Submitted:

03 May 2023

Posted:

09 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental investigation

2.1. Subsection Specimen preparation

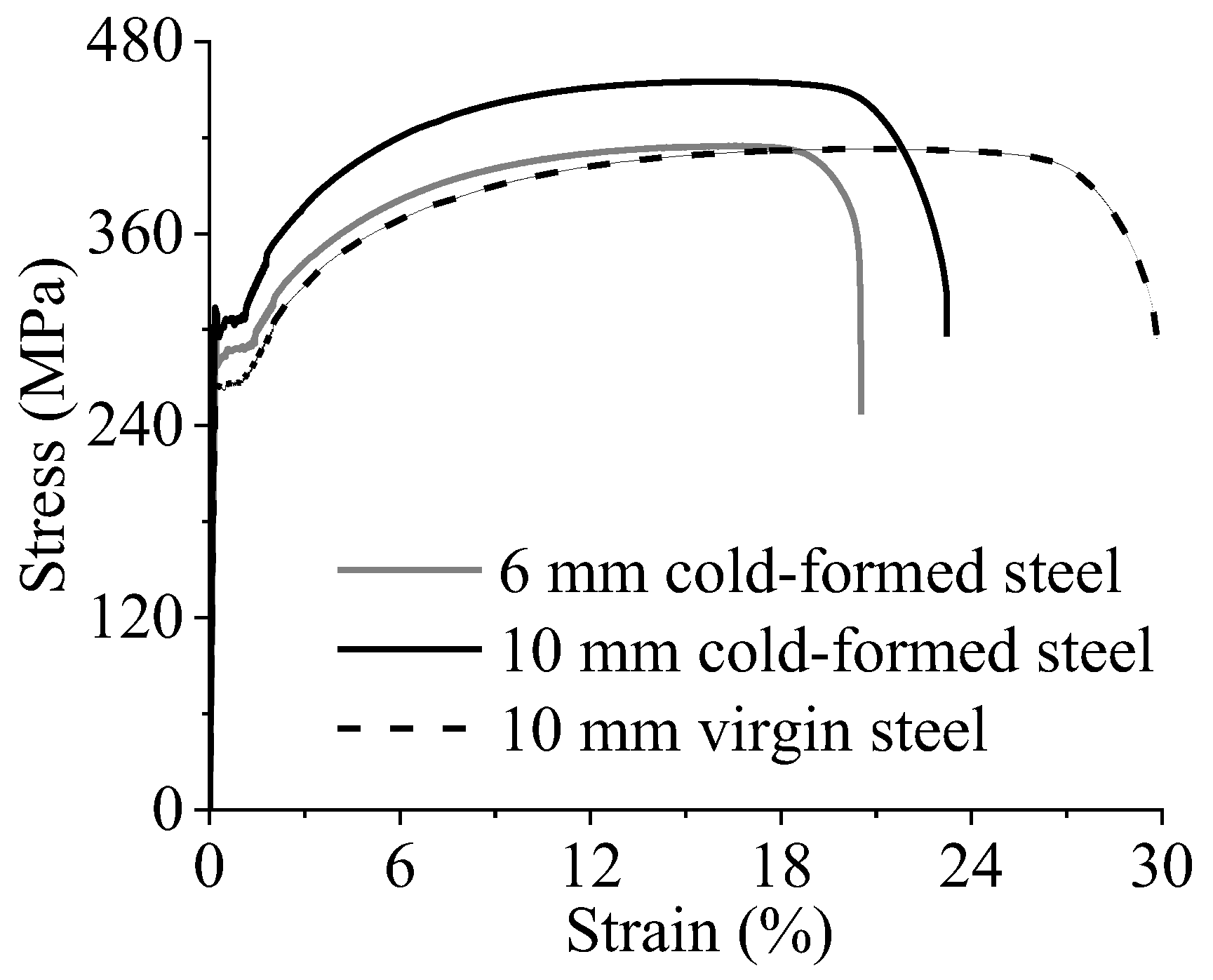

2.2. Mechanical properties of cold-formed thick-walled steel

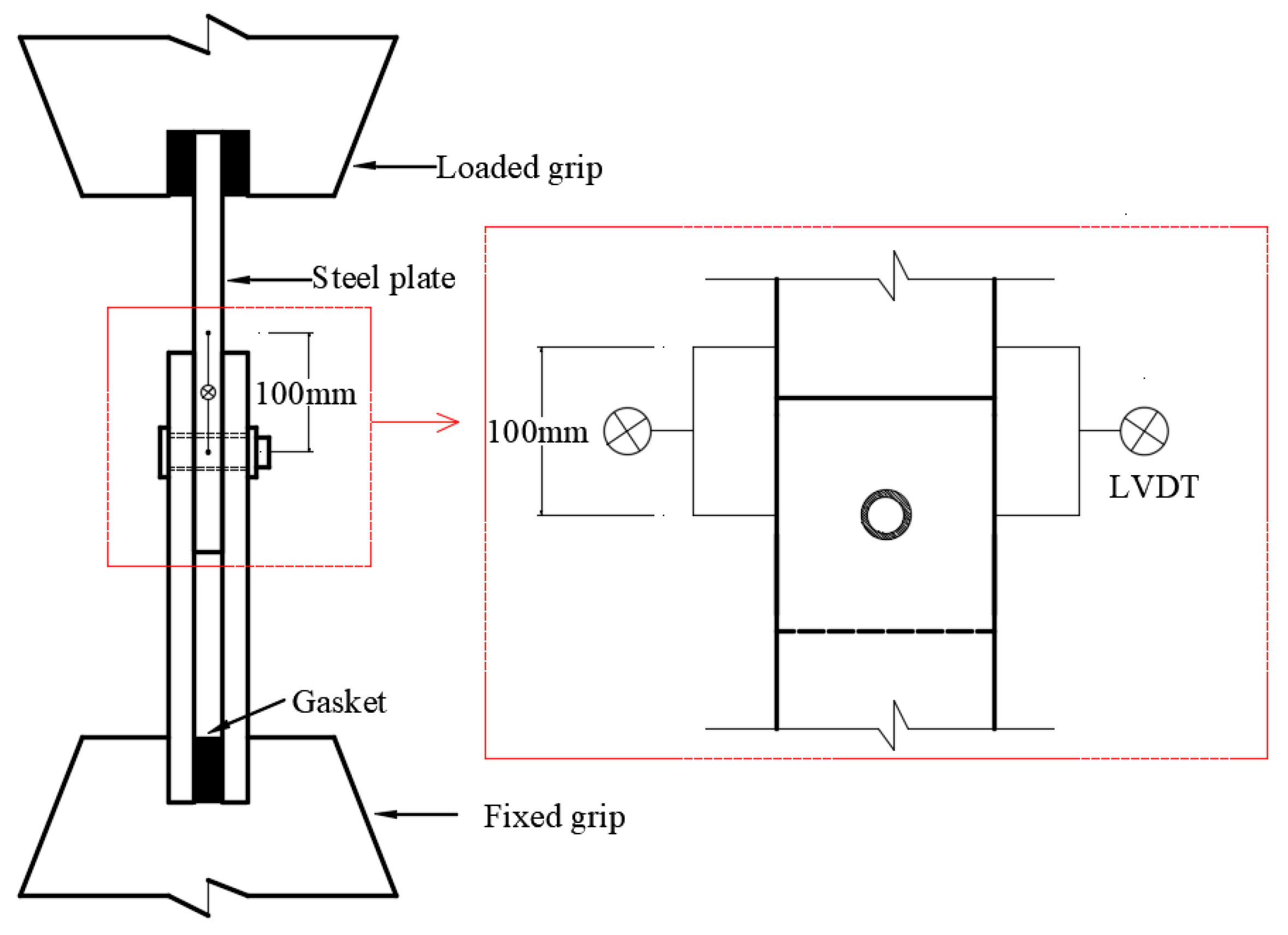

2.3. Test method

3. Experimental observations and test results

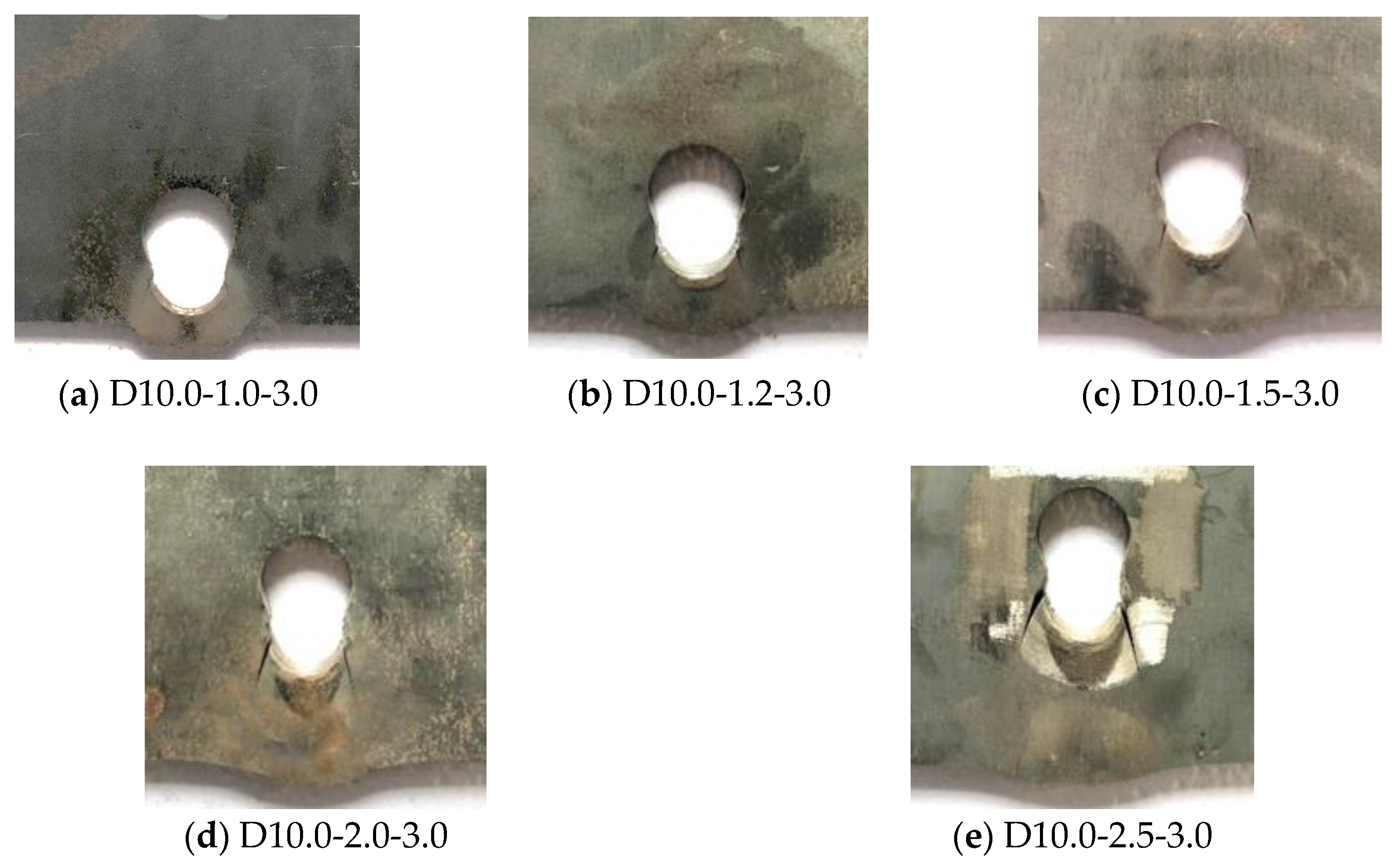

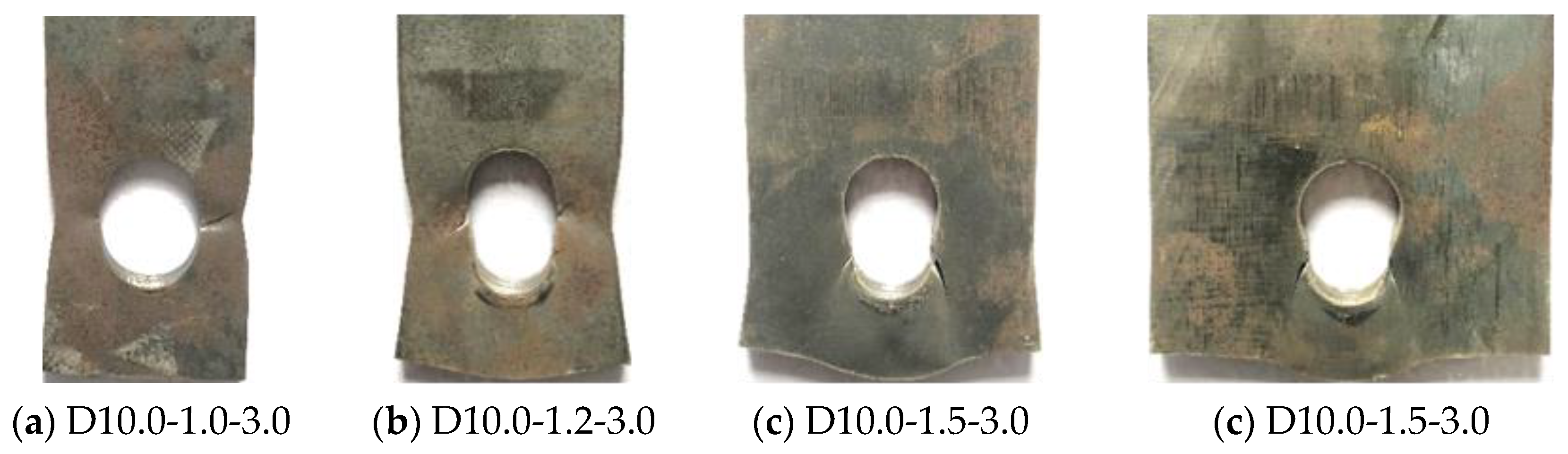

3.1. Failure modes

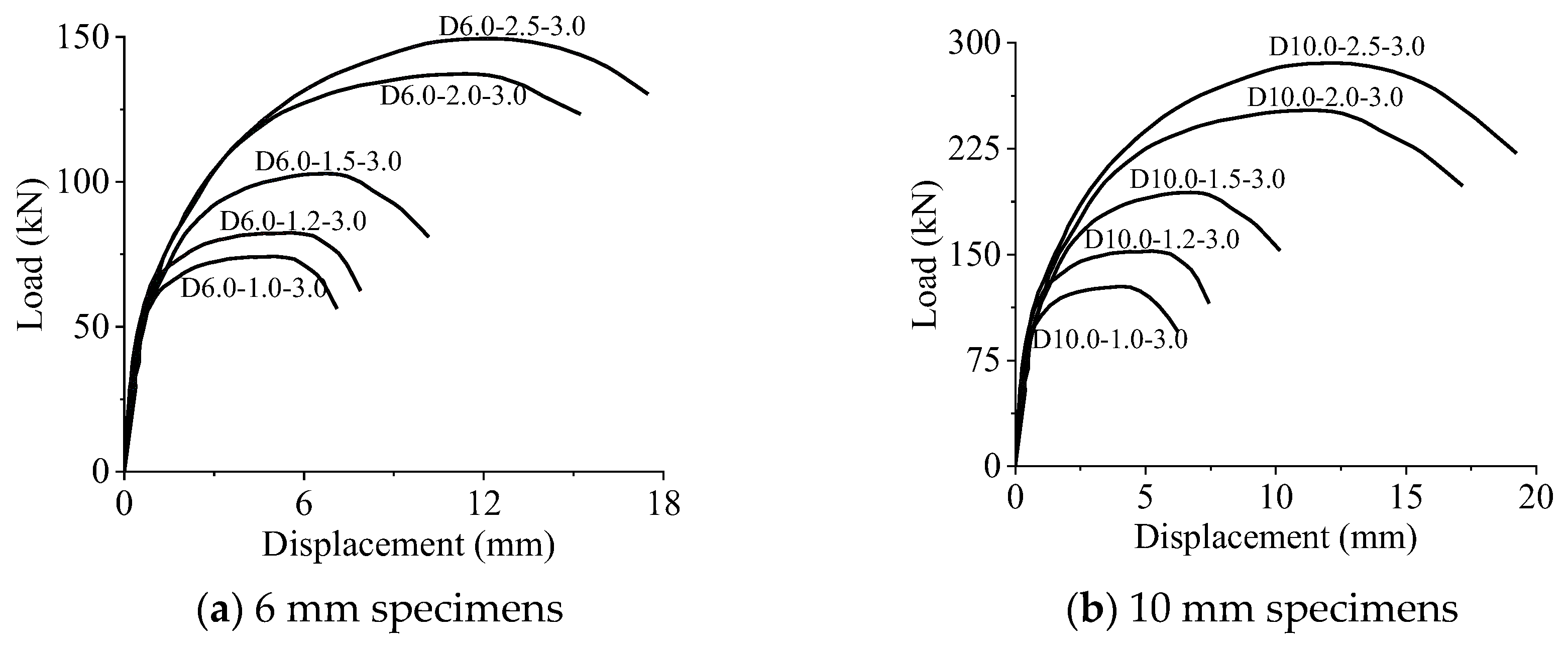

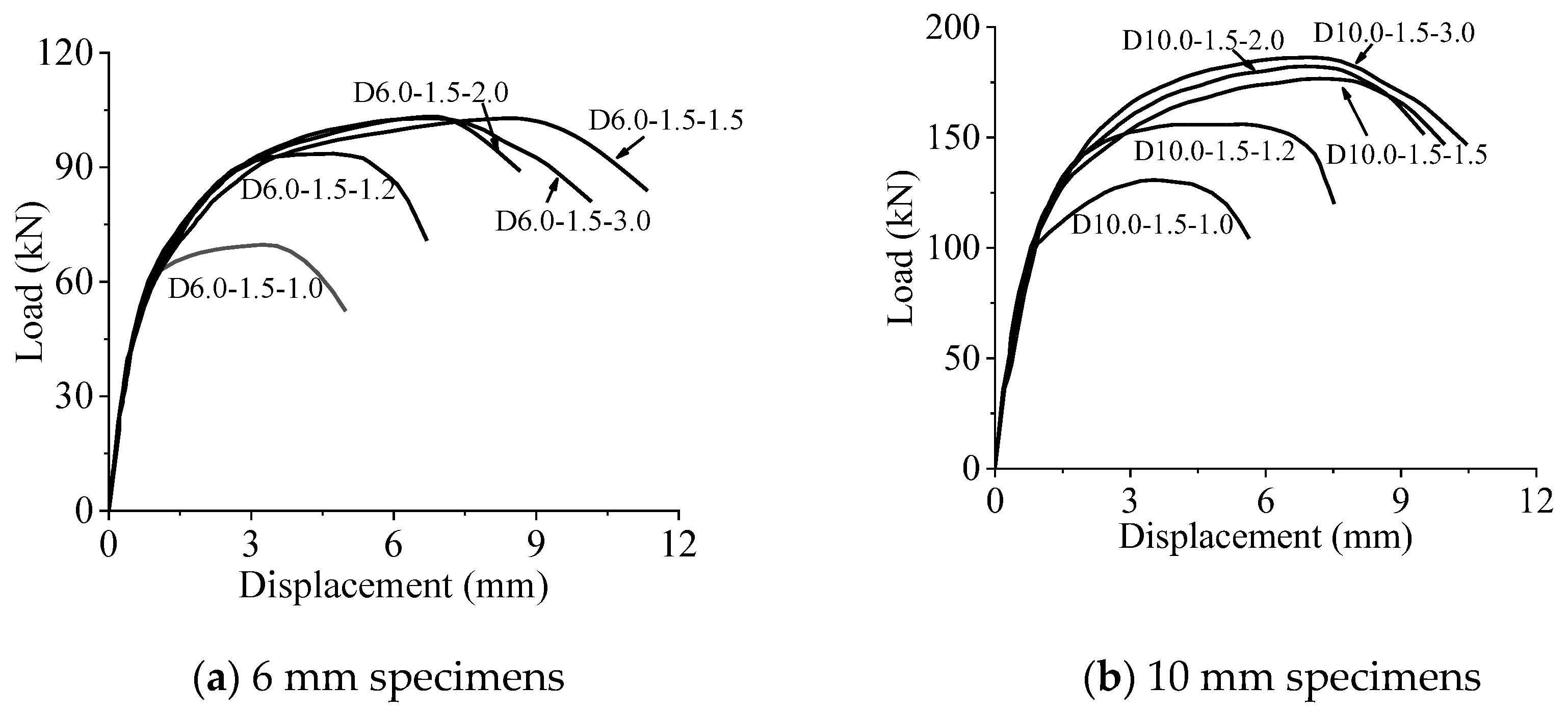

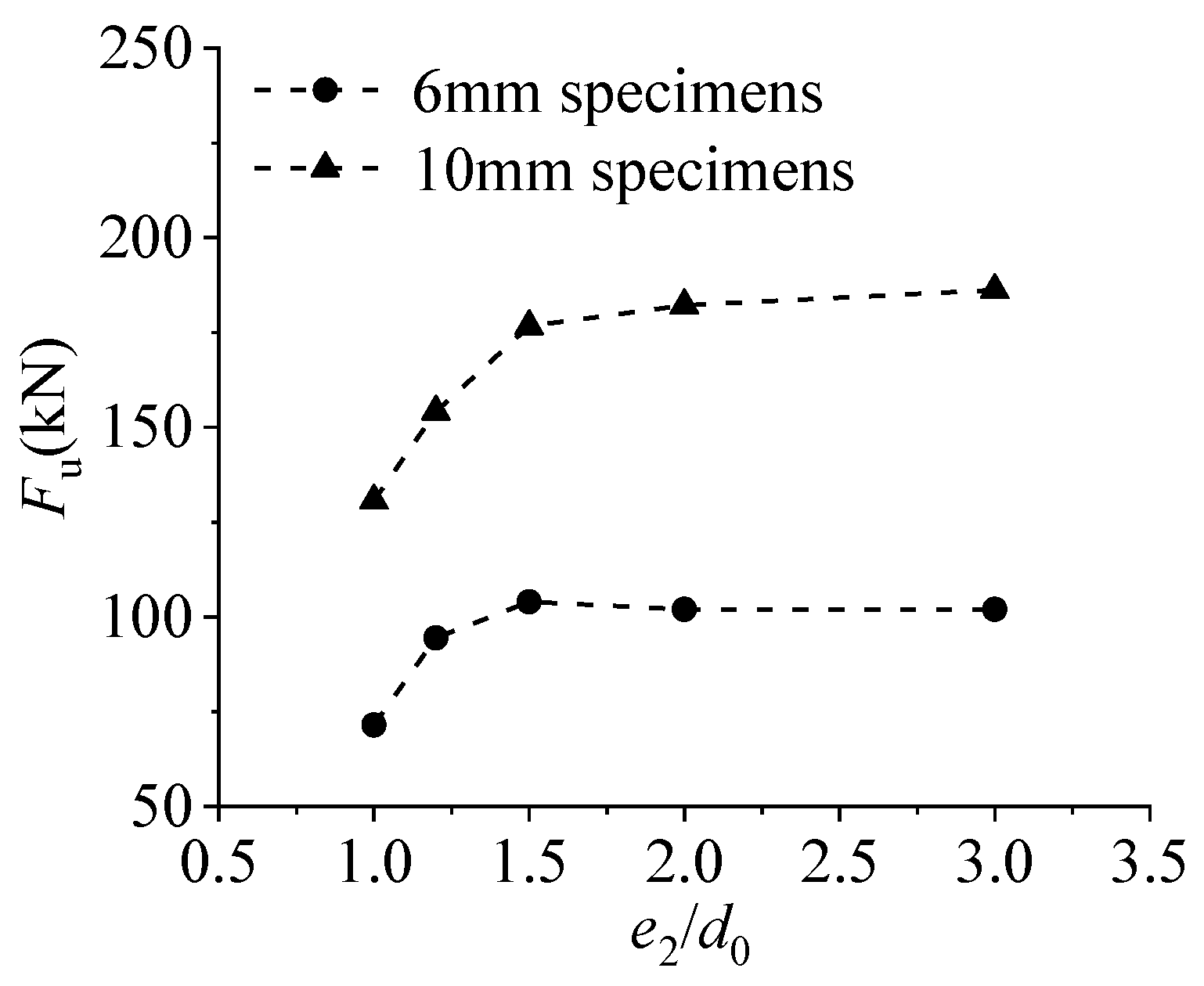

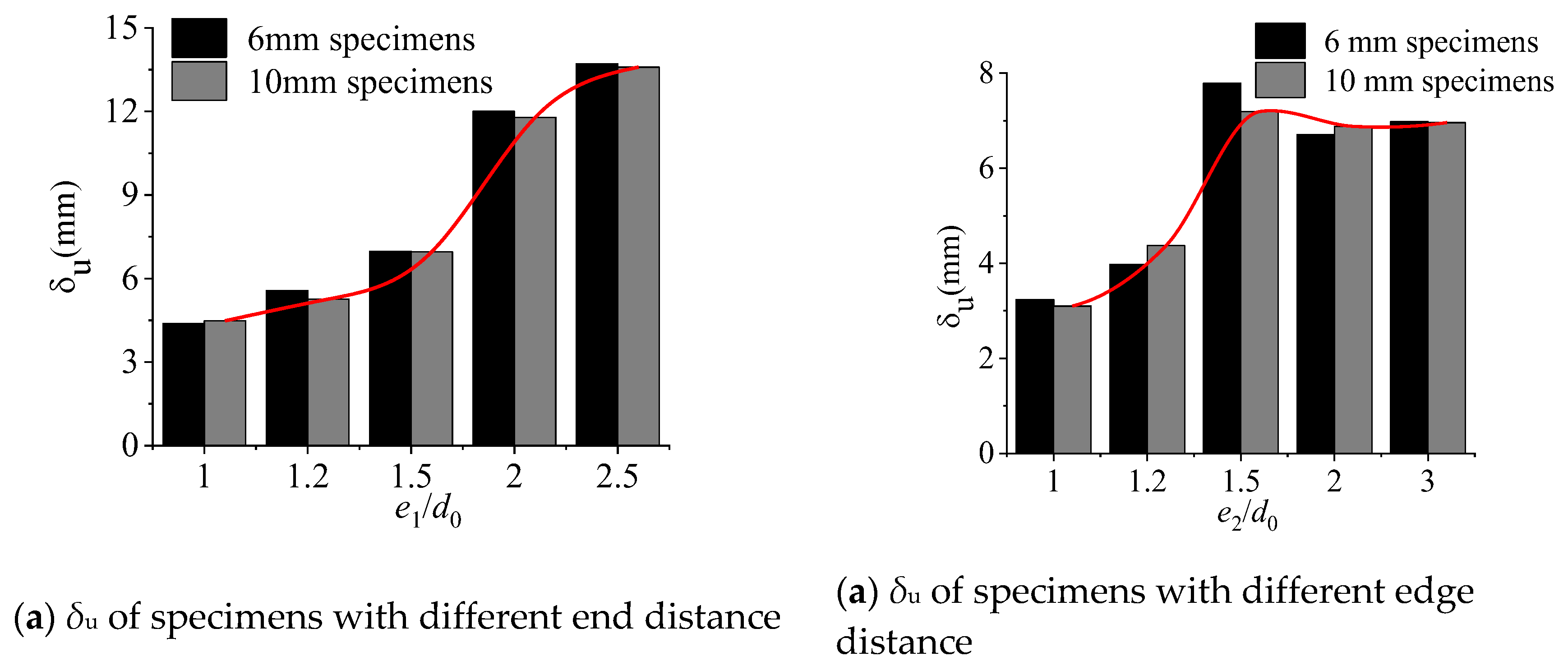

3.2. Bearing resistance and deformation

4. Discussion

