1. Introduction

Plant origin press-cakes are rest raw materials that are discarded as industrial by-products after food processing & production processes by food industries. These include press-cakes discarded after oil manufacturing and refining processes (e.g., rapeseed press-cake, hemp press-cake) and after drink manufacturing processes (e.g., soy press cake, oat press cake from soy and oat milk processing, respectively) [

1]. Usually discarded press-cakes are utilised as animal feed due to their nutrient profile including significant concentrations of proteins and amino acids, but are not directly utilised as food additive, materials, and ingredients for human consumption. This is primarily due to the presence of antinutrient factors and lack of sensory qualities which may make them distasteful for consumers [

2].

As interest in repurposing rest raw materials such as plant origin press-cakes has received high traction in the past decade, several pre-treatment strategies such as ultrasonication [

3,

4], fermentation by microbes & hydrolysis using enzymes [

5] and extrusion cooking [

6] have been utilised by researchers to biorefine the source matrix to increase bioavailability and concentration of proteins, starch etc., to reduce antinutrient concentrations and enhance sensory qualities of plant origin press cakes. These strategies have helped to process plant origin press-cakes for their utilisation in the development of new and improved food systems and products.

Extrusion refers to a food processing technique that involves cooking and shaping plant-based ingredients into various products including puffed snacks & meat-like products. The process takes place in an extruder, a machine that combines heat, pressure, and shear to cook and shape the ingredients. The plant-based ingredients, such as soy protein, pea protein, and wheat gluten, are blended with water and other additives to form a dough-like mixture. The mixture is then fed into the extruder, where it is subjected to high heat and pressure. The high heat and pressure cause the ingredients to cook and denature, resulting in a homogeneous mass that can be shaped and cut into the desired form. Extrusion is widely used in the production of meat analogues, such as veggie burgers, sausages, and nuggets, due to its ability to produce products with a meat-like texture, flavour, and appearance. The process can also be used to produce products with other textures, such as crunchy or chewy, and can be customized to achieve the desired product properties.

For the production and development of plant-based meat analogue products, high moisture extrusion cooking (HMEC, moisture content up to 70% w/w water) is mostly utilised as it favourably produces a meat-like fibrous structure in the extrudate after completion of the extrusion cooking process [

7]. However, HMEC has some disadvantages. The most significant drawback of products developed using HMEC is the cost of setting up the infrastructure, extra peripherals (cooling die at the end of the barrel) and the cost of producing the goods, which in turn increase the selling price of produced goods [

8]. Another drawback is the uncertainty over the sustainability of HMEC process. For a technology that is directed at producing consumer goods for a targeted consumer bracket in the market where sustainability plays a very important factor, the widespread utilisation of HMEC for producing goods may hamper the sales of such goods as consumers may choose more sustainably produced products.

As a result, LMEC (Low Moisture Extrusion Cooking) has also been utilised by researchers for the development of extrudates which can be used in the development of plant-based meat analogue products [

9,

10]. LMEC typically uses moisture levels ranging from 10%-40% [

7]. This low moisture level is important for achieving the desired texture and stability of the final product, as well as to prevent spoilage and microorganism growth. By maintaining a low moisture environment, the heat and pressure generated by the extruder can cook the ingredients thoroughly and create a homogeneous mass, which can then be shaped and cut into the desired form. thus, specific moisture level used can vary depending on the ingredients, processing conditions, and desired end-product properties, thus there are many possibilities when it comes to choosing the various permutations-combinations available for physical parameters. Similarly, the temperature range used in LMEC can vary depending on the specific application, ingredients, and desired end-product properties. In general, the temperature range for LMEC is typically between 120°C to 200°C [

11]. The high temperatures generated in the extruder, along with the pressure, contribute to the cooking and denaturation of the ingredients. The temperature must be high enough to ensure thorough cooking and proper gelatinization of the starch, but not so high as to cause degradation or thermal destruction of the ingredients.

Among all plant origin press-cakes, soy press cake has the most potential for being repurposed as a valorised ingredient for the development of meat analogue products due to its high protein and nutrient content, widespread availability, and low cost. The by-product of soy drink manufacturing and tofu manufacturing process, called as okara has recently been identified as a potential high protein, high fibre product to be used as animal feed. Along with these factors, the moisture and temperature of extrusion cooking of press-cakes is equally important, especially considering the potential use of these extrudates for the preparation of meat analogues. The main difference between okara produced from tofu manufacturing and okara produced from soy drink manufacturing lies in the coagulation step. Tofu production involves intentional coagulation to separate curds from the whey, resulting in a more substantial and moister okara. In contrast, soy drink manufacturing focuses on producing a liquid beverage, so the soy milk is usually filtered, resulting in a drier and finer okara. These factors influence the characteristics and properties of okara from these 2 different sources. Therefore, comparison of okara from different origins (soy drink and tofu manufacturing) is necessary for investigating their potential for development of meat analogue products. Okara is currently being studied for its potential as additive for production of extruded snacks [

12]. High moisture extrusion is preferred generally by manufacturing enterprises, although low moisture extrusion is also used [

13,

14] but is currently not as popular as HMEC.

Keeping in account the potential of LMEC for production of meat analogue products and how the modulation of extrusion cooking moisture and cooking temperature are important for obtaining desirable chemical, morphological, functional, and sensory properties, press-cakes produced via extrusion with two different moisture concentrations (30% and 60%) and varying cooking temperature were developed for this study. The chemical, morphological, functional & sensory properties of soy press cakes were analysed and compared prior to and post extrusion cooking process, along with samples of meat analogues which included the addition of extruded press cakes in small amounts (3%-6%) for evaluating changes in these properties. Through this, the possibility of utilising soy press cakes for the development of meat analogue products is investigated, and the extrusion regimen with best moisture and temperature parameters is presented.

2. Materials and Methods

2.1. Raw materials

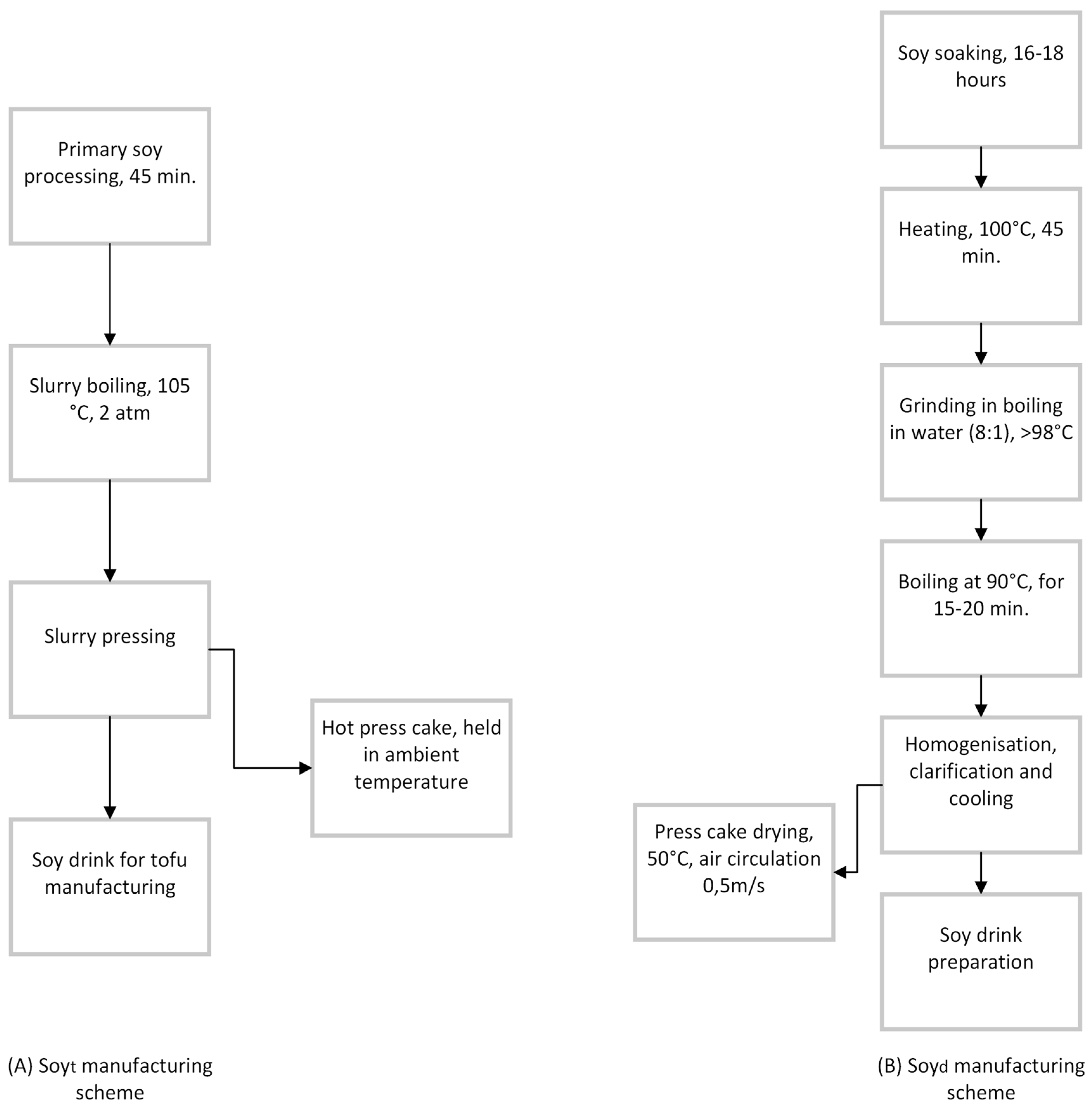

Two samples of dried soy press-cakes, Soy

d and Soy

t (sourced from Berief Food GmbH, Germany as residues from soya drink manufacturing and JSC Sojalita, Lithuania (residues from tofu manufacturing) respectively. A texturized soy flour for meat analogue matrix (from Imlitex, Argentina) named Soy

m, was used for the study. The technological scheme for obtaining Soy

d and Soy

t is shown in

Figure 1. For tofu production (

Figure 1a), the soybeans were processed in a single tank and the processing time was 45 minutes. The prepared slurry was boiled at 105 °C (the mass was heated with hot water vapor) and the pressure was set to 2 atmospheres. After heating, the slurry was pressed to produce a hot pomace which was cooled outside the production premises by outdoor air. The production of soy drink (

Figure 1b) starts with soaking (16-18 hours). This is followed by heat treatment, which may last up to 2 hours in total. The mass is heated to 100 °C for 45 minutes followed by grinding in boiling water at a ratio of 1:8 (minimum temperature of 98 °C), finally being boiled at 90 °C for 15-20 minutes. It is then homogenised, clarified, and cooled. Soy

t thermal process takes less than half the time it takes for Soy

d. Samples were stored at room temperature prior to analysis. The scheme to produce soy press cake samples has been described in figure 1.

