Submitted:

29 June 2023

Posted:

30 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Experimental design

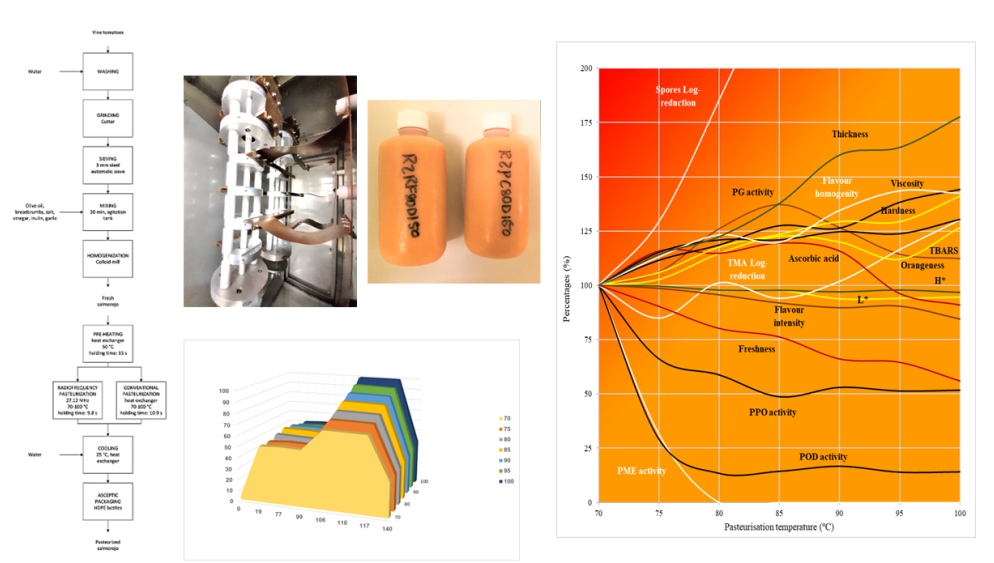

2.2. Salmorejo ingredients and manufacturing process

2.3. Microbiological analyses

2.4. Pasteurisation conditions

2.5. Enzyme relative activities

2.6. Physicochemical analyses

2.7. Sensory analysis

3. Results

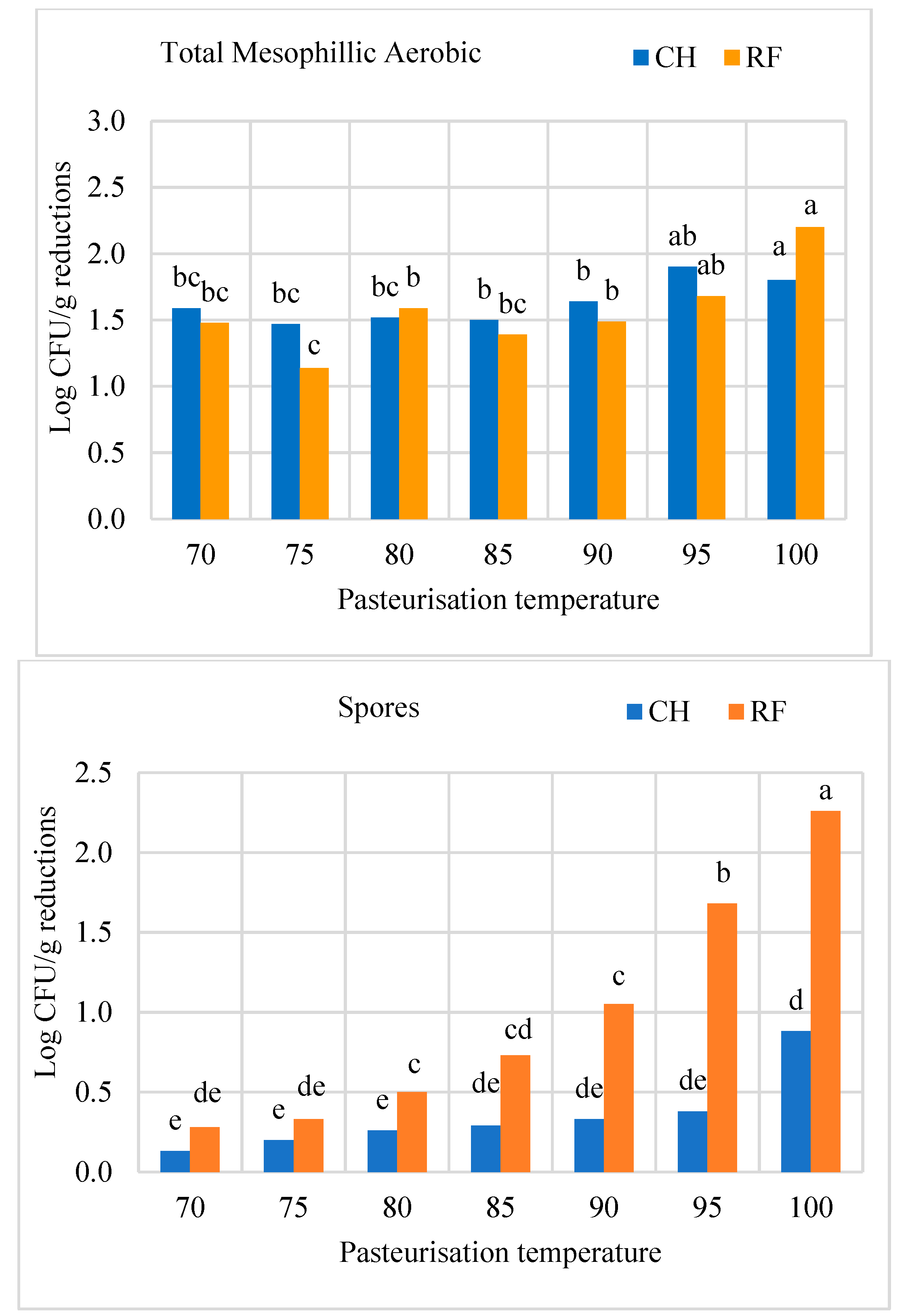

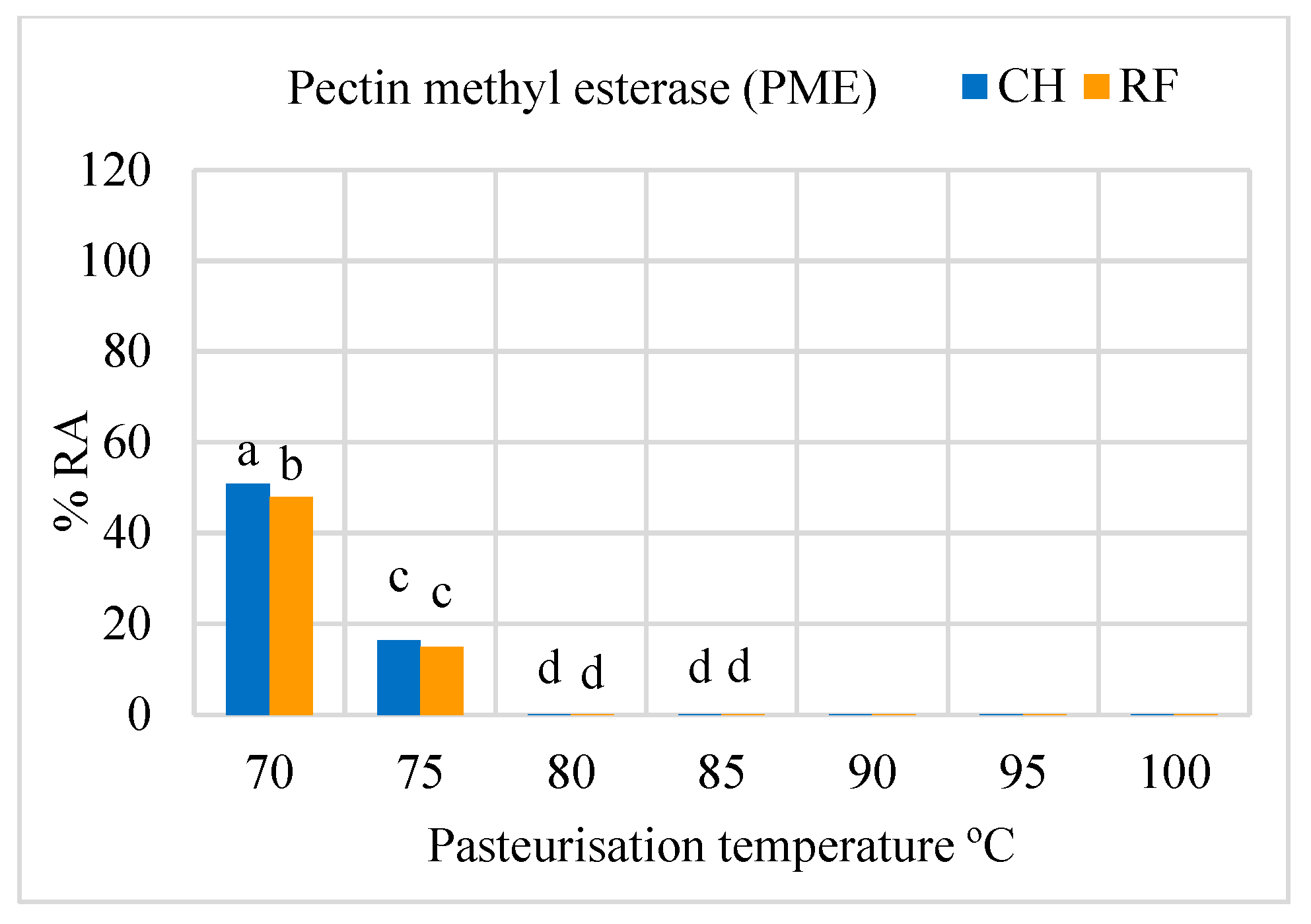

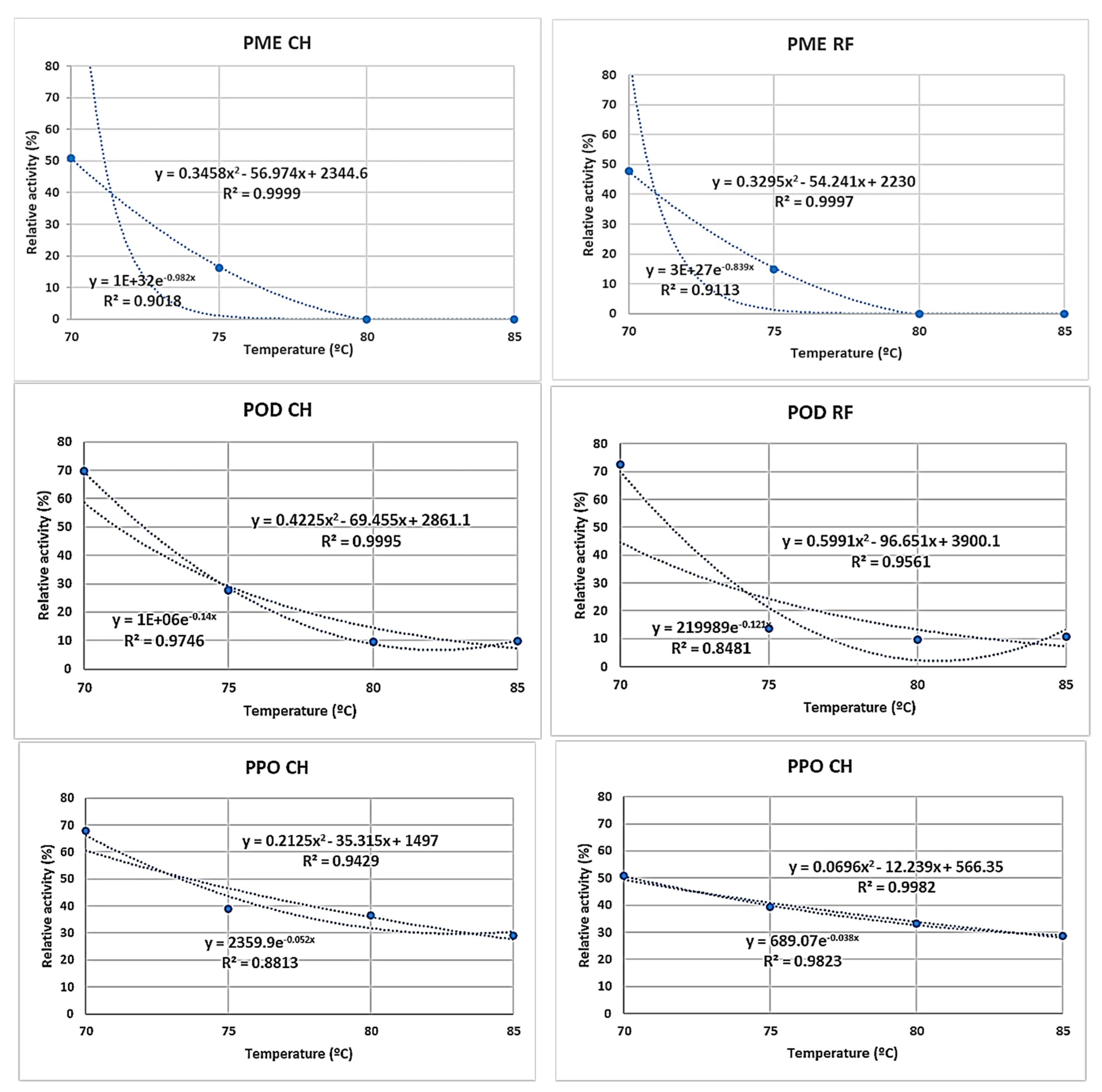

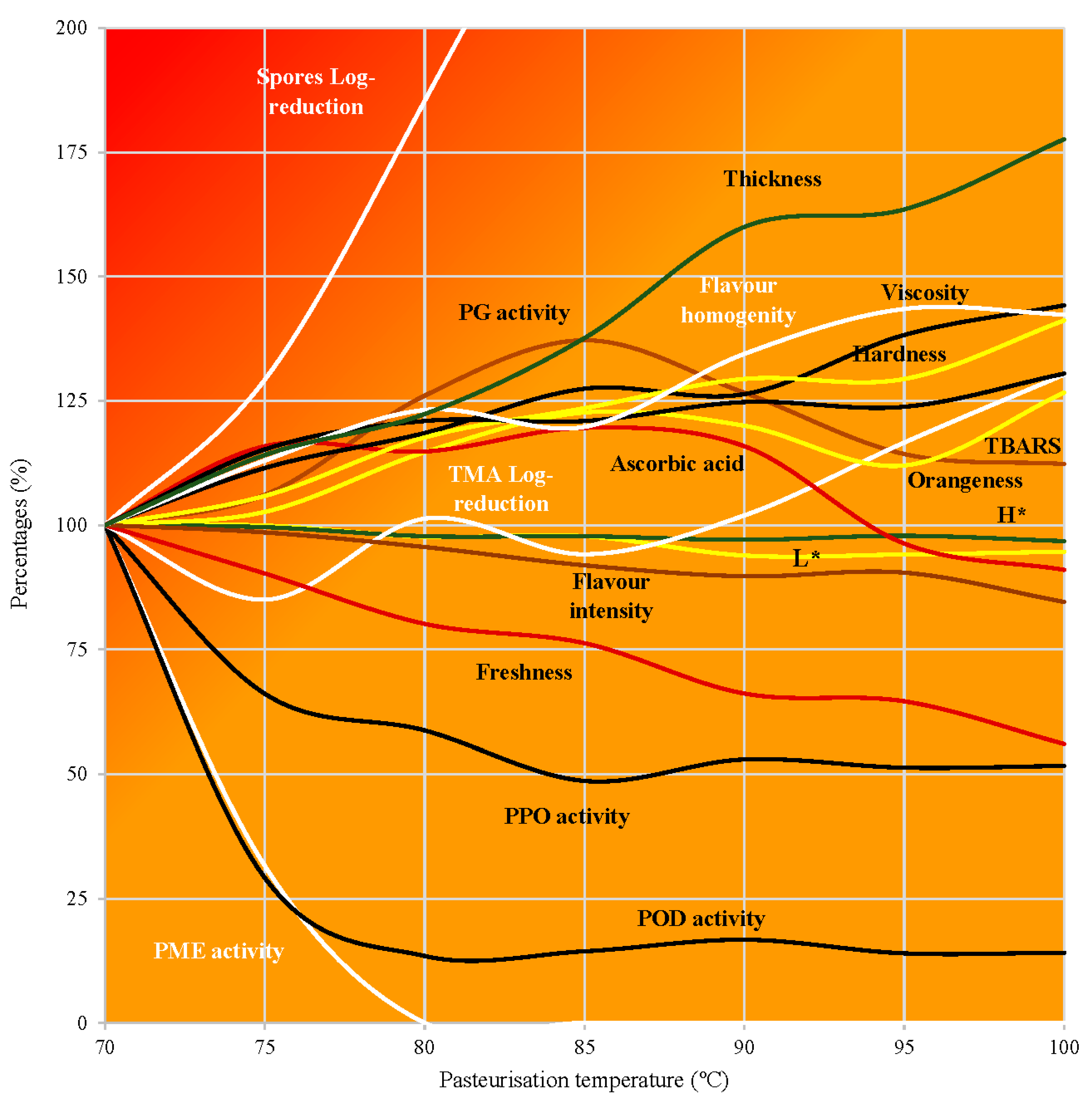

3.1. Microbiological and enzyme inactivation

3.2. Thermal damage

3.3. Sensory changes

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alimarket Informe 2022 Del Mercado de Gazpachos y Cremas Refrigeradas En España. Available online: https://www.alimarket.es/alimentacion/informe/353959/informe-2022-del-mercado-de-gazpachos-y-cremas-refrigeradas-en-espana.

