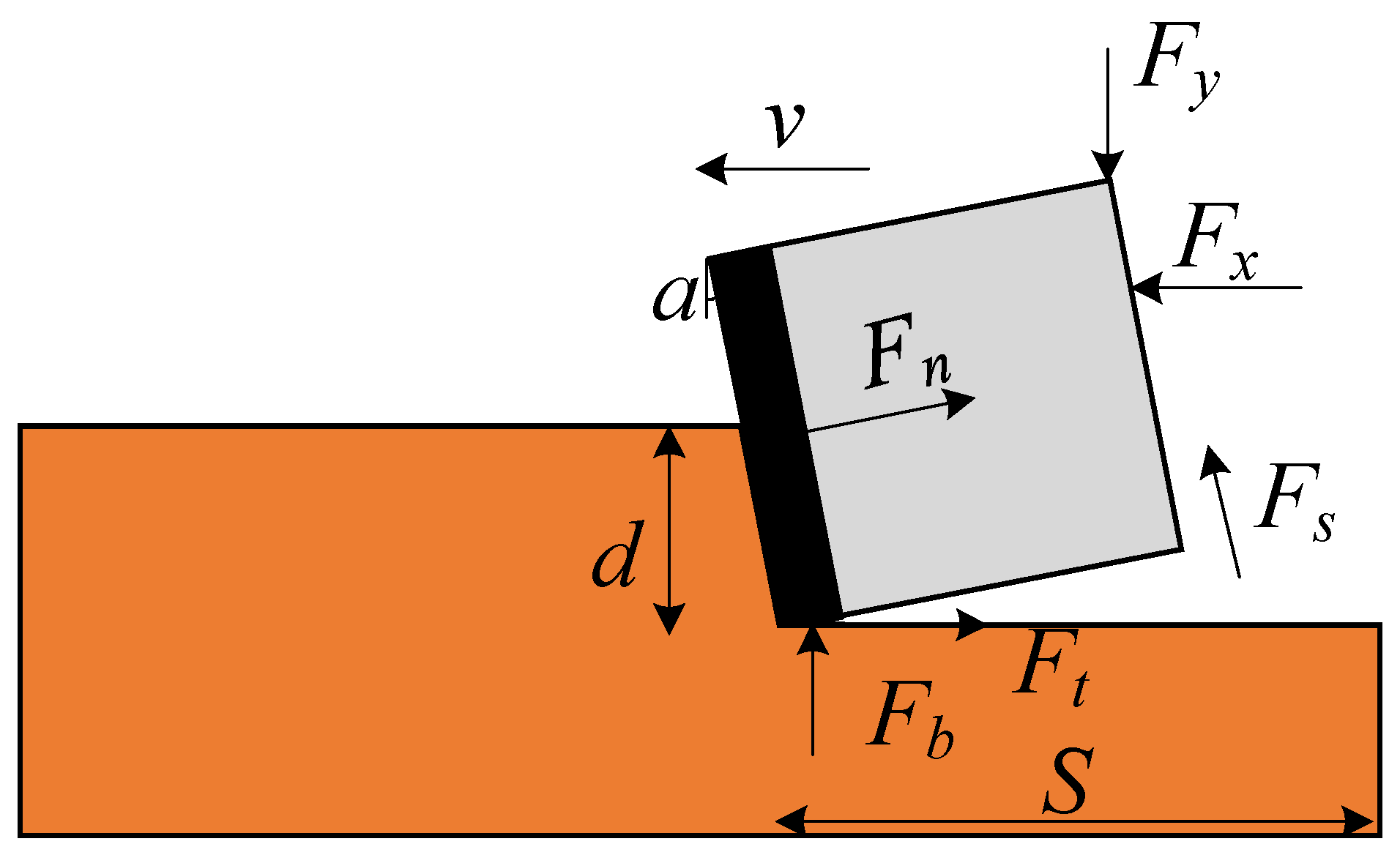

3.2. Finite Element Model Assumptions and Evaluation Guidelines

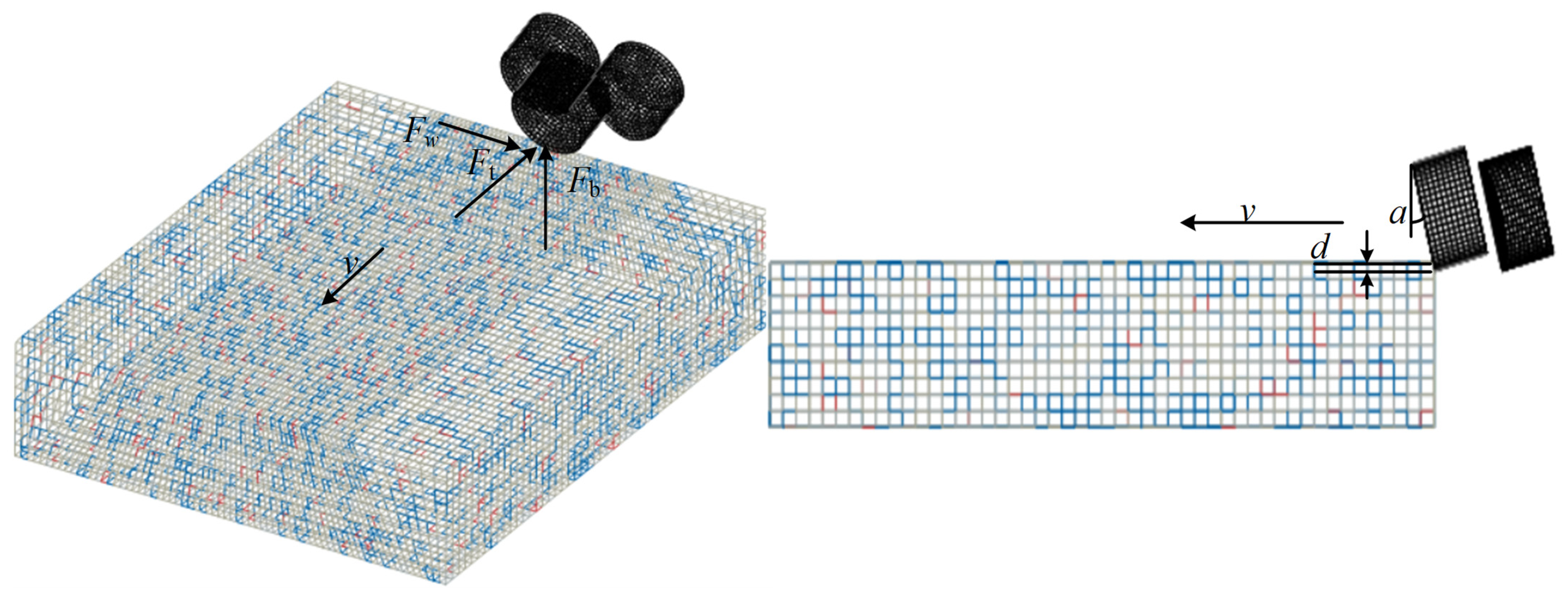

3.3. Finite Element Modeling

4. Results and Discussion