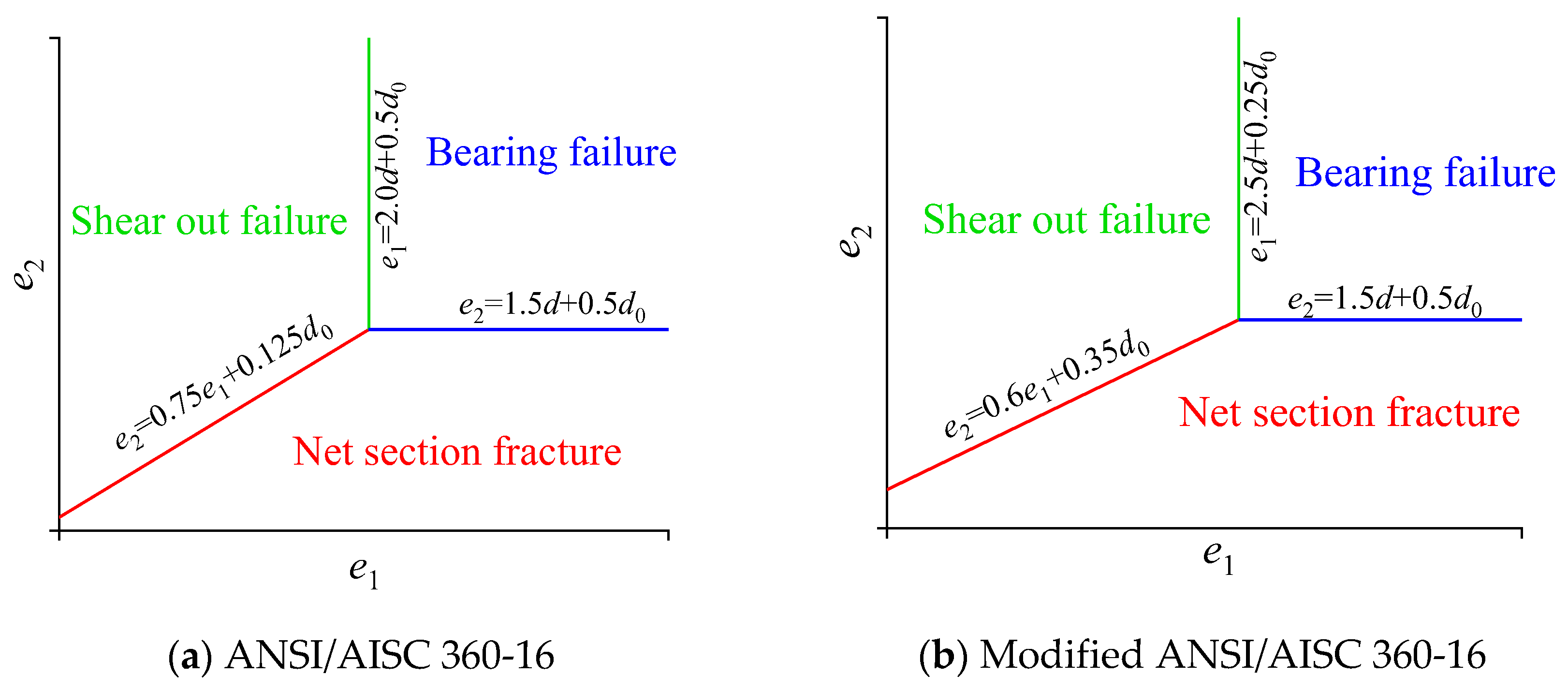

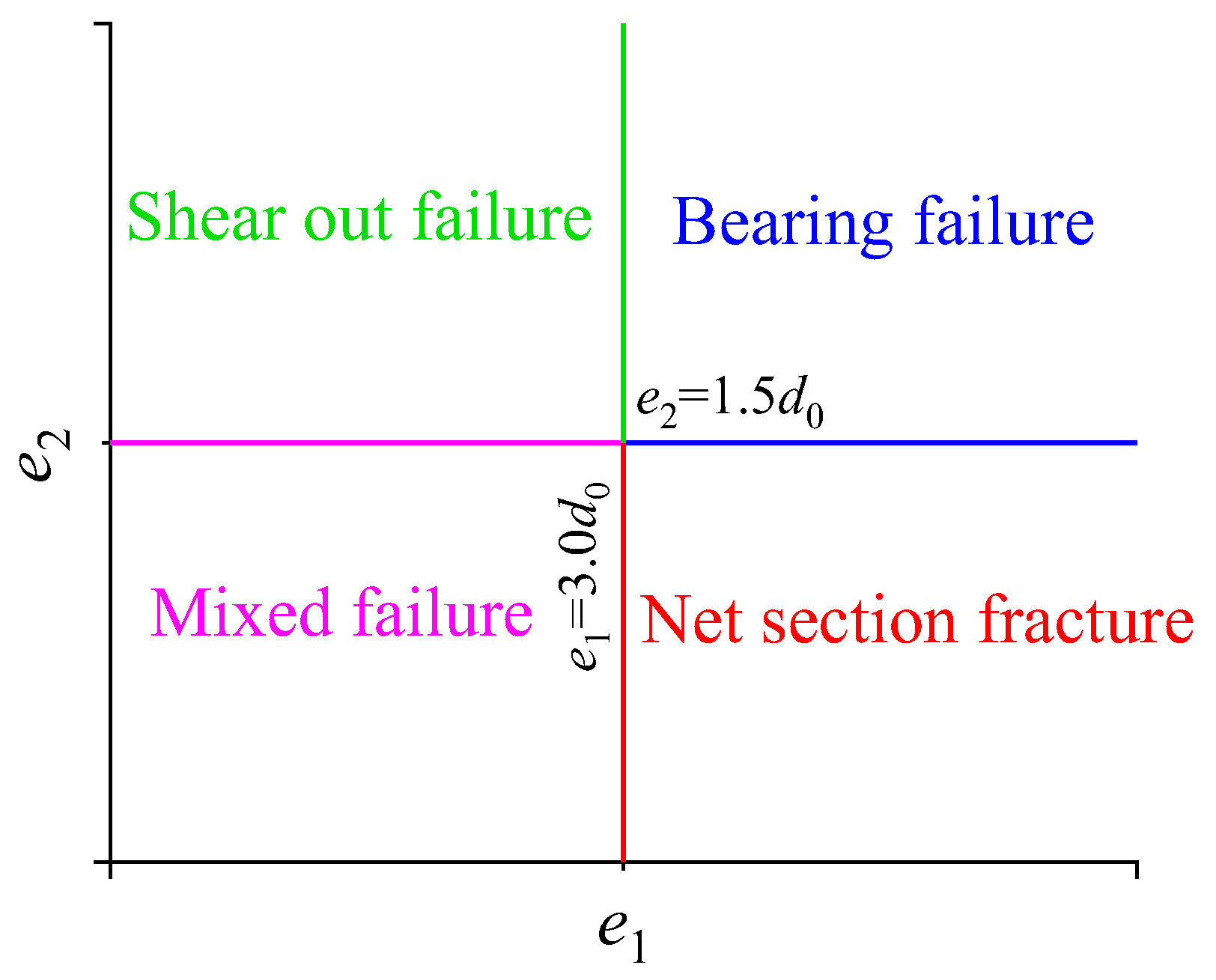

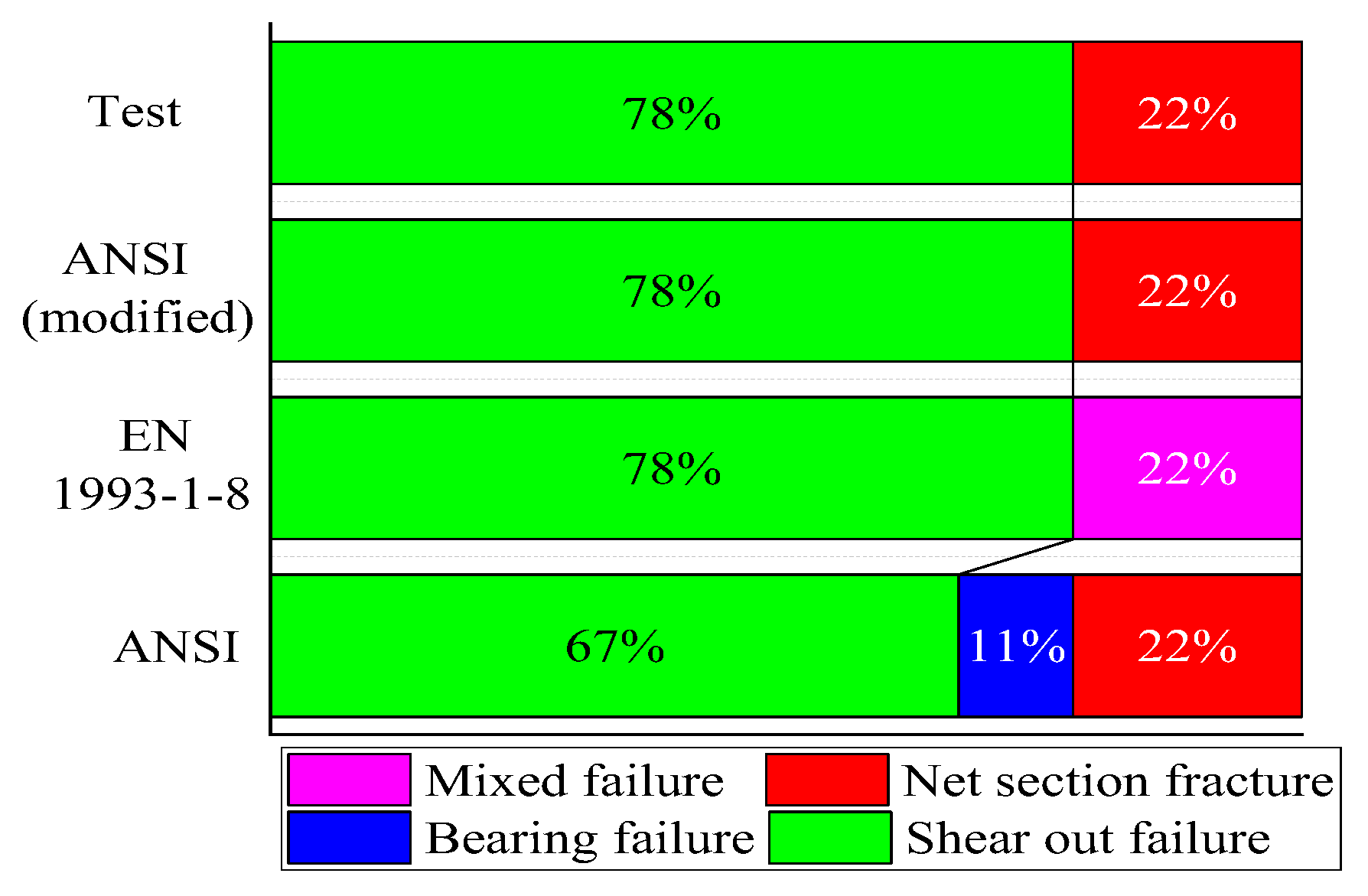

4.1. Comparison of failure modes

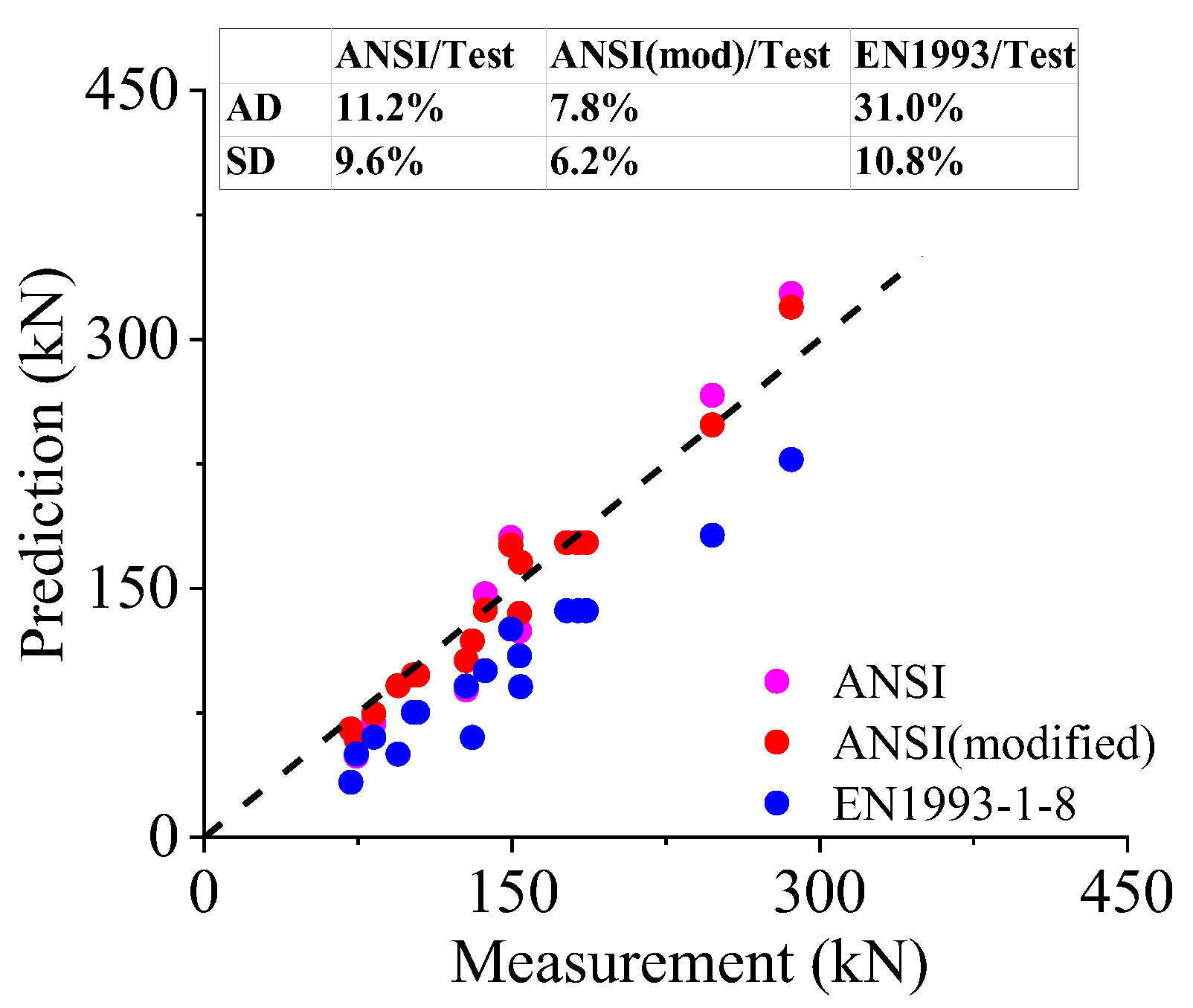

4.2. Comparison of bearing resistance

5. Conclusions

References

- American Iron and Steel Institute. North American Specification for the Design of Cold-Formed Steel Structural Members. AISI S100-12, Washington DC, 2012.

- CEN. Eurocode 3: Design of Steel Structures. Part 1-3: General Rules-Supplementary Rules for Cold-Formed Members and Sheeting. EN 1993-1-3, European Committee for Standardization, Brussels, 2006.

- GB 50018-2002; Technical Code of Cold-Formed Thin-Walled Steel Structures. Standardization Administration of the People’s Republic of China: Beijing, 2002. (In Chinese)

