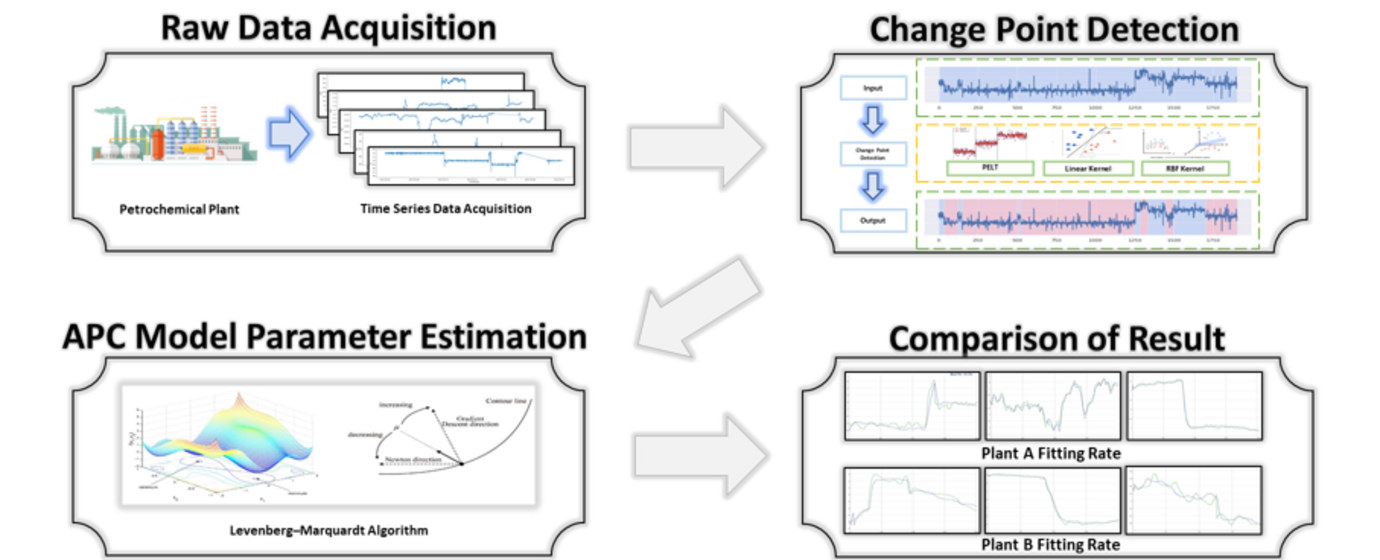

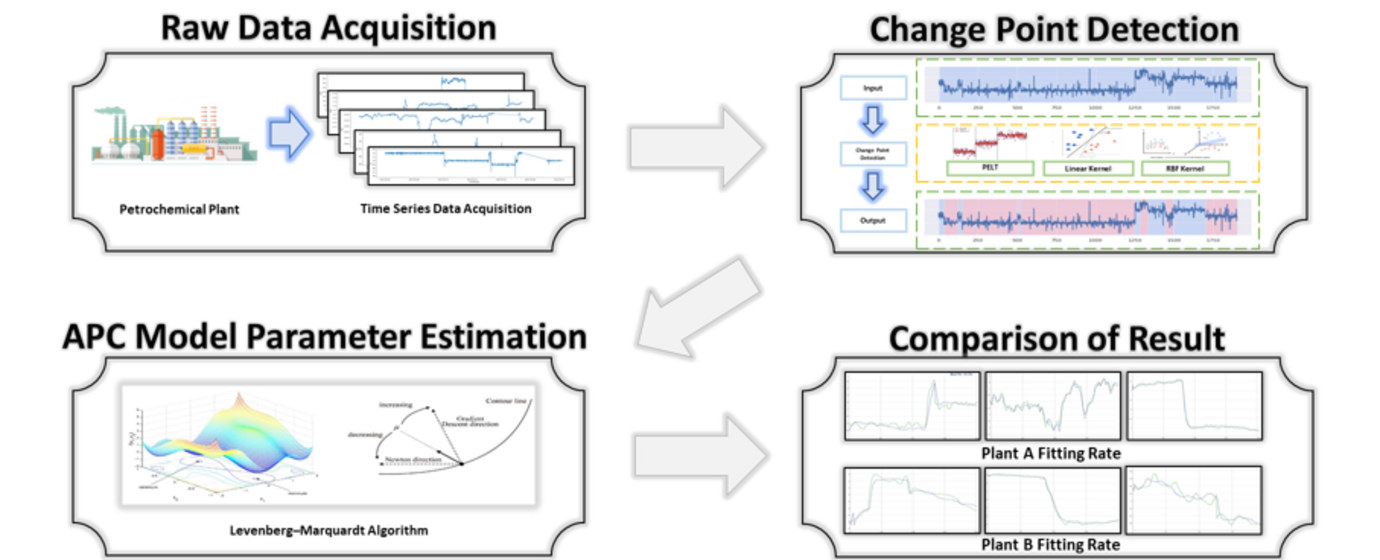

Most petrochemical plants still maintain a Proportional-Integral-Differential controller(PID) system, which is a feedback control system. However, gradually, the PID system is being extended and introduced to the Advanced Process Controller (APC) system, which is an integrated control system of feedforward and feedback that predicts external influences in advance. In the process of conducting on-site plant tests and calculating APC model parameter for the application of APC systems, a problem arises that Model Parameter are implemented differently depending on the proficiency of APC engineers. To minimize this problem, a technique for estimating APC model parameter without a plant test is required. In order to estimate the APC model parameter, it is necessary to train on dynamic interval data. In this paper, we use statistical techniques such as PELT, Linear Kernel, and Radial Basis Function Kernel of Change Point Detection (CPD) to extract dynamic data with minimum Mean Absolute Error (MAE) from time series data of a real petrochemical plant. Then, the hyper parameter is fixed and the APC model parameter is estimated by learning the dynamic section data. By applying the estimated APC model parameter to the APC Model Tool and measuring the fitting rate, it was confirmed that it is possible to estimate the APC model parameter with excellent control performance without plant test.