Submitted:

09 August 2023

Posted:

10 August 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusion

Supplementary Materials

References

- N. Sakihama, T. Mitamura, A. Kaneko, T. Horii, K. Tanabe, Long PCR Amplification of Plasmodium falciparum DNA Extracted from Filter Paper Blots, Exp Parasitol. 97 (2001) 50–54. https://doi.org/10.1006/EXPR.2000.4591. [CrossRef]

- F. Ansah, J. Suurbaar, D. Darko, N.G. Anabire, S.O. Blankson, B.K.S. Domson, A. Soulama, P. Kpasra, J.D. Chirawurah, L. Amenga-Etego, P. Kanyong, G.A. Awandare, Y. Aniweh, Development of Cooperative Primer-Based Real-Time PCR Assays for the Detection of Plasmodium malariae and Plasmodium ovale, The Journal of Molecular Diagnostics. 23 (2021) 1393–1403. https://doi.org/10.1016/J.JMOLDX.2021.07.022. [CrossRef]

- W.A. Azmi, A.F.M. Rizki, Y. Djuardi, I.M. Artika, J.E. Siregar, Molecular insights into artemisinin resistance in Plasmodium falciparum: An updated review, Infection, Genetics and Evolution. 112 (2023) 105460. https://doi.org/10.1016/J.MEEGID.2023.105460. [CrossRef]

- H. Torkashvand, S.A. Dehdast, M. Nateghpour, A.M. Haghi, G.C. Fard, T. Elmi, M. Shabani, F. Tabatabaie, Antimalarial nano-drug delivery system based on graphene quantum dot on Plasmodium falciparum: Preparation, characterization, toxicological evaluation, Diam Relat Mater. 132 (2023) 109670. https://doi.org/10.1016/J.DIAMOND.2022.109670. [CrossRef]

- G.C. Chemwor, B.M. Andagalu, I.A. Onyango, B.H. Opot, R.O. Okoth, R.A. Yedah, J.A. Juma, E.W. Mwakio, D.M. Wakoli, J.G. Amwoma, A.C. Cheruiyot, D.W. Juma, B.R. Ogutu, T.E. Egbo, E.C. Garges, A.L. Roth, E. Kamau, O.J. Watson, H.M. Akala, Therapeutic response to artemisinin combination therapies among individuals with Plasmodium falciparum single infection vs mixed Plasmodium species infections: a retrospective posthoc analysis in Kisumu County, western Kenya, International Journal of Infectious Diseases. 132 (2023) 17–25. https://doi.org/10.1016/J.IJID.2023.04.008. [CrossRef]

- S.-J. Xu, H.-M. Shen, Y.-B. Cui, S.-B. Chen, B. Xu, J.-H. Chen, Genetic diversity and natural selection of rif gene (PF3D7_1254800) in the Plasmodium falciparum global populations, Mol Biochem Parasitol. 254 (2023) 111558. https://doi.org/10.1016/J.MOLBIOPARA.2023.111558. [CrossRef]

- L. Dong, W. Li, Q. Xu, J. Gu, Z. Kang, J. Chen, X. Xu, X. Zhang, X. Zhang, H. Jiang, M. Guan, A rapid multiplex assay of human malaria parasites by digital PCR, Clinica Chimica Acta. 539 (2023) 70–78. https://doi.org/10.1016/J.CCA.2022.12.001. [CrossRef]

- A. Taghdiri, P.G. Nejad Almani, I. Sharifi, M.A. Mohammadi, S. Salari, Detection of malaria with light microscopy and Nested polymerase chain reaction (Nested PCR) methods in peripheral blood expansions and investigation of the genetic diversity of Plasmodium species by 18S rRNA gene in Southeast of Iran, Microb Pathog. 137 (2019) 103782. https://doi.org/10.1016/J.MICPATH.2019.103782. [CrossRef]

- C.R.F. Chagas, J. Harl, G. Valkiūnas, Co-infections of Plasmodium relictum lineages pSGS1 and pGRW04 are readily distinguishable by broadly used PCR-based protocols, with remarks on global distribution of these malaria parasites, Acta Trop. 217 (2021) 105860. https://doi.org/10.1016/J.ACTATROPICA.2021.105860. [CrossRef]

- H. Frickmann, C. Wegner, S. Ruben, C. Behrens, H. Kollenda, R. Hinz, S. Rojak, N.G. Schwarz, R.M. Hagen, E. Tannich, Evaluation of the multiplex real-time PCR assays RealStar malaria S&T PCR kit 1.0 and FTD malaria differentiation for the differentiation of Plasmodium species in clinical samples, Travel Med Infect Dis. 31 (2019) 101442. https://doi.org/10.1016/J.TMAID.2019.06.013. [CrossRef]

- H. Mirahmadi, M. Rahmati-Balaghaleh, M. Afzalaghaee, M. Zarean, S.A. Shamsian, A. Mehravaran, V. Raissi, S. Etemadi, Detection of malaria using blood smear by light microscopy, RDT and nested-PCR for suspected patients in south-eastern Iran, Gene Rep. 25 (2021) 101339. https://doi.org/10.1016/J.GENREP.2021.101339. [CrossRef]

- X. Xiong, A. Hou, S. Yi, Y. Guo, Z. Zhao, Z. Wu, H. Cheng, K. Li, Z. Li, Y. Ren, Y. Wang, Analysis of oral microorganism diversity in healthy individuals before and after chewing areca nuts using PCR-denatured gradient gel electrophoresis, Animal Nutrition. 4 (2018) 294–299. https://doi.org/10.1016/J.ANINU.2018.07.001. [CrossRef]

- A. El-Latif Hesham, V.K. Gupta, B.P. Singh, Use of PCR-denaturing gradient gel electrophoresis for the discrimination of Candida species isolated from natural habitats, Microb Pathog. 120 (2018) 19–22. https://doi.org/10.1016/J.MICPATH.2018.04.027. [CrossRef]

- C. Banerjee, S. Nag, M. Goyal, D. Saha, A.A. Siddiqui, S. Mazumder, S. Debsharma, S. Pramanik, U. Bandyopadhyay, Nuclease activity of Plasmodium falciparum Alba family protein PfAlba3, Cell Rep. 42 (2023) 112292. https://doi.org/10.1016/J.CELREP.2023.112292. [CrossRef]

- S.-J. Xu, H.-M. Shen, Y.-B. Cui, S.-B. Chen, B. Xu, J.-H. Chen, Genetic diversity and natural selection of rif gene (PF3D7_1254800) in the Plasmodium falciparum global populations, Mol Biochem Parasitol. 254 (2023) 111558. https://doi.org/10.1016/J.MOLBIOPARA.2023.111558. [CrossRef]

- Y. Wu, S. Leyk, H. Torabi, K. Höhn, B. Honecker, M. del P.M. Tauler, D. Cadar, T. Jacobs, I. Bruchhaus, N.G. Metwally, Plasmodium falciparum infection reshapes the human microRNA profiles of red blood cells and their extracellular vesicles, IScience. 26 (2023) 107119. https://doi.org/10.1016/J.ISCI.2023.107119. [CrossRef]

- Z. Xiang, D. Li, S. Wang, T. Shen, W. He, M. Li, W. Zeng, X. Chen, Y. Wu, L. Cui, Z. Yang, A simple alkali lysis method for Plasmodium falciparum DNA extraction from filter paper blood samples, Mol Biochem Parasitol. 254 (2023) 111557. https://doi.org/10.1016/J.MOLBIOPARA.2023.111557. [CrossRef]