- Pinilla, M.J.; Plaza, L.; Sánchez-Moreno, C.; De Ancos, B.; Cano, M.P. Hydrophilic and Lipophilic Antioxidant Capacities of Commercial Mediterranean Vegetable Soups (Gazpachos). J. Food Sci. 2005, 70. [Google Scholar] [CrossRef]

- Vioque, M.; de la Cruz-Ares, S.; Gómez, R. Preliminary Investigation on the Physicochemical and Functional Properties of Commercial Salmorejo Found in Spanish Supermarkets. Foods 2021, 10. [Google Scholar] [CrossRef] [PubMed]

- Lopez, P.; Sanchez, A.; Vercet, A. Thermal Resistance of Tomato Polygalacturonase and Pectinmethylesterase at Physiological PH. Z Leb. Unters Forsch A 1997, 204, 146–150. [Google Scholar] [CrossRef]

- Crelier, S.; Robert, M.-C.; Claude, J.; Juillerat, M.-A. Tomato (Lycopersicon Esculentum) Pectin Methylesterase and Polygalacturonase Behaviors Regarding Heat-and Pressure-Induced Inactivation. 2001. [CrossRef]

- Stoforos, N.G.; Crelier, S.; Robert, M.C.; Taoukis, P.S. Kinetics of Tomato Pectin Methylesterase Inactivation by Temperature and High Pressure. J. Food Sci. 2002, 67, 1026–1031. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Soliva-Fortuny, R.; Martín-Belloso, O. Comparative Study on Color, Viscosity and Related Enzymes of Tomato Juice Treated by High-Intensity Pulsed Electric Fields or Heat. Eur. Food Res. Technol. 2008, 227, 599–606. [Google Scholar] [CrossRef]

- Mannozzi, C.; Rompoonpol, K.; Fauster, T.; Tylewicz, U.; Romani, S.; Rosa, M.D.; Jaeger, H. Influence of Pulsed Electric Field and Ohmic Heating Pretreatments on Enzyme and Antioxidant Activity of Fruit and Vegetable Juices. Foods 2019, 8. [Google Scholar] [CrossRef]

