Submitted:

02 June 2023

Posted:

05 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Discussion

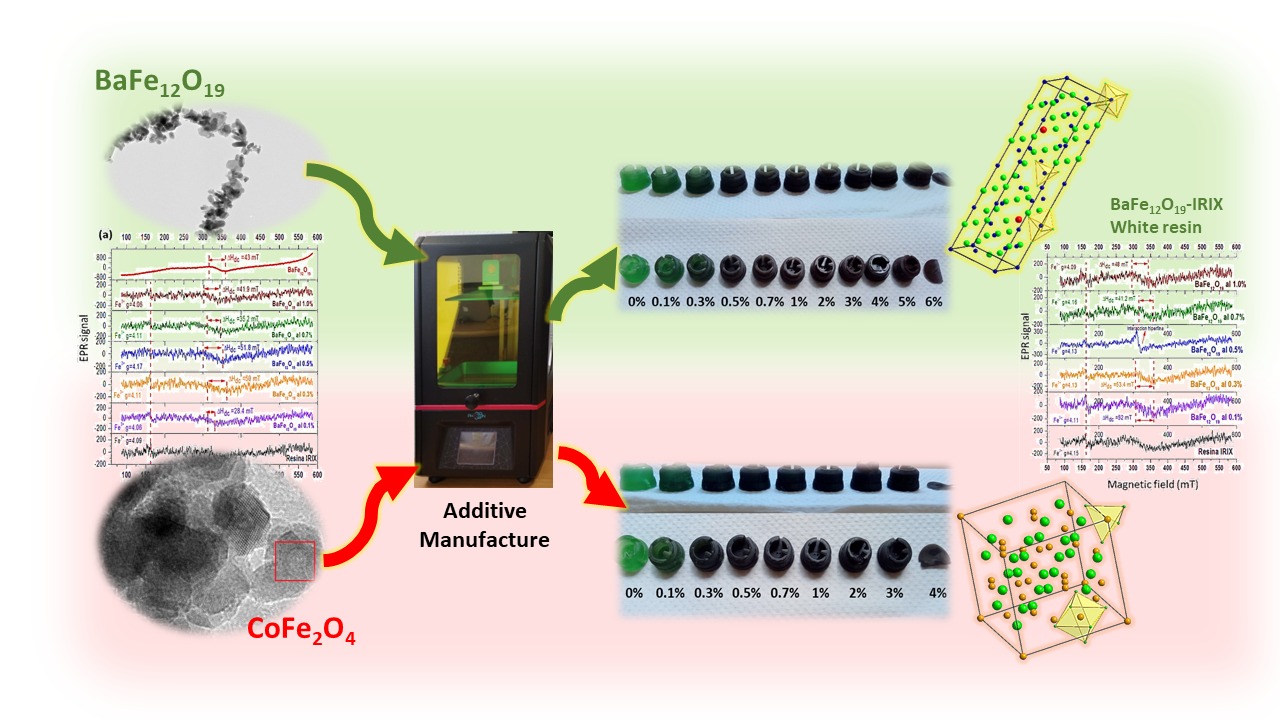

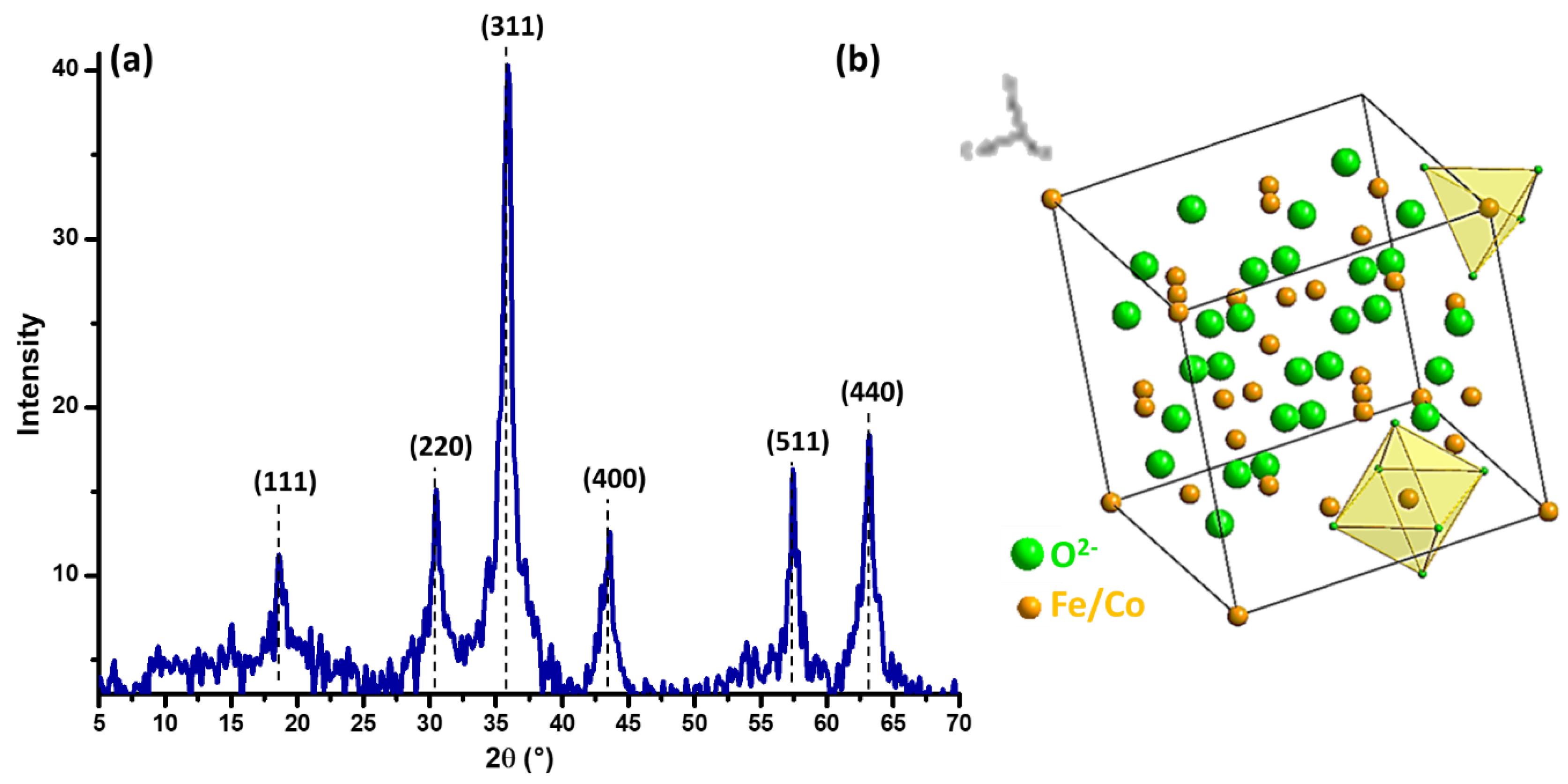

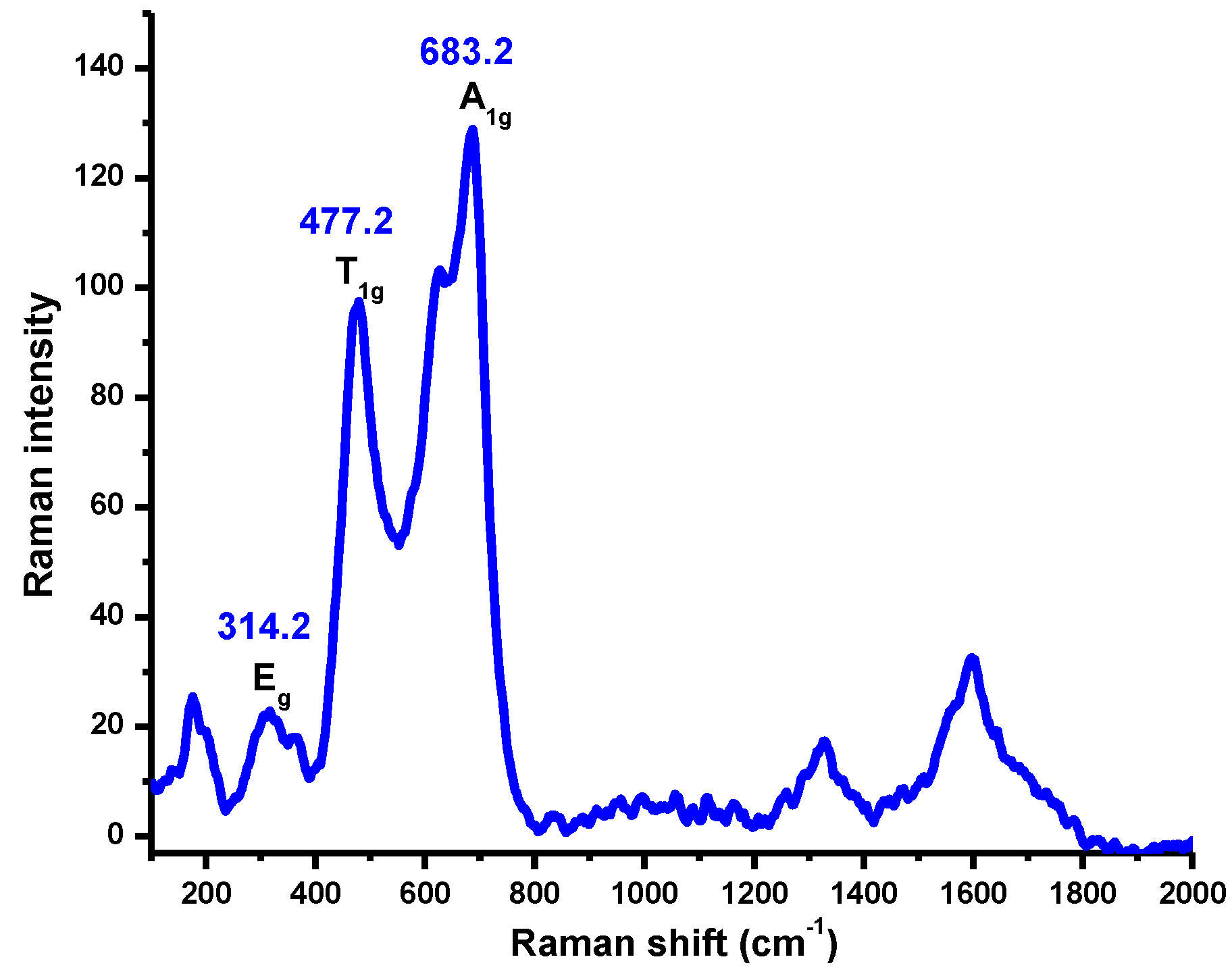

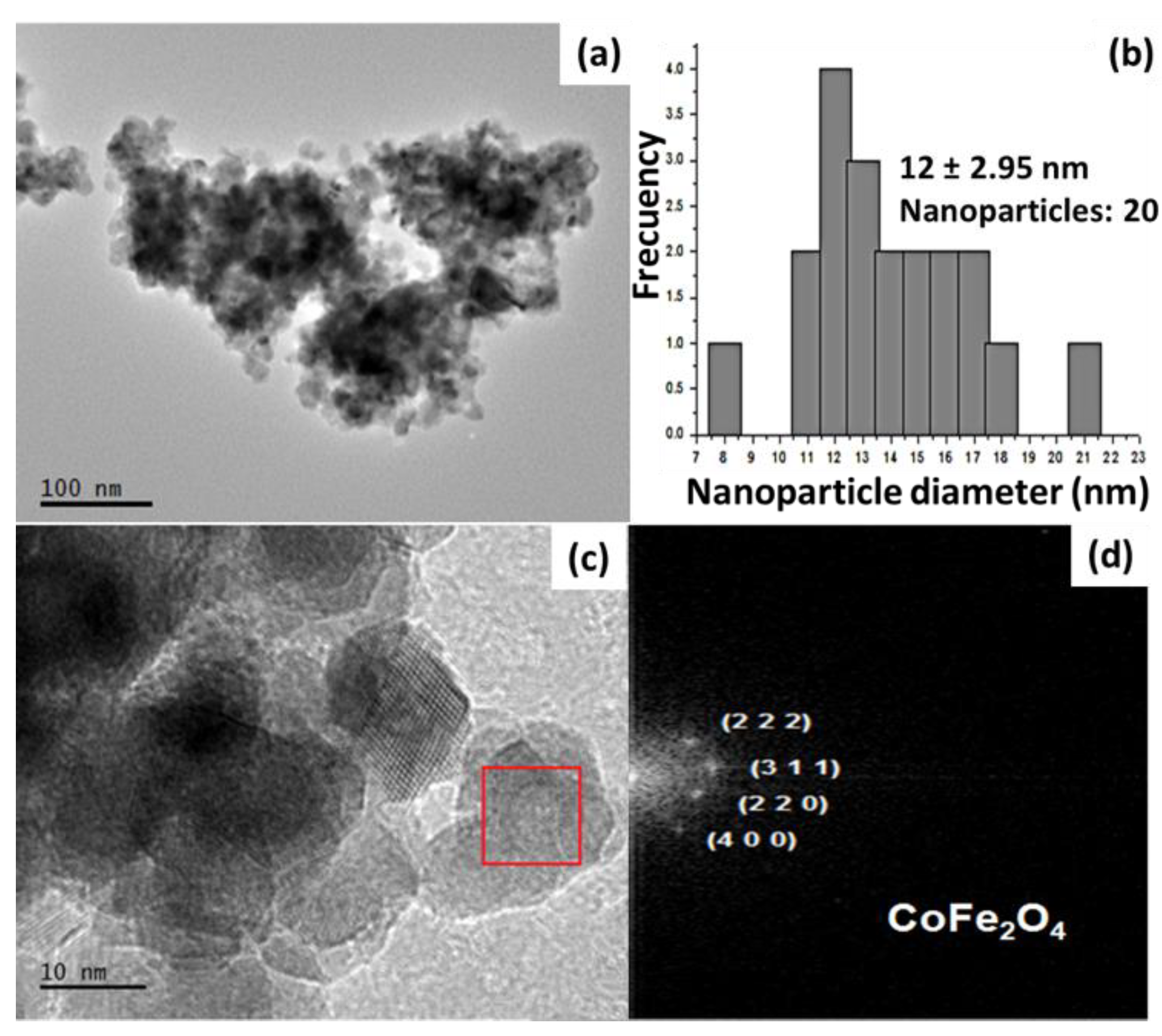

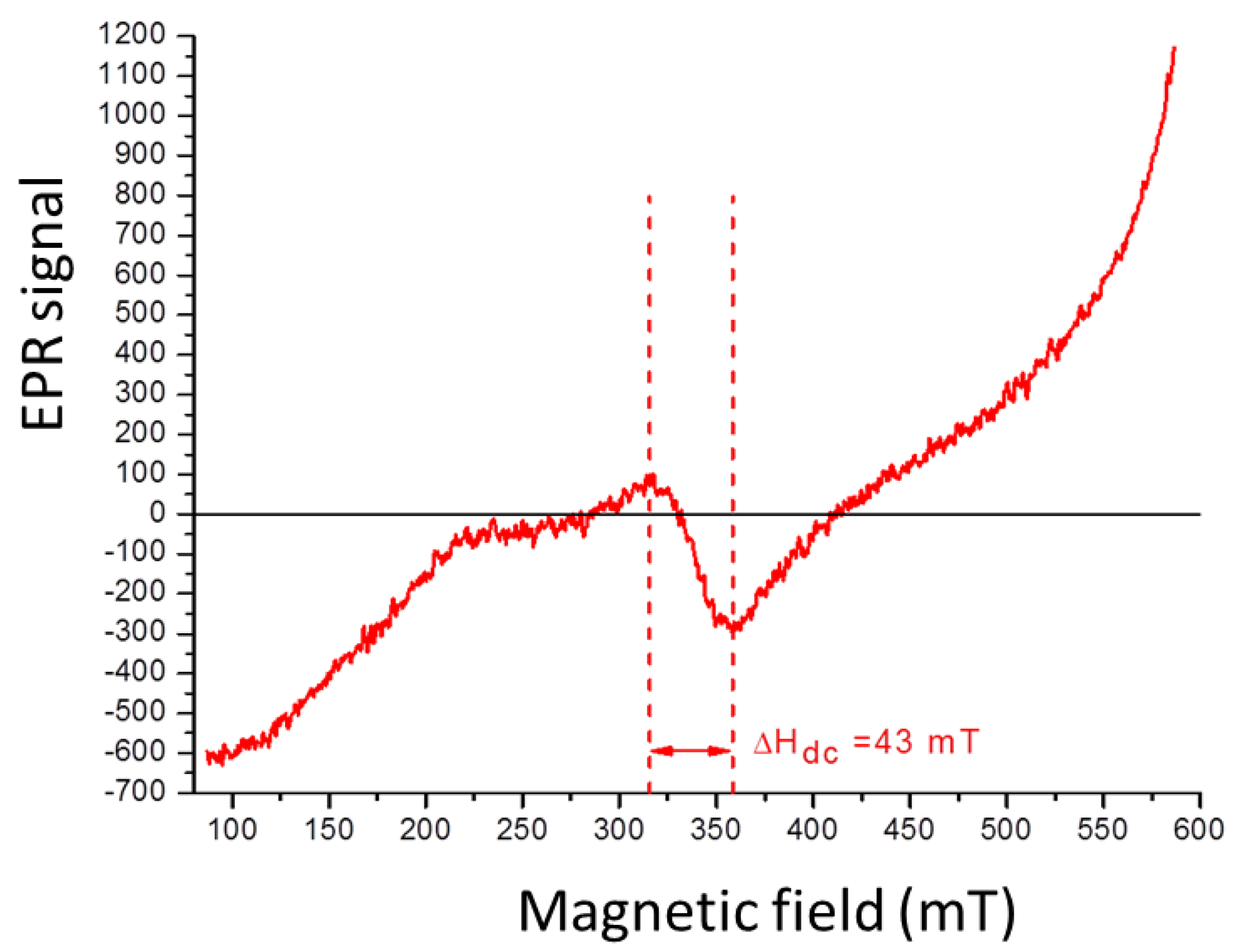

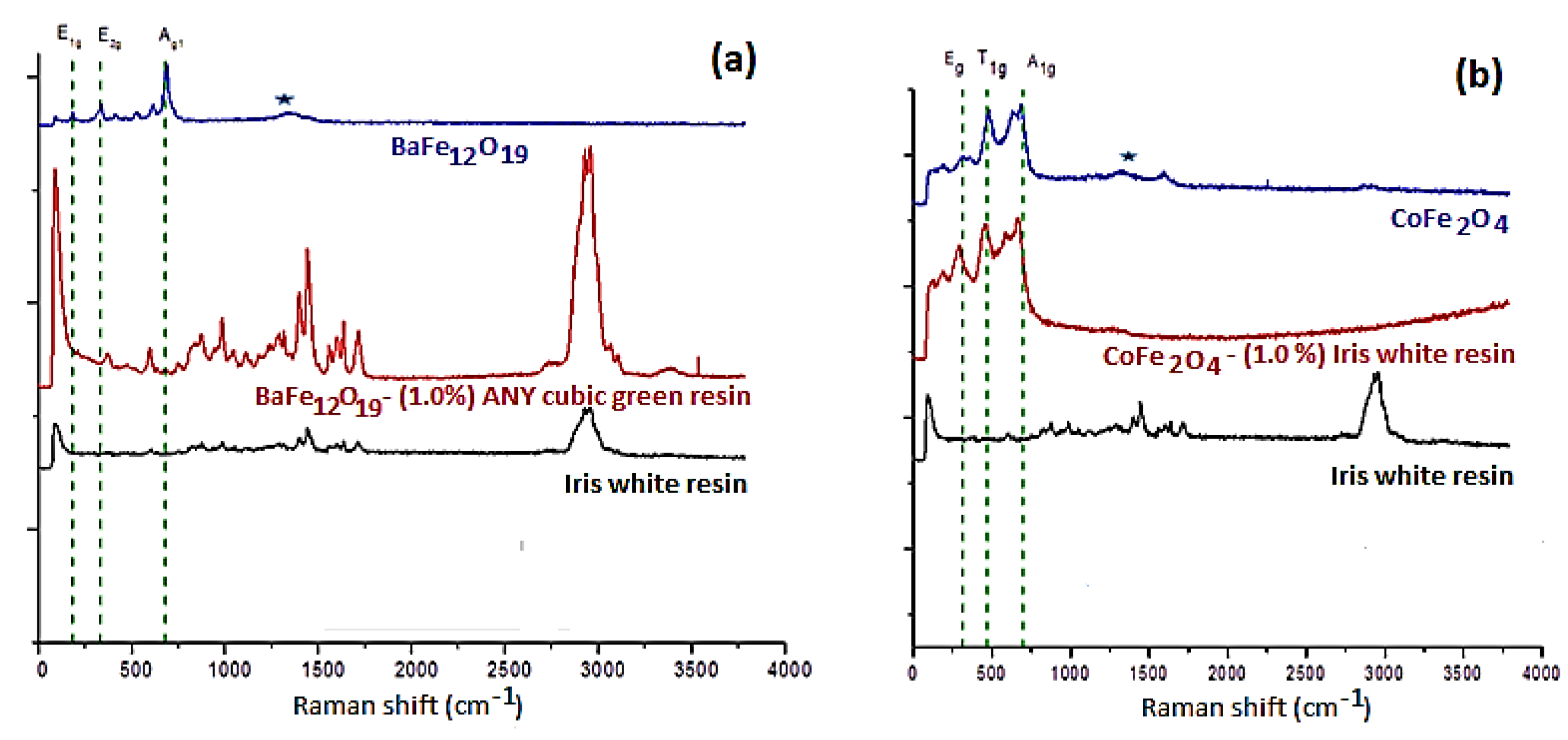

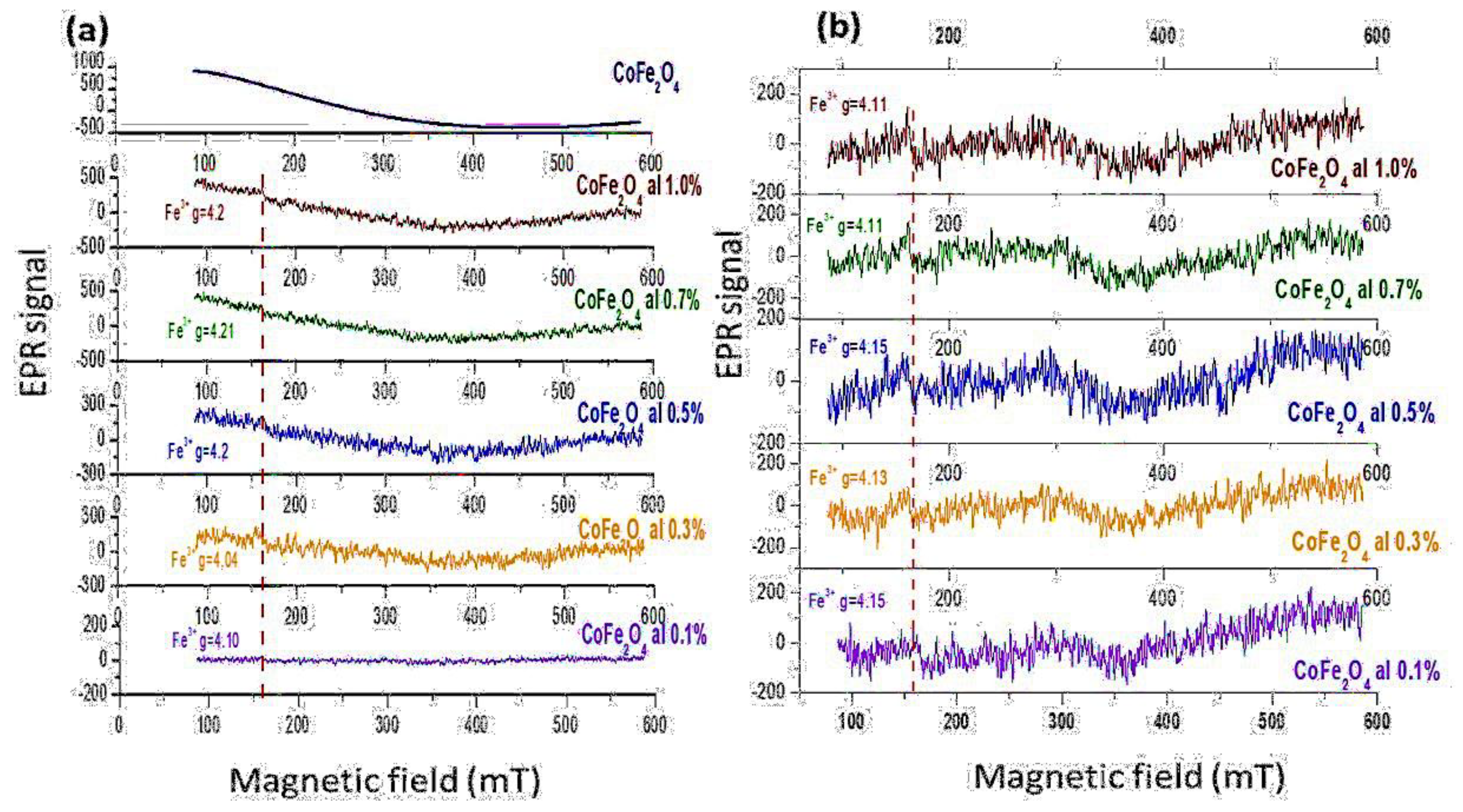

2.1. Characterization of CoFe2O4

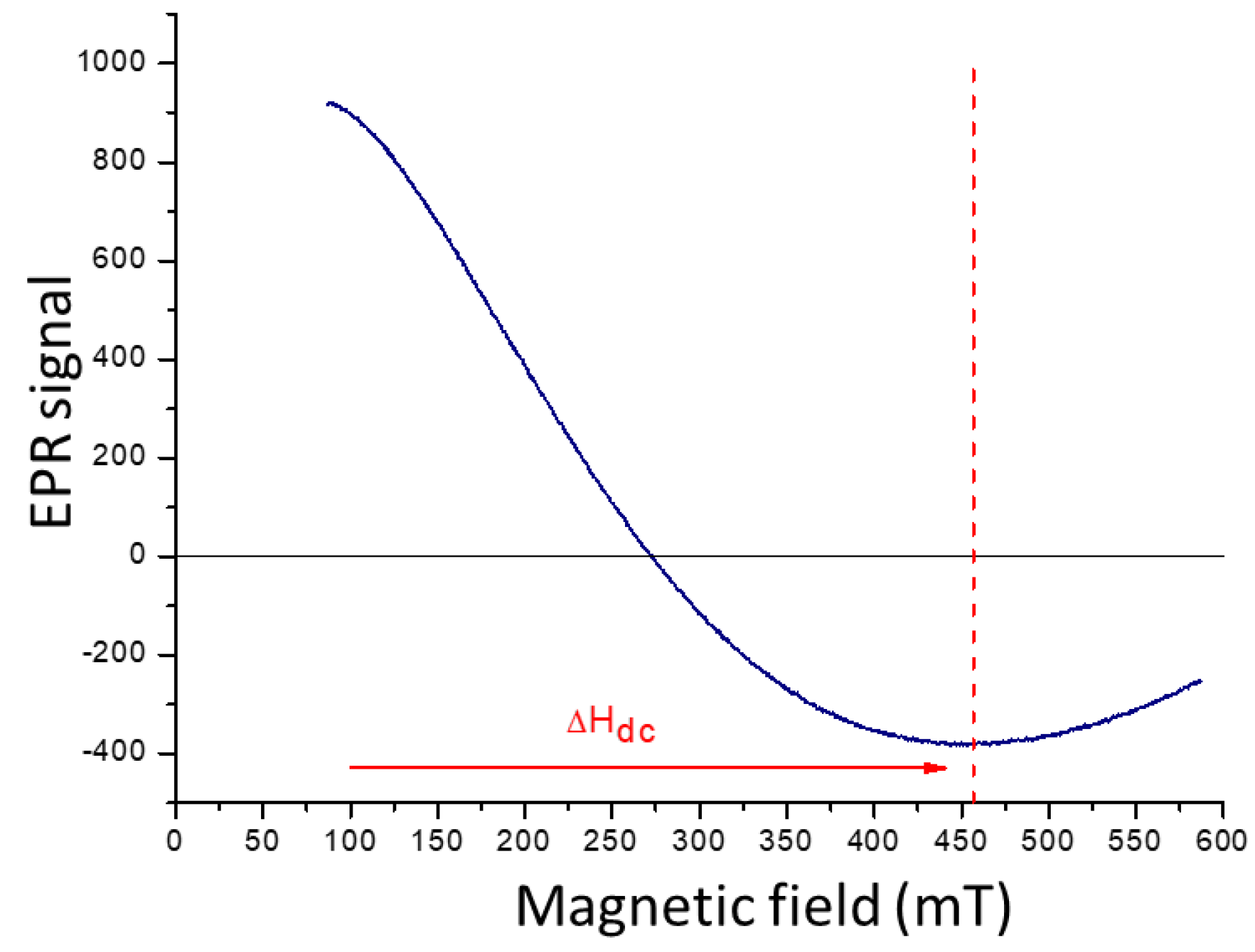

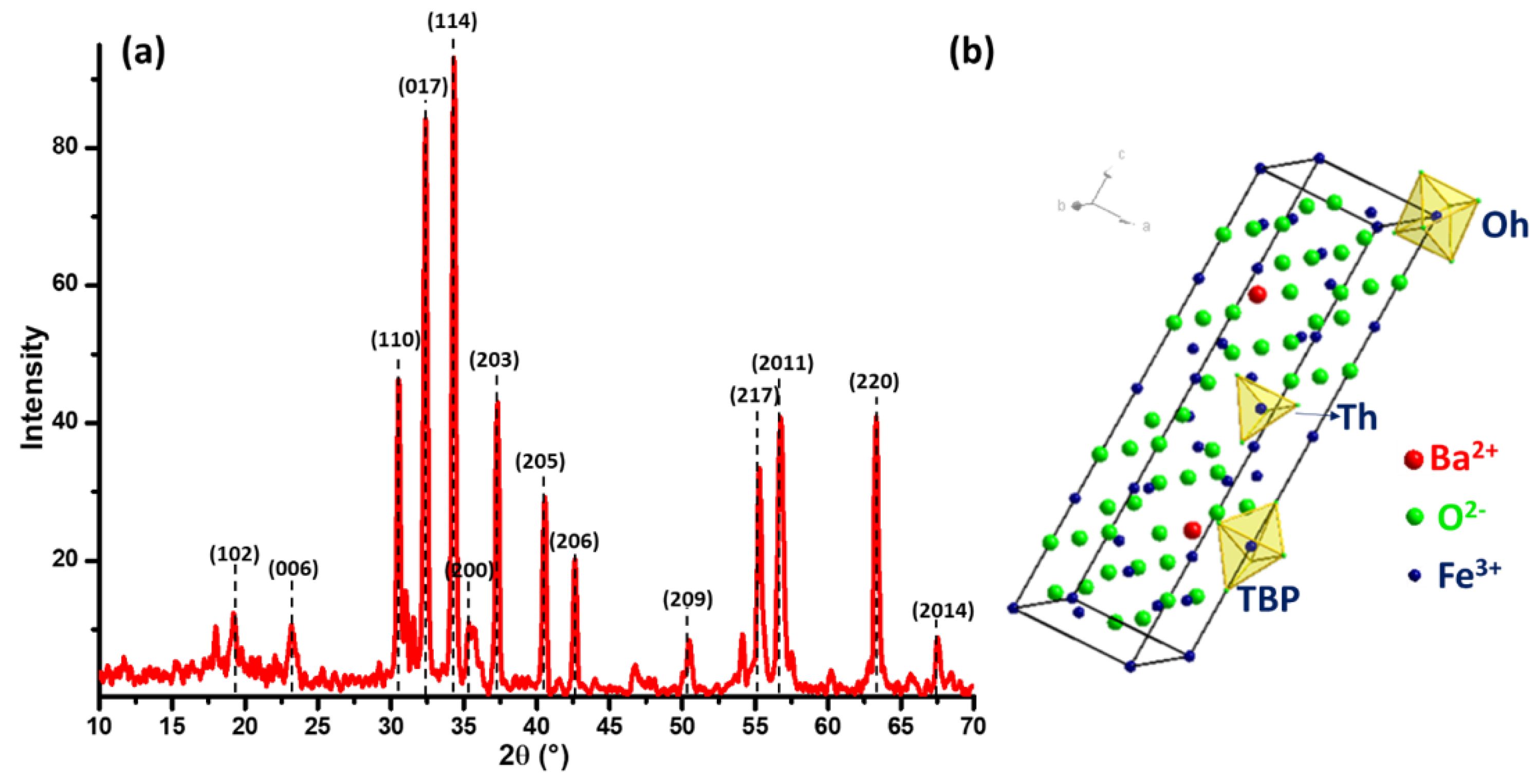

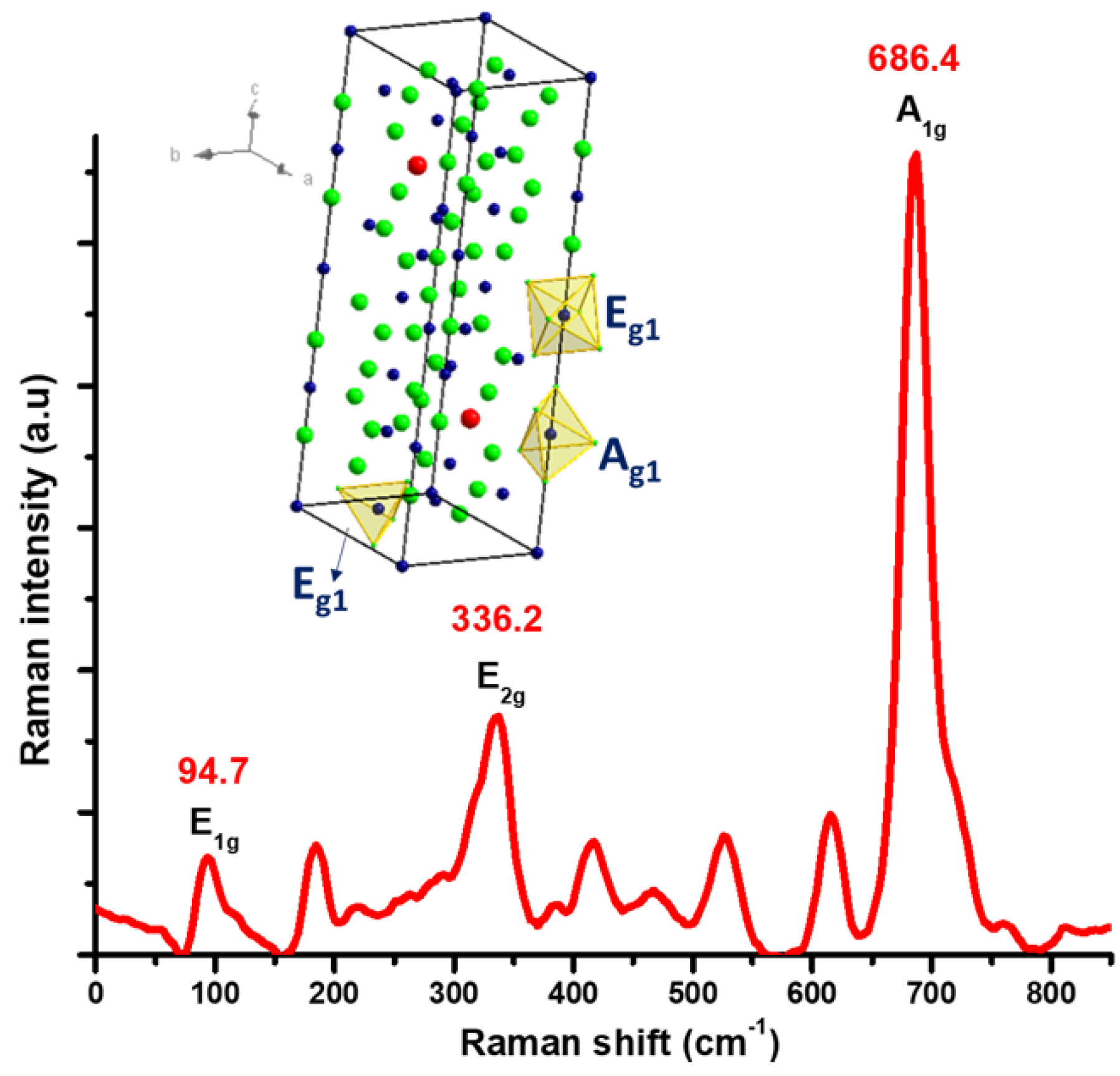

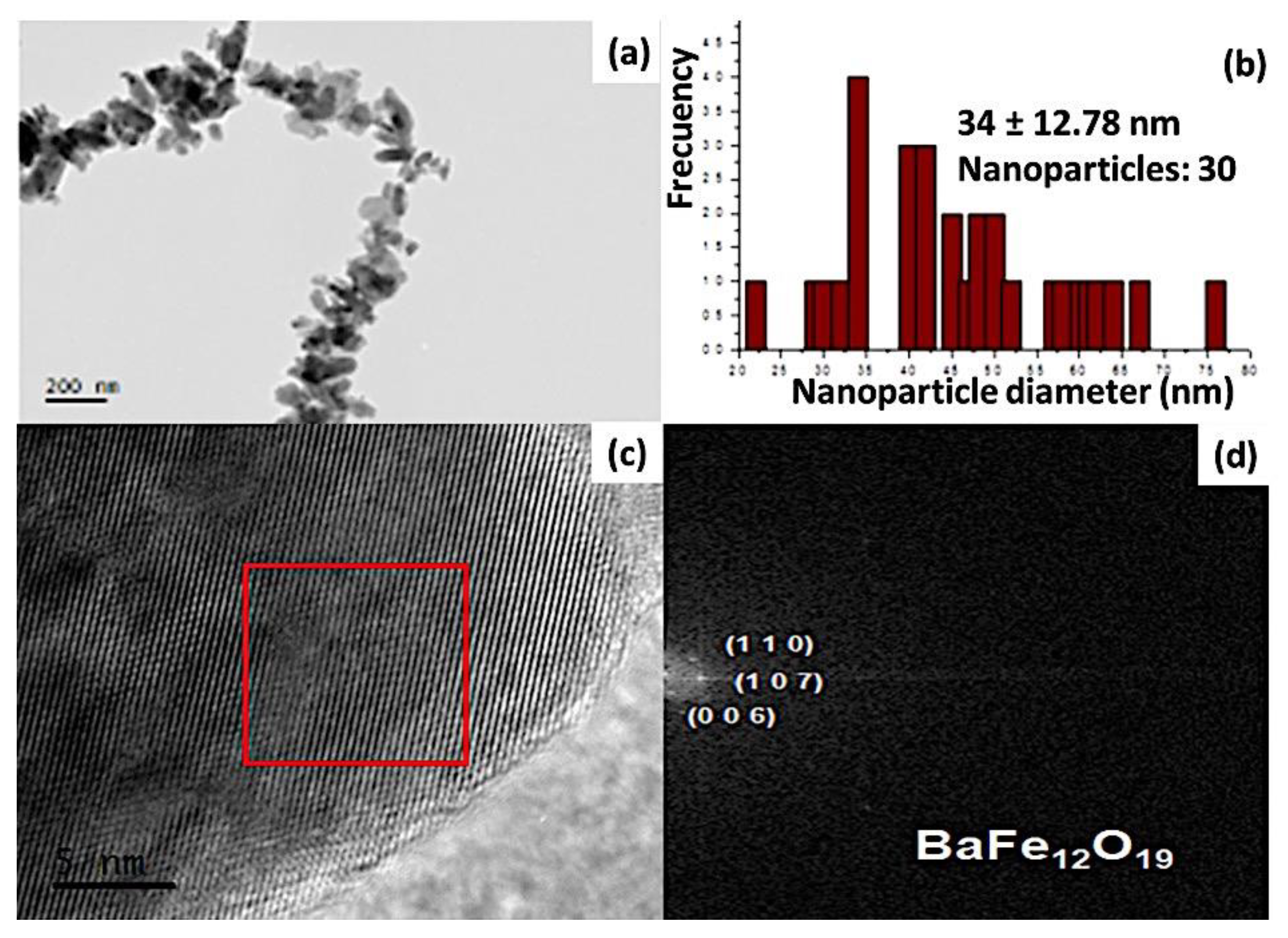

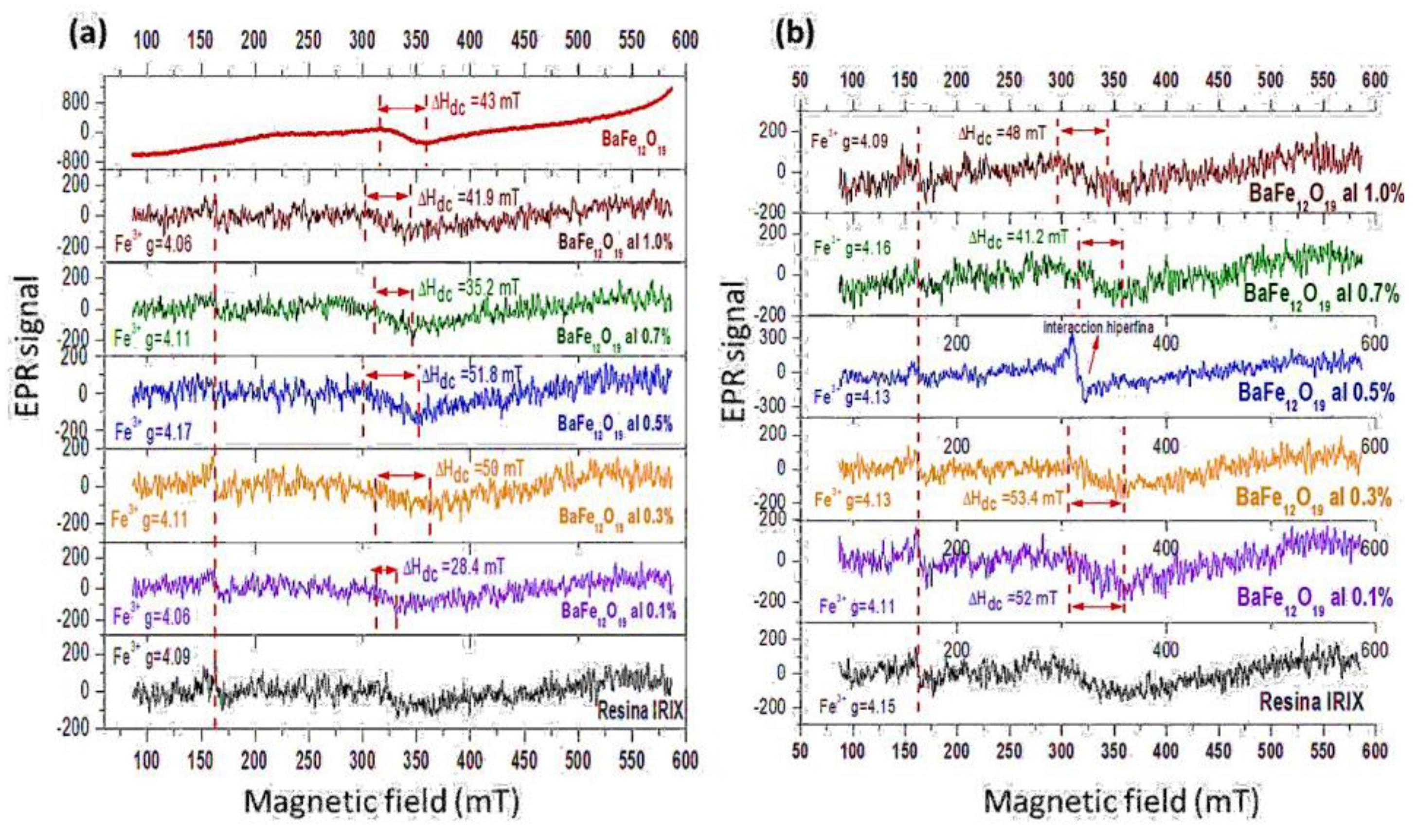

