1. Introduction

There is an urgent run for decarbonization of the energy system as main action to tackle dramatic climate changes as a result of the anthropogenic activity. The development of hydrogen-related technologies is expected to have a key role into such energy system transition towards a deep reduction of greenhouse gases emissions[

1]. The public and private support for the development of hydrogen technologies is enormous, being a pillar of the R&D and Innovation Programs around the World, and in particular at the Green Deal of the European Union [

2,

3]. One of the targets is the combination of hydrogen production technologies with renewable energy generation as net-zero emission energy source. Such combination decoupled renewable intermittent electricity production from the demand, reducing curtailment of wind and PV production [

4] by the accumulation of production in excess into the hydrogen vector, that would act as storage[

5]. Offshore wind farms are very attractive for the deployment of new wind capacity for their good energy performance. One of the most important issues affecting the techno-economic viability of offshore electricity production is the energy transport to the energy networks, directly dependent on the distance to shore [

6]. Some authors reported that hydrogen transport by ship or pipeline may be competitive with subsea cables for long distance, high power and low electricity price[

7]. Such networks may be electric, or molecular, what has brought attention to the production of off-shore hydrogen [

8,

9].

Hydrogen is considered one of the options for a future decarbonization of hard-to-abate sectors, where direct electrification is a paramount challenge. Apart of some specific industrial processes, as steel manufacturing or petrochemical refineries, that may implement or use huge amounts of hydrogen, now based on fossil reforming and/or gasification, heavy duty mobility is critical. There is a need to provide long autonomy to heavy duty vehicles, and specially, to aviation and shipping [

10,

11]. There are a number of future alternatives [

12] for hydrogen carriers, including ammonia, synthetic natural gas, or other organic compounds, that would play a role as multipurpose vector for transportation and use.

Different alternatives for the evacuation of off-shore hydrogen to the demand are evaluated, what includes the transport from the off-shore generation site to a distribution network connecting node. Such analysis includes the operation as energy hub of the shore connection to the networks.

2. Materials and Methods

The delivery of Hydrogen production offshore to the onshore transport and distribution networks includes the implementation of the following infrastructure: the transport to the shore, likely a port or similar, the bunkering and the hydrogen storage. Such infrastructure should be compatible with the needs of the off takers, as ships or a distribution network for local consumers, as well as inland transport.

2.1. Transport to shore

There are multiple options for the delivery of energy production offshore. Such options may be the transport of hydrogen or a hydrogenated compound, either by a pipeline of by a transport vessel, or electricity, for its conversion into hydrogen onshore[

13]. There are a few analysis with a direct comparison between offshore cables and offshore hydrogen pipeline[

14]. Cost structures in both cases depends on several items of different nature. In particular, transmission efficiency in terms of energy are higher in pipelines, but O&M costs are much lower for cables. In the particular case of hydrogen pipelines, materials must be chosen carefully, both to minimize diffusion leakage and to improve resistance to hydrogen embrittlement (HE). The current number of specific hydrogen pipes has been made on low grade steels [

15] operating at relatively low pressure, less than 10 MPa. Nevertheless, high capacity hydrogen pipelines requires high-strength and high-pressure, being a challenge in current demo-projects worldwide that still requires some R&D.[

16]

For the case of hydrogen transportation by ship, some authors have analyzed alternatives based on the use of compressed hydrogen (cH2), liquid hydrogen (lH2), ammonia (NH3), and light organic compounds (LOHC)[

17]. Those analysis are mainly devoted to long distance transport, for instance, for intercontinental hydrogen logistics from port to port.

2.2. Hydrogen bunkering and distribution.

Ports are one of the critical infrastructures into the energy transition. They constitute critical transportation hubs for the international commerce. They can be considered as well energy hubs [

18] from the point of view of the import/export of energy products, as LNG, coal or oil. To that energy product list, hydrogen and its derivatives is called to be another asset, not only as fuel to feed transportation vessels into a decarbonized marine sector [

19], but also as shore connections with offshore energy generation facilities. In that sense, harbor infrastructures must be ready to operate in a uncertain context regarding the type of fuel that will be used in a net-zero scheme by the international shipping fleet, or even to adapt to a multiple fuel fleet [

20]. Ammonia, Hydrogen and Methanol are the decarbonized flexible fuels that are proposed for decarbonization.

Hydrogen bunkering at ports is also facing regulation issues. The maritime sector is regulated by the international safety code for ships using gases or other low-flashpoint fuels (IGF Code). This code contains mandatory standards for the disposal, installation, control and monitoring of equipment and systems that use low-flash point fuels, as it is the case of hydrogen with a flash point below 60 ºC. The Code is mandatory under the International Convention for the Safety of Life at Sea (SOLAS), but it has been elaborated focused on LNG[

21]. On the other hand, SAE J2601 standard establishes safety limits and performance requirements for gaseous hydrogen fuel dispensers. Criteria include maximum fuel temperature at the dispenser nozzle, maximum fuel flow rate, maximum pressure rise rate, and other performance criteria, but limited to heavy and light duty road vehicles. For ships, such standards are not available and new standards should be issued in view of the efforts for maritime transport decarbonization. Currently, one of the options for hydrogen bunkering is in the form of ammonia, but it might depend on the evolution of the maritime fuel (or combinations of fuels) finally adopted.

