1. Introduction

Renewable energy sources are the most environmental friendly, economical, and convenient way of producing electricity. The nonrenewable energy production method releases a deleterious element Carbon dioxide to the environment which is a leading cause of global climate change. According to 2016 U S Renewable Generation statistic about 37% of the renewable energy comes from wind energy [

1]. Ocean wave energy is increasing its popularity among all the existing renewable energy sources due to its purity, availability, high compactness of power and dirt free nature. According to National Ocean Service (NOS), ocean covers more than 70% of the earth surface [

2]. Winds thrashing through this vast surface of ocean and create thousands of large ocean waves. These waves can travel through with less energy loss. Energy inside of these waves can be easily harnessed to generate huge amount of electrical energy. It is approximated that only 0.2% of the ocean’s energy would be sufficient to power up the whole world. Ocean wave energy has high power density with great availability in nature. Ocean wave energy has also higher conversion efficiency compared to wind and solar [

3].

The internet is a widely spread and flexible way of communication. The internet of Things (IoT) brings a significant change to the usage of internet. IoT devices enable us to control devices from a far distance. It seems IoT encompasses the physical entity of the world. Internet is now not only limited to the massive use of computer networks, but it spreads out to interconnect heterogeneous devices to operate those devices over the Internet. So, the user can enjoy operating these devices from any part of the world.

Internet of things (IoT) offers a lot of opportunities for the improvement of renewable energy sector. This paper is dedicated to analyzing and measuring the performance of electrical energy extraction from ocean wave energy converter (WEC) using IoT devices. The real time data from the ocean is needed to effectively analyze the performance of the generated power. IoT devices are used in this case to wirelessly transfer of ocean data to the control room that is placed anywhere in this world. One of the major advantages of using IoT devices is that this device can monitor and control from any place of this world. A large number of various IoT based sensors integrated with the WEC model works for the measurement of ocean wave parameters. The ocean wave sensors that are used in this research are wireless voltage meter, wireless AC current meter, wireless Resistance sensor, wireless temperature sensor, wireless Accelerometer, wireless pressure meter, wireless water level sensor. These sensors are available to purchase from MONNET company. AC Current meter and voltage meter are needed to measure generated electrical power. According to maximum power transfer theorem, measurement of both load side and generator side resistance are required to maximize the power transfer, Resistance sensors are used in this purpose. Temperature sensor and water level sensor informs the control room about the condition of water in the ocean. Wireless accelerometer is needed to determine the speed of wave and generator shaft speed. Data obtained from IoT devices is translated into actionable information to enhance the performance of ocean WEC and reducing risk of using this converter. The user can enjoy using these IoT devices remotely. However, the operation of the whole power system can be controlled remotely via Internet. IoT will be so ubiquitous to cover every aspect of human life in near future including renewable energy generation and management. Nowadays Machine learning is used in digital renewable energy system for data collection and monitoring process [

4].

IoT application has been broadened to support power and energy system with observing and control of wind turbine and photovoltaic (PV) installation among other energy systems [

5].

Firstly, the importance, environmental and economic impact of this research is described. Then the background and relevant theory are presented with related equations in the overall system model section. The overall performance is also discussed at the end of this section. Then the proposed model with IoT sensors and devices is illustrated for feasible application.