2.2. Reagents

The following reagents were used for the chemical analysis of the samples: Distilled water, sunflower oil, sodium hydroxide, hydrochloric acid, TRIS(tris(hydroxymethyl) aminomethane), calcium chloride monohydrate, BAPNA (Nα-Benzoyl-DL-arginine 4-nitroanilide hydrochloride), DMSO (Dimethyl sulfoxide), glacial acetic acid, triethylamine, Carrez I and II solutions, standard acrylamide solution (1000 µg/L), potassium bromide, potassium bromate, concentrated sulfuric acid, sodium thiosulfate pentahydrate, sodium chloride, ethyl acetate, methanol (analytical grade), isooctane (2,2,4-trimethylpentane), potassium hydroxide, citric buffer, acetonitrile, glucose, fructose, saccharose, perchloric acid, saturated sodium bicarbonate solution, Dansyl chloric solution, ammonia solution (25%), histamine standard solution ( 1 mg/ml), inner standard solution of diamine heptane, Kjeldahl catalyst tablets, sulfuric acid (95 to 98 % by weight, without nitrogen impurities), hydrogen peroxide solution, antifoam, sodium hydroxide, boric acid, methyl redonium, bromocresol green, ammonium sulphate (purity by weight of not less than 99,9 %), standard trypsin solution, TRIS buffer.

2.3. Extrusion process

Pre-treatment: Soy samples (Soyt, Soyd) were hydrated approximately to 30% or 60% moisture before processing. Hydrated samples were allowed to equilibrate overnight at 4 °C.

Extrusion: Coarse, raw press-cake powders (Soyt, Soyd) were extruded using a co-rotating twin-screw extruder ZE25Rx40D-UTXmi (KraussMaffei Berstorff GmbH, Germany) composed of eleven segmented barrels. The screws had a diameter of 26.6 mm, a length to diameter ratio (L/D ratio) of 40:1, and 100 rpm was set as the screw speed. The barrel diameter was 26.9 mm and die head with three circular holes had a diameter of 3.5 mm. Extrusion was carried out under four different conditions for each raw material by varying processing temperature and initial sample moisture. Two different temperature profiles throughout the eleven-barrel segments were applied as follows (in °C): i) 18, 65, 85, 95, 100, 105, 110, 110, 110, 110 and product exit temperature (recorded); ii) 18, 65, 85, 95, 105, 110, 120, 120, 120, 120 and product exit temperature (recorded). Extruded samples were marked in Latin numerals with respect to maximum extrusion temperature and moisture of the samples:

I – press-cakes extruded at moisture content of 30% and maximum temperature of 110°C

II – press-cakes extruded at moisture content of 30% and maximum temperature of 120°C

III – press-cakes extruded at moisture content of 60% and maximum temperature of 110°C

IV – press-cakes extruded at moisture content of 60% and maximum temperature of 120°C

The following process parameters were monitored during extrusion: product temperature in different zones, die pressure, motor load, and product throughput.

The specific mechanical energy (SME) was calculated according to the following expression (Hu et al., 1993):

where extruder constant speed was 100 rpm, max screw speed was 1200 rpm and motor power were set to 26 kW.

2.4. Scanning electron microscopy (SEM) analysis

Morphology of untreated and extruded soy press-cakes was investigated using a FEI Quanta 200 FEG scanning electron microscope. Extruded samples prior to SEM analysis were freeze-dried in a SP Scientific Freeze Dryer (SP Industries, USA). Press-cakes were mounted on metal stubs using adhesive tape. Images were taken at a magnification of 5000x.

2.5. Preparation of meat analogues

Meat analogues were prepared by addition of 3% (w/w), and 6% (w/w) extruded press-cake samples to the matrix containing industrially textured soy protein, water, emulsion, and oil. Additional spices were not added to the meat analogue matrix to recognise the base matrix’s sensory properties. The emulsion was produced by blending industrial emulsifier, water, and oil. Two batches of each analogue were prepared to carry out analysis of cooked and uncooked meat analogue samples weighing 100 gms each. The prepared meat analogues were cooked in a conventional oven with cooking parameters set at 180 °C temperature for 20 minutes. It was adequate to reach an internal temperature of more than 75 °C. The cooked samples were wrapped using aluminium foil and placed in labelled trays. They were held at a temperature of 60 °C before using them for sensory analysis. The cooked samples were also used for texture and colour analysis.

Samples were coded as per the following abbreviation scheme:

MC - Control matrix (from textured soy protein, water, emulsion, and oil) without extruded press cakes.

MT - meat analogue matrix supplemented with extruded Soyt press cakes. Latin numerals from I-IV denote conditions under which press cakes were extruded (see section 2.3) and 3% or 6% indicates the amount of press cakes in matrix (w/w).

MD - meat analogue matrix supplemented with extruded Soyd press cakes. Greek number I-IV shows under which conditions press cakes were extruded (see section 2.3) and 3% or 6% indicates the amount of press cakes in matrix (w/w).

2.6. Determining the chemical composition of press-cakes and meat analogues

The chemical composition of untreated press-cakes, extruded press-cakes and uncooked meat analogues were determined based on standard methodologies. The composition of amino acid content in extruded press-cakes and raw meat analogues were analysed using the A300 Amino Acid Analyser (MembraPure GmbH, Germany), which uses ion exchange chromatography including a reaction with ninhydrin in post-column and detection in the spectrum of the visible region. Analysis of fatty acid contents was carried out using standardised gas chromatographic methods ISO 12966-1:2015 and ISO 12966-2:2017 defined by AOAC (American Association of Analytical Chemists). Humidity was determined using the traditional oven method ISO 712:2009. The saturated fatty acid contents were determined using the gravimetric method AOAC 922:06 and AOAC 963.15:2003. Analysis of nitrogen and protein contents were carried out using the Kjeldahl method ISO 20483:2006. Sugar contents were determined using chromatographic methods, and salt content was determined using standard titration method ISO 3634:1979. Enzymatic gravimetric method was used for determination of fibre content AOAC 985.29:1990.

2.7. Determination of trypsin inhibitor activity

The anti-nutritional trypsin inhibitor activity was determined using the method described by Clifford et al. [

15] The trypsin inhibition activity is presented as milligrams of trypsin inhibited per gram of sample. Briefly, 1 gram of each sample was weighed, shaken with of 10 mM sodium hydroxide and pH was adjusted to 9.4-9.6. The slurry was left overnight followed by shaking and filtering through a filter paper.

The absorbance of the samples was measured at 410 nm using the Hanover 3000 spectrophotometer. Triplicate results of absorbance were noted, averaged, and used for calculation of trypsin inhibitor activity using the following formula:

where,

2.8. Analysis of functional properties of non-extruded press-cakes, extruded press-cakes, and meat analogues

2.8.1. Water holding capacity and oil holding capacity

Determination of water holding capacity (WHC) and oil holding capacity (OHC) was performed using the method described by Sadh et al. [

16] with some modifications. Slurries of samples in water were prepared by adding 0.8 g of sample to 15 mL pre-weighted centrifuge tube and pouring 12 mL of distilled water and shaking manually for 1 minute. The tubes were centrifuged for 10 minutes at 3000 x g. After centrifugation the fugate was discarded and the tubes were weighed again. The WHC or OHC was expressed as grams of water or oil, respectively, bound to per gram of sample.

2.8.2 Cooking loss

The meat analogues of known weight were cooked in a convection oven at 180 °C for 20 minutes. The samples were allowed to cool to 60 °C and then weight again. Calculation of cooking loss was done by subtracting the initial weight and the final weight, further dividing it by the original weight of the samples. The cooking loss was expressed in percentage.

2.10. Texture and colour analysis of meat analogues

The texture profile analysis was carried out for samples of cooked meat analogues using Instron 3343 machine (Instron Engineering Group, High Wycombe, England) equipped with a load cell of 1kN. The samples were cut into 2.0×2.0×2.0 cm and were compressed perpendicularly using a cylindrical probe of 0.5 cm. The testing conditions were done via two cycles consecutively at a compression of 70% and crosshead movement at a speed of 1 mm/s.

