Introduction

Silicon wafers warp under residual

stress when they are thinned by grinding or plated with a thin layer of a

different material. Bifurcation and geometric instability of silicon wafers

occur at critical residual stresses that serve as the basis for evaluating the

significance of large deformations.

The magnitude of warpage strongly

depends on the thickness of the silicon substrate. Before the thinning process,

silicon wafers are generally thick enough to resist film stresses, and the

magnitude of warpage is small.

Unfortunately, the warpage

behavior of thin wafers is very different from that of thick ones. The first

one is the magnitude of warpage. The warpage can be so large that it shows

highly nonlinear behavior, or even bifurcation behavior, where the warped

shapes are asymmetric cylinders. Commercial equipment to measure small warpage

of bare wafers automatically compensates or minimizes gravitational effects

using a well-designed three-point support system. However, thinned wafers are

so flexible, and the warpage so great, that measurement with commercial

equipment is difficult. In large thin wafers the out of plane deflection can

exceed 8-10 times the wafer thickness.

Also, the corresponding dies

(chips) show a deformation but it is almost bifurcated. A thin die can be

bifurcated if the ratio between die deflection and die thickness is [3–10],

In real cases,

bifurcation is only possible for ultra-thin dies or if the residual stress is very high.

While, the 8”

thin wafers can have bifurcations even with not high deformations, the ratio

between wafer deflection and wafer thickness is [3–10],

For a t =

200 um thick wafer the bifurcation occurs with a deflection greater than 350

um.

1. Stresses and the Curvatures in a Linear Elastic Plate

Plate theory

is an approximate theory. It turns out to be an accurate theory provided the

plate is relatively thin but also that the deflections are small relative to

the thickness (deflection/t < 0.75) and when the ratio between the thickness t and

the plate width L is t/L <1/20. The plate showing the same elastic behavior in all

directions is called isotropic [1].

In case the plate

has different elastic properties in the two orthogonal directions is called

orthotropic. The elastic problem for an orthotopic plate, in the form developed

by Lagrange, is

Ex, Ey

Young's modules in x, y directions.

νij

(i, j = x, y)

is Poisson's ratio

of the substrate characterizing the compressive strain in the j direction

(direction of the effect) produced by the tensile stress in the i direction

(direction of the stress).

For the symmetry

conditions expressed by Green's relations, we also have

.

The Stresses

and the Curvatures in a Linear Elastic Plate are

Kx

and Ky are the curvatures in the x and y direction.

This important

assumption of small slope,

, means that the

theory to be developed will be valid when the deflections are small compared to

the overall dimensions of the plate.

In this work

we will analytically calculate the deflection and curvature of a silicon plate

and an annular silicon plate coated on one side with an aluminum layer with a

thickness of 4.5 um

2. The Moment-Curvature Equations

Consider a

plate subjected to bending moments

Mx and

My, with no other

loading (Plates subjected to Pure Bending without

twisting,

). From equilibrium considerations, these moments

act at all points within the plate they are constant throughout the plate. The

moment-curvature equations are un the set of coupled partial differential

equations,

The moment

curvature equations are analogous to the beam moment-deflection equation. The

factor Dx, Dy, is called the

plate stiffness or flexural rigidity and plays the same role in

the plate theory as does the flexural rigidity term E*I in the

beam theory.

Solving for the derivatives,

For a plate with axial symmetry (wafer), the relations 2.1, 2.2, 2.3 and 2.4 become

For an

isotropic plate the equations are simplified,

The bending moment

Mx and

My induced by the layer are,

From equilibrium considerations, these moments act at all points within the plate – they are constant throughout the plate.

Equations 2.13 and 2.14 are combined to describe film stresses in terms of substrate curvatures:

where , are the corresponding intrinsic film stresses in the respective directions, in the other hand, material properties E and v correspond to those of substrate.

The relationships 2.18 and 2.19 are

Stoney's formulas for isotropic coated rectangular substrate. Rearranging the relations (2.11) and (2.12),

Integrating the first two equations, the plate deflection can be written,

A = B = C = 0, if

Once the deflection w(x,y) is known, all other quantities in the plate can be evaluated.

