1. Introduction

Iron aluminide intermetallic compounds possess advantageous properties such as high specific strength, high specific stiffness and strength at intermediate temperatures and excellent corrosion resistance in oxidizing and sulfidizing atmospheres [

1,

2]. These features make the FeAl intermetallic compound a very attractive material for structural applications at elevated temperatures in hostile environments. However, industrial application of iron aluminides has been hampered because of its low ductility at room temperature and its poor creep resistance [

2]. It was found that nanocrystalline structure obtained by mechanical alloying can improved ductility of intermetallics [

3]. Consequently, there is a large scope for research to produce FeAl structural materials with nanostructure. Thermal spray processes also have been used to deposit nanostructured intermetallic coatings through ball- milled intermetallic compound feedstocks [

4,

5,

6]. However, high temperature during spraying would change the composition and microstructure design of the feedstocks and consequently deteriorates the properties of the coatings.

In the last decade, the emerging cold spraying (or cold gas dynamic spray) has evolved tremendous expectation in fabrication of nanocrystalline materials. In this process, no heat source is used to melt powder particles. A coating is formed through the intensive plastic deformation of particles upon impact in a solid state at a temperature well below the melting point of the spray material. The low temperature characteristic, and high deposition rate as well make cold spraying technique as an efficient process to deposit metal [

7,

8,

9], composite [

10,

11,

12] and even cermet materials [

13,

14,

15] with a limited influence on the microstructure of feedstocks. Therefore, cold spraying was expected to be a potential process to deposition of nanostructured FeAl coating. Our previous study has indicated that the nanostructured FeAl intermetallic [

16] and FeAl/Al

2O

3 composite [

17] coating can be produced by cold-spraying of mechanically alloyed powders and followed by post-spraying annealing treatment.

It was well known that coating microstructure has significant influence on the properties of coating. For a cold-sprayed coating, the limited bonding at the interface between the deposited particles may result in anisotropy of coating microstructure and consequently lower mechanical strength. Several investigations have demonstrated the effect of annealing on the properties of cold sprayed coatings [

18,

19,

20,

21,

22]. Our previous study [

23] also found that the erosion resistance of cold-sprayed FeAl coating prepared by post-spray annealing at 950

oC was higher than that of heat-resistant 2520 stainless steel under abrasive temperature of 800

oC by a factor of three. Therefore, the annealing treatment may provide an approach to modify the microstructure and properties of cold-spray nanostructured FeAl coating. However, it was noted that cold-sprayed nanostructured FeAl coating has the lower thermal stability, therefore, the nanograin growth would occur accompanying microstructure improvement during annealing treatment, which would decrease coating property such as microharness [

24].

Therefore, the aim of the present paper is to investigate the effect of annealing temperature on the development of the microstructure including phase structure and nanograin size and microhardness of the nanostructured cold-sprayed FeAl coatings and the relationship between coating microstructure and hardness was examined.

2. Experimental materials and procedures

2.1. Materials

The commercially available Fe (99.8 wt.%, 54 μm, Youxinglian Nonferrous Metals Ltd, Beijing, China) and Al (99.5 wt.%, 74 μm, Youxinglian Nonferrous Metals Ltd, Beijing, China) powders were used as starting materials to produce a Fe

60Al

40 (at.%) powder mixture. The ball-milling process was carried out in a high-energy ball mill (ND-4L, Nanjing University, Nanjing, China) for 36 hours under an argon atmosphere. The details of this experimental step have been described elsewhere [

16]. The as-milled Fe(Al) alloy powder was sieved to a size less than 30 μm and used as the feedstock for spraying deposition.