2.11. Sensory analysis of meat analogues

A quantitative descriptive analysis of 12-point scale was performed by a consumer jury made up of 6 panellists. The jury analysed the produced meat analogues’ perception characteristics and determined the optimal treatment conditions like suitable temperature and humidity for the extrusion process. A suitable amount of press-cake added in the matrix and optimal storage temperature of the raw meat analogues. The range of scores for the scale was between 1-12, where 1 = not intensive and 12 = very intensive. The jury’s main goal was to produce sensory descriptors to describe the characteristics of samples. The jury’s sessions were conducted in the KTU Food Institute’s sensory laboratory (Kaunas, Lithuania).

2.12. Statistical analysis

All the experiments were carried out in triplicates. The results were reported as mean ± standard deviation (SD). The two-way analysis of variance (2-way ANOVA) was used for considering significant differences in extruded press-cake samples followed by a post hoc test using LSD (Least significant difference), and three-way analysis of variance (3-way ANOVA) was utilised to consider the significant differences in meat analogue samples to study the significance of independent factors as well as their interactions. At p ≤ 0.05, the samples were statistically significant. The analysis was performed using IBM SPSS 27.0 software (IBM Corporation, New York, USA).

3. Results

3.1. Extrusion of press-cakes

In this study, extrusion was conducted to process soy press-cakes before using them for the preparation of meat analogues. It has been demonstrated that soy press cakes contain significant amounts of antinutritional compounds, such as trypsin inhibitors and polyphenols that limit their potential as plant-based superfoods. However, application of heat can decrease the amounts of these anti nutritional factors [

17]. Our reason for applying extrusion to soy press-cakes, along with finding the best combination of moisture and temperature conditions during extrusion cooking to produce meat analogues with desired chemical, functional and sensory properties was to also reduce the content of trypsin inhibitors significantly while not diminishing the quality and quantity of protein and amino acids natively available.

Changing the conditions of extrusion could produce extrudates with different physicochemical and functional properties. Therefore, two parameters (extrusion temperature and moisture) were modulated to produce different samples: see

Table 1). Preliminary tests showed that when maximum temperature of the barrel zones (

Tmax) was higher than 120°C, press-cakes started to burn. Therefore, two extrusion regimes with lower temperature (

Tmax of 110°C and 120°C) were utilised for experiments.

The specific mechanical energy (SME) is an important parameter when assessing extrusion process and is defined as the mechanical energy input required to obtain a unit weight of material through the [

18]. From data presented in

Table 1 it is obvious that the moisture content of press-cakes had more influence on

SME, than temperature of the barrel. It was observed that the value of

SME was lower for both soy press-cakes as the humidity of press-cake was increased and it is consistent with the data from other studies using twin-screw extruders [

19,

20]. Comparing the SME for Soy

t and Soy

d samples, it is apparent that SME of Soy

t samples was higher than Soy

d samples in all cases. This could be attributed to the fact that the production of Soyt press cakes involve coagulation of soy curd, which produces press cake that has higher moisture and is softer than press cakes produced from soy drink manufacturing, where no coagulation step takes place. In general, increasing moisture content of raw soy press-cake led to decreased viscosity of the wet mass in the barrel, reduced conversion ratio of extruder mechanical energy into heat energy, also decreased force necessary to push the wet mass through the die, thus reducing the friction between wet mass and screw shaft and extruder barrel [

19] and consequently motor load and the value of SME decreased (

Table 1). It can also be noticed that increasing moisture of the press-cakes lowers die pressure and increases throughput of the press-cake mass through the extruder and this is consistent with the fact that at higher feed moisture the press-cake mass is less viscous, it can flow more easily, this in turn shortens the mean residence time of the press-cake in the extruder barrel and the press-cake mass can pass through the die more readily, and these findings are consistent with data presented in other studies [

19].