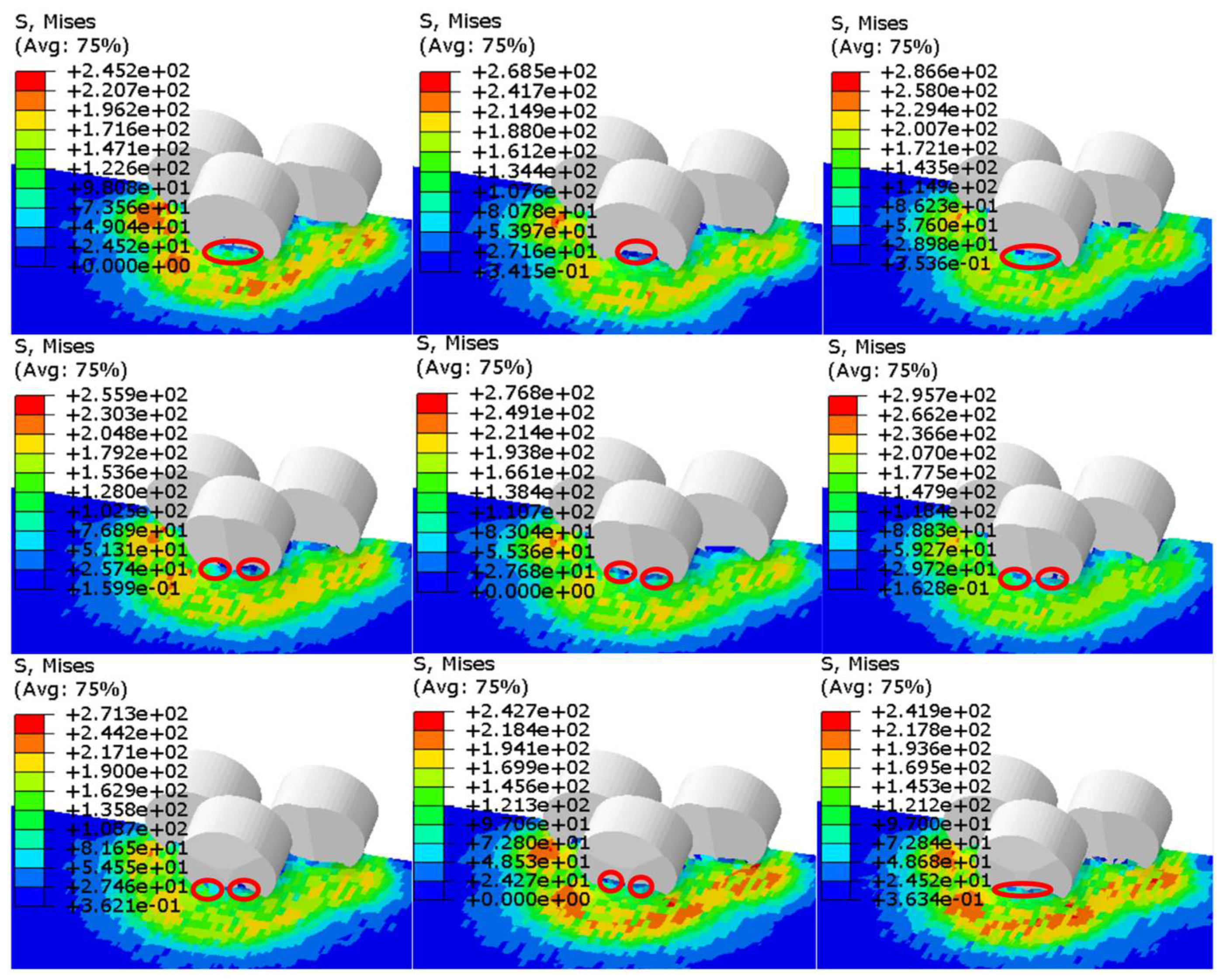

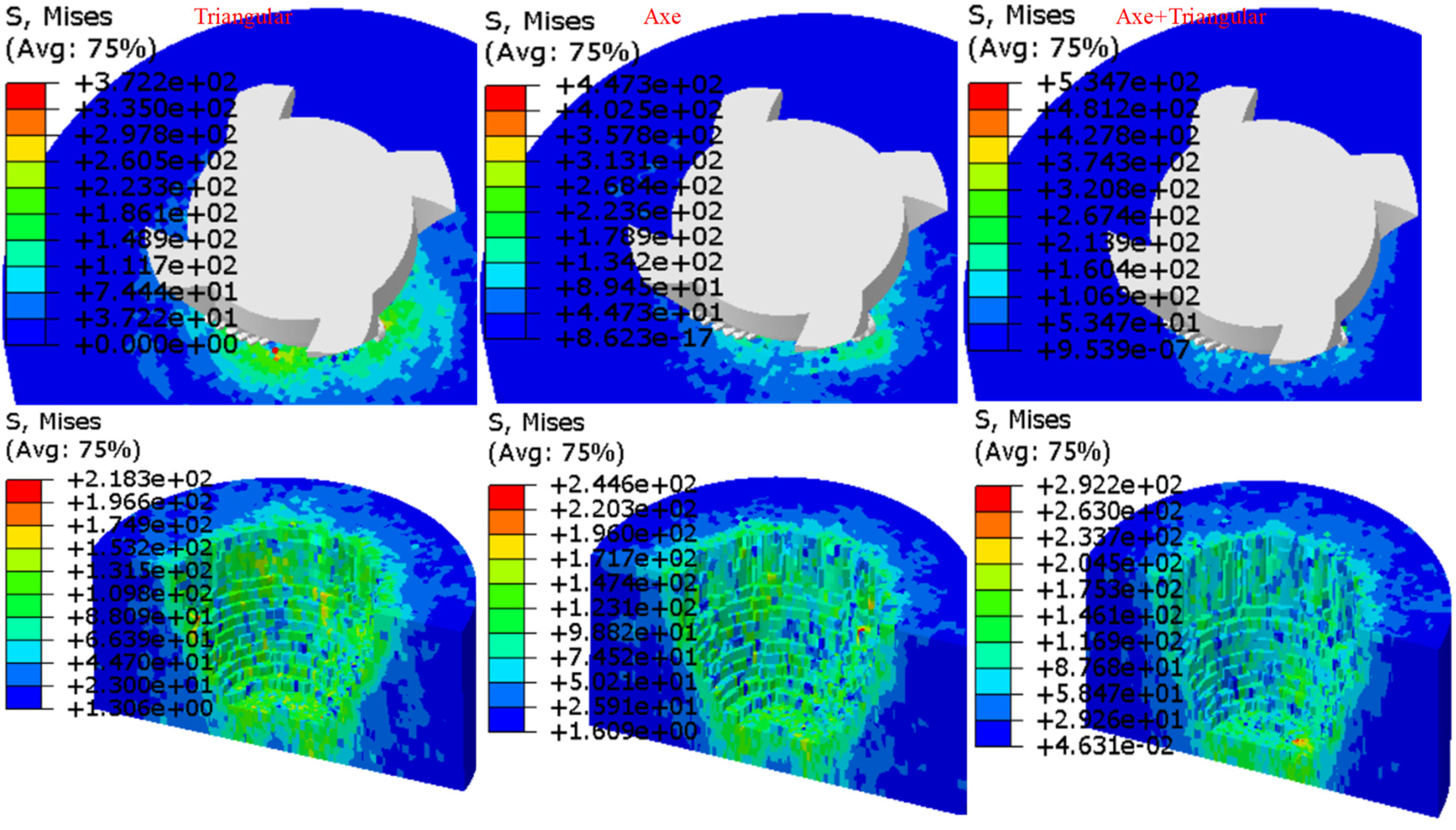

4.1. Rock-Breaking Characteristics Analysis

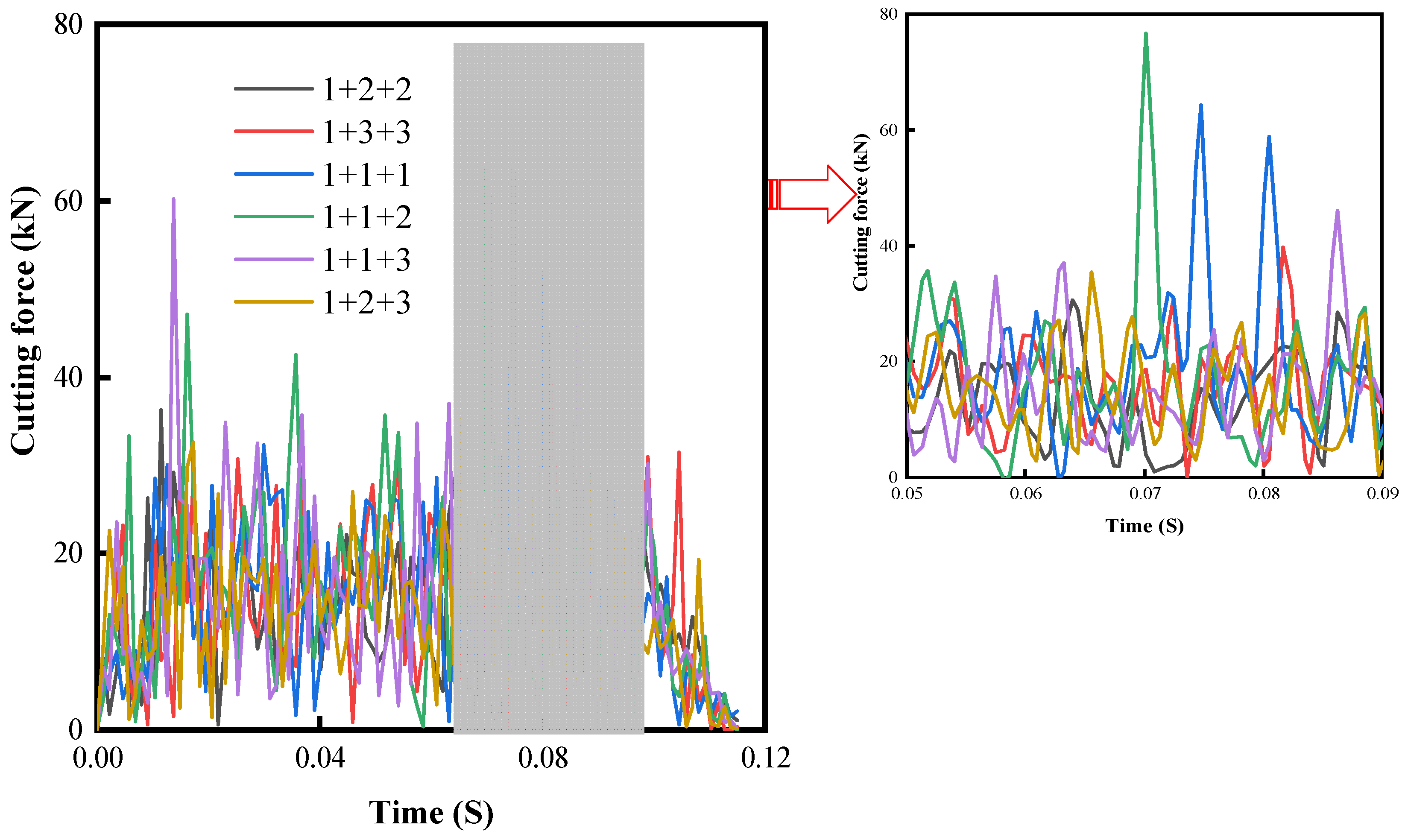

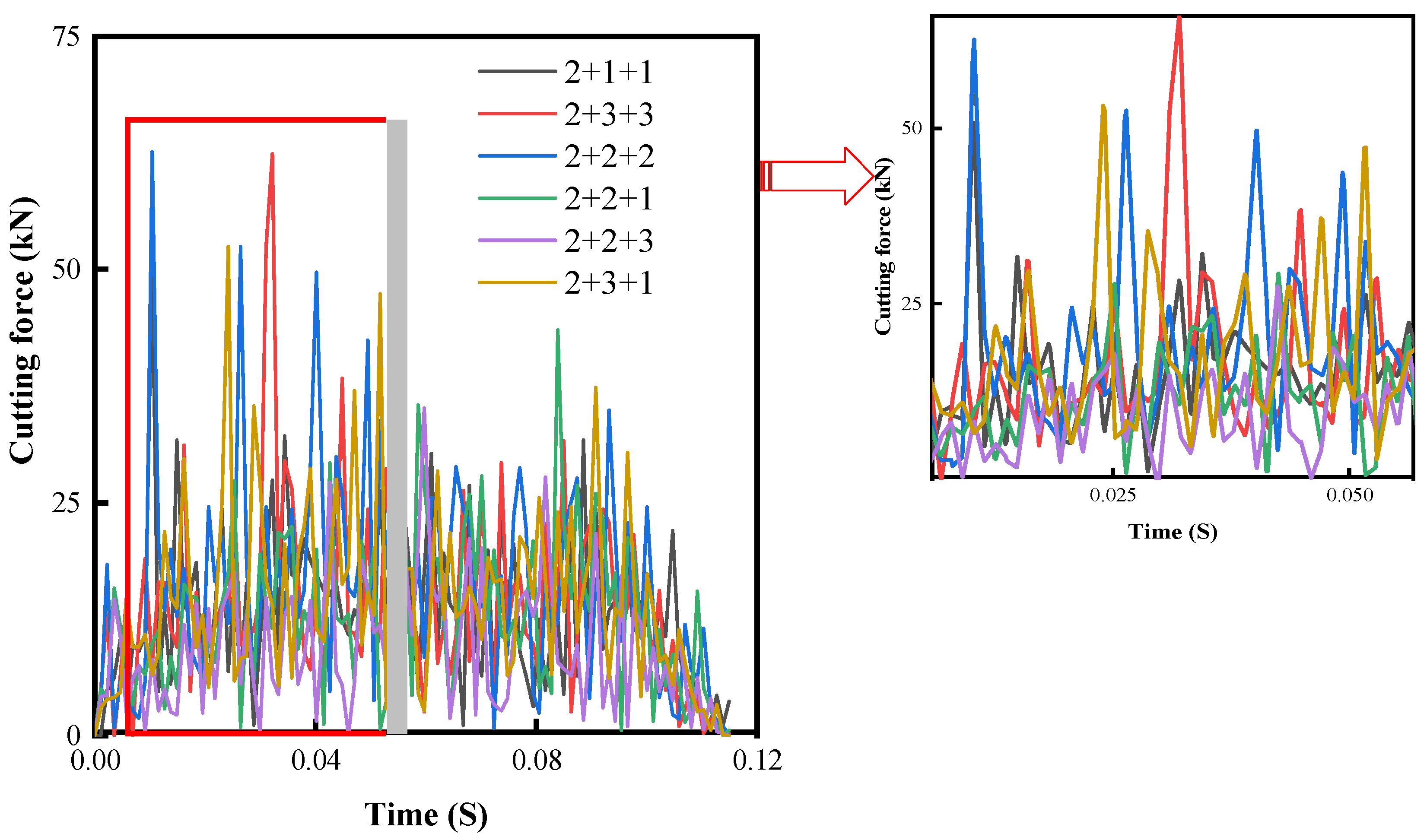