2. Overall System Model

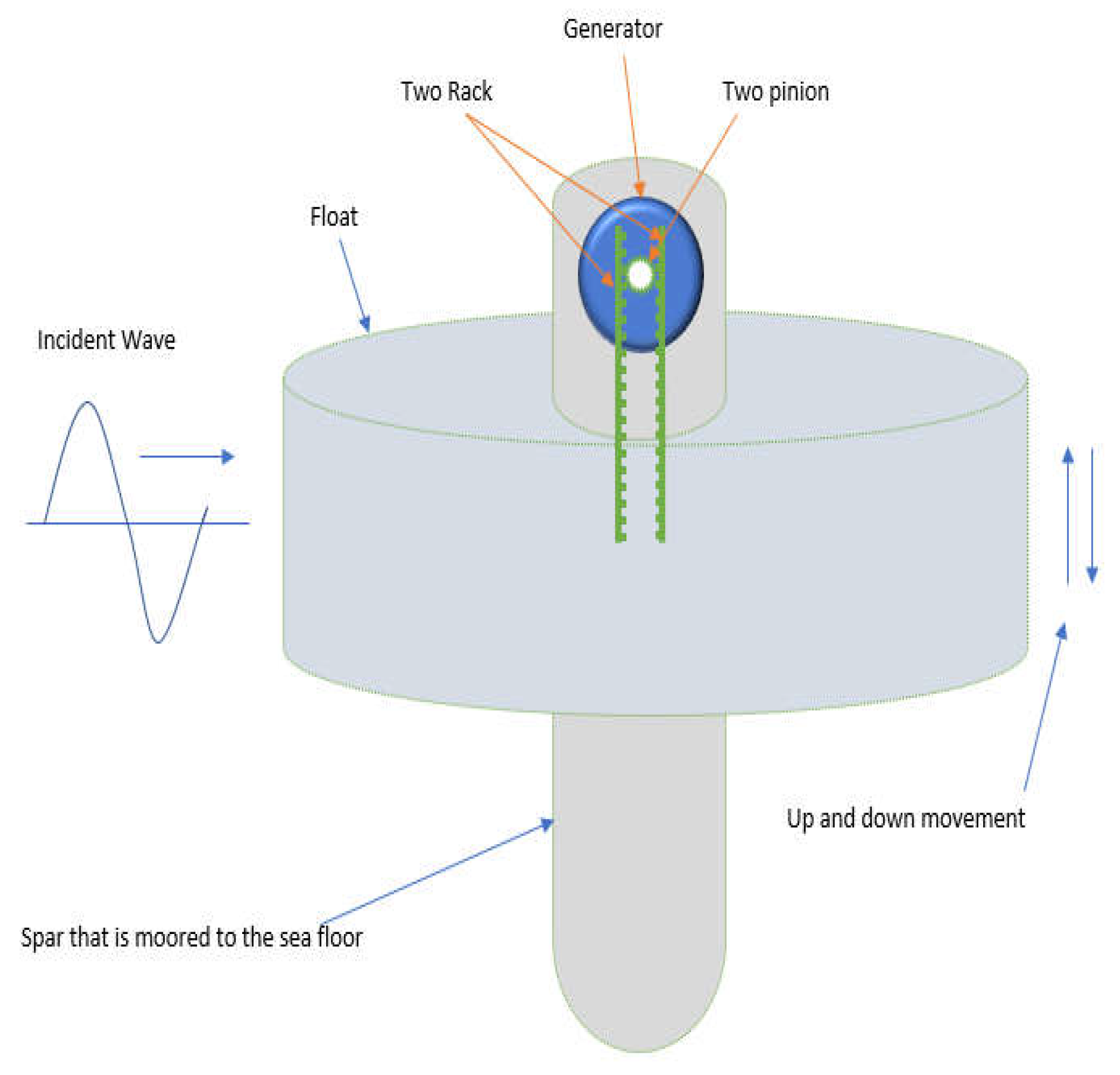

This Wave Energy Converter (WEC) comprise of a buoy or float that is partly submerged into the ocean water. The submerged buoy is continuously experienced force of the ocean waves. The buoy moves up and down due to this force. The movement of the buoy is then transformed into a one-way rotation by rack and pinion mechanism. This rotational motion propels the generator turbine through a gear box to generate electricity.

Figure 1 illustrates the WEC model that will be used in this research. The real time data from those IoT devices will be taken and monitored to get maximum power of the generator. The IoT devices will also help to determine the power calculation from the converter. Each WEC can also be equipped with IoT devices such as Boron LTE to deliver real time monitoring of ocean WEC and to collect the sensors data wirelessly [

6]. These IoT platform can be utilized to record the measured output voltage to thrive a power output model of the ocean power which is also known as power curve. Numerous topics related to ocean power generation could be monitored similar to the interactions across the harmonious ocean waves, constituting the ocean wave power farm, exploring various water level topologies with the help of IoT. The real-time monitoring of the ocean WEC reduces human involvement as much as possible. The IoT provides an auspicious solution to deliver an online tracking and control for the operation of the sensors that are installed with the model.

The wave wave elevation of a regular sinusoidal ocean wave

where, A is the wave amplitude,

is angular velocity, and

the initial phase of the wave.

The wave excitation force for a half way submerged buoy can be calculated as

where,

is the water surface elevation and

is the coefficient of excitation force. The amplitude of

can be calculated by

here,

is the coefficient of radiation resistance that are evaluated in the research paper [

7,

8]. The value of

is contemplated very small in this research, so the phase angle can be presumed to be zero [

9].

The wave number

for infinite water depth is

where,

is the angular velocity and

is the wavelength of the wave.