2.2. Characterization of BaFe12O19 Nanoparticles

2.3. Additive Manufacturing Process

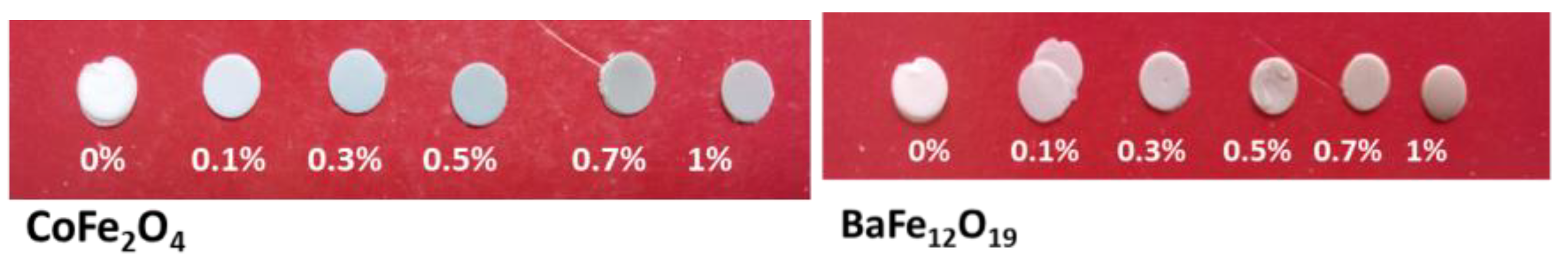

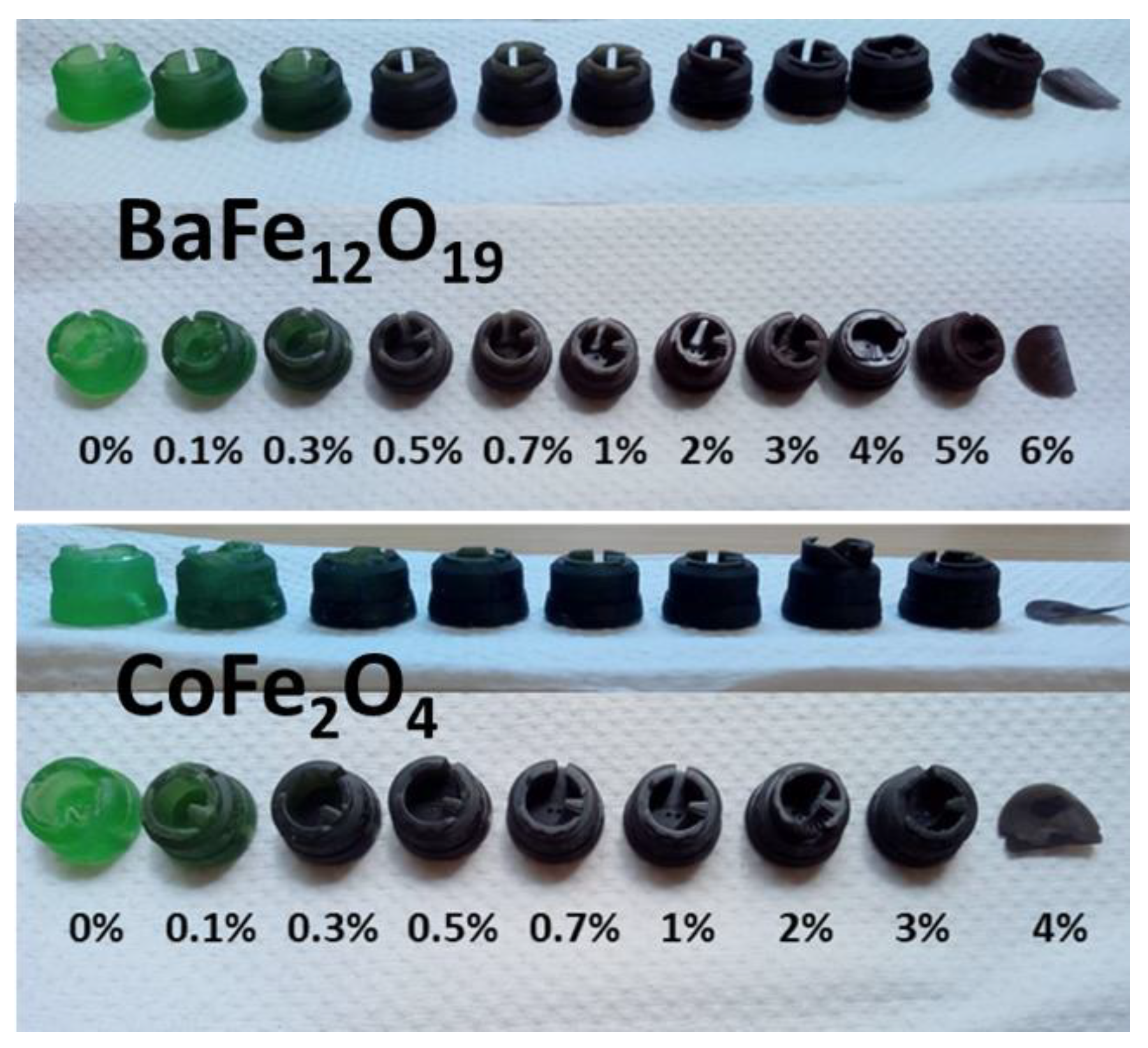

2.3.1. Ferrite – IRIX Resin

2.3.2. Ferrite – ANY Cubic Green Resin

2.3.3. Characterization of Composite Nanostructured Samples

3. Materials and Methods

3.1. Materials

3.2. Methods

3.3. Synthesis of BaFe12O19 Nanoparticles

3.4. Synthesis of CoFe2O4 Nanoparticles

3.5. Obtaining Nanostructured Materials

3.6. Additive Manufacturing Process

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Trukhanov, A.V.; Tishkevich, D.I.; Podgornaya, S.V.; Kaniukov, E.; Darwish, M.A.; Zubar, T.I.; Timofeev, A.V.; Trukhanova, E.L.; Kostishin, V.G.; Trukhanov, S.V. Impact