- Stratakos, A.C.; Delgado-Pando, G.; Linton, M.; Patterson, M.F.; Koidis, A. Industrial Scale Microwave Processing of Tomato Juice Using a Novel Continuous Microwave System. Food Chem. 2016, 190, 622–628. [Google Scholar] [CrossRef]

- Arjmandi, M.; Otón, M.; Artés, F.; Artés-Hernández, F.; Gómez, P.; Aguayo, E. Microwave Flow and Conventional Heating Effects on the Physicochemical Properties, Bioactive Compounds and Enzymatic Activity of Tomato Puree. J. Sci. Food Agric. 2017, 97, 984–990. [Google Scholar] [CrossRef]

- Pérez-Tejeda, G.; Vergara-Balderas, F.T.; López-Malo, A.; Rojas-Laguna, R.; Abraham-Juárez, M. del R.; Sosa-Morales, M.E. Pasteurization Treatments for Tomato Puree Using Conventional or Microwave Processes. J. Microw. Power Electromagn. Energy 2016, 50, 35–42. [Google Scholar] [CrossRef]

- Arjmandi, M.; Otón, M.; Artés, F.; Artés-Hernández, F.; Gómez, P.; Aguayo, E. Continuous Microwave Pasteurization of a Vegetable Smoothie Improves Its Physical Quality and Hinders Detrimental Enzyme Activity. Food Sci. Technol. Int. 2017, 23, 36–45. [Google Scholar] [CrossRef] [PubMed]

- Makroo, H.A.; Rastogi, N.K.; Srivastava, B. Enzyme Inactivation of Tomato Juice by Ohmic Heating and Its Effects on Physico-Chemical Characteristics of Concentrated Tomato Paste. J. Food Process Eng. 2017, 40, 1–10. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frigola, A. Ascorbic Acid Is the Only Bioactive That Is Better Preserved by High Hydrostatic Pressure than by Thermal Treatment of a Vegetable Beverage. J. Agric. Food Chem. 2010, 58, 10070–10075. [Google Scholar] [CrossRef]

- Odriozola-Serrano, I.; Soliva-Fortuny, R.; Martín-Belloso, O. Changes of Health-Related Compounds throughout Cold Storage of Tomato Juice Stabilized by Thermal or High Intensity Pulsed Electric Field Treatments. Innov. Food Sci. Emerg. Technol. 2008, 9, 272–279. [Google Scholar] [CrossRef]

- Elez-Martínez, P.; Suárez-Recio, M.; Martín-Belloso, O. Modeling the Reduction of Pectin Methyl Esterase Activity in Orange Juice by High Intensity Pulsed Electric Fields. J. Food Eng. 2007, 78, 184–193. [Google Scholar] [CrossRef]

- Moejes, S.N.; van Boxtel, A.J.B. Energy Saving Potential of Emerging Technologies in Milk Powder Production. Trends Food Sci. Technol. 2017, 60, 31–42. [Google Scholar] [CrossRef]

- Tuta, S.; Palazoğlu, T.K. Finite Element Modeling of Continuous-Flow Microwave Heating of Fluid Foods and Experimental Validation. J. Food Eng. 2017, 192, 79–92. [Google Scholar] [CrossRef]

- Ahmed, J.; Ramaswamy, H.S. Microwave Pasteurization and Sterilization of Foods. In Handbook of Food Preservation; Rahman, M.S., Ed.; Boca Raton, 2007; pp. 691–712. [Google Scholar]

- Probst, L.; Frideres, L.; Pedersen, B.; Amato, F.; Luxembourg, P. Sustainable, Safe and Nutritious Food; European, Union, Ed.; 2015. [Google Scholar]

- Abea, A.; Gou, P.; Guàrdia, M.D.; Picouet, P.; Kravets, M.; Bañón, S.; Muñoz, I. Dielectric Heating: A Review of Liquid Foods Processing Applications. Food Rev. Int. 2022, 1–19. [Google Scholar] [CrossRef]

- Salazar-González, C.; Martín-González, M.F.S.; López-Malo, A.; Sosa-Morales, M.E. Recent Studies Related to Microwave Processing of Fluid Foods. Food Bioprocess Technol. 2012, 5, 31–46. [Google Scholar] [CrossRef]

- Vadivambal, R.; Jayas, D.S. Non-Uniform Temperature Distribution during Microwave Heating of Food Materials-A Review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Kumar, P.; Coronel, P.; Truong, V.D.; Simunovic, J.; Swartzel, K.R.; Sandeep, K.P.; Cartwright, G. Overcoming Issues Associated with the Scale-up of a Continuous Flow Microwave System for Aseptic Processing of Vegetable Purees. Food Res. Int. 2008, 41, 454–461. [Google Scholar] [CrossRef]

- Kubo, M.T.K.; Curet, S.; Augusto, P.E.D.; Boillereaux, L. Multiphysics Modeling of Microwave Processing for Enzyme Inactivation in Fruit Juices. J. Food Eng. 2019, 263, 366–379. [Google Scholar] [CrossRef]

- Yu, J.; Gleize, B.; Zhang, L.; Caris-Veyrat, C.; Renard, C.M.G.C. Microwave Heating of Tomato Puree in the Presence of Onion and EVOO: The Effect on Lycopene Isomerization and Transfer into Oil. Lwt 2019, 113, 108284. [Google Scholar] [CrossRef]

- Kim, W.J.; Park, S.H.; Kang, D.H. Inactivation of Foodborne Pathogens Influenced by Dielectric Properties, Relevant to Sugar Contents, in Chili Sauce by 915 MHz Microwaves. LWT 2018, 96, 111–118. [Google Scholar] [CrossRef]

- Lyu, X.; Peng, X.; Wang, S.; Yang, B.; Wang, X.; Yang, H.; Xiao, Y.; Baloch, A.B.; Xia, X. Quality and Consumer Acceptance of Radio Frequency and Traditional Heat Pasteurised Kiwi Puree during Storage. Int. J. Food Sci. Technol. 2018, 53, 209–218. [Google Scholar] [CrossRef]

- Siefarth, C.; Tran, T.B.T.; Mittermaier, P.; Pfeiffer, T.; Buettner, A. Effect of Radio Frequency Heating on Yoghurt, i: Technological Applicability, Shelf-Life and Sensorial Quality. Foods 2014, 3, 318–335. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, D.; Zhou, X.; Cui, Y.; Jiao, S.; Shi, X. Development of a Pasteurization Method Based on Radio Frequency Heating to Ensure Microbiological Safety of Liquid Egg. Food Control 2021, 123, 107035. [Google Scholar] [CrossRef]