Another important issue is the connection with onshore networks, currently under development and implementation by several H

2 clusters. Such networks are mostly relying in the capacity of the existing natural gas network for the transport of blended natural gas/hydrogen admixtures [

22]. In that case, hydrogen produced offshore may be directly injected into a gas network.

2.3. Hydrogen storage

There are plenty of option for hydrogen storage available or under development, as compressed and liquid hydrogen, hydrates, metal hydrides, adsorption, and chemical formation of hydrogenated molecules[

23]. Hydrogen storage at ports should be aligned with their role as fuel exchange hub connecting fuel bunkering for ships, clean energy delivery from offshore production, and clean fuel distribution to the shore networks. Liquified Hydrogen and Ammonia are the two main options that has been proposed to store hydrogen at ports, as well as decarbonized fuel for ships. Some analysis has been reported with techno-economical comparison between liquid hydrogen, ammonia and LNG taking into account their environmental and economic impact[

12]. One of the main key performance parameters is the fuel boil-off during transportation and storage, that is several times higher in the case of liquid hydrogen than ammonia as a consequence of a much lower storage temperature (-253 ºC vs. -33 ºC at standard pressure).

Respect to the alternatives for decarbonizing maritime transport, it is not so clear which will be the most suitable fuel [

24] in the future. Either hydrogen, ammonia or other vectors as dimethyl ether (DME), or methanol, have their own pros and cons. Ammonia is a very interesting option due to the existence of plenty of infrastructures and a consolidated market worldwide. The hydrogen storage at ports in form of ammonia will depend on the practical utilization of such substance as marine fuel in a high fraction of vessels.

3. Hydrogen transport.

3.1. Hydrogen transport by pipelines.

The design of a subsea gas pipeline is influenced by multiple factors, some of the most important being performance, pressure rating, pressure drop and depth [

25]. In the case of transporting hydrogen through a pipeline, materials must be chosen carefully, both to minimize diffusion leakage and to improve resistance to hydrogen embrittlement (HE). Hydrogen embrittlement is a deterioration mechanism of the mechanical properties of materials (mainly in steel pipes). In this mechanism the atomic hydrogen diffuses into the material, and it is deposited in the reticular structure of the metal, being able to create cracks and cause fractures [

26]. The implementation of dedicated hydrogen pipelines, specially at subsea levels, requires a reliable verification of HE avoidance and the deep understanding of such phenomena in high pressure pipelines. The severity of hydrogen embrittlement depends on the hydrogen diffused in the pipe structural material, the mechanical stress, and the microstructural defects of the material. Hydrogen diffusion and penetration will depend on hydrogen partial pressure and the cyclic stress by static loads during operation. Blended hydrogen mixtures with natural gas or carbon dioxide inhibited hydrogen embrittlement [

27], but such mixtures are hardly likely for the transportation of hydrogen produced offshore, as the expected product will be hydrogen from electrolysis processes. Such circumstances make difficult to reuse existing subsea pipelines for gas transport to carry offshore hydrogen to shore, as it should be needed a lot of pending research and understanding about the degradation of current gas pipeline steels for reuse for hydrogen transportation [

28].

In practical engineering as in existing hydrogen infrastructures, low-alloy steel tubes are preferred for hydrogen pipelines as X42 and X52 steel pipes recommended by ASME B31.12 standards. Some recent scenario analysis for hydrogen logistics follow this recommendation[

29]. The use of higher-grade steels, X65, X70 and higher, for hydrogen transport are being investigated, what may imply a review of ASME standards, as main reference for gas transmission and distribution piping systems.

Respect to cost estimates for hydrogen pipelines, according to a report provided by the transmission system operators (TSOs) for the European Hydrogen Backbone, it is reported between 0.17 and 0.32 €/kg/1000 km for new pipe diameter between 500 and 1200 mm.

3.2. Hydrogen transport by ship.

The alternatives for hydrogen transport by ships are directly connected to the storage options that would be available, namely compressed hydrogen (cH2), liquified hydrogen (lH2), ammonia (NH3) or other hydrogenated compound as light organic hydrocarbons (LOHC) or methanol. Such facilities are expected to be available onshore, and, in particular, in the vicinity of ports, and it might play a role as energy hubs [

18]. The available reports about long distance hydrogen transport shows how shipping is a sensible alternative between ports[

7,

19].