3.2. Physical and technological characteristics of non-extruded and extruded press-cakes

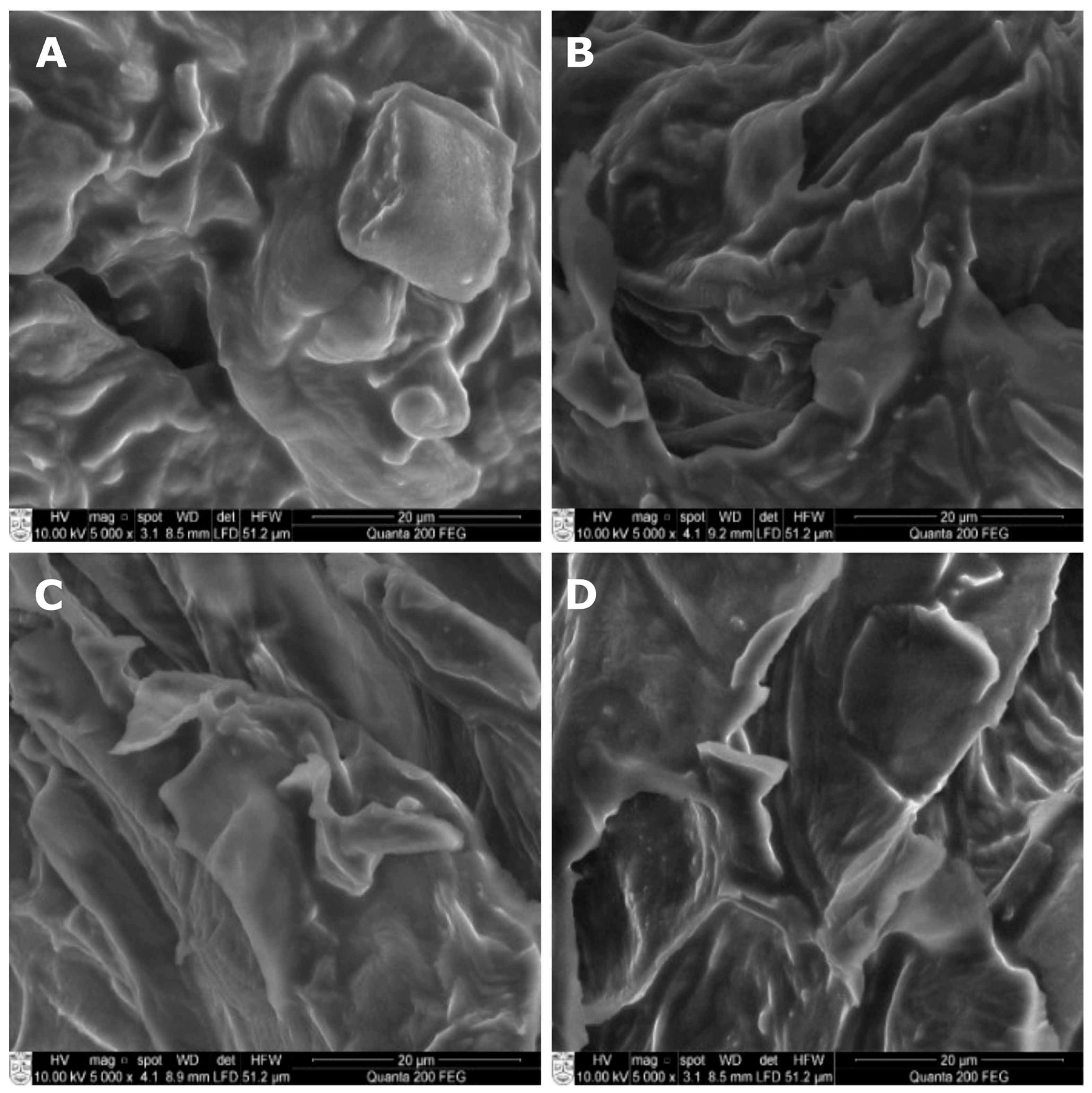

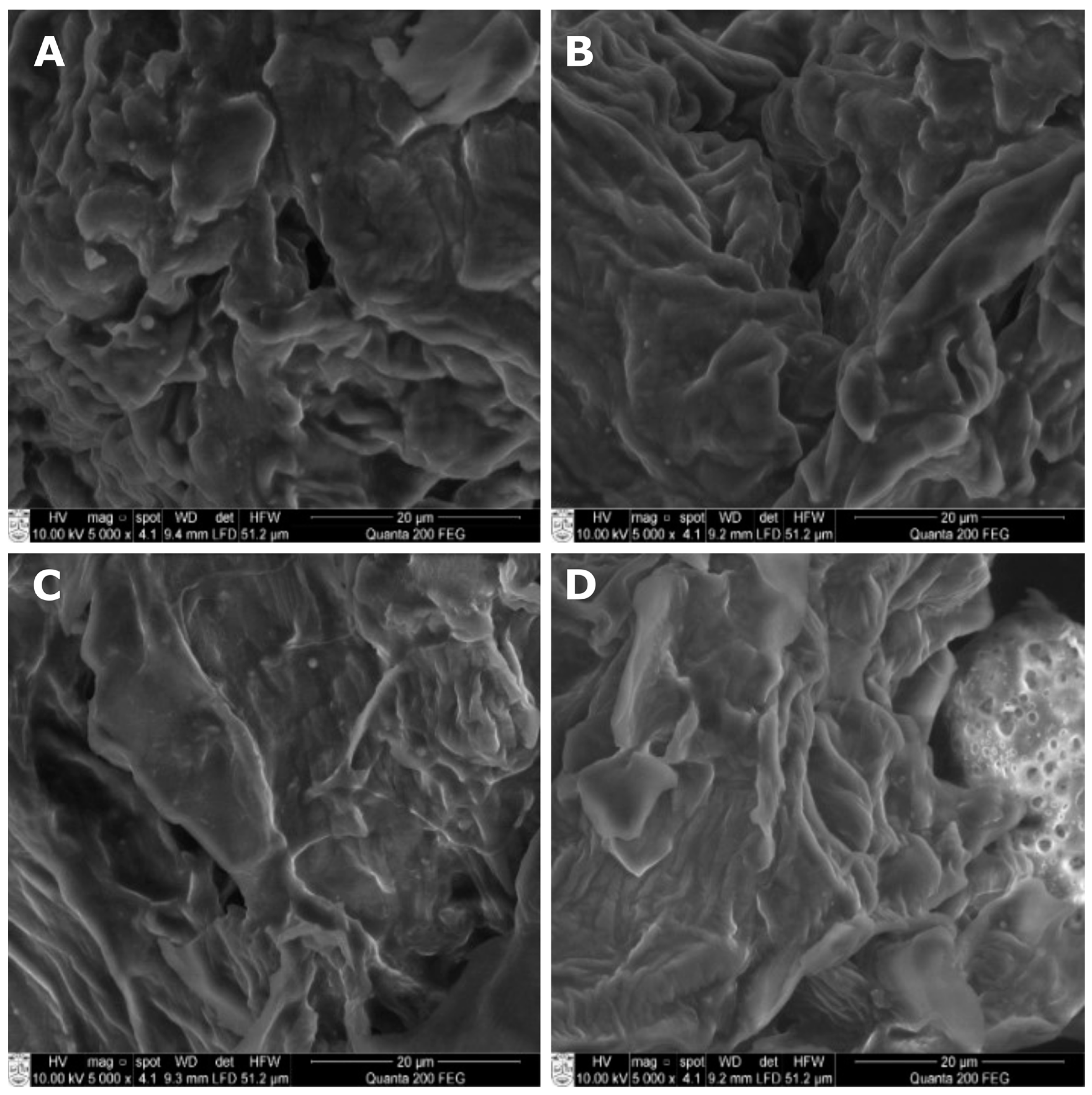

3.2.1. Structure

Scanning electron microscopy (SEM) was used to investigate structural changes of soy press-cakes after undergoing extrusion at different conditions. SEM images of untreated soy press-cakes and extruded samples are presented in

Figure 2, and figures 3 & 4 respectively. All extruded press-cakes were subjected to freeze-drying prior to SEM analysis. It is evident that the structure of both untreated soy samples is similar, that is, the surface of the particles is quite flat with visible flaking (

Figure 2A,B).

Meanwhile, from SEM images of extruded press-cakes some structural changes can be observed (see

Figure 3 and

Figure 4). After extrusion, independently of the processing temperature or moisture of the samples, strands are formed on the surface of the particles, also some voids appear. Extruded press-cakes at a moisture content of 30% show some plasticity, especially it is visible in extruded Soy

t press-cakes (

Figure 3A,B).

As the material cools, it sets into a porous structure. In present study the formation of porous surfaces is clearly visible for press-cakes extruded at higher moisture content (60%) and temperature (120 °C) as the surface is more strand-like and more holes occur (see

Figure 3D and

Figure 4D).

3.2.2. Water-holding and Oil-holding capacity

In developing food texture, WHC plays an important role. WHC reflects the protein's ability to retain water and shape the protein gel network. The higher the value of WHC, the greater the juiciness of meat analogue [

20]. Our study showed that with increasing temperature and humidity in the extrusion process, the water-holding capacity of the samples increased (

Table 2).

Untreated Soy

d had the lowest water-holding capacity, but after extrusion it increased almost 3 times and surpassed Soy

t. Meanwhile, WHC of untreated Soy

t was lower compared to extruded samples. Soy

d is treated with heat process (with similar temperature regime) for double the time as with Soy

t and with additional mechanical pressure. This may have led to increased denaturation of the proteins prior to the extrusion process resulting in the poor water retention observed

. The water-holding capacity of extruded press-cakes increased with increasing temperature and increasing humidity and evolved similarly for both types of soy samples. After extrusion, WHC increased by 31% for Soy

t and by 24% for Soy

d. This suggests that the protein in the press-cakes can form a gel network by hydrophobic interactions, which takes place due to increase in temperature. Our results are in tandem with the study conducted by Bae et al. [

22] who reported increasing water-holding capacities which was demonstrated by the exposure of hydrophobic groups and the unfolding of protein structure with increasing temperature after extrusion.

OHC of extruded soy press-cakes increased compared to untreated press-cakes. Also, slightly higher OHC for untreated press-cakes was observed and is characteristic of Soy

t (1.99 ± 0.23 g/g) compared to Soy

d, which had a lower value i.e., 1.59 ± 0.16 g/g. After extrusion, the oil holding capacity increased by 47% for Soy

t (comparing untreated press cake to highest result, which was conceived by extrusion at 120°C and 60% humidity) and 87% for Soy

d (at same comparison). This increase occurred as the temperature and humidity of the extrusion increased. This was reported due to enhanced porosity of fibres present in press-cake samples, which gave rise to the ability to trap oil droplets. Temperature and humidity independently had a significant effect (

p < 0.05) on the oil holding capacity, unlike their interaction which did not have a significant effect (

p > 0.05). A high lipid retention capacity is necessary to prevent the creation of fat pockets which apart from being unappealing to the user, can also lead to the degradation of products [

23] and creates a juicy texture.

3.3. Nutritional characteristics of non-extruded and extruded press-cakes

3.3.1. Nutritional composition of press cake samples

The results of nutritional analysis of treated and untreated press cake samples have been described in

Table 3. Untreated press cakes of Soy

t had 9,73 g fat per 100-gram dry matter, Soy

d - 11,87 g/100g dm. In Soy

t after extrusion I and II fat content increased up to 15,31 g/100 g dm, but for extrusion III and IV fat amount remained almost the same as in untreated press cakes with values 9,57g and 10,71g respectively.

After extrusion in Soyt samples saturated fatty acid amount and monounsaturated fat amount at I and II extrusion variation increased along with temperature from 2,24 to 2,33 and from 2,89 to 2,97, at III and IV - from 1,85 to 1,96 and from 2,12 to 3,01 g/100g dm respectively. In Soyd saturated fatty content changed without clear tendency with lowest value of 2,26 g/100 g dm (III) to highest - 3,59 g/100g dm (IV). Same tendency was observed in monounsaturated fatty acids amount with lowest value of 3,50 g/100g dm (III) and highest 4,87 g/100g dm (IV). After extrusion in both soy samples poly unsaturated fatty acid amount (PUFA) decreased by increasing temperature and humidity, but in different proportions. In Soyt PUFA decreased from 10,18 (I) to 5,60 (III), in Soyd - from 9,82 (I) to 5,46 (IV) g/100 g dm. None of the samples had trans-fatty acids.

Untreated Soy

t and Soy

d samples had 36,26g/100g dm and 29,74 g/100g dm of protein, respectively. After extrusion in Soy

t samples protein amount remained very similar varying from 33,45g/100g dm (II) to 33,69/100g dm (IV). In Soy

d case protein amount after extrusion increased up to 34,36g/100g dm (IV). This result might appear due to high temperature, screw speed and moisture, which resulted in more insoluble extruded products, indicative of cross-linking reactions which possibly created some covalent bonds [

24].

Increasing temperature increased the total sugar content in soy press-cakes. This occurred because some simple carbohydrates might have decomposed under high temperature and humidity. In untreated Soyt and Soyd samples total sugar was equal 0,16g/100g dm. After extrusion this amount increased but without tendency attached to humidity or temperature and reached from 1,61g/100g dm (IV) to 4,14g/100gm dm (II) for Soyt and from 1,19g/100g dm (III) to 2,06g/100g dm (II) for Soyd.

Untreated press cakes reported similar fibre content. For Soy

t it was 50,27g/100g dm, and for Soy

d it was 51,19 g/100g dm. After extrusion in both press cakes, fibre content lowered. Soy

t decreased to 35,99g/100g dm (III) and 39,94g/100g dm (IV). For Soy

d dietary fibres decreased to 37,28g/100g dm (II) to 41,77g/100g dm (IV). Dietary fibres are an essential aspect of nutritional value due to their effect on the betterment of health as their consumption leads to lower incidences of developing several diseases. In the study conducted by Rajput et al, [

25] it has been stated that extrusion-cooking, fermenting, crushing, brewing, and frying may change the physico-chemical characteristics of dietary fibre.

3.3.2. Trypsin inhibitor levels in press cake samples

Trypsin inhibitors in the digestive tract are responsible for impairing the function of trypsin enzymes. Inactivation of these inhibitors is possible at elevated processing temperatures [

26]. The activity of trypsin inhibitor can be utilised as a potential measure of processing to get hypoallergenic properties of protein isolates. As the trypsin inhibitor is heat-labile, extrusion caused the trypsin inhibitor activity to degrade significantly. Trypsin inhibitor levels of treated and untreated press cake samples are displayed in

Table 4.

Trypsin inhibitor activity lowered from 0,83mg/g up to 0,64 mg/g dm in Soy

t press-cakes (

Table 3), while the lowest activity was observed in Soy

d (III) at 0.51 mg/g dm. On the other hand, untreated Soy

d showed trypsin inhibitor activity at 1,74 mg/g dm. Soy

d (II) also showed high trypsin inhibitor levels at 1.36 mg/g dm. Soy

t (II) was the only sample from Soy

t group to show high trypsin inhibitor levels at 1.07 mg/g dm.