- Muñoz, I.; de Sousa, D.A.B.; Guardia, M.D.; Rodriguez, C.J.; Nunes, M.L.; Oliveira, H.; Cunha, S.C.; Casal, S.; Marques, A.; Cabado, A.G. Comparison of Different Technologies (Conventional Thermal Processing, Radiofrequency Heating and High-Pressure Processing) in Combination with Thermal Solar Energy for High Quality and Sustainable Fish Soup Pasteurization. Food Bioprocess Technol. 2022, 15, 795–805. [Google Scholar] [CrossRef]

- Ramaswamy, H.; Tang, J. Microwave and Radio Frequency Heating:. 2008, 14, 423–427. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, Y.; Cui, B.; Fu, H.; Chen, X.; Wang, Y. Radio Frequency Energy Inactivates Peroxidase in Stem Lettuce at Different Heating Rates and Associate Changes in Physiochemical Properties and Cell Morphology. Food Chem. 2021, 342, 128360. [Google Scholar] [CrossRef]

- Arjmandi, M.; Otón, M.; Artés-Hernández, F.; Gómez, P.A.; Artés, F.; Aguayo, E. Effect of Microwave Treatments on the Quality of a Smoothie. Acta Hortic. 2018, 1194, 1481–1486. [Google Scholar] [CrossRef]

- Igual, M.; García-Martínez, E.; Camacho, M.M.; Martínez-Navarrete, N. Effect of Thermal Treatment and Storage on the Stability of Organic Acids and the Functional Value of Grapefruit Juice. Food Chem. 2010, 118, 291–299. [Google Scholar] [CrossRef]

- Marszałek, K.; Mitek, M.; Skąpska, S. Effect of Continuous Flow Microwave and Conventional Heating on the Bioactive Compounds, Colour, Enzymes Activity, Microbial and Sensory Quality of Strawberry Purée. Food Bioprocess Technol. 2015, 8, 1864–1876. [Google Scholar] [CrossRef]

- Brugos, A.F.O.; Gut, J.A.W.; Tadini, C.C. Inactivation Kinetics of Pectin Methyl Esterase in the Microwave-Assisted Pasteurization of Orange Juice. Lwt 2018, 97, 603–609. [Google Scholar] [CrossRef]

- Calero-Pastor, M.; Clemente, G.; Fartdinov, D.; Bañon, S.; Muñoz, I.; Sanjuán, N. Upscaling via a Prospective LCA: A Case Study on Tomato Homogenate Using a Near-to-Market Pasteurisation Technology. Sustain. 2022, 14, 1–27. [Google Scholar] [CrossRef]

- Abea, A.; Gou, P.; Guardia, M.D.; Bañon, S.; Muñoz, I. Combined Effect of Temperature and Oil and Salt Contents on the Variation of Dielectric Properties of a Tomato-Based Homogenate. Foods 2021, 10, 3124. [Google Scholar] [CrossRef]

- Abea, A.; Kravets, M.; Gou, P.; Guàrdia, M.D.; Felipe, X.; Bañón, S.; Muñoz, I. Modeling of Radio Frequency Heating of Packed Fluid Foods Moving on a Conveyor Belt: A Case Study for Tomato Puree. Innov. Food Sci. Emerg. Technol. 2023, 86, 103386. [Google Scholar] [CrossRef]

- ISO 4833-1 International Organization for Standarization. Microbiology of the food chain — Horizontal method for the enumeration of microorganisms — Part 1: Colony count at 30 °C by the pour plate technique. (ISO 4833-1). https://www.iso.org/standard/53728.html.

- Encyclopedia of Food Microbiology. Encyclopedia of Food Microbiology. In Encyclopedia of Food Microbiology; Robinson, R.K., Batt, C.A., Pradip, P.B., Eds.; Academic P.; A Harcourt Science and Technology Company London,, 2000; ISBN 0-12-227070-3. [Google Scholar]

- Dufort, E.L.; Etzel, M.R.; Ingham, B.H. Thermal Processing Parameters to Ensure a 5-Log Reduction of Escherichia Coli O157:H7, Salmonella Enterica, and Listeria Monocytogenes in Acidified Tomato-Based Foods. Food Prot. Trends 2017, 37, 409–418. [Google Scholar]

- Fachin, D.; Van Loey, A.M.; Ly Nguyen, B.; Verlent, I.; Indrawati, A.; Hendrickx, M.E. Inactivation Kinetics of Polygalacturonase in Tomato Juice. Innov. Food Sci. Emerg. Technol. 2003, 4, 135–142. [Google Scholar] [CrossRef]

- Vervoort, L.; Van Der Plancken, I.; Grauwet, T.; Verlinde, P.; Matser, A.; Hendrickx, M.; Van Loey, A. Thermal versus High Pressure Processing of Carrots: A Comparative Pilot-Scale Study on Equivalent Basis. Innov. Food Sci. Emerg. Technol. 2012, 15, 1–13. [Google Scholar] [CrossRef]

- Sánchez-Mata, M.C.; Cámara-Hurtado, M.; Díez-Marqués, C.; Torija-Isasa, M.E. Comparison of High-Performance Liquid Chromatography and Spectrofluorimetry for Vitamin C Analysis of Green Beans (Phaseolus Vulgaris L.). Eur. Food Res. Technol. 2000, 210, 220–225. [Google Scholar] [CrossRef]

- Botsoglou, N.A.; Fletouris, D.J.; Papageorgiou, G.E.; Vassilopoulos, V.N.; Mantis, A.J.; Trakatellis5, A.G. Rapid, Sensitive, and Specific Thiobarbituric Acid Method for Measuring Lipid Peroxidation in Animal Tissue, Food, and Feedstuff Samples. Food Chem 1994, 42, 1931–1937. [Google Scholar] [CrossRef]

- AOAC, A. of O.A.C. Official Methods of Analysis of AOAC International, 1990. [Google Scholar]

- ISO 8586-1:1993 - Sensory Analysis — General Guidance for the Selection, Training and Monitoring of Assessors — Part 1: Selected Assessors.

- ISO 8586-2:1994 - Sensory Analysis — General Guidance for the Selection, Training and Monitoring of Assessors — Part 2: Experts.

- Macfie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L. V. Designs to Balance the Effect of Order of Presentation and First-Order Carry-over Effects in Hall Tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- FDA Guidance for Industry: Juice Hazard Analysis Critical Control Point Hazards and Controls Guidance, First Edition | FDA; Department of Health and Human Services, Food and Drug Administration. Ce: US, 2004.

- Lamya, D. Efecto De Las Altas Presiones Hidrostáticas Sobre El Gazpacho Y Zumo De Uva, (Tesis Doctoral). Universidad Autónoma de Barcelona. Barcelona-España, 2004.

- Kessler, H.G. Lebensmittel- Und Bioverfahrenstechnik -Molkereitechnologie; Verlag, A., Kessler, K., Eds.; München, 2006.