For orthotropic plate, the deflection equations 2.17 is written,

The relationships 2.22 and 2.23 are Stoney's formulas for orthotropic coated rectangular substrate.

If we assume a homogeneously deposited film, the stress in the two axes is isotropic and homogeneous (Circular Plate),

this for the general transformation rule

and

and

The equation 2.23 is Stoney' s formula for coated Circular Plate and the deflection

w(r) is,

In the linear region, an increase in stress leads to a proportional increase in the curvature and a preservation of the spherical shape. Outside the linear region a further increase in stress, the shape rapidly transforms from spherical to cylindrical with a dominant curvature in a preferential direction. This phenomenon is called bifurcation of curvature.

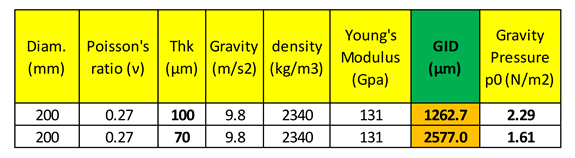

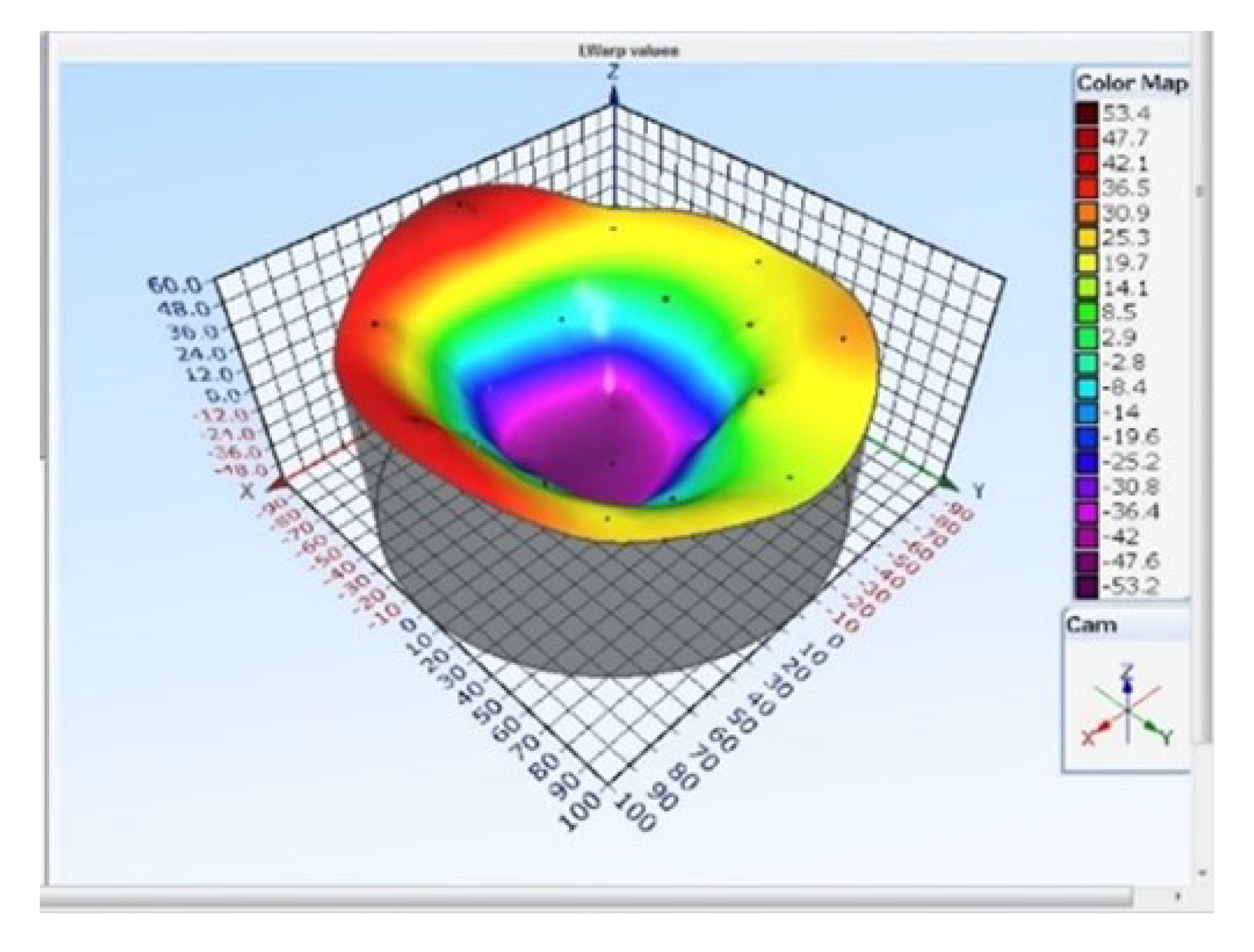

Figure 1 show a 720 µm thick wafer coated with a 4.5 µm thick AlCu layer.

We can calculate the residual stress of the thin film from warp measurements before and after AlCu layer deposition and from equation 2.23. The ΔCBow measurement is about 100 um (parabolic shape) and the residual stress is about 85 MPa (Silicon Young Modulus E = 131 GPa, ν=0.27, ts = 720 um, tf = 4.5 um) and the curvature is k= 0.024 1/m. The warpage have been measured with an MX-204 equipment (E+H Metrology).