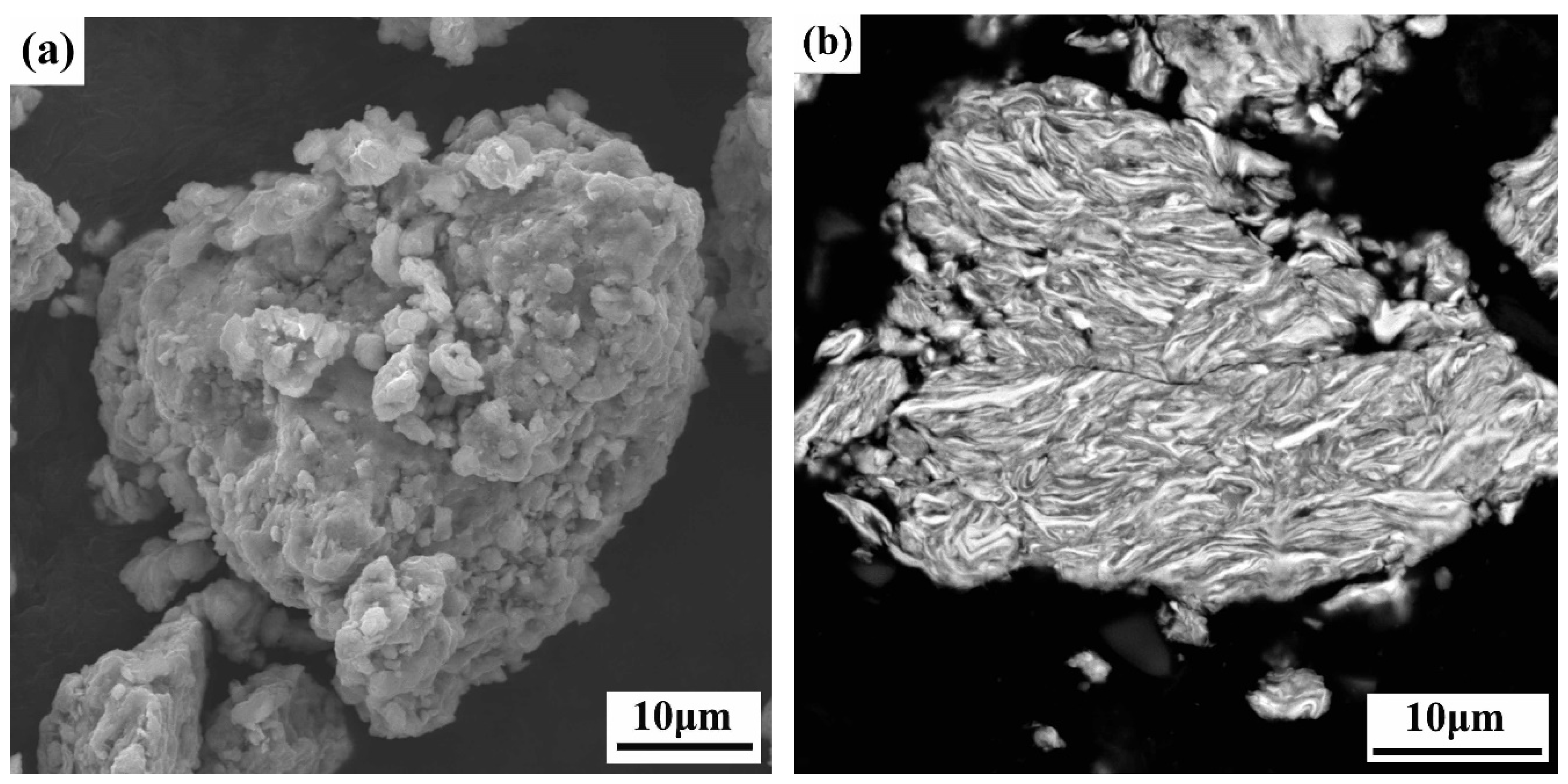

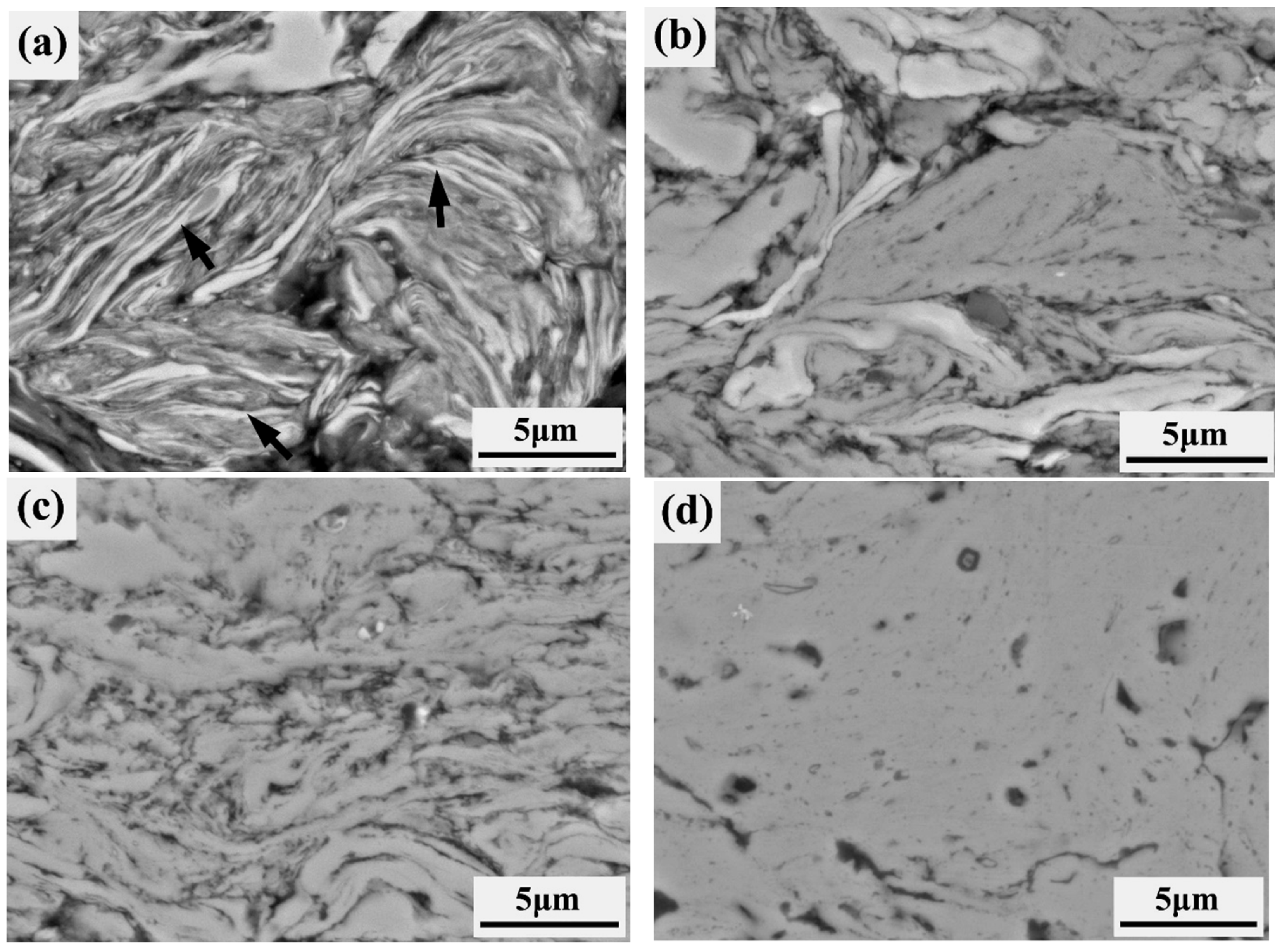

Figure 1 shows typical SEM images of the morphology and cross-sectional microstructure of the as-milled feedstock. The as-milled powder presented an irregular morphology, which is typical of milled powders and is generally attributed to the continuous welding and fracturing of particles caused by the collision of balls. It can be noted in

Figure 1b that a fine lamellar structure is present in the powder. Two distinguishable regions with different microstructural characteristics can be clearly observed.