In the case of the application to offshore electricity and its conversion into hydrogen, it is important to consider the feasibility of the transformation process offshore from hydrogen to the transported vector. In most of the cases, it is considered the offshore production of hydrogen by electrolysis. The addition of a hydrogen liquefaction plant or an ammonia synthesis facility for its loading in a transportation ships makes much more complex the structure and equipment to be installed and operated in an aggressive environment. In that sense, the liquefaction offshore hydrogen or its conversion offshore into a vector as ammonia or any other synthetic seems to be handicapped respect to the evacuation of compressed hydrogen.

3.3. Hydrogen transport by truck.

The most mature transportation mean for hydrogen is trucks, which are the preferred option for short distance within the delivery capacity of such vehicles. For the case of compressed hydrogen in tube trailers, their capacity is relatively small, of the order of 300 kg/truck[

30]. Liquid hydrogen trucks are able to transport of the order of 5000 kg of Hydrogen per vehicle. In this case, this option is not available, except as one of the pathways to distribute hydrogen stored at ports.

4. Hydrogen storage

The alternatives for hydrogen storage at ports depend on the type of hydrogen compound that would dominate the sustainable maritime transport. The compatibility between low-carbon fuel bunkering, storage at port, and the hydrogenated compound to transport offshore production to port should be granted, either by an easy physical exchange, or by an efficient transformation between energy vectors (electricity-hydrogen, hydrogen-ammonia, gasification, liquefaction). There are already a lot of uncertainties about which will be the preferred onboard fuel for shipping. Liquid hydrogen is one of the options [

31], as well as ammonia [

10]. In particular, both seems more suitable for long range transport respect to compressed hydrogen due to the higher energy density onboard [

32].

5. Hydrogen bunkering and distribution

The hydrogen hub on shore will distribute hydrogen for its consumption in a variety of applications, that may include industrial off-takers, refueling stations, injection into local transport networks, ships bunkering or any other delivery option. For such distribution there are two main options: by local pipelines, or by truck. The choice will depend on the transport capacity required and other regulation aspects. For high capacity pipes is the more cost effective option, either by a new brand pipe for distribution (> 10 tons/day) or using hydrogen admixtures in existing natural gas pipelines for transport (> 100 tons/day) [

33]. On the contrary, urban and local hydrogen distribution with capacities lower than 10 tons/day, will be more cost effective with compressed gaseous hydrogen at a cost of around 0.65-1.63 €/kgH2. Vessel bunkering system will depend on the infrastructure that will be needed to fuel the maritime fleet.

6. Cost Analysis

Cost is one of the main criteria for decisionmakers. At the current stage of development of the hydrogen economy, there are perspectives of cost reduction in every level of the hydrogen value chain as a consequence of the huge investment effort for development and innovation. The current cost analysis may be done according with the current state of the art, and including cost reduction for the near future. Nevertheless, decision may be obviously affected by the expected lifetime and retrofitting cost of infrastructures, especially when CAPEX costs are dominant.