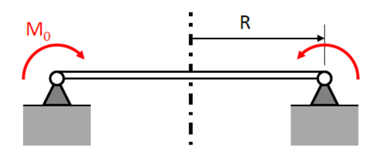

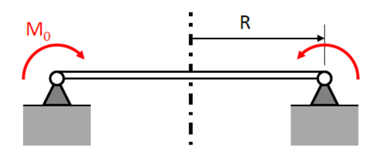

Another way to obtain the same result eq. 2.23 is to solve the

Equation of the Elastic Surface w(x,y) for circular plate supported and loaded with radial moment

Mo at the outer edge is,

By integrating this equation 2.25 we obtain

,

and

are determined by the boundary conditions,

Constant moments (and tensions) across the plate. The bending moment

induced by the coated layer is,

replacing in the (2.24) and (2.25),

we have found the equation (2.23).

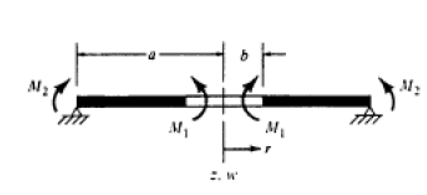

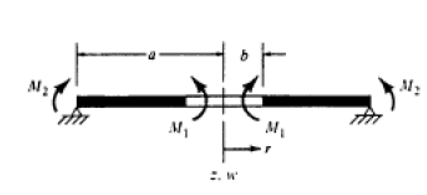

3. Coated Circular plate with a Circular Hole at the Center

Let us Begin with a discussion of the bending of plate by the momentum

Mi and

Me uniformly distributed along the inner and outer boundaries,

,

and

are determined by the equation (2.21) with the BC (1)

Form the equation 3.1 and BC, the annular plate deflection

w(r) is,

The sum of substrate curvatures does not depend on

r,

and in the case

Re Ri

In particular cases,

a) Mi = Me = M0 the equation 3.2, 3.3 and 3.1 become

In this special case, for low defletion before di bifurcation, the annular plate and plate have the same curvature and deflection.

The bending moment M

0 induced by the coated layer is

The equation 3.7 is the same as equation 2.27.