2.2. Coating preparation and annealing treatment

The cold spraying system developed in Xi’an Jiaotong University was used for materials deposition. The detail information about the system is described elsewhere [

9]. A spray gun with a converging–diverging de Laval type nozzle of a throat diameter of 2 mm was adopted. The divergent nozzle is 100 mm in length with an exit diameter of 6 mm. Nitrogen gas was employed as both accelerating and powder feeding gases used at a pressure of 2.0 and 2.5 MPa, respectively, and at a temperature of 500

oC in the pre-chamber of spray gun. The standoff distance from the nozzle exit to the substrate was 20 mm. During deposition, sandblasted stainless steel plates were used as a substrate, the gun was manipulated by a robot and at a traverse speed of 40 mm/s relative to the substrate.

Following cold spraying, as-sprayed coating samples were annealed for different times at the temperatures of up to 1100oC in a furnace in an argon atmosphere.

Table 1.

Processing parameters in cold spraying.

Table 1.

Processing parameters in cold spraying.

| Accelerating gas |

N2

|

| Powder carrying gas |

N2

|

| Accelerating gas pressure, MPa |

2.0 |

| Powders carrying gas pressure, MPa |

2.5 |

| Accelerating gas temperature, oC |

350 |

| Gun traverse speed over substrate, mm/s |

40 |

| Standoff distance, mm |

20 |

2.3. Coating characterization

The phase transformation of the cold-sprayed FeAl coating during annealing treatment was analyzed by X-ray diffraction diffractometer (XRD, XRD-6000, Shimadzu, Kyoto, Japan) using Cu-Kα radiation. The microstructure evolution of coating was examined by scanning electron microscopy (SEM, Quanta 200, FEI, Czechoslovakia) equipped with energy dispersive X-ray analysis (EDX). The morphology and grain size in the as-sprayed and annealed coatings were investigated by transmission electron microscope (TEM, JEM-200CX, JEOL, Japan). Hardness was measured using a Vickers microhardness tester with a 100 g load and averaging the results of 10 measurements.

3. Results and discussion

3.1. Microstructure of the as-sprayed coating

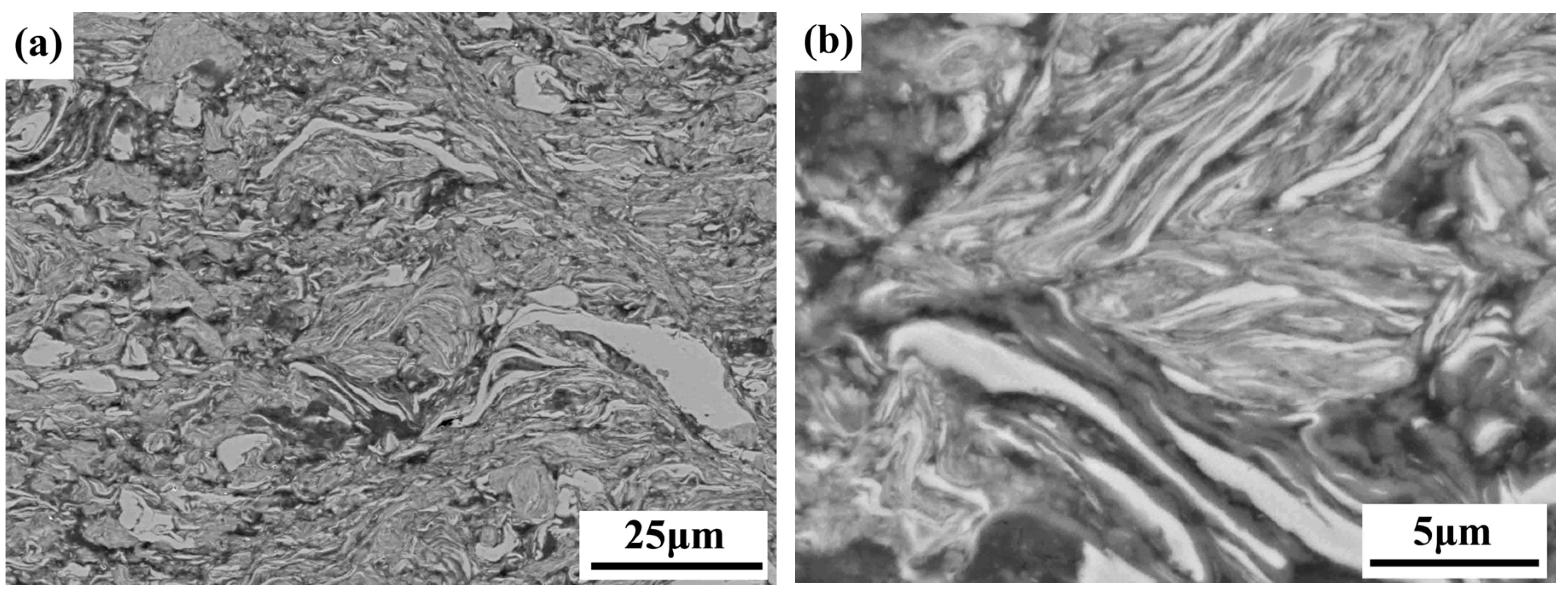

Figure 2 shows typical microstructure of the as-sprayed coating. Apart from the refined lamellar structure, some thicker layers with a white contrast appeared on the coating microstructure. According to EDX analysis results, the thicker white layer was a Fe-rich phase and the fine lamella was a Fe(Al) solid solution with high Al content. It was noted that this lamellar structure evolved not only from the particle deformation but also from the inner microstructure of the milled powder, as shown in

Figure 1b.