- D. Choubey, B. Deshmukh, A.G. Rao, A. Kanyal, A.K. Hati, S. Roy, K. Karmodiya, Genomic analysis of Indian isolates of Plasmodium falciparum: Implications for drug resistance and virulence factors, Int J Parasitol Drugs Drug Resist. 22 (2023) 52–60. https://doi.org/10.1016/J.IJPDDR.2023.05.003. [CrossRef]

- A. Ebrahimzadeh, B. Fouladi, A. Fazaeli, High rate of detection of mixed infections of Plasmodium vivax and Plasmodium falciparum in South-East of Iran, using nested PCR, Parasitol Int. 56 (2007) 61–64. https://doi.org/10.1016/J.PARINT.2006.12.001. [CrossRef]

- A. Wångdahl, R.T. Bogale, I. Eliasson, I. Broumou, F. Faroogh, F. Lind, G. Vashchuk, A. Hildell, S. Franson, E. Hallberg, I. Grip, I. Nordling, A. Gervin, S. Kaitoly, B. Tekleab, K. Wyss, A. Requena-Méndez, O. Hertting, A. Färnert, Malaria parasite prevalence in Sub-Saharan African migrants screened in Sweden: a cross-sectional study, The Lancet Regional Health - Europe. 27 (2023) 100581. https://doi.org/10.1016/J.LANEPE.2022.100581. [CrossRef]

- A.K.D.J. Fall, C. Dechavanne, A. Sabbagh, A. Garcia, D. Courtin, F. Migot-Nabias, Combined polymorphisms involving the IgG heavy chain and Fc gamma receptors among Fulani and non-Fulani in Benin: implications for the natural protection of young Fulani against Plasmodium falciparum malaria infections, Infection, Genetics and Evolution. 112 (2023) 105461. https://doi.org/10.1016/J.MEEGID.2023.105461. [CrossRef]

- C.C. Hermsen, D.S.C. Telgt, E.H.P. Linders, L.A.T.F. Van De Locht, W.M.C. Eling, E.J.B.M. Mensink, R.W. Sauerwein, Detection of Plasmodium falciparum malaria parasites in vivo by real-time quantitative PCR, Mol Biochem Parasitol. 118 (2001) 247–251. https://doi.org/10.1016/S0166-6851(01)00379-6. [CrossRef]

- N.E.P. Fernandas, H. Silveira, A.S. Franco, A.P. Arez, J.M. Forte, V.E. Do Rosário, Detection of malaria parasites in paraffin-embedded spleen and placental tissues by nested PCR, Trans R Soc Trop Med Hyg. 95 (2001) 293–294. https://doi.org/10.1016/S0035-9203(01)90237-8. [CrossRef]

- C. Maier, T. Calafut, Polypropylene: The Definitive User’s Guide and Databook, Elsevier Science, 2008. https://books.google.dk/books?id=AWaSJd9Non8C.

- H.E. Bair, D.R. Falcone, M.Y. Hellman, G.E. Johnson, P.G. Kelleher, Hydrolysis of polycarbonate to yield BPA, J Appl Polym Sci. 26 (1981) 1777–1786. https://doi.org/10.1002/APP.1981.070260603. [CrossRef]

- B.K. Gale, M.A. Eddings, S.O. Sundberg, A. Hatch, J. Kim, T. Ho, S.M. Karazi, Low-Cost MEMS Technologies, Reference Module in Materials Science and Materials Engineering. (2016). https://doi.org/10.1016/B978-0-12-803581-8.00530-0. [CrossRef]

- A.P. Agrawal, S. Ali, S. Rathore, Finite element stress analysis for shape optimization of spur gear using ANSYS, Mater Today Proc. 64 (2022) 1147–1152. https://doi.org/10.1016/J.MATPR.2022.03.404. [CrossRef]

- M. Karthick, C. Siva Ramakrishna, R. Pugazhenthi, N. Gudadhe, S. Baskar, Renu, R. Kumar, Contact stress analysis of xylon coated spur gear using ANSYS workbench, Mater Today Proc. (2023). https://doi.org/10.1016/J.MATPR.2023.03.572. [CrossRef]

- A. Chinnamahammad Bhasha, K. Balamurugan, Fracture analysis of fuselage wing joint developed by aerodynamic structural materials, Mater Today Proc. 38 (2021) 2555–2562. https://doi.org/10.1016/J.MATPR.2020.07.561. [CrossRef]

- M. Malika, R. Bhad, S.S. Sonawane, ANSYS simulation study of a low volume fraction CuO–ZnO/water hybrid nanofluid in a shell and tube heat exchanger, Journal of the Indian Chemical Society. 98 (2021) 100200. https://doi.org/10.1016/J.JICS.2021.100200. [CrossRef]

- M. Bhola, S. Singh, Analysis of heat transfer of turbulent channel using different geometries using ANSYS, Mater Today Proc. 64 (2022) 1223–1228. https://doi.org/10.1016/J.MATPR.2022.03.701. [CrossRef]

- L. Dong, W. Li, Q. Xu, J. Gu, Z. Kang, J. Chen, X. Xu, X. Zhang, X. Zhang, H. Jiang, M. Guan, A rapid multiplex assay of human malaria parasites by digital PCR, Clinica Chimica Acta. 539 (2023) 70–78. https://doi.org/10.1016/J.CCA.2022.12.001. [CrossRef]

- C. Costales, M.J. Broadhurst, I. Budvytiene, N. Banaei, Clinical accuracy of malaria loop-mediated isothermal amplification assay as a stand-alone screening tool at a non-endemic Northern California regional health system, Diagn Microbiol Infect Dis. 103 (2022) 115680. https://doi.org/10.1016/J.DIAGMICROBIO.2022.115680. [CrossRef]

- H. Pian, M. Yang, X. Sun, Z. Zheng, Sandwich hybridization-based loop-mediated isothermal amplification (SHB-LAMP) for high-throughput detection of malaria RNA from asymptomatic infections, Sens Actuators B Chem. 365 (2022) 131973. https://doi.org/10.1016/J.SNB.2022.131973. [CrossRef]

- L.P.Y. Zen, M.Y. Lai, S. Izzati binti Rozlan, M.H. Abdul Hamid, J. Jelip, R. Nani Mudin, Y.L. Lau, End-point detection of loop-mediated isothermal amplification (LAMP) on malaria by direct observation with colorimetric dyes, Exp Parasitol. 239 (2022) 108310. https://doi.org/10.1016/J.EXPPARA.2022.108310. [CrossRef]

- S. Picot, M. Cucherat, A.L. Bienvenu, Systematic review and meta-analysis of diagnostic accuracy of loop-mediated isothermal amplification (LAMP) methods compared with microscopy, polymerase chain reaction and rapid diagnostic tests for malaria diagnosis, International Journal of Infectious Diseases. 98 (2020) 408–419. https://doi.org/10.1016/J.IJID.2020.07.009. [CrossRef]

- R. Struijk, A. van den Ouden, J. Louwerse, K. Čurová, R. Burggrave, B. McNally, T. de Groot, B. Mulder, G. de Vos, Ultrafast RNA extraction-free SARS-CoV-2 detection by direct RT-PCR using a rapid thermal cycling approach, Diagn Microbiol Infect Dis. 107 (2023) 115975. https://doi.org/10.1016/J.DIAGMICROBIO.2023.115975. [CrossRef]

- J.K. Brons, S.N. Vink, M.G.J. de Vos, S. Reuter, U. Dobrindt, J.D. van Elsas, Fast identification of Escherichia coli in urinary tract infections using a virulence gene based PCR approach in a novel thermal cycler, J Microbiol Methods. 169 (2020) 105799. https://doi.org/10.1016/J.MIMET.2019.105799. [CrossRef]