of the Nanocarbon on Magnetic and Electrodynamic Properties of the Ferrite/Polymer Composites. Nanomaterials 2022, 12, 868. [Google Scholar] [CrossRef] [PubMed]

- Houbi, A.; Aldashevich, Z.A.; Atassi, Y.; Bagasharova Telmanovna, Z.; Saule, M.; Kubanych, K. Microwave Absorbing Properties of Ferrites and Their Composites: A Review. J Magn Magn Mater 2021, 529, 167839. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization Behavior of Poly(ε-Caprolactone)/Layered Double Hydroxide Nanocomposites. J Appl Polym Sci 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Zhou, B.; Xu, W.; Syed, A.A.; Chau, Y.; Chen, L.; Chew, B.; Yassine, O.; Wu, X.; Gao, Y.; Zhang, J.; et al. Design and Fabrication of Magnetically Functionalized Flexible Micropillar Arrays for Rapid and Controllable Microfluidic Mixing. Lab Chip 2015, 15, 2125–2132. [Google Scholar] [CrossRef] [PubMed]

- Kesner, S.B.; Howe, R.D. Design Principles for Rapid Prototyping Forces Sensors Using 3-D Printing. IEEE/ASME Transactions on Mechatronics 2011, 16, 866–870. [Google Scholar] [CrossRef] [PubMed]

- Löwa, N.; Fabert, J.-M.; Gutkelch, D.; Paysen, H.; Kosch, O.; Wiekhorst, F. 3D-Printing of Novel Magnetic Composites Based on Magnetic