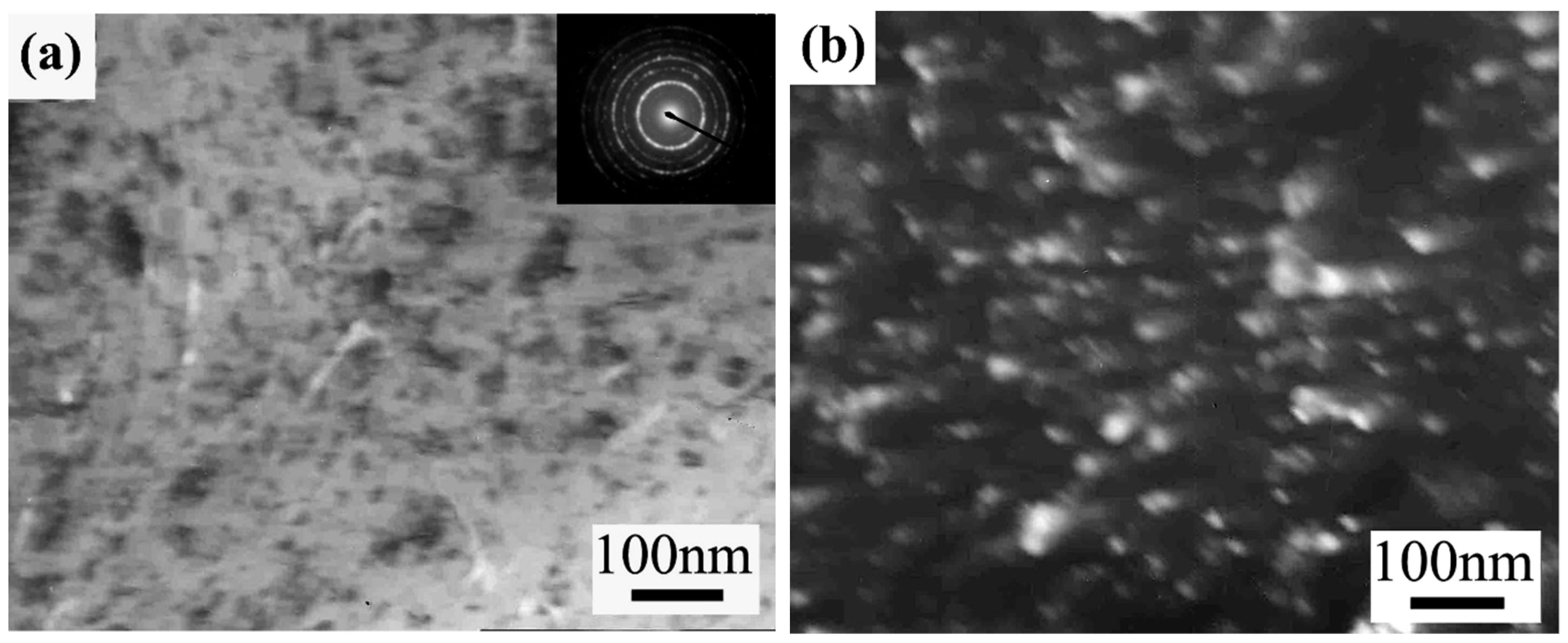

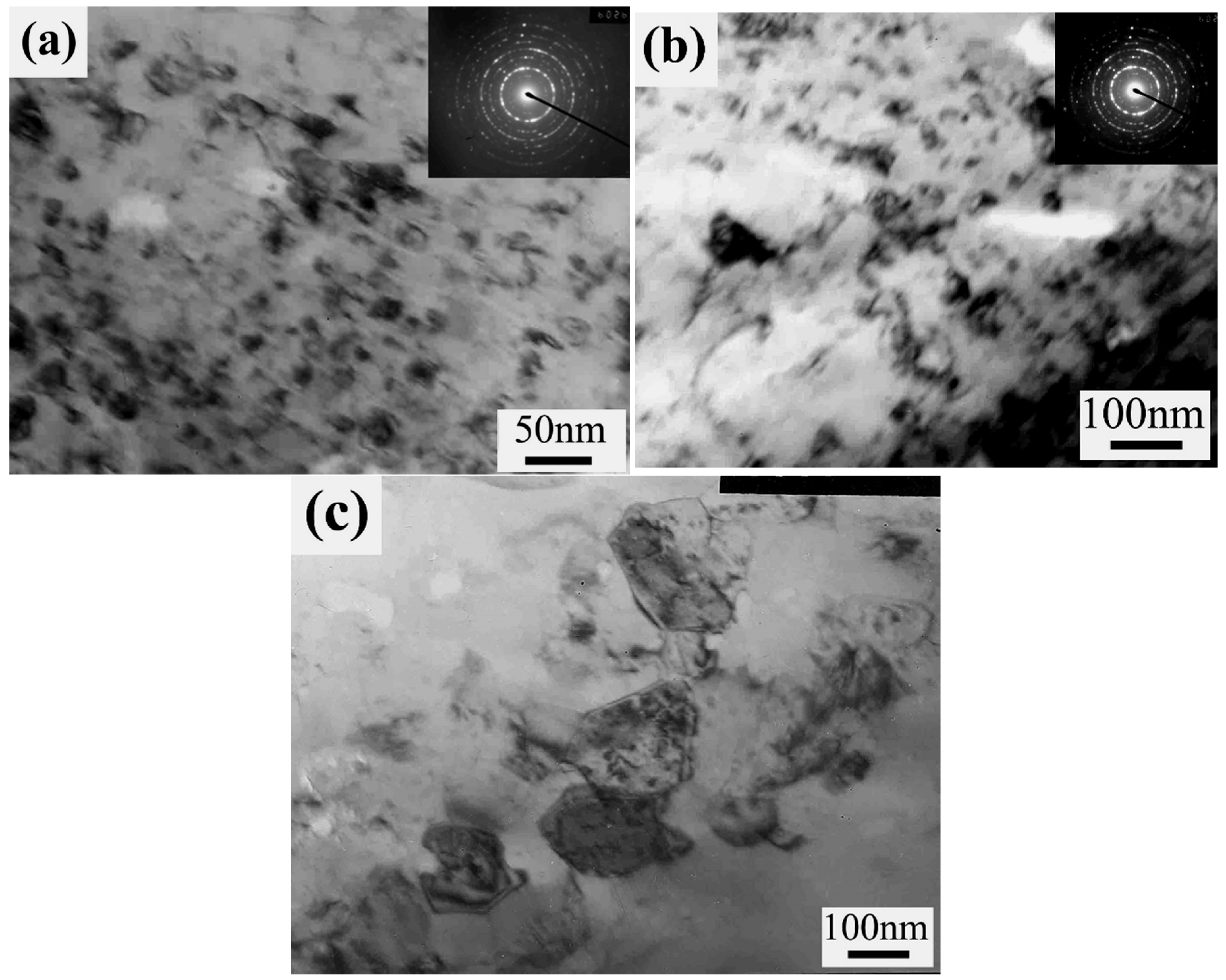

Figure 3 shows a TEM image of the as-sprayed Fe(Al) alloy coating. Typical grains observed in the coating were in an equiaxed morphology and in a grain size range from 10-50 nm. The corresponding SAD pattern revealed the bcc-α-Fe structure. It can be clearly recognized that the nanocrystalline Fe(Al) solid solution alloy coating was produced by cold-spraying of the mechanically alloyed powder.

3.2. Effect of annealing on phase structure

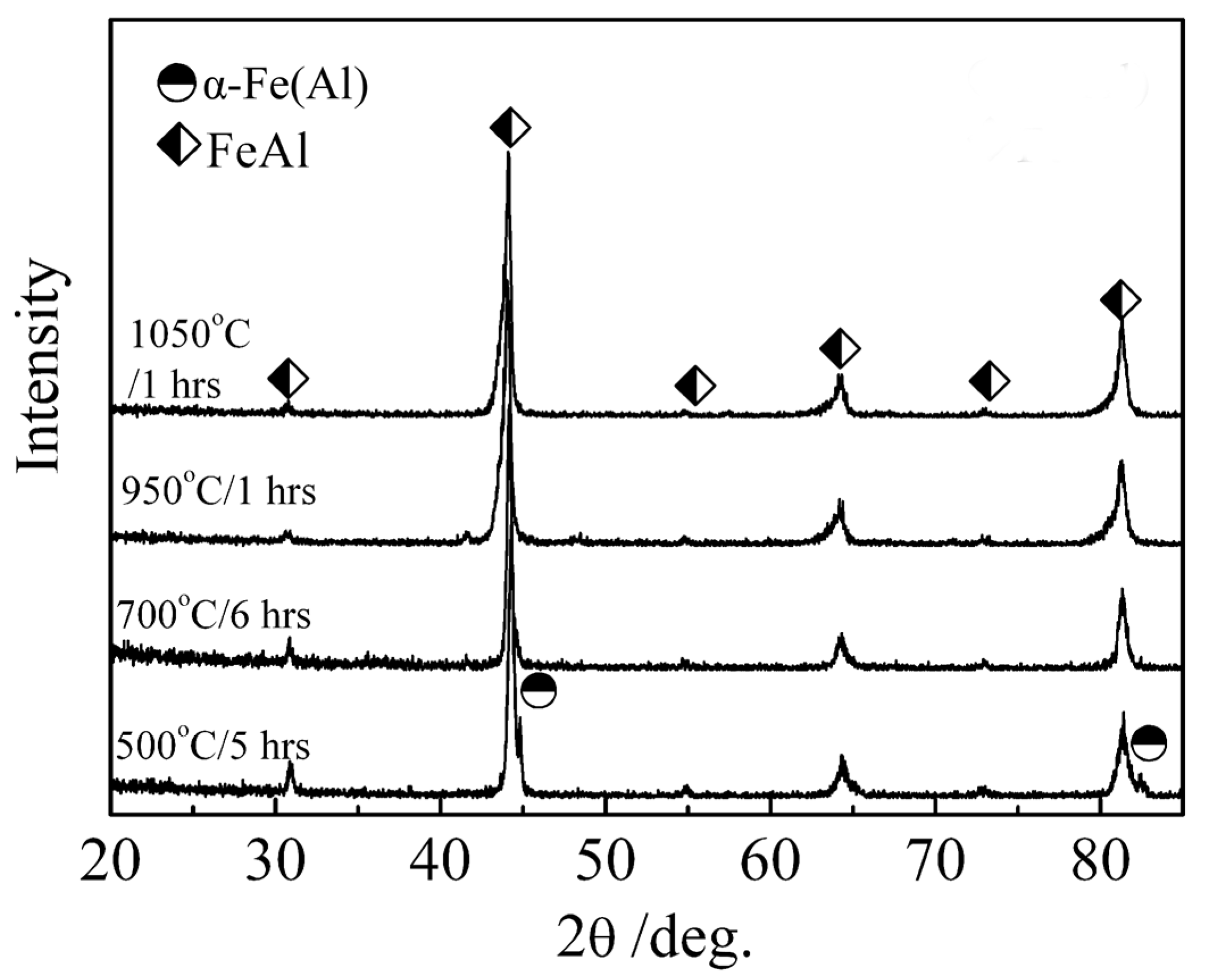

Figure 4 shows XRD patterns of the cold-sprayed FeAl coating after annealing treatment. After annealed at 500

oC for 5 hours, the coating mainly consisted of FeAl phase. However, a small fraction of Fe(Al) still retained in the coating. This remnant Fe(Al) will completely transform to FeAl through increasing annealing time [

16] or raising annealing temperature. After annealed at 700

oC for 6 hours, the diffraction peaks of Fe(Al) disappeared completely and only diffraction peaks of FeAl intermetallic compound phase were present in the XRD patterns. By raising temperature to 950 and 1050

oC, respectively, the phase structure of the deposit kept unchangeable and still FeAl intermetallic compound phase was present in the deposit.