- M. Zhang, C. Liu, Y. Shi, J. Wu, J. Wu, H. Chen, Selective endpoint visualized detection of Vibrio parahaemolyticus with CRISPR/Cas12a assisted PCR using thermal cycler for on-site application, Talanta. 214 (2020) 120818. https://doi.org/10.1016/J.TALANTA.2020.120818. [CrossRef]

- Y. kun Lou, H. Qin, E. Molodysky, B.J. Morris, Simple microwave and thermal cycler boiling methods for preparation of cervicovaginal lavage cell samples prior to PCR for human papillomavirus detection, J Virol Methods. 44 (1993) 77–81. https://doi.org/10.1016/0166-0934(93)90009-G. [CrossRef]

- M.R. Uribe, S. Adams, K. Barracchini, J. Hackett, F. Marincola, D. Stroncek, An alternative PCR-based method for monitoring thermal cycler performance, Hum Immunol. 64 (2003) S177. https://doi.org/10.1016/J.HUMIMM.2003.08.338. [CrossRef]

- J. Nabuti, A.R. Fath Elbab, A. Abdel-Mawgood, M. Yoshihisa, H.M.H. Shalaby, Highly efficient photonic PCR system based on plasmonic heating of gold nanofilms, Biosens Bioelectron X. 14 (2023) 100346. https://doi.org/10.1016/J.BIOSX.2023.100346. [CrossRef]

- T. Higashi, H. Minegishi, A. Echigo, Y. Nagaoka, T. Fukuda, R. Usami, T. Maekawa, T. Hanajiri, Nanomaterial-assisted PCR based on thermal generation from magnetic nanoparticles under high-frequency AC magnetic fields, Chem Phys Lett. 635 (2015) 234–240. https://doi.org/10.1016/J.CPLETT.2015.06.070. [CrossRef]

- B.E. Gama, F. do E.S. Silva-Pires, M.N.K.R. Lopes, M.A.B. Cardoso, C. Britto, K.L. Torres, L. de Mendonça Lima, J.M. de Souza, C.T. Daniel-Ribeiro, M. de Fátima Ferreira-da-Cruz, Real-time PCR versus conventional PCR for malaria parasite detection in low-grade parasitemia, Exp Parasitol. 116 (2007) 427–432. https://doi.org/10.1016/J.EXPPARA.2007.02.011. [CrossRef]

- M.J. Godin, A. Sebastian, I. Albert, S.E. Lindner, Long-read genome assembly and gene model annotations for the rodent malaria parasite Plasmodium yoelii 17XNL, Journal of Biological Chemistry. 299 (2023) 104871. https://doi.org/10.1016/J.JBC.2023.104871. [CrossRef]

- Y. Cao, C. Ye, C. Zhang, G. Zhang, H. Hu, Z. Zhang, H. Fang, J. Zheng, H. Liu, Simultaneous detection of multiple foodborne bacteria by loop-mediated isothermal amplification on a microfluidic chip through colorimetric and fluorescent assay, Food Control. 134 (2022) 108694. https://doi.org/10.1016/J.FOODCONT.2021.108694. [CrossRef]

- X. Cao, S. Ge, X. Zhou, Y. Mao, Y. Sun, W. Lu, M. Ran, A dual-signal amplification strategy based on pump-free SERS microfluidic chip for rapid and ultrasensitive detection of non-small cell lung cancer-related circulating tumour DNA in mice serum, Biosens Bioelectron. 205 (2022) 114110. https://doi.org/10.1016/J.BIOS.2022.114110. [CrossRef]

- Z. Zhou, X. Lan, L. Zhu, Y. Zhang, K. Chen, W. Zhang, W. Xu, Portable dual-aptamer microfluidic chip biosensor for Bacillus cereus based on aptamer tailoring and dumbbell-shaped probes, J Hazard Mater. 445 (2023) 130545. https://doi.org/10.1016/J.JHAZMAT.2022.130545. [CrossRef]

- Z. Gao, L. Jin, C. Jia, X. Wang, J. Zhao, S. Feng, X. Guo, A droplet digital PCR chip with passive bubble removal for absolute nucleic acid quantification, Sens Actuators B Chem. 392 (2023) 134109. https://doi.org/10.1016/J.SNB.2023.134109. [CrossRef]

- W. Su, J. Qiu, Y. Mei, X.E. Zhang, Y. He, F. Li, A microfluidic cell chip for virus isolation via rapid screening for permissive cells, Virol Sin. 37 (2022) 547–557. https://doi.org/10.1016/J.VIRS.2022.04.011. [CrossRef]

- Y. Lu, Z. Tong, Z. Wu, X. Jian, L. Zhou, S. Qiu, C. Shen, H. Yin, H. Mao, Multiple exosome RNA analysis methods for lung cancer diagnosis through integrated on-chip microfluidic system, Chinese Chemical Letters. 33 (2022) 3188–3192. https://doi.org/10.1016/J.CCLET.2021.12.045. [CrossRef]

- E. Kim, G.Y. Lee, S.M. Yang, H.Y. Kim, Rapid and accurate on-site identification of Lactobacillus delbrueckii subspecies in dairy products using direct polymerase chain reaction with microfluidic chip, LWT. 179 (2023) 114635. https://doi.org/10.1016/J.LWT.2023.114635. [CrossRef]

- C. Wu, L. Liu, Z. Ye, J. Gong, P. Hao, J. Ping, Y. Ying, TriD-LAMP: A pump-free microfluidic chip for duplex droplet digital loop-mediated isothermal amplification analysis, Anal Chim Acta. 1233 (2022) 340513. https://doi.org/10.1016/J.ACA.2022.340513. [CrossRef]

- F. Parvizi, A. Parvareh, R. Heydari, Fabrication of a hydrophobic surface as a new supported liquid membrane for microfluidic based liquid phase microextraction device using modified boehmite nanoparticles (AlOO-NSPO), Microchemical Journal. 189 (2023) 108514. https://doi.org/10.1016/J.MICROC.2023.108514. [CrossRef]

- F. Zarghampour, Y. Yamini, E. Alipanahpour Dil, A. Shokrollahi, G. Javadian, A new microfluidic-chip device followed by sensitive image analysis of smart phone for simultaneous determination of dyes with different acidic–basic properties, Talanta. 254 (2023) 124168. https://doi.org/10.1016/J.TALANTA.2022.124168. [CrossRef]

- D. Zhang, R. Gao, S. Huang, Y. Huang, J. Zhang, X. Su, S. Zhang, S. Ge, J. Zhang, N. Xia, All-in-one microfluidic chip for 30-min quantitative point-of-care-testing of nucleic acids, Sens Actuators B Chem. 390 (2023) 133939. https://doi.org/10.1016/J.SNB.2023.133939. [CrossRef]

- K. Yang, J. Pan, G. Deng, C. Hua, C. Zhu, Y. Liu, L. Zhu, Mkit: A mobile nucleic acid assay based on a chitosan-modified minimalistic microfluidic chip (CM3-chip) and smartphone, Anal Chim Acta. 1253 (2023) 341030. https://doi.org/10.1016/J.ACA.2023.341030. [CrossRef]

- A.M. Kaba, H. Jeon, A. Park, K. Yi, S. Baek, A. Park, D. Kim, Cavitation-microstreaming-based lysis and DNA extraction using a laser-machined polycarbonate microfluidic chip, Sens Actuators B Chem. 346 (2021) 130511. https://doi.org/10.1016/J.SNB.2021.130511. [CrossRef]

- S. Su, G. Jing, M. Zhang, B. Liu, X. Zhu, B. Wang, M. Fu, L. Zhu, J. Cheng, Y. Guo, One-step bonding and hydrophobic surface modification method for rapid fabrication of polycarbonate-based droplet microfluidic chips, Sens Actuators B Chem. 282 (2019) 60–68. https://doi.org/10.1016/J.SNB.2018.11.035. [CrossRef]