- American Iron and Steel Institute. North American Specification for the Design of Cold-Formed Steel Structural Members. AISI S100-16, Washington DC, 2016.

- GB 50018-201X (draft standard for discussion); Technical Code of Cold-Formed Steel Structures. (In Chinese)

- American Institute of Steel Construction. Specification for Structural Steel Buildings. ANSI/AISC 360-16, Chicago, 2016.

- CEN. Eurocode 3: Design of Steel Structures. Part 1-8: Design of Joints. EN 1993-1-8, European Committee for Standardization, Brussels, 2005.

- Guo, Y. J.; Zhu, A. Z.; Pi, Y. L.; Tin-Loi, F. Experimental study on compressive strengths of thick-walled cold-formed sections. Journal of Constructional Steel Research. 2007, 63, 718–723. [Google Scholar] [CrossRef]

- Hu, S. D.; Ye, B.; Li, L. X. Material properties of thick-wall cold-rolled welded tube with a rectangular or square hollow section. Construction and Building Materials. 2011, 25, 2683–2689. [Google Scholar] [CrossRef]

- Wang, Y. B.; Lyu, Y. F.; Li, G. Q.; Liew, J. R. Behavior of single bolt bearing on high strength steel plate. Journal of Constructional Steel Research. 2017, 137, 19–30. [Google Scholar] [CrossRef]

- Kim, T. S.; Kuwamura, H.; Kim, S. H.; <monospace> </monospace>Lee, Y.; Cho, T. Investigation on ultimate strength of thin-walled steel single shear bolted connections with tow bolts using finite element analysis. Thin-Walled Structures. 