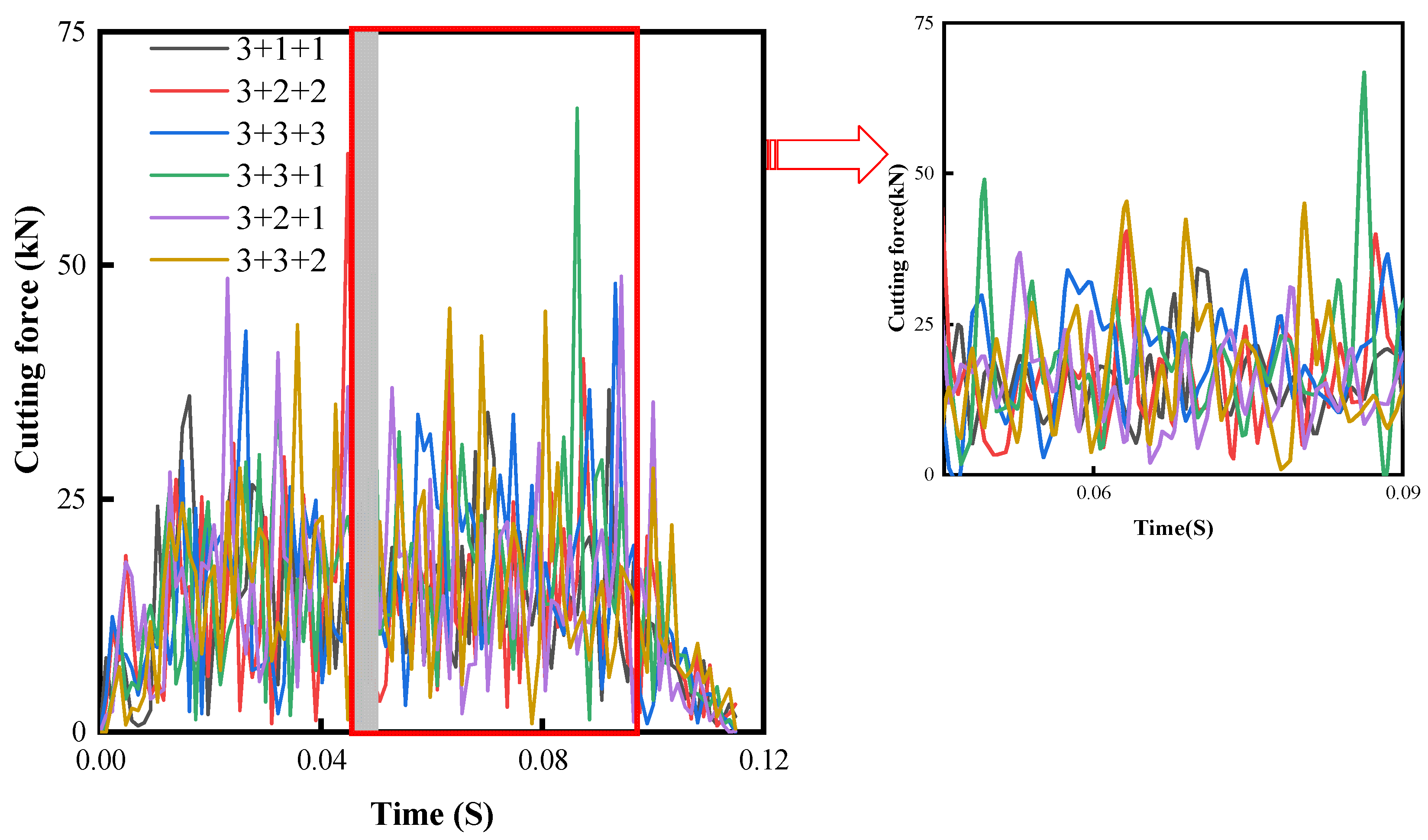

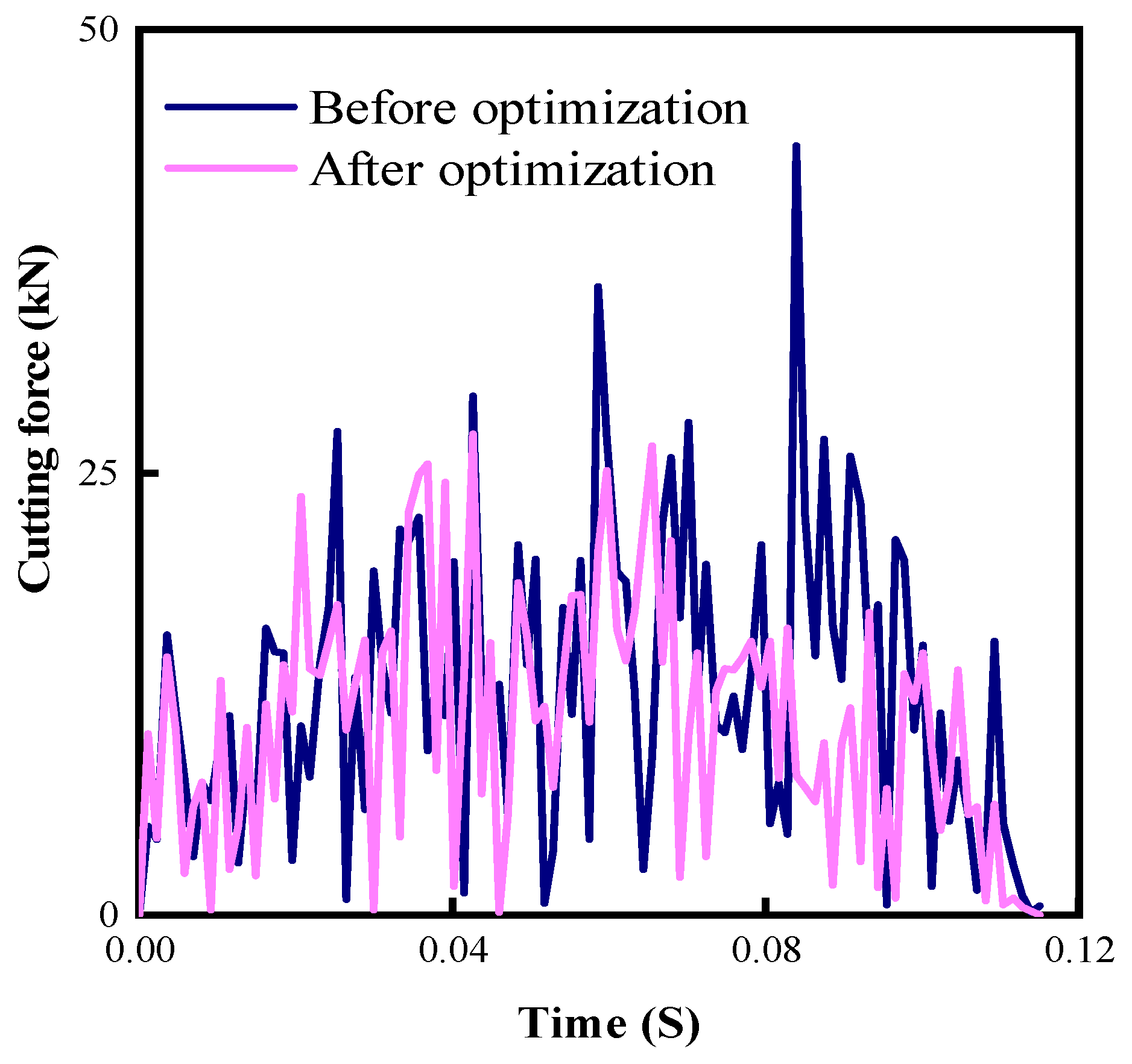

4.2. Cutting Force Analysis

4.3. Mechanical-Specific Energy Analysis

5. Cutter Spacing Optimization and Bit Rock Breaking Simulation

