Submitted:

19 June 2023

Posted:

20 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

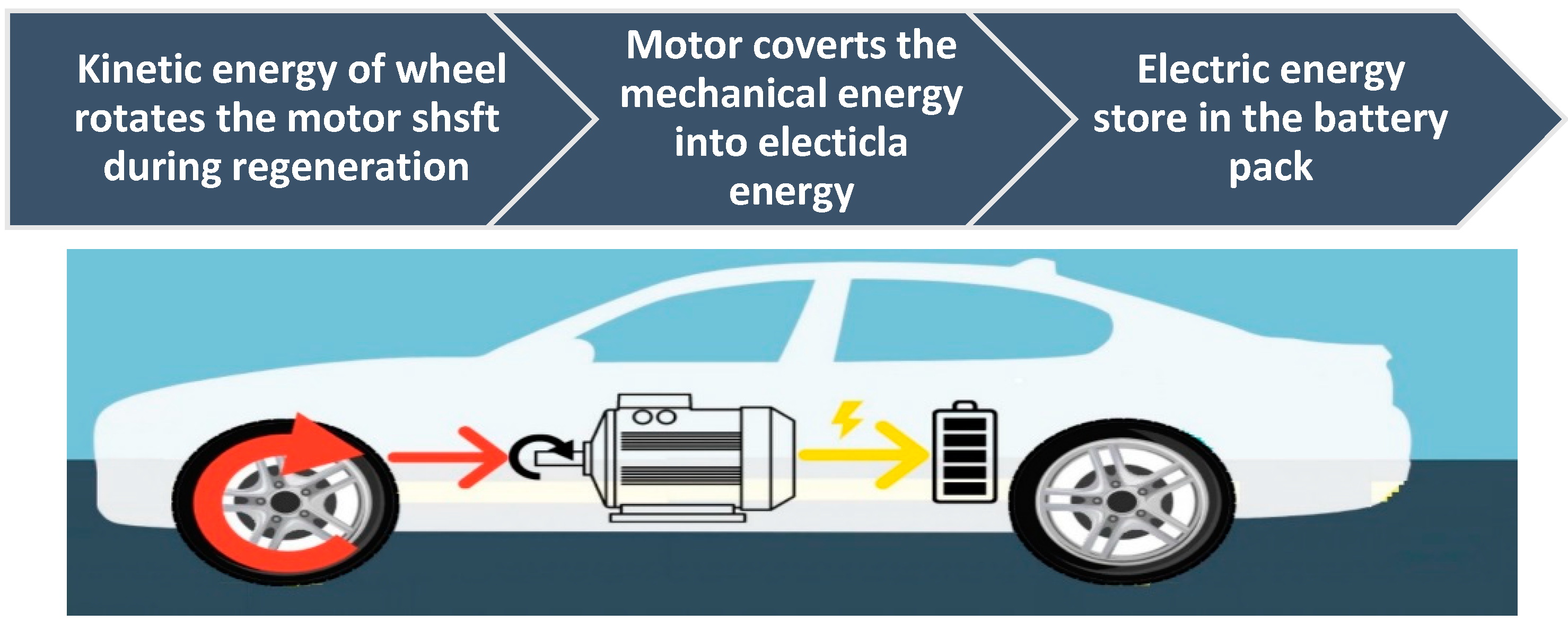

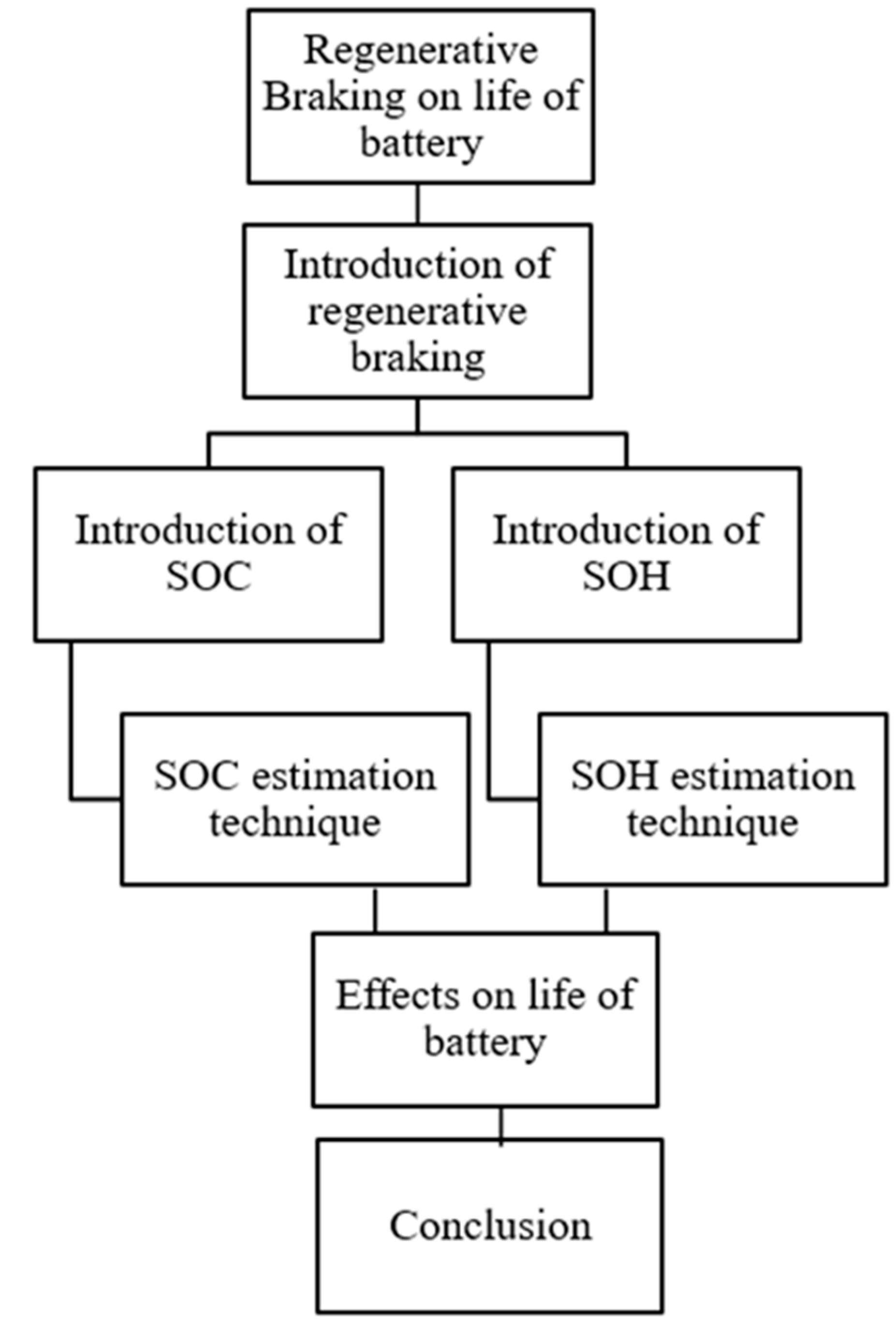

2.1. Regenerative Braking

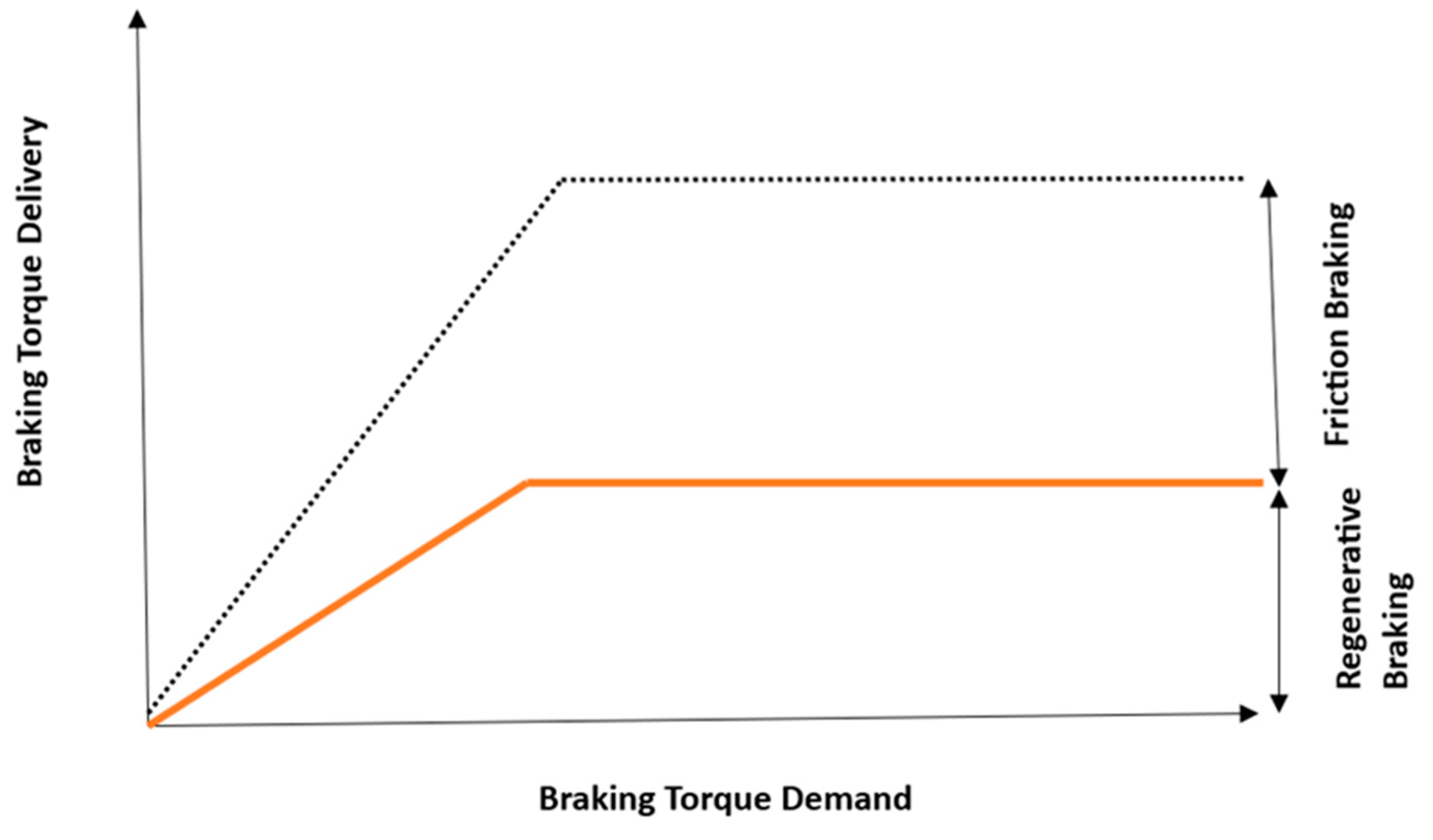

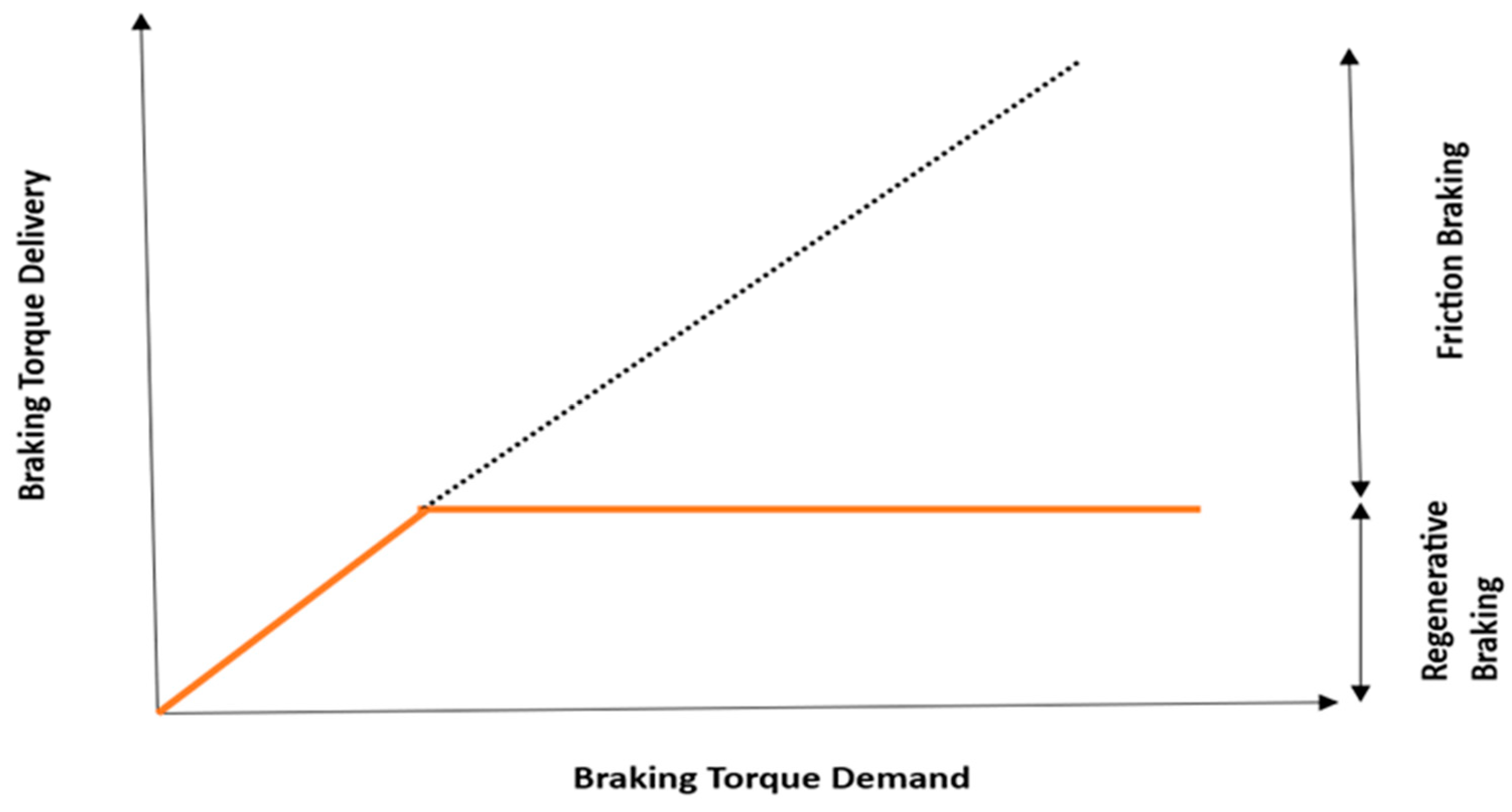

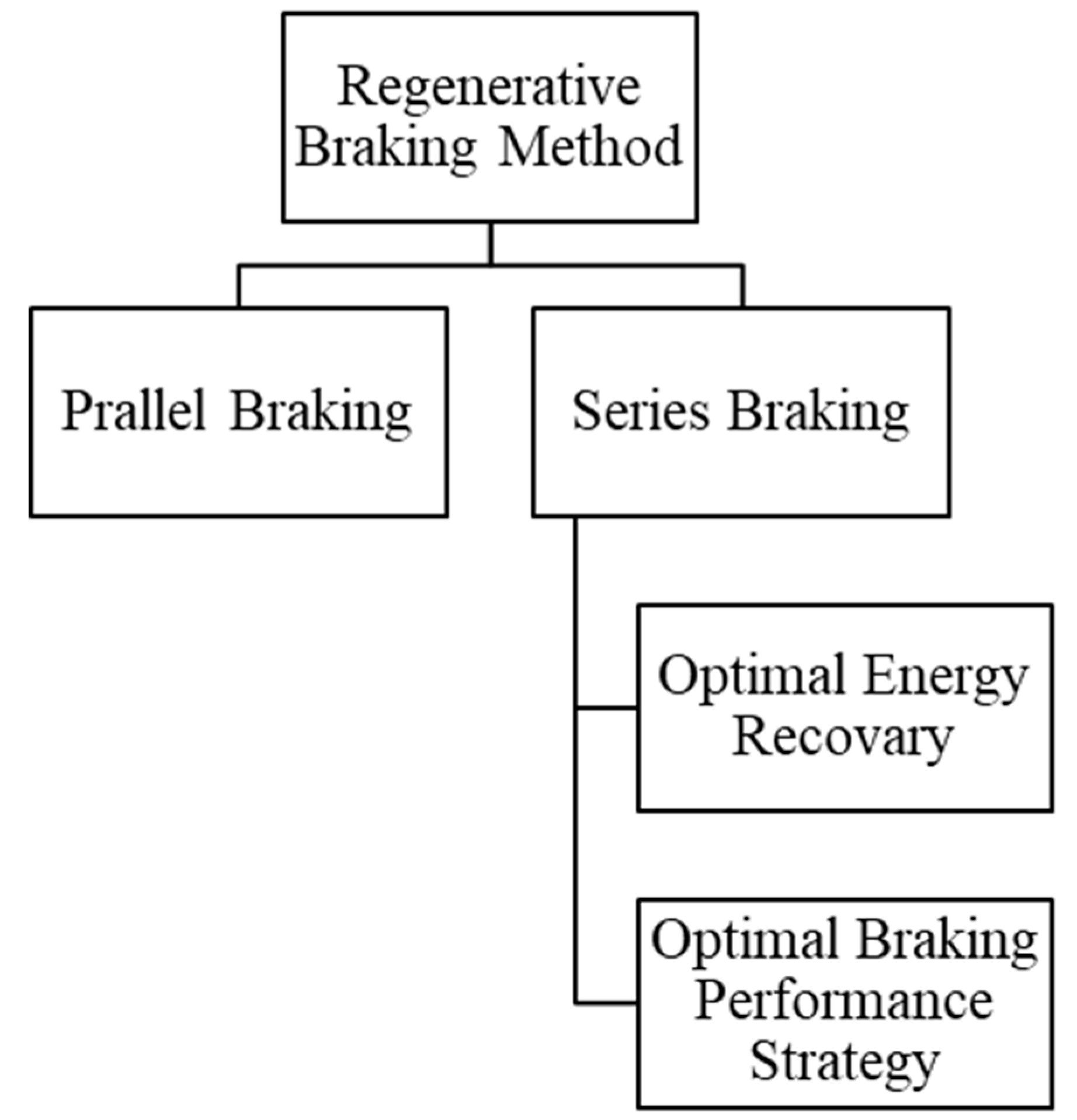

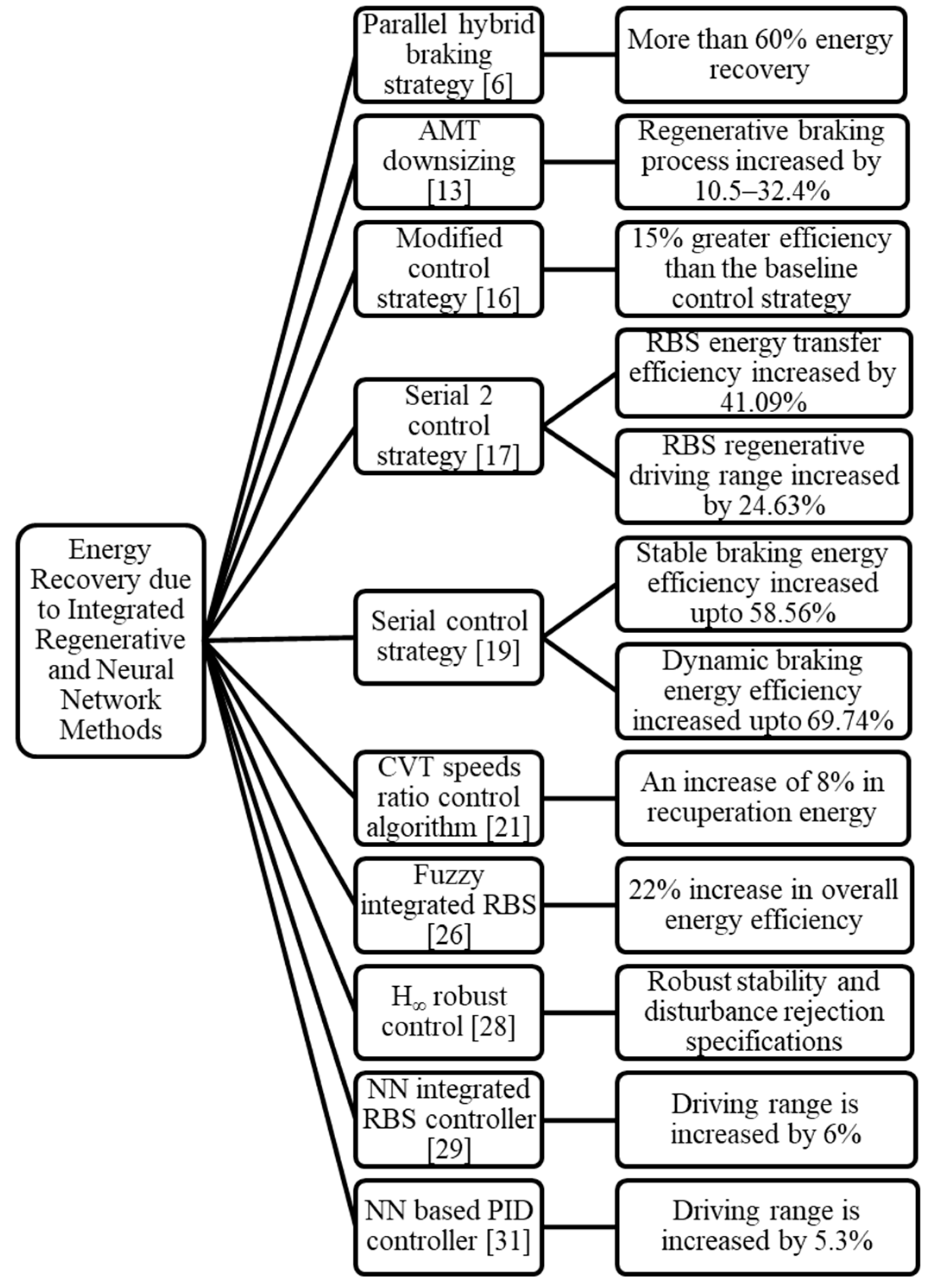

2.1.1. Different Regenerative Braking Strategies

2.1.2. Combined Regenerative Braking and Fuzzy Logics System

2.1.3. Other Regenerative Braking System Strategies

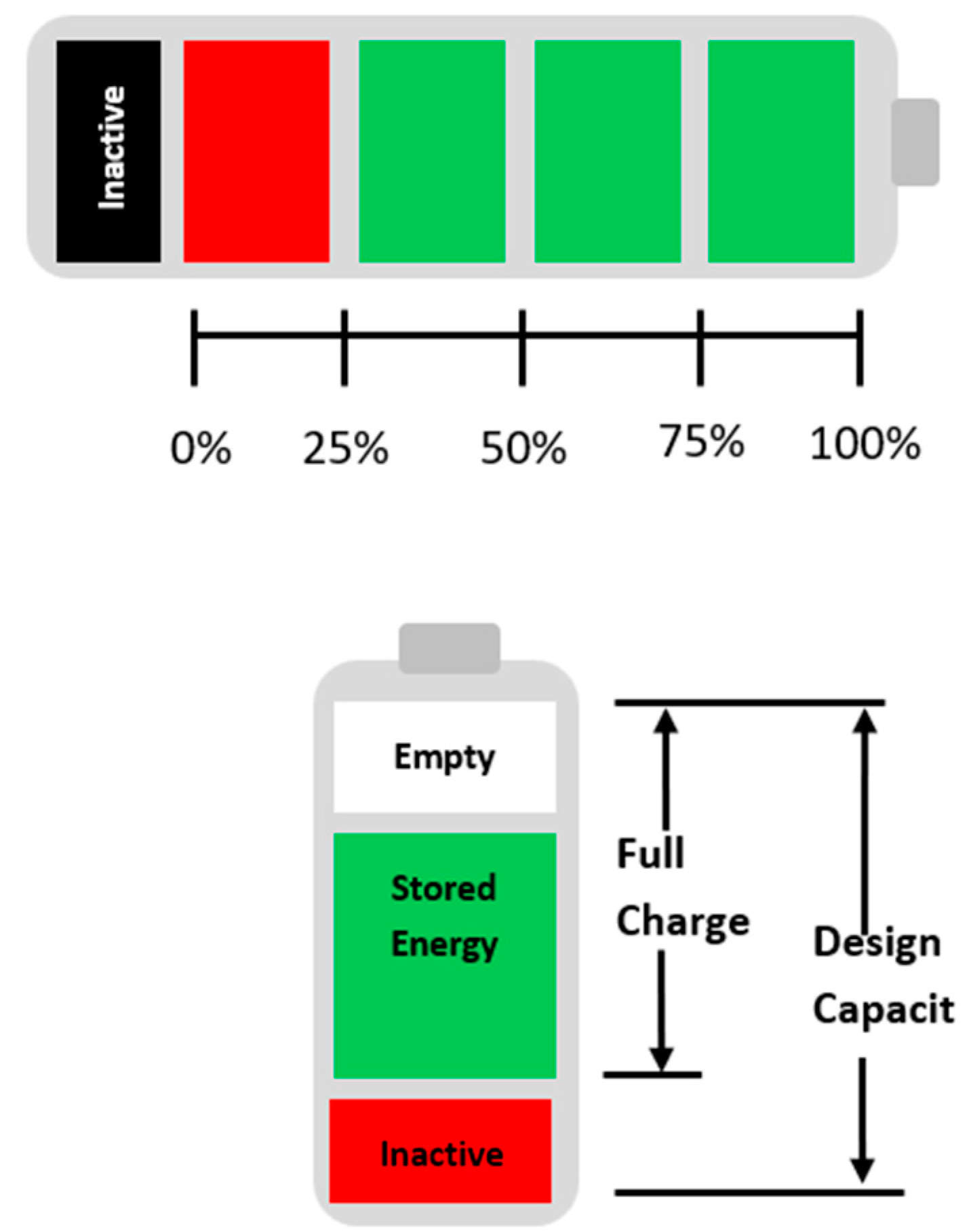

2.2. State of Charge (SOC) of Battery

2.2.1. Types of SOC Estimation Techniques

- (a).