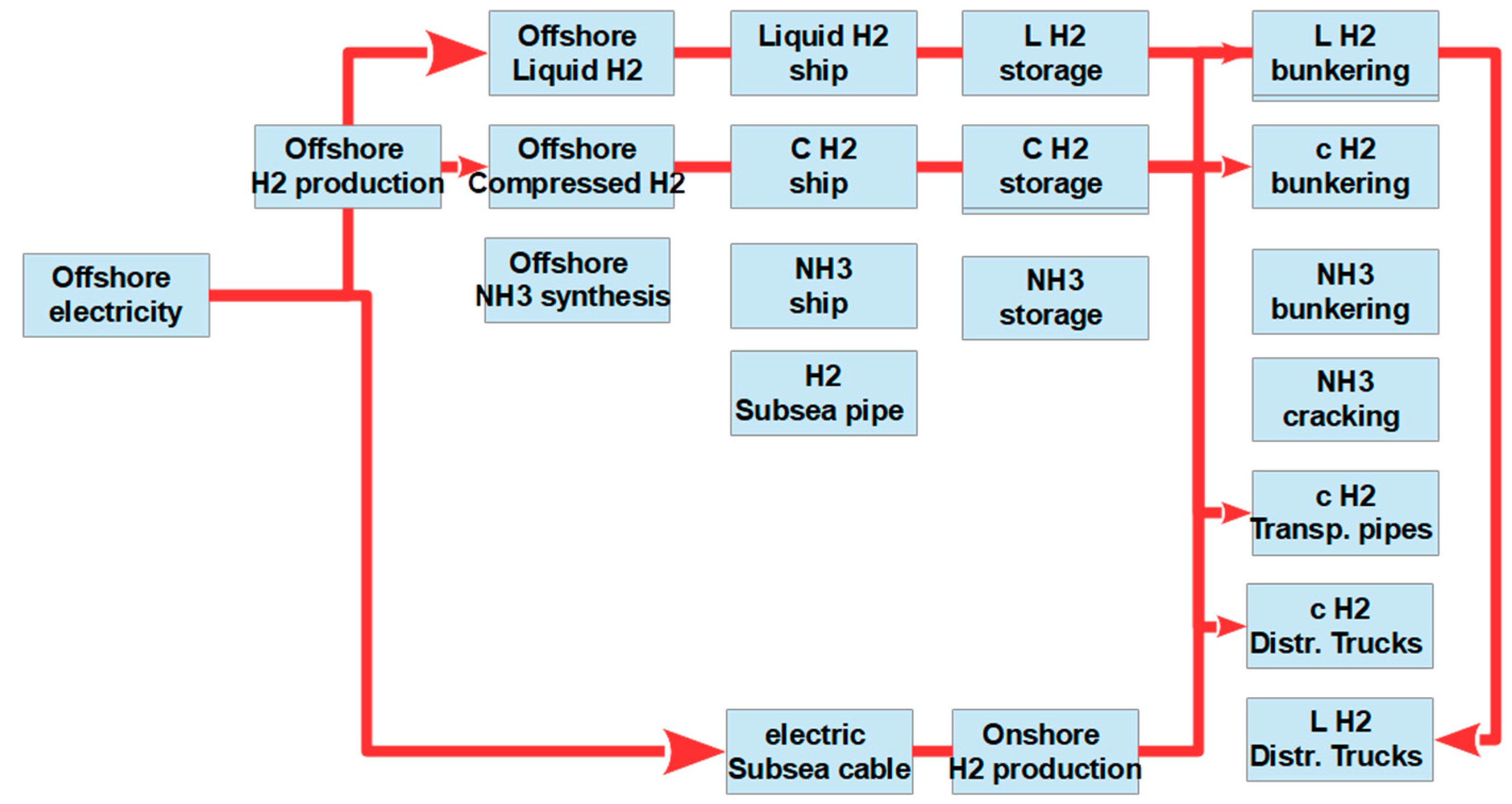

From the previous analysis, the realistic alternatives for the delivery of energy produced offshore and its integration into a hydrogen system onshore are the direct transport of electricity by subsea cables, hydrogen subsea pipeline or liquid/compressed hydrogen vessels (

Figure 1). The electrolysis facility for the production of hydrogen may be installed either at the offshore platform, or onshore, being their cost similar. If the storage and bunkering is done in the form of ammonia or LHOC, additional transformation costs should be added.