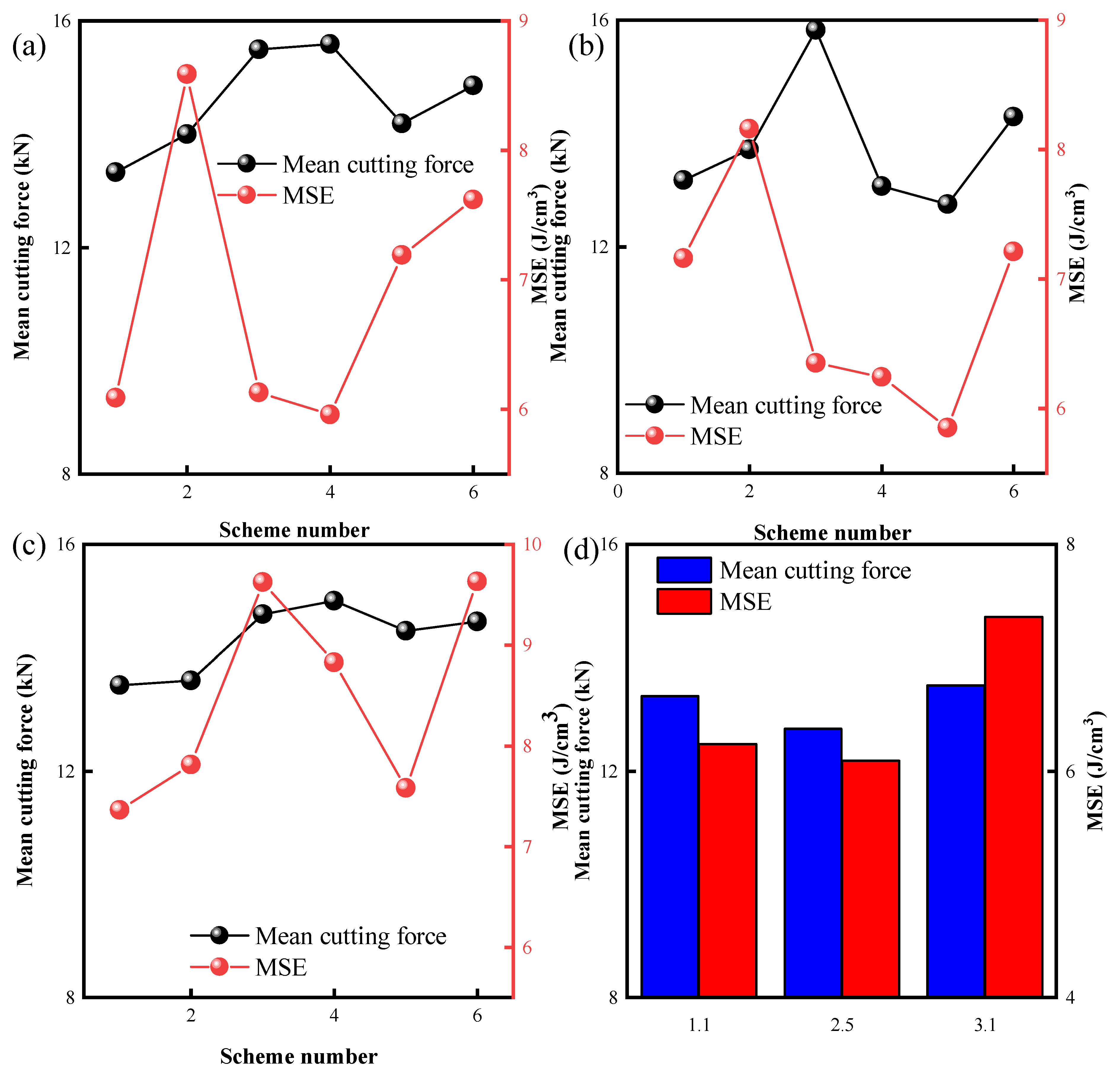

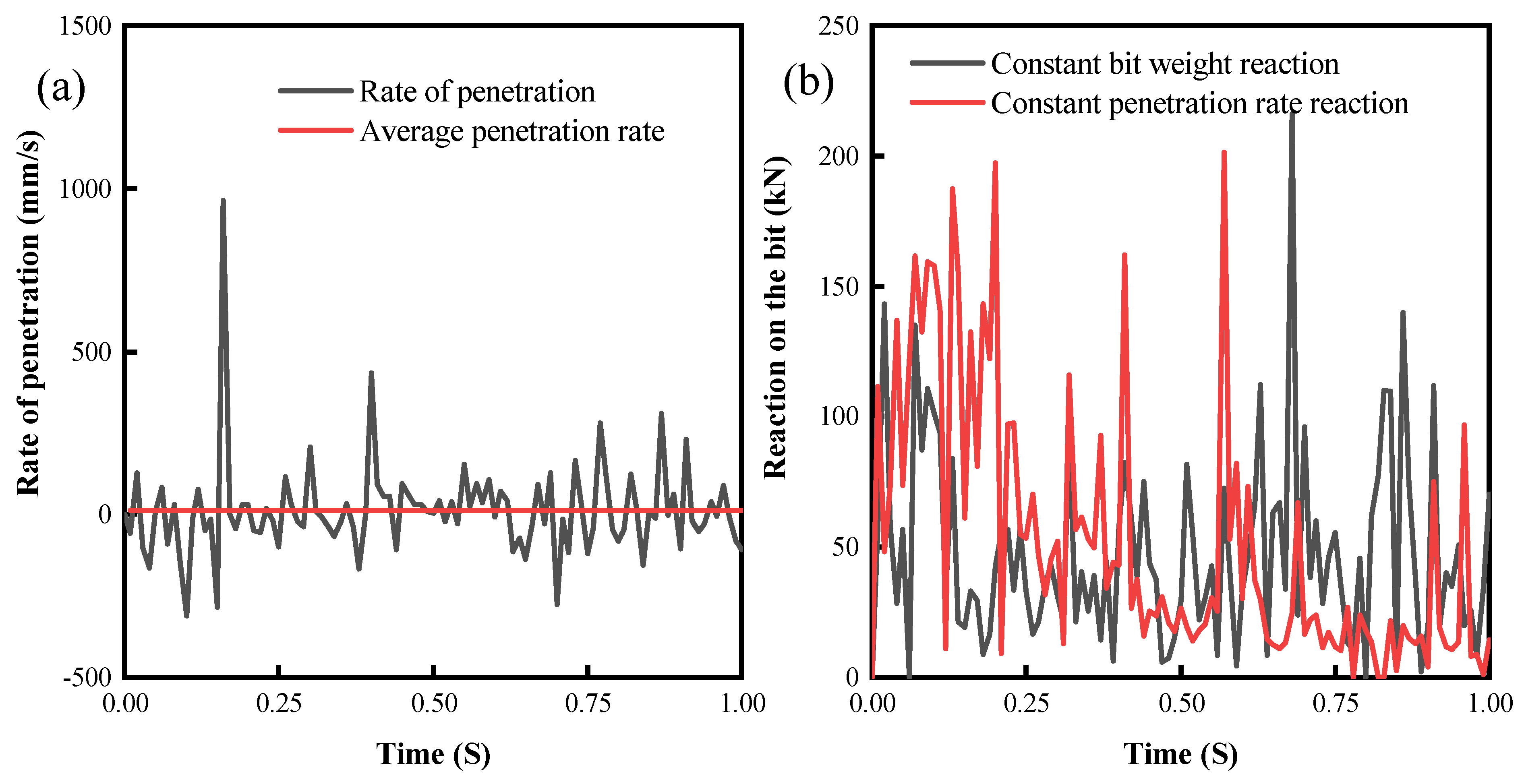

5.1. Analysis of Sampling Results

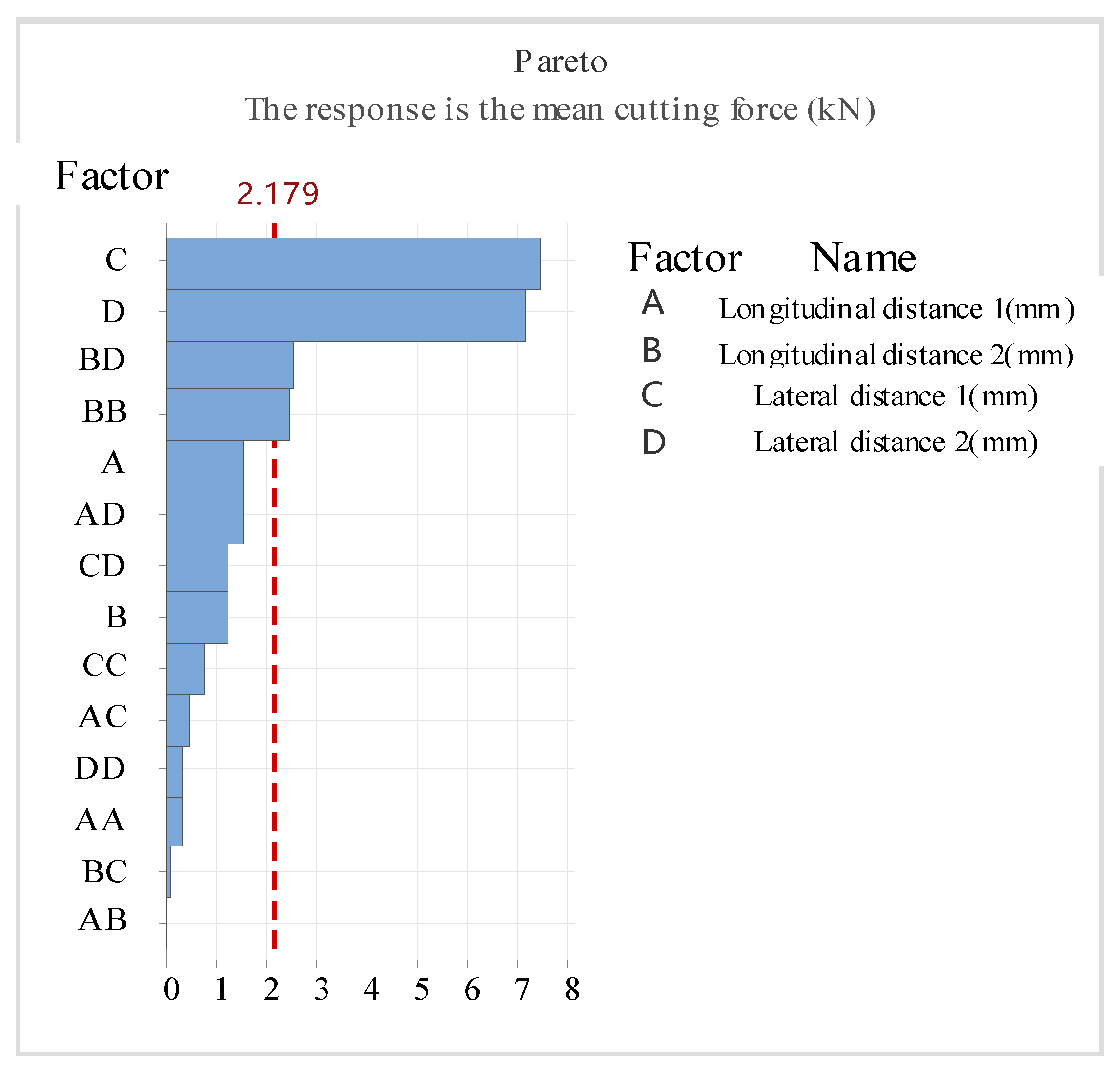

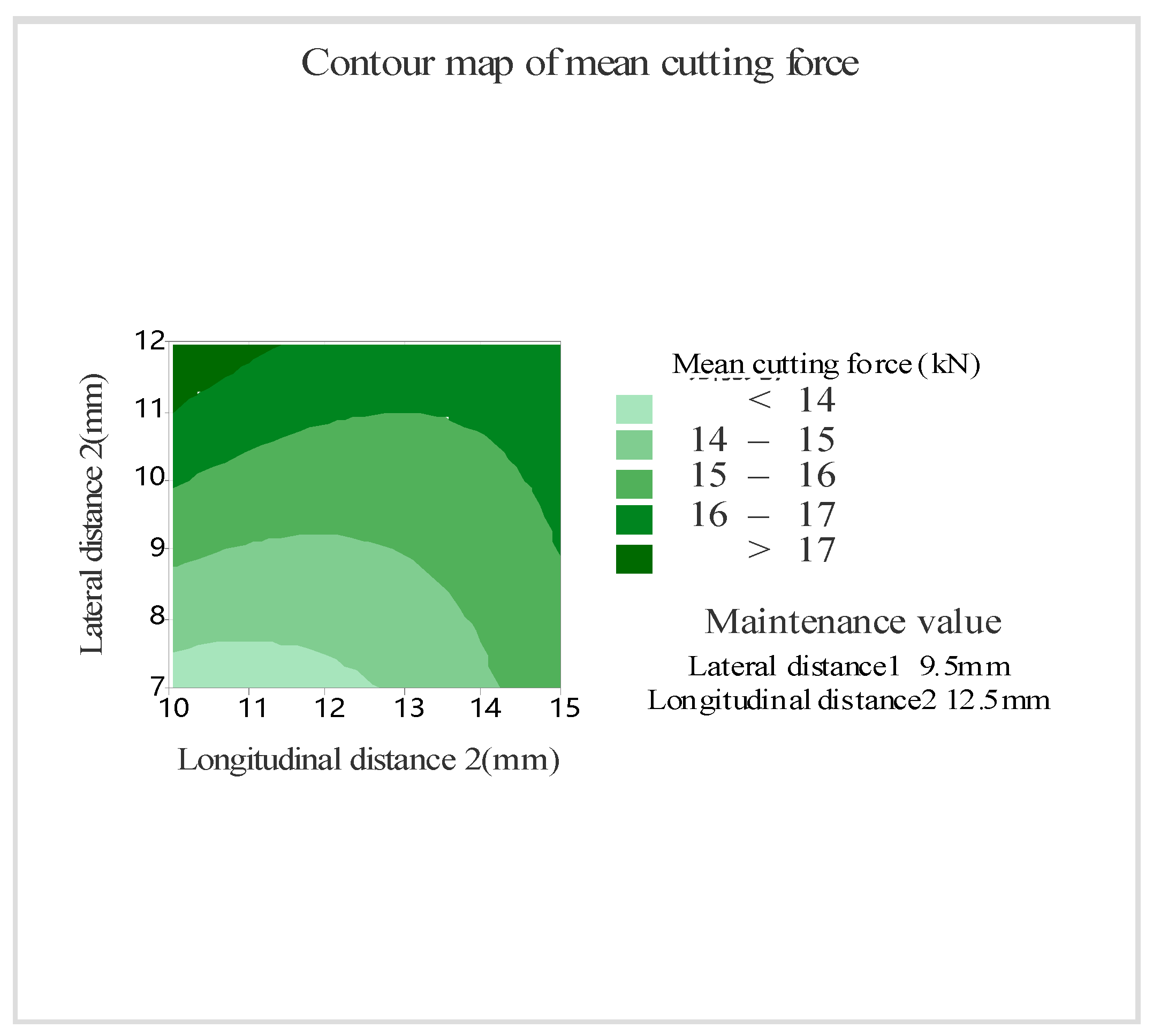