3.3. Evolution of coating microstructure during annealing treatment

Figure 5 shows the microstructure of cold-sprayed FeAl coating annealed at 200

oC, 500

oC, 700

oC and 950

oC, respectively. After annealing at 200

oC, the microstructure of the coating showed no obvious change compared to that of the as-sprayed coating. The refine white and gray lamellar structure existed in the as-sprayed coating was still visible as marked by arrows in

Figure 5a, which indicates that elemental diffusion did not occur under this condition. This result was in agreement with the XRD analysis of the phase evolution of coating in the previous paper [

16]. However, when raising annealing temperature to 500

oC, the above-mentioned fine lamellar structure almost completely disappeared due to the high thermal reactivity and short diffusion distance of nanostructured FeAl coating. In addition, white Fe-rich zones (relatively thick layers) in the as-sprayed coating (

Figure 2) became not obvious in contrast because of elements diffusion within the coating as shown in

Figure 5b. This fact means that the heterogeneous feature in the as-sprayed coating can be modified through annealing treatment. The diffusion in the coating led to the elimination of the micro-pores and the uniform distribution of elements. After annealing at 700

oC, the heterogeneous structure of element completely disappeared and the microstructure of the coating was significantly improved. With raising annealing temperature to 950

oC, the microstructure of the coating became very dense and homogeneous. The lamellar structures in the as-sprayed coating had completely disappeared through solid-state diffusion. Therefore, the homogenization of the coating microstructure was achieved through post-spray annealing treatment.

Figure 6 shows the results of TEM observations of the microstructure of the FeAl coating after annealing at different temperatures. The coating annealed at 500

oC for 25 hours was clearly composed of FeAl nanograin of a size range from 10-50 nm [

16]. After annealed at 700

oC for 5 hours, the grain size in the coating exhibited a certain increase and still less than 100 nm as shown in

Figure 6b. Generally, the nanograin would grow rapidly with raising annealing temperature. The enhanced thermal stability of the nanocrystalline structure in the cold sprayed FeAl coating was associated with Al solute drag [

25], zener pinning [

26] by aluminum-iron oxide and aluminum oxide phases at grain boundaries, and reduction of grain boundary energy by Al segregation and chemical ordering [

27]. With raising temperature to 950

oC, the FeAl grain significantly grew and the grains size reached to about 200 nm as shown in

Figure 6c. The change of grain size in the cold sprayed FeAl coating during annealing treatment was in agreement with the results observed by Morris et. al. [

28] in annealing milled nanostructured FeAl. They found that the grain size changed slightly at low temperature and significantly increased at higher temperatures (above 900

oC). Those facts suggest that the nanostructure of cold-sprayed FeAl coating can be maintained up to a temperature less than 950

oC.