- Direct measurement: This method takes advantage of physical battery features such as voltage and impedance.

- (b).

- Book-keeping estimation: To calculate the SOC, this approach takes the discharging current as input and integrates it over time.

- (c).

- Adaptive systems: The adaptive systems are self-designing and can modify the SOC for various discharging situations automatically. Adaptive methods for SOC estimation have been created in a variety of ways.

- (d).

- Hybrid methods: In hybrid models, the benefits of each SOC estimate strategy are merged to produce an estimation performance that is globally optimal. The literature indicates that hybrid strategies provide accurate SOC estimation as compared to individual methodologies [35].

| Category | Model | Characteristics |

|---|---|---|

| Direct measurement [39,40,41,42,43] |

(i) Open circuit voltage method (ii) Terminal voltage method (iii) Impedance method (iv) Impedance spectroscopy method |

|

| Book-keeping estimation[44,45,46,47,48] | (i) Coulomb counting method (ii) Modified Coulomb counting method |

|

| Adaptive systems[41,49] | (i) BP neural network (ii) RBF neural network (iii) Support vector machine (iv) Fuzzy neural network (v) Kalman filter (vi) Model-based |

|

| Hybrid methods[50,51,52,53] | (i) Coulomb counting and EMF combination (ii) Coulomb counting and Kalman filter combination (iii) Per-unit system and EKF combination |