5.2. Analysis of Optimization Results

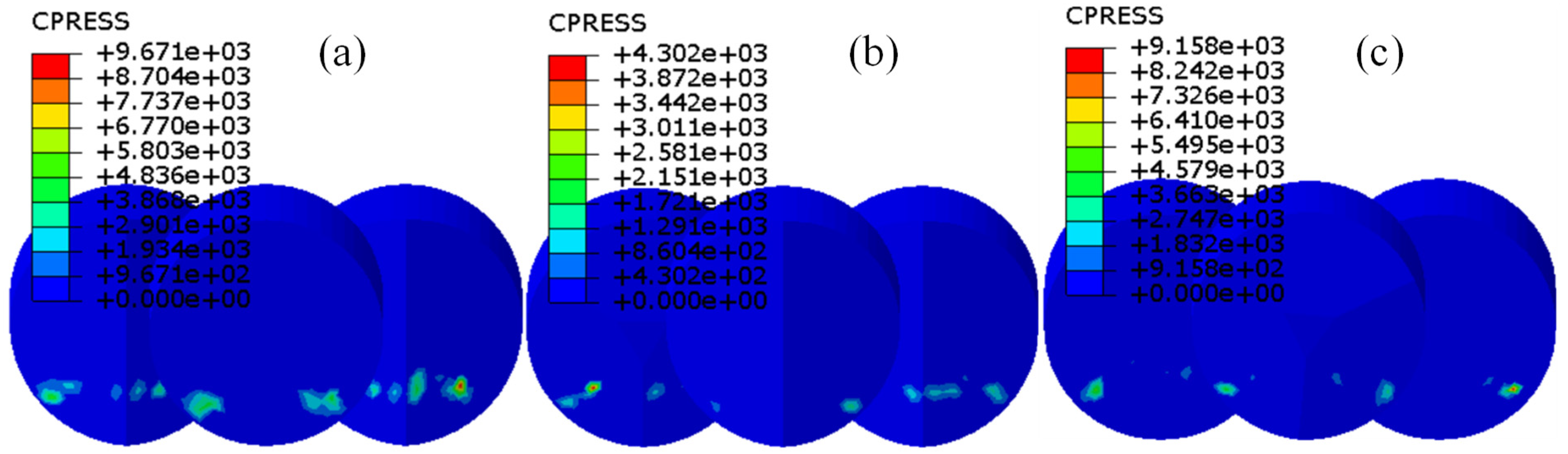

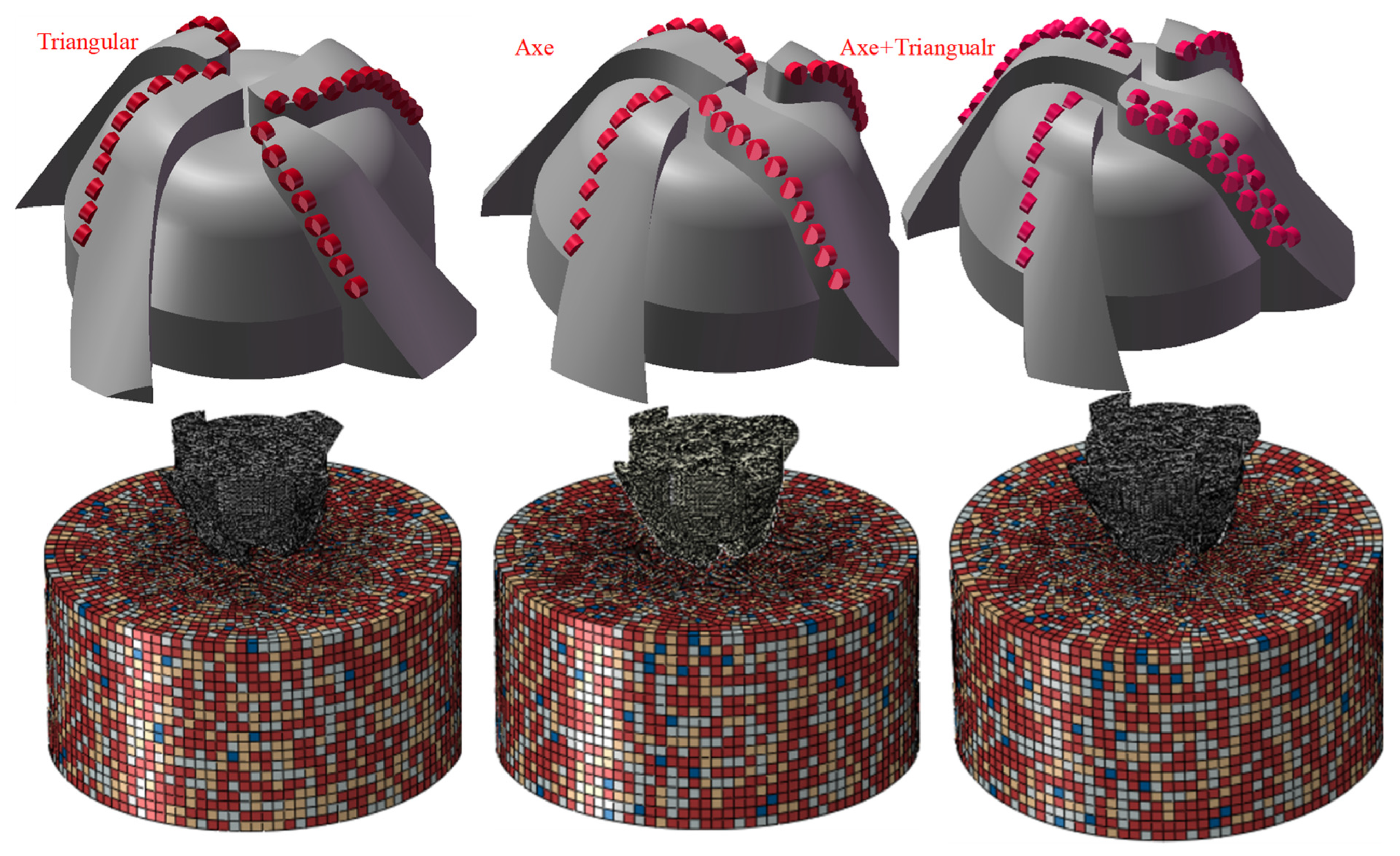

5.3. Full-Size Bit Rock Breaking Simulation

5.4. Field Applications.

6. Conclusions

- (1)