3.3.3. Amino acid composition of press cake samples

The results of amino acid’s analysis have been shown in

Table 5. In Soy

t, essential amino acids histidine and valine increased in number at 30% humidity, while in Soy

d, all essential amino acids increased at the temperature of 110°C except phenylalanine which increased only at the temperature of 120°C. Similarly, while all non-essential and conditionally non-essential amino acids were lower in extruded Soy

t press-cakes, Soy

d showed an increase in non-essential and conditionally non-essential amino acids at 110°C temperature except serine which increased at 120°C.

In all samples all essential amino acids were detected in significant amounts. Upon comparison, Soyt and Soyt extruded samples on average reported higher levels of almost all amino acids than Soyd and Soyd extruded samples. This could be attributed to higher protein content in Soyt and Soyt extruded samples, as well as to the different processes by which soy drink press cake and tofu press cake are produced. Due to the presence of coagulation step in the production of Soyt press cakes, there might by a higher degree of hydrolysis of soy proteins which may explain higher content of almost all amino acids detected in Soyt and Soyt extruded samples.

3.4. Analysis of meat analogues produced from non-extruded and extruded press-cakes

3.4.1. Texture profile analysis of prepared meat analogues from treated and untreated press cake samples

Texture profile analysis (TPA) is useful as the textural characteristics derived from TPA correlates with the sensory assessment of textural characteristics [

27]. The capability to retain fat, oil, and water-holding capacity, as well as their gelling and emulsifying properties which can be measured via texture analysis are all factors to consider. The sensory characteristics and rheological properties of different foods have been compared using parameters found in texture profile analysis such as hardness, adhesiveness, cohesiveness, springiness, and gumminess [

28]. The most evaluated parameter for texture analyses is hardness or firmness, which is the force required to achieve a physical deformation to the original structure. This texture property is crucial for meat analogue products such that they are not deformed during the process of cooking [

29]. The results of texture profile analysis of press cake samples have been displayed in

Table 6. In our samples, hardness decreased after the addition of extruded press-cakes. The lowest measure of hardness was noted when 6% of extruded press-cakes were added to the meat analogues, while the highest was observed at I extrusion conditions and 3% added press cakes. Hardness for meat analogues with extruded Soy

t and Soy

d press-cakes were between 9 – 30 N and 9 – 24 N, respectively. Samples are coded with following abbreviations:

MA-C – control, without press-cakes.

M – meat analogue

MT – meat analogue with press cakes from tofu production

MD – meat analogue with press cakes from soy drink production.

I-IV – shows which extrusion regime was used for certain press cake that was used in meat analogue (as mentioned in methodology section 2.3)

3%, 6% - amount of extruded press cakes added to meat analogue.

The texture profile analysis depicts that the addition of extruded press-cakes to the meat analogue matrix did show some significant effect and improved its hardness, springiness and gumminess as compared to the control meat analogue. The results of texture profile analysis show similar characteristics of meat analogues with extruded press-cakes to that of meat patties.

Springiness of meat analogue samples containing extruded Soyt and Soyd press-cakes had values between 1.5– 5.8 mm and 2.4– 2.9 mm, respectively. Applied extrusion regimens had a significant effect on the springiness of samples, except for sample MT I 3% (p < 0.05). Gumminess lowered with the addition of extruded press-cakes to meat analogue matrix. It can be noted that the gumminess of the meat analogues with the addition of 6% of extruded Soyt press-cakes was lower while meat analogues with the addition of 3% of extruded press cakes was higher in most cases. All values were statistically significant (p < 0.05).

The texture of meat analogues containing 6% of Soyd press-cakes extruded at IV extrusion conditions and 32% texturized soy protein as the base matrix resembled the closest to the texture of meat patties.

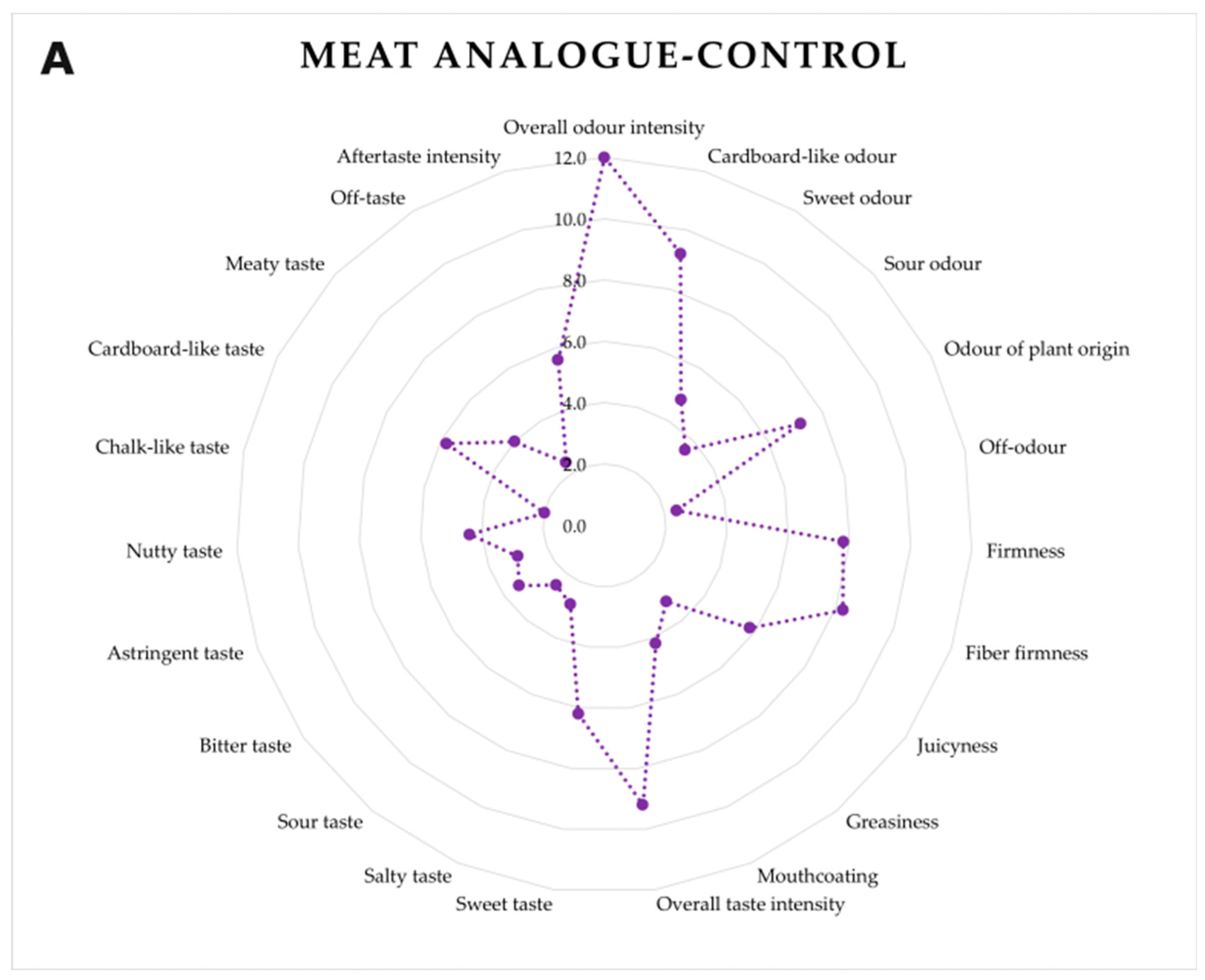

3.4.2. Sensory analysis of prepared meat analogues from treated and untreated press cake samples

Sensory assessment by trained panellists were conducted on the following samples:

MA-C – control, without press-cakes.

M – meat analogue

MT – meat analogue with press cakes from tofu production

MD – meat analogue with press cakes from soy drink production.

I-IV – shows which extrusion regime was used for certain press cake that was used in meat analogue (as mentioned in methodology section 2.3)

3%, 6% - amount of extruded press cakes added to meat analogue.