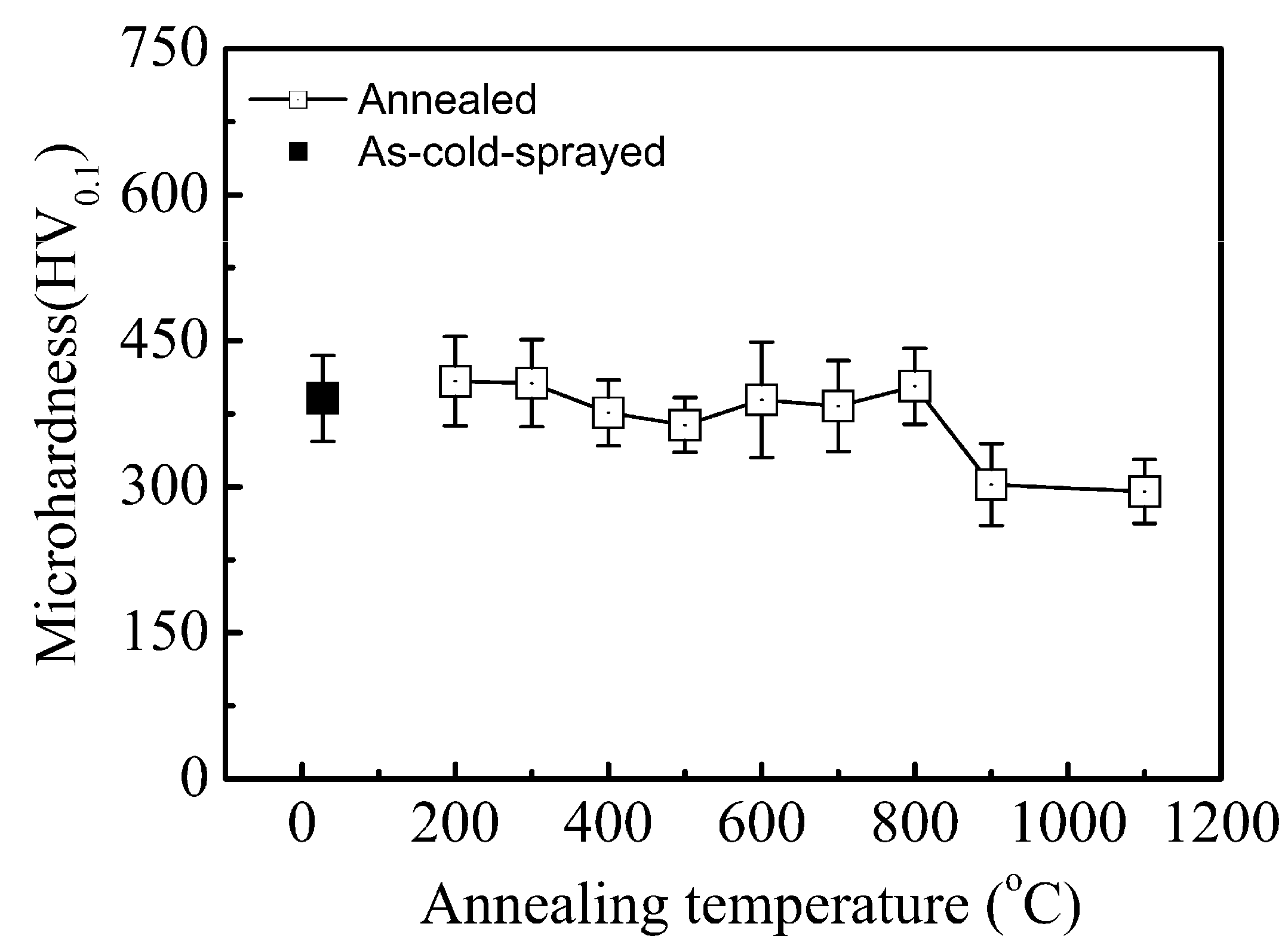

3.4. Effect of annealing treatment on microhardness of FeAl Coating

Figure 7 shows the effect of annealing temperature on the microhardness of the cold-sprayed FeAl coating [

24]. It was seen that the coating microhardness changed little and kept about 400 Hv

0.1 when annealed at a temperature below 800

oC. Such change can be attributed to the change of FeAl coating microstructure. Investigation [

29] on the thermal stability of milled FeAl powders showed that recovery and reordering took place at temperature ranging from 100 to 250

oC, while recrystallization and grain growth were delayed to higher temperatures. In the present study, as revealed by XRD analysis, the phase transformation from Fe(Al) alloy to FeAl occurred at annealing temperature of 500

oC. The significant increase in the grain size took place at a temperature from 700 to 950

oC. A significant decrease in coating microhardness at annealing temperature from 800 to 900

oC is well consistent with the occurrence of rapid grain growth as observed by TEM mentioned above. Therefore, the fact that the annealing at 900

oC caused significant decrease of the coating microhardness can be attributed to the nanograin growth. Although the cohesion between the deposited particles was improved after annealing at 950

oC, as shown in

Figure 5d, the strength of FeAl coating would be lowered owing to the coarsening of the FeAl grain. With further raising annealing temperature to 1100

oC, the microhardness of the coating change little and had a microhardness about 300 Hv

0.1, which was similar to that of the HVOF FeAl coating with coarse grain [

6]. Therefore, the size control of FeAl grain through annealing of cold-sprayed nanostructured FeAl alloy can be of significant importance.

4. Conclusions

The effect of annealing treatment on the microstructure, microhardness and phase structure of cold-sprayed nanostructured FeAl coating was investigated. It was found that annealing treatment provided an effective approach to control the microstructure and microhardness of the cold sprayed FeAl coating. After annealing at a temperature less than 700oC, minimal grain growth of the FeAl nanograin was observed accompanied by the microstructure improvement of the cold sprayed coating at the elevated treatment temperatures. The microhardness of the cold-sprayed FeAl coating remained about 400 Hv0.1 when annealed at the temperatures of below 800oC and decreased significantly with increasing annealing temperature to 900oC, which may be attributed to the grain growth of the FeAl nanograin and the softening of the matrix during annealing treatment.

Acknowledgements

The present work is supported by the National Natural Science Foundation of China (No.51001056 and 52161012). The author, Hong-Tao Wang, also thanks the support from the Natural Science Foundation of Jiangxi Province (No.20192BAB206006).

References

- Tortorelli, P.F.; Natesan, K. Critical factors affecting the high-temperature corrosion performance of iron aluminides. Mater. Sci. Eng. A 1998, 258, 115–25. [Google Scholar] [CrossRef]

- Stoloff, N.S. Iron Aluminides: present status and future prospects. Mater. Sci. Eng. A 1998, 258, 1–14. [Google Scholar]

- McFadden, S.X.; Mishra, R.S.; Valiev, R.Z.; Zhilyaev, A.P.; Mukherjee, A.K. Low-temperature superplasticity in nanostructured nickel and metal alloys. Nature 1999, 398, 684–86. [Google Scholar] [CrossRef]

- Kumar, S.; Selvarajan, V.; Padmanabhan, P.V.A.; Sreekumarand, K.P. Characterization and comparison between ball milled and plasma processed iron-aluminium thermal spray coatings. Surf. Coat. Technol. 2006, 201, 1267–75. [Google Scholar]

- Hearley, J.A.; Little, J.A.; Sturgeon, A.J. The effect of spray parameters on the properties of high velocity oxy-fuel NiAl intermetallic coatings. Surf. Coat. Technol. 2000, 123, 210–18. [Google Scholar] [CrossRef]

- Ji, G.; Grosdidier, T.; Liao, H.L.; Morniroli, J.P.; Coddet, C. Spray forming thick nanostructured and microstructured FeAl deposits. Intermetallics 2005, 13, 596–607. [Google Scholar] [CrossRef]

- Ajdelsztajn, L.; Jodoin, B.; Schoenung, J.M. Synthesis and mechanical properties of nanocrystalline Ni coatings produced by cold gas dynamic spraying. Surf. Coat. Technol. 2006, 201, 1166–72. [Google Scholar] [CrossRef]