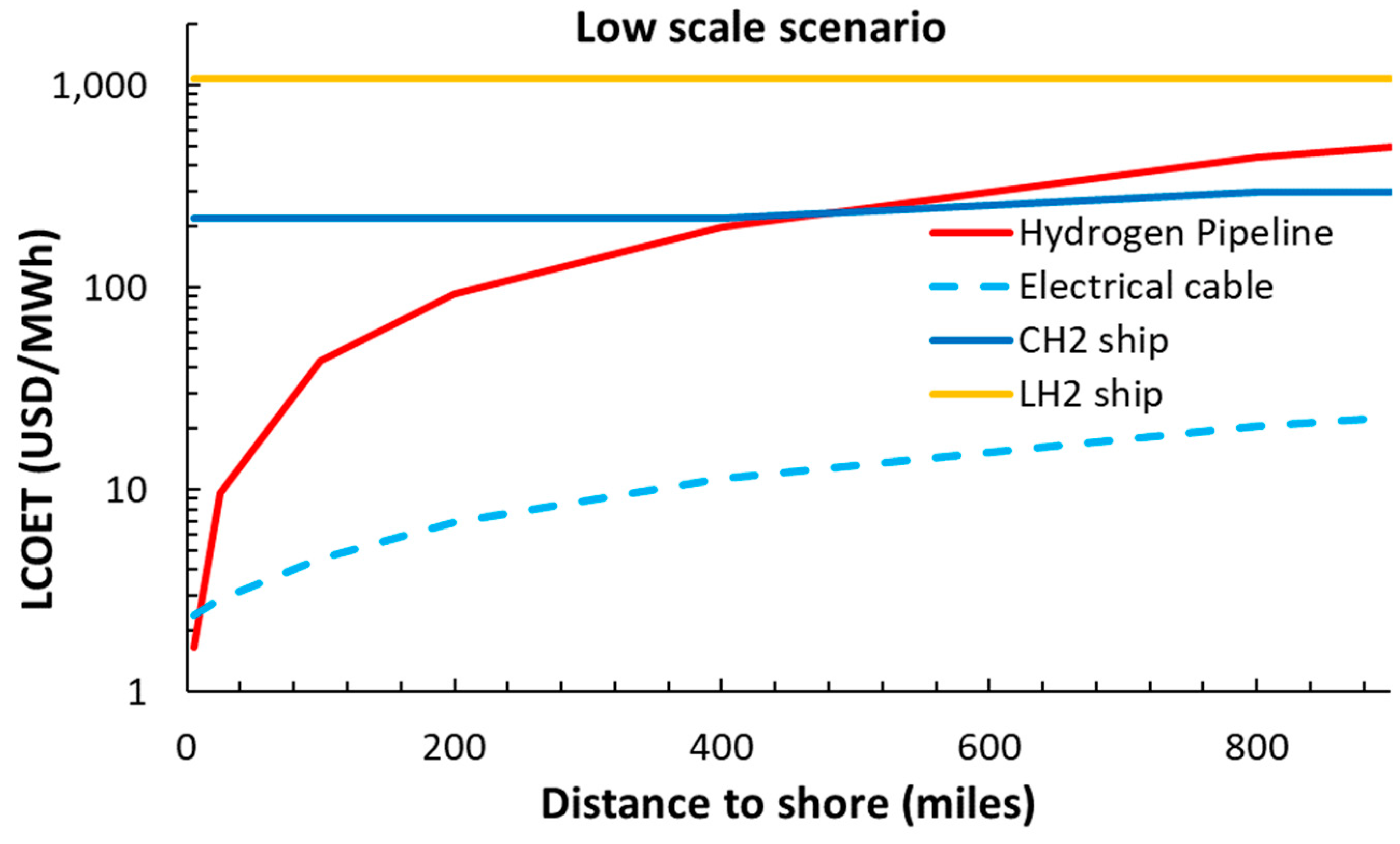

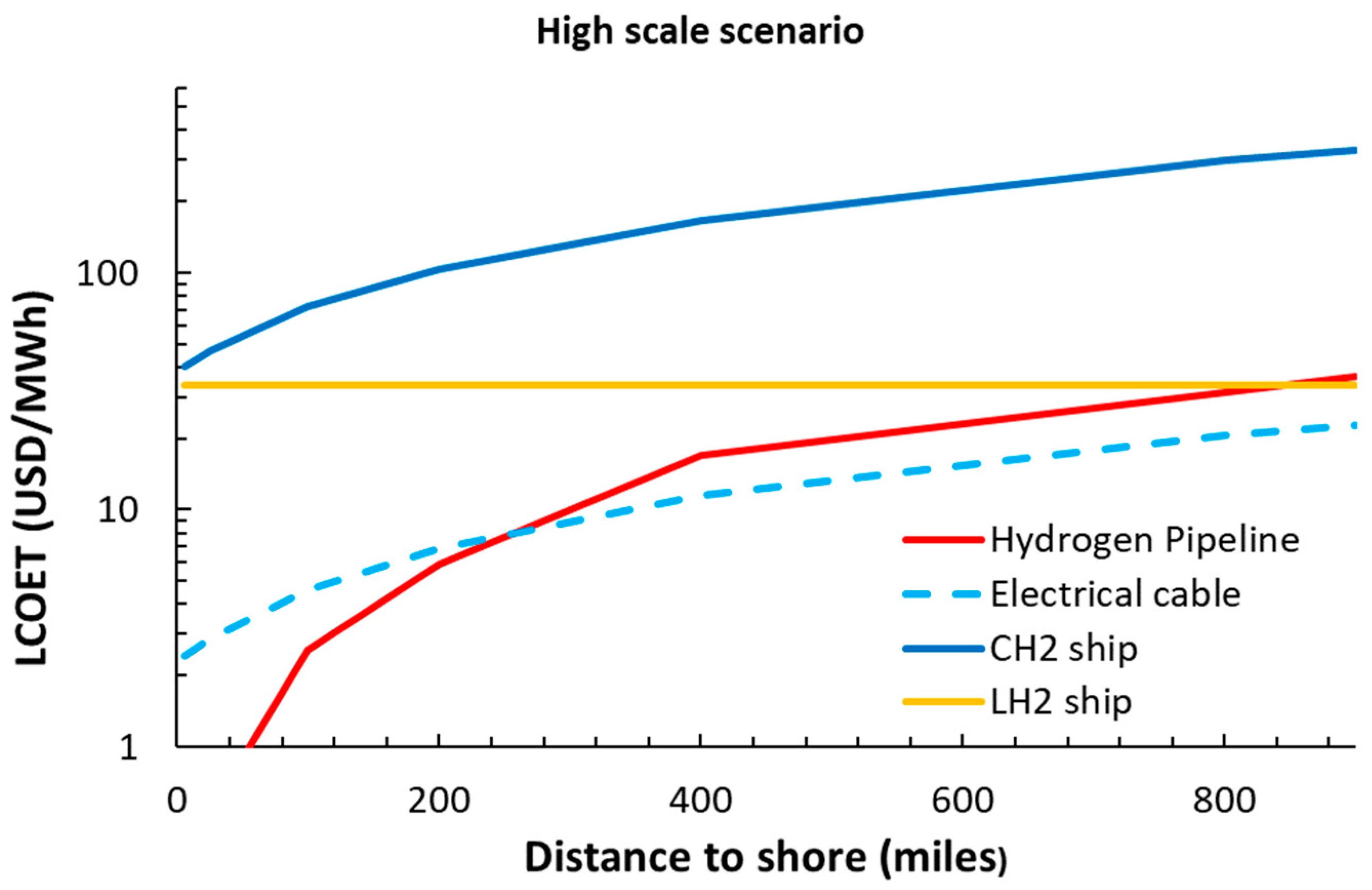

The levelized cost of the energy transport (LCOET) from an offshore location to shore has been evaluated from the classical definition, taking into account CAPEX, OPEX of each transport technology, a 25-years lifetime and a annual capacity factor of 60% to account for the total amount of energy to be evacuated from the offshore plant.