- Y. Wang, Q. He, Y. Dong, H. Chen, In-channel modification of biosensor electrodes integrated on a polycarbonate microfluidic chip for micro flow-injection amperometric determination of glucose, Sens Actuators B Chem. 145 (2010) 553–560. https://doi.org/10.1016/J.SNB.2009.11.068. [CrossRef]

- W. Bi, S. Cai, T. Lei, L. Wang, Implementation of blood-brain barrier on microfluidic chip: Recent advance and future prospects, Ageing Res Rev. 87 (2023) 101921. https://doi.org/10.1016/J.ARR.2023.101921. [CrossRef]

- D. Zhang, R. Gao, S. Huang, Y. Huang, J. Zhang, X. Su, S. Zhang, S. Ge, J. Zhang, N. Xia, All-in-one microfluidic chip for 30-min quantitative point-of-care-testing of nucleic acids, Sens Actuators B Chem. 390 (2023) 133939. https://doi.org/10.1016/J.SNB.2023.133939. [CrossRef]

- H.N. Açıkgöz, A. Karaman, M.A. Şahin, Ö.R. Çaylan, G.C. Büke, E. Yıldırım, İ.C. Eroğlu, A.E. Erson-Bensan, B. Çetin, M.B. Özer, Assessment of silicon, glass, FR4, PDMS and PMMA as a chip material for acoustic particle/cell manipulation in microfluidics, Ultrasonics. 129 (2023) 106911. https://doi.org/10.1016/J.ULTRAS.2022.106911. [CrossRef]

- M.T. Guler, Fabricating plasma bonded microfluidic chips by CO2 laser machining of PDMS by the application of viscoelastic particle focusing and droplet generation, J Manuf Process. 73 (2022) 260–268. https://doi.org/10.1016/J.JMAPRO.2021.11.016. [CrossRef]

- B. Jiang, H. Guo, D. Chen, M. Zhou, Microscale investigation on the wettability and bonding mechanism of oxygen plasma-treated PDMS microfluidic chip, Appl Surf Sci. 574 (2022) 151704. https://doi.org/10.1016/J.APSUSC.2021.151704. [CrossRef]

- Q. Tang, X. Li, C. Lai, L. Li, H. Wu, Y. Wang, X. Shi, Fabrication of a hydroxyapatite-PDMS microfluidic chip for bone-related cell culture and drug screening, Bioact Mater. 6 (2021) 169–178. https://doi.org/10.1016/J.BIOACTMAT.2020.07.016. [CrossRef]

- X. Liu, S. Li, Fabrication of a Three-Layer PDMS Pneumatic Microfluidic Chip for Micro Liquid Sample Operation, SLAS Technol. 25 (2020) 151–161. https://doi.org/10.1177/2472630319870126. [CrossRef]

- Q. Song, J. Sun, Y. Mu, Y. Xu, Q. Zhu, Q. Jin, A new method for polydimethylsiloxane (PDMS) microfluidic chips to maintain vacuum-driven power using Parylene C, Sens Actuators B Chem. 256 (2018) 1122–1130. https://doi.org/10.1016/J.SNB.2017.10.006. [CrossRef]

- S.Y. Lee, J.H. Kim, S.W. Oh, Combination of filtration and immunomagnetic separation based on real-time PCR to detect foodborne pathogens in fresh-cut apple, J Microbiol Methods. 201 (2022) 106577. https://doi.org/10.1016/J.MIMET.2022.106577. [CrossRef]

- H.J. Lee, S. Choi, I.S. Cho, J.Y. Yoon, R.D. Jeong, Development and application of a reverse transcription droplet digital PCR assay for detection and quantification of Plantago asiatica mosaic virus, Crop Protection. 169 (2023) 106255. https://doi.org/10.1016/J.CROPRO.2023.106255. [CrossRef]

- P. Kheiroddin, V.D. Gaertner, P. Schöberl, E. Fischer, J. Niggel, P. Pagel, B.M.J. Lampl, A. Ambrosch, M. Kabesch, Gargle pool PCR testing in a hospital during medium and high SARS-CoV-2 incidence, Journal of Hospital Infection. 127 (2022) 69–76. https://doi.org/10.1016/J.JHIN.2022.05.018. [CrossRef]

- N. Guan, Y. Li, H. Yang, P. Hu, S. Lu, H. Ren, Z. Liu, K. Soo Park, Y. Zhou, Dual-functionalized gold nanoparticles probe based bio-barcode immuno-PCR for the detection of glyphosate, Food Chem. 338 (2021) 128133. https://doi.org/10.1016/J.FOODCHEM.2020.128133. [CrossRef]

- J.A. Huber, H.G. Morrison, S.M. Huse, P.R. Neal, M.L. Sogin, D.B. Mark Welch, Effect of PCR amplicon size on assessments of clone library microbial diversity and community structure, Environ Microbiol. 11 (2009) 1292. https://doi.org/10.1111/J.1462-2920.2008.01857.X. [CrossRef]

- N. Hofmann, F. Mwingira, S. Shekalaghe, L.J. Robinson, I. Mueller, I. Felger, Ultra-Sensitive Detection of Plasmodium falciparum by Amplification of Multi-Copy Subtelomeric Targets, PLoS Med. 12 (2015) e1001788. https://doi.org/10.1371/JOURNAL.PMED.1001788. [CrossRef]