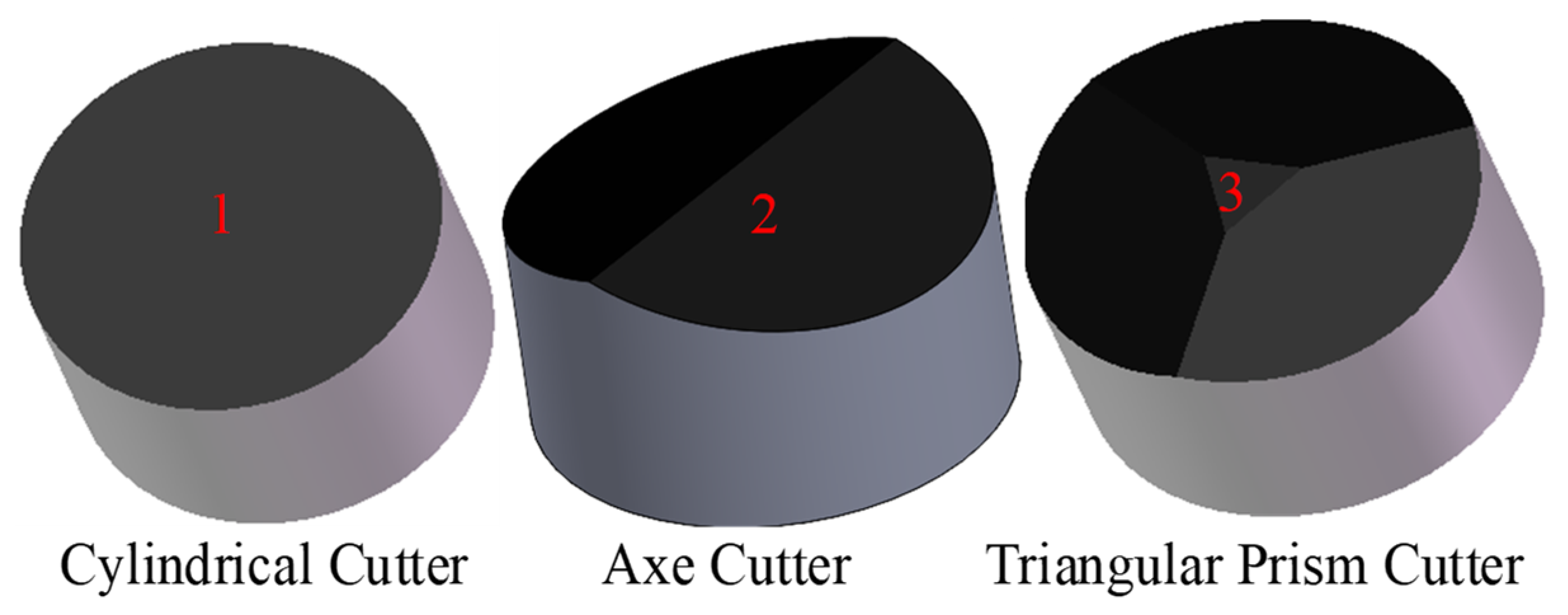

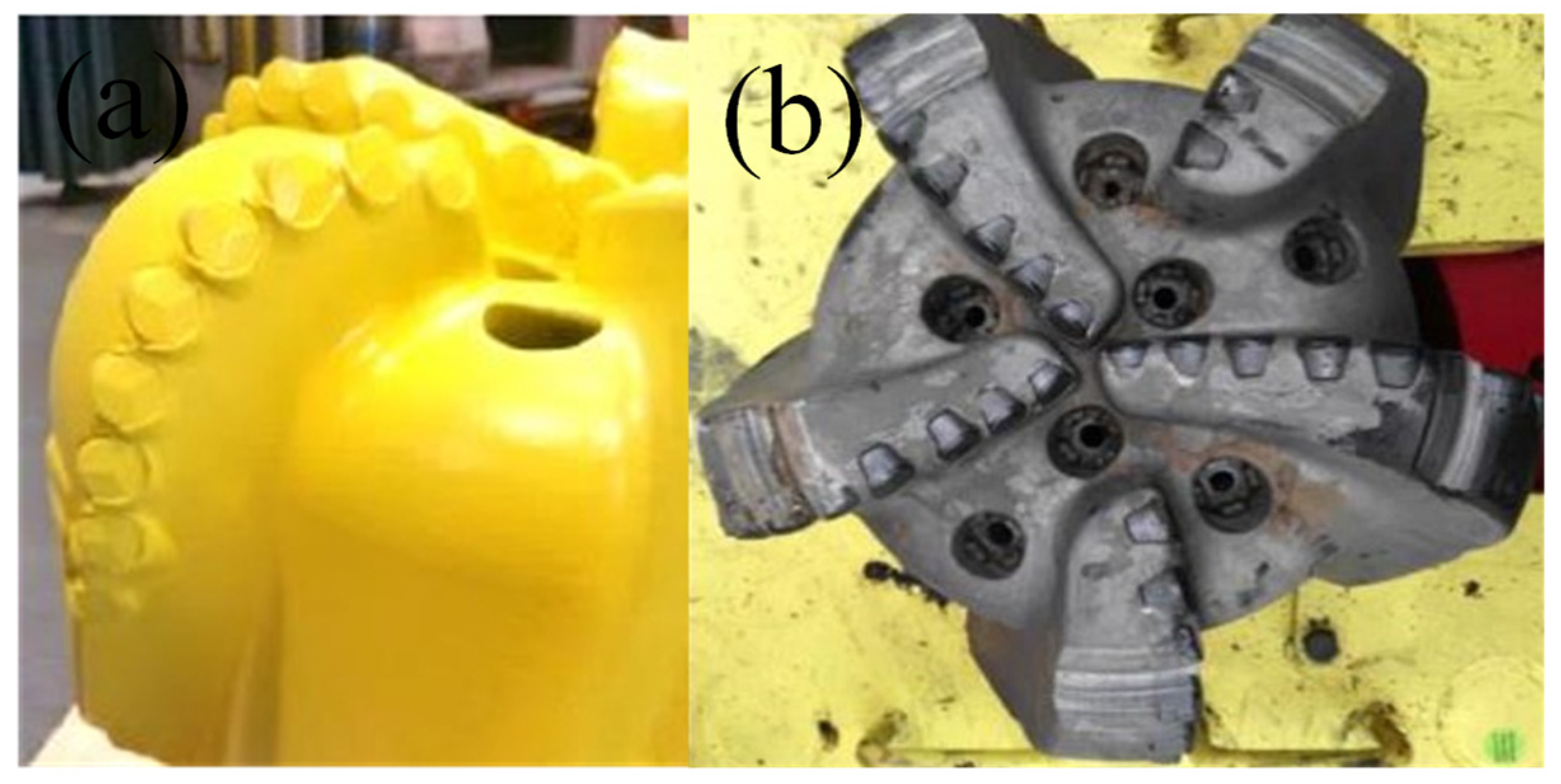

- Compared with the cylindrical cutter, axe and triangular prism PDC cutters have not only a shear crushing effect on the rock but also a crushing effect, which is easier to penetrate into the hard rock. The crushing effect of the axe cutter is more obvious and aggressive, which is suitable for the front row of the blade, and the triangular prism cutter is more stable in drilling, which is suitable for the back row of the blade.

- (2)

- The axe cutter is in the front row, and the rear row arrangement of the triangular prism cutter and the axe cutter is the best solution. The optimal spacing is 10 mm transverse spacing and 7 mm longitudinal spacing between the rear row of the triangular prism cutter and the front row of the axe cutter, and 10.06 mm transverse spacing and 7 mm longitudinal spacing between the rear row of the axe cutter and the front row of cutters.