|

2.2.2. SOC Estimation Technique in Modern Vehicle

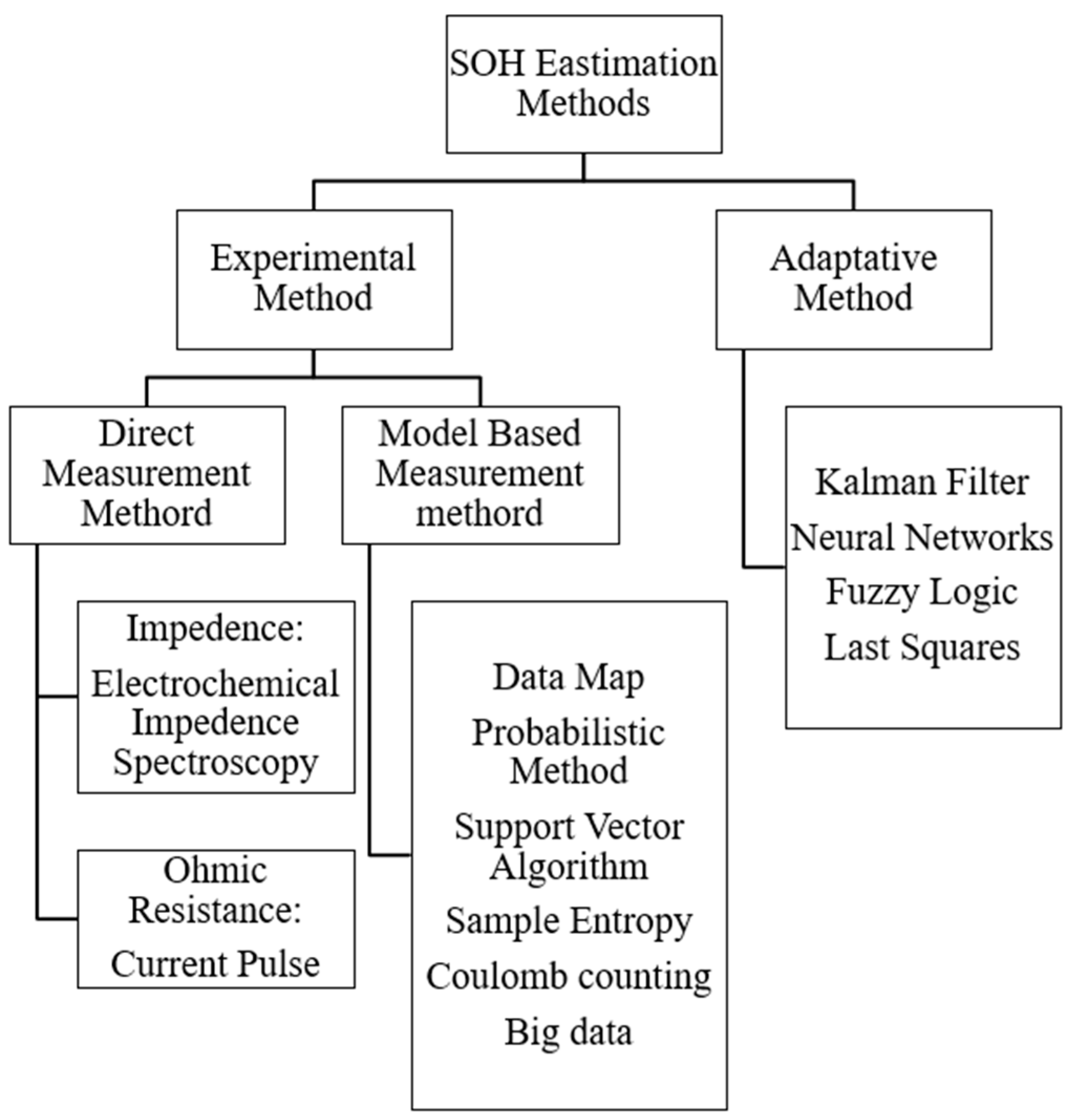

2.3. State of Health (SOH) of Battery:

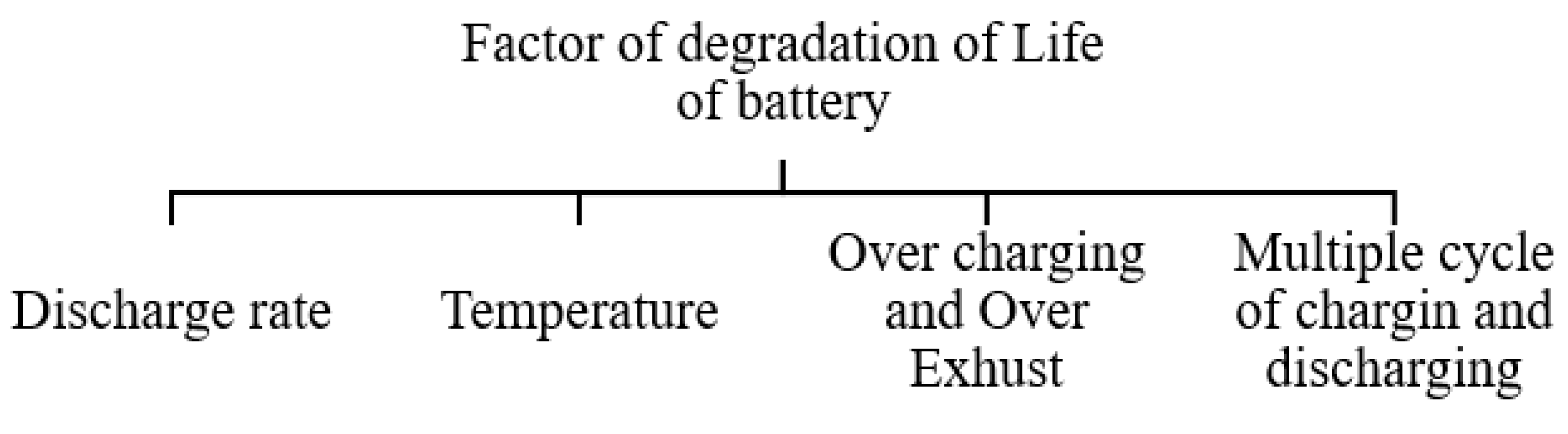

2.4. Effect of Regenerative Braking on the Life of Battery:

3. Conclusions

- Various regenerative braking techniques have been introduced to extract the energy from the braking phenomenon. Two basic techniques are implemented i.e., the parallel hybrid braking system and the fully controllable hybrid braking system. The fully controllable hybrid braking system further included sub-strategies like optimal braking performance and optimal braking energy recovery which is based on the braking distribution of the vehicle.

- Based on this, many authors have compared these strategies and stated their pros and cons. Moreover, the conventional regenerative braking is merged with the ABS and CVT offered maximum performance. Higher regenerative braking efficiency was also achieved by downsizing the AMT as more energy loss is observed by lowering the braking torque. The high speed of the rotor caused iron loss which reduced energy recovery efficiency due to regenerative braking.

- A combined H∞ controller is implemented in the RBS which used the fuzzy logic systems to provide optimal performance while considering the SOC of the battery. The H∞ controller was further combined with PID and SMC to further improve the braking process.

- In the field of SOC estimation, there has been a lot of research into the use of model-based and data-driven estimating methods. In SOC estimation, both model-based and data-driven approaches have shown significant results. A model-based strategy is theoretically the best approach but it has high complexity compared to other methods.

- The conventional coulomb counting method and occasionally corrected by EKF tracking with pre-defined battery model gives better results as well as an adaptive nonlinear observer design that compensates for nonlinearity and achieves better estimation accuracy.

- SOH is related to battery ageing; various methods are developed to estimate the accurate SOH. From the estimation, it can be determined when the battery should be replaced. In EVs regenerating barking is used to improve the battery life. A higher level of regeneration can reduce battery ageing.

- It is found that if the temperature is too low or high, the battery life further deteriorates due to the current occurring due to the regenerative braking. It is stated that 25 °C provides optimal conditions which slow down the battery ageing process due to the RBS.

- It has been also found that the Li-plating increases with the higher SOC, higher charging currents and low temperature. Therefore, at low temperatures, the ageing of the battery increases and becomes susceptible to changes in the load profile.

- Also, the battery is prominently deteriorated because of the charging current for longer periods even having the low current intensity that promotes the Li-plating.

- A higher degree of regeneration braking ameliorates the battery life by reducing the battery’s DOD by using shorter and lower recharging currents. It also reduces the battery life degradation even at high SOC and high temperature. So, only a high level of regenerative braking for low recharging currents is preferred for battery life.

- It has also been found that regenerative braking increases the internal resistance of the battery which eventually increases the temperature of the Li-ion battery.

- Therefore, many control strategies have been introduced that included a fuzzy logic controller. The fuzzy controller adjusted the regenerative braking ratio by observing real-time battery SOC and temperature to prevent the battery temperature rise.

- The RBS system is also used with an ultracapacitor to increase the battery life. Furthermore, the H-bridge switching technique and fuzzy logic based PWM controller is used to transfer energy to ESS.

- The electric motor torque and battery charging power have also been taken into account in the hierarchical control while adjusting the regenerative braking ratio. For preventing battery ageing, motor size is optimized or reduced to a certain extent.

- The H∞ controller also protected the battery from parameter perturbation and excessive charging current obtained during the regenerative braking. SRG drive system improved regenerative recovery energy while keeping the smoothness in the charging current and improving the battery lifetime.

- The ultracapacitors allowed quick vehicle acceleration and deceleration with minimum energy loss while keeping the main battery safe. The ultracapacitors are used to reduce the peak current which reduces the battery life. Besides that, ultracapacitors provide high burst power when the battery’s SOC is low.