2009, 47, 1191–1202. [Google Scholar] [CrossRef]

- Može ,P.; Beg, D. High strength steel tension splices with one or two bolts. Journal of Constructional Steel Research. 2010, 66, 1000–1010. [CrossRef]

- Salih, E. L.; Gardner, L.; Nethercot, D. A. Bearing failure in stainless steel bolted connections. Engineering Structures. 2011, 33, 549–562. [Google Scholar] [CrossRef]

- Može, P.; Beg, D. A complete study of bearing stress in single bolt connections. Journal of Constructional Steel Research. 2014, 95, 126–140. [Google Scholar] [CrossRef]

- The, L. H.; Uz, M. E. Ultimate shear-out capacities of structural-steel bolted connections. Journal of Structural Engineering. 2015, 141, 04014152-1-04014152-9. [Google Scholar]

- Xing, H. Y.; Teh, L. H.; Jiang, Z. Y.; <monospace> </monospace>Ahmed, A. Shear-out capacity of bolted connections in cold-reduced steel sheets. Journal of Structural Engineering. 2020, 146, 04020018-1-04020018-10. [Google Scholar] [CrossRef]

- He, Y. C.; Wang, Y. C. Load-deflection behaviour of thin-walled plates with a single bolt in shearing. Thin-Walled Structures. 2011, 49, 1261–1276. [Google Scholar] [CrossRef]

- He, Y. C.; Wang, Y. C. Load-deflection behaviour of thin-walled plates with multiple bolts in shearing. Thin-Walled Structures. 2012, 55, 51–63. [Google Scholar] [CrossRef]

- GB/T 228.1-2010; Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. Standardization Administration of the People’s Republic of China: Beijing, 2010. (In Chinese).

- Clements, D. D. A.; Teh, L. H. Active shear planes of bolted connections failing in block shear. Journal of Structural Engineering. 2013, 139, 320–327. [Google Scholar] [CrossRef]

- Cai, Q.; Driver, R. G. Prediction of bolted connection capacity for block shear failures along atypical paths. Engineering Journal. AISC. 2010, 47, 213–221. [Google Scholar]

- Teh, L. H.; Deierlein, G. G. Effective shear plane model for tearout and block shear failure of bolted connections. Engineering Journal. AISC. 2017, 54, 181–194. [Google Scholar]