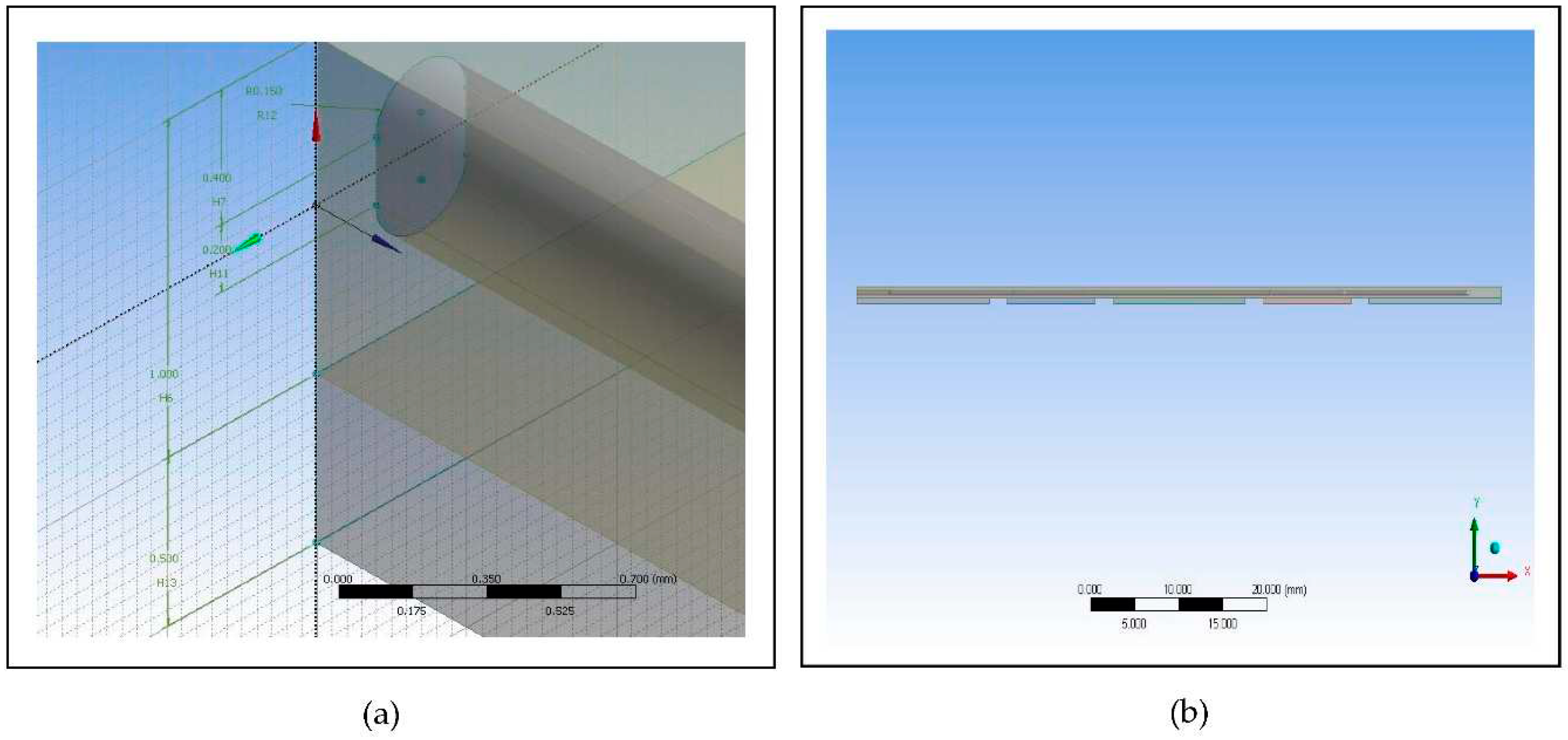

| Material Property | Unit | [24] | [25] | [26] |

| Melting Point | 432.15 | 428.15 | 408.15 | |

| Thermal Conductivity | 0.8 | 0.24 | 0.15 | |

| Specific Heat | 1.8 | 1.2 | 1.46 | |

| Density | 920 | 1200 | 970 | |

| aPolypropylene | ||||

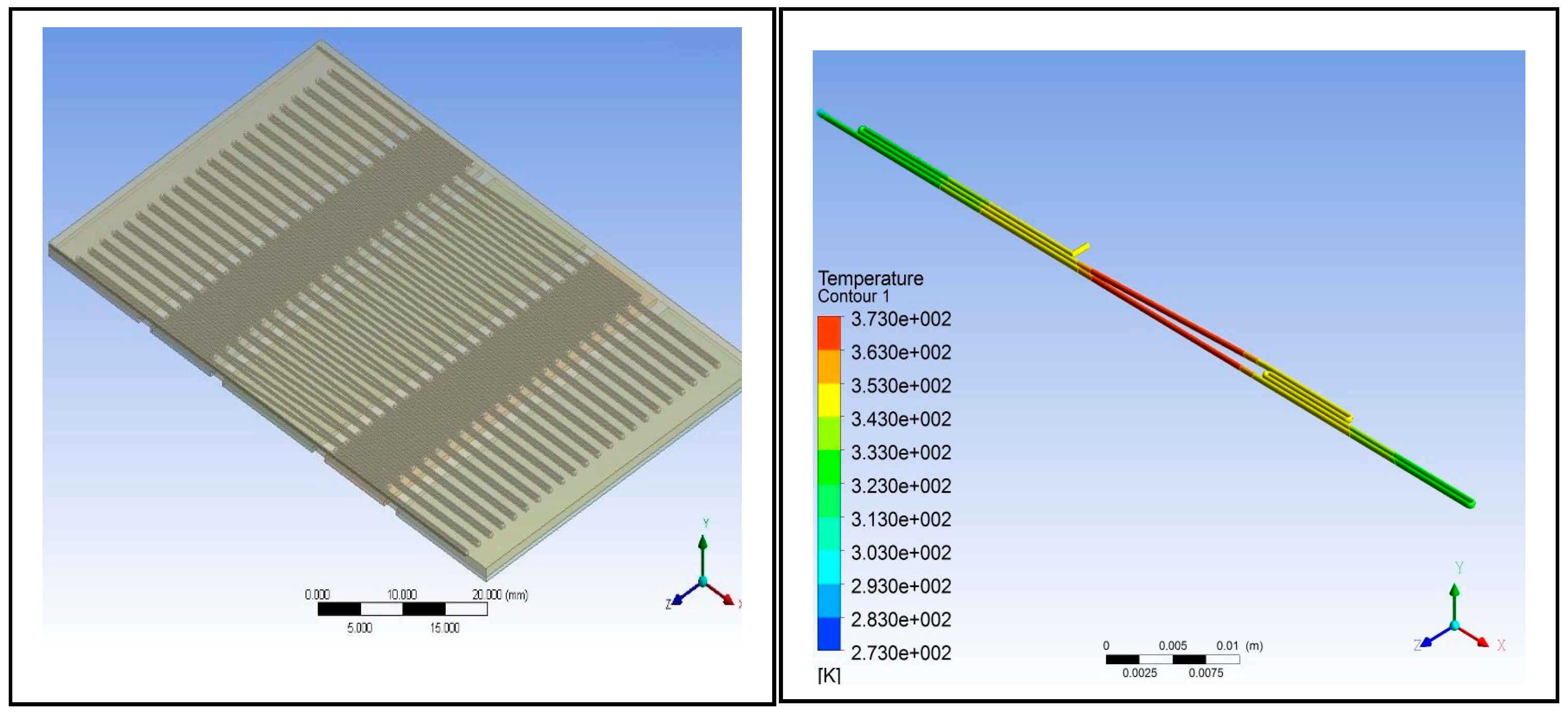

| Total Length Calculation | ||||

|---|---|---|---|---|

| Design | Radius (mm) | Circumference (mm) | Length (mm) | Total Length (mm) |

| - | - | 30 | 30 | |

| 0.25 | 1.570796327 | 14 | 30 | |

| 0.25 | 1.570796327 | 27 | 30 | |

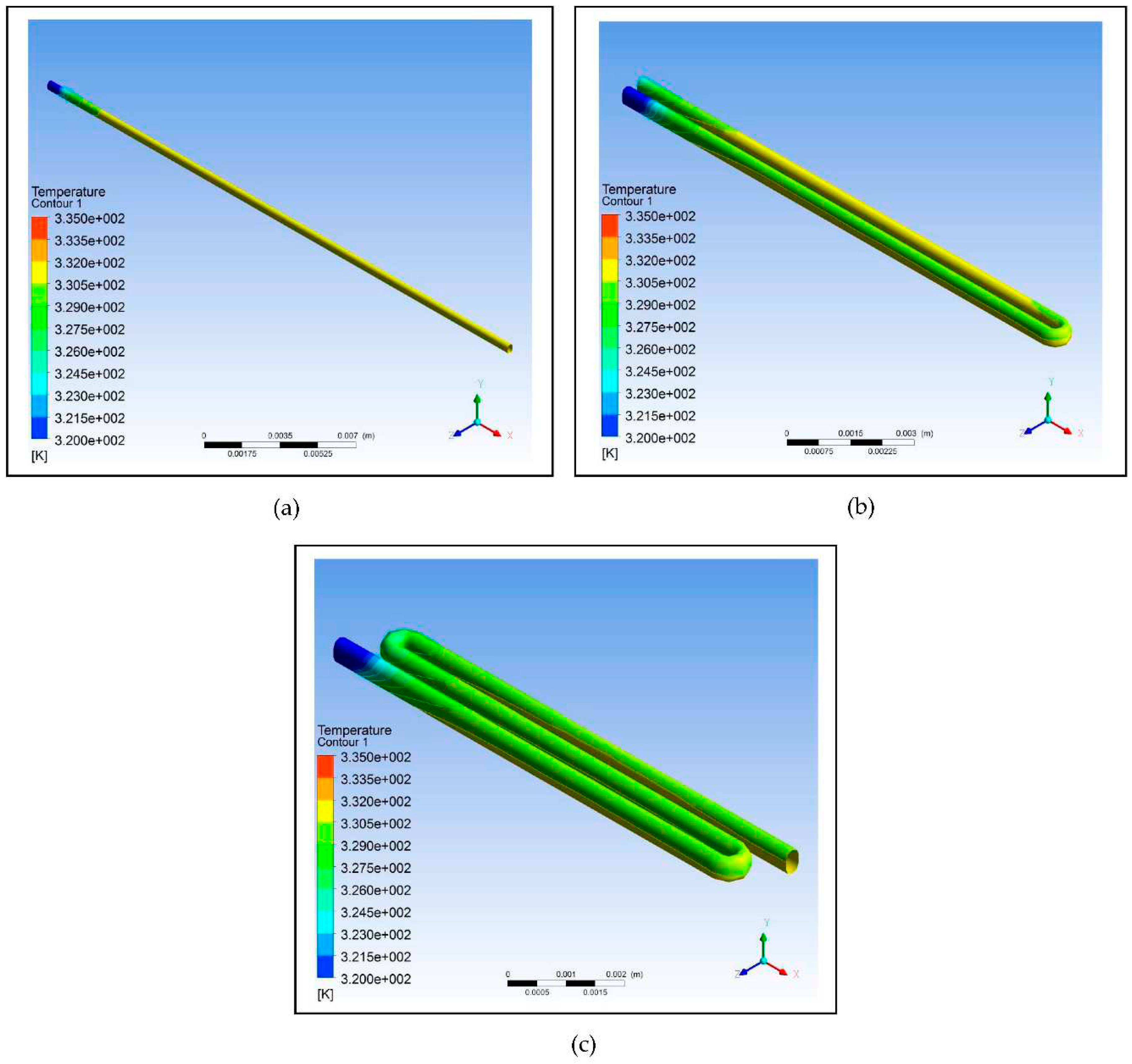

| Region | Residence Time (s) | Length (µm) | Passes | Volume | Volumetric Flowrate | Speed (µm/s) |