- Various regenerative braking techniques have been introduced to extract the energy from the braking phenomenon. Two basic techniques are implemented i.e., the parallel hybrid braking system and the fully controllable hybrid braking system. The fully controllable hybrid braking system further included sub-strategies like optimal braking performance and optimal braking energy recovery which is based on the braking distribution of the vehicle.

- Based on this, many authors have compared these strategies and stated their pros and cons. Moreover, the conventional regenerative braking is merged with the ABS and CVT offered maximum performance. Higher regenerative braking efficiency was also achieved by downsizing the AMT as more energy loss is observed by lowering the braking torque. The high speed of the rotor caused iron loss which reduced energy recovery efficiency due to regenerative braking.

- A combined H∞ controller is implemented in the RBS which used the fuzzy logic systems to provide optimal performance while considering the SOC of the battery. The H∞ controller was further combined with PID and SMC to further improve the braking process.

- In the field of SOC estimation, there has been a lot of research into the use of model-based and data-driven estimating methods. In SOC estimation, both model-based and data-driven approaches have shown significant results. A model-based strategy is theoretically the best approach but it has high complexity compared to other methods.

- The conventional coulomb counting method and occasionally corrected by EKF tracking with pre-defined battery model gives better results as well as an adaptive nonlinear observer design that compensates for nonlinearity and achieves better estimation accuracy.

- SOH is related to battery ageing; various methods are developed to estimate the accurate SOH. From the estimation, it can be determined when the battery should be replaced. In EVs regenerating barking is used to improve the battery life. A higher level of regeneration can reduce battery ageing.

- It is found that if the temperature is too low or high, the battery life further deteriorates due to the current occurring due to the regenerative braking. It is stated that 25 °C provides optimal conditions which slow down the battery ageing process due to the RBS.

- It has been also found that the Li-plating increases with the higher SOC, higher charging currents and low temperature. Therefore, at low temperatures, the ageing of the battery increases and becomes susceptible to changes in the load profile.

- Also, the battery is prominently deteriorated because of the charging current for longer periods even having the low current intensity that promotes the Li-plating.

- A higher degree of regeneration braking ameliorates the battery life by reducing the battery’s DOD by using shorter and lower recharging currents. It also reduces the battery life degradation even at high SOC and high temperature. So, only a high level of regenerative braking for low recharging currents is preferred for battery life.

- It has also been found that regenerative braking increases the internal resistance of the battery which eventually increases the temperature of the Li-ion battery.

- Therefore, many control strategies have been introduced that included a fuzzy logic controller. The fuzzy controller adjusted the regenerative braking ratio by observing real-time battery SOC and temperature to prevent the battery temperature rise.

- The RBS system is also used with an ultracapacitor to increase the battery life. Furthermore, the H-bridge switching technique and fuzzy logic based PWM controller is used to transfer energy to ESS.

- The electric motor torque and battery charging power have also been taken into account in the hierarchical control while adjusting the regenerative braking ratio. For preventing battery ageing, motor size is optimized or reduced to a certain extent.

- The H∞ controller also protected the battery from parameter perturbation and excessive charging current obtained during the regenerative braking. SRG drive system improved regenerative recovery energy while keeping the smoothness in the charging current and improving the battery lifetime.

- The ultracapacitors allowed quick vehicle acceleration and deceleration with minimum energy loss while keeping the main battery safe. The ultracapacitors are used to reduce the peak current which reduces the battery life. Besides that, ultracapacitors provide high burst power when the battery’s SOC is low.

4. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao Y, Chen L, Ehsani M. Investigation of the effectiveness of regenerative braking for EV and HEV. SAE transactions. 1999 Jan 1:3184-90. [CrossRef]

- Yoong MK, Gan YH, Gan GD, Leong CK, Phuan ZY, Cheah BK, Chew KW. Studies of regenerative braking in electric vehicle. In2010 IEEE Conference on Sustainable Utilization and Development in Engineering and Technology 2010 Nov 20 (pp. 40-45). IEEE.

- Cikanek SR, Bailey KE. Regenerative braking system for a hybrid electric vehicle. InProceedings of the 2002 American Control Conference (IEEE Cat. No. CH37301) 2002 May 8 (Vol. 4, pp. 3129-3134). IEEE.

- Gao Y, Ehsani M. Electronic Braking System of EV And HEV- Integration of Regenerative Braking, Automatic Braking Force Control and ABS. SAE transactions. 2001 Jan 1:576-82.

- Nian X, Peng F, Zhang H. Regenerative braking system of electric vehicle driven by brushless DC motor. IEEE Transactions on Industrial Electronics. 2014 Jan 14;61(10):5798-808. [CrossRef]

- Gao Y, Chu L, Ehsani M. Design and control principles of hybrid braking system for EV, HEV and FCV. In2007 IEEE Vehicle Power and Propulsion Conference 2007 Sep 9 (pp. 384-391). IEEE.

- Xu G, Li W, Xu K, Song Z. An intelligent regenerative braking strategy for electric vehicles. Energies. 2011 Sep;4(9):1461-77. [CrossRef]

- Dixon JW, Ortuzar ME. Ultracapacitors+ DC-DC converters in regenerative braking system. IEEE Aerospace and Electronic Systems Magazine. 2002 Nov 7;17(8):16-21. [CrossRef]

- Guo J, Wang J, Cao B. Regenerative braking strategy for electric vehicles. In2009 IEEE Intelligent Vehicles Symposium 2009 Jun 3 (pp. 864-868). IEEE.

- Peng D, Zhang Y, Yin CL, Zhang JW. Combined control of a regenerative braking and antilock braking system for hybrid electric vehicles. International Journal of Automotive Technology. 2008 Dec;9(6):749-57. [CrossRef]

- Zhang J, Lv C, Gou J, Kong D. Cooperative control of regenerative braking and hydraulic braking of an electrified passenger car. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. 2012 Oct;226(10):1289-302. [CrossRef]

- Ahn JK, Jung KH, Kim DH, Jin HB, Kim HS, Hwang SH. Analysis of a regenerative braking system for hybrid electric vehicles using an electro-mechanical brake. International Journal of Automotive Technology. 2009 Apr;10(2):229-34. [CrossRef]

- Li L, Wang X, Xiong R, He K, Li X. AMT downshifting strategy design of HEV during regenerative braking process for energy conservation. Applied energy. 2016 Dec 1;183:914-25. [CrossRef]

- Lv C, Zhang J, Li Y, Yuan Y. Mechanism analysis and evaluation methodology of regenerative braking contribution to energy efficiency improvement of electrified vehicles. Energy Conversion and Management. 2015 Mar 1;92:469-82. [CrossRef]

- Tur O, Ustun O, Tuncay RN. An introduction to regenerative braking of electric vehicles as anti-lock braking system. In2007 IEEE intelligent vehicles symposium 2007 Jun 13 (pp. 944-948). IEEE. [CrossRef]

- Junzhi Z, Yutong L, Chen L, Ye Y. New regenerative braking control strategy for rear-driven electrified minivans. Energy Conversion and Management. 2014 Jun 1;82:135-45. [CrossRef]

- Qiu C, Wang G. New evaluation methodology of regenerative braking contribution to energy efficiency improvement of electric vehicles. Energy Conversion and Management. 2016 Jul 1;119:389-98. [CrossRef]

- Ko J, Ko S, Son H, Yoo B, Cheon J, Kim H. Development of brake system and regenerative braking cooperative control algorithm for automatic-transmission-based hybrid electric vehicles. IEEE Transactions on Vehicular Technology. 2014 May 21;64(2):431-40. [CrossRef]

- Qiu C, Wang G, Meng M, Shen Y. A novel control strategy of regenerative braking system for electric vehicles under safety critical driving situations. Energy. 2018 Apr 15;149:329-40. [CrossRef]

- Paul D, VelenisE, Cao D, Dobo T. Optimal μ-Estimation-Based regenerative braking strategy for an AWD HEV. IEEE Transactions on Transportation Electrification. 2016 Aug 25;3(1):249-58.

- Yeo H, Hwang S, Kim H. Regenerative braking algorithm for a hybrid electric vehicle with CVT ratio control. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. 2006 Nov 1;220(11):1589-600. [CrossRef]

- Panagiotidis M, Delagrammatikas G, Assanis D. Development and use of a regenerative braking model for a parallel hybrid electric vehicle. SAE transactions. 2000 Jan 1:1180-91. [CrossRef]

- Cacciatori E, Bonnet B, Vaughan ND, Burke M, Price D, Wejrzanowski K. Regenerative braking strategies for a parallel hybrid powertrain with torque controlled IVT. SAE technical paper. 2005 Oct 24:01-3826. [CrossRef]

- Bailey KE, Powell BK, Villec GN. ABS/traction assist/regenerative braking application of hardware-in-the-loop. InProceedings of the 1998 American Control Conference. ACC (IEEE Cat. No. 98CH36207) 1998 Jun 26 (Vol. 1, pp. 503-507). IEEE.

- Li X, Xu L, Hua J, Li J, Ouyang M. Regenerative braking control strategy for fuel cell hybrid vehicles using fuzzy logic. In2008 International Conference on Electrical Machines and Systems 2008 Oct 17 (pp. 2712-2716). IEEE.

- Zhang JM, Song BY, Cui SM, Ren DB. Fuzzy logic approach to regenerative braking system. In2009 International Conference on Intelligent Human-Machine Systems and Cybernetics 2009 Aug 26 (Vol. 1, pp. 451-454). IEEE.

- Chuanwei, Z. Experimental Research on H∞ Control for Regenerative Braking of Electric Vehicle. In2010 International Conference on Electrical and Control Engineering 2010 Jun 25 (pp. 940-943). IEEE.

- Ye M, Bai Z, Cao B. Robust sliding model control for regenerative braking of electric vehicle. In2006 CES/IEEE 5th International Power Electronics and Motion Control Conference 2006 Aug 14 (Vol. 3, pp. 1-4). IEEE.

- Cao J, Cao B, Xu P, Bai Z. Regenerative-braking sliding mode control of electric vehicle based on neural network identification. In2008 IEEE/ASME International Conference on Advanced Intelligent Mechatronics 2008 Jul 2 (pp. 1219-1224). IEEE. [CrossRef]

- Gao H, Gao Y, Ehsani M. A neural network based SRM drive control strategy for regenerative braking in EV and HEV. InIEMDC 2001. IEEE International Electric Machines and Drives Conference (Cat. No. 01EX485) 2001 Jun 17 (pp. 571-575). IEEE. [CrossRef]

- Cao J, Cao B, Chen W, Xu P. Neural network self-adaptive PID control for driving and regenerative braking of electric vehicle. In2007 IEEE international conference on automation and logistics 2007 Aug 18 (pp. 2029-2034). IEEE. [CrossRef]

- Piller S, Perrin M, Jossen A. Methods for state-of-charge determination and their applications. Journal of power sources. 2001 Jun 1;96(1):113-20. [CrossRef]

- Baccouche I, Jemmali S, Mlayah A, Manai B, Amara NE. Implementation of an improved Coulomb-counting algorithm based on a piecewise SOC-OCV relationship for SOC estimation of li-IonBattery. arXiv preprint arXiv:1803.10654. 2018 Mar 27.

- Sauer DU, Bopp G, Jossen A, Garche J, Rothert M, Wollny M. State of Charge–What do we really speak about. InThe 21st international telecommunications energy conference 1999 Jun (pp. 6-9).

- Chiasson J, Vairamohan B. Estimating the state of charge of a battery. InProceedings of the 2003 American Control Conference, 2003. 2003 Jun 4 (Vol. 4, pp. 2863-2868). IEEE.