Nanoparticles and Photopolymers. J Magn Magn Mater 2019, 469, 456–460. [Google Scholar] [CrossRef]

- Chaudhary, V.; Mantri, S.A.; Ramanujan, R.V.; Banerjee, R. Additive Manufacturing of Magnetic Materials. Prog Mater Sci 2020, 114, 100688. [Google Scholar] [CrossRef]

- Peng, E.; Wei, X.; Herng, T.S.; Garbe, U.; Yu, D.; Ding, J. Ferrite-Based Soft and Hard Magnetic Structures by Extrusion Free-Forming. RSC Adv 2017, 7, 27128–27138. [Google Scholar] [CrossRef]

- Fedorov, I.; Barhanko, D.; Hallberg, M.; Lindbaeck, M. Hot Turbine Guide Vane Performance Improvement With Metal Additive Manufacturing at Siemens Energy. In Proceedings of the Volume 2C: Turbomachinery — Design Methods and CFD Modeling for Turbomachinery; Ducts, Noise, and Component Interactions; American Society of Mechanical Engineers, June 7 2021.

- SIEMENS Industrialize Additive Manufacturing. Available online: https://www.siemens.com/global/en/markets/machinebuilding/additivemanufacturing.html (accessed on 18 May 2023).

- GE Research TECHNOLOGY DOMAIN: Additive Manufacturing. Available online: https://www.ge.com/research/technology-domains/additive-manufacturing (accessed on 18 May 2023).

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dental Materials 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Flores