Regarding the Electrical Cable, the infrastructure cost has three different components: the branch cost which represents the cost associated to the cable that joins both end stations, the onshore station cost, and the offshore station cost. The annual O&M is estimated as the 0.67% of the installation cost. The CAPEX for the cost evaluation of a dedicated hydrogen pipeline is divided into cost of materials, cost of construction (survey, pipe laying and other labor costs) and cost associated to engineering, project management, inspection, repair, etc. The total O&M costs, excluding electricity, is estimated around 0, 8% of the total costs of the pipeline. In the case of liquid H2 ships, the CAPEX includes the infrastructure cost of the liquefaction plant, the cost of the storage tanks and the cost associated to the operation of the ships. In this model it has been considered the option of time charter, because it seems the most appropriate charter type for this context. The OPEX is estimated around 3% of the cost of the liquefaction plant and 3% of the storage tanks. For the case of the compressed H2 ship, the CAPEX includes the cost of the compression plant, the storage tanks and the ship charter. Like in the LH2, the considered option is time charter. The annual O&M will be estimated as the 6% of the cost of the compression plant and an O&M cost of 2000 €/year per storage module in the compression plant.

The sizing and unitary cost of the hydrogen transport system depends on the amount of energy to deliver and the distance, what depends on the power capacity of the offshore plant. Two scenarios have been evaluated, a low scale scenario as typical case for a small 21-MW offshore wind farm, and a high scale scenario with a 1-GW wind park. Those evaluations are shown in

Figure 2 and

Figure 3.

Obviously, the cost of the alternatives for offshore hydrogen transport to shore are highly dependent on the scale. That is similar onshore, which main alternative for short distances and capacity is compressed hydrogen by truck. In the case of an offshore facility this option is not available. From the cost analysis, there is a dramatic impact of the amount of yearly energy to deliver, especially for molecule transportation. Direct electric transport to the shore by a subsea cable is the more viable option for a wide range of distances and transmission capacities, with LCOET below 10 $/MWh. For distances below 900 miles (aprox. 1500 km), liquid hydrogen is the less competitive for the low scenario, but it is more competitive than compressed hydrogen when a high transport capacity is demanded, being comparable with subsea cables and pipeline transport for long distances (1500 km and above). For the high capacity scenario, hydrogen transport by pipeline is estimated to be competitive above 350 miles, with a levelized cost of transport between 10 and 20 $/MWh.

7. Conclusions

The introduction of hydrogen is key for the decarbonization of multiple sectors of the economy. It has been shown an analysis of the alternatives for the particular case of producing offshore renewable electricity and its transformation into hydrogen as for shore distribution, including their implementation for maritime transport and port decarbonization. Among the different options analyzed for evacuating hydrogen from offshore renewable energy, the most technically and economically viable option is transporting the renewable electricity generated offshore by submarine cable to land where hydrogen production plant is located. The generation and transport of renewable electricity is a mature and well-known technology, as well as a lower cost and higher maturity of the facilities to produce hydrogen on shore.

In the case of direct hydrogen generation offshore, an alternative option for the evacuation of green hydrogen produced to land is by compressed gaseous hydrogen using subsea pipelines. The use of low alloy steels is preferred for hydrogen transport by pipelines. The ASME B31.12-2019 standard recommends the use of X42 and X52 steel pipes. However, some experts consider that higher grade steels such as X70 steel could be used in the future. Steel pipes, although valid for the transport and distribution of hydrogen blended with natural gas, require a more detailed study for working with 100% hydrogen, mainly caused by the embrittlement effect on the material. Flexible pipes get a considerable reduction in installation and maintenance costs. Due to the current limitations of diameters and admissible pressures for flexible hydrogen pipes, their use would be mostly applicable on a small scale. Plastic lines with higher diameters and operating pressures are expected to be developed in the following years.

Hydrogen transport by ship is intended for long distances, mainly port-to-port. The transport by means of compressed hydrogen is simpler, but it is limited by the small amount of energy that can be transported. Ammonia and LOHC offshore facilities are not recommended due to the complexity and extra costs derived from the construction and O&M. However, it could be needed to use sites further away from the port, due to the lack of space in ports.

Regarding the LCOET comparison between hydrogen transportation by pipeline and by ship, the cost of compressed hydrogen transported by ship is lower than liquid hydrogen for some GWh/year scenario. Following the LCOET, pipelines is the best solution for distances above 450 km for high scale scenario delivering of the order of TWh/year. In opposition to the low scale scenario, liquid hydrogen by ships is more competitive than compressed.