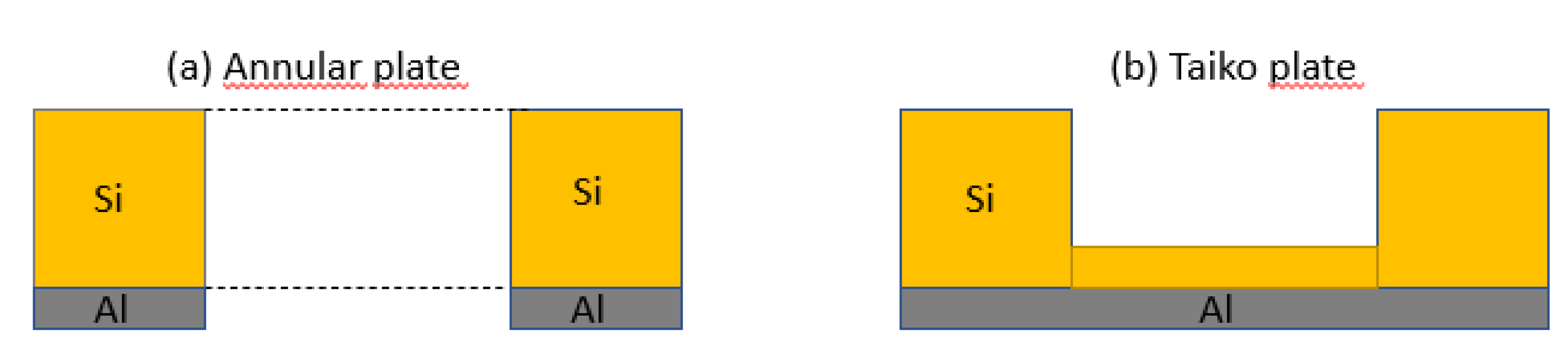

Figure 2.

Annular plate and plate have the same curvature and deflection.

Figure 2.

Annular plate and plate have the same curvature and deflection.

b) Mi = 0, Me≠0

For

Mi = µ*Me, 0 <= µ <= 1.

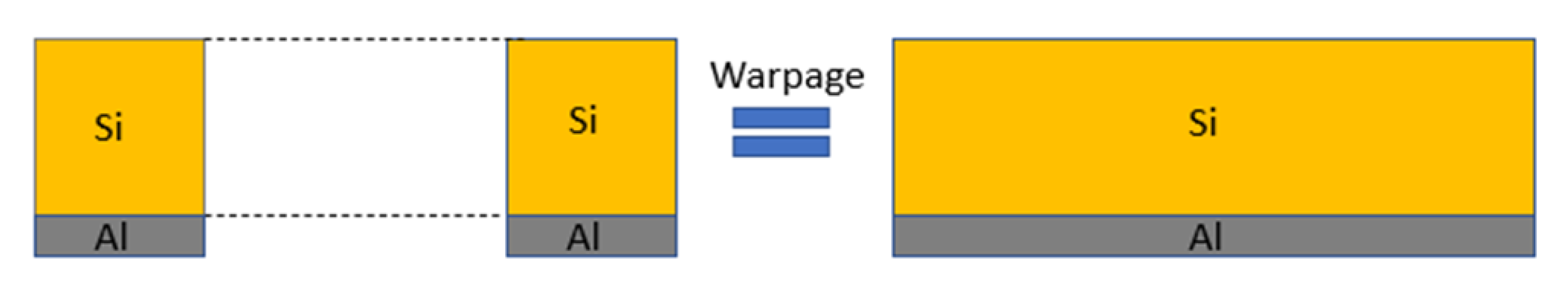

In general, gaining a control on the warpage determined by the BSM residual stress can benefit the whole semiconductor industry and disclose future developments.

Moreover, it is known that with the increase of the size, the handling of a thinned wafer becomes more and more critical.