|---|---|---|---|---|---|---|

| Annealing (58°C) | 15 | 15000 | 1.5 | 2.94E+09 | 1.96E+08 | 1500 |

| Extension (72°C) | 20 | 10000 | 3 | 3.92E+09 | 1.96E+08 | 1500 |

| Denaturation (95°C) | 10 | 15000 | 1 | 1.96E+09 | 1.96E+08 | 1500 |

| Spaces | 5.3 | 8000 | 1.05E+09 | 1.96E+08 | 1500 | |

| Total | 153 | 75500 | 3 | 9.87E+09 |

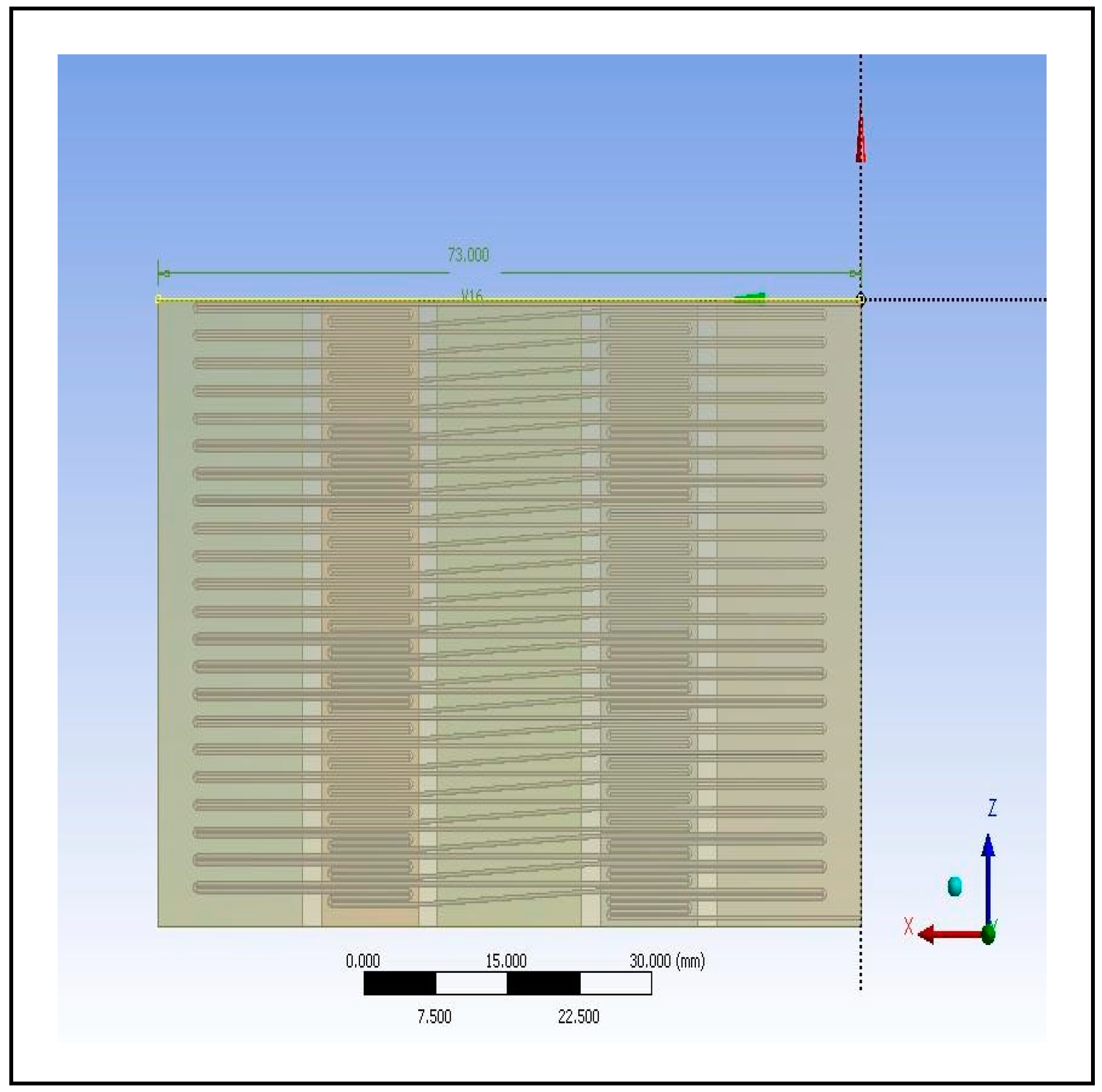

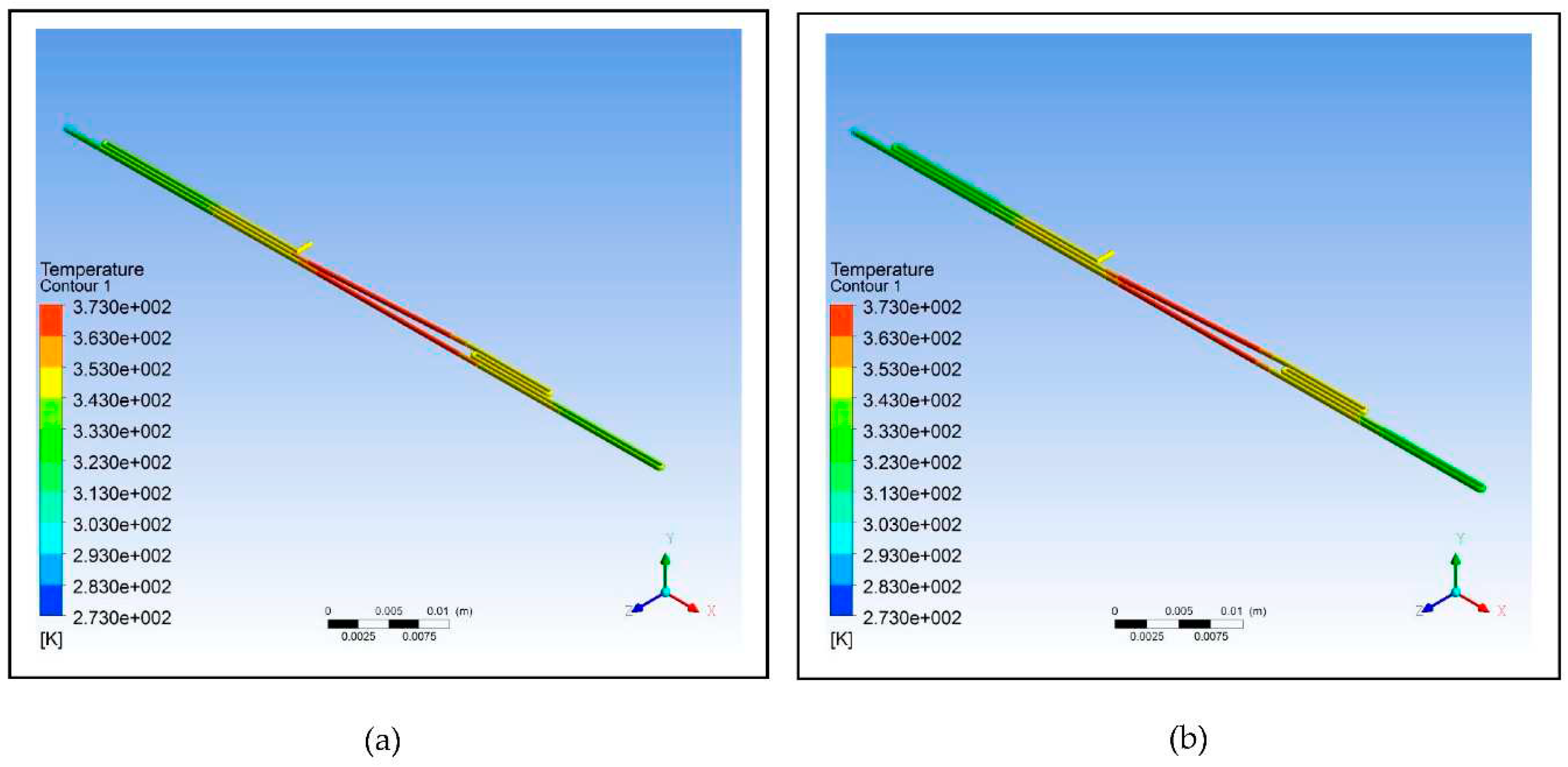