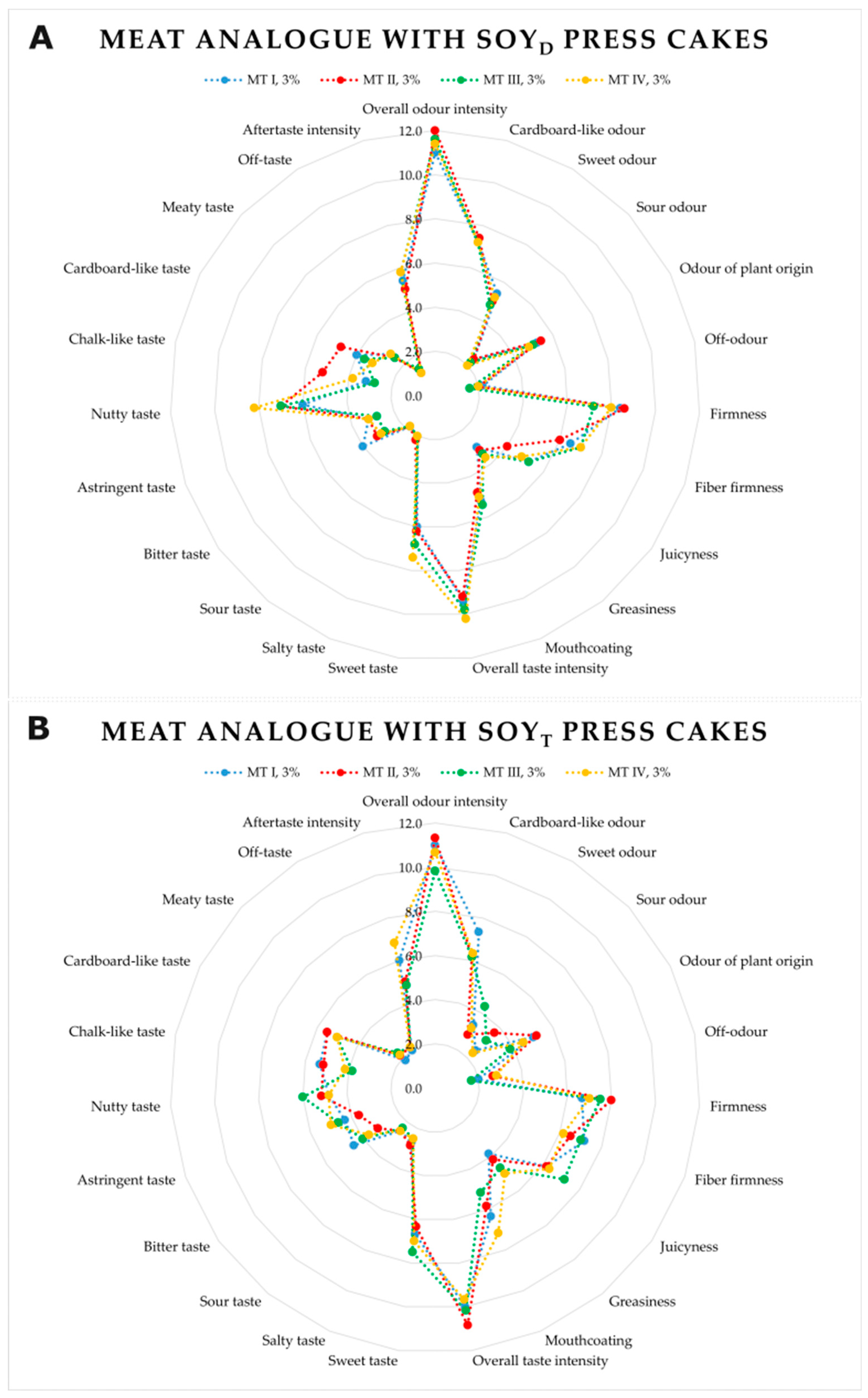

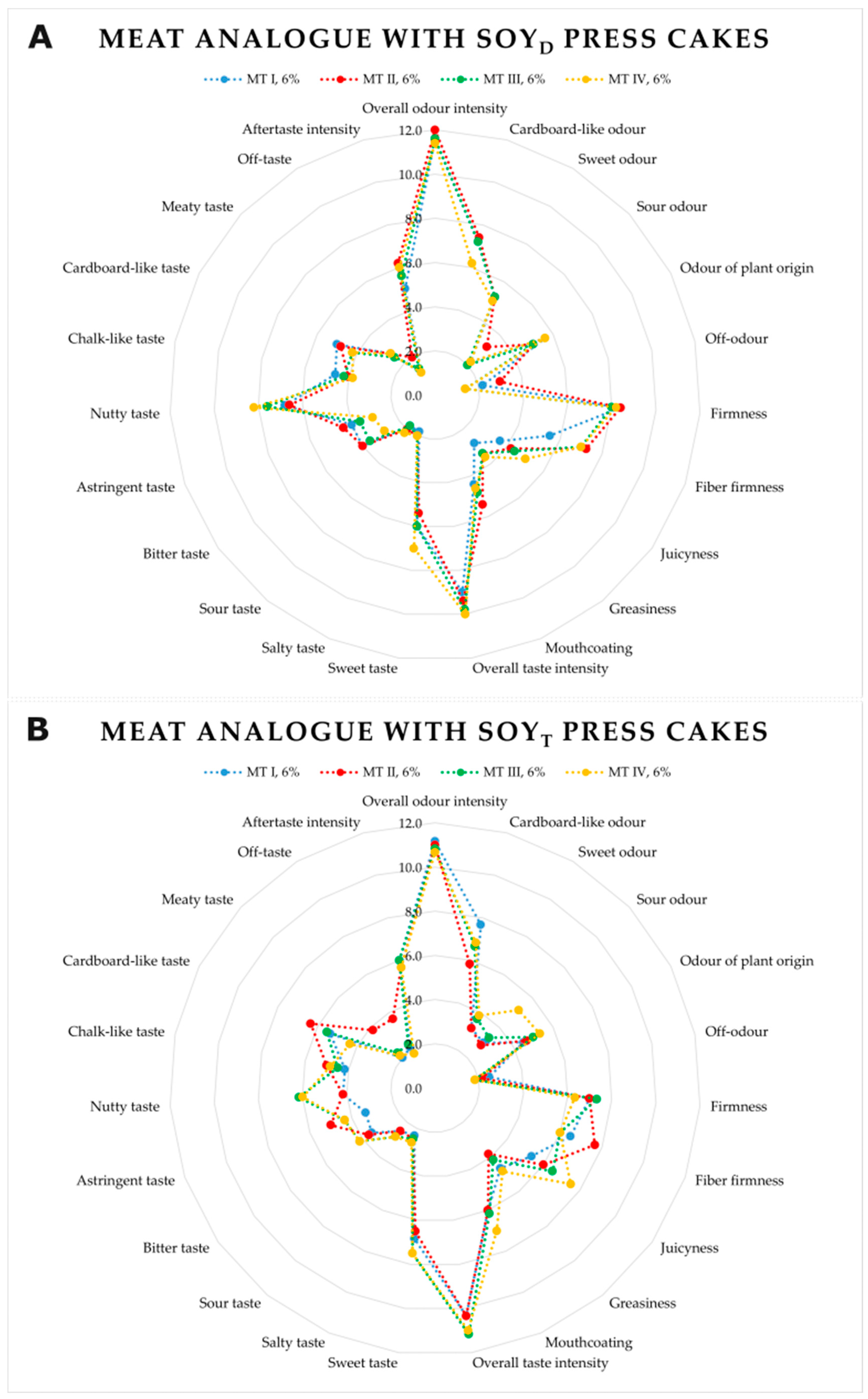

Sensory evaluation of the samples was comparable between control sample and experimental samples prepared from either 3% or 6% of Soy

d or Soy

t press cake (

Figure 5,

Figure 6 and

Figure 7). For example, almost all samples (including control sample) rated extremely high on overall odour intensity (around 11/12 out of 12). Differences were most clearly observed in nutty taste profile, where control samples (

Figure 5A) were rated almost half of the score (4.4/12) that was assigned to samples produced by the addition of Soy

d (

Figure 6A and

Figure 7A) press cakes (between 7-8/12). For meat analogues prepared with the addition of Soy

t press cake, the nutty taste profile was not markedly different from control samples (

Figure 6B and

Figure 7B). Almost all samples reported lower ratings for negative sensory descriptors which include off odour, bitter taste, sour taste, and off taste.

Interestingly, all samples including control also reported lower scores for the sensory descriptor “meaty taste”. Instead, a pronounced nutty taste was reported to be more prevalent across all samples prepared with Soyd and Soyt press cakes.

Compared with control sample, the firmness and fibres firmness of all samples prepared with Soyd and Soyt press cakes were reportedly higher. On overall comparison of the meat analogues with extruded press-cakes, meat analogue made by adding 6% of Soyd press-cakes extruded at IV conditions showed the highest scores (overall acceptability – 11,2 out of 12) suggesting capability of this meat analogue matrix to be well accepted by the consumers if launched in the market.

4. Discussion

Our study investigates the application of varying moisture and temperature during low & high moisture extrusion cooking processes on soy press cakes produced as by-products from soy drink and tofu manufacturing for the development of plant-based meat analogue products. This study compares the morphology, physico-chemical composition, functional parameters, and sensory qualities of unextruded and extruded soy press cakes, and samples of meat analogues produced with the addition of small amounts of press cake.

Our results indicate for the extrusion process of press-cake samples, temperature and humidity independently showed significance (

p < 0.05), whereas their interactions did not have any significance (

p > 0.05). This is shown by the fact that increasing moisture of press cakes from low moisture to high moisture (> 60%) has a more significant effect on specific mechanical energy of extruder screw than the barrel temperature (

Table 1) which has a bigger role in extrudates being different in their properties. Specifically, soy press cakes originating from tofu manufacturing process exhibited higher specific mechanical energy compared to soy press cakes originating from soy drink manufacturing process. The mechanical energy imparted by the twin screws helps in thorough mixing and kneading of the soy press cake. The high shear forces and intense mechanical action break down the protein matrix and distribute the heat evenly, leading to effective heat transfer and cooking of the material. Specific mechanical energy also influences the pressure build-up within the extruder and the residence time of the material inside the barrel. Higher values typically lead to increased pressure and longer residence time. This can be beneficial for soy press cake extrusion as it allows for better oil extraction, improved starch gelatinization, and reduced antinutritional factors. However, excessive specific mechanical energy may lead to overcooking or degradation of the proteins and other nutrients, so it needs to be controlled within an optimal range.

When comparing the morphology of treated and untreated soy press cake samples via scanning electron microscopy, there are clear surface-level changes between the appearance of untreated and treated soy press cake samples. The flakiness and flatness of untreated soy press cakes disappeared upon extrusion, and we observe the presence of few threads like striations and some gaps at the surface, indicating that the extruded press- cake is not as flat as it was prior to extrusion. According to Aguilera et al. [

29] during extrusion at the die “puffing” of the material occurs, which is mainly due to flashing-off of superheated vapour and to the release of normal stresses. This results in the difference in surface topography of the extruded material, causing it to become “texturized.” The specific mechanical energies of soy press cakes from soy drink and tofu manufacturing process also support the findings of high-resolution imaging via scanning electron microscopy. Specific mechanical energy has a significant impact on the morphological & textural properties of the extrudate obtained from soy press cake. By controlling the specific mechanical energy, it is possible to influence factors such as expansion ratio, bulk density, texture, and nutritional characteristics of the final product. Adjusting the specific mechanical energy can help achieve the desired extrudate characteristics in terms of texture, shape, and size.