- Hu C, Youn BD, Chung J. A multiscale framework with extended Kalman filter for lithium-ion battery SOC and capacity estimation. Applied Energy. 2012 Apr 1;92:694-704.

- Zhang R, Xia B, Li B, Cao L, Lai Y, Zheng W, Wang H, Wang W. State of the art of lithium-ion battery SOC estimation for electrical vehicles. Energies. 2018 Jul;11(7):1820. [CrossRef]

- Hannan MA, Lipu MH, Hussain A, Mohamed A. A review of lithium-ion battery state of charge estimation and management system in electric vehicle applications: Challenges and recommendations. Renewable and Sustainable Energy Reviews. 2017 Oct 1;78:834-54. [CrossRef]

- Yanhui Z, Wenji S, Shili L, Jie L, Ziping F. A critical review on state of charge of batteries. Journal of Renewable and Sustainable Energy. 2013 Mar 27;5(2):021403. [CrossRef]

- Ng KS, Moo CS, Chen YP, Hsieh YC. State-of-charge estimation for lead-acid batteries based on dynamic open-circuit voltage. In2008 IEEE 2nd International Power and Energy Conference 2008 Dec 1 (pp. 972-976). IEEE. [CrossRef]

- Anbuky AH, Pascoe PE. VRLA battery state-of-charge estimation in telecommunication power systems. IEEE Transactions on Industrial Electronics. 2000 Jun;47(3):565-73. [CrossRef]

- Ran L, Junfeng W, Haiying W, Gechen L. Prediction of state of charge of lithium-ion rechargeable battery with electrochemical impedance spectroscopy theory. In2010 5th IEEE Conference on Industrial Electronics and Applications 2010 Jun 15 (pp. 684-688). IEEE. [CrossRef]

- Huet, F. A review of impedance measurements for determination of the state-of-charge or state-of-health of secondary batteries. Journal of power sources. 1998 Jan 30;70(1):59-69. [CrossRef]

- Lee S, Kim J, Lee J, Cho BH. State-of-charge and capacity estimation of lithium-ion battery using a new open-circuit voltage versus state-of-charge. Journal of power sources. 2008 Dec 1;185(2):1367-73. [CrossRef]

- Ng KS, Moo CS, Chen YP, Hsieh YC. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Applied energy. 2009 Sep 1;86(9):1506-11.

- Xie J, Ma J, Bai K. Enhanced coulomb counting method for state-of-charge estimation of lithium-ion batteries based on peukert’s law and coulombic efficiency. Journal of Power Electronics. 2018;18(3):910-22.

- Baccouche I, Mlayah A, Jemmali S, Manai B, Amara NE. $ Implementation of a Coulomb counting algorithm for SOC estimation of Li-Ion battery for multimedia applications. In2015 IEEE 12th International Multi-Conference on Systems, Signals & Devices (SSD15) 2015 Mar 16 (pp. 1-6). IEEE. [CrossRef]

- Baccouche I, Jemmali S, Mlayah A, Manai B, Amara NE. Implementation of an improved Coulomb-counting algorithm based on a piecewise SOC-OCV relationship for SOC estimation of li-IonBattery. arXiv preprint arXiv:1803.10654. 2018 Mar 27.

- Jeong YM, Cho YK, Ahn JH, Ryu SH, Lee BK. Enhanced Coulomb counting method with adaptive SOC reset time for estimating OCV. In2014 IEEE Energy Conversion Congress and Exposition (ECCE) 2014 Sep 14 (pp. 1313-1318). IEEE. [CrossRef]

- How DN, Hannan MA, Lipu MH, Ker PJ. State of charge estimation for lithium-ion batteries using model-based and data-driven methods: A review. Ieee Access. 2019 Sep 18;7:136116-36. [CrossRef]

- Plett, GL. Kalman-filter SOC estimation for LiPB HEV cells. InProceedings of the 19th International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium & Exhibition (EVS19) 2002 Oct (pp. 527-538).

- Sepasi S, Ghorbani R, Liaw BY. Improved extended Kalman filter for state of charge estimation of battery pack. Journal of Power Sources. 2014 Jun 1;255:368-76. [CrossRef]

- Peng S, Chen C, Shi H, Yao Z. State of charge estimation of battery energy storage systems based on adaptive unscented Kalman filter with a noise statistics estimator. Ieee Access. 2017 Jul 11;5:13202-12. [CrossRef]

- Liu L, Chen Z, Wang C, Lin F, Wang H. Integrated system identification and state-of-charge estimation of battery systems. IEEE Transactions on Energy conversion. 2012 Oct 26;28(1):12-23. [CrossRef]

- Kim MJ, Chae SH, Moon YK. Adaptive Battery State-of-Charge Estimation Method for Electric Vehicle Battery Management System. In2020 International SoC Design Conference (ISOCC) 2020 Oct 21 (pp. 288-289). IEEE.

- El Din MS, Hussein AA, Abdel-Hafez MF. Improved battery SOC estimation accuracy using a modified UKF with an adaptive cell model under real EV operating conditions. IEEE transactions on transportation electrification. 2018 Feb 5;4(2):408-17. [CrossRef]

- He Z, Yang Z, Cui X, Li E. A method of state-of-charge estimation for EV power lithium-ion battery using a novel adaptive extended Kalman filter. IEEE Transactions on Vehicular Technology. 2020 Oct 20;69(12):14618-30. [CrossRef]

- Wang J, Cao B, Chen Q, Wang F. Combined state of charge estimator for electric vehicle battery pack. Control Engineering Practice. 2007 Dec 1;15(12):1569-76. [CrossRef]

- Kim J, Cho BH. State-of-charge estimation and state-of-health prediction of a Li-ion degraded battery based on an EKF combined with a per-unit system. IEEE Transactions on Vehicular Technology. 2011 Sep 23;60(9):4249-60. [CrossRef]

- Zhang J, Xia C. State-of-charge estimation of valve regulated lead acid battery based on multi-state Unscented Kalman Filter. International Journal of Electrical Power & Energy Systems. 2011 Mar 1;33(3):472-6. [CrossRef]

- Sun F, Hu X, Zou Y, Li S. Adaptive unscented Kalman filtering for state of charge estimation of a lithium-ion battery for electric vehicles. Energy. 2011 May 1;36(5):3531-40. [CrossRef]

- Venugopal, P. State-of-Health estimation of li-ion batteries in electric vehicle using IndRNN under variable load condition. Energies. 2019 Jan;12(22):4338. [CrossRef]

- Shi G, Chen S, Yuan H, You H, Wang X, Dai H, Wei X. Determination of optimal indicators based on statistical analysis for the state of health estimation of a Lithium-ion battery. Frontiers in Energy Research. 2021 Jun 16;9:262. [CrossRef]

- Xu Z, Yan X, Huang B, Wang Y, Dong D, Liu Z. The Effect of Charge Behavior on Lithium Battery SOH. In2020 3rd International Conference on Advanced Electronic Materials, Computers and Software Engineering (AEMCSE) 2020 Apr 24 (pp. 658-661). IEEE.

- Lin CP, Cabrera J, Denis YW, Yang F, Tsui KL. SOH estimation and SOC recalibration of lithium-ion battery with incremental capacity analysis & cubic smoothing spline. Journal of The Electrochemical SOCiety. 2020 May 12;167(9):090537. [CrossRef]

- Mater, IJ. Effect of ambient temperature, C-rate and SOH on the charge and discharge performance and self-temperature of LCO batteries. Int. J. Electroactive Mater. 2021;9:1-1.