- Putnik, P.; Bursać Kovačević, D.; Herceg, K.; Levaj, B. Influence of Antibrowning Solutions, Air Exposure, and Ultrasound on Color Changes in Fresh-Cut Apples during Storage. J. Food Process. Preserv. 2017, 41. [Google Scholar] [CrossRef]

- Spagna, G.; Barbagallo, R.N.; Chisari, M.; Branca, F. Characterization of a Tomato Polyphenol Oxidase and Its Role in Browning and Lycopene Content. J. Agric. Food Chem. 2005, 53, 2032–2038. [Google Scholar] [CrossRef] [PubMed]

- Ramesh, M.N. Pasteurization and Food Preservation. In Handbook of Food Preservation; CRC Press, Boca Raton: FL, 2007; pp. 571–585. [Google Scholar]

- Picouet, P.A.; Hurtado, A.; Jofré, A.; Bañon, S.; Ros, J.M.; Guàrdia, M.D. Effects of Thermal and High-Pressure Treatments on the Microbiological, Nutritional and Sensory Quality of a Multi-Fruit Smoothie. Food Bioprocess Technol. 2016, 9, 1219–1232. [Google Scholar] [CrossRef]

- Beegum, S.; Sagar, V.R.; Kar, A.; Varghese, E.; Singh, S.; Neema, M.; Prakash, K.; Aparna, V. Effect of Pasteurization Methods on Enzyme Activities, Microbial and Sensory Evaluations in Ready to Serve Watermelon Juice (Citrullus Lanatus). Int.J.Curr.Microbiol.App.Sci 2019, 8, 2708–2717. [Google Scholar] [CrossRef]

- Anthon, G.E.; Sekine, Y.; Watanabe, N.; Barrett, D.M. Thermal Inactivation of Pectin Methylesterase, Polygalacturonase, and Peroxidase in Tomato Juice. J. Agric. Food Chem. 2002, 50, 6153–6159. [Google Scholar] [CrossRef]

- Mantovani, C.; Clémente, E. Peroxidase and Polyphenoloxidase Activity in Tomato in Natura and Tomato Purée. Acta Sci. - Technol. 2010, 32, 91–97. [Google Scholar] [CrossRef]

- López, P.; Sánchez, A.C.; Vercet, A.; Burgos, J. Thermal Resistance of Tomato Polygalacturonase and Pectinmethylesterase at Physiological PH. Zeitschrift fur Leb. -Untersuchung und -forsch. 1997, 204, 146–150. [Google Scholar] [CrossRef]

- Houben, K.; Jamsazzadeh Kermani, Z.; Van Buggenhout, S.; Jolie, R.P.; Van Loey, A.M.; Hendrickx, M.E. Thermal and High-Pressure Stability of Pectinmethylesterase, Polygalacturonase, β-Galactosidase and α-Arabinofuranosidase in a Tomato Matrix: Towards the Creation of Specific Endogenous Enzyme Populations Through Processing. Food Bioprocess Technol. 2013, 6, 3368–3380. [Google Scholar] [CrossRef]

- Terefe, N.S.; Gamage, M.; Vilkhu, K.; Simons, L.; Mawson, R.; Versteeg, C. The Kinetics of Inactivation of Pectin Methylesterase and Polygalacturonase in Tomato Juice by Thermosonication. Food Chem. 2009, 117, 20–27. [Google Scholar] [CrossRef]

- Vigneshwaran, G.; More, P.R.; Arya, S.S. Non-Thermal Hydrodynamic Cavitation Processing of Tomato Juice for Physicochemical, Bioactive, and Enzyme Stability: Effect of Process Conditions, Kinetics, and Shelf-Life Extension. Curr. Res. Food Sci. 2022, 5, 313–324. [Google Scholar] [CrossRef] [PubMed]

- Anthon, G.E.; Sekine, Y.; Watanabe, N.; Barrett, D.M. Thermal Inactivation of Pectin Methylesterase in Tomato Homogenate. J. Agric. Food Chemestry 2002, 50, 6153–6159. [Google Scholar] [CrossRef]

- Terefe, N.S.; Gamage, M.; Vilkhu, K.; Simons, L.; Mawson, R.; Versteeg, C. The Kinetics of Inactivation of Pectin Methylesterase and Polygalacturonase in Tomato Juice by Thermosonication. Food Chem. 2009, 117, 20–27. [Google Scholar] [CrossRef]

- Wang, J.; Law, C.L.; Mujumdar, A.S.; Xiao, H.-W. The Degradation Mechanism and Kinetics of Vitamin C in Fruits and Vegetables During Thermal Processing Innovative Drying, Blanching, Osmotic Dehydration Technologies and Mechanisms View Project Ministry of Agriculture (MoA) Funding View Project The Degrad. In Drying Technologies for Foods; 2017; pp. 275–301.

- Elez-Martínez, P.; Martín-Belloso, O. Effects of High Intensity Pulsed Electric Field Processing Conditions on Vitamin C and Antioxidant Capacity of Orange Juice and Gazpacho, a Cold Vegetable Soup. Food Chem. 2007, 102, 201–209. [Google Scholar] [CrossRef]

- Odriozola-Serrano, I.; Aguiló-Aguayo, I.; Soliva-Fortuny, R.; Gimeno-Añó, V.; Martín-Belloso, O. Lycopene, Vitamin C, and Antioxidant Capacity of Tomato Juice as Affected by High-Intensity Pulsed Electric Fields Critical Parameters. J. Agric. Food Chem. 2007, 55, 9036–9042. [Google Scholar] [CrossRef]

- Sánchez-Moreno, C.; Plaza, L.; De Ancos, B.; Cano, M.P. Impact of High-Pressure and Traditional Thermal Processing of Tomato Purée on Carotenoids, Vitamin C and Antioxidant Activity. J. Sci. Food Agric. 2006, 86, 171–179. [Google Scholar] [CrossRef]

- Pérez-Conesa, D.; García-Alonso, J.; García-Valverde, V.; Iniesta, M.D.; Jacob, K.; Sánchez-Siles, L.M.; Ros, G.; Periago, M.J. Changes in Bioactive Compounds and Antioxidant Activity during Homogenization and Thermal Processing of Tomato Puree. Innov. Food Sci. Emerg. Technol. 2009, 10, 179–188. [Google Scholar] [CrossRef]

- Arjmandi, M.; Otón, M.; Artés, F.; Artés-Hernández, F.; Gómez, P.A.; Aguayo, E. Semi-Industrial Microwave Treatments Positively Affect the Quality of Orange-Colored Smoothies. J. Food Sci. Technol. 2016, 53, 3695. [Google Scholar] [CrossRef]