Arias, Q.Y. Síntesis y Caracterización de Materiales Nanoestructurados de Ferrita, IIM UNAM. CDMX, México, 2014.

- Olga Ivanova, Christopher Williams, T.C. Additive Manufacturing (AM) and Nanotechnology: Promises and Challenges. Rapid Prototyp J 2013, 19. [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Computer-Aided Design 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Chandramohan, P.; Srinivasan, M.P.; Velmurugan, S.; Narasimhan, S. V Cation Distribution and Particle Size Effect on Raman Spectrum of CoFe2O4. J Solid State Chem 2011, 184, 89–96. [Google Scholar] [CrossRef]

- MORALES-MORALES, J.A. Síntesis de Nano Polvos de Hematita A-Fe2O3 Por El Método de Precipitación Controlada. Ciencia en Desarrollo 2017, 8. [Google Scholar] [CrossRef]

- Erdem, D.; Bingham, N.S.; Heiligtag, F.J.; Pilet, N.; Warnicke, P.; Heyderman, L.J.; Niederberger, M. CoFe2O4 and CoFe2O4-SiO2 Nanoparticle Thin Films with Perpendicular Magnetic Anisotropy for Magnetic and Magneto-Optical Applications. Adv Funct Mater 2016, 26. [Google Scholar] [CrossRef]

- Widodo, R.D.; Manaf, A. Physical Characteristics and Magnetic Properties of BaFe12O19/SrTiO3 Based Composites Derived from Mechanical Alloying. AIP Conf Proc 2016, 1725, 20098. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).