Regarding the hydrogen bunkering, currently, the most viable option is through compressed gaseous hydrogen. Other options such as ammonia or methanol are still under development. In the short term, the hydrogen introduction in maritime applications seems to be suitable for low and medium speed vessels, where energy consumption is moderate and weight is not a very important factor; as well as on short journeys, in which stops in ports are made daily or with a similar frequency. They may also be also applicable for ships destined for navigation in inland or port waters. Liquid hydrogen might be considered when the hydrogen consumption would grow as to transport and deliver hydrogen for high capacity vessels.

Author Contributions

Conceptualization, Enrique Saborit, Alberto Abánades; methodology, Enrique Saborit, Eduardo García-Rosales t; formal analysis, Gema Maria Rodado Nieto; investigation, Pablo Martínez Fondón, Enrique Saborit,, Gema Maria Rodado Nieto; resources, M. Dolores Storch de Gracia.; writing—original draft preparation, Alberto Abánades; writing—review and editing, Enrique Saborit; funding acquisition, M. Dolores Storch de Gracia. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by CDTI (Centre for the Development of Industrial Technology Ministry of Science and Innovation) of Spain. Grant number MIG-20201001, project “Generación, almacenamiento y distribución de hidrógeno verde offshore”.

Data Availability Statement

“Not applicable”.

Conflicts of Interest

“The authors declare no conflict of interest.” “The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results”.

References

- Abánades, A. Perspectives on Hydrogen. Energies 2023, 16. [Google Scholar] [CrossRef]

- Seck, G.S.; Hache, E.; Sabathier, J.; Guedes, F.; Reigstad, G.A.; Straus, J.; Wolfgang, O.; Ouassou, J.A.; Askeland, M.; Hjorth, I.; et al. Hydrogen and the decarbonization of the energy system in europe in 2050: A detailed model-based analysis. Renew. Sustain. Energy Rev. 2022, 167, 112779. [Google Scholar] [CrossRef]

- European Commision Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en.

- Limpens, G.; Jeanmart, H. Electricity storage needs for the energy transition: An EROI based analysis illustrated by the case of Belgium. Energy 2018, 152, 960–973. [Google Scholar] [CrossRef]

- Ehteshami, S.M.M.; Chan, S.H. The role of hydrogen and fuel cells to store renewable energy in the future energy network – potentials and challenges. Energy Policy 2014, 73, 103–109. [Google Scholar] [CrossRef]

- Martinez, A.; Iglesias, G. Mapping of the levelised cost of energy for floating offshore wind in the European Atlantic. Renew. Sustain. Energy Rev. 2022, 154, 111889. [Google Scholar] [CrossRef]

- d’Amore-Domenech, R.; Leo, T.J.; Pollet, B.G. Bulk power transmission at sea: Life cycle cost comparison of electricity and hydrogen as energy vectors. Appl. Energy 2021, 288, 116625. [Google Scholar] [CrossRef]

- Cheng, C.; Hughes, L. The role for offshore wind power in renewable hydrogen production in Australia. J. Clean. Prod. 2023, 391, 136223. [Google Scholar] [CrossRef]

- Ibrahim, O.S.; Singlitico, A.; Proskovics, R.; McDonagh, S.; Desmond, C.; Murphy, J.D. Dedicated large-scale floating offshore wind to hydrogen: Assessing design variables in proposed typologies. Renew. Sustain. Energy Rev. 2022, 160, 112310. [Google Scholar] [CrossRef]

- Otto, M.; Chagoya, K.L.; Blair, R.G.; Hick, S.M.; Kapat, J.S. Optimal hydrogen carrier: Holistic evaluation of hydrogen storage and transportation concepts for power generation, aviation, and transportation. J. Energy Storage 2022, 55, 105714. [Google Scholar] [CrossRef]

- Stadler, P. Cost evaluation of large scale hydrogen production for the aviation industry; 2014. [Google Scholar]

- Al-Enazi, A.; Bicer, Y.; Okonkwo, E.C.; Al-Ansari, T. Evaluating the utilisation of clean fuels in maritime applications: A techno-economic supply chain optimization. Fuel 2022, 322, 124195. [Google Scholar] [CrossRef]

- Seo, Y.; Park, H.; Lee, S.; Kim, J.; Han, S. Design concepts of hydrogen supply chain to bring consumers offshore green hydrogen. Int. J. Hydrogen Energy 2023, 48, 15126–15142. [Google Scholar] [CrossRef]

- Miao, B.; Giordano, L.; Chan, S.H. Long-distance renewable hydrogen transmission via cables and pipelines. Int. J. Hydrogen Energy 2021, 46, 18699–18718. [Google Scholar] [CrossRef]