- Koltun, S.J.; MacIntosh, A.J.; Goodrich-Schneider, R.M.; Klee, H.J.; Hutton, S.F.; Sarnoski, P.J. Sensory and Chemical Characteristics of Tomato Juice from Fresh Market Cultivars with Comparison to Commercial Tomato Juice. Flavour Fragr. J. 2021, 36, 121–136. [Google Scholar] [CrossRef]

- Zhu, Y.; Sims, C.A.; Klee, H.J.; Sarnoski, P.J. Sensory and Flavor Characteristics of Tomato Juice from Garden Gem and Roma Tomatoes with Comparison to Commercial Tomato Juice. J. Food Sci. 2018, 83, 153–161. [Google Scholar] [CrossRef]

- Viljanen, K.; Lille, M.; Heiniö, R.L.; Buchert, J. Effect of High-Pressure Processing on Volatile Composition and Odour of Cherry Tomato Purée. Food Chem. 2011, 129, 1759–1765. [Google Scholar] [CrossRef]

- Aguiló-Aguayo, I.; Odriozola-Serrano, I.; Quintão-Teixeira, L.J.; Martín-Belloso, O. Inactivation of Tomato Juice Peroxidase by High-Intensity Pulsed Electric Fields as Affected by Process Conditions. Food Chem. 2008, 107, 949–955. [Google Scholar] [CrossRef]

- Nisha, P.; Singhal, R.S.; Pandit, A.B. Kinetic Modelling of Colour Degradation in Tomato Puree (Lycopersicon Esculentum L.). Food Bioprocess Technol. 2011, 4, 781–787. [Google Scholar] [CrossRef]

- Shi, J.; Wu, Y.; Bryan, M.; Le Marc, M. Oxidation and Isomerization of Lycopene under Thermal Treatment and Light Irradiation in Food Processing. Prev. Nutr. Food Sci. 2002, 7, 179–183. [Google Scholar] [CrossRef]

- Dutta, C.; Chowdhury, B.R.; Chakraborty, R.; Raychaudhuri, U. Incorporation of Turmeric-Lime Mixture during the Preparation of Tomato Puree. African J. Biotechnol. 2007, 6, 795–798. [Google Scholar] [CrossRef]

- Illera, A.E.; Sanz, M.T.; Trigueros, E.; Beltrán, S.; Melgosa, R. Effect of High Pressure Carbon Dioxide on Tomato Juice: Inactivation Kinetics of Pectin Methylesterase and Polygalacturonase and Determination of Other Quality Parameters. J. Food Eng. 2018, 239, 64–71. [Google Scholar] [CrossRef]

- Kaur, C.; George, B.; Jaggi, S.; Kapoor, H. Viscosity and Quality of Tomato Juice as Affected by Processing Methods. J. Food Qual. 2007, 30, 864–877. [Google Scholar] [CrossRef]

| Attributes1 | Definition |

|---|---|

| Appearance | |

| Orange colour | Intensity of orange colour |

| Smooth surface | Intensity of homogeneous and soft surface |

| Odour/flavour | |

| Intensity | Intensity of overall odour/flavour |

| Tomato | Intensity of tomato odour/flavour |

| Garlic | Intensity of garlic odour/flavour |

| Vinegar | Intensity of vinegar odour/flavour |

| Homogeneity | Odour in which no attribute stands out |

| Fresh | Intensity of odour/flavour which corresponds to a freshly made product |

| Acidity | Basic taste sensation elicited by citric acid |

| Non-oral texture | |

| Viscosity with spoon | Difficulty with which salmorejo flows using a teaspoon |

| Oral texture | |

| Mouth-feel | Degree to which juice is thick, coats the mouth and difficulty to swallow |

| Temperature ºC | Raw | 70 | 75 | 80 | 85 | 90 | 95 | 100 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| M | M | M | M | M | M | M | M | RMSE | ||

| pH | CH | 3.60 | 3.86 a | 3.82 ab | 3.82 ab | 3.79 b | 3.85 a | 3.85 a | 3.83 a | 0.01 |

| RF | 3.59 | 3.83 ab | 3.80 ab | 3.80 ab | 3.80 ab | 3.79 b | 3.82 ab | 3.79 b | ||

| D-ascorbic acid | CH | 12.2 | 9.2 b | 10.7 a | 11.3 a | 11.7 a | 10.1 a | 8.4 b | 9.7 b | 0.12 |

| mg 100 ml-1 | RF | 14.8 | 9.7 b | 11.2 a | 10.4 a | 10.9 a | 11.9 a | 9.8 ab | 7.5 c | |

| TBARS | CH | 0.37 | 0.38 b | 0.39 b | 0.43 ab | 0.46 ab | 0.45 ab | 0.42 ab | 0.51a | 0.01 |

| mg MDA Kg-1 | RF | 0.33 | 0.37 b | 0.38 b | 0.43 ab | 0.46 ab | 0.45 ab | 0.42 ab | 0.44 ab | |

| Lightness | CH | 47.2 | 58.5 a | 57.9 ab | 56.4 ab | 56.6 ab | 55.0 b | 55.8 b | 55.6 b | 0.50 |

| CIE L* | RF | 48.1 | 59.3 a | 59.6 a | 58.4 a | 58.3 a | 55.3 b | 54.8 b | 55.7 b | |

| Redness | CH | 21.2 | 19.4 c | 20.6 bc | 22.1 ab | 22.2 ab | 22.5 ab | 22.6 ab | 23.7 a | 0.23 |

| CIE a* | RF | 19.9 | 19.4 c | 19.3 c | 20.3 bc | 20.8 bc | 21.9 ab | 22.0 ab | 21.8 ab | |

| Yellowness | CH | 24.9 | 34.1 b | 35.7 ab | 37.4 a | 37.6 a | 37.3 a | 37.6 a | 37.4 a | 0.64 |

| CIE b* | RF | 22.5 | 35.0 ab | 34.5 ab | 34.7 ab | 35.0 ab | 36.2 ab | 36.9 ab | 37.4 a | |

| Hue angle | CH | 32.7 | 60.4 a | 60.1 ab | 59.4 ab | 59.4 ab | 58.9 ab | 59.7 ab | 57.7 b | 0.80 |

| CIE h* | RF | 30.0 | 61.0 a | 60.8 a | 59.3 ab | 59.3 ab | 58.9 ab | 59.1 ab | 59.8 ab | |

| Viscosity 1 | CH | (1) | 20.9 b | 23.3 b | 23.0 b | 25.5 ab | 25.2 ab | 27.3 a | 29.7 a | 1.93 |

| mPa s | RF | (1) | 19.9 b | 23.1 b | 22.6 b | 24.1 b | 22.0 b | 28.6 a | 28.8 a | |