- Diao W, Jiang J, Zhang C, Liang H, Pecht M. Energy state of health estimation for battery packs based on the degradation and inconsistency. Energy Procedia. 2017 Dec 1;142:3578-83. [CrossRef]

- Moura SJ, Chaturvedi NA, Krstić M. PDE estimation techniques for advanced battery management systems-Part II: SOH identification. In2012 American Control Conference (ACC) 2012 Jun 27 (pp. 566-571). IEEE. [CrossRef]

- Cacciato M, Nobile G, Scarcella G, Scelba G. Real-time model-based estimation of SOC and SOH for energy storage systems. IEEE Transactions on Power Electronics. 2016 Feb 26; 32(1):794-803. [CrossRef]

- Hatzell KB, Sharma A, Fathy HK. A survey of long-term health modeling, estimation, and control of lithium-ion batteries: Challenges and opportunities. In2012 American Control Conference (ACC) 2012 Jun 27 (pp. 584-591). IEEE. [CrossRef]

- Lipu MH, Hannan MA, Hussain A, Hoque MM, Ker PJ, Saad MM, Ayob A. A review of state of health and remaining useful life estimation methods for lithium-ion battery in electric vehicles: Challenges and recommendations. Journal of cleaner production. 2018 Dec 20; 205:115-33. [CrossRef]

- Cuma MU, Koroglu T. A comprehensive review on estimation strategies used in hybrid and battery electric vehicles. Renewable and Sustainable Energy Reviews. 2015 Feb 1;42:517-31. [CrossRef]

- Qin T, Zeng S, Guo J, Skaf Z. State of health estimation of li-ion batteries with regeneration phenomena: a similar rest time-based prognostic framework. Symmetry. 2016 Dec 24;9(1):4. [CrossRef]

- Lee PY, Kim J. Impact analysis of deterioration and SOH estimation based on multiple regression analysis. In2019 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific) 2019 May 8(pp. 1-6). IEEE. [CrossRef]

- Anselma PG, Kollmeyer P, Lempert J, Zhao Z, Belingardi G, Emadi A. Battery state-of-health sensitive energy management of hybrid electric vehicles: Lifetime prediction and ageing experimental validation. Applied Energy. 2021 Mar 1;285:116440. [CrossRef]

- Yang S, Zhang C, Jiang J, Zhang W, Zhang L, Wang Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. Journal of Cleaner Production. 2021 Sep 10;314:128015. [CrossRef]

- Dalal M, Ma J, He D. Lithium-ion battery life prognostic health management system using particle filtering framework. Proceedings of the Institution of Mechanical Engineers, Part O: Journal of Risk and Reliability. 2011 Mar 1;225(1):81-90. [CrossRef]

- Sarıkurt T, Ceylan M, Balikçi A. An analytical battery state of health estimation method. In2014 IEEE 23rd International Symposium on Industrial Electronics (ISIE) 2014 Jun 1 (pp. 1605-1609). IEEE.

- Yang D, Wang Y, Pan R, Chen R, Chen Z. A neural network-based state-of-health estimation of lithium-ion battery in electric vehicles. Energy Procedia. 2017 May 1;105:2059-64. [CrossRef]

- Saha B, Goebel K. Modeling Li-ion battery capacity depletion in a particle filtering framework. In Annual Conference of the PHM Society 2009 (Vol. 1, No. 1).

- Wang L, Pan C, Liu L, Cheng Y, Zhao X. On-board state of health estimation of LiFePO4 battery pack through differential voltage analysis. Applied energy. 2016 Apr 15; 168:465-72. [CrossRef]

- Lin HT, Liang TJ, Chen SM. Estimation of battery state of health using probabilistic neural network. IEEE transactions on industrial informatics. 2012 Oct 4; 9(2):679-85. [CrossRef]

- Goebel K, Saha B, Saxena A, Celaya JR, Christophersen JP. Prognostics in battery health management. IEEE instrumentation & measurement magazine. 2008 Jul 25; 11(4):33-40.

- Torai S, Nakagomi M, Yoshitake S, Yamaguchi S, Oyama N. State-of-health estimation of LiFePO4/graphite batteries based on a model using differential capacity. Journal of Power Sources. 2016 Feb 29; 306:62-9.

- Bloom I, Cole BW, Sohn JJ, Jones SA, Polzin EG, Battaglia VS, Henriksen GL, Motloch C, Richardson R, Unkelhaeuser T, Ingersoll D. An accelerated calendar and cycle life study of Li-ion cells. Journal of power sources. 2001 Oct 15; 101(2):238-47. [CrossRef]

- Anselma PG, Kollmeyer P, Belingardi G, Emadi A. Multi-objective hybrid electric vehicle control for maximizing fuel economy and battery lifetime. In2020 IEEE Transportation Electrification Conference & Expo (ITEC) 2020 Jun 23 (pp. 1-6). IEEE. [CrossRef]

- Fang L, Li J, Peng B. Online Estimation and Error Analysis of both SOC and SOH of Lithium-ion Battery based on DEKF Method. Energy Procedia. 2019 Feb 1; 158:3008-13. [CrossRef]

- Berecibar M, Gandiaga I, Villarreal I, Omar N, Van Mierlo J, Van den Bossche P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renewable and Sustainable Energy Reviews. 2016 Apr 1; 56:572-87. [CrossRef]

- Kim T, Qiao W, Qu L. Online SOC and SOH estimation for multicell lithium-ion batteries based on an adaptive hybrid battery model and sliding-mode observer. In2013 IEEE energy conversion congress and exposition 2013 Sep 15 (pp. 292-298). IEEE. [CrossRef]

- Dong G, Han W, Wang Y. Dynamic Bayesian Network-Based Lithium-Ion Battery Health Prognosis for Electric Vehicles. IEEE Transactions on Industrial Electronics. 2020 Nov 4; 68(11):10949-58. [CrossRef]

- Balagopal B, Chow MY. The state of the art approaches to estimate the state of health (SOH) and state of function (SOF) of lithium Ion batteries. In2015 IEEE 13th International Conference on Industrial Informatics (INDIN) 2015 Jul 22 (pp. 1302-1307). IEEE. [CrossRef]

- Keil P, Jossen A. Aging of lithium-ion batteries in electric vehicles: Impact of regenerative braking. World Electric Vehicle Journal. 2015 Mar;7(1):41-51. [CrossRef]

- Huang J, Qin D, Peng Z. Effect of energy-regenerative braking on electric vehicle battery thermal management and control method based on simulation investigation. Energy Conversion and Management. 2015 Nov 15; 105:1157-65. [CrossRef]

- Carrilero I, Ansean D, Viera JC, Fernandez Y, Pereirinha PG, González M. Impact of fast-charging and regenerative braking in LiFePO4 batteries for electric bus applications. In2017 IEEE vehicle power and propulsion conference (VPPC) 2017 Dec 11 (pp. 1-6). IEEE. [CrossRef]

- Asif RM, Yousaf A, Rehman AU, Shabbir N, Sadiq MT. Increase battery time by improvement in regenerative braking with storage system in hybrid vehicle. Journal of Applied and Emerging Sciences. 2019 Jul 9;9(1):pp-53. [CrossRef]

- Keil P, Jossen A. Impact of dynamic driving loads and regenerative braking on the aging of lithium-ion batteries in electric vehicles. Journal of the electrochemical society. 2017 Oct 11; 164(13):A3081. [CrossRef]

- Wu J, Wang X, Li L, Du Y. Hierarchical control strategy with battery aging consideration for hybrid electric vehicle regenerative braking control. Energy. 2018 Feb 15; 145:301-12. [CrossRef]

- Long B, Lim ST, Bai ZF, Ryu JH, Chong KT. Energy management and control of electric vehicles, using hybrid power source in regenerative braking operation. Energies. 2014 Jul; 7(7):4300-15. [CrossRef]

- Cao B, Bai Z, Zhang W. Research on control for regenerative braking of electric vehicle. InIEEE International Conference on Vehicular Electronics and Safety, 2005. 2005 Oct 14 (pp. 92-97). IEEE.

- Zhu Y, Wu H, Zhang J. Regenerative braking control strategy for electric vehicles based on optimization of switched reluctance generator drive system. IEEE Access. 2020 Apr 24; 8:76671-82. [CrossRef]

- Naseri F, Farjah E, Ghanbari T. An efficient regenerative braking system based on battery/ultracapacitor for electric, hybrid, and plug-in hybrid electric vehicles with BLDC motor. IEEE Transactions on Vehicular Technology. 2016 Sep 20; 66(5):3724-38.

- Dixon JW, Ortúzar M, Wiechmann E. Regenerative braking for an electric vehicle using ultracapacitors and a buck-boost converter. In17th Electric Vehicle Symposium (EVS17), (Canada) 2000 Oct 13.

- Carter R, Cruden A, Hall PJ. Optimizing for efficiency or battery life in a battery/ultracapacitor electric vehicle. IEEE Transactions on Vehicular Technology. 2012 Feb 22; 61(4):1526-33.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).