Another important aspect is the gravitational force (Gravity Induced Deflection (GID)). As the final thickness decreases, the wafer becomes progressively less able to support its weight,

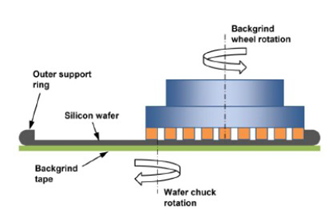

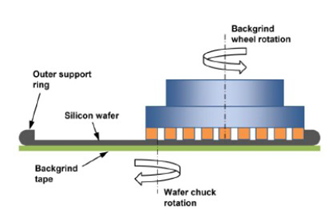

For this reason, in 2008 DISCO proposed the patented taiko process, which consists in a back-grinding method that leaves an annular region around the whole wafer. This solution, which is now a standard, allows an easier handling of the wafer itself and a reduction of the warpage. The unground edge ring of the thinned wafer greatly improves wafer strength and facilitates handling of the thin wafer,

This process method leaves a ring (approximately 3 mm) on the wafer outer edge and thin grinds only the inner area of the backside wafer. The taiko palate wafer can be considered as an annular plate bound to a circular plate. In case the thickness of the circular plate is much smaller than the thickness of the circular ring, we can neglect the effect of the constraint and calculate the taiko wafer deflection using the equation 3.7, with t

s= 450 µm + t

inner. On a 720 µm wafer we deposited a 4.5 µm thick layer of AlCu and performed the Taiko process after the taiko process the inner area has a thickness of 70 µm and the circular ring has a thickness of 450 µm (h

r = 450 um, t

inner= 70 µm and w = 3.7 mm). In

Figure 3 a schematic drawing of the taiko plate is show.