The best water-holding and oil holding capacity were demonstrated in Soy

d press-cakes extruded at 120°C and 60% humidity having a protein content of 15.3%, and the best bulk density was observed in Soy

d press-cakes extruded at 110 °C and 30% humidity having a protein content of 26.1%. During extrusion, a new spatial structure of proteins is likely to form which may result in improved water retention. As okara produced from soy drink manufacturing processes is usually drier and finer compared to okara produced from tofu manufacturing process, we observe an increase in WHC in Soy

d press cakes before and after extrusion which may be due to protein unfolding upon extrusion cooking. Increased WHC can create an analogue matrix which can hold more moisture and would lead to a more pleasant and acceptable in-mouth feel. On the other hand, the binding of fat with other biomolecules, in particular proteins and carbohydrates affects the texture properties and other qualities of food. In formulations, the ability of proteins to absorb and retain fat and to interact with lipids in emulsions and other food systems is important. Oil holding in meat analogue matrix occurs due to the interactions between the proteins and fats in the product. When press cake is processed and combined with other ingredients to create a meat analogue, the proteins in the press cake can form a network that entraps and holds the oil within the product. This network helps to prevent the oil from leaching out of the product, giving the meat analogue a more moist and juicy texture [

22]. Moreover, the hydrophobic domains of proteins influence fat absorption. Therefore, depending on the extent of the polar side chains of amino acids present on the surface of protein molecules, the oil holding ability of the samples can differ. When compared with the study conducted by Wu et al. [

35] where the press cakes were fermented, our proposed results from WHC and OHC analysis are quite similar and lie within the same range.

The WHC and OHC of press cakes affects the textural properties of press cakes, specifically due to the method used to produce press cakes. Combined with varying extrusion parameters, these are the main factors which contribute to the differences in natural texture of okara produced from either tofu manufacturing, where it is generally softer and moister due to high moisture content, or from soy drink manufacturing where natural consistency is reported to be drier and finer. Texture analysis revealed Soy

d press-cakes extruded at 120°C with 60% moisture resembles native meat the closest. Hardness increased as the amount of extruded press-cakes in the meat analogues increased (from 3% to 6%). Detected firmness values can be attributed to the use of rapeseed oil in the matrix, which induces protein-protein interaction. Hyun et al. [

36] findings matched our observations, in which rapeseed oil formed a dense protein gel network of soy protein isolate matrix due to hydrophobic interaction between the oil globule and the hydrophobic peptides in the protein.

The results of nutritional analysis of press cake samples revealed that in the case of Soy

d, in all extrusion regimen variations the fat amount increased up to 16,84 (I) from 14,40 (III). However, this high amount of ω-6 linoleic acid in press cakes adds to health benefits & can also easily oxidize through extrusion [

31]. We also see a decrease in total dietary fibres content in our press cake samples after extrusion for both low and high moisture extrusion regimens. Vaculova et al., [

32] reported that after extrusion, the physico-chemical properties and the number of fibres varies, and is dependent on the material, its composition, and the process parameters. Increasing process parameters weaken the bonds between polysaccharide chains, causing them to split. Glycosidic linkages in the polysaccharides of dietary fibre can also be disrupted. Trypsin inhibition assay results show that as extrusion temperature and humidity increased, there was an increase in the inactivation of trypsin inhibitors. These results are concurrent with the study conducted by Liener et al. [

33] where antinutrients such as trypsin lowered at elevated temperatures and humidity. The remaining trypsin can be lowered during the cooking process of meat analogues at high temperatures to inactivate heat-sensitive factors [

34].

Amino acid’s analysis indicated the most abundant amino acids in all samples were glutamic and aspartic acid, which are responsible for giving rise to delicate umami taste. This led us to hypothesize that extruded press-cakes might improve overall taste and sensory acceptance of produced meat analogue matrix. Compared to untreated press-cakes glutamic and aspartic acid amount after extrusion in Soyd samples remained almost unchanged. In Soyt case the amount of glutamic and aspartic acid after extrusion at lower humidity showed only slight changes, whereas their levels decreased by half after extrusion at higher humidity levels. It is interesting to note that the same extrusion regimen led to either increase or decrease of a particular amino acid (e.g., levels of serine in Soyt IV and Soyd IV after extrusion with same conditions) for soy press cakes depending on the method of press cake production. This peculiarity may shed additional light in the differences between the nutritional and sensory characteristics of press cake produced using different production strategies. For example, there are some amino acids that are known to impart sweet taste (serine, glycine, threonine, alanine, and proline). These amino acids were detected in significant amounts in almost all untreated samples which also led us to hypothesize that along with significant amounts of glutamic and aspartic amino acids, other amino acids can form pleasant, sweet, and delicate taste which may resemble meat. However, we also hypothesize that combinations of differing concentrations of these amino acids are generated by the method of press cake production, along with conditions of extrusion.

Sensory analysis revealed Soy

d press cake, extruded at 120°C with 60% moisture added to meat analogue samples in 6% concentration scored the highest in overall consumer acceptance which is aggregated from multiple criteria among panellists. This is an interesting result as in natural state, okara produced from soy drink manufacturing processes is reported to be finer and drier compared to okara produced via tofu production. This shows that extrusion moisture plays an important role in radically changing the sensory property of soy press cakes, and even a small addition (3% or 6%) of the extruded press cakes can improve a pronounced nutty flavour, while also reducing the sensations of bitterness and astringency. These properties can be used in the production of other products, such as chips and snacks. Prior to consumption, the product’s appearance is critical for attracting consumers and establishing expectations. As a result, it is necessary to provide good sensory qualities that can be experienced before and after consumption of the product [

37]. To create positive expectations, meat analogues should have a similar overall appearance to familiar meat products. The recreation of the distinctive appearance, taste, flavour, aroma, texture, mouthfeel, and moistness of conventional meat products is another challenge for developing meat analogues [

38].

Overall, our findings focus on the differences in the morphological, functional, nutritional, textural, and sensory properties between soy press cakes produced via different manufacturing processes, and how variation in extrusion parameters can change these properties. For the production of meat analogue prototypes, it is essential to consider the origin of press cakes and the moisture and temperature of extrusion cooking. Based on the analysis of the extruded press cakes it can be concluded that in terms of morphological, nutritional, functional and flavour characteristics, soy press cakes are highly suitable for further development as a component of meat analogues.

5. Conclusions

As global food production and supply chains are currently shown to be vulnerable due to current geo-political and global public health situations, it is plausible to assume that demands for food are inevitable going to increase soon, perhaps sooner than predicted. Therefore, it is imperative to develop new strategies for both development of products and the production of said products that can keep up with global demand, while not compromising on nutritional value, consumer acceptability and production scaling.

To further investigate the potential of modifying extrusion conditions to produce meat analogues, it is crucial to design studies that explore the combination of extrusion with fermentation and/or hydrolysis of press cake to produce meat analogues. Razavizadeh et. al. [

5] reported that fermentation and hydrolysis of soy press cakes improve the functional properties and reduces protein oxidation along with increased overall consumer acceptability of produced meat analogues. Therefore, future studies are needed to assess the compatibility of different press cake pre-treatment methods, including fermentation, hydrolysis, ultrasonication etc. with produced extrudates performed on press cakes of different plant origins, such as hemp press cakes.

To conclude, our findings indicate that different extrusion regimens result in differences in the physico-chemical, morphological, functional, and sensory properties of produced extrudates. The choice of the method of producing the press cakes is equally important, as we noticed in sensory assessment that Soyd press cakes reported a higher “meaty” taste than Soyt press cakes, but in overall sensory comparison Soyt extrudates were more acceptable. Therefore, our results thus identify soy press cake sourced from both soy drink and tofu manufacturing process extruded at 120°C with 60% moisture using a twin-screw extruder as suitable to be utilised in the development of meat analogue products, however extrusion conditions will greatly affect the final desired outcome.

Author Contributions

All authors contributed to the study conception and design. All authors read and approved the final manuscript. CRediT authorship contribution statement; Conceptualization, Aditya Bali and Alvija Šalaševičienė; Formal analysis, Aelita Zabulionė, Shreya Kumar, Dovilė Liudvinavičiūtė and Laura Pečiulytė; Funding acquisition, Alvija Šalaševičienė; Investigation, Aelita Zabulionė, Shreya Kumar, Dovilė Liudvinavičiūtė, Laura Pečiulytė, Ramunė Rutkaitė and Alvija Šalaševičienė; Methodology, Aelita Zabulionė, Dovilė Liudvinavičiūtė, Laura Pečiulytė, Ramunė Rutkaitė and Per Ertbjerg; Resources, Alvija Šalaševičienė; Supervision, Alvija Šalaševičienė; Validation, Aelita Zabulionė; Visualization, Aditya Bali and Aelita Zabulionė; Writing – original draft, Aditya Bali, Aelita Zabulionė, Dovilė Liudvinavičiūtė and Ramunė Rutkaitė; Writing – review & editing, Aditya Bali, Dovilė Liudvinavičiūtė, Ramunė Rutkaitė, Per Ertbjerg and Alvija Šalaševičienė.