| Specimen ID | t (mm) | e1/d0 | e2/d0 | d0 (mm) |

|---|---|---|---|---|

| D6.0-1.0-3.0 | 6.0 | 1.0 | 3.0 | 26.0 |

| D6.0-1.2-3.0 | 6.0 | 1.2 | 3.0 | 26.0 |

| D6.0-1.5-3.0 | 6.0 | 1.5 | 3.0 | 26.0 |

| D6.0-2.0-3.0 | 6.0 | 2.0 | 3.0 | 26.0 |

| D6.0-2.5-3.0 | 6.0 | 2.5 | 3.0 | 26.0 |

| D6.0-1.5-1.0 | 6.0 | 1.5 | 1.0 | 26.0 |

| D6.0-1.5-1.2 | 6.0 | 1.5 | 1.2 | 26.0 |

| D6.0-1.5-1.5 | 6.0 | 1.5 | 1.5 | 26.0 |

| D6.0-1.5-2.0 | 6.0 | 1.5 | 2.0 | 26.0 |

| D10.0-1.0-3.0 | 10.0 | 1.0 | 3.0 | 26.0 |

| D10.0-1.2-3.0 | 10.0 | 1.2 | 3.0 | 26.0 |

| D10.0-1.5-3.0 | 10.0 | 1.5 | 3.0 | 26.0 |

| D10.0-2.0-3.0 | 10.0 | 2.0 | 3.0 | 26.0 |

| D10.0-2.5-3.0 | 10.0 | 2.5 | 3.0 | 26.0 |

| D10.0-1.5-1.0 | 10.0 | 1.5 | 1.0 | 26.0 |

| D10.0-1.5-1.2 | 10.0 | 1.5 | 1.2 | 26.0 |

| D10.0-1.5-1.5 | 10.0 | 1.5 | 1.5 | 26.0 |

| D10.0-1.5-2.0 | 10.0 | 1.5 | 2.0 | 26.0 |

| Steel plate | E(Gpa) | fy(Mpa) | fu(Mpa) | εu(%) | ∆(%) |

|---|---|---|---|---|---|

| 6 mm cold-formed | 201.0 | 287.0 | 418.3 | 16.8% | 20.5% |

| 10 mm cold-formed | 204.0 | 295.0 | 455.0 | 17.0% | 23.5% |

| 10 mm virgin | 193.0 | 269.4 | 415.3 | 21.6% | 29.0% |

| Specimen | Failure mode | Fu(kN) | Fu /fudt | δu (mm) |

|---|---|---|---|---|

| D6.0-1.0-3.0 | Shear out | 74.2 | 1.23 | 4.38 |

| D6.0-1.2-3.0 | Shear out | 82.7 | 1.37 | 5.57 |

| D6.0-1.5-3.0 | Shear out | 102.0 | 1.69 | 6.98 |

| D6.0-2.0-3.0 | Shear out | 137.0 | 2.28 | 12.00 |

| D6.0-2.5-3.0 | Shear out | 149.5 | 2.48 | 13.71 |

| D10.0-1.0-3.0 | Shear out | 127.7 | 1.17 | 4.48 |

| D10.0-1.2-3.0 | Shear out | 153.7 | 1.41 | 5.26 |

| D10.0-1.5-3.0 | Shear out | 186.2 | 1.71 | 6.96 |

| D10.0-2.0-3.0 | Shear out | 247.7 | 2.27 | 11.78 |

| D10.0-2.5-3.0 | Shear out | 286.2 | 2.62 | 13.59 |

| Specimen | Failure mode | Fu(kN) | Fu /fudt | Fu /fuAnet | δu (mm) |

|---|---|---|---|---|---|

| D6.0-1.5-1.0 | Net section fracture | 71.5 | − | 0.95 | 3.24 |

| D6.0-1.5-1.2 | Net section fracture | 94.5 | − | 1.05 | 3.98 |

| D6.0-1.5-1.5 | Shear out | 104.0 | 1.73 | − | 7.79 |

| D6.0-1.5-2.0 | Shear out | 102.0 | 1.69 | − | 6.71 |

| D6.0-1.5-3.0 | Shear out | 102.0 | 1.69 | − | 6.98 |

| D10.0-1.5-1.0 | Net section fracture | 130.7 | − | 0.96 | 3.10 |

| D10.0-1.5-1.2 | Net section fracture | 154.2 | − | 0.94 | 4.37 |

| D10.0-1.5-1.5 | Shear out | 176.7 | 1.62 | − | 7.19 |

| D10.0-1.5-2.0 | Shear out | 182.2 | 1.67 | − | 6.88 |

| D10.0-1.5-3.0 | Shear out | 186.2 | 1.71 | − | 6.96 |

| specimen | e1/d0 | e2/d0 | failure modes | |||

| test | prediction | |||||

| ANSI | ANSI-modified | EC | ||||

| D6.0(10.0)-1.0-3.0 | 1.0 | 3.0 | S | S | S | S |

| D6.0(10.0)-1.2-3.0 | 1.2 | 3.0 | S | S | S | S |

| D6.0(10.0)-1.5-3.0 | 1.5 | 3.0 | S | S | S | S |

| D6.0(10.0)-2.0-3.0 | 2.0 | 3.0 | S | S | S | S |

| D6.0(10.0)-2.5-3.0 | 2.5 | 3.0 | S | B | S | S |

| D6.0(10.0)-1.5-1.0 | 1.5 | 1.0 | N | N | N | M |

| D6.0(10.0)-1.5-1.2 | 1.5 | 1.2 | N | N | N | M |

| D6.0(10.0)-1.5-1.5 | 1.5 | 1.5 | S | S | S | S |

| D6.0(10.0)-1.5-2.0 | 1.5 | 2.0 | S | S | S | S |

| specimen | e1/d0 | e2/d0 | Bearing resistance (kN) | |||

| test | prediction | |||||

| ANSI | ANSI-modified | EC | ||||

| D6.0-1.0-3.0 | 1.0 | 3.0 | 74.2 | 48.9 | 58.7 | 50.2 |

| D6.0-1.2-3.0 | 1.2 | 3.0 | 82.7 | 68.5 | 74.3 | 60.2 |

| D6.0-1.5-3.0 | 1.5 | 3.0 | 102.0 | 97.8 | 97.8 | 75.2 |

| D6.0-2.0-3.0 | 2.0 | 3.0 | 137.0 | 146.7 | 136.9 | 100.3 |

| D6.0-2.5-3.0 | 2.5 | 3.0 | 149.5 | 180.6 | 176.1 | 125.4 |

| D6.0-1.5-1.0 | 1.5 | 1.0 | 71.5 | 65.2 | 65.2 | 33.1 |

| D6.0-1.5-1.2 | 1.5 | 1.2 | 94.5 | 91.3 | 91.3 | 50.0 |

| D6.0-1.5-1.5 | 1.5 | 1.5 | 104.0 | 97.8 | 97.8 | 75.2 |

| D6.0-1.5-2.0 | 1.5 | 2.0 | 102.0 | 97.8 | 97.8 | 75.2 |

| D10.0-1.0-3.0 | 1.0 | 3.0 | 127.7 | 88.7 | 106.5 | 91.0 |

| D10.0-1.2-3.0 | 1.2 | 3.0 | 153.7 | 124.2 | 134.9 | 109.2 |

| D10.0-1.5-3.0 | 1.5 | 3.0 | 186.2 | 177.5 | 177.5 | 136.5 |

| D10.0-2.0-3.0 | 2.0 | 3.0 | 247.7 | 266.2 | 248.4 | 182.0 |

| D10.0-2.5-3.0 | 2.5 | 3.0 | 286.2 | 327.6 | 319.4 | 227.5 |

| D10.0-1.5-1.0 | 1.5 | 1.0 | 130.7 | 118.3 | 118.3 | 60.1 |

| D10.0-1.5-1.2 | 1.5 | 1.2 | 154.2 | 165.6 | 165.6 | 90.6 |

| D10.0-1.5-1.5 | 1.5 | 1.5 | 176.7 | 177.5 | 177.5 | 136.5 |

| D10.0-1.5-2.0 | 1.5 | 2.0 | 182.2 | 177.5 | 177.5 | 136.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).