| Design | Relative Deviation | |

|---|---|---|

| No Loop | 0.65 | 1.12 |

| One Loop | 0.80 | 1.39 |

| Two Loops | 0.88 | 1.52 |

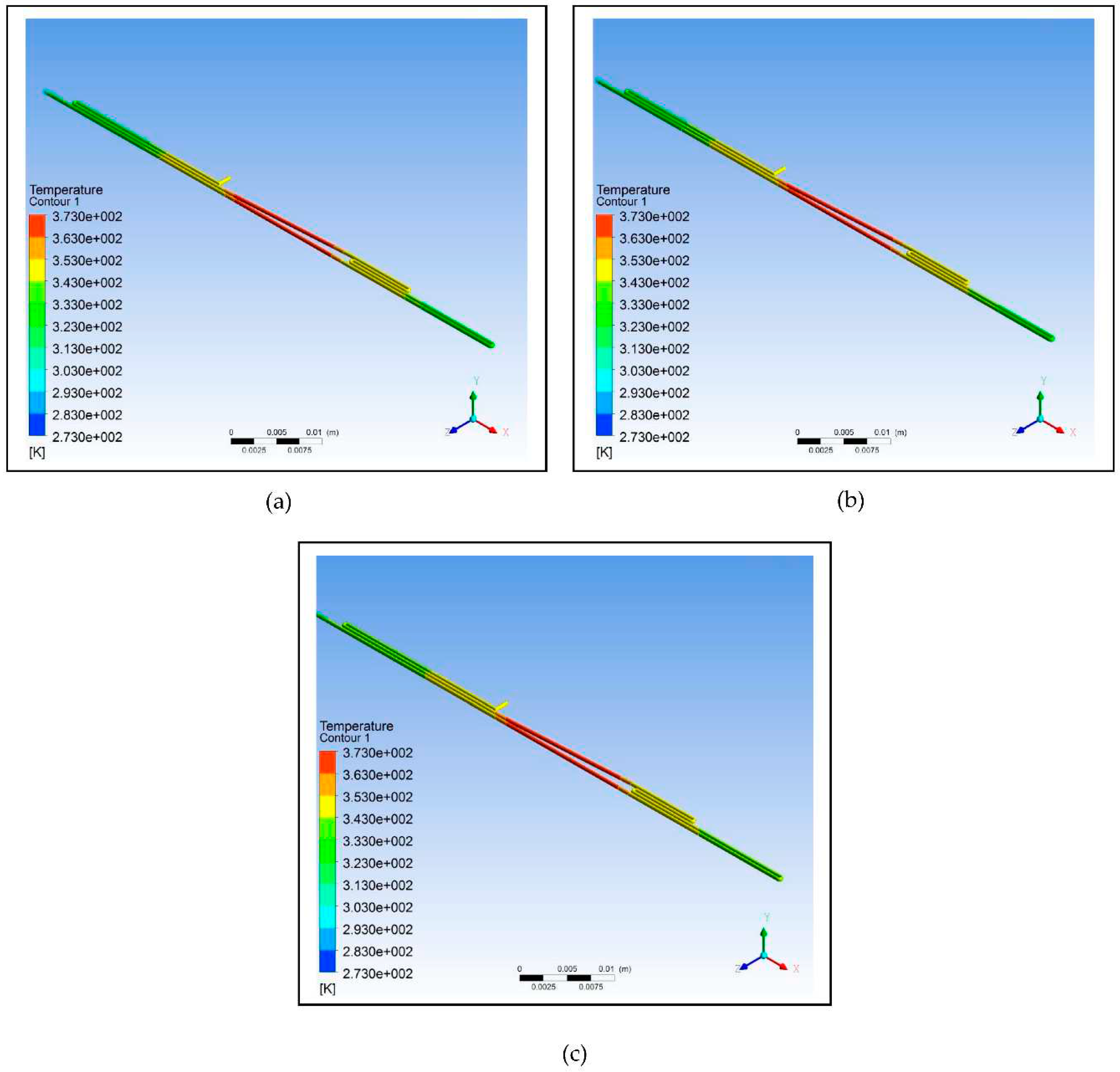

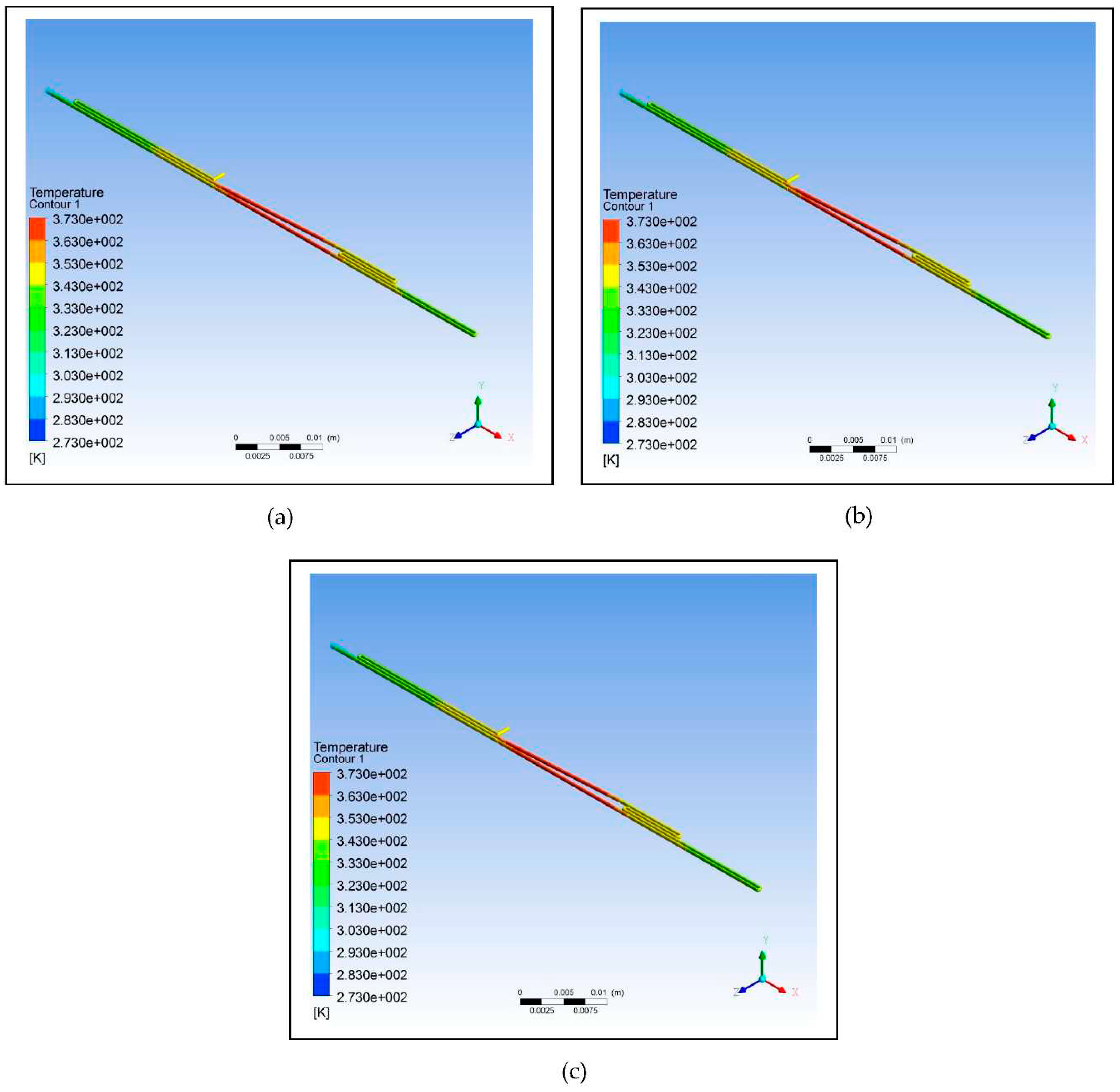

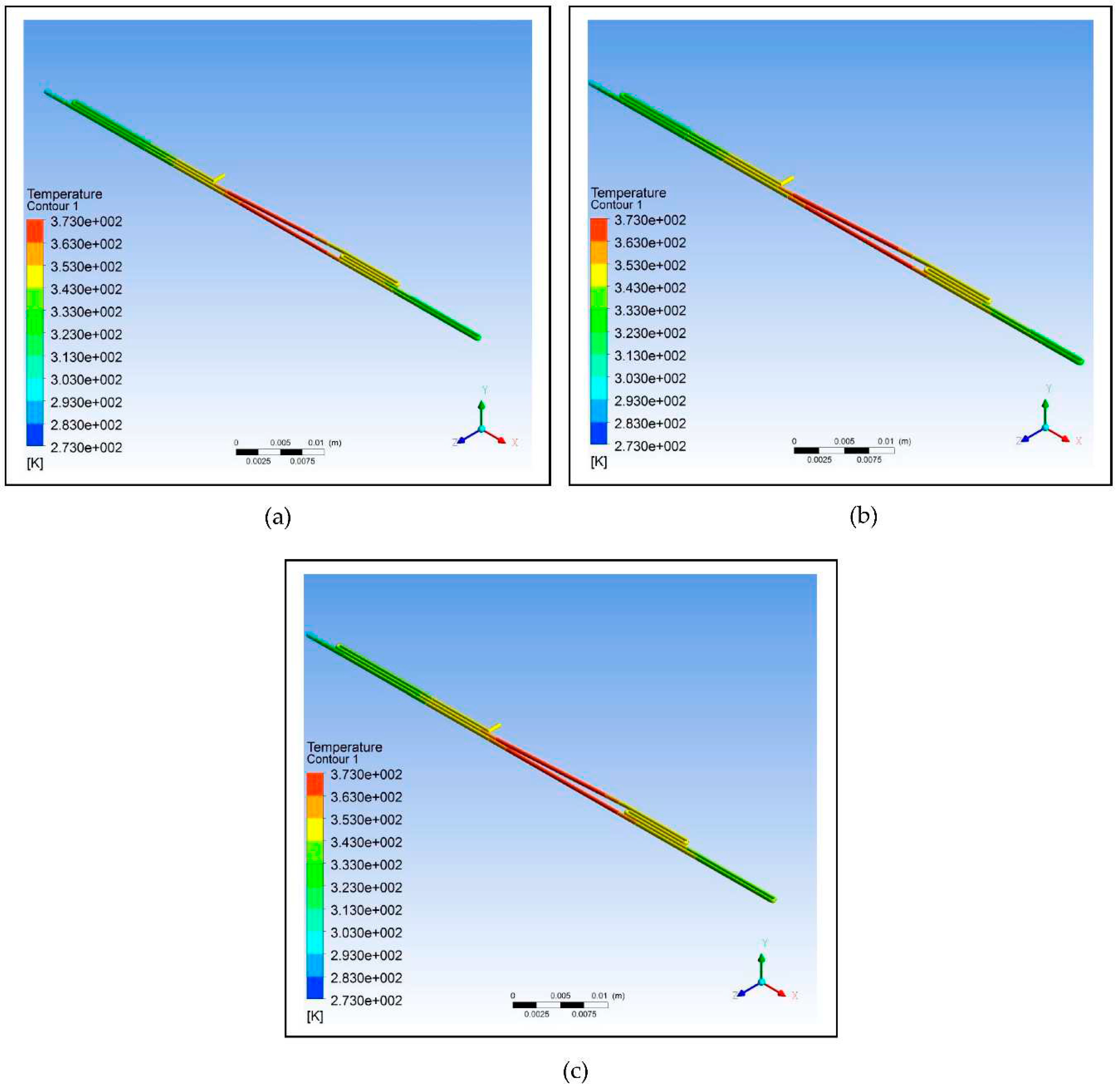

| 58°C, 72°C, 95°C | 60°C, 74°C, 97°C | 63°C, 77°C, 100°C | ||||

|---|---|---|---|---|---|---|

| Material | Relative Deviation | Relative Deviation | Relative Deviation | |||

| 0.94 | 3.21 | 2.84 | 5.82 | 6.90 | 25.00 | |

| 1.92 | 8.61 | 3.15 | 10.00 | 6.92 | 26.70 | |

| 2.78 | 14.00 | 3.47 | 14.00 | 6.93 | 29.00 | |

| Parameter | Design 1 | Design 2 |

|---|---|---|

| Diameter | 300 | 500 |

| Length | 200 | 300 |

| Relative Deviation | 0.94 | 2.31 |

| 3.21 | 5.96 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).