- Wang, H.; Tong, Z.; Zhou, G.; Zhang, C.; Zhou, H.; Wang, Y.; Zheng, W. Research and demonstration on hydrogen compatibility of pipelines: a review of current status and challenges. Int. J. Hydrogen Energy 2022, 47, 28585–28604. [Google Scholar] [CrossRef]

- Andrews, R.M.; Gallon, N.; Huising, O.J.C. Assessing damaged pipelines transporting hydrogen. J. Pipeline Sci. Eng. 2022, 2, 100066. [Google Scholar] [CrossRef]

- Noh, H.; Kang, K.; Seo, Y. Environmental and energy efficiency assessments of offshore hydrogen supply chains utilizing compressed gaseous hydrogen, liquefied hydrogen, liquid organic hydrogen carriers and ammonia. Int. J. Hydrogen Energy 2023, 48, 7515–7532. [Google Scholar] [CrossRef]

- Damman, S.; Steen, M. A socio-technical perspective on the scope for ports to enable energy transition. Transp. Res. Part D Transp. Environ. 2021, 91, 102691. [Google Scholar] [CrossRef]

- Chen, P.S.-L.; Fan, H.; Enshaei, H.; Zhang, W.; Shi, W.; Abdussamie, N.; Miwa, T.; Qu, Z.; Yang, Z. A review on ports’ readiness to facilitate international hydrogen trade. Int. J. Hydrogen Energy 2023, 48, 17351–17369. [Google Scholar] [CrossRef]

- Al-Enazi, A.; Okonkwo, E.C.; Bicer, Y.; Al-Ansari, T. A review of cleaner alternative fuels for maritime transportation. Energy Reports 2021, 7, 1962–1985. [Google Scholar] [CrossRef]

- Aneziris, O.; Gerbec, M.; Koromila, I.; Nivolianitou, Z.; Pilo, F.; Salzano, E. Safety guidelines and a training framework for LNG storage and bunkering at ports. Saf. Sci. 2021, 138, 105212. [Google Scholar] [CrossRef]

- Cristello, J.B.; Yang, J.M.; Hugo, R.; Lee, Y.; Park, S.S. Feasibility analysis of blending hydrogen into natural gas networks. Int. J. Hydrogen Energy 2023, 48, 17605–17629. [Google Scholar] [CrossRef]

- Bosu, S.; Rajamohan, N. Recent advancements in hydrogen storage - Comparative review on methods, operating conditions and challenges. Int. J. Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Bilgili, L. A systematic review on the acceptance of alternative marine fuels. Renew. Sustain. Energy Rev. 2023, 182, 113367. [Google Scholar] [CrossRef]

- Nogueira, A.C.; Mckeehan, D.S. Chapter 11 - Design and Construction of Offshore Pipelines; CHAKRABARTI, S.K.B.T.-H. of O.E., Ed.; Elsevier: London, 2005; pp. 891–937. ISBN 978-0-08-044381-2. [Google Scholar]

- Li, H.; Niu, R.; Li, W.; Lu, H.; Cairney, J.; Chen, Y.-S. Hydrogen in pipeline steels: Recent advances in characterization and embrittlement mitigation. J. Nat. Gas Sci. Eng. 2022, 105, 104709. [Google Scholar] [CrossRef]

- Liu, C.; Yang, H.; Wang, C.; Zhang, H.; Ding, R.; Ai, L.; Fan, X.; Zhang, R.; Xu, X.; Ning, Y.; et al. Effects of CH4 and CO on hydrogen embrittlement susceptibility of X80 pipeline steel in hydrogen blended natural gas. Int. J. Hydrogen Energy 2023. [Google Scholar] [CrossRef]

- Laureys, A.; Depraetere, R.; Cauwels, M.; Depover, T.; Hertelé, S.; Verbeken, K. Use of existing steel pipeline infrastructure for gaseous hydrogen storage and transport: A review of factors affecting hydrogen induced degradation. J. Nat. Gas Sci. Eng. 2022, 101, 104534. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S. Economic Analysis on Hydrogen Pipeline Infrastructure Establishment Scenarios: Case Study of South Korea. Energies 2022, 15. [Google Scholar] [CrossRef]

- Yang, C.; Ogden, J. Determining the lowest-cost hydrogen delivery mode. Int. J. Hydrogen Energy 2007, 32, 268–286. [Google Scholar] [CrossRef]

- Ratnakar, R.R.; Gupta, N.; Zhang, K.; van Doorne, C.; Fesmire, J.; Dindoruk, B.; Balakotaiah, V. Hydrogen supply chain and challenges in large-scale LH2 storage and transportation. Int. J. Hydrogen Energy 2021, 46, 24149–24168. [Google Scholar] [CrossRef]

- Ustolin, F.; Campari, A.; Taccani, R. An Extensive Review of Liquid Hydrogen in Transportation with Focus on the Maritime Sector. J. Mar. Sci. Eng. 2022, 10. [Google Scholar] [CrossRef]

- Bloomberg. Hydrogen Economy Outlook Key messages; 2020. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).