The power extracted from ocean wave can be represented [

9] by the following equation

where,

is the excitation force,

generator side resistance,

R is the load side resistance,

is angular velocity of the wave, m is equal to inductive component,

Sb is equivalent of the capacitive element.

Therefore, the maximum power can be calculated by

The value of and in (1) can be obtained from the IoT sensors and with a constant initial phase angle, the power extraction of the ocean wave can easily be determined by (5) and (6) .

The generator power can be determined by the following equation,

where, V and I are the generator voltage and current flowing to the load.

The real time value of V and I can be obtained by the IoT based wireless voltmeter and AC current meter that are mentioned earlier in this paper. The conversion efficiency can be measured by dividing the generator power by wave power.

The overall performance of the generator can be estimated by (8).

3. Design Methodology

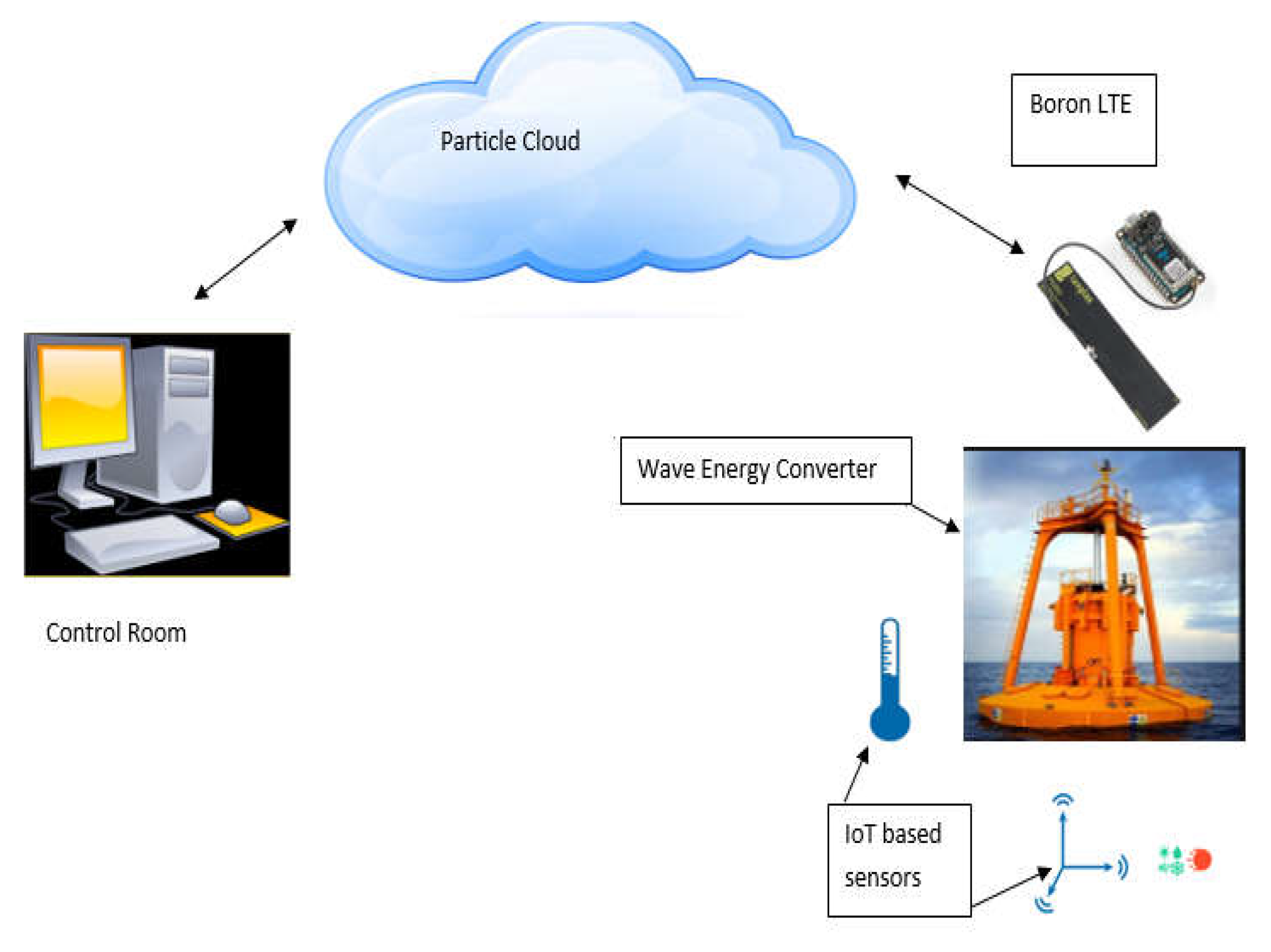

The wave energy converter is equipped with an IoT platform in this case Boron LTE.