Acknowledgments and Funding

This research is a part of project, “Disaggregation of Conventional Vegetable Press Cakes by Novel Techniques to Receive New Products and to Increase the Yield” (DISCOVERY) H2020 activity ERA-NET SUSFOOD2. Research was funded by national/regional sources LR Ministry of Agriculture TM-18 1/2, and co-funding by the European Union's Horizon 2020 research and innovation programme.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shakeel A, Saeed MS, Aslam HKW, Naheed N, Shoaib MH, Razal MS, Noor A Extraction of soya milk from different varieties 0 of soya beans and comparative study for better nutrition with buffalo milk. J Global Innov Agricult Soc Sci 2015, 3, 146–151. [CrossRef]

- P. Ancuta, A. Sonia Oil press-cakes and meals valorisation through circular economy approaches: A review. Applied Sciences 2020, 10, 7432. [CrossRef]

- K. Trakselyte-Rupsiene, G. Juodeikiene, G. Alzbergaite, D. Zadeike, E. Bartkiene, F. Ozogul, L. Rueller, J. Robert, J.M.F. Rocha Bio-refinery of plant drinks press cake permeate using ultrafiltration and lactobacillus fermentation into antimicrobials and its effect on the growth of wheatgrass in vivo. Food Biosci. 2022, 46, 101427.

- Vaitkeviciene, R.; Bendoraitiene, J.; Degutyte, R.; Svazas, M.; Zadeike, D. Optimization of the Sustainable Production of Resistant Starch in Rice Bran and Evaluation of Its Physicochemical and Technological Properties. Polymers 2022, 14, 3662. [Google Scholar] [CrossRef]

- Seyedmahmood Razavizadeh, Gitana Alenčikienė, Lina Vaiciulyte-Funk, Per Ertbjerg, Alvija Šalaševičienė, Utilization of fermented and enzymatically hydrolyzed soy press cake as ingredient for meat analogues. LWT 2022, 165, 113736. [CrossRef]

- Martin A, Naumann S, Osen R, Karbstein HP, Emin MA. Extrusion Processing of Rapeseed Press Cake-Starch Blends: Effect of Starch Type and Treatment Temperature on Protein, Fiber, and Starch Solubility. Foods. 2021, 10, 1160. [CrossRef] [PubMed] [PubMed Central]

- Schmid, E.- M., Farahnaky, A., Adhikari, B., & Torley, P. J. (). High moisture extrusion cooking of meat analogs: A review of mechanisms of protein texturization. Comprehensive Reviews in Food Science and Food Safety 2022, 1– 37. [CrossRef]

- Morrison, Oliver, “Why high moisture extrusion could solve alt meat’s nutritional as well as structural challenges.” Food Navigator. 2022. Available online: https://www.foodnavigator.com/Article/2022/03/24/Why-high-moisture-extrusion-could-solve-alt-meat-s-nutritional-as-well-as-structural-challenges.

- Jung-Soo Lee, Hyewon Oh, Inyoung Choi, Chan Suk Yoon, Jaejoon Han, Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology, LWT 2022, 157, 113056.

- S.M. Beck, K. Knoerzer, M. Foerster, S. Mayo, C. Philipp, J. Arcot Low moisture extrusion of pea protein and pea fibre fortified rice starch blends Journal of Food Engineering. 2018, 231, 61–71.

- Miller, R.C. Low Moisture Extrusion: Effects of Cooking Moisture on Product Characteristics. Journal of Food Science 1985, 50, 249–253. [Google Scholar] [CrossRef]

- Aussanasuwannakul, A.; Teangpook, C.; Treesuwan, W.; Puntaburt, K.; Butsuwan, P. Effect of the Addition of Soybean Residue (Okara) on the Physicochemical, Tribological, Instrumental, and Sensory Texture Properties of Extruded Snacks. Foods 2022, 11, 2967. [Google Scholar] [CrossRef] [PubMed]

- Chiang, J.H., Loveday, S.M., Hardacre, A.K., Parker M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Structure. 2019, 19, 100102. [CrossRef]

- Prinyawiwatkul, W., Beuchat, L.R., Phillips D. and Resurreccion V.A. Modeling the effects of peanut flour, feed moisture content, and extrusion temperature on physical properties of an extruded snack product. International Journal of Food Science and Technology. 1995, 30, 37–44. [CrossRef]

- et al. Clifford Smith et al. The Determination of Trypsin Inhibitor Levels in Foodstuffs. Journal of the Science of Food Science and Agriculture [online]. 1980, 31, 341–350, [viewed on 7th January 2021]. [Google Scholar] [CrossRef]

- Sadh Kumar Pardeep et al. Fermentation approach on phenolic, antioxidants and functional properties of peanut press cake. Food Bioscience [online]. 2018, 22, 113–120, [viewed on 9th January 2021]. [CrossRef]

- Vidal, Natalia P., et al. "Enhancing the nutritional value of cold-pressed oilseed cakes through extrusion cooking." Innovative Food Science & Emerging Technologies. 2022, 77, 102956.

- Karunanithy C, Muthukumarappan K, Gibbons WR. Effect of extruder screw speed, temperature, and enzyme levels on sugar recovery from different biomasses. ISRN Biotechnol. 2012, 2013, 942810. [CrossRef] [PubMed] [PubMed Central]

- Köksel, H., Ryu, G.-., Başman, A., Demiralp, H., & Ng, P. K. W. Effects of extrusion variables on the properties of waxy hulless barley extrudates. Nahrung – Food 2004, 48, 19–24. [CrossRef]

- Yongfeng Ai, Karen A. Cichy, Janice B. Harte, James D. Kelly, Perry K.W. Ng, Effects of extrusion cooking on the chemical composition and functional properties of dry common bean powders. Food Chemistry 2016, 211, 538–545. [CrossRef]

- Wi, G.; Bae, J.; Kim, H.; Cho, Y.; Choi, M.-J. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461. [Google Scholar] [CrossRef]

- Bae, J., et al. Evaluation of the Physicochemical and Structural Properties and the Sensory Characteristics of Meat Analogues Prepared with Various Non-Animal Based Liquid Additives. Foods 2020, 9, 461–463 PMID 32276505. [CrossRef] [PubMed]

- Zanette, B., et al. Comparison of physicochemical and functional properties of surimi and protein isolate obtained from mechanically deboned meat of chicken. International Food Research Journal [online]. 2015, 22 (4), 1374-1379. ISSN 2231 7546. Available online: http://www.ifrj.upm.edu.my/22%20(04)%202015/(9).pdf.

- K. Maurya and P. P. Said. Extrusion Processing on Physical and Chemical Properties of Protein Rich Products-An Overview. Journal of Bioresource Engineering and Technology. 2014, 1, 67–73. Available online: http://jakraya.com/journal/pdf/5-jbetArticle_2.pdf.

- Rajput, H., et al. Dietary fibre in foods: a review. Journal of Food Science and Technology. 2012, 49, 255–266. [CrossRef]

- Khan, K., et al. Fortification of Spaghetti with Edible Legumes. I. Physicochemical, Antinutritional, Amino Acid, and Mineral Composition. Cereal Chemistry [online]. 1986, 63, 210–215, [viewed 3rd March 2021]. Available online: https://www.cerealsgrains.org/publications/cc/backissues/1986/Documents/chem63_210.pdf.

- Chandra, M. V., et al. Texture Profile Analysis and Functional Properties of Gelatin from the Skin of Three Species of Fresh Water Fish. International Journal of Food Properties [online]. 2015, 81, 572–584. [CrossRef]

- Bourne, M. C., et al. Parameters of Texture Profile Analysis. Food Science and Technology Research [online]. 2013, 19, 519–521. [CrossRef]

- Onega, E., et al. A comparison between two methods (Warner-Bratzler and Texture profile analysis) for testing either raw meat or cooked meat. Meat Science. 2005, 69, 527–536. [CrossRef]

- Aguilera, J.M. and Kosikowski, F.V. Ultrastructural changes occurring during thermoplastic extrusion of soybean grits. Journal of Food Science. 1976, 41, 1209–1213. [CrossRef]

- Simopoulos, A. P., et al. An Increase in the Omega-6/Omega-3 Fatty Acid Ratio Increases the Risk for Obesity. Nutrients. 2016, 8, 128–131. [CrossRef]

- Vaculova, K., et al. The effects of extrusion on the content and properties of dietary fibre components in various barley cultivars. Journal of Cereal Science [online]. 2016, 68, 132–139. [CrossRef]

- Liener, I. E. Implications of antinutritional components in soybean foods. Crit Rev Food Sci Nutrition [online]. 1994, 34, 31–67. [Google Scholar] [CrossRef] [PubMed]

- Albert, C., et al. Methods and procedures for reducing soy trypsin inhibitor activity by means of heat treatment combined with chemical methods. Scientific Journal of Sapientia University. 2018, 11, 58–80. [CrossRef]

- Wu, W., Hua, Y., Lin, Q., & Xiao, H. Effects of oxidative modification on thermal aggregation and gel properties of soy protein by peroxyl radicals. International Journal of Food Science and Technology 2011, 46, 1891–1897. [CrossRef]

- Hyun, Y. J., Mok, Y. S., & Jang, D. I. Transesterification of vegetable oils in pulsed-corona plasma discharge process. Journal of the Korean Applied Science and Technology 2012, 29, 81–87.

- Delwiche, J. The impact of perceptual interactions on perceived flavor. Food Quality and Preference. 2004, 15, 137–146. [Google Scholar] [CrossRef]

- Kinchila, A. J., et al. Role of Sensory Evaluation in Consumer Acceptance of Plant-Based Meat Analogs and Meat Extenders: A Scoping Review. Foods. 2020, 9, 1334. [CrossRef] [PubMed]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).