- (3)

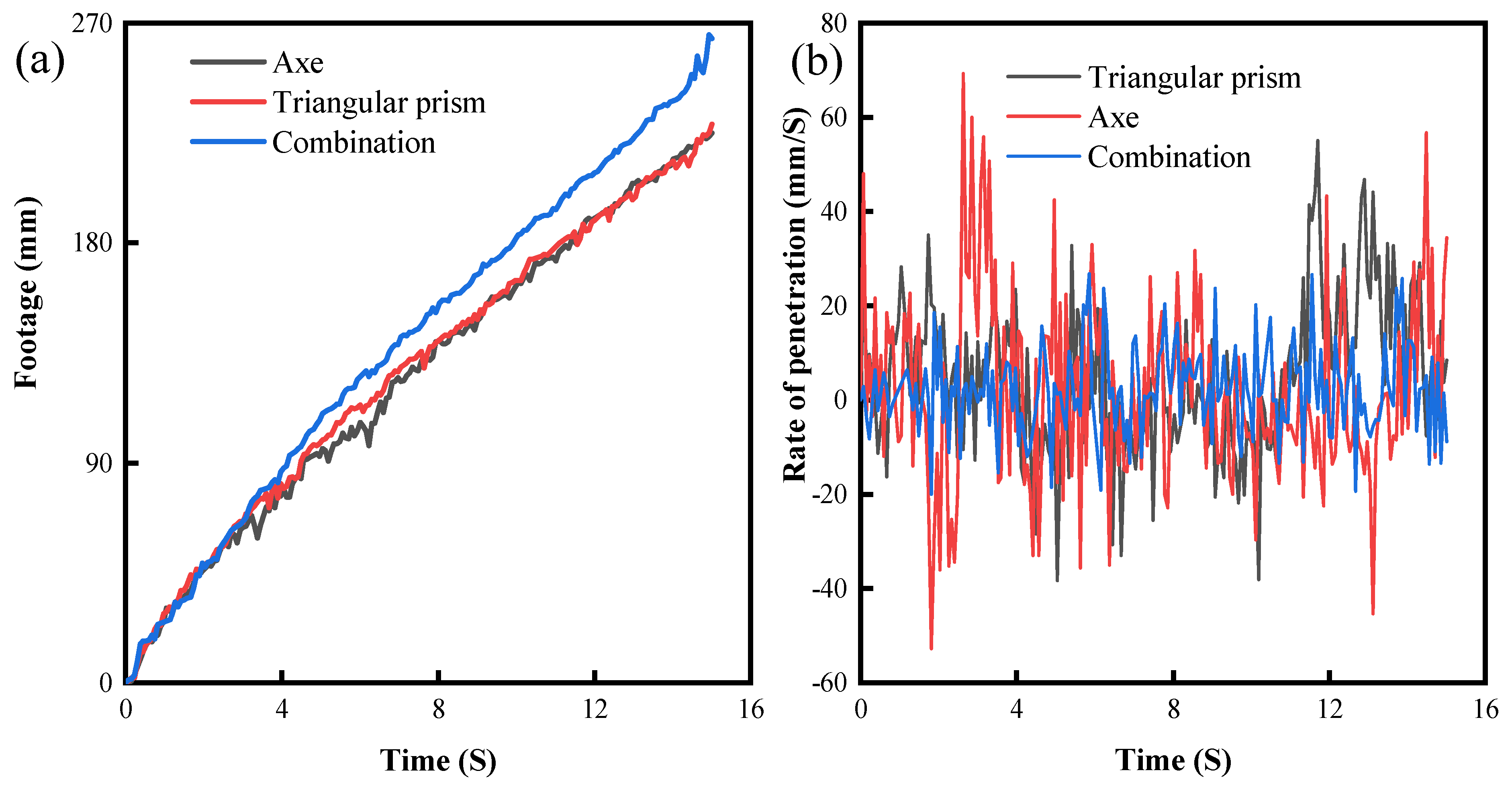

- Compared with the PDC bit with axe cutter and triangular prism cutter, the PDC bit with the best combination for cutter placement has 16.8% and 16.6% higher footage respectively. The instantaneous ROP change during drilling is significantly less volatile and in a more stable state, which can effectively reduce the occurrence of stick-slip phenomenon, make it easier to penetrate into hard rock, maintain stable WOB, and keep efficient drilling.

- (4)

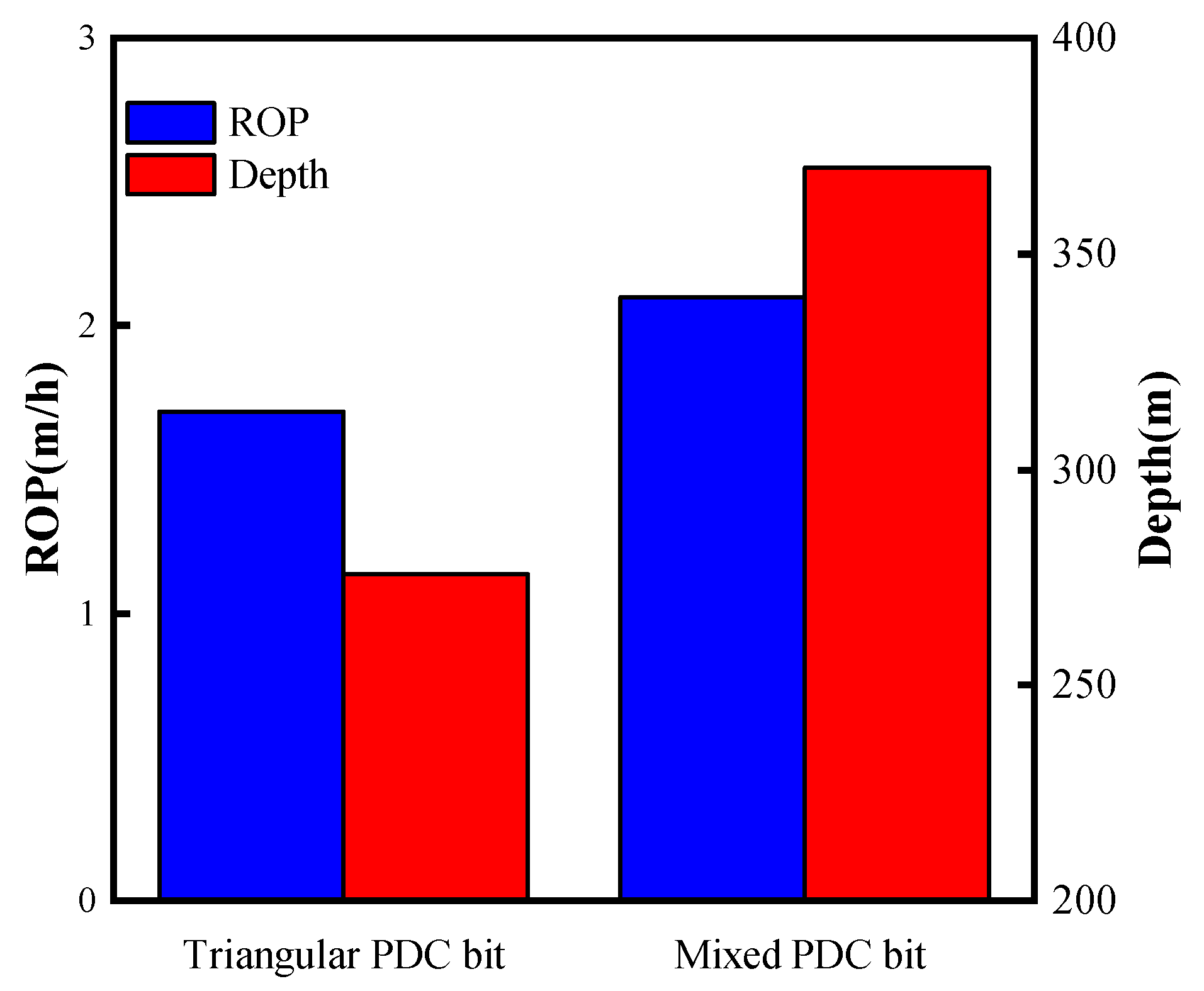

- The field application of the bit shows that the ROP and footage of the PDC drill bit with the mixed arrangement of cutters are significantly improved compared with the PDC bit with triangular prism cutters, which can effectively reduce the drilling cost in complex formations.

Author Contributions

Funding

Conflicts of Interest

References

- Gao, D. Some research advances in well-engineering technology for unconventional hydrocarbon. Nat. Gas Ind. B 2022, 9, 41–50. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; He, D.; Wei, Y.; Li, J.; Jia, A.; Chen, J.; Zhao, Q.; Li, Y.; Li, J.; et al. Theory, technology, and prospects of conventional and unconventional natural gas. Pet. Explor. Dev. 2018, 45, 604–618. [Google Scholar] [CrossRef]

- Gu, J.; Huang, K. Role of Cobalt of Polycrystalline Diamond Compact (PDC) in Drilling Process. Diam. Relat. Mater. 2016, 66, 98–101. [Google Scholar] [CrossRef]

- Shao, F.; Liu, W.; Gao, D.; Zhao, X. Development and Verification of Triple-Ridge-Shaped Cutter for PDC Bits. SPE J. 2022, 27, 3849–3863. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, G.; Huang, Z.; Sheng, M.; Wu, X.; Yang, J. Analytical Modelling of Rock Cutting Force and Failure Surface in Linear Cutting Test by Single PDC Cutter. J. Pet. Sci. Eng. 2019, 177, 306–316. [Google Scholar] [CrossRef]

- Ma, Y.; Huang, Z.; Li, Q.; Zhou, Y.; Peng, S. Cutter Layout Optimization for Reduction of Lateral Force on PDC Bit Using Kriging and Particle Swarm Optimization Methods. J. Pet. Sci. Eng. 2018, 163, 359–370. [Google Scholar] [CrossRef]

- Xi, Y.; Wang, W.; Fan, L.; Zha, C.; Li, J.; Liu, G. Experimental and Numerical Investigations on Rock-Breaking Mechanism of Rotary Percussion Drilling with a Single PDC Cutter. J. Pet. Sci. Eng. 2022, 208, 109227. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, D.; Zhao, Y.; Gao, K.; Zhang, C.; Lü, X. 3D Numerical Simulation Study of Rock Breaking of the Wavy PDC Cutter and Field Verification. J. Pet. Sci. Eng. 2021, 203, 108578. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, H.; Li, J.; Zhang, K.; Ou, Y.; Lu, Z.; Shi, J. A Method for Evaluating the Rock Breaking Efficiency of Cutters and Optimizing the PDC Cutter Profile—A Study of Igneous Rock Formations in Shunbei Oilfield. Energies 2022, 15, 6686. [Google Scholar] [CrossRef]

- Xiong, C.; Huang, Z.; Yang, R.; Sheng, M.; Shi, H.; Dai, X.; Wu, X.; Zhang, S. Comparative Analysis Cutting Characteristics of Stinger PDC Cutter and Conventional PDC Cutter. J. Pet. Sci. Eng. 2020, 189, 106792. [Google Scholar] [CrossRef]