- Shukla, V.; Elliott, G.S.; Kear, B.H.; McCandlish, L.E. Hyperkinetic deposition of nanopowders by supersonic rectangular jet impingement. Scripta Mater. 2001, 44, 2179–82. [Google Scholar] [CrossRef]

- Li, C.-J.; Li, W.Y. Deposition characteristics of titanium coatings in cold spraying. Surf. Coat. Technol. 2003, 167, 278–83. [Google Scholar] [CrossRef]

- Morelli, D.T.; Elmoursi, A.A.; Van Steenkiste, T.H.; Gorkiewicz, D.W.; Gillispie, B. Kinetic spray of aluminum metal matrix composites for thermal management applications. Thermal spray 2003: Advancing the science and applying the technology; Marple, B.R., Moreau, C., Eds.; ASM International: OH, 2003; pp. 85–90. [Google Scholar]

- Van Steenkiste, T.H.; Elmoursi, A.; Gorkiewicz, D.; Gillispie, B. Fracture study of aluminum composite coatings produced by the kinetic spray method. Surf. Coat. Technol. 2005, 194, 103–10. [Google Scholar] [CrossRef]

- Li, W.-Y.; Zhang, G.; Zhang, C.; Elkedim, O.; Liao, H.; Coddet, C. Effect of ball milling of feedstock powder on microstructure and properties of TiN particle-reinforced Al alloy-based composites fabricated by cold spraying. J. Therm. Spray Technol. 2008, 17, 316–22. [Google Scholar] [CrossRef]

- Lima, R.S.; Karthikeyan, J.; Kay, C.M.; Lindemann, J.; Berndt, C.C. Microstructural characteristics of cold-sprayed nanostructured WC-Co coatings. Thin Solid Films 2002, 416, 129–35. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, C.H.; Hwang, S.Y. Superhard nano WC-12%Co coating by cold spray deposition. Mater. Sci. Eng. A 2005, 391, 243–48. [Google Scholar] [CrossRef]

- Gao, P.H.; Li, C.-J.; Yang, G.J.; Li, Y.G.; Li, C.X. Influence of substrate hardnes transition on built-up of nanostructured WC–12Co by cold spraying. Appl. Surf. Sci. 2010, 256, 2263–68. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J.; Li, C.X.; Zhang, Q.; Li, W.Y. Microstructural characterization of cold-sprayed nanostructured FeAl intermetallic compound coating and its ball-milled feedstock powders. J. Therm. Spray Technol. 2007, 16, 669–76. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J.; Li, C.X. Effect of heat treatment on the microstructure and property of cold-sprayed nanostructured FeAl/Al2O3 intermetallic composite coating. Vacuum 2008, 83, 146/52. [Google Scholar] [CrossRef]

- Li, W.Y.; Li, C.-J.; Liao, H.L. Effect of annealing treatment on the microstructure and properties of cold-sprayed Cu coating. 2006, 15, 206/11. [Google Scholar] [CrossRef]

- Borchers, C.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Formation of persistent dislocation loops by ultra-high stain-rate deformation during cold spraying. Acta Mater. 2005, 53, 2991–3000. [Google Scholar] [CrossRef]

- Decker, M.K.; Neiser, R.A.; Gilmore, D.; Tran, H.D. Microstructureand properties of cold spray nickel. Thermal Spray 2001: New surfaces for a new millennium; Berndt, C.C., Khor, K.A., Lugscheider, E.F., Eds.; May 28-30, 2001 (Singapore); ASM International, 2001; p. 433/39. [Google Scholar]

- McCune, R.C.; Donlon, W.T.; Popoola, O.O.; Cartwright, E.L. Characterization of copper Layers produced by cold gas-dynamic spraying. J. Therm. Spray Technol. 2000, 9, 73–82. [Google Scholar] [CrossRef]

- Li, W.Y.; Guo, X.P.; Verdy, C.; Dembinski, L.; Liao, H.L.; Coddet, C. Improvement of microstructure and property of cold-sprayed Cu-4 at.%Cr-2 at.%Nb alloy by heat treatment. Scripta Mater. 2006, 55, 327–30. [Google Scholar] [CrossRef]

- Li, C.-J.; Wang, H.T.; Yang, G.J.; Bao, C.G. Characterization of high-temperature abrasive wear of cold-sprayed FeAl intermetallic compound coating. J. Therm. Spray Technol. 2011, 20, 227–33. [Google Scholar] [CrossRef]

- Wang, H.T.; Li, C.-J.; Yang, G.J. influence of hard phase on the properties of cold-sprayed FeAl intermetallic compound coatings (In chinese). Materials Protection 2010, 43, 93–94. [Google Scholar]

- Knauth, P.; Charaï, A.; Gas, P. Grain growth of pure nickel and of a Ni-Si solid solution studied by differential scanning calorimetry on nanometer-sized crystals. Scripta Metall. Mater. 1993, 28, 325–30. [Google Scholar] [CrossRef]

- Boylan, K.; Ostrander, D.; Erb, U.; Palumbo, G.; Aust, K.T. An in-situ tem study of the thermal stability of nanocrystalline Ni. Scripta Metall. Mater. 1991, 25, 2711–16. [Google Scholar]

- Gao, Z.; Fultz, B. The thermal stability of nonocrystalline Fe---Si---Nb prepared by mechanical alloying. Nanostructured Mater. 1993, 2, 231–40. [Google Scholar] [CrossRef]

- Morris, D.G.; Gutierrez-Urrutia, I.; Munoz-Morris, M.A. Scripta Mater. 2007, 57, 369/72.

- Gialanella, S.; Amils, X.; Barò, M.D.; Delcroix, P.; Le Caër, G.; Lutterotti, L.; Suriñac, S. Microstructural and kinetic aspects of the transformations induced in a FeAl alloy by ball-milling and thermal treatments. Acta Mater. 1998, 46, 3305–16. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).