| Viscosity 2 | CH | (1) | 0.82 c | 0.86 bc | 1.08 ab | 1.16 a | 1.18 a | 1.19 a | 1.20 a | 0.02 |

| Pa s | RF | (1) | 0.80 c | 0.91 b | 0.95 b | 1.00 b | 1.04 b | 1.07 a | 1.15 a | |

| Deformation | CH | (1) | 4.1 d | 4.3 d | 4.6 cd | 5.0 bc | 5.2 b | 5.1 b | 5.7 a | 0.10 |

| Energy mJ | RF | (1) | 3.9 d | 4.0 d | 4.5 cd | 4.8 bc | 5.2 b | 5.1 b | 6.0 a | |

| Hardness | CH | (1) | 0.18 c | 0.19 bc | 0.21 ab | 0.21 ab | 0.21 ab | 0.21 ab | 0.23 a | 0.00 |

| N | RF | (1) | 0.16 c | 0.17 c | 0.19 bc | 0.21 ab | 0.23 a | 0.23 a | 0.25 a |

| Temperature ºC | Raw | 70 | 75 | 80 | 85 | 90 | 95 | 100 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| M | M | M | M | M | M | M | M | RMSE | ||

| Orangeness | CH | 4.4 | 5.5 b | 6.1 ab | 6.4 ab | 6.4 ab | 6.5 ab | 6.7 ab | 6.8 a | 0.31 |

| RF | 4.2 | 5.0 c | 6.0 ab | 6.3 ab | 6.3 ab | 6.6 ab | 6.4ab | 7.0 a | ||

| Smooth Surface | CH | 2.7 | 6.8 | 6.7 | 6.5 | 6.1 | 6.5 | 5.8 | 5.5 | 0.64 |

| RF | 3.0 | 6.9 | 6.9 | 6.6 | 6.4 | 6,4 | 6.3 | 6.0 | ||

| Odour Intensity | CH | 6.9 | 6.6 a | 6.0 a | 5.6 a | 5.7 a | 5.7 ab | 5.4 ab | 5.0 b | 0.38 |

| RF | 7.0 | 6.5 a | 6.2 a | 5.7 a | 5.8 a | 5.4 ab | 5.5 ab | 5.1 b | ||

| Flavour Intensity | CH | 7.1 | 6.7 a | 6.8 ab | 6.3 bc | 6.2 bc | 5.9 bc | 6.0 bc | 5.5 c | 0.56 |

| RF | 7.7 | 7.3 a | 6.6 ab | 6.7 ab | 6.3 bc | 6.3 bc | 6.3 bc | 6.0 bc | ||

| Odour Homogeneity | CH | 3.3 | 4.3 b | 4.9 b | 5.4 ab | 5.8 ab | 6.1 a | 6.6 a | 6.4 a | 0.47 |

| RF | 3.3 | 4.8 b | 5.1 b | 5.5 ab | 5.8 ab | 5.8 ab | 6.1 a | 6.2 a | ||

| Flavour Homogeneity | CH | 3.3 | 4.3 b | 4.9 b | 5.4 ab | 5.8 ab | 6.1 a | 6.6 a | 6.4 a | 0.47 |

| RF | 3.3 | 4.8 b | 5.1 b | 5.5 ab | 5.7 ab | 5.8 ab | 6.1 b | 6.2 a | ||

| Fresh Odour | CH | 6.7 | 6.4 a | 5.5 b | 4.7 c | 4.7 cd | 4.2 de | 3.8 de | 3.6 e | 0.56 |

| RF | 6.8 | 6.6 a | 5.7 b | 5.0 c | 4.8 cd | 4.9 cd | 4.3 de | 4.3 de | ||

| Fresh Flavour | CH | 6.9 | 6.4 a | 5.6 b | 5.0 c | 4.8 cd | 4.1d | 3.8 d | 3.3 de | 0.69 |

| RF | 7.2 | 6.5 a | 6.0 ab | 5.3 c | 5.0 c | 4.4 cd | 4.5 cd | 3.9 d | ||

| Tomato Odour | CH | 6.3 | 4.5 a | 3.9 ab | 3.6 bc | 3.8 bc | 3.7 bc | 3.5 c | 3.2 c | 0.36 |

| RF | 6.2 | 4.2 b | 4.1 b | 3.9 ab | 3.8 bc | 3.7 bc | 3.8 bc | 3.5 c | ||

| Vinegar Odour | CH | 5.1 | 4.4 a | 4.6 a | 3.9 ab | 3.9 ab | 3.6 ab | 3.6 ab | 3.1 b | 0.59 |

| RF | 4.9 | 4.8 a | 4.4 a | 4.0 ab | 4.1 ab | 3.8 ab | 3.4 ab | 3.3 b | ||

| Vinegar Flavour | CH | 5.4 | 5.5 a | 4.6 a | 4.5 a | 4.4 ab | 3.6 bc | 3.5 bc | 3.2 c | 0.30 |

| RF | 4.9 | 5.0 a | 4.4 a | 4.4 a | 4.4 ab | 3.7 bc | 3.8 bc | 3.4 c | ||

| Garlic Odour | CH | 5.0 | 3.3 | 3.5 | 3.3 | 3.4 | 3.1 | 3.2 | 3.1 | 0.56 |

| RF | 5.0 | 3.5 | 3.5 | 3.2 | 3.4 | 3.4 | 3.2 | 3.0 | ||

| Garlic Flavour | CH | 4.3 | 4.2 | 3.9 | 3.7 | 3.6 | 3.7 | 3.6 | 3.5 | 0.83 |

| RF | 4.4 | 4.3 | 3.9 | 3.6 | 3.6 | 3.4 | 3.2 | 3.5 | ||

| Acidity | CH | 5.2 | 5.4 a | 4.8 a | 4.2 ab | 4.2 ab | 4.1 ab | 4.0 ab | 3.8 b | 0.32 |

| RF | 5.3 | 5.0 a | 4.7 a | 4.4 ab | 4.4 ab | 4.3 ab | 4.5 ab | 4.1 b | ||

| Spoon Consistency | CH | 3.8 | 4.1 d | 5.0 d | 5.2 cd | 6.1 c | 6.9 ab | 7.0 ab | 7.7 a | 0.30 |

| RF | 4.1 | 4.4 d | 4.7 d | 5.2 cd | 5.6 c | 6.7 ab | 6.9 ab | 7.4 a | ||

| Mouth Feeling | CH | 3.2 | 3.4 d | 3.6 d | 3.9 cd | 4.3 c | 4.6 ab | 5.2 ab | 5.5 a | 1.27 |

| RF | 3.1 | 3.0 d | 3.5 d | 3.7 cd | 3.8 c | 4.7 ab | 4.6 ab | 5.7 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).