- Ayop, A.Z.; Bahruddin, A.Z.; Maulianda, B.; Prakasan, A.; Dovletov, S.; Atdayev, E.; Rani, A.M.A.; Elraies, K.A.; Ganat, T.A.; Barati, R.; et al. Numerical Modeling on Drilling Fluid and Cutter Design Effect on Drilling Bit Cutter Thermal Wear and Breakdown. J. Pet. Explor. Prod. Technol. 2020, 10, 959–968. [Google Scholar] [CrossRef]

- Li, S.; Zhu, X.; Liang, K.; Deng, Y.; Liu, H. Numerical Simulation Study on Optimizing the Conical Cutter Bit to Break Deep Strata. Recent Pat. Eng. 2023, 18. [Google Scholar] [CrossRef]

- Crane, D.; Zhang, Y.; Douglas, C.; Song, H.; Gan, X.; Lin, Z.; Mueller, L.; Skoff, G.; Self, J.; Krough, B. Innovative PDC Cutter with Elongated Ridge Combines Shear and Crush Action to Improve PDC Bit Performance. In Proceedings of the Day 3 Wed, March 08, 2017; SPE: Manama, Kingdom of Bahrain, 2017; p. D031S014R004. [Google Scholar]

- Shao, F.; Liu, W.; Gao, D.; Ye, Y. Study on Rock-Breaking Mechanism of Axe-Shaped PDC Cutter. J. Pet. Sci. Eng. 2021, 205, 108922. [Google Scholar] [CrossRef]

- Yoan Mardiana, R.; Pasaribu, S. The Effects of PDC Cutter Geometries to the Drilling Dynamics in Various Geothermal Rocks: A Comprehensive Study Using Advanced Drilling Dynamics Simulation. IOP Conf. Ser. Earth Environ. Sci. 2022, 1014, 012006. [Google Scholar] [CrossRef]

- Kunshin, A.A.; Buslaev, G.V.; Reich, M.; Ulyanov, D.S.; Sidorkin, D.I. Numerical Simulation of Nonlinear Processes in the “Thruster—Downhole Motor—Bit” System While Extended Reach Well Drilling. Energies 2023, 16, 3759. [Google Scholar] [CrossRef]

- Wang, C.; Li, S.; Zhang, L. Evaluation of Rock Abrasiveness Class Based on the Wear Mechanisms of PDC Cutters. J. Pet. Sci. Eng. 2019, 174, 959–967. [Google Scholar] [CrossRef]

- Zeng, Y.; He, W.; Zhang, Z.; Shi, H.; Zhou, J.; Ding, S.; Ma, G. Rock-Breaking Performances of Innovative Triangular-Shaped Polycrystalline Diamond Compact Cutter. Rev. Sci. Instrum. 2021, 92, 035115. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, H.; Kuang, Y.; Xie, H.; Qin, C. 3D Numerical Simulation of Rock Cutting of an Innovative Non-Planar Face PDC Cutter and Experimental Verification. Appl. Sci. 2019, 9, 4372. [Google Scholar] [CrossRef]

- Chen, C.; Yan, J.; Zou, Y.; Luo, H. Geometric Evolvement, Simulation, and Test of a Bionic Lateral PDC Reamer Bit Inspired by Capra Sibirica Horn. Appl. Bionics Biomech. 2022, 2022, 1–11. [Google Scholar] [CrossRef]

- Huang, Z.; Xie, D.; Xie, B.; Zhang, W.; Zhang, F.; He, L. Investigation of PDC Bit Failure Base on Stick-Slip Vibration Analysis of Drilling String System plus Drill Bit. J. Sound Vib. 2018, 417, 97–109. [Google Scholar] [CrossRef]

- Tian, K.; Detournay, E. Influence of PDC Bit Cutter Layout on Stick–Slip Vibrations of Deep Drilling Systems. J. Pet. Sci. Eng. 2021, 206, 109005. [Google Scholar] [CrossRef]

- Wang, Y.; Ni, H.; Wang, R.; Huang, B.; Liu, S.; Zhang, H. Numerical Simulation Research on Cutting Rock with a PDC Cutter Assisted by an Impact Force. Adv. Civ. Eng. 2022, 2022, 1–9. [Google Scholar] [CrossRef]

- Akbari, B.; Miska, S. The Effects of Chamfer and Back Rake Angle on PDC Cutters Friction. J. Nat. Gas Sci. Eng. 2016, 35, 347–353. [Google Scholar] [CrossRef]

- Zhu, X.; Dan, Z. Numerical Simulation of Rock Breaking by PDC Bit in Hot Dry Rocks. Nat. Gas Ind. B 2019, 6, 619–628. [Google Scholar] [CrossRef]

- Jamaludin, A.A.; Mehat, N.M.; Kamaruddin, S. Investigating the Effects of PDC Cutters Geometry on ROP Using the Taguchi Technique. J. Phys. Conf. Ser. 2017, 908, 012041. [Google Scholar] [CrossRef]

- Lam, K.Y.; Nélieu, S.; Benoit, P.; Passeport, E. Optimizing Constructed Wetlands for Safe Removal of Triclosan: A Box–Behnken Approach. Environ. Sci. Technol. 2020, 54, 225–234. [Google Scholar] [CrossRef] [PubMed]

- Silva, T.P.; Ferreira, A.N.; De Albuquerque, F.S.; De Almeida Barros, A.C.; Da Luz, J.M.R.; Gomes, F.S.; Pereira, H.J.V. Box–Behnken Experimental Design for the Optimization of Enzymatic Saccharification of Wheat Bran. Biomass Convers. Biorefinery 2022, 12, 5597–5604. [Google Scholar] [CrossRef]

- Bass, J.D. Elasticity of Minerals, Glasses, and Melts. In AGU Reference Shelf; Ahrens, T.J., Ed.; American Geophysical Union: Washington, DC, USA, 2013; ISBN 978-1-118-66819-1. [Google Scholar]

- Zhang, Y.; Wong, L.N.Y.; Chan, K.K. An Extended Grain-Based Model Accounting for Microstructures in Rock Deformation. J. Geophys. Res. Solid Earth 2019, 124, 125–148. [Google Scholar] [CrossRef]

- Peng, J.; Wong, L.N.Y.; Teh, C.I.; Li, Z. Modeling Micro-Cracking Behavior of Bukit Timah Granite Using Grain-Based Model. Rock Mech. Rock Eng. 2018, 51, 135–154. [Google Scholar] [CrossRef]

- Hofmann, H.; Babadagli, T.; Zimmermann, G. A Grain Based Modeling Study of Fracture Branching during Compression Tests in Granites. Int. J. Rock Mech. Min. Sci. 2015, 77, 152–162. [Google Scholar] [CrossRef]

- Wang, L, Bo L, Feng L. Mechanical properties of heterogeneous rock under uniaxial compression based on mineral crystal model. Chinese Journal of Geotechnical Engineering 2020, 42, 542–550. (In Chinese) [CrossRef]

- Zhang, Z.; Zhao, D.; Zhao, Y.; Zhou, Y.; Tang, Q.; Han, J. Simulation and Experimental Study on Temperature and Stress Field of Full-Sized PDC Bits in Rock Breaking Process. J. Pet. Sci. Eng. 2020, 186, 106679. [Google Scholar] [CrossRef]

- El-Sheikh, S.M.; Barhoum, A.; El-Sherbiny, S.; Morsy, F.; El-Midany, A.A.-H.; Rahier, H. Preparation of Superhydrophobic Nanocalcite Crystals Using Box–Behnken Design. Arab. J. Chem. 2019, 12, 1479–1486. [Google Scholar] [CrossRef]

| Parameters | Quartz Mineral | Feldspar Mineral | Mica Mineral | Other Mineral |

|---|---|---|---|---|

| Volume content /(%) | 24 | 49 | 24 | 3 |

| Density /(kg/m3) | 2650 | 2600 | 3050 | 1650 |

| Elastic /(GPa) | 51 | 42 | 33 | 24 |

| Linear stiffness ratio | 1.1 | 1.3 | 1.7 | 3.7 |

| Parallel modulus of elasticity | 51 | 42 | 33 | 24 |

| Bonding stiffness ratio | 1.1 | 1.3 | 1.7 | 3.7 |

| Tensile strength /(MPa) | 126±16 | 105±16 | 98±13 | 77±9 |

| Bonding strength /(MPa) | 196±42 | 162±28 | 146±22 | 105±0 |

| Friction angle /(°) | 19.5 | 22.4 | 17.3 | 23.7 |

| Serial Number | Factors | Cutting Force break//Average Value E/kN | |||

|---|---|---|---|---|---|

| A/mm | B/mm | C/mm | D/mm | ||

| 1 | 15.0 | 12.5 | 12.0 | 9.5 | 16.7153 |

| 2 | 12.5 | 15.0 | 7.0 | 9.5 | 14.4970 |

| 3 | 12.5 | 12.5 | 12.0 | 12.0 | 18.6900 |

| 4 | 15.0 | 12.5 | 9.5 | 12.0 | 15.7510 |

| 5 | 10.0 | 10.0 | 9.5 | 9.5 | 14.5990 |

| 6 | 12.5 | 12.5 | 9.5 | 9.5 | 15.1812 |

| 7 | 15.0 | 12.5 | 9.5 | 7.0 | 14.7283 |

| 8 | 10.0 | 12.5 | 12.0 | 9.5 | 16.0326 |

| 9 | 15.0 | 12.5 | 7.0 | 9.5 | 14.6482 |

| 10 | 10.0 | 12.5 | 9.5 | 7.0 | 13.7766 |

| 11 | 15.0 | 10.0 | 9.5 | 9.5 | 15.4635 |

| 12 | 12.5 | 10.0 | 7.0 | 9.5 | 14.6482 |

| 13 | 12.5 | 12.5 | 9.5 | 9.5 | 15.1812 |

| 14 | 10.0 | 12.5 | 7.0 | 9.5 | 14.2570 |

| 15 | 12.5 | 12.5 | 7.0 | 7.0 | 13.2620 |

| 16 | 12.5 | 12.5 | 9.5 | 9.5 | 15.1812 |

| 17 | 12.5 | 15.0 | 12.0 | 9.5 | 18.2124 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).