Figure 2 illustrates the overall system.

The sensors respond in real-time conditions and are designed to monitor ocean wave parameter such as speed of the ocean wave, water level, temperature and the conditions of the ocean which are essential for determining the generated electrical power and overall efficiency of the generator. All these sensor data will be uploaded to the particle cloud via the Boron LTE with the help of mobile cellular network. The control room will receive the data and will provide the necessary response to the generator for getting maximum power production. The core performance of the ocean WEC depends largely on the condition of the ocean wave. An almost similar assessment of this has been done in [

10]. Using IoT devices, the historical data and the daily data can be obtained to enhance performance of the power production, optimize the operation, and develop long term reliability of the system.

The future Ocean WEC will be auto adjusted to the sensors and the application of control strategies using IoT can optimize those sensors at any weather condition. The power production can be highly optimized through a continuous and real time collection of superior quality data which can be determined by using the proposed model in terms of error free, precision, and absolute. The operator can differentiate between the ideal and actual performance of the system using IoT, and can easily detect any complications to provide a sustainable solution for it.

The IoT devices will allow quick access to all the ocean wave parameters. However, the better performance of energy converter largely rely on trusted and identified measures of wave parameters, documenting, managing and retrieval of these data. IoT sensors and IoT-based devices are best for this purpose. IoT devices are best known for maintaining reliable performance with scheduled plans [

11].

4. Conclusions

In this research, the performance of the ocean WEC has been estimated using IoT monitoring and analyzing real-time data. This paper also provides a clear view of integrating IoT with Ocean WEC to get maximum power production. By analyzing the performance, it is obvious that the ocean WEC can meet its technological advancement through IoT which will provide an opportunity for the operator to ensure maintenance strategy development, reduce uncertainty, maintain the reliability of the system, and enhance annual energy production. The operator can get maximum benefits from IoT implementation and assessment such as accumulating data to optimize performance, instrumenting WEC with sensors, forecasting and protecting operation through IoT. Some barriers like establishing security, communication protocol, and limiting device access to the internet can be resolved in the future work.

References

- buy clean energy. Available online: http://buycleanenergy.org/why.

- National Ocean Service. Available online: https://oceanservice.noaa.gov/facts/oceanwater.html.

- Brekken, T. Fundamentals of ocean wave energy conversion, modeling, and control. Proc. IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4-7 July 2010; pp. 3921–3966. [Google Scholar]

- Arcos, J.; Alfredo, C.; Quiterio, G. M.; Fausto, P. G. M. Machine Learning for Wind Turbine Blades Maintenance Management. Energies 2017, 11.1, 13. [Google Scholar] [CrossRef]

- Bedi, G.; Venayagamoorthy, G. K.; Singh, R. Navigating the Challenges of Internet of Things (IoT) for Power and Energy Systems, Clemson University Power Systems Conference (PSC).

- Srbinovski, B.; Conte, G.; Morrison, A. P.; Leahy, P.; Popovici, E. ECO: An IoT platform for wireless data collection, energy control and optimization of a miniaturized wind turbine cluster: Power analysis and battery life estimation of IoT platform. 2017 IEEE International Conference on Industrial Technology (ICIT). IEEE, 2017,412-417.

- Johannes Falnes, Ocean waves and oscillating systems: linear interactions including wave-energy extraction, Cambridge university press, 200.

- Hulme, A. The wave forces acting on a floating hemisphere undergoing forced periodic oscillations. Journal of Fluid Mechanics 1982, 121, 443–463. [Google Scholar] [CrossRef]

- Amin, M. S.; Bora Karayaka, H.; Yanik, P.; Sang, Y. Suboptimal Control of a Rack and Pinion Based Wave Energy Converter Power Take-off System. SoutheastCon 2021, 1–7. [Google Scholar]

- Lun, Y. F.; Mochida, A.; Murakami, S.; Yoshino, H.; Shirasawa, T. Numerical simulation of flow over topographic features by revised k˘ϵ models. Journal of Wind Engineering and Industrial Aerodynamics 2003, 91, 231–245. [Google Scholar] [CrossRef]

- Alhmoud, L. Reliability improvement for high-power IGBT in wind energy applications. IEEE Transactions on Industrial Electronics 2018, 65.9, 7129–7137. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).