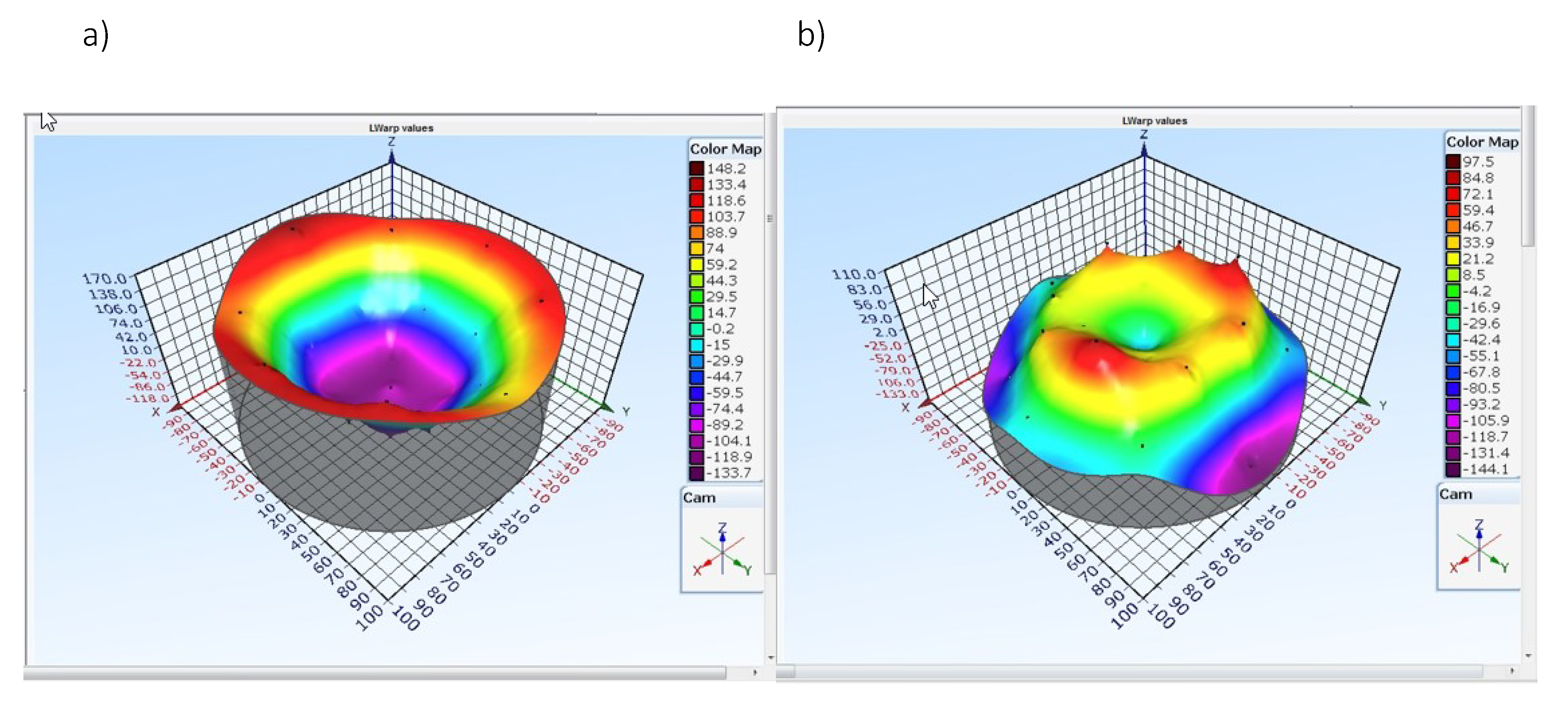

As we have previously shown the layer stress is 85 MPa. The deflection of a taiko wafer without AlCu layer and with AlCu layer are represented,

Figure 4. The warpage have been measured with an MX-204 equipment (E+H Metrology). We using the equations 2.29, 3.9 and 3.7 we can verify that the taiko wafer warpage with a 4.5 AlCu with a residual stress of 85 MPa has about the same warpage value of a 520 um thick ring plate or circular plate (450 um+70 um) with the same layer. This result is valid if we are very far from the bifurcation condition [

2,

3,

4,

5,

6,

7,

8,

9,

10].

Conclusion

The Lagrange-Kirchhoff model for the deformation for a taiko silicon plate silicon is proposed. Under the conditions of validity of the linear theory of thin plates, the model is in agreement with the experimental data. A predictive model of a taiko silicon plate deformation, under bifurcation conditions, will be the subject of future work.

References

- Timoshenko “Theory of Plates and Shells” MC GRAW HILL.

- V. Vinciguerra and A. Landi, "On the Way to understand the Warpage in 8' Taiko Semiconductor Wafers for Power Electronics Applications (Si and SiC)," in 2021 22nd International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Virtual, 2021.

- H. Liu, J. Han, X. Tian, F. Dong, S. Chen and L. Lu, "Accurate determination of bifurcation points for ground silicon wafers considering anisotropy using FEM method," Materials Research Express, vol. 6, no. 9, 7 2019. [CrossRef]

- D. K. Shin and J. J. Lee, "Analysis of asymmetric warpage of thin wafers on flat plate considering bifurcation and gravitational force," IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 4, no. 2, pp. 248 - 258, Feb. 2014. [CrossRef]

- N. J. Salamon and C. B. Masters, "Bifurcation in isotropic thinfilm/substrate plates," International Journal of Solids and Structures, vol. 32, no. 3-4, pp. 473-481, Febbruary 1995. [CrossRef]

- C. B. Masters and N. J. Salamon, "Geometrically nonlinear stress-deflection relations for thin film/substrate systems with a finite element comparison," J. Appl. Mech., vol. 61, no. 4, pp. 872-878 (7 pages), Dec 1994. [CrossRef]

- L.B. Freund and S. Suresh, Thin Film Materials: Stress, Defect Formation and Surface Evolution, Cambridge: Cambridge University Press, 2004.

- L. B. Freund, "Substrate curvature due to thin film mismatch strain in the nonlinear deformation range," Journal of the Mechanics and Physics of Solids, vol. 48, no. 6, pp. 1159-1174, 2000. [CrossRef]

- V. Vinciguerra, G. L. Malgioglio and A. Landi, "Modelling the Elastic Energy of a Bifurcated Wafer: A benchmark of the Analytical Solutions vs. the ANSYS Finite Element Analysis," Composite Structures, 114996, vol. 281, 2022.

- L. B. Freund, J. A. Flora and E. Chason, "Extensions of the Stoney formula for substrate curvature to configurations with thin substrates or large deformations," Applied Physics Letters, vol. 74, no. 